- How to properly place a septic tank and filter facilities on the site

- Use of anaerobic bacteria to decompose sludge

- Constructions of drain pits from concrete rings

- How to build a sewer storage tank?

- Features of the cesspool device without a bottom

- Construction stages

- Video description

- How to choose the best place for a septic tank

- Pit preparation

- Installation of rings and sewer pipes

- Sealing and waterproofing

- Manhole installation and backfill

- How does the septic tank start up

- What rules must be observed when maintaining a septic tank

- The frequency of cleaning the well. Private service cost

- How to unfreeze a hole

- What is a hydro seal

- We prepare a solution to eliminate a pressure leak

- We prepare the solution ourselves

- Leak sealing technology

- Other applications for hydraulic seals

- Safety

- Details

- Funds. Review

- Solutions for silting a septic tank with a bottom

- How to get rid of grease and soap

- Carrying out installation work

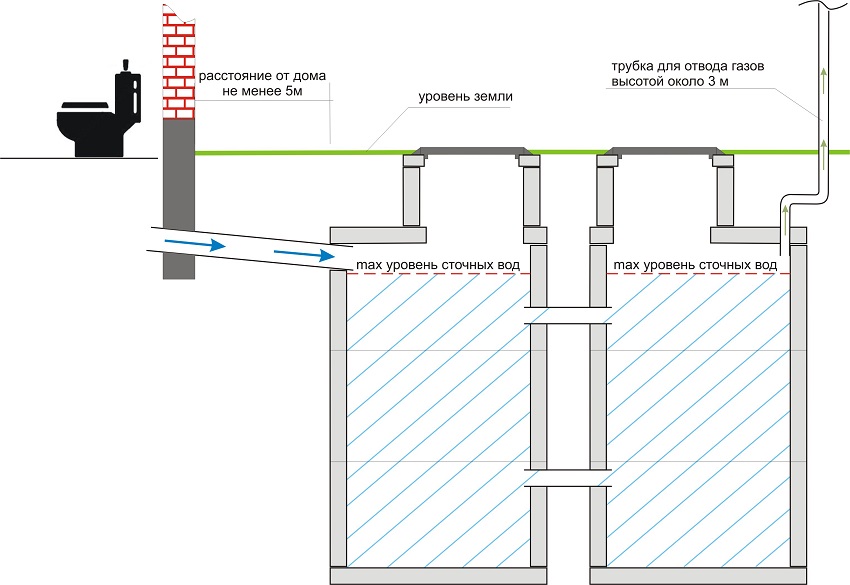

How to properly place a septic tank and filter facilities on the site

Requirements for the placement of treatment facilities and soil filtration facilities that complement them are contained in various SNiPs, SPs, and SanPiNs. Moreover, there are discrepancies in the numbers between the standards. However, it is possible to give quite definite recommendations:

- The septic tank must be located at least 5 m from the house. And from the border with a neighboring site - at least 1 m. If neighbors live on the site, then it is advisable to increase this distance to 4 m or more.

- The filter well is located no closer than 8 m from the house. Filtration fields with a capacity of up to 15 m³ / day - no closer than 15 m from the house.

- The minimum distance from the treatment and filtering facility to the source of water supply (well or well) is 15 m, if the facilities are located against the flow of groundwater. Or 30 m, if downstream.

- The distance between the septic tank and the reservoir is determined in each case individually, depending on the category of the reservoir, its size, etc.

- The distance between the treatment plant and the underground gas pipeline depends on the pressure in it. If the pressure is low (not higher than 0.005 MPa), then this distance should be at least 1 m (according to SP * "Gas distribution systems. Updated edition of SNiP", Table B.1).

Often in settlements there are internal norms for the placement of treatment facilities, and then you need to focus on them.

In addition, it is worth evaluating the terrain of the site:

- The treatment and filtering facilities are located lower in relief relative to the source of water supply so that the flow of groundwater is not directed away from them towards the well or well.

- The treatment plant, if possible, is installed at the point of the site where it will not be flooded with melt water in the spring.

Use of anaerobic bacteria to decompose sludge

The second option is to run bacteria into the sump. Just look for the ones that don't need to be oxygenated and run them in early spring because bacterial activity drops dramatically during the cold season.Until autumn, your drains will be a safe liquid without silt deposits. They can be pumped out directly to the garden. But the sediment on the walls will still have to be additionally removed with chemistry, and then the well should be sealed.

To decompose the sludge at the bottom of sewer wells, bacteria are used that do not need to be fed with oxygen, so look for the term "anaerobic bacteria" on the packaging

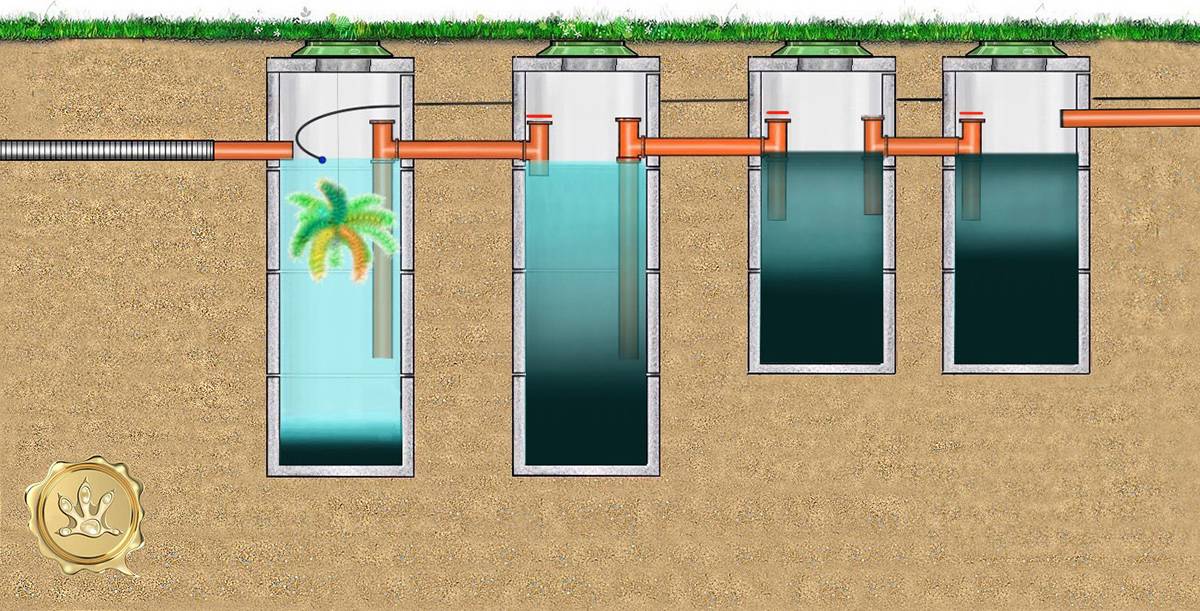

Only after complete cleaning can you use the well as a filtration field for a septic tank, like Topas, with a forced overflow system or gravity (depending on the terrain of your site). You can also have a simpler option: dig another well higher, for example, into three rings, concrete the bottom and make it a sump. A shallow mine is easier to maintain, and silt is easier to pump out. Connect both wells with an overflow system so that the old, deeper one acts as a filter and gradually sucks in the drains. Moreover, in this embodiment, it will not silt.

And it is not worth filling the well with soil. After restoration, it will serve for more than a dozen years. Remember that drains must be in the system of your homemade septic tank for at least three days, after which they can go into the ground. And the option that you have used up to this time can spoil the water in nearby drinking wells, and the soil on the site will also suffer.

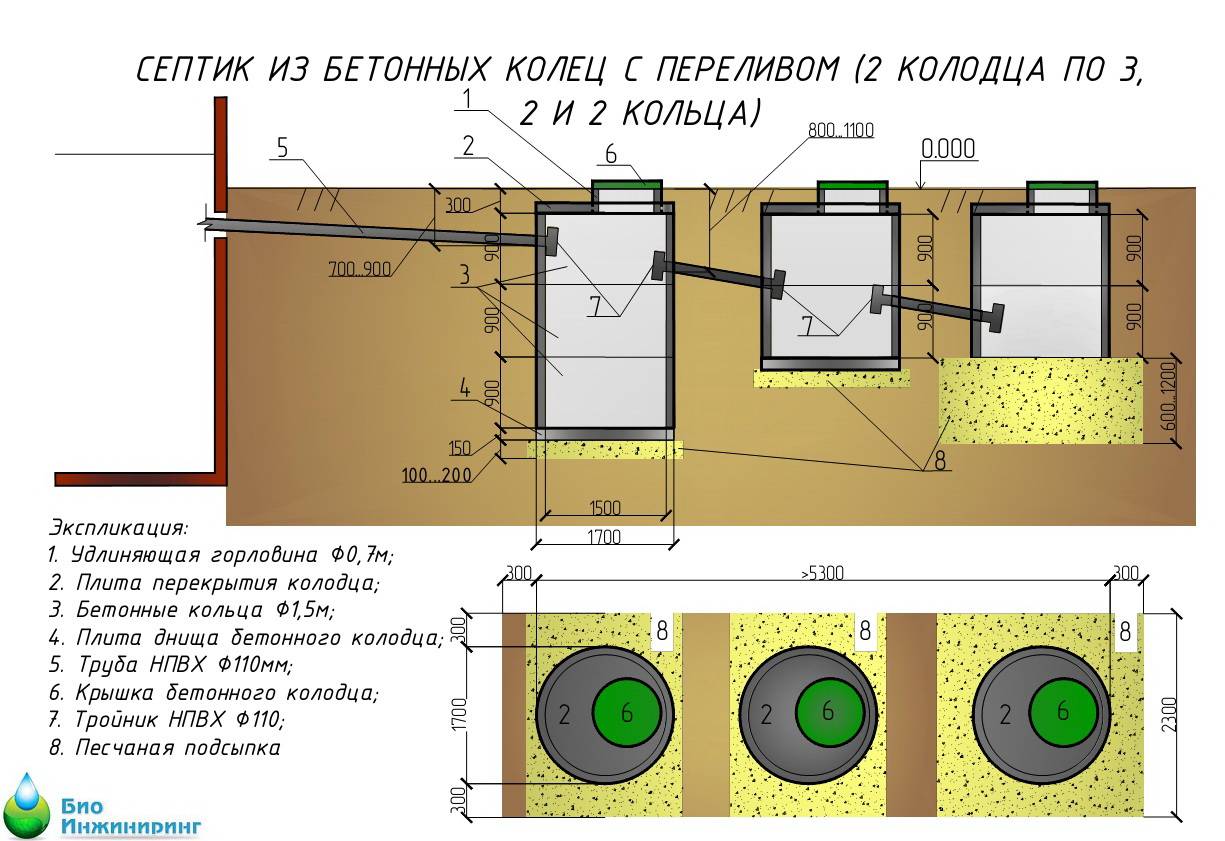

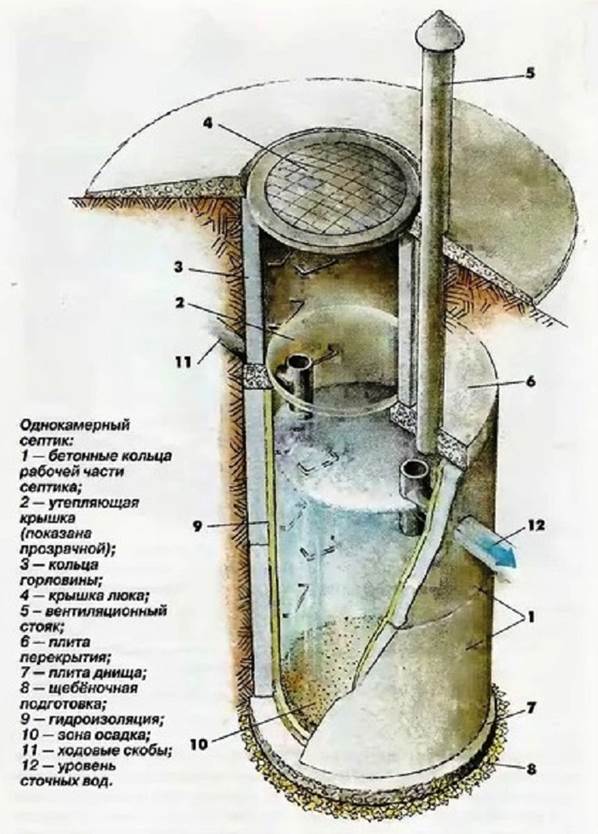

Constructions of drain pits from concrete rings

To understand the causes of the displacement and determine the method of repair, it is necessary to have a good understanding of the structural features of sewer structures. For the most part, they are buried in the ground, therefore, you need to be able to understand the characteristics of the soil. First, let's recall the technology of mounting drives from concrete rings.

How to build a sewer storage tank?

There are many options for building a drain pit, without which the local sewer system would be inferior.

A volumetric tank, buried in the ground at some distance from the house, serves to collect wastewater. As a building material for the assembly of the structure, cement pouring, ready-made concrete rings, brickwork and even rubber car tires are used.

Scheme of a storage sewer tank, during the assembly of which 2 standard concrete rings were used, and the function of the bottom is performed by a building slab made of concrete

Let us dwell on a storage well made of reinforced concrete or concrete rings. Large (with a diameter of 1 m or more) parts are quite heavy, so both transportation and installation of components is carried out with the help of special equipment and workers.

But durable and fairly wear-resistant elements of a cylindrical shape are of low cost, so half of all cesspools in summer cottages and small cottages are built from them. For the construction of an underground structure, 2-3 factory-made rings will be required.

It is difficult and irrational to make similar parts on your own, while all the components of the storage tank are on sale:

- rings of standard diameter;

- closed element for bottom device;

- round floor slabs;

- necks of smaller diameter (additional);

- plates with a hole for the hatch.

Rings for assembling a sewer well in a summer cottage can be made with your own hands. A step-by-step guide to making them is given here, we recommend that you familiarize yourself with very useful information.

After preliminary calculations, they acquire the necessary kit, from which they assemble the sewer well. Before installing concrete parts, it is necessary to dig a pit, slightly larger than the cesspool in width and depth.

Part closed on one side, performing the function of the bottom, can be replaced with a reinforced concrete slab. It is placed on a leveled base and fastened with staples to the bottom ring.

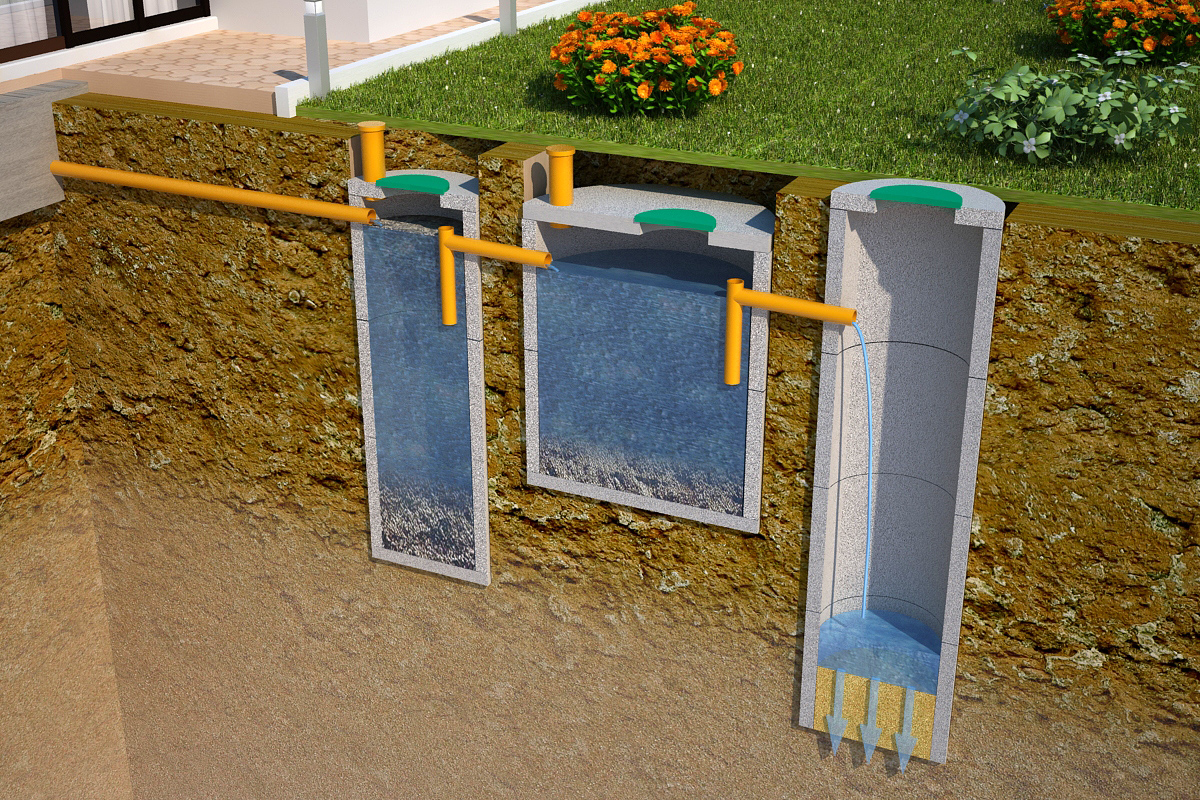

The first element is placed on a flat base - the bottom of the structure, then put on top of each other from 1 to 4 rings, carefully sealing the joints. To protect concrete, mastic or other waterproofing is applied on both sides (external and internal).

After backfilling, only part of the neck and the technical hatch remain visible on the surface. It is needed for regular maintenance - pumping out accumulated waste.

An article that analyzes all possible construction options will introduce the traditional schemes and rules for calculating the depth of the drain pit.

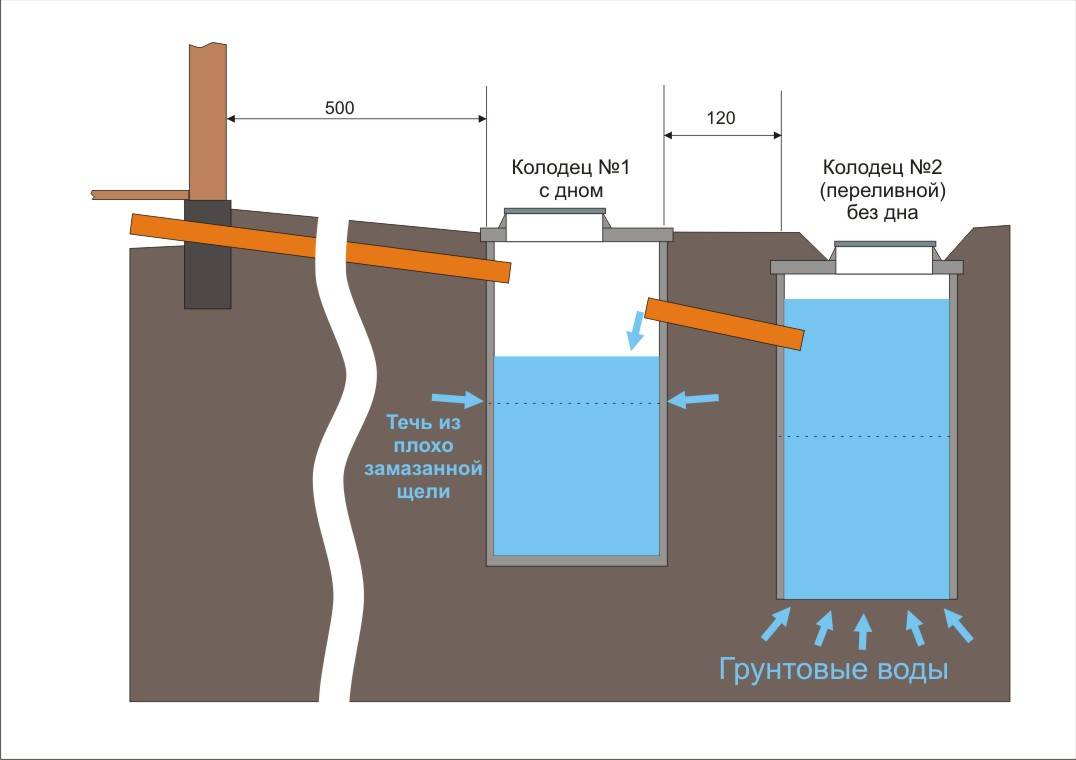

Features of the cesspool device without a bottom

A drain pit without a bottom is no longer a storage tank, but a structure with partial filtration of wastewater. The lower part of the cesspool is not clogged, but is equipped with a kind of filter - a thick layer of sand and gravel. The loose "cushion" passes through itself a liquid medium directly into the ground, retaining solid and large particles.

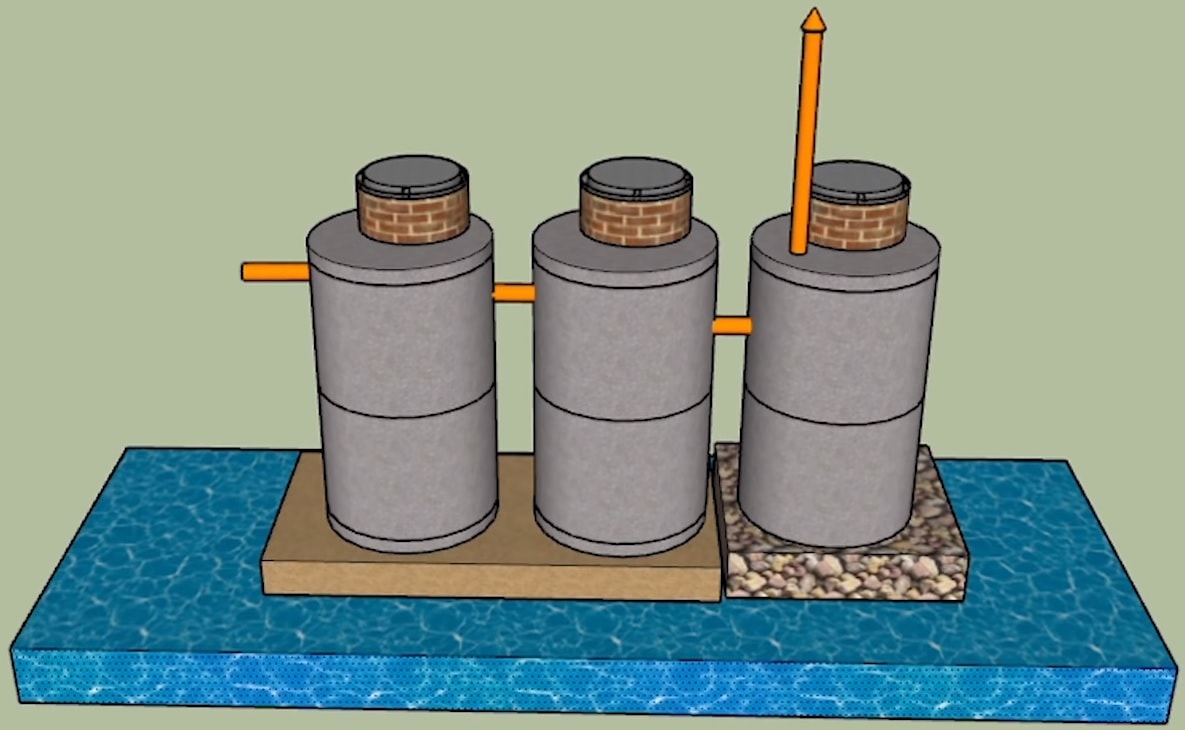

If you want to build the simplest treatment plant, you need at least two tanks: the first is the same storage tank, and the second is a filter well.

In the first, solid wastes settle and are partially processed, and the settled liquid flows into the next tank.Further anaerobic cleaning and liquid penetration into the soil takes place in it.

A scheme of a septic tank made of concrete rings, consisting of 3 chambers: a storage tank and two filter wells. If the elements of one of the parts sag or shift, the entire system will fail

If the only container is made filtering, cleaning will be ineffective, and wastewater will remain as dangerous to the environment. In addition, the filter - a sand-pebble mixture - will have to be changed over time, since pollution and clogging of its waste will occur quickly enough.

If you want to make a pit without a bottom so that you don't have to call vacuum trucks more often, one tank is not a way out. The construction of a cesspool with a soil filter occurs in the same sequence as a conventional drive, with one exception.

Instead of arranging a sealed bottom, it is necessary to pour a thick layer of sand, and then gravel. Do not forget about two important requirements: the enclosing soil must be sandy, in extreme cases, sandy loam, and groundwater must be 1 m or more below the soil filter covering the bottom.

Construction stages

Installation is carried out in the following order:

- A place is selected, an installation scheme is built, and the parameters of the septic tank are calculated.

- A hole is being dug.

- Rings are installed, pipes are connected.

- Sealing and waterproofing works are underway.

- Covers are installed.

- Backfilling is underway.

Video description

The order of work and the installation of a septic tank from concrete rings on the video:

How to choose the best place for a septic tank

The structure is mounted above the groundwater level.The best location is at the maximum distance from the house (at least 7 meters, but not more than 20, so as not to increase the cost of pipeline construction). It is logical to have a septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving the tanker-vacuum truck is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage truck does not need to drive into the yard, and the hoses will not roll on the beds or paths (otherwise, when the hose is rolled up, the waste can get into the garden).

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of rings and their waterproofing. The bottom is covered with rubble and concreted.

Preparing a pit for a septic tank from concrete rings

Installation of rings and sewer pipes

Rings for a septic tank are installed using lifting equipment, which saves a lot of time (when compared with manual installation). Fixation of the seams is provided with cement mortar, metal ties (brackets, plates) are additionally placed.

The crucial moment is the process of installing rings

Sealing and waterproofing

Sealing the seams of the septic tank from concrete rings is carried out on both sides of the structure. For this, cement and coating protective solutions are used. Inside the well, you can install ready-made plastic cylinders. Such additional costs will make the system 100% hermetic.

In the process of waterproofing concrete rings for a septic tank, the joints are treated with liquid glass, mastic based on bitumen or polymer, concrete mix.To prevent freezing (and destruction) of the structure in winter, it is recommended to insulate it with a layer of polystyrene foam.

Sealing joints and waterproofing a septic tank from concrete rings

Manhole installation and backfill

The wells are covered with concrete slabs, with holes for manholes. In the first two wells, ventilation is necessary to remove methane (gas appears as a result of the vital activity of anaerobic bacteria). To backfill the installed floors, use the soil taken out of the pit (backfill).

Backfilling of finished wells

How does the septic tank start up

In order for the system to begin to function effectively, the erected septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- A new septic tank is filled with wastewater and defended for 10-14 days. Then it is loaded with sludge from an operating anaerobic septic tank (2 buckets per cubic meter).

- You can buy ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes that are intended for other treatment systems).

Ready to run septic tank from the rings

What rules must be observed when maintaining a septic tank

There are simple rules that support the quality of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (and preferably in 2-3 years), bottom heavy fats are cleaned. The volume of sludge must not exceed 25% of the volume of the tank. During cleaning, part of the sludge is left to restore the microflora.

- Quality of work.Effluent at the outlet of the system must be cleaned by 70%. Analysis of wastewater in the laboratory will determine the acidity index, which will allow you to know the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after enhanced ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (wet environment).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

The frequency of cleaning the well. Private service cost

We all understand that the cleanliness of a well depends on how competently it is equipped, as well as on proper care for it.

To carry out general cleaning less often, you need to follow some rules:

1. We all imagine a well, which is usually round and open at the top. If left as it is, dust, leaves and other debris will get into it, which will lead to instant water pollution. The simplest and most logical solution is to close it. The easiest way is to make a cover (wooden or plastic), but we advise you to build a full-fledged mini-house, inside of which there will be a well.

2. Approaches to the structure must be protected from the entry of animals, in particular cats and dogs. Their fur is also a source of pollution. To do this, you can make a fence.

3. Make it a rule to inspect the walls of the well at least once a year, armed with a flashlight. In order to do this better, lower a powerful lantern on a rope inside the mine.That will allow you to see a large area.

4. It is also necessary to make the structure safe for children by enclosing it.

5. If you find any object in the water, you need to remove it very quickly, and if it turned out to be a dead animal, then you must clean the water from the well. To do this, you will need a pump to bail out all the water, disinfect the shaft, and then fill the structure with clean water. If you need to go down, it is strictly forbidden to do it alone, you must be insured from above in order to help you get out if something happens.

By fulfilling all care requirements, the frequency of cleaning will be approximately once a year, and sometimes less often. It should be understood that in any case, during operation, various deposits and bacteria will accumulate on the walls. Due to seasonal temperature fluctuations, cracks can appear, concrete rings can shift, and dirt can accumulate in the resulting cracks.

The water may become cloudy and acquire an unpleasant odor. After some time, these signs will disappear, but this only means that all suspended particles, i.e. mud, settled to the bottom. These and other deviations will become the reason why you need to immediately clean the well and the water in it.

Well, and, in addition, the competent installation of the structure initially, the installation of a clay castle, laying the filter on the bottom, etc. is of great importance.

You do not have to do all the cleaning work yourself, because often there is not enough time for this and if you are ready to pay for this service, you can contact a private trader. The price for this type of service is from 4000 rubles.and depends on the degree of pollution and the depth of the well. The cost of repairs and other works is usually negotiable.

How to unfreeze a hole

As a rule, the freezing of the drain pit in winter is prevented by the snow layer and the thermal insulation system, but it happens that at very low temperatures the waste freezes. What to do if the cesspool freezes in winter?

It is possible to defrost waste in a cesspool using an extension cord, copper wire, a steel rod 20-30 cm long and a gripper.

In cases where only the sewer pipe is frozen, it is wrapped with a copper conductor, which is connected to the phase wire. Under the influence of current, the thawing of the pipe will take 2-3 hours.

When the entire pit freezes, a steel rod is driven into the middle, to which a copper conductor is attached. This is followed by the phase voltage supply. In this case, the pit will thaw for at least 24 hours. After the work is completed, the voltage is first turned off, and then the rod and wires are removed.

The further functionality of the sewer system depends on how well the work will be done.

Among the most popular cleaning methods of the structure are:

- manual cleaning with a bucket that is tied to a rope;

- pumping with a fecal pump;

- pumping out the pit with a cesspool machine;

- biological treatment with biological preparations containing bacteria;

- chemical cleaning.

How to remove sludge from a cesspool with a bucket? To do this, it is necessary to dilute the silt itself with water, take a bucket and a rope. You tie the bucket to a rope and lower it yourself to the bottom of the pit, scoop up the waste and all the liquid, and so gradually pull it out.This is a rather unpleasant procedure, as disgusting aromas come from the device. Moreover, it is only possible if your pit is without a bottom and has a shallow depth. After completing the procedure, be sure to fill the bottom with gravel in order to facilitate subsequent cleaning of the bottom. Cleaning sludge from cesspools by hand must be carried out in a special protective suit in order to avoid the ingress of toxic gases into the body.

How to clean a cesspool of silt using a fecal pump? This is an automated, easy way. You will need a fecal or water pump, as well as a special sealed container for waste disposal. If you have an automatic pump, then you need to place it inside the pit, it will filter out sewage and pump it out on its own as it fills up. If semi-automatic, then you will need to control the pumping process. Liquefy the liquid before pumping it out, pump it out and dispose of the waste. Flush the hole with water and pump it out again. The fecal pump crushes large human waste.

If you have sludge in the cesspool, then you can also clean it with the help of special biobacteria. There are special biological preparations for cleaning cesspools. It can be powder, liquid or tablets, all this is added inside the structure. They reduce the mass of liquid and solid household waste by 80%, moreover, they interrupt and completely remove unpleasant odors from the site, prevent the appearance of sludge, clean the sewage pipes and walls of the device from sludge. All this increases the service life of the plant.Moreover, these biological preparations are completely environmentally friendly and safe for adults, children and animals. As part of biological products there are special microorganisms (bacteria), it is they, getting into the drains, that begin to act and destroy the unpleasant odor and decompose sewage. For example, you can choose . These drugs are used in all seasons, except for winter, as they freeze and die. All features of the use of bacteria are indicated on the back of the packages with them. As a rule, you just need to throw them into the structure every 2-3 weeks and wash the device regularly with water.

How to get rid of sludge in a cesspool using chemicals? If your device is silted up in winter, then instead of biological products you need to use a chemical preparation. For example, nitrate oxidizers. They are similar in composition to nitrate fertilizer and are considered environmentally friendly. As a result, a waste product is formed from the action, which can be used for fertilizer. Formaldehyde and ammonium salts are generally strictly prohibited, as they are unsafe for humans due to toxicity.

Chemical reagents thin the sludge, eliminate unpleasant odors and reduce the volume of domestic wastewater. They work even in an aggressive environment, if there is household chemical waste.

The device of the drain pit and the principles of its functioning. Reasons for the rapid filling of the tank. Ways to release the container from the contents.

What is a hydro seal

Hydraulic seal is a special composition of slurries that are capable of very fast hardening, making it possible to eliminate pressure leaks.It is usually impractical to use hydraulic solutions in such situations, they are simply washed out with water, without even having time to harden.

Until the hydraulic seal was invented, most well craftsmen used wooden plugs or tow, which, when swollen, prevented water from seeping into the structure. But these materials had one serious drawback - they began to rot very quickly, emitting unpleasant odors, which caused changes in the taste and quality of water.

The appearance of a hydraulic seal made it possible to significantly improve the quality of work and increased the service life of the repair site, which became important. However, even in our time, there are companies that instead use the old-fashioned method of fixing leaks to reduce costs, without even thinking about the consequences.

In the photo - a damaged section of the seam between the reinforced concrete rings

In addition, keep a close eye on what the wells are trying to stop live leaks. Remember that a mixture of sand, cement and liquid glass, which is used by about 80% of the craftsmen, cannot stop them efficiently and reliably.

When working with a hydraulic seal, all recommendations related to surface preparation must be taken into account, and when cracks and seams are small, they should be enlarged with a perforator to the required size. If the instructions are followed, it is able to withstand even a very serious pressure of water.

We prepare a solution to eliminate a pressure leak

From the previous paragraph, we learned what a hydraulic seal is for. This fast-hardening material is able to return solidity to structures in a matter of minutes.

When purchasing material, pay attention to the presence of a certificate from the seller, which confirms the safety of the components used in the hydroseal for drinking water

We can recommend such materials as "Waterplug" and "Peneplug", which are used in conjunction only with "Pinecrit" and "Pinetron". Mixtures instantly seize when interacting with strong water pressure, with simultaneous expansion and the formation of a waterproof layer.

Materials from other manufacturing companies that also specialize in the production of instant mixtures for blocking pressure leaks are used in the same way.

Particular attention should be paid to the correct use with the attached instruction

We prepare the solution ourselves

When you decide to make the mixture yourself, be sure to follow the recommendations of the manufacturer. The volume of the dry mixture depends on the activity of the leak.

Most often, the proportion is 1 kg of well seals per 150 g of water. In another way, you can calculate as follows - five parts of the mixture are taken for one part of water.

The mortar should be mixed at a water temperature close to 20°C. The kneading is done as quickly as possible - no more than 30 seconds, which should resemble dry earth.

Do not knead a large volume at once, consider its instant setting. In this regard, it is more reasonable to prepare the mixture in parts, and after applying one pressure leak to the place, immediately begin to prepare the next one.

Leak sealing technology

- The first step is to prepare the surface for work.To do this, using a perforator or a jackhammer, the internal cavity of the leak should be freed from exfoliated loose concrete.

- This area to be repaired must be widened to a width of 25 mm and deepened to 50 mm or more. In this case, the shape of the hole should be similar to a funnel.

- Stir in a clean container a certain amount of the mixture, the volume of which is necessary to seal the leak. Form a lump of mortar with your hands and press it with a sharp movement into the embroidered hole. Hold the seal in place for 2-3 minutes.

Other applications for hydraulic seals

Using fast-hardening solutions, you can effectively resist:

- leaks of liquids from reinforced concrete tanks;

- water breakthroughs in tunnels, basements, galleries, shafts, galleries;

- defects that may appear in the bowl of pools and other artificial reservoirs;

- capillary leaks, which often appear at the junction of walls and floors, as well as between foundation blocks.

Safety

After use, the tool must be immediately washed from the remnants of the mixture, otherwise, when they finally harden, it can only be cleaned mechanically and with great difficulty.

Details

Funds. Review

For start-up use, certain means should be used. These include:

1.Bioforce Septic Shock, which is sold in bottles of one liter. It contains enzymes and aerobic bacteria. For a one-cube septic tank, one bottle is used. If the volume of the septic tank is larger, then you will have to buy several bottles of the product. One container costs about 900 rudders.

2. Means Dr. Robik 509 in the form of a liter container. With the help of the drug, an effective cleaning of the septic tank is carried out.First you need to pump out the old drains, and add the agent, counting on the volume of the septic tank of 2 thousand liters, you need one bottle. A bottle costs about 630 rubles.

To support the fermentation processes, as well as to clean the pits, special preparations are used. These include:

1. Dr. Robik marking 309 is used all year round. The product is in the form of a liquid, sold in a 1 liter bottle. One bottle is used for a septic tank of 2 thousand liters. It is necessary to introduce the agent into the inspection hole. A bottle of the product costs about 750 rubles.

2. Dr. Robik marking 409 is used to clean the cesspool all year round. It is better to pour the product into the pit in spring or summer. Bottle 409 is enough for a septic tank of 2 thousand liters. The tool costs 630 rubles. for one bottle.

Solutions for silting a septic tank with a bottom

The bottom part of the septic tank can become silted up in factory-made septic tanks. Such septic tanks have a bottom. The reason for this phenomenon is the small number of bacteria in the container.

Attention! Microorganisms can be killed by alkali, acids or bleach contained in cleaning solutions.

How to get rid of grease and soap

Fats and soap suds that enter bottomed septic tanks cause septic tanks to overflow. Raids do not allow drains to move quickly through the system, traffic jams form.

Attention! Grease traps will help to overcome the formation of fatty plugs. Fat and soap plugs can be removed using two methods:

Fat and soap plugs can be removed using two methods:

- mechanical,

-chemical.

The chemical method is more effective than the first. It is easy to put into practice. It is necessary to pour a special preparation into the sink or toilet bowl.This process should be repeated until the capacity of the sewer is restored.

Special preparations should be used to remove soap suds and fat deposits. These include:

1.ROETECH K-87 is an efficient crop capable of handling paper splitting, soap, grease. One bottle is enough for a 1 cubic meter septic tank. The tool costs 800 rubles.

2.BIOFORCE DRAINAGE COMFORT is a highly effective product, available in sachets to be dissolved in a 10 liter bucket. One sachet is enough to clean 50 meters of sewage pipeline from grease and soap deposits. One pack contains ten sachets. The drug costs 2 thousand 770 rubles.

3. Dr. Robik marking 809 is a special agent for dissolving soap deposits. Well cleans the overflow pipes, the first compartment of the septic tank. One bottle is enough to clean stones and sediments from a septic tank soap two cubic meters in size. The product is poured into the toilet, or injected through the inspection hatch. The bottle costs 630 rubles.

How to make a tap for treated wastewater

If the septic tank overflows with water from a large number of residents, then it is necessary to build a well for drainage or a filtration field. If the septic tank does not have enough power, then the problem will not be solved. If the daily discharge of water exceeds more than 1/3 of the entire capacity of the tank, then it is necessary to build a well or construct a drainage field.

Attention! In this situation, you can dismantle the septic tank, install a new structure of the required size.

Carrying out installation work

Before starting construction work, a detailed plan should be drawn up and a suitable site selected.In addition to the desire to preserve the aesthetic appearance of the landscape, it should be noted that the cesspool should be located:

- not less than five meters from the residential building;

- not less than 30 meters from a source of drinking water;

- in a place accessible for the entry of special vehicles of vacuum trucks.

To make a two-chamber cesspool of concrete rings, you must:

- Dig two pits in a suitable place (sometimes one spacious pit is enough).

- Concrete the bottom of the pit, in which the sump will be built. After drying, cracks almost inevitably form in the concrete, which must be repaired to ensure sufficient tightness. This step will take about a week or more.

Concrete rings should be lowered into the pit carefully so as not to damage the structure.

The joints of concrete rings must be carefully sealed and treated with a layer of waterproofing

- Install concrete rings at the bottom of the second pit.

- Lay a layer of drainage on the bottom: crushed stone, broken brick, etc.

- Lay sewer pipes that are connected to the house, as well as connecting the sections of the cesspool to each other.

- Check the tightness of the structure, correct the identified shortcomings.

- Install ceilings with a hatch and a vent over each section of the cesspool.

- Backfill the structure with soil.

A cesspool of this type is much more convenient than a conventional one; the increased costs of its construction will soon pay off.