- Film bonding method 2

- How to perform diffusion soldering

- Preparation for work

- How to join cross-linked polyethylene

- Installation with compression fittings

- Connection with electrofusion fittings

- crimp method

- Which way is better

- Methods for welding polypropylene pipes

- Types of connection of metal pipes with plastic

- Features of threaded connections

- flange connection

- Other methods of threadless connection of metal and plastic pipes

- Welding a polypropylene pipe with fittings

- How to connect plastic pipes without a soldering iron?

- Use of flanges

- Connection with press fittings

- The use of couplings (HDPE)

- Bonding elements

- Advantages

- PVC soldering secrets and safety measures

- Connection of polypropylene pipes with metal

- Conclusion

Film bonding method 2

You can connect the edges of the panels as follows: clamp them between 2 smooth strips of metal so that the edges of the film protrude from under them by about 1 cm, and melt them with the flame of an alcohol lamp or blowtorch.

Xylene and trichlorethylene heated to 70-75°C can also be used for film bonding. At a temperature of 30 ° C, film panels can be glued together with 80% acetic acid

If you have chosen one of the above substances to bond the film parts, use extreme caution when working with them.

The film can be glued with BF-2 or BF-4 adhesives, having previously treated the surfaces to be joined with a 25% solution of chromic anhydride. PK-5 glue is best suited for joining polyamide film panels. Be sure to iron the seam obtained after gluing with a warm iron heated to a temperature of 50 - 60 ° C.

More recently, superglue has appeared on sale, which is designed specifically for plastic film. It gives a very strong, waterproof and elastic bond. In addition, it is absolutely odorless, and the compounds are transparent and almost invisible. With one bottle of glue with a capacity of 50 ml, it is possible to glue a seam 15 - 20 m long.

Since Super Glue contains household solvents, it is recommended that you follow the same precautions when handling it as you would when using household chemicals. When stored in sealed packaging, the shelf life of the adhesive is not limited. If it dries, it is enough to dilute it with acetone to restore its original properties.

If it dries, it is enough to dilute it with acetone to restore its original properties.

Superglue is also useful for repairing the finished film coating. The method of its application in this case is as follows. Using a brush or stick, apply a thin layer of adhesive around the damaged area on the outside of the film cover. Let it dry for 2 hours. Then cut out a patch of the required size from the film, attach it to the damaged area and smooth it well. Superglue can even glue old film. However, you should know that it is best to repair the film coating in sunny weather.

If you want to sew film panels with threads, overlap them on top of each other. Stitch infrequently. To increase the strength of the seam, make a paper lining. This method of connecting film webs is most often used if it is necessary to patch the film coating before it is pulled onto the frame or when an already stretched film is torn. Minor damage to the film can be sealed with adhesive tape.

This problem is often faced by owners of summer cottages, greenhouses, home craftsmen, and even car owners. After failures, people start looking for information on the topic. Is it possible to glue polyethylene at all? In the article you will find the answer to this question.

How to perform diffusion soldering

Docking of the ends is carried out directly by socket soldering or with the help of couplings. The coupling is a shaped piece that is used as a connecting link. It is appropriate for pipes with a diameter up to 63 mm. Instead of a coupling, cutting pipes of a larger diameter than the welded area are suitable. The section of the pipe and the coupling at the junction is melted, providing a reliable fastening.

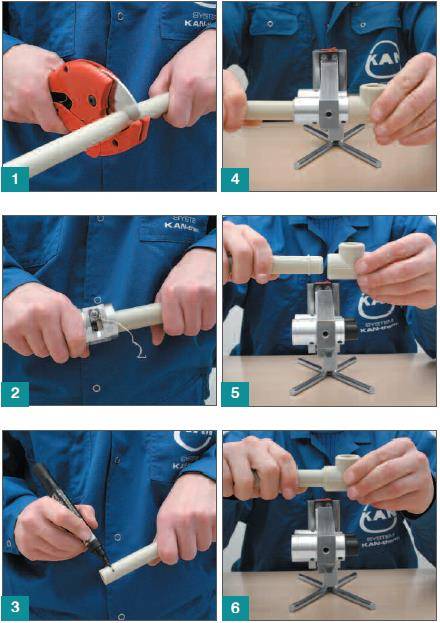

Pipe cutting

The socket connection requires precise joining of the pipe elements. The edges must be perfectly protected. Irregularities and burrs after trimming are not allowed. After the ends are melted by the apparatus, their diffuse connection occurs. If errors occur during trimming, a leak or a gap in the joint will form when the water is supplied.

Preparation for work

The workspace needs to be cleaned, remove unnecessary items. Construction debris and dust should not get into the connection of pipes made of cross-linked polyethylene. Accurate cuts and measurements require good lighting. The temperature in the room is +10-25°C, average humidity.This is needed more for quality work (comfort).

Insulation for a water supply pipe: how to insulate it in the ground at a shallow depth To organize year-round water supply, ...

Polyethylene foam insulation can be used as a heat-insulating material. Its inner diameter must correspond to the outer section of the pipeline. Couplings do not isolate completely. The insulation is cut and mounted after the final laying of the line.

How to join cross-linked polyethylene

The choice of connection method for PEX pipes depends on the pressure in the system and the temperature of the water (heat carrier). Possible pressure surges are taken into account. For the central water supply, this figure is 2.5-7.5 bar. In autonomous heating, the pressure is up to 2 bar. In a centralized one, it can reach 8 bar.

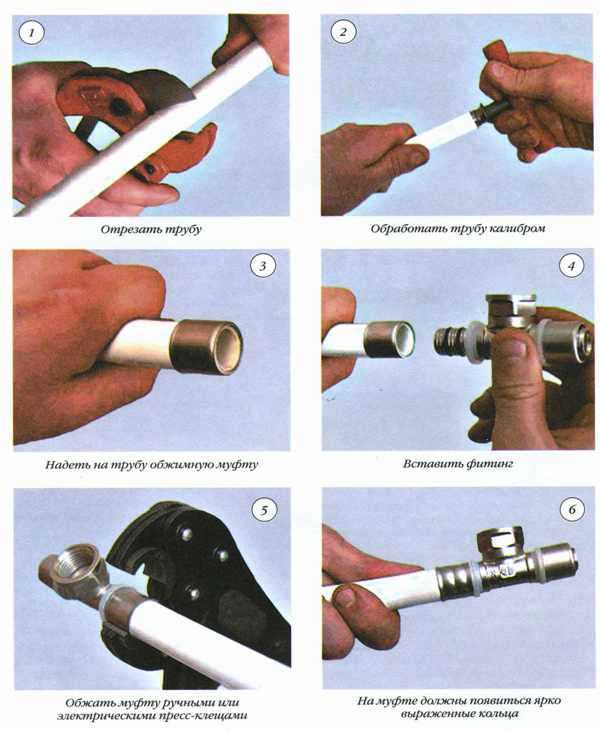

Do-it-yourself installation of XLPE pipes can be done in the following ways:

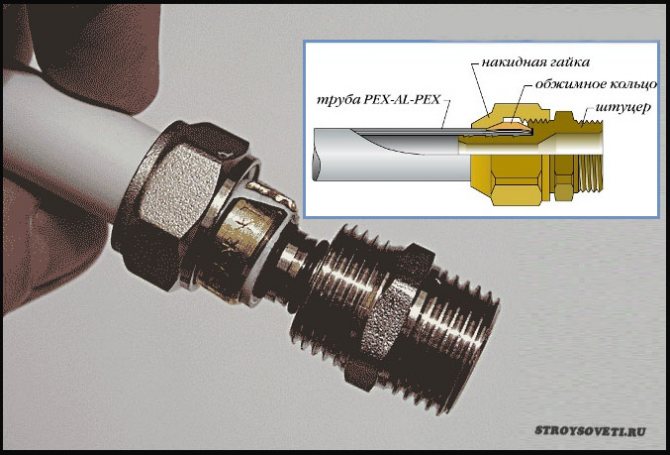

- Crimp. The simplest method is used for plumbing systems. Compression fittings consist of three parts - a nut, a split ring and a fitting.

- Pressing. The shrinkage property is used. The coupling consists of a press ring and a fitting. Additionally, you need an expander and a hand press.

Installation with compression fittings

The connection of the water supply pipe is made with compression fittings. They are made from

Compression fitting

food brass. This material has a high resistance to dezincification. An alternative is polyphenylsulfone connectors (PPSU). They are used for flush mounting, as they have a solid construction.

Mounting Features:

- A minimum of tools - two gas wrenches, a pipe cutter.

- For fixation, only muscular strength is needed.

- Easy dismantling, which is convenient for creating temporary pipelines.

For connection, a crimp nut is installed on the end of the pipe. Then the split ring is mounted. The plug must be inserted as far as it will go. The compression nut is screwed onto the fitting

It is important not to pinch, controlling muscle effort

Connection with electrofusion fittings

For welding cross-linked polyethylene, special fittings are needed. They are made of polyethylene grades PE-80, PE-100. Inside are heating elements in the form of spirals. On the outer part of the structure there are two connectors for connecting electrical contacts. When the current passes, the spirals heat up, the material of the pipes and fittings is welded.

Electrofusion fitting

Electrofusion fitting

The procedure for using electrofusion fittings.

- Stripping the outer part of the pipeline, the distance is less than half the fitting on each side of the pipe.

- Installing the coupling up to the internal limiter.

- Installation of contacts of the welding machine.

- The choice of mode depends on the type of PEX, the diameter and thickness of the line.

After switching off the welding machine, the contacts must be disconnected. End welding for pipes of small diameter and wall thickness is unacceptable. It will not provide the proper quality and reliability of the connection.

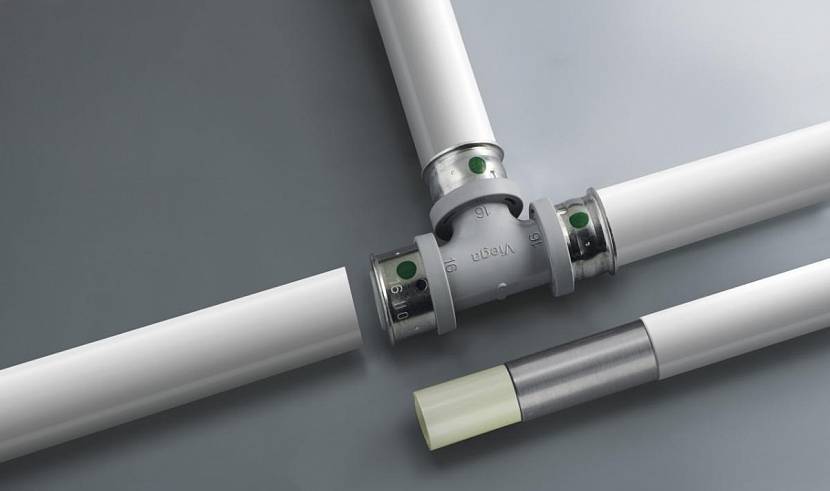

crimp method

The connection is mechanical, but differs from the compression method. A feature of crimp couplings is the formation of a permanent connection. Additional tools - collet expander and press fitting. A simple installation method is to install the coupling on the end of the pipe and press it.But this method does not guarantee reliability.

Alternative method of installing a ferrule.

Crimp connection

- The press ring is put on the pipe.

- An expander is inserted into the socket, increasing the diameter of the pipe to the size of the fitting.

- Instead of an expander, a fitting is mounted.

- A ring is stretched onto the structure and compressed with a mechanical or pneumatic press.

If, after checking the system, a leak or other defects are found, the connection assembly must be completely removed for dismantling. Therefore, it is recommended to leave a small margin of length in the places where the couplings are mounted.

Which way is better

To organize a water supply or heating system with open installation of pipelines, you can choose compression couplings. These are serviced connections, they need to be tightened periodically for reliability. They are also used for laying temporary highways.

Press tongs for metal-plastic pipes: a tool for crimping In modern systems of heat and water supply of houses, metal-plastic (otherwise - metal-polymer) pipes are becoming more common. They have a number of clear advantages over traditional…

The crimp method can be used for flush mounting. But I do the final laying and hiding of pipelines after checking the integrity of the system. It should work at maximum pressure for several hours. After that, the integrity and tightness of the connections are checked.

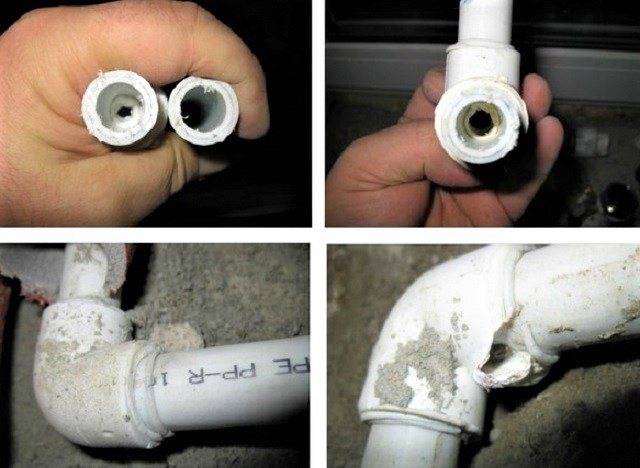

Methods for welding polypropylene pipes

To connect polypropylene pipes, several welding methods are used, depending on their diameter, wall thickness and application:

- Butt. The technique is used for joining elements of large diameter pipelines used in the industrial and municipal sectors.The process occurs by simultaneous heating with a flat disk of pipe ends previously cut at an angle of 90 degrees, after which their edges are pressed against each other with force on a special machine.

- Coupling. The technology is practically not used in the welding of polypropylene pipes (mainly with HDPE), the connection is made using electrofusion couplings, into which both ends of the pipe elements are inserted. When an electric current is passed, the inner case heats up, becomes softer and loses its rigidity. As a result of this process, it is compressed under the pressure of the outer shell, forming a strong one-piece joint between the connected elements (active hardening). After cooling, the effect of active hardening remains, pressing the coupling tightly against the pipes.

- The flared method. A method widely used in everyday life and in all areas of industry consists in connecting the two ends of a polypropylene pipe using polypropylene fittings. For heating in everyday life and industry, special welding machines (irons) and heating nozzles are used, which simultaneously heat the surface of the pipe and the inside of the fitting, after which the elements are joined.

Rice. 2 Welding device - soldering iron

Types of connection of metal pipes with plastic

Today, there are two ways to perform this procedure:

- Threaded connection. It is used when tubular products are connected, the diameter of which does not exceed 40 mm.

- Flange connection. It is optimal for a large cross-section of pipes, since tightening the threads in such cases will require considerable physical effort.

Features of threaded connections

To understand how a plastic pipe is connected to a metal pipe using a thread, you should study the fittings that are used for these purposes. In fact, such a part is an adapter. On the side to which the metal pipeline will be connected, the fitting has a thread. On the opposite side is a smooth sleeve, to which a plastic pipe is soldered. Also on sale are models with which you can connect dissimilar lines in larger quantities and fittings for making bends and turns.

The threaded coupling is selected depending on the type of plastic pipe - for soldering, with a crimp or compression connection

To connect a steel pipe to a polypropylene one, you have to perform the following sequence of actions:

- remove the coupling from the steel communication at the site of its intended connection with the plastic branch of the pipeline. You can also cut off a piece of an old pipe, apply grease or oil and make a new thread with a thread cutter;

- walk along the thread with a cloth, fasten a layer of fum-tape or tow on top, cover the surface with silicone. Wind 1-2 turns onto the thread so that the edges of the seal follow their course;

- screw on the fitting. Perform this operation with an adapter from a plastic pipe to a metal one without using a key. Otherwise, the product may crack. If, when you open the tap, a leak appears, tighten the adapter.

The convenience of the design of this part is that it simplifies the procedure for connecting metal pipes with polypropylene pipes at turns and bends. Interestingly, if necessary, the shape of the fitting can be changed.Heat it up with a building hair dryer up to +140˚С and give this part the required configuration.

flange connection

As mentioned above, metal and plastic pipes of large diameter are connected in a similar way. The final design is collapsible. The technology of such a connection of a plastic pipe with a metal one without a thread is as simple as in the case of using a threaded adapter.

carefully and evenly cut the pipe at the intended connection;

put a flange on it and install a rubber gasket

She will act as a sealant;

carefully slide the flange onto this sealing element;

do the same with the other pipe;

Bolt both flanges together.

One of the options for switching from metal to plastic is a flange connection, in which case a flange is first soldered to the polymer pipe

Advice. Tighten the bolts evenly, without moving parts and without excessive force.

Other methods of threadless connection of metal and plastic pipes

To implement this technology, in addition to flanges, the following devices are also used:

Special clutch. This part is for sale in a building materials store. However, with certain skills, you can do it yourself. This adapter consists of the following components:

- corps. It is best to make it from high-strength steel or cast iron;

- two nuts. They are located on both sides of the clutch. If you are going to make such an adapter with your own hands, use bronze or brass for the production of nuts;

- four metal washers.They are installed in the inner cavity of the coupling;

- rubber pads. They are used to seal the connection. It is impossible to specify their exact number in advance.

The diameter of gaskets, washers and nuts must correspond to the section of the pipeline elements. Connect a metal pipe with a plastic one without a thread using such a coupling in the following sequence:

- Insert the ends of the pipes through the nuts to the middle of the coupling. Also, thread the tubulars through the gaskets and washers.

- Tighten the nuts until tight. The gaskets must be compressed.

The connection is durable and strong enough.

Using a Gebo type fitting, the connection can be made quickly and effortlessly, the main thing is to choose the right diameter

Fitting Gebo. This part consists of the following elements:

- corps;

- nuts;

- clamping rings;

- clamping rings;

- sealing rings.

The connection is very simple.

- Unscrew the coupling completely.

- Put all the above elements on the ends of the pipes to be connected.

- Fix the joint with nuts.

Welding a polypropylene pipe with fittings

Main steps:

- preparation of the necessary tool.

- pipeline planning.

- pipe cutting.

- welding of pipes and fittings.

Fittings and accessories are usually attached to plastic pipes by welding. This will require a special soldering iron with several nozzles that are suitable in size to the diameters of the pipe and fittings. Before starting welding, it will be necessary to clean the area where the fitting enters it. To do this, the aluminum foil is removed if a pipe with an aluminum layer is used.

Soldering a polypropylene pipe with a fitting

Then the fittings for polypropylene pipes and the pipe itself are evenly heated with a soldering iron with an appropriate nozzle and connected to each other.

When gluing pipe parts and fittings, rotation of the parts must be avoided. The soldering of the elements must be securely fixed at the time of their cooling. Otherwise, the connection will not be tight and will leak during operation.

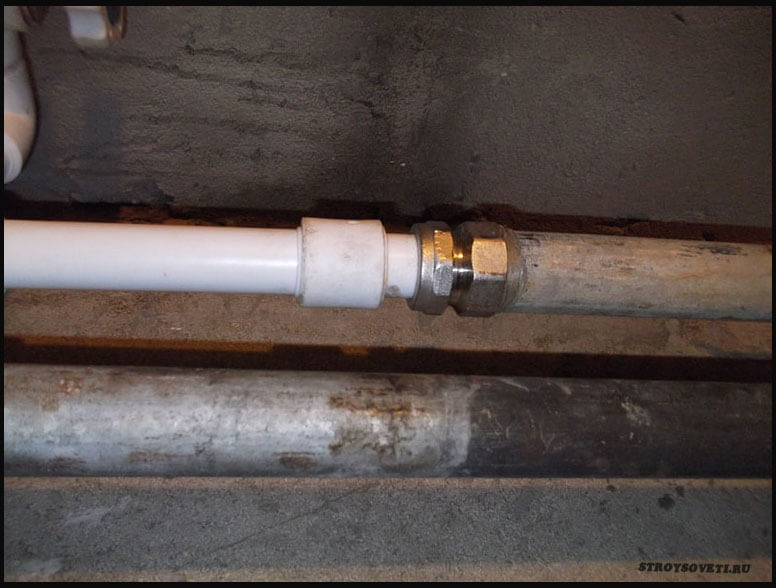

With a combined connection with a metal water pipe, a different connection method will be required, including both welding and a threaded connection. Typically, such a combined connection is required when connecting plumbing equipment.

First of all, before starting work, turn off the risers and drain the water in the system. After that, the old water supply is dismantled.

To speed up the dismantling of the old water supply, you can simply use the grinder - cut the old metal pipes into pieces.

The soldering process is shown in detail in the video below.

After the dismantling work is completed, it is necessary to remove the old valves, clean the part of the water supply line leading to the riser with a cable and proceed with the installation of a new valve. This will help to avoid a blockage in the water supply on this old section of water supply.

Before installation, it is necessary to put the filter on the mixer. This will prolong the life of the washing machine, which can be connected to the water supply system in this place.

After all this, you can install a combined fitting. The threaded metal part is attached to the mixer, and the plastic part is welded to the pipes.

How to connect plastic pipes without a soldering iron?

Before moving on to tie-in technologies in polypropylene pipelines, you need to dwell on the methods of connecting different plastic pipes without welding. There are several ways to achieve the desired goal. Some of them are not used very often, others, on the contrary, are used by almost all masters. The most popular methods include 6 technologies.

- Electric saddles. They are used for plastic products of one type - for low-density polyethylene. It straightens out when voltage is applied from the network.

- Docking of PP pipes using flanges. This connection is considered the most reliable: bolts are used for it, they are screwed into the holes provided in the elements.

- The use of special elements - pipes of a larger diameter, they have sockets, sealing cuffs. The joints are securely protected with rubber seals. This option is suitable for non-pressure pipelines.

- Connecting elements with couplings. Before installation, threads are cut on the pipe. To ensure maximum tightness of the segment, it is wrapped with tow, FUM tape or coated with a special plumbing paste. However, the best option is a welded joint.

- Use of practical compression elements, or press fittings, made of steel or cast iron. This option is suitable when the diameter of the pipes is small. The advantages of fittings are a wide range that allows you to mount sections of pipelines at different angles.

- The use of adhesive. This method has a serious limitation. It is completely unsuitable for hot water pipes. There is an exception: these are brands that can withstand high temperatures. Glue is applied to the parts, connected, then left to dry.This is a minus, since a sufficiently large break in the operation of communication is needed. Many masters have branded this method as the most unreliable.

Each owner will answer the question in his own way how to crash into a polypropylene pipe without soldering. The decision regarding the method of operation will necessarily be influenced by the type of elements used, their size and the purpose of a particular pipeline.

Use of flanges

Such a connection is obtained as reliable as possible: the joints are able to withstand pressure up to 16 atmospheres and high temperatures. The diameter of the pipeline for which this operation is possible is from 20 to 1200 mm.

First, a cut is made at both ends of the elements to be joined, but make sure that burrs do not form. Then gaskets are installed on them, the maximum distance from the end is 10 mm

Flanges are put on rubber seals, bolted together and carefully tightened.

Connection with press fittings

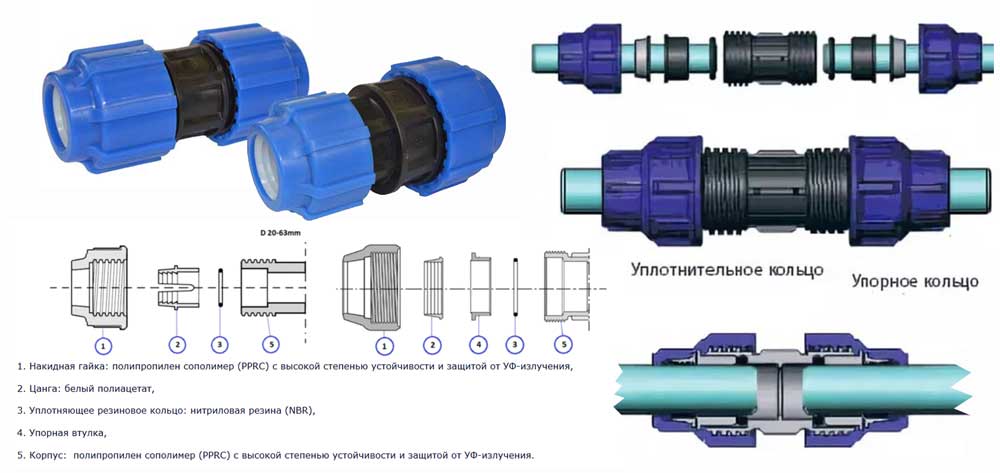

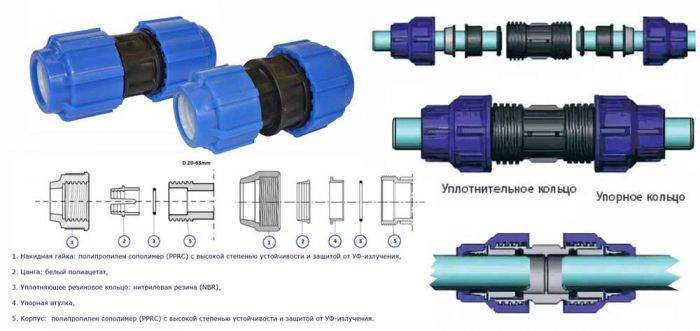

This is the second popular method used where it is necessary to provide a branch or turn of the pipeline. The compression fitting consists of a cover, a body, a clamping ring, a thrust ring and a bushing.

Before the operation, the ends of the polypropylene pipes are cut perpendicular to the axis, the burrs are removed, the elements are cleaned of dust and degreased. They are put on nuts unscrewed from the fittings, then clamping rings are installed. Insert the elements into the fitting until it stops, then tighten the fasteners on each of them.

The use of couplings (HDPE)

This is the main type of compression fitting. This type of connection is suitable for both pressure and non-pressure pipelines. After cutting the edges of the elements to be joined, they are inserted into the coupling, making sure that the joint of the parts is exactly in the middle of the coupling.Then the nuts are tightened.

Clamp connection fasteners are used where the pipeline is close to the floor or wall. In this case, the coupling is unscrewed, all its parts are put on the pipe in order, then the nut is tightened. On the opposite side, an American fitting is screwed with an already fixed polypropylene pipe.

Bonding elements

This method is used as an addition (for example, when using fittings), since adhesive compositions are not very reliable. In this case, the edges of the parts to be glued must be roughened. For this purpose, after cutting the pipes, their edges are treated with sandpaper.

Prepared surfaces are degreased. Glue is applied to all areas where the fitting will be installed. The segments are connected, the correct position is checked, fixed for a minute, then left to dry completely. The composition sets in a quarter of an hour, but it takes at least a day to dry completely.

Advantages

- low cost;

- chemical inertness - does not react with either alkalis or acids; water does not acquire an extraneous taste or smell;

- corrosion resistance; resistance to aggressive environments;

- durability - the first pipes have worked for more than fifty years;

- smooth inner surface - such pipes do not "overgrow" with calcium salts, like metal ones;

- tolerate freezing with water inside and do not burst like metal ones;

- not afraid of temperature changes (in the range from -20 ° C to 40 ° C):

- plastic polyethylene easily tolerates soil movements;

- manufacturability - easy and quick installation;

- polyethylene is environmentally friendly - its production and disposal do not lead to environmental pollution;

- light weight facilitates their installation, storage, transportation.

PVC soldering secrets and safety measures

Soldering work should be carried out in a room with positive temperature. It must be taken into account that the colder it is, the longer the elements will warm up. However, there are a number of other rules that must be observed.

Features of soldering PVC pipes:

- The power of the iron should be 1200 watts.

- The manual device is used for pipes with a diameter of up to 32 mm. For large sizes, professional equipment is used.

- Before starting work, the device must be warmed up for 5-10 minutes. This is necessary for the device with nozzles to reach the desired parameters.

- After soldering, it is forbidden to scroll the connection. Otherwise, it may violate the integrity of the seam. You can only straighten the distortions so that the connection does not leak.

- No need to apply a lot of force to compress the parts. Otherwise, the gap will be filled with hot plastic and disrupt the patency.

- No gaps between the pipe joint and the inside of the fitting are allowed. Otherwise, leaks will occur under pressure.

- The soldered area must be completely cool before use.

- After completion of work, the iron is cleaned of plastic. So on the device there will be no carbon deposits, and the elements for soldering will not be damaged.

Use a flat wooden stick for cleaning. So the teflon will not be damaged. Metal objects can scratch the surface and make the nozzle unusable, because the plastic will begin to stick to the coating.

The soldering machine should be placed in such a way that it is stable.

The soldering machine should be placed in such a way that it is stable.

When working with power tools, it is important to observe safety precautions.Otherwise, you may get burned or injured. Work with protective gloves

The room must be clean and dust-free. Otherwise, the particles will settle on the plastic and disrupt the quality of the soldering.

You need to work with protective gloves. The room must be clean and dust-free. Otherwise, the particles will settle on the plastic and disrupt the quality of the soldering.

The soldering iron is placed horizontally on the surface. During operation, it is forbidden to turn off the equipment. Work begins when the iron is fully heated. In modern models, this is indicated by an indicator. For old-style options, wait 20 minutes.

The soldering of polyethylene pipes does not have a complex technology. Welding may have features if you solder reinforced products

However, it is important to take precautions. Soldering pipes correctly will help the basic secrets and rules. Also, follow the instructions exactly.

Also, follow the instructions exactly.

Also, follow the instructions exactly.

Connection of polypropylene pipes with metal

The question remains how to connect polypropylene pipes (under high pressure conditions) with metal ones? There are 2 methods. You need to choose one of them, starting from the radius.

1. For products with a radius of up to 20 mm, threaded connections on the metal part of the system must be used. Fittings, on one side of which there is an ordinary coupling for mounting to plastic, and on the other, with the necessary thread, are sold everywhere. In order to seal steel threads, use flax with drying oil or modern sealing materials. This will ensure the durability of the connection.

2. For larger sizes, it is better to use flange connections.An iron thread with a radius of 300 mm cannot be screwed by hand, even if you are a strong man. So how then to combine a metal pipe and a polypropylene pipe if they are of large diameter? Use special adapters that can be purchased at the store.

Thread and flanges allow you to connect metal and polypropylene pipes without soldering, which is very convenient.

Conclusion

Having figured out how to properly join PP pipes, you can very quickly assemble high-quality plumbing at home.

The video in this article will tell you more about its topic.

Hello dear reader! If you need to lay a cold water pipeline, you can use low-pressure polyethylene (HDPE) products - an inexpensive and practical material. Each material has its own subtleties and installation features. In this article, we will tell readers how to connect a HDPE pipe.

Polyethylene is a widely used and well-known plastic. But they began to make pipes from it not too long ago - about 50 years ago. The name "LDPE" comes from the way the polyethylene is produced and is not related to the quality of the plastic.

Pipes can be black, bright blue, black with blue and yellow stripes, gray (for sewers), rarely other colors. Blue or black products with blue stripes are intended for drinking water supply, black products are for technical purposes. Diameters - from 16 to 1600 mm. They are made as measured products with a length of 12 m or in coils (if the diameter does not exceed 160 mm)