- Why is there a ventilation shaft in the apartment - How are the mines arranged?

- Ventilation shaft technology

- Mine device

- Auxiliary channels

- Reasons for the inflexibility of the law

- 7 Step by step installation instructions

- Why does a private house need ventilation

- What are ventilation systems, are they necessary in non-residential premises of MKD

- Regulations

- in plain language

- Rules for installing ventilation structures

- Checking and arranging the ventilation shaft

- Prices for the popular antifungal agent Ceresit ct 99

- Prohibition of the second - changing the cross section of ventilation ducts and shafts

- Ventilation shaft in a multi-storey building diagram

- Reasons why a mine may stop working

- Ventilation passage through the roof types, installation

- Roof ventilation units

- The sequence of actions for mounting the node through the roof

- About ventilation ducts

- What causes poor ventilation in the apartment

- The result of construction

Why is there a ventilation shaft in the apartment - How are the mines arranged?

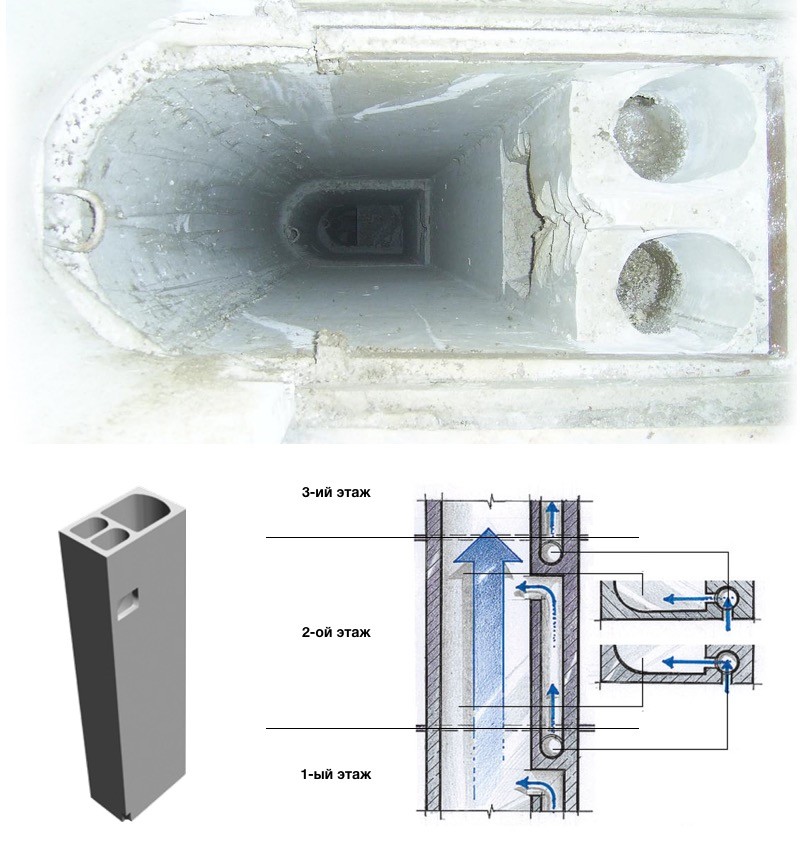

In panel houses, ventilation shafts are concrete blocks that are installed on top of each other. In order for the ventilation shaft device to really work, a perfectly vertical channel must be made.

The mine takes its beginning on the basement floor, and ends on the roof, where the air currents exit. You need to understand that the dimensions of the ventilation shaft in a multi-storey building are 30 cm by 60 cm. The lines themselves are made of metal or plastic. This choice of material is due to the fact that they are quite easy to clean and they last a long time.

It is also important to protect the barrel from debris and precipitation - a stainless metal umbrella copes with this.

The problem is that even if the mine is clogged and the air exchange is disturbed, then do the cleaning yourself the channel does not work out - this should be done by the management company.

Ventilation shaft technology

As we have already understood, the ventilation box in the kitchen consists of two or three holes. If you look at the statistics, then a three-channel ventilation duct is more common. With them, the ventilation of the kitchen or plumbing unit is more active, harmful substances and unpleasant odors leave the room.

Mine device

The main channel, which has an air duct box, is a ventilation shaft and looks standard as a rectangle with sides of 30 × 60 cm. It, like the sewer riser, passes through each floor and air moves through it from the basement to the attic.

Auxiliary channels

We figured out the main shaft, there are two more channels left. Classical ventilation has two additional channels, oval or rectangular. Dimensions ventilation duct as standard 130 and 125 mm. If you didn’t notice before that your house has ventilation, then look for lattice boxes in the kitchen or bathroom, they will be found there. Fresh oxygen enters the room through them, and unpleasant odors disappear.Due to the fact that the plywood box is located in different rooms, the incoming and outgoing flows do not mix when moving. It turns out that if the doors are closed tightly while cooking in the kitchen, then the smells of the food being prepared will not get into other rooms, but will disappear through the ventilation shaft. Outgoing air masses are mixed 2-3 meters above the level of the apartment.

You will have to make ventilation in the kitchen using one of two preferred types of boxes:

-

Concrete;

-

Gypsum.

And already based on this information, it turns out that the decorative pipe box is performed:

-

oblique;

-

Direct.

Reasons for the inflexibility of the law

Ventilation boxes are an important component of ventilation systems, on which not only comfort, but also the safety of living depends in many respects. So, natural ventilation, despite all its shortcomings, is the only system that can prevent:

So, natural ventilation, despite all its shortcomings, is the only system that can prevent:

- destruction of a building due to a gas explosion;

- fire due to gas leakage;

- tragedy due to the accumulation of carbon monoxide in the room, which can be detected using special sensors.

In addition, the general house air exchange system ensures the removal of moisture, unpleasant odors and harmful substances, such as carbon dioxide, from the premises.

The photo clearly shows the design of the ventilation duct. And even non-specialists understand that they are thin-walled, and therefore unsuitable for placing any heavy objects on their surfaces. The presence of which over time can lead to cracks, other consequences with a subsequent decrease in the efficiency of the ventilation system

Efficient air exchange allows you to create a microclimate in the building, the parameters of which will meet the requirements of relevant documents, the main of which is GOST 30494-2011.

At the same time, it is easy to reduce the efficiency of the ventilation system or make it generally inoperable - it is enough to make changes to the design of the box.

Let them be minor, but another user can do the same, and another neighbor decides to install a fan that the system was not designed to use. Such actions will complicate the situation, as a result of which we can expect the occurrence of reverse thrust and other troubles.

Other reasons for the decrease in the efficiency of the ventilation system and ways to restore it, we considered in the next article.

Often, ventilation ducts are self-supporting structures. For example, this is exactly how things are in the houses of the P-44 project. And this means that each element of the ventilation box relies on the one below it. At the same time, they cannot withstand significant transverse loads. As a result, even with conventional drilling, cracks may occur. The result is a weakening of the structure, sediment, which often leads to the fact that air circulation is disturbed.

It should be understood that ventilation ducts are not load-bearing structures, therefore, when drilling and placing heavy cabinets on their surfaces, shrinkage and cracks often occur. That in itself reduces the efficiency of ventilation systems.

To prevent the occurrence of such consequences, it is forbidden at the legislative level to change the design of the boxes.

7 Step by step installation instructions

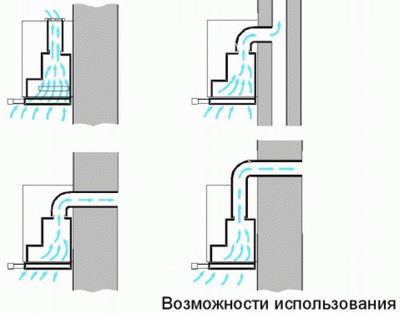

The procedure for installing a ventilation duct on a roof structure is not too complicated.It can be easily performed by anyone, but for this you need to be guided by the following instructions:

- 1. First of all, you should deal with the installation location of the pass-through unit on the roof.

- 2. On the upper wave of the metal tile, it is necessary to draw the contours of the future hole, applying the template that comes with the element itself.

- 3. After that, cut a hole on top with a chisel and scissors for metal, and also make several holes in the lower layers of the roofing cake.

- 4. Following the template, you need to drill several holes for the screws.

- 5. Then it remains to clean the roof surface from moisture and dust residues.

- 6. Apply a layer of sealant to the bottom of the gasket.

- 7. Then it is necessary to lay the gasket in the right place and fix the passage element in it. After making sure of the reliability and correct location of the structure, you can proceed to fixing. For this, screws are used.

- 8. At the end, it is necessary to ensure the tightness of the ventilation outlet to the roof from the attic.

Based on the foregoing, there are practically no difficulties in installing a ventilation duct on the roof. If you draw up the right project in advance, make calculations and study the installation instructions, the future ventilation system will work in the best possible way. At the same time, the operational life of the roof, which has gone through a lot of changes due to the appearance of a new node, will not be reduced in any way. But for this you need to responsibly treat the upcoming work and follow the basic installation rules.

Why does a private house need ventilation

Structurally, residential buildings are closed spaces, reliably isolated from the external environment. Walls, doors and windows protect the premises from precipitation, warm and cold air, dust, animals and insects.

However, such isolation from the outside world has the following side effects:

- When people breathe, carbon dioxide is produced, which in high concentrations is harmful to health. If you do not get rid of it, then feeling unwell is the least of the possible troubles.

- Constant dampness. The vital activity of people (washing, wet cleaning, taking water procedures, cooking) is inextricably linked with the formation of high humidity.

- Accumulation of carbon monoxide from the operation of heating boilers. And this is a real threat to life.

Incorrect calculation of the removal of exhaust air masses from the premises leads to complex and sometimes insoluble issues.

What are ventilation systems, are they necessary in non-residential premises of MKD

The ventilation system of the building and its premises includes channels, air ducts and special equipment that ensures proper circulation and exchange of indoor and outdoor air. Moreover, modern systems and solutions make it possible to achieve the necessary circulation for different types of premises and parts of the building, take into account the indicators of external and internal air, provide additional protection from dust, gas combustion particles, and other harmful factors. For non-residential areas of MKD, the following rules and regulations apply:

- when transferring premises from non-residential and residential, it is unacceptable to block or dismantle the ventilation ducts that are part of a single MKD system;

- ventilation of non-residential premises must comply with the sanitary standards regulated for residential buildings;

- many works to change the characteristics or transfer of ventilation fall under the redevelopment or reorganization, i.e. require special approvals for the project.

It is also necessary to take into account the types of activities for which the non-residential premises of the MKD are used. In some cases, it is allowed to open shops and catering establishments, points for the provision of personal services to the population. In order to eliminate negative impacts on the home's occupants, the owner of the space must design and approve a proper ventilation system.

Regulations

The development of a project for a new apartment building, including all its systems, is carried out in accordance with the norms of the Civil Code of the Russian Federation, Decree of the Government of the Russian Federation No. 87. To design a new ventilation system in an MKD, or to make changes to existing equipment for air exchange, the following guidelines must be taken into account :

- SP 60.13330.2012 (download);

- SP 54.13330.2016 (download);

- SP 336.1325800.2017 (download).

These are the three main sets of rules that designers' decisions must comply with. In particular, according to SP 60.13330.2012, it is necessary to choose solutions that meet the standards of sanitary, environmental and other safety, according to acceptable indicators of air purity, noise protection for ventilation equipment. According to SP 54.13330.2016, he will check the performance of ventilation ducts and air ducts within the framework of a single ventilation system at home, compliance with microclimate indicators.

in plain language

Non-residential premises in MKD can be used to place an office, trade or service enterprises, to open small cafes and restaurants (with significant restrictions). In each of these cases, non-residential premises must have a ventilation system:

- providing own needs for the owner or tenant of non-residential premises, visitors and business clients (for example, the air exchange system for a cafe will include hoods, air conditioners, and other professional equipment);

- keeping the general ventilation and air conditioning system for the MKD unchanged (in particular, it is unacceptable to close up the ventilation ducts provided for by the original project for the house);

- corresponding to energy efficiency indicators, since for MKD this is one of the mandatory standards.

To carry out work on ventilation systems in an existing non-residential premises, MKDs may require redevelopment and (or) reorganization projects. They must be coordinated with the Moscow Housing Inspectorate, since this department oversees the conduct of any work in the housing stock of Moscow. Moreover, if changes are made to the general ventilation system of the house, or if load-bearing structures or common house property are involved in the work, it is additionally necessary to obtain the consent of the owners of the house.

The ventilation system includes hoods, ducts, channels and other elements of air exchange

Rules for installing ventilation structures

Installation of ventilation ducts is already the very last stage in the process of arranging an air ventilation system in a room. The first thing to do is to design it. The effective operation of the air ventilation system in the future depends precisely on a well-designed project.It is the drawn up project that determines the type, power level, dimensions, layout specifics, the required area and type of air duct section.

You can design a ventilation system yourself, but for this you need to have at least basic knowledge in this area. After all, incorrect calculations can lead to excessive duct noise, insufficient air exchange with its help, etc. Therefore, if there is even the slightest doubt, it is better to entrust the design to professionals.

The second stage is the purchase of all necessary materials, components and tools, if necessary. The quantity and parameters of all necessary parts must be purchased in full accordance with the project in order to avoid unnecessary costs of money and time. After all, if you buy components at your discretion, then later you will have to spend time again searching for and buying the right parts.

Checking and arranging the ventilation shaft

It is with these works that any installation of the hood in the kitchen should begin. If there is a problem with the mine, then no most modern and powerful systems will improve the air quality in the room. If you install a hood in a new house, then there may be a violation of the functionality of the vertical channel. The reasons are various, but most often these are gross deviations from building codes and regulations. There is no natural ventilation - call the representatives of the construction company to fix the problem. In our case, the ventilation passage was clogged with mortar during masonry work.

The ventilation passage was clogged with mortar

It is required not only to clean it, but also to install an exhaust hood with a check valve to ensure continuous natural ventilation. This is a strict safety requirement; if it is violated, the gas workers will not give permission to connect the stove.

Ventilation after cleaning

Step 1. Remove the decorative grille, make an audit of the shaft. Slightly expand and align the edges of the hole.

Step 2. Install an MDF board of the appropriate size into it, secure it with two spacers. The plate is required to prevent clogging of the channel with mortar.

Installed MDF board

Spacers

Step 3. Make a box according to the dimensions of the connected air duct; a check valve will be installed in it. The device works only when the hood is turned on, it is a permanently open type. Due to this, the mandatory requirement of gas workers is fulfilled.

Box

Step 4. Attach two bars of metal reinforcement to the wall. To do this, fix the dowels and install the rods with their help.

Two bars of metal reinforcement

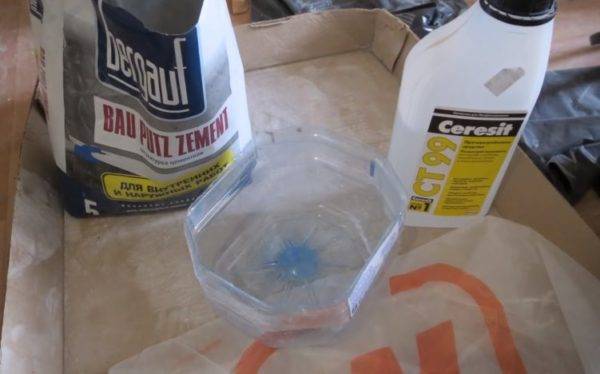

Step 5. Prepare a cement-sand mortar, be sure to add a special liquid to it that inhibits the reproduction of fungi and pathogenic microorganisms. The fact is that the hood captures fat and feeds it into the canal; special additives are used to prevent negative consequences.

Mortar mix and anti-fungal liquid

Prices for the popular antifungal agent Ceresit ct 99

Antifungal agent Ceresit ct 99

Step 6. Level the box and fill it with mortar. The next day, the solution will gain sufficient strength, disconnect the box from the mass with a sharp metal object and remove it.

The box is level

The box is fixed with mortar

The box is removed by sawing

Do not rush, the mortar has not yet gained maximum strength and may be damaged. Experienced builders advise wrapping the box in place with several layers of plastic wrap before installing it. After the mass has solidified, the element can be easily removed from the ventilation shaft.

Mine after removing the box

Step 7. Insert a plastic pipe into the hole and also throw it with a mass. It is necessary to form a round hole. Work carefully, do not clog the channel, do not allow solution to enter it.

plastic pipe

Pipe fixing

Forming a round hole

Wall covered with gypsum plaster

Never use gypsum plaster while making holes. This is very poor material in all respects.

For the mine, it is important that it is hygroscopic and absorbs a lot of moisture. Mushrooms and mold will definitely appear on such a surface, over time the affected area increases, brown spots will appear on the front surface of the wall.

Plastic, metal and grout perfectly transmit the noise generated due to the vibration of the fan blades. During the operation of the hood, unpleasant sounds are heard in the room. To reduce them, it is recommended that all pipelines at the points of contact with the vertical ventilation duct be glued with noise-absorbing tapes. It can be ordinary thick tape, the specific material does not matter. The main thing is that it should be plastic and extinguish multidirectional dynamic forces.

The pipe is lined with sound-absorbing material

The pipe is inserted into the previously prepared hole

Silicone sealant applied around the pipe

Duct assembly

Check valve mounted on silicone sealant

Now it remains to well level the wall surfaces near the prepared entrances and then proceed with the installation of the hood.

Prohibition of the second - changing the cross section of ventilation ducts and shafts

During redevelopment, it is forbidden to change the cross section of ventilation ducts and shafts. This requirement may seem rather strange. Especially if you suddenly lacked a few centimeters to fit a standard kitchen set into your dimensions, and making custom-made furniture turns out to be several times more expensive. Why not demolish a part of the wall with ventilation ducts in it and move it a little deeper, narrowing the neighbors' ducts a little?

During redevelopment, it is forbidden to change the cross section of ventilation ducts and shafts. This requirement may seem rather strange. Especially if you suddenly lacked a few centimeters to fit a standard kitchen set into your dimensions, and making custom-made furniture turns out to be several times more expensive. Why not demolish a part of the wall with ventilation ducts in it and move it a little deeper, narrowing the neighbors' ducts a little?

Such a decision would be unfounded. Typical reinforced concrete ventilation slabs have certain diameters and sections of ventilation ducts or shafts. At the same time, the designers consider a certain amount of air that must flow through the channels and it does not have a reserve. It is enough to narrow the channel, creating at least a small obstacle in its cross section, as soon as the thrust will decrease, and the neighbors will immediately feel it. But even if everything goes smoothly and no one notices anything, then problems will arise later if you suddenly want to sell the apartment. In this case, you cannot avoid an inspection by the BTI, whose specialists will calculate the discrepancy, issue a fine and force everything to be redone in the reverse order.

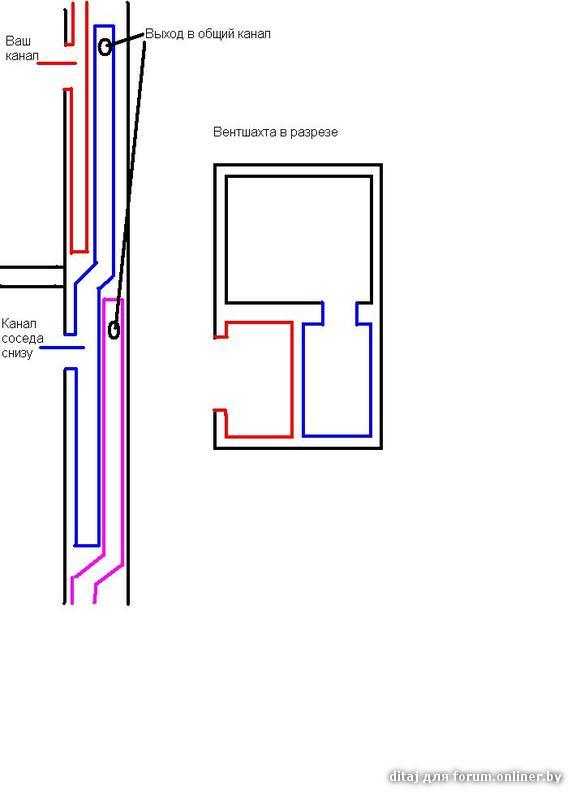

Ventilation shaft in a multi-storey building diagram

If we consider the schemes in which the exhaust air will be collected in the attic, then they also cannot be called ideal. To use such a scheme, an attic is required. And in both cases there are significant disadvantages.

The presence of a common collector creates additional resistance to traction, and if the ventilation shaft in a multi-storey building releases air into the attic, then unpleasant odors will accumulate there. In new houses, air is taken in through a special installation, which is placed in the basement. The purified air will be supplied to all apartments, and when it gets dirty, the exhaust fan will take it away.

Reasons why a mine may stop working

A typical problem with the air duct is the back flow of air. It all depends on the features of the system used. For example, all mines in an apartment send waste streams to a common channel.

If an individual channel in one of the apartments fails, this will not affect the performance of the entire system. But if there are several such apartments, then the air flow simply cannot push itself further, respectively, it will go down. The last floors will draw in the exhaust air. Usually in this case they decide to bring their channel directly to the roof. The culprit for the violation of air exchange in individual apartments may be a plastic double-glazed window, the lack of a gap between the floor.

Ventilation passage through the roof types, installation

Warm air is generated in living quarters for a variety of reasons. By its nature, it rises up through coverings, into higher rooms or outdoors. Most of the warm air is formed, of course, during the heating season.

Therefore, it is very important to properly adjust the system and ventilation units, in particular, so that the air circulates in the house, and only recycled air comes out.

The exit path of ventilation to the roof and passage through the roof is carried out from exhaust and other air circulation channels in the building.

Roof ventilation units

The forced exit of recycled air from the building is a key task of the roof outlet of recycled air. The correct installation of this system must be carried out in accordance with GOST-15150. It contains data on the distance of the ventilation passage to the edge of the slab and the standard parameters of openings in floor slabs. Passage nodes are also suitable for the removal of chimneys, which are used for buildings with wood-burning hearths - a fireplace, a stove, etc.

Roof ventilation depends on the exhaust ducts and the type of roof. It is divided into several types of forms:

Ventilation passage nodes are openings in the roof slab. They are equipped with aluminum ventilation pipes, designed specifically for placement on the roof. Experts recommend using aluminum pipes 1 mm thick. But the sizes of ventilation are different, but choosing an individual option is not difficult.

Ventilation systems with metal pipes are:

To select the correct nodes for the passage through the roof, the following characteristics are taken into account:

- humidity level;

- volumes of gas emissions;

- boundaries of air temperature fluctuations;

- degree of accumulation and formation of dust.

During the installation work, it is necessary to take into account some of the nuances:

- roof pitch;

- the distance between the ridge and the penetration;

- materials from which the roof is created;

- the area of the room directly under the roof.

On reinforced concrete material, the nodes of the passage through the roof are fastened with anchor bolts. The bolts themselves are placed in "glasses" during the installation process. It is also necessary to use plates with holes, which are designed specifically for the passage of ventilation through the roof. If the width of the opening does not correspond to a solid ribbed or hollow slab, places made of monolithic concrete are equipped in the passage zones.

If ventilation is carried out through a roof with a metal crate, the installation process is similar, but metal "glasses" are used.

A large building with a considerable number of residential, industrial or warehouse premises requires ventilation ducts to be provided even during the planning period of the building.

The sequence of actions for mounting the node through the roof

- The series and model of the special seal ring is selected.

- The soft part is pulled onto the pipe.

- The base is shaped according to the surface of the roof. For corrugated board, it is most difficult to adapt the base due to its ribbed surface.

- Sealant is applied under the flange for waterproofing.

- The flange is attached to the base with screws.

About ventilation ducts

- without valves;

- with valves;

- with thermal insulation;

- without thermal insulation;

- with a controller that monitors the position of the valves.

Systems with a manual type of adjustment are used in cases where the system does not need constant monitoring of operating modes. This ventilation system control method consists of:

An electric single-turn mechanism controls the operation of the valve - closes and opens it. The valve itself is made of stainless steel with a thickness of 0.8 mm.

The nodes through the soft roof are mounted on a base of galvanized steel, which is installed together with a layer of thermal insulation.Warm material should be no thinner than 5 cm, mineral wool is best suited for this. Later it will be possible to place special deflectors in the heat insulator - an aerodynamic device that is attached to the top of the ventilation or chimney pipe. Designed to disperse the flow of outgoing recycled air. At the end of the installation of the ventilation blades, plastic tubes made of plastic are carried inside, through which the electrical wiring passes.

A properly equipped unit will function for a long time and even muffle extraneous noise from the outside.

What causes poor ventilation in the apartment

Decades have passed since the development of the current SNiPs. Most apartments and houses today have plastic windows and metal entrance groups, which are almost 100% tight. This creates significant problems for the implementation of natural air circulation inside the housing.

Inefficient ventilation causes gas accumulation during an emergency leak, which, in turn, creates an explosive situation.

Moreover, the lack of normal air exchange leads to other negative consequences:

- The concentration of harmful substances increases, primarily carbon dioxide produced during breathing, and carbon monoxide released during cooking in the kitchen.

- A high concentration of moisture vapor leads to the formation of condensation on the windows, walls and ceilings of the apartment, which causes the development of mold and mildew, the appearance of an unpleasant smell of rot and dampness in the housing.

- A damp, musty atmosphere is an ideal breeding ground for a variety of pathogens.

This problem can be solved in the warm season by opening the vents and windows, but in winter this option disappears, especially if there are children at home. The only viable solution to the problem is the organization of the supply and exhaust system inside the apartment with your own hands.

The result of construction

As we have already noticed, repairing ventilation is not an easy task and it will take a couple of days for a quality repair, and even if not in one room, it will take a couple of days. Having the right electrical tool for repair will greatly facilitate the task. To visually understand how each repair step looks like, it will not be superfluous to view the corresponding videos on the Internet.

WATCH VIDEO

In terms of attracting specialists to repair, do not expect to cope with repairs cheaply: although firms offer to solve this problem quickly and without monumental investments, the final amount is rather big. Therefore, it is better to do this work on your own, because there is nothing super complicated here, which an ordinary person cannot do.

source: