- Gas pipeline construction

- Procedure for obtaining technical specifications

- Equipment for gasification of a private house

- Providing gas from a gas tank

- Use of gas cylinders

- Samples and examples of documents

- What to consider when building a garage?

- Procedure for obtaining technical specifications

- Phased connection of gas to the garage

- The end of gasification (gas connection to the house) is also an important stage

- Video description

- What has changed in the rules for gasification of a private house

- Video description

- Conclusion

- Rules for gasification of a private house

- How to conduct gas to a country house

- Gas garage heating overview of different types of equipment

- Advantages of gas heating in the garage

- Stationary gas equipment

- Mobile gas equipment

- Features of heating a garage with gas from cylinders

- Current requirements for garage spaces

- Connecting a gas stove in the garage

- Location of heating boilers

- What should be the gas pipeline to a private house

- Choosing the "right" gas boiler

- Choosing the "right" gas boiler

- Rules for installing wall-mounted gas boilers in an apartment

- How to make everything perfect

- Filling the gas tank

- Conclusion of an agreement

Gas pipeline construction

The gas pipeline for a private house consists of 2 parts: the gap from the main pipeline to the land plot and part of the system inside the boundaries of the land plot. The owner of the gas distribution system is responsible for the first part, and the construction is carried out at his expense. Construction and installation works of the second part are provided by the owner of the property. They can only be produced by a specialized company licensed for such activities.

All gas equipment and system elements must comply with the specification issued by the designer and have a quality certificate. In the process of commissioning, optimal gas flow rates are established.

Procedure for obtaining technical specifications

The technical conditions for gas supply to the garage will be issued by the gas service at the place of ownership of the facility.

Application form for obtaining technical conditions for gasification: you can apply for a facility being designed, under construction or put into operation

The owner of the premises should submit the application itself for drawing up the contract, as well as the following documentation:

- documents on the ownership of land;

- identity card or official document confirming the authority of the representative;

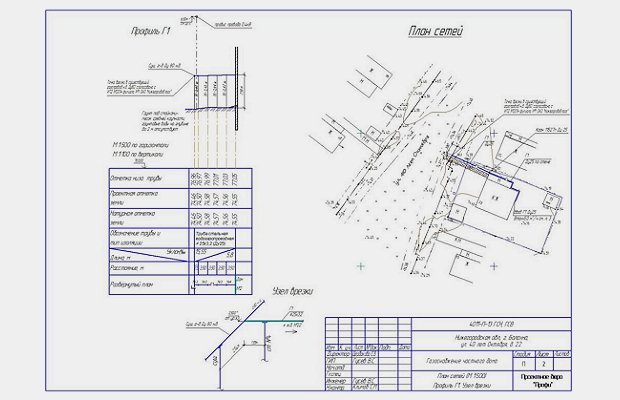

- topographic plan of the territory with the building;

- registration certificate;

- consent of the gas distribution company;

- plan of the garage along with smoke and ventilation ducts.

Upon issuance, the customer receives the pressure parameters at the point of connection to the gas network, the minimum and maximum indicators of gas use per unit of time, a description of the features of the system and the allowable gas flow.

The owner of the garage with technical specifications in his hands has the right to go to court if he is refused connection.The decision is usually made in favor of the plaintiff. The opportunity to apply to the court is also used in case of refusal to issue technical specifications.

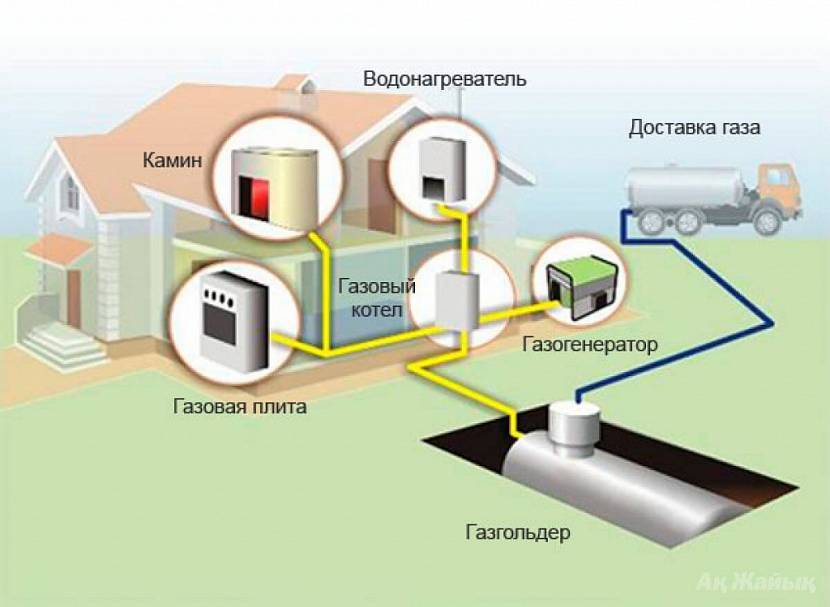

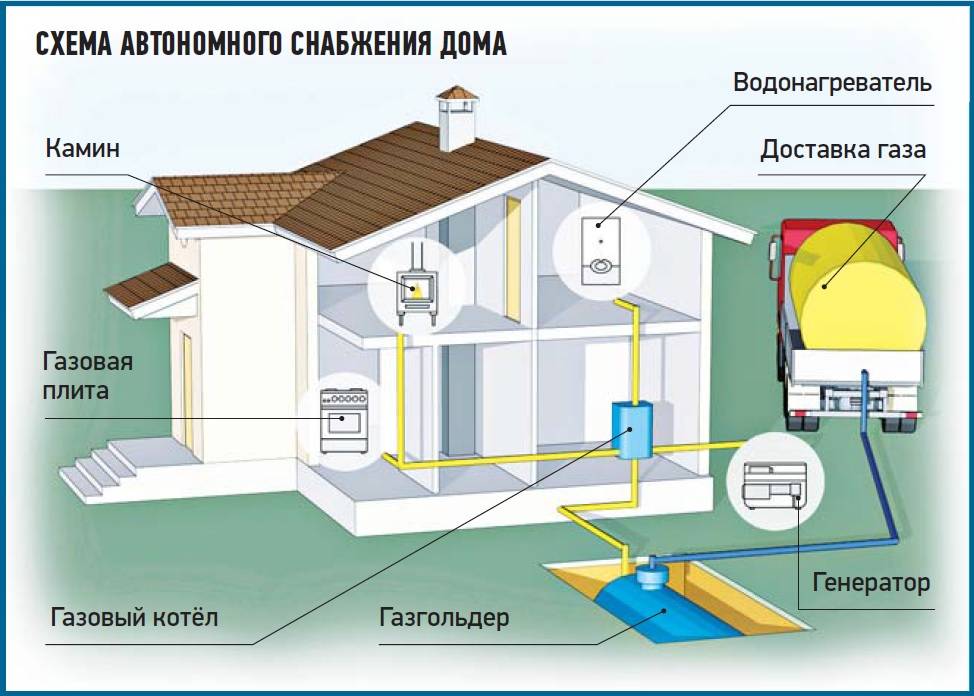

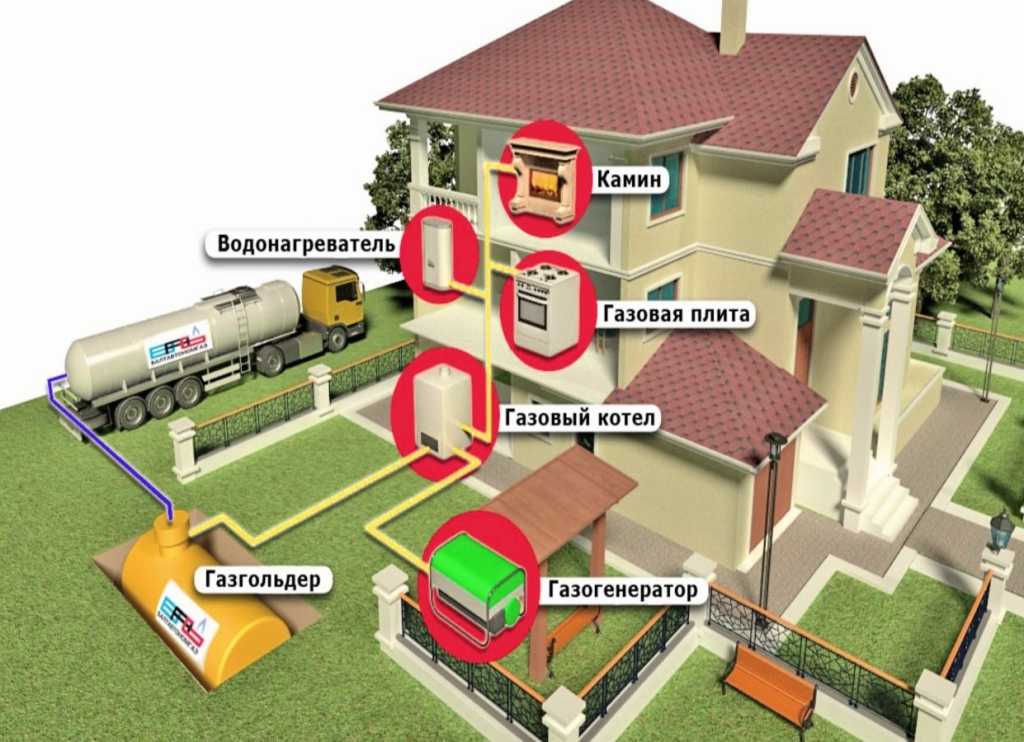

Equipment for gasification of a private house

- total heated area.

- Number of connection nodes (only a boiler or column, stove, etc. will work)

- Financial expenses.

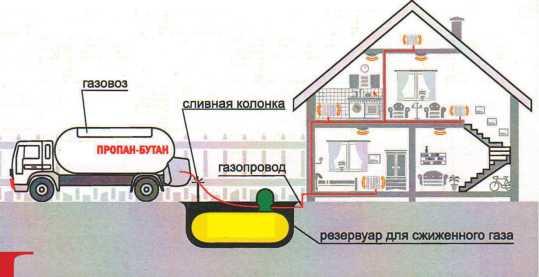

Providing gas from a gas tank

- The gas is extracted from the propane-butane mixture during the process of liquid evaporation.

- After refueling into the gas tank, pressure is created during the evaporation of liquefied gas.

- The produced gas enters the reducer, which controls the supply pressure to the pipeline.

- Gas is supplied to heating units in a residential building.

Use of gas cylinders

To complete this project you will need:

- Install a special burner for liquefied gas in a gas boiler. The exception is the new generation condensing boilers of famous European brands. Units from Buderus, Viessmann often have a built-in function that allows you to switch equipment from main gas to bottled gas without changing the burner.

- Combine several cylinders into a single network.

- Connect the network to the reducer with several cylinders on each side.

There is no need to coordinate with the gas service and make a project for gasification in case of installation of bottled gas supply

The main attention should be paid to compliance with fire safety rules.

Samples and examples of documents

Here you can see what they look like and download samples of the necessary documents.

- Application for gasification of a private house (application for a connection agreement).

- Situational plan of the land plot for gasification.

- Project (scheme) of gasification of a private house - floor plan.

- Agreement for the verification of a gas meter (Agreement on the maintenance of in-house or in-house gas equipment - VKGO).

- Request for the issuance of technical conditions for connection (technological connection) of a capital construction object to the gas distribution network.

- Request for calculation of the planned maximum hourly gas consumption.

- Request to change attachment point.

- Application for the provision of additional documents to the application for connection.

- Consent of the owner of the gasified facility to the construction of a gas pipeline.

- Consent of the copyright holder to connect to the gas pipeline.

- Form of power of attorney for the representative of the Applicant.

What to consider when building a garage?

It is also worth considering that the garage will quickly fill up with all sorts of useful things - gardening equipment, children's bicycles, a lawn mower, a trailer, as well as a huge number of others, without which life will lose all meaning. Of course, many will want to get a workbench with a decent set of tools. Well, when all this fits in the garage, there will probably simply not be room for a car. That is why it makes sense to get a garage for two cars or a garage with an additional utility unit. Moreover, it is desirable that the entrance to the garage is not opened from the house. Yes, it is attractive and convenient to get into the garage in windy October weather without even going outside. But very often frame garages are saturated with such not-too-pleasant smells as the aromas of fuels and lubricants, paint, exhaust gases or just gasoline. Well, every time you open the door from the house to the garage, some of this aroma will spread throughout the house.Not a very pleasant prospect, is it? In addition, when opening the doors, part of the heat from the frame house passes into the garage, which is also not always good.

A heat exchanger is an energy-saving device when a heat exchanger located in a heat exchanger transfers indoor air to heat from the room. This system is convenient all year round: it not only ensures a constant air flow, quality and quantity, but also helps to save energy, which is becoming more and more expensive every day.

In modern buildings, a central dust collection system is becoming as common as a centralized supply of heat or water. Own homeowners sometimes hesitated or cleaning activities are necessary for the central system, but those who shop, says they can't imagine that, after the house will again twitch the portable vacuum pump and breathe dust into the space. The central vacuum cleaner is equipped with a convenient home equity boiler room, garage, basement, storage room or outdoors, and the apartment can be placed in a dark room or on a balcony.

It would also be better to forget about the garage located in the basement. Of course, it looks very good on projects - there is no need to allocate extra space for construction, and the garage will not spoil the surrounding landscape. That's only when the snow melts and after the rain, the garage will literally fill up. And nothing can be done about it. In addition, in winter the descent to the garage is very often covered with frost. In such a situation, you can only pull the car out of the garage with a tractor or at least a winch. Is it worth experiencing such problems? Wouldn't it be easier to just build an above ground garage?

Procedure for obtaining technical specifications

The technical conditions for gas supply to the garage will be issued by the gas service at the place of ownership of the facility.

Application form for obtaining technical conditions for gasification: you can apply for a facility being designed, under construction or put into operation

The owner of the premises should submit the application itself for drawing up the contract, as well as the following documentation:

- documents on the ownership of land;

- identity card or official document confirming the authority of the representative;

- topographic plan of the territory with the building;

- registration certificate;

- consent of the gas distribution company;

- plan of the garage along with smoke and ventilation ducts.

Upon issuance, the customer receives the pressure parameters at the point of connection to the gas network, the minimum and maximum indicators of gas use per unit of time, a description of the features of the system and the allowable gas flow.

The owner of the garage with technical specifications in his hands has the right to go to court if he is refused connection. The decision is usually made in favor of the plaintiff. The opportunity to apply to the court is also used in case of refusal to issue technical specifications.

Phased connection of gas to the garage

The process consists of 6 steps, and the first step is to choose a gas supply option. It is selected based on the heated area, the volume of the room, the average residence time and the number of people simultaneously in the garage.

In the future, draft specifications are drawn up. The local gas service will consider the application within 1 month.For buildings more than 200 m away from the local pipe, alternative connection options will be needed.

At the next stage, a technical connection to the gas system is made. The tie-in is carried out by specialists of the gas service. The consumer should count on expenses in the amount of 25-50 thousand rubles. The cost of work includes the cost of tie-in and laying.

A tie-in is made into a high-pressure gas pipeline for laying communications of individual value - one of the methods is shown in the figure

A tie-in is made into a high-pressure gas pipeline for laying communications of individual value - one of the methods is shown in the figure

The most expensive component can be a garage gasification project. All equipment and planned gas communications of the garage are applied to the diagram. Each device, as well as the chimney, is “put” at the exact location.

The procedure includes 2 alternatives:

Then they proceed to the installation of gas-using installations such as boilers, stoves, gas heat guns, etc. At this stage, customers turn to gas workers and lay down work contracts.

After installing gas appliances, the consumer still does not receive fuel. Employees of the gas distribution organization must first check the safety of the devices, make sure that the operating conditions are met. The owner of the garage makes an application for this and waits for about 2 weeks until the specialists arrive at the place.

Upon arrival, gas service employees will instruct you on safety rules and seal the meter. The check will be confirmed by a receipt, and soon it will be possible to talk about connecting gas to the garage as a fait accompli.

The end of gasification (gas connection to the house) is also an important stage

At the final stage of gasification of the house, it remains to be instructed on the safe use of gas equipment, conduct a trial run, and conclude an agreement for seasonal maintenance of the system. If a gas tank is installed, then it is necessary to conclude an agreement for systematic gas supplies.

The last "touch" is to give the project documentation (or an approved copy) for safekeeping in the archive, in case later redevelopment is needed or any clarifications are required.

Video description

Visually about the progress of work and the cost of gasification at home, see the following video:

What has changed in the rules for gasification of a private house

Until 2016, it was quite difficult to even approximately predict how much it would cost to connect gas to a private house, as there was no legislative regulation and control. This led to the fact that monopolists could single-handedly set the timing of gasification and its cost. But, with the adoption of new laws, the maximum time for gasification was limited to one and a half years.

The cost and timing of the approval and implementation of a gasification project for a private house are now regulated by law. This means that the party ordering the services can now take a more active part in the control of work and demand their timely completion.

Video description

What other questions arise about the cost of connection, described in the video:

Conclusion

Although gasification of a private house is a long, tedious, and expensive process, its importance cannot be overestimated.Everyone who has the opportunity to gasify their homes does it first of all, especially since with the adoption of new laws, the population has the opportunity to predict the timing of the work.

Rules for gasification of a private house

The procedure for gasification of a residential building is determined by PP No. 1314 dated 12/30/2013. According to the Law of August 22, 2004 No. 122-FZ (as amended in 2019), private homeowners are assigned to the 1st group of gas consumers. Taking into account the latest changes in legislation, a gas consumption rate of up to 5 cubic meters per hour has been established for them. In this case, the connection will cost 20,000 rubles and will be made within 1 year, provided that the point of insertion into the main is located no further than 200 m. at 50,000 rubles, and the period is increased to 1.5 years.

Reference. For the specified amount, the district administration ensures that the gas pipe is connected directly to the house and issues technical conditions for connection. The owner of the property himself decides on the development of the project, gas distribution around the house and installation of equipment. The quality of the work performed is evaluated by a special commission.

How to conduct gas to a country house

It is good if the gasification program extends to a country house located in a village that falls under this project. A garden house within the boundaries of a fairly large settlement differs from a country house. A country house and a country estate in a small village very often may not have communications. If the regional gasification program has bypassed the locality in which the summer cottage is located, then its owner will face many obstacles.In fact, the owner can conduct gas to his rightful property. However, in reality, there are quite a few nuances, especially when it comes to SNT.

Gas garage heating overview of different types of equipment

Heating a garage space is a topical issue for many car owners. This is not only a manifestation of caring for your favorite vehicle, but also a great way to organize a workshop, an additional area for storing things you need in the household. Gas heating of the garage has become widespread today. If the garage is located on your site so that it can be connected to the main gas pipeline, then the issue of heating is practically solved. Garage heating can also be autonomous; for its arrangement, you can choose both portable and stationary equipment.

Advantages of gas heating in the garage

- Low cost compared to electricity;

- Economical consumption - to maintain the optimum temperature in the garage, you do not need large volumes of fuel;

- The possibility of using gas in cylinders for arranging autonomous heating;

- Gas is a natural fuel that burns completely and does not emit harmful substances into the air.

However, there are certain difficulties when installing gas heating:

- The acquisition of the necessary equipment will require a solid initial investment;

- Connecting gas installations on your own is prohibited by law, for this you will need a specialist;

- There are safety requirements for such equipment that must be met.

Stationary gas equipment

Stationary gas heating in the garage - boiler

This includes special boilers, to which a system of water pipes is attached.To install them, you will need permission from the gas service, as well as the arrangement of supply and exhaust ventilation. Since the garage is considered a fire hazardous object, the boiler is taken out to a separate room with dimensions of at least 4 sq.m. with walls covered with non-combustible materials. According to the norms, the boiler room must also have a door with a width of at least 800 mm.

The advantage of using a stationary boiler is the possibility of full-fledged, round-the-clock heating of the building. In this case, you do not need to control the operation of the equipment. At the same time, installing a boiler will require significant investments from you, which will pay off only in the long run. This option should be considered by those car owners who plan to open a workshop or a small production in the garage.

Mobile gas equipment

In this case, we are talking about non-permanent (periodic) heating of the garage using various heating devices that are powered by natural or liquefied gas cylinders. These can be heat guns, burners and convectors.

Gas guns are powerful heating devices with a small burner, the heat from which is quickly distributed around the room with the help of a fan. They are convenient to use for short-term, as well as local heating of the room. The disadvantage of the device is the release of combustion products into the air, which quickly accumulate in the room. Thus, you will need the arrangement of high-quality ventilation.

Mobile garage heating with gas - heat gun

Gas convectors can be equipped with a fan that promotes the rapid circulation of heated air masses, as well as a thermostat. They are compact, inexpensive, safe to use, compatible with LPG systems. But, like gas guns, they require ventilation or a special chimney.

The simplest portable devices are burners. They are connected to both large cylinders and mini-cartridges with gas. Due to their open flames, burners are considered unsafe for permanent use in a garage.

Features of heating a garage with gas from cylinders

According to fire safety rules, gas cylinders should be stored in a special cabinet made of metal. It should be located away from flammable objects and heating devices. Make sure that the cabinet is located above the floor line - so if there is a gas leak, you can quickly notice and fix the problem.

Heating the garage with gas from cylinders in a special cabinet

The choice of gas equipment for the garage depends on the frequency and purpose of its use, the financial capabilities of the customer. On the one hand, the installation of a stationary boiler is not cheap, on the other hand, heating with cylinders causes a lot of inconvenience. During severe frosts, cylinders have to be changed every 2-4 days, which also translates into a considerable amount. And don't forget about garage fire safety.

Hi all! Sandwich garages are my passion. I can talk about them day and night. I can tell =)

Current requirements for garage spaces

June 6th, 2020the Rules for the design of gas supply systems SP 402.1325800.2018 came into force, which were approved based on the order of the Ministry of Construction and Housing and Public Utilities No. 789/pr dated 05.12.2018.

The 50 mm margin between the sides of the stove and the meters still applies. As before, a 40 cm height interval from the same appliances to the burners should be observed. The new norms also do not prohibit the installation of double-glazed windows in rooms with boilers, but only if the structure of the glasses allows them to be knocked out without much effort.

Connecting a gas stove in the garage

For this and other equipment, only sealed hoses made from safe materials are suitable. The length of the connecting elements should not exceed 1.5 meters.

The most reliable and durable bellows gas hoses are made of stainless steel under a resistant polymer coating, protected from aggressive environments.

Gas will definitely not be connected if the new requirements for stoves are not met:

- for gas stoves under a canopy, you need to use protection against blowing;

- the stove must have a “gas-control” system, and between the tap and the hose - a dielectric coupling from stray current;

- gas appliance for cooking must comply with GOST 33998;

- from the slab to the opposite wall, at least 1 m of margin should be left.

Slabs for the garage, as well as for residential premises, should be purchased only from certified manufacturers, along with supporting documents for these devices.

Location of heating boilers

It is impossible to install a gas boiler / column / boiler in the same space with the car. The way out of the problem will be the furnace compartment.Basic and additional requirements apply for a finished or attached garage space. Norms of the 2nd type will have to be clarified with the local gas service.

A gas boiler in the garage can be used, for example, for heating water or arranging a warm water floor system

Installation of a boiler in a garage will be acceptable if the building meets the following parameters:

- non-freezing structure with an area of at least 4 m² and a height of 2 m or more;

- the door opens outward, and its width is at least 80 cm;

- the walls are made of non-combustible or slightly combustible materials;

- there is a window for ventilation and light, approximately 1 m² in size.

The garage must have supply and exhaust ventilation. Its condition should be checked with a piece of paper. In a working system, in the supply ducts, the air will repel the sheet, and in the exhaust ducts, it will attract.

What should be the gas pipeline to a private house

We all know about the explosive properties of gas, so there can be no talk of any initiative in this matter. However, you will have to collect all the necessary documents, make a project, submit applications to the appropriate authorities, etc. So, get ready to visit various services and queues. Consider all the requirements that cannot be violated.

In the photo - a gas supply project for a private house

All materials, from pipes to welding electrodes, must be of high quality and have certificates

The location of all elements of the pipeline is also very important. Collapsible connections should be located only in open places. Be sure to provide free access to them

This will allow at any time to assess their condition and, if necessary, carry out repairs.It is forbidden to wall up pipes and other nodes of the gas network in the walls or foundation of the building. It is also unacceptable to run the gas pipeline through platbands, plywood walls, transoms, door and window frames and temporary partitions. True, sometimes they allow a gas pipeline to be laid through a specially made channel in the wall, but only in special cases and after the approval of the project.

Be sure to provide free access to them. This will allow at any time to assess their condition and, if necessary, carry out repairs. It is forbidden to wall up pipes and other nodes of the gas network in the walls or foundation of the building. It is also unacceptable to run the gas pipeline through platbands, plywood walls, transoms, door and window frames and temporary partitions. True, sometimes they allow a gas pipeline to be laid through a specially made channel in the wall, but only in special cases and after the approval of the project.

Distortions are also not allowed, all pipes must run strictly vertically, horizontal sections have a slope of 0.002–0.005 m towards the instruments. If we are talking about a riser, then in this case a skew of a maximum of 2 mm per meter is allowed. They are located mainly in the stairwells or in the kitchen, but in bathrooms and living rooms it is forbidden to do this. Cranes also require special attention, they must be installed so that the cork axis is parallel to the wall. The stop nut must not be placed on the side of the wall.

Photo of gas supply pipes of a private house

It is very important to maintain distance. There must be at least 2.2 meters from the bottom of the pipe to the floor, and 10 cm of free space must be left between the upper side of the gas pipe and the ceiling. Also, pipes should not be placed close to the walls, as this will make visual control difficult.

If this distance is not specified in the project, then a gap must be left, the minimum value of which will be equal to the radius of the pipe, but not exceeding 10 cm. The gas pipeline must be located on the supports rather tightly, gaps are not allowed

Also, pipes should not be placed close to the walls, as this will make visual control difficult. If this distance is not specified in the project, then a gap must be left, the minimum value of which will be equal to the radius of the pipe, but not exceeding 10 cm. The gas pipeline must be located on the supports rather tightly, gaps are not allowed.

Choosing the "right" gas boiler

It is possible to purchase a suitable gas boiler on your own

It is worth paying special attention to each component of the equipment. In particular, this applies to the body material itself, the chimney (if any), as well as the ignition system.

In addition, you need to find out which option for connecting to gas takes place.

The most popular devices are boilers made of cast iron and steel. If choosing between the two, preference should be given to the latter, since cast iron is considered a fairly heavy metal. A convenient boiler is one that has an electric fuse installed.

Particular attention should be paid to the chimney. Since the products of combustion are aggressive, it is necessary that this part be made of durable material.

Alloy steel is considered ideal. However, there is equipment where there is no chimney as such (the device is equipped with fans).

Choosing the "right" gas boiler

It is possible to purchase a suitable gas boiler on your own

It is worth paying special attention to each component of the equipment. In particular, this applies to the body material itself, the chimney (if any), as well as the ignition system.

In addition, you need to find out which option for connecting to gas takes place.

The most popular devices are boilers made of cast iron and steel. If choosing between the two, preference should be given to the latter, since cast iron is considered a fairly heavy metal. A convenient boiler is one that has an electric fuse installed.

Particular attention should be paid to the chimney. Since the products of combustion are aggressive, it is necessary that this part be made of durable material.

Alloy steel is considered ideal. However, there is equipment where there is no chimney as such (the device is equipped with fans).

Rules for installing wall-mounted gas boilers in an apartment

Usually, in an apartment, a gas boiler is installed in the kitchen, since a gas main is already connected to it, there is water supply and sewerage. That is, a priori, all the requirements for the installation of gas equipment have already been met - it remains only to connect the boiler. This state of affairs automatically reduces the cost of laying utilities and energy. It is forbidden to install a gas boiler in rooms with high humidity - in the bathroom, laundry room, etc.

There are several additional requirements for wall-mounted boilers:

- The wall or partition for hanging the boiler must be able to withstand it - do not hang the equipment on a drywall or other light partition.

- If the wall is decorated with combustible materials (wallpaper, vinyl, plastic, MDF, fiberboard), then a 3 mm thick non-combustible material gasket is installed between the gas wall-mounted boiler and the wall. In this case, the boiler must be fastened with special hardware, which provide a distance from the boiler body to the wall of at least 4-5 cm.

- The minimum distance from the boiler to the ceiling and walls of the room is 0.5 meters. The distance from the boiler to the floor is 0.8 meters.

Before installation and start-up of gas equipment, all relevant documents must be obtained. The main condition for installing a boiler in a private house that runs on gas is that an agreement is first concluded on connecting a gas main, and a project is drawn up for installing gas equipment and gasifying the house. These documents are developed and approved by the gas supplier in the region.

How to make everything perfect

In order for the garage boiler room not to cause complaints from regulatory authorities, the following basic principles should be taken into account during its installation:

- The room must be equipped with efficient and reliable forced-type ventilation. The removal of combustion products must be carried out through an air pipe, the outlet of which is located on the roof (at a normalized height).

- All fire safety regulations must be strictly followed. At the same time, the number of boilers in the room should not exceed 4 pcs. with a total power of up to 190-210 kW.

- The boiler must be at least 100 cm away from the garage wall.

- The minimum size of the garage in which the installation of boilers is allowed is 6.5 sq.m with a height of at least 2 m.

- A heat-resistant solid base (foundation) must be built on the floor under the boiler. Flammable materials must not be placed around the boiler.

- Connection of communications must be carried out professionally, taking into account all norms.

Increased requirements apply when using gas. When a gas boiler is installed in the garage, coordination is necessary already at the design stage. A permit must be obtained for the diversion of the gas pipeline and gas consumption standards must be established. Installation of gas boilers must be carried out in strict accordance with the regulations: SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000.

Filling the gas tank

The gas tank is refueled through a filling valve using a special vehicle - a gas carrier machine (tank capacity can reach up to 55 m³), the process of filling the tank with gas is monitored by a level gauge that indicates the degree of filling the tank in percent.

The tank is filled to a level of 85% of the total volume, the remaining 15% of the tank is designed to accommodate the gaseous phase, which is formed as a result of the evaporation of the liquid.

Rice. 21 Filling the gas tank with liquefied gas

Choosing the option of autonomous gas supply for a country house, many opt for underground storage tanks for liquefied gas - gas tanks. In doing so, they will have to face not only the very high cost of the tank, but also the further costs of regular maintenance and technical inspections.

Conclusion of an agreement

After drawing up the project documentation and obtaining permission to gasify the capital structure, the parties enter into a connection agreement. This document is concluded in accordance with the procedure established by the Civil Code of the Russian Federation.According to the contract, the contractor (GRO) is obliged to connect a house or other permanent structure to the gas distribution network, taking into account all the parameters specified in the technical specifications. In turn, the applicant must pay for technological connection services. The contract is concluded in writing in two copies. Each of the parties receives one copy, which contains the following conditions:

- list of technical works on connection;

- obligations of the parties;

- terms of work;

- the cost of the gas supply project (except when the project is developed by a third party);

- the amount and terms of payment by the applicant for technological connection;

- the procedure for delimiting the ownership of gas consumption and gas distribution networks;

- responsibility of the parties for non-compliance with the terms of the contract.

Here are the main terms of the contract. Depending on the region, the location of the facility, the distance of the gas pipeline from the site and other reasons, additional clauses may be included in the contract.

The procedure for gasification of an individual residential building under a comprehensive service agreement

The terms for concluding an agreement and connecting gas supply to a capital structure are strictly regulated by law, depending on the category of the applicant. Owners of residential, country and garden houses belong to the first category of applicants, since hourly gas consumption does not exceed 20 m3.

If the gas pipeline runs close to the house, then the draft agreement is sent to the owner within 5 days, excluding weekends. In other cases, the draft contract must be sent to applicants of the first category within 15 days. The applicant has 10 days to consider the contract.On disagreement with any clause of the contract, the homeowner must notify the contractor during this time. The contract is considered concluded from the day when the contractor receives a copy signed by the customer. Changing the conditions is possible with the mutual consent of the parties and is formalized by an additional agreement.