- How to equip

- Installation of a submersible electric pump for installation in a well

- Plant commissioning and testing

- Necessary tools and materials

- Preservation of the pump for the winter

- Detailed view of the problem

- Installation of the surface apparatus

- Mounting the pump in the well

- Rules for installing a surface option

- Immersion depth

- Using a drain pump to clean a well

- 3 Installation of the submersible unit

- 3.1 Necessary materials and tools

- 3.2 Trench preparation

- 3.3 How to lay the water supply?

- 3.4 Mounting the pump

- 3.5 How to lower the pump?

- Correct connection

- One- and two-pipe pumps - which ones to choose?

- What should be a good pump?

How to equip

The first thing that is required is to decide on the location of the well device.

- The distance from the well to the nearest sewage discharge point (street restroom, compost heap), according to SNiP 30-02-97, should be at least 8 meters (the more, the better). If you are planning to install a septic tank in the future, or your neighbors have it, then the distance to its “aeration field” (a special area for draining processed effluents) should be at least 15 meters.

- The distance from the well shaft to the foundation of the house is not regulated, but, given the load of the building on the ground, it should be at least 4 meters (a lot depends on the type of soil and type of foundation, so specialist advice is desirable).

- The closer the well is to the installation site of the system in the house, the cheaper and more reliable it will be.

Having limited the search field based on the above conditions, the place under the well in most cases is determined using the ancient, but reliable, dowsing method. Sometimes an exploratory well of small diameter is pierced.

Digging wells is an extremely dangerous occupation, so it is better if you entrust it to specialists.

If you decide to dig a well yourself, then for this you will need equipment:

- shovels,

- containers for excavation of soil,

- strong rope,

- scrap,

- also requires a device (usually a gate) for lifting the earth and a ladder, as well as,

- water pump.

Most often, a well is arranged using well rings, so we will consider just such an option.

Having marked a circle on the ground with a diameter of ten centimeters larger than the ring, we take out the soil to a depth of 80 centimeters and level the bottom. We place the first ring in the center and check it for the horizon. It is on this that the verticality of the mine depends in the future.

In a circle, we select the ground inside the ring, which will fall under its own weight, then in the center. If the soil is soft, then the sequence of actions is reversed: first the middle is removed, then the edges.

As we deepen, we install the next ring on top, seal the joint with a special solution, fasten the rings with brackets and continue to dig further. We bring the depth of the mine until water appears and leave the well for a day, giving it the opportunity to fill up. Then we fix the water level and pump it out.

If the level is insufficient (usually three or four rings are considered to be filled), then we continue to lower the rings, reaching the desired depth.If the water level is sufficient, then we select the sand to the end of the lower ring and fill the bottom with a layer of washed rubble ten to fifteen centimeters thick, then we lay large stones on top to a thickness of twenty to thirty centimeters.

Silicon, basalt or granite are best suited for this purpose. Limestone must not be used! It spoils the quality of the water.

After that, you should take care of the "pressure seal" of the pipeline from the mine.

We dig to a depth of at least one and a half meters (the lower the “pressure outlet”, the less likely the pipeline will freeze in winter) to the outer wall of the well and punch a hole for future communication. The “house” should be installed from above after the installation of the pipeline, as well as making a clay or concrete hydraulic lock around the perimeter of the well.

Installation of a submersible electric pump for installation in a well

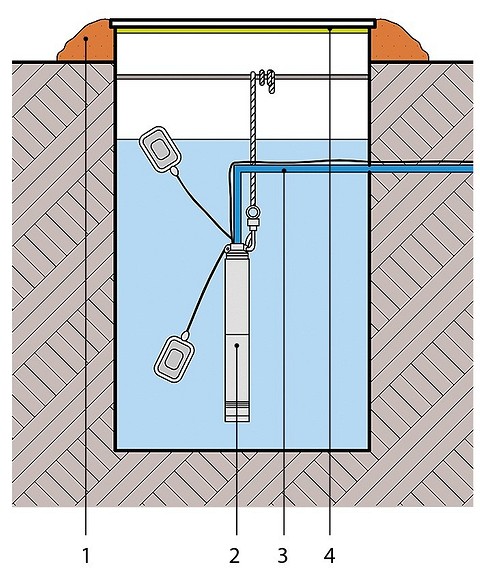

To install a submersible electric pump in a well, work is performed in the following order:

- Screws into the outlet of the unit a plastic adapter for connecting the pressure pipe. In the absence of a built-in check valve, install your own, mounting it first at the outlet of the electric pump, then screw the fitting to connect HDPE pipes.

- A pipe is attached to the pump and fixed with a plastic cuff, a cable is threaded into the ears of the housing and its ends are connected at the outlet using two special clamps, the free end is screwed to the main cable with electrical tape.

- Connects the power cable, cable and pressure hose together with electrical tape or ties in 1 meter increments, while making sure that the power cord is secured without tension.

- The electric pump is lowered into the well to a predetermined depth.To do this, measure and cut the pressure pipe of the desired length, insert it into the head, to which the cable is tied.

- After diving, you can immediately check the operation of the electric pump without connecting to the pipeline, if the liquid supply corresponds to the passport data, connect the entire water line and then control and regulate the operation of the equipment with automatic devices.

Rice. 8 Preparation of the downhole electric pump for immersion

To connect the borehole pump to the water supply system, devices are used that automate its operation, prevent frequent starting and reduce the load on the line. They can be independently mounted in one module, installed in a residential area or left in a caisson pit with a borehole tip.

Plant commissioning and testing

The first start-up after installation or the restoration of the system's performance after a long "dry" period is simple, although it requires certain manipulations. Its purpose is to fill the system with water before the first connection to the network.

This is a simple procedure that does not require special skills. There is a plug on the pump that needs to be removed.

A simple funnel is inserted into the hole, through which the system is filled - it is important to fill in the supply pipe and the pump with a hydraulic accumulator. A little patience is required at this stage - it is important not to leave air bubbles

Pour water up to the neck of the cork, which is then twisted again. Then, with a simple automobile pressure gauge, the air pressure in the accumulator is checked. The system is ready to start.

To make it clearer how to test a pumping station, we have prepared 2 galleries for you.

Part 1:

Part 2:

Necessary tools and materials

When preparing a water supply plan, the length of the pipes is calculated and the material of the line is selected. A common option is products made of PVC or propylene. Plastic pipes do not rust, no plaque is deposited on the walls. To prevent freezing of the line, a casing-insulation made of foamed polystyrene or polyethylene is used. You will need consumables for the installation of the pipeline:

- couplings;

- tee;

- fitting;

- ball valve.

Tools for work:

- shovel;

- perforator;

- grinder or hacksaw;

- roulette;

- pipe cutter

Installation of equipment is best done with a partner. He will help dig a trench, insure when lowering the unit into the well.

Preservation of the pump for the winter

The main task is to free the pipeline system from water so that it is not torn apart by ice.

For this, drain taps and pipes are used. If the water supply system is equipped with a check valve, it must be opened so that the water flows back into the well.

The submersible pump should be removed from the well and carried out a routine inspection: if necessary, clean and lubricate. Many summer residents do not bother with such an event, leaving the mechanism to hibernate at a depth.

In principle, this should not cause much harm to technology, but still there is a danger of its silting, liming, or simply theft by various "dashing people" who are hungry for someone else's good.

We conserve the pumping station installed on the surface in the same way. We drain the water from the working cavities of the pump itself, from the damper tank and tubes. As for whether to remove the pump from the well and take the pumping equipment with them, each owner decides for himself.

Detailed view of the problem

The submersible pump is always located in the water column, so it has much less chance of freezing. For example, if the well is equipped with an insulated cover on top, and the distance to the water surface in it is more than 2 meters, then the maximum ice thickness in it will be no more than 20-30 cm. And this is provided that no one will use the well all winter, breaking the ice: let's say it is located in a summer cottage.

Accordingly, the danger of freezing of the equipment itself, immersed in the water column, is practically not threatened. Another thing is the supply hose. If the hose is equipped with a check valve that prevents water from rolling back into the well, then freezing, ice can break it. Therefore, for the winter, the water supply system should be freed from water if you do not intend to use the well at this time of the year. But if you live in a suburban area all year round, then you need to take care of the thermal insulation of pipes and hoses.

Surface-mounted pumping systems should also be carefully insulated if you intend to use them in the winter. There are several options for installing them:

- Inside the well shaft, on a special shelf.

- In the insulated booth next to the well.

- In the basement or basement of a residential building.

In all these cases, the water mains leading from the water source to the house should be carefully insulated. Pumping systems located outside are also well insulated; for this purpose, electric self-heating cables can be used. Provided sufficient insulation, pumping systems can easily be used year-round.

Installation of the surface apparatus

For autonomous water supply, the presence of an aquifer in the mine at a depth of 8 meters allows the use of an inexpensive and reliable unit that can be installed above the source with your own hands.

In order to connect a surface pump without errors to draw water in a well, you must follow the step-by-step instructions. The sequence in the installation will ensure trouble-free operation of the water supply system:

- we carry out design and preparatory work in the same way as the described option for installing a submersible product;

- in a caisson buried at the well below the freezing level of the soil, we fix the pump on a fixed base with bolts or anchors. Between the unit and the base we put a rubber anti-vibration gasket;

- we connect a non-return valve and a coarse filter to a water pressure hose no longer than 10 meters. The second end of the pipe is combined with the suction pipe of the pump;

- we connect the water pipe leading to the house to the pressure pipe of the apparatus and lay it in the trench along with the cable according to the option with a deep device;

- we lead the hose with the wire into the technical room and connect it to the hydraulic accumulator with the automation system;

- we lower the hose with a check valve and a filter through a hole in the wall of the well, made at a depth below the freezing level of the soil, into the aquifer. The filling hole on the pump is used to fill the suction pipe with water. We start the device and pump liquid into the system, squeezing air out of the pressure hose;

- we close the distribution valve of the internal water consumption system in the house and, after venting air, we fill the accumulator, creating a standard pressure of up to 3.5 atmospheres.

Mounting the pump in the well

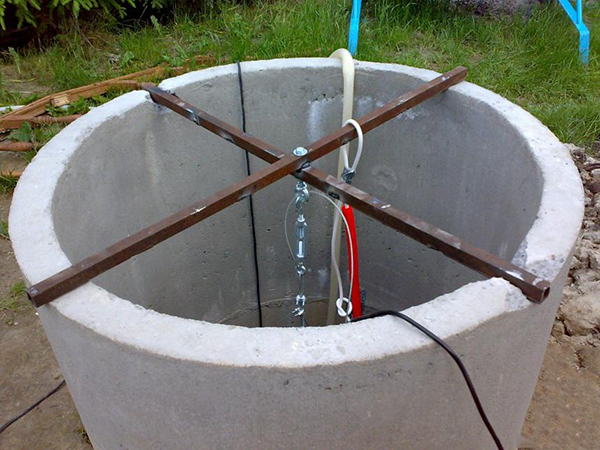

To hang the pump in the well, you need to weld the mounting frame. The dimensions of the well rings may vary, which affects the length of the frame support arm. Ideally, it should reach the very center, that is, equal to the radius of the concrete ring. The frame is attached one and a half meters below ground level, in the place where the water pipe passes through the wall of the well.

Drill a hole in the wall of the well below the freezing depth of the soil. A plastic sleeve of a larger diameter is inserted into it than the water supply hose. All joints are treated with sealant. To fix the pump in the well to the frame, a nylon cable is used, metal with zinc coating or stainless steel. Diameter 2 mm. Duplex clips are used for secure fastening. The main thing is that the cable does not lose its characteristics during prolonged contact with water.

Important elements of the pump piping:

1. tee with ball valve - installed as close as possible to the base frame, so that it is easy to reach. A ball valve is needed to drain water from the system if necessary;

2. non-return valve - installed immediately before the pump. It is necessary so that water from the hose does not go back to the pump.

It is important to choose a good hose that can withstand pressure and does not transmit vibrations to joints and pipes laid in the ground. This is interesting: Can the installation of an electric heated towel rail be considered prevention of fungus?

This is interesting: Can the installation of an electric heated towel rail be considered a prevention of the appearance of a fungus?

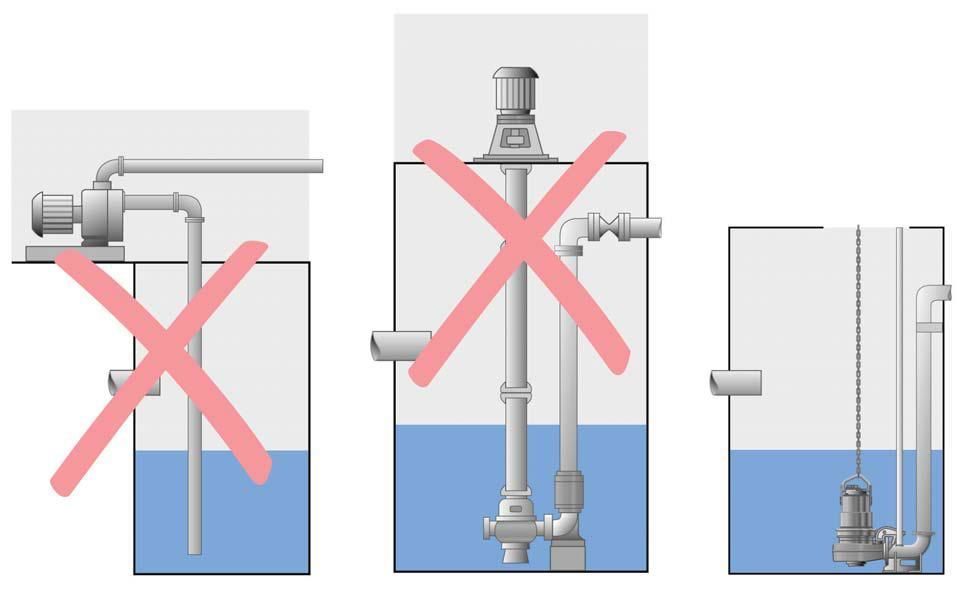

Rules for installing a surface option

Surface pumps are not often used for this type of water supply, since they are only suitable for shallow hydraulic structures, up to eight meters deep.

And yet, this option has the right to exist, and its installation is no more complicated than the installation of submersible equipment.

Surface pumps are easier to install and cheaper than submersible models, but they are only effective for wells up to eight meters deep.

Mount the device as follows:

- The surface pump is installed in a special caisson or a separate room.

- A hose of suitable length is connected to the suction port of the pump.

- A non-return valve is attached to the other end of the hose (a protective measure that prevents water from draining when the pump is finished).

- A protective mesh filter is installed on the valve, which prevents the penetration of various contaminants into the pump housing.

- The hose is lowered into the well.

At this point, the installation can be considered complete and a test run of the pump can be made. To install such a pump in a well, a special adapter is often used. In this case, the hose is connected to the adapter, and the adapter is connected to the pump. The rest of the installation procedure is exactly the same.

It is a little more difficult to install a surface pump equipped with an external ejector into the well. In this case, two hoses must be lowered into the well. In addition to the suction, a pressure hose is also mounted. It is connected to the side fitting of the ejector using a special outlet.

Except check valve and filter an ejector must also be installed at the end of the suction hose.It should be remembered that surface pumps are very sensitive to contaminants in the water supplied from the well.

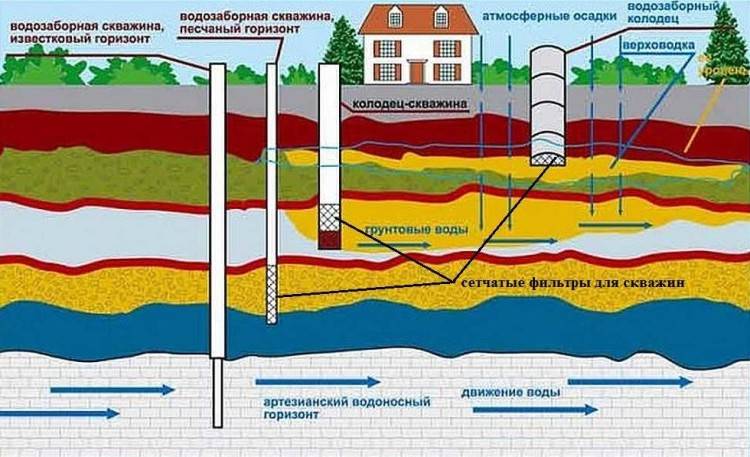

Immersion depth

Before you fix the pump in the well, you need to calculate the depth of its immersion. To do this, you need to know two quantities: static and dynamic water level. The static level is when the volume of water in the well reaches its maximum and suppresses the pressure of underground sources with its pressure. The dynamic level is measured as a function of the pump power. This is when the amount of water pumped out equals the amount of incoming water. The difference between the static and dynamic levels determines the performance of the well (its debit).

IMPORTANT! The pump must be submerged at least one meter below the dynamic water level. Both of these values are measured during drilling and recorded in the well passport

It is quite easy to measure the static depth yourself. Do not use the well during the day. Tie a load to the rope and lower it to the bottom. Then measure the wet section of the rope with a tape measure.

Both of these values are measured during drilling and recorded in the well passport. It is quite easy to measure the static depth yourself. Do not use the well during the day. Tie a load to the rope and lower it to the bottom. Then measure the wet section of the rope with a tape measure.

With dynamic depth, things are more complicated. It is necessary to immerse the pump in the well, turn it on and gradually lower it until the water stops decreasing. After that, measure the depth with a rope with a load. If the water does not stop decreasing until the well is completely empty, then the pump is too powerful and in your case it is not suitable.

Using a drain pump to clean a well

In the process of selecting a suitable type of drainage pump, it is very important to carefully study the instructions provided with the device, since certain models can only pump clean water. At the same time, there are pumps that work well with contaminated water, including those containing small inclusions and fibers.

For easier cleaning of the well, it is better to use models of drainage pumps equipped with a float. Usually this role is played by a certain switch that floats on the surface and turns off the pump when it reaches the bottom.

Otherwise, the operation of the drain pump must be constantly monitored to avoid overheating of the engine, since the water in which the unit is immersed cools it.

A person does not need to dive into the well on his own, the drainage pump works automatically, but you need to set it up correctly:

- First, the pump plunges to a depth of 1 m without reaching the bottom,

- The device turns on, as a result of which the water is cleaned of dirt,

- Further, clean water enters the well under pressure, which leads to the destruction of silt growths at the bottom,

- During operation, the pump periodically rises to the surface and its filter is cleaned. These actions are repeated until silt deposits appear on the filter.

- For major cleaning work, it is better to use a powerful pump, but a less powerful apparatus is also suitable for maintaining cleanliness.

- Recently, the following practice has been very often used: a well is cleaned with a powerful pump a couple of times a year. The cleaning itself usually takes about a week, after which the pump is stored in a dry, clean room.

The use of one or another model of drainage pumps depends primarily on the specific circumstances: the degree of contamination, the depth of the well, as well as other conditions. Depending on what characteristics this or that pump is endowed with, its cost will also be set.

All work is done by hand, so there will be no costs for this. Before buying, the instructions must be fully studied and after that you can already make a purchase.

3 Installation of the submersible unit

Different models of pumps have different properties, designs, characteristics. But installing a pump in a well, its principles are approximately the same for all mechanisms.

Installation of a submersible pump in a well should begin with digging a trench for the pipeline, making holes in the foundation of the house for pipes and cables. Then the pump is lowered into the source. Then you can install the battery, relay, and connect the cable.

3.1 Necessary materials and tools

Before starting work, you should draw up an installation diagram and select the pipe material. Today, PVC pipes are popular, they are convenient and practical. It is also necessary to prepare tools and materials:

- shovel, crowbar;

- puncher or electric drill;

- a hammer;

- tape measure, pencils, square;

- hacksaw for metal, grinder;

- pipe cutters, pipe benders;

- profile pieces;

- metal cable;

- pipes.

3.2 Trench preparation

Installing a submersible pump in a well begins with laying a trench. For the pipeline, it is desirable to choose a section where the pipes can be laid straight, without bends. The advantages of this are that:

- the amount of work will be less;

- there will be a higher pressure in the pipeline;

- fewer connections during installation, which means that leakage is unlikely.

They dig a trench about 1 - 1.5 m and a width of 0.5 m. The bottom of the trench is freed from foreign particles. Next, a layer of sand 10-20 cm thick is laid, which is covered with a geotextile sheet. They then wrap the pipes.

3.3 How to lay the water supply?

For plumbing, metal or polymer pipes are used, made of stainless steel or, if it is a polymer, then plastic and polypropylene. Sometimes a garden hose is used instead of pipes, but it is only suitable for temporary use, for summer plumbing.

Pipes are laid in a trench and connected. It is desirable to insulate the water supply by wrapping it with a heat insulator and placing it in an asbestos or sewer pipe. This design is laid in a trench. Insulation protects the water supply from negative external influences.

A hole is punched in the wall of the well for the pipe to enter. A sleeve is inserted into it, fixed with concrete and sealed. Then a layer of mastic is applied for waterproofing. The end of the pipe is inserted into the sleeve by 25 cm, a valve is installed on it for emergency draining of the liquid. The distance from the tap to the pump is measured and a pipe of the appropriate length is prepared.

3.4 Mounting the pump

How to install a pump in a well? Submersibles are lowered into the well on nylon or galvanized cables. It is not recommended to lower the pump into the source on steel cables, they quickly become unusable. The cable should be fixed with a strong steel frame. It is made from a corner. A hole is made in the frame through which a fixed cable is pulled.

Replacing the pump in the well

The pump is placed at the end of the pipe, and the cable along it.If the pump does not have a check valve, it is installed on the outlet. A coupling is attached to the valve, and then a pipe. The cable is attached to the pipe with clamps or electrical tape. The wire must be firmly fixed, but not stretched.

3.5 How to lower the pump?

Installation of the pump in the well ends with the lowering of the apparatus with a cable and cable into the casing. Lowered to the desired depth, the pump is fixed with a cable for a steel frame. Next, the pipe should be connected to the tee sanitary ware. To do this, go down into the well shaft.

Next, the cable is led out through the trench and brought into the house along with the pipe through a hole in the foundation.

Correct connection

Installation of the submersible apparatus and installation of the surface apparatus are carried out with a connected pressure pipe. Despite the difference in use, both pressure and suction hoses must meet the following requirements in terms of their parameters:

- rigidity - pressure drops should not affect the shape of the pipe;

- wear resistance - abrasive elements in water should not damage it;

- frost resistance - not deformed during operation at low temperatures;

- environmental safety - drinking hose must be made of materials that do not emit toxic substances;

- operating temperature range from +1 °С to +40 °С.

These requirements are met by products made of polyvinyl chloride (metal-plastic and polypropylene), shown in promotional photos. Hoses are used to lift water and move it to a house or a drive in a country house, and fixing them on the nozzles of the pump, tee, adapter is carried out using fittings.

One- and two-pipe pumps - which ones to choose?

Installation and connection of a household pumping station is carried out only in cases when a well is drilled in a country house with a depth of no more than 20 m. If the aquifers lie in the ground below, there will be no sense from a compact pump. In such situations, a special submersible pump should be installed.

When selecting the equipment of interest to us, one should pay attention to its technical parameters and modes of operation, and not only to the cost of the pumping station. First of all, it is necessary to determine the type of suction pipeline. Pumping station

Pumping station

It happens:

- ejector (in other words - two-pipe);

- single-pipe.

Single tube stations are very simple in design. In them, the liquid from the well enters the body of the pumping equipment used through the only available line. Do-it-yourself installation of such a unit is done without problems, and quickly enough. Pumps with two pipes are structurally more complex device. But the efficiency of its functioning is many times higher and more reliable than single-pipe equipment.

In the ejector pumping station, the rise of water is provided by a vacuum, which is formed due to a special wheel. It was originally installed in the unit. The increase in rarefaction is due to the inertia of the fluid, which makes a circular motion when the equipment is turned on. Due to this scheme, pumps with two pipes are always characterized by low power, while having a high efficiency. They are able to lift liquid from great depths. Therefore, the installation of a two-pipe pumping station is recommended for depths of 10–20 m. If the well depth is less than 10 m, feel free to install equipment with one line.It will do its job one hundred percent.

What should be a good pump?

First you need to select and purchase a suitable pump, as well as a number of materials necessary for its successful installation. The pump is usually taken submersible, while it is very desirable that it be centrifugal.

Unlike centrifugal models, vibratory pumps cause dangerous vibrations in the well, which can lead to the destruction of the soil and casing. Such models are especially dangerous for sand wells, which are less stable than artesian counterparts.

The power of the pump must match the productivity of the well. In addition, the immersion depth for which a particular pump is designed should be taken into account. A model designed to work at a depth of 50 m can supply water from a depth of 60 meters, but the pump will soon break down.

A submersible centrifugal pump is the best choice for a well. Its performance, dimensions and other indicators should be correlated with the characteristics of its own water source

Another risk factor is the level of drilling quality. If an experienced team drilled, the well will be better able to withstand the destructive effect. And for wells created by one's own hands or by the efforts of “shabashniki”, it is recommended to use not just a centrifugal pump, but special models for wells.

Such devices better tolerate the loads associated with pumping water heavily polluted with sand, silt, clay particles, etc. Another important point is the diameter of the pump. It must match the dimensions of the casing

It is important to take into account the features of the power supply of the pump. For wells, both single-phase and three-phase devices are used.

For four-inch pipes, finding equipment is easier than for three-inch pipes. It is good if this moment is taken into account at the well planning stage. The greater the distance from the pipe walls to the pump housing, the better. If the pump passes into the pipe with difficulty, and not freely, you need to look for a model with a smaller diameter.