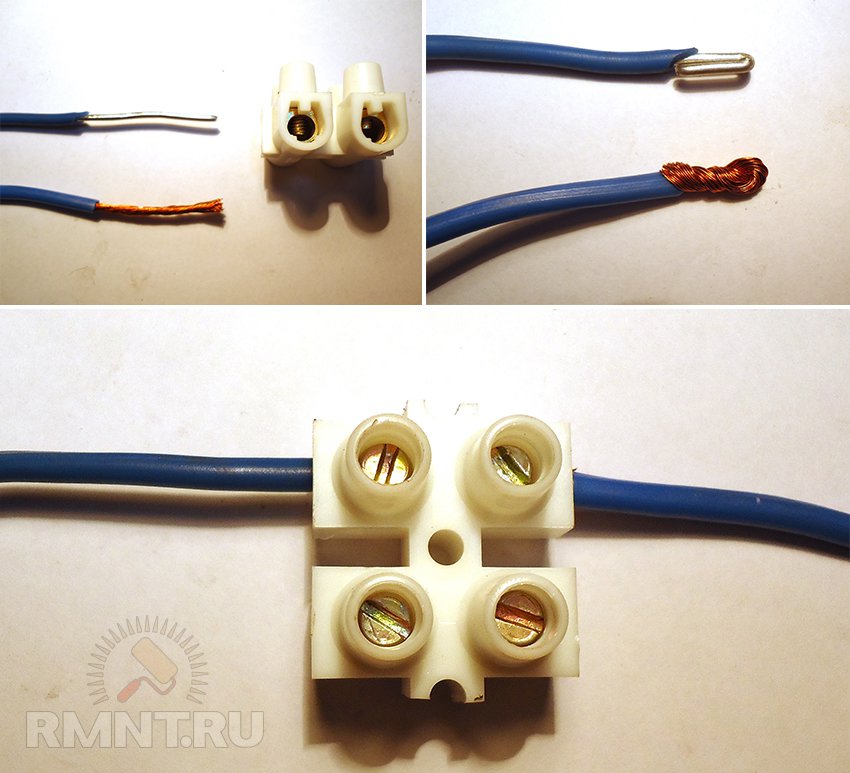

Terminal block

A fairly convenient way to connect aluminum wire to copper is to use a terminal block for this. This device is a clip made of polymer insulating material. Inside it there are several contacts-terminals with outputs from different sides of the case.

To connect the wires, their ends are stripped and inserted into opposite outputs of one terminal. In it, they are fixed with clamping bolts located at each of the outputs. Therefore, to connect the stripped ends of the wires, you only need a screwdriver.

The block is easily cut across with a knife or scissors, depending on how many wires you need to connect to each other. Each terminal has a through passage. Therefore, when fixing the wires, you should not insert them too deeply to prevent direct contact between copper and aluminum.

To prevent moisture from getting inside the terminals, or accidental mechanical damage, the pads are installed inside protective junction boxes.You can do without it if you purchase a complex option - a terminal box, inside which a ready-to-use block is mounted.

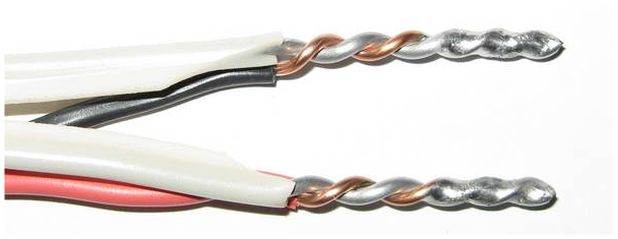

How to make a twist

As mentioned above, direct twisting of aluminum wires with copper is unacceptable. However, in a number of situations, there is no other way out due to the lack of special connecting devices at hand. Also a similar way has a number of advantages:

- Does not require the use of special tools.

- Fast and convenient.

- Makes it possible to quickly join the wires at home.

Stranding aluminum wires with copper wires is allowed as a temporary measure until special clamping devices are purchased. For more or less long-term use of twisting, a number of prerequisites will need to be met:

- The connection is made by the method of mutual twisting of two stripped ends. A simple winding of one core around another, straight, is not allowed.

- The stripped end of the copper wire should be tinned to reduce the electrochemical potential. For this, tin solder is used.

- After twisting, the bare parts of the cores are covered with a moisture-repellent coating, such as varnish or silicone paste.

- The number of turns of twisting is also important - the thinner the connected cores, the more there should be. So, for wiring d \u003d 1 mm, the minimum number of turns should not be less than five.

- On top of the twist, for its reliable fixation, special plastic cone-shaped tips with a spring inside are put on.

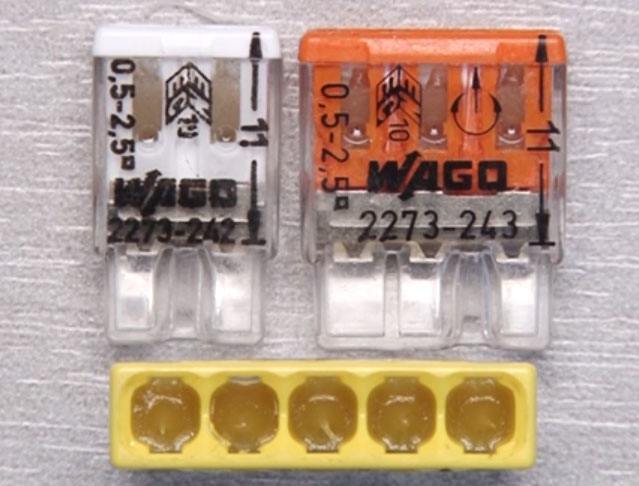

We use modern pads with spring clips

Not so long ago, modified terminals equipped with spring clips were introduced to the market for electrical equipment and components. Disposable (conductors are inserted without the possibility of further removal) and reusable (equipped with a lever that allows you to get and insert cables) blocks are available.

We use modern pads with spring clips Wago terminals

| wago terminal blocks | Current (A) | Number of connections wired | Conductor cross section/ (mm²) | Presence of contact paste |

|---|---|---|---|---|

| 222-413 | 32 | 3 | 0,08-4,0 | without pasta |

| 222-415 | 32 | 5 | 0,08-4,0 | without pasta |

Disposable terminal blocks allow you to connect single-core conductors with a cross section in the range of 1.5-2.5 mm2. According to the manufacturers, such pads can be used to connect cables in systems with a current of up to 24 A. However, professional electricians are skeptical about this statement and do not recommend applying loads above 10 A to the terminals.

We use modern pads with spring clips

Reusable pads are equipped with a special lever (usually it is painted orange) and allow you to connect cables with any number of cores. The permissible cross section of the connected conductors is 0.08-4 mm2. Maximum current - 34A.

To connect using these terminals, do the following:

- remove 1 cm of insulation from the conductors;

- raise the terminal lever up;

- insert the wires into the terminal;

- lower the lever.

Leverless terminals simply click into place.

They are designed to connect any type of single-core wires, including copper wires with aluminum wires with a cross section of 1.5 to 2.5 mm2

As a result, the cables will be securely fixed in the block.The cost of making such a connection will be more significant, but you will spend much less time on the job and save yourself from the need to use any additional tools.

In a flat-spring clamp, the wire with stripped insulation is simply inserted into the hole of the Wago terminal until it stops.Electrical connectors with mortise contact

Electrochemical corrosion

However, in the recent past, aluminum wires were widely used in construction. As a result, in most residential buildings built up to the 90s, aluminum in-house wiring is less expensive, but also less durable. Partial replacement if necessary household power lines, or when laying branches from it, it becomes necessary to connect aluminum wires with copper ones.

It would seem that this is difficult? To make a simple twist of two conductive wires, you do not need to have deep knowledge in electrical work. But, the connection of copper and aluminum wiring is directly prohibited by the rules for installing electrical equipment. This is due to such a phenomenon as electrochemical corrosion of metals.

This process is characteristic of all metals without exception, even the so-called "noble". It only flows in them with different intensity - some are covered with a destructive corrosive coating rather quickly, while others only over a long time. But under certain conditions, the process of electrochemical corrosion can increase many times over.

One example of this is the direct connection of copper and aluminum wire.Having different electrolytic potentials associated with a different conductivity index, they act as catalysts for corrosion processes relative to each other. As a result of the operation of such bimetallic wiring, destructive chemical reactions will occur at the junctions of different cores.

It is permissible to connect metal conductors together, the electrochemical potential at the junction does not exceed 0.6 milliwatts. Then corrosion will not quickly form at the junction, and the conductivity indicator will deteriorate. The lower this indicator, the more compatible the conductors are with each other.

| Conductor metal | Copper and its alloys | Lead and tin | Aluminum | Duralumin - mini | Steel plain | Stainless steel | Galvanized | Chrome plated |

| Copper, its alloys | 0,25 | 0,65 | 0,35 | 0,45 | 0,1 | 0,85 | 0,2 | |

| Lead and tin | 0,25 | 0,4 | 0,1 | 0,2 | 0,15 | 0,6 | 0,05 | |

| Aluminum | 0,65 | 0,4 | 0,3 | 0,2 | 0,55 | 0,2 | 0,45 | |

| Duralumin - mini | 0,35 | 0,1 | 0,3 | 0,1 | 0,25 | 0,5 | 0,15 | |

| Steel plain | 0,45 | 0,2 | 0,2 | 0,1 | 0,35 | 0,4 | 0,25 | |

| Stainless | 0,1 | 0,15 | 0,55 | 0,25 | 0,35 | 0,75 | 0,1 | |

| Galvanized | 0,85 | 0,6 | 0,2 | 0,5 | 0,4 | 0,75 | 0,45 | |

| Chromium | 0,2 | 0,05 | 0,45 | 0,15 | 0,25 | 0,1 | 0,65 |

As you can see from the table, aluminum with copper, when docked, gives a potential indicator of 0.65 mV, which is unacceptable by the rules of the PUE. The connection of copper with aluminum will be covered with a layer of plaque, which increases the resistance directly at the junction. As a result, the wiring in this place begins to overheat, the braid melts, which is fraught with the most negative consequences - a short circuit and a fire. To avoid this, you can not twist directly copper with aluminum. If the need arises for such a docking, you should use one of the methods below, and connect the wires with conductors of different metals.

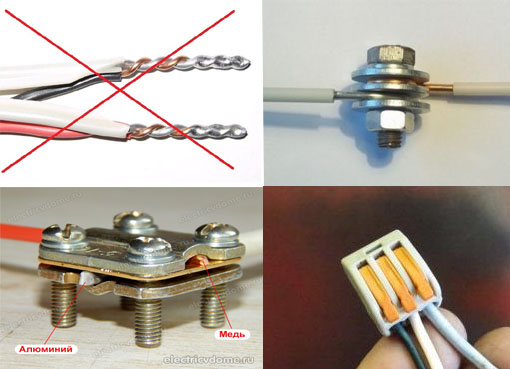

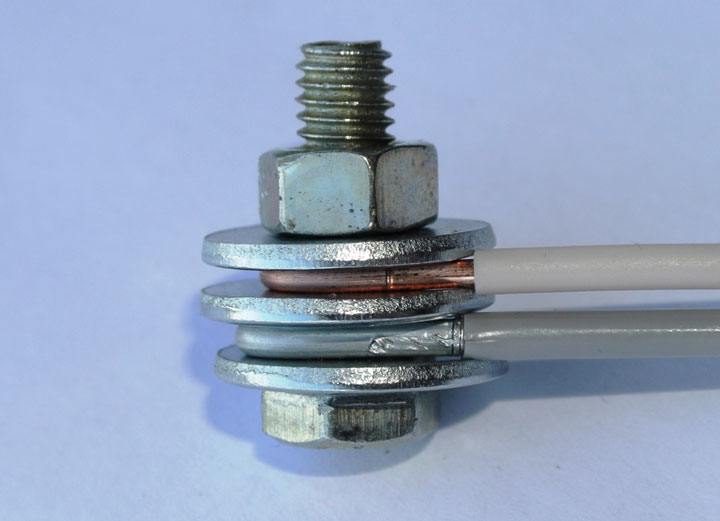

Connection through bolt and steel washers

One of the valid options for how to connect aluminum and copper wires is to use it as a conductor for docking a desktop bolt with nut and washersseparating different metals. The electrochemical potential at the junction of ordinary steel with aluminum is 0.2 mV, and steel with copper is 0.45 mV. Therefore, a steel bolt with steel washers is perfect as an intermediate conductor when connecting wires made of different metals.

The docking procedure step by step looks like this:

- We twist the stripped ends of both connected wires into rings with the help of round-nose pliers or pliers. Their size must correspond to the diameter of the threaded part of the bolt.

- We put the first wire on the bolt as far as it will go, pressing it to the head.

- After that, a steel washer is put on, which serves as a separator. Its width should be sufficient to exclude direct contact between aluminum and copper.

- Then we put on a ring of the second wire. It should be put on so that when the nut is tightened, the ring is not pulled tighter around the bolt shaft.

- From above we put on another washer, which will press the ring of the upper wire.

- To avoid weakening the contact over time, it is recommended to install an engraver between the nut and the top washer.

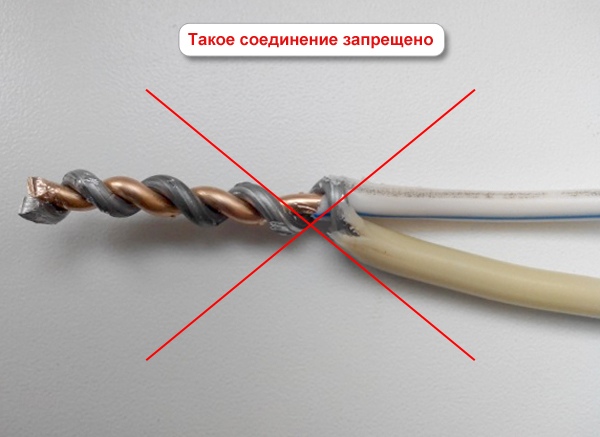

How not to combine copper and aluminum

How not to combine copper and aluminum

We connect the wires with a twist

Twisting

Most often, ordinary twist is used to connect wires. This is a simple method that does not require the use of additional devices. At the same time, twisting is the least reliable option for connecting conductors, especially if they are made of different materials.

Each metal has a tendency to some change in its size with temperature changes.For different metals, the thermal expansion coefficient is different. Due to this material property, a gap may appear in the joint when the temperature changes. It will lead to an increase in contact resistance, as a result of which heat will begin to be generated, the cables will oxidize and the connection will be broken.

Bandage twist

Of course, this takes far from one year, but if your plans include the construction of a durable and high-quality network, it is better to abandon the connection using the twisting method in favor of a more reliable option.

The method is suitable for connecting cables of different diameters. Twisting allowed solid and stranded wires, but in such a situation, a conductor with several cores must first be tinned with solder so that it turns into a single-core one.

Connection of wires by welding

The cables are twisted, after which the connection is sealed. For sealing, a protective varnish with waterproof properties is well suited. In order for the connection to be of the highest quality, it is recommended to solder the copper cable before starting work.

Twisted wire connection

The number of turns in the connection is selected in accordance with the diameter of the cable. If the conductor diameter does not exceed 1 mm, we make at least 5 turns. When twisting thicker wires, we make at least 3 turns.

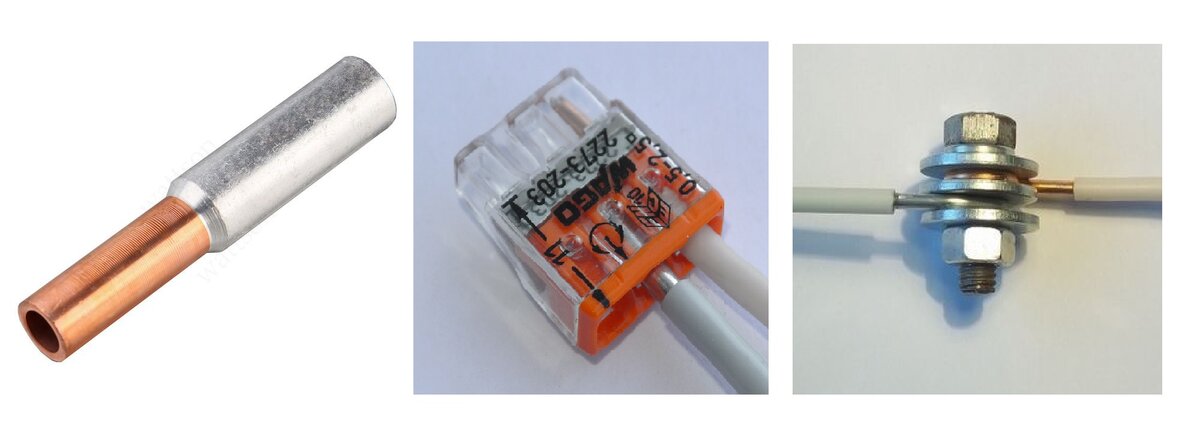

We make a permanent connection of wires

The main difference between this option and the previously considered threaded method is the inability to disassemble the connection without destroying the wires. In addition, you will have to buy or rent a special device - a riveter.

Actually, the wires are connected with rivets.Strength, affordable cost, simplicity and high speed of work - these are the main advantages of a one-piece connection.

Heat shrink tubing for twist or crimp insulation

The riveter works on an extremely simple principle: a steel rod is pulled through the rivet and cut off. There is some thickening along the length of such a rod. In the process of pulling the rod through the rivet, the latter will expand. Rivets of various diameters and lengths are available on the market, which allows you to choose a device for connecting cables of almost any section.

Reliable crimped wire connection

We work in the following order.

First step. We clean the insulating material from the conductors.

Second step. We make rings at the ends of the cables with a size slightly larger than the diameter of the rivet used.

Third step. We alternately put on the rivet a ring of aluminum wire, a spring washer, then a ring of copper cable and a flat washer.

Fourth step. We insert the steel rod into our riveter and forcefully squeeze the handles of the tool until it clicks, which will indicate that the excess length of the steel rod has been trimmed. This completes the connection.

How to connect the wires correctly

You have familiarized yourself with the basic methods for self-connecting aluminum and copper wires. Each method has its own characteristics, disadvantages, advantages and preferred applications. Choose the most suitable option, follow the instructions and very soon all the necessary connections will be ready.

When using stranded conductors of wires and cables, it is necessary to use special crimping lugs or solder the ends of the wires

Successful work!

Wago clamps

On sale today you can find clamps, original German from Wago, manufactured by other companies under license, or counterfeit. Accordingly, the quality of the devices will be different.

The stripped ends of the wires are clamped into them using spring-loaded terminals or elastic-rigid steel plates. Inside the device is an antioxidant paste that reduces the likelihood of corrosion when different metals come into contact. In this case, it is steel with copper and aluminum. According to their operational and technical features, Wago devices are divided into:

The stripped ends of the wires are clamped into them using spring-loaded terminals or elastic-rigid steel plates. Inside the device is an antioxidant paste that reduces the likelihood of corrosion when different metals come into contact. In this case, it is steel with copper and aluminum. According to their operational and technical features, Wago devices are divided into:

- Reusable. They can be easily removed by disconnecting the wiring if necessary. To do this, just press the spring-loaded clip, or flip the latch. This allows you to quickly perform any electrical work. However, in some cases there are complaints about the insufficient density of the joint. As a result of loose contact, at peak load, heating and burning of the conductive core may occur.

- Disposable. When inserting a conductive core into the clamp, it is very firmly fixed in it. It will take a lot of force to remove the wire, which is fraught with damage or even breakage of its clamped end. This option allows you to achieve a very tight connection, but during repair work, or when replacing part of the wiring, the old fixed clips are simply cut out and replaced with new ones.

We make the connection using the terminal block

Example of connecting copper and aluminum conductors

The method of connecting conductors with special terminal blocks is gaining more and more popularity. In terms of reliability, this option loses to the previous one, but it also has its advantages.

Wire connection

Terminals make it possible to connect wires as quickly, simply and efficiently as possible. In this case, it is not necessary to form rings or insulate connections - the blocks are designed in such a way that the possibility of contact between the bare parts of the cables is excluded.

Terminal box

The connection is made as follows.

First step. We clean the insulation from the connected ends of the wires by about 0.5 cm.

Second step. We insert the cables into the terminal block and clamp with a screw. We tighten it with a little effort - aluminum is a fairly soft and brittle metal, so it does not need extra mechanical stress.

Terminal blocks are very often used when connecting lighting devices to aluminum wires. Multiple twists lead to a rapid break in such conductors, as a result of which practically nothing remains of their length. In such situations, a block will come in handy, because only a centimeter length of cable is enough to connect with it.

The terminals are also very well suited for connecting broken cables laid in the wall, when new wiring is impractical, and the remaining length of the conductors is not enough to make connections by other methods.

Important note! Blocks can only be plastered if they are installed in a junction box. Terminal box

Terminal box