- What is a coaxial chimney

- The principle of operation of a coaxial chimney

- Advantages and disadvantages of the design of a coaxial chimney

- Options for gas ducts for a country house

- Selection Guide

- Chimney of solid fuel boiler

- Chimney from galvanized pipe

- Coaxial chimney for a geyser

- Installation Requirements

- Mounting

- Coaxial chimney for gas boiler

- Step-by-step instructions for building a smoke exhaust system

- outside the building

- Inside the house

- Features for installation in an apartment

- How to check and adjust the draft in the chimney of a gas boiler

- Why does the boiler blow out and how to fix it

- Video: how to check draft in a gas boiler

- Boiler structures and chimney outlet

- Methods for installing chimneys

What is a coaxial chimney

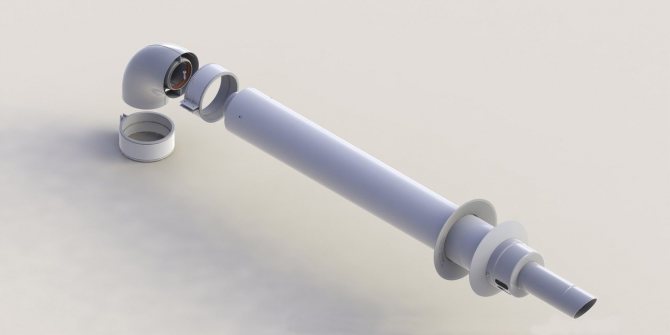

The concept of "coaxial" is used to refer to any structure consisting of two objects located around a common axis. In the case of a coaxial type chimney, this is a flue channel consisting of pipes of different sections.

The distance between the pipes is the same along the entire length of the chimney, including swivel elbows, bends and other elements. This is achieved through special jumpers, which are located along the entire length of the chimney.

The coaxial chimney is made of two pipes with a common central axis, separated by special internal jumpers

The principle of operation of a coaxial chimney

The channel between the inner and outer pipes provides a constant supply of fresh air, which is necessary to maintain combustion processes. The inner pipe is a channel for removing flue gases and other combustion products. In fact, the special design of the coaxial pipe allows the chimney to perform two functions at once: the removal of harmful substances and forced ventilation.

Flue gases are removed through the internal channel, and fresh air enters the combustion chamber through the annulus

The main scope of coaxial chimneys is wall and floor gas boilers with a closed combustion chamber, gas water heaters and convectors. With solid fuel equipment, coaxial type chimneys are not used.

Advantages and disadvantages of the design of a coaxial chimney

Among the advantages of coaxial type chimneys are:

- Versatility. Installation of a coaxial pipe is carried out by its output through a load-bearing wall, ceiling or roofing. Depending on the needs, you can choose the required dimensions of the chimney.

A coaxial chimney can be led out in the traditional way through ceilings and roofs, but it is much easier to do this through a load-bearing wall if a boiler with a closed combustion chamber is used

- Environmental friendliness. The higher the efficiency of the heating equipment, the better the fuel burns. This, in turn, reduces the concentration of harmful substances and gas released into the atmosphere.

- Efficiency increase.Due to natural heat exchange with the inner pipe, heated air enters the combustion chamber, which significantly increases the efficiency of heating equipment. At the same time, fuel consumption becomes noticeably lower.

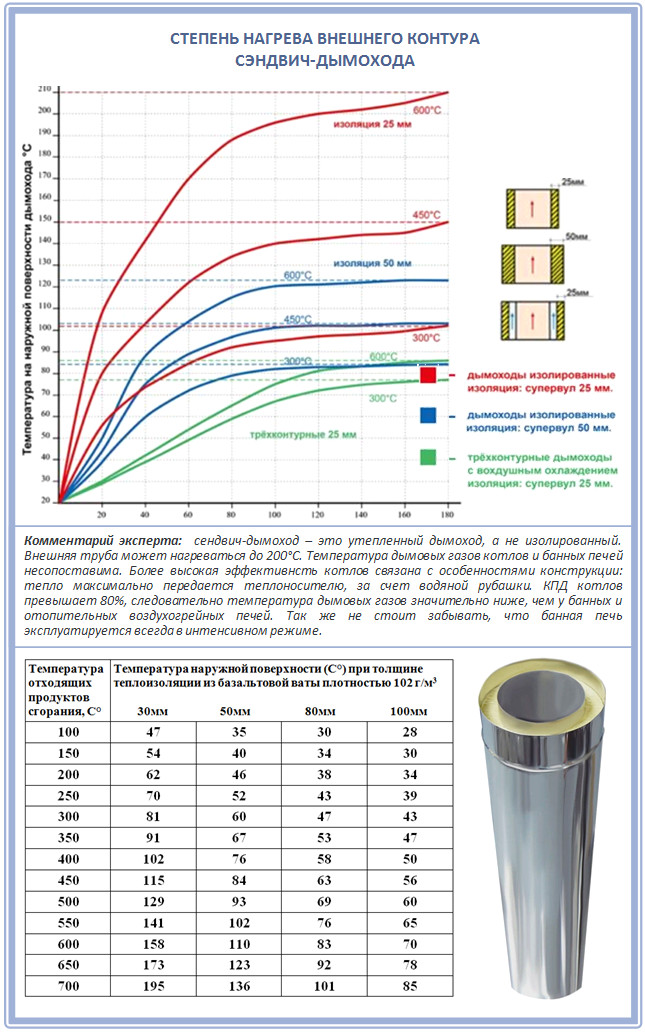

- Safety. The cold air entering through the outer pipe cools the combustion products that are discharged through the inner channel. The risk of fire and burnout of the chimney is minimized.

- Ease of installation. To assemble the chimney, no special tools or special skills in construction are required. The design of the chimney allows you to quickly install and put into operation any equipment with a closed combustion chamber.

Despite many advantages, the design of a coaxial pipe is not without drawbacks. At temperatures below -15 ° C, the coaxial chimney can freeze severely.

This is due to the fact that, in fact, it is an advantage of the design under consideration - cold air is heated due to the temperature of the flue gases escaping to the outside. The products of combustion are strongly cooled and can condense at the outlet of the chimney, which leads to severe icing on the chimney head.

One of the main advantages of a coaxial chimney turns into its main disadvantage - at low temperatures outside, combustion products condense and ice freezes on the pipe head

To prevent icing, you should choose special devices designed to operate at negative temperatures, as well as more carefully calculate the cross section of the chimney.

Options for gas ducts for a country house

To discharge combustion products with a relatively low temperature (up to 120 ° C) emitted by gas boilers, the following types of chimneys are suitable:

- three-layer modular stainless steel sandwich with non-combustible insulation - basalt wool;

- a channel made of iron or asbestos-cement pipes, protected by thermal insulation;

- ceramic insulated systems such as Schiedel;

- brick block with a stainless steel pipe insert, covered from the outside with heat-insulating material;

- the same, with an internal polymer sleeve of the FuranFlex type.

Three-layer sandwich device for smoke removal

Let us explain why it is impossible to build a traditional brick chimney or put an ordinary steel pipe connected to a gas boiler. The exhaust gases contain water vapor, which is a product of the combustion of hydrocarbons. From contact with cold walls, moisture condenses out, then events develop as follows:

- Thanks to numerous pores, water penetrates into the building material. In metal chimneys, condensate flows down the walls.

- Since gas and other high-efficiency boilers (on diesel fuel and liquefied propane) operate periodically, frost has time to grab moisture, turning it into ice.

- Ice granules, increasing in size, peel the brick from the inside and out, gradually destroying the chimney.

- For the same reason, the walls of an uninsulated steel flue closer to the head are covered with ice. The passage diameter of the channel decreases.

Ordinary iron pipe insulated with non-combustible kaolin wool

Selection Guide

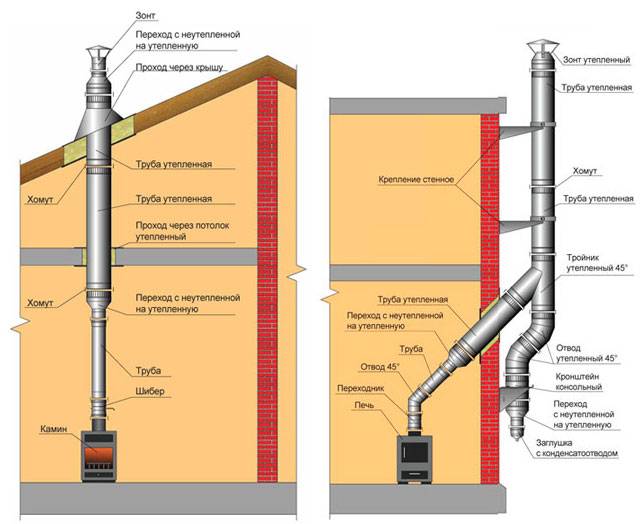

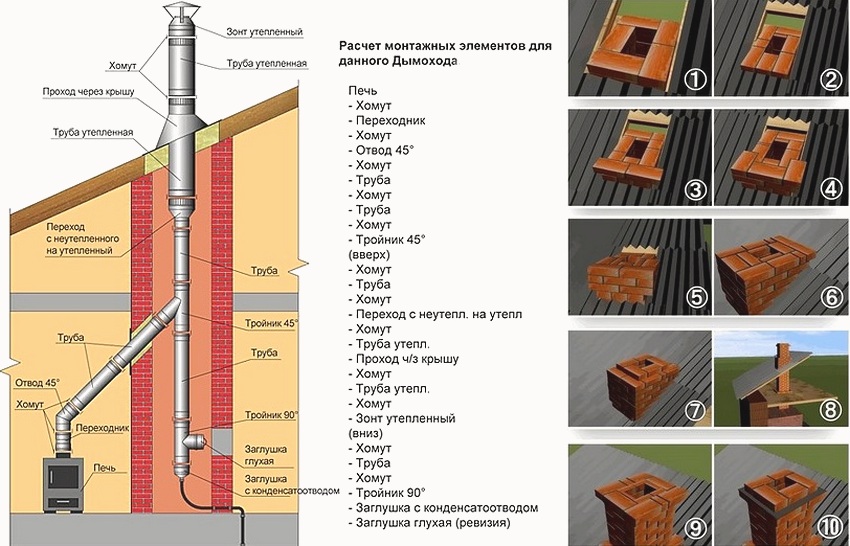

Since we initially undertook to install an inexpensive version of the chimney in a private house, suitable for do-it-yourself installation, we recommend using a stainless steel pipe sandwich. Installation of other types of pipes is associated with the following difficulties:

- Asbestos and thick-walled steel pipes are heavy, which complicates the work.In addition, the outer part will have to be sheathed with insulation and sheet metal. The cost and duration of construction will definitely exceed the assembly of a sandwich.

- Ceramic chimneys for gas boilers are the best choice if the developer has the means. Systems such as Schiedel UNI are reliable and durable, but too expensive and out of reach for the average homeowner.

- Stainless and polymer inserts are used for the reconstruction - lining of existing brick channels, previously built according to old projects. Specially fencing such a structure is unprofitable and pointless.

Flue variant with ceramic insert

A turbocharged gas boiler can also be connected to a conventional vertical chimney by organizing the supply of outside air through a separate pipe. The technical solution should be implemented when a gas duct has already been made in a private house, brought to the roof. In other cases, a coaxial pipe is mounted (shown in the photo) - this is the most economical and correct option.

Noteworthy is the last, cheapest way to build a chimney: make a sandwich for a gas boiler with your own hands. A stainless pipe is taken, wrapped in basalt wool of the required thickness and sheathed with galvanized roofing. The practical implementation of this solution is shown in the video:

Chimney of solid fuel boiler

The mode of operation of wood and coal heating units involves the release of hotter gases. The temperature of the combustion products reaches 200 ° C or more, the smoke channel warms up completely and the condensate practically does not freeze.But it is replaced by another hidden enemy - soot deposited on the inner walls. Periodically, it ignites, causing the pipe to heat up to 400-600 degrees.

Solid fuel boilers are suitable for the following types of chimneys:

- three-layer stainless steel (sandwich);

- single-wall pipe made of stainless or thick-walled (3 mm) black steel;

- ceramics.

Brick gas duct of rectangular section 270 x 140 mm is lined with an oval stainless pipe

It is contraindicated to put asbestos pipes on TT-boilers, stoves and fireplaces - they crack from high temperatures. A simple brick channel will work, but due to roughness it will become clogged with soot, so it is better to sleeve it with a stainless insert. Polymer sleeve FuranFlex will not work - the maximum operating temperature is only 250 ° C.

Chimney from galvanized pipe

At the stage of designing ventilation for a geyser, choosing a material, opt for a galvanized pipe. Taking into account the heating temperature during the disposal of combustion products from the room, a wall thickness equal to 0.5 millimeters is selected at a heating temperature of 400 °.

When choosing pipes for a geyser, the configuration of the future hood is taken into account - single-circuit or double-circuit.

In the second case, the pipe is applicable for sandwich and coaxial chimneys.

They differ in that in the sandwich system, basalt wool is laid between the two pipes, in the coaxial chimney, on the contrary, air circulates. Due to their properties and ease of installation of gas column hoods, sandwich chimneys are popular today.

Coaxial chimney for a geyser

This is a modern and quite popular version of the chimney these days, which is used for turbocharged columns, characterized by the presence of a closed combustion chamber. Its design is represented by a pipe in a pipe, while smoke is removed from the column through the central pipe, and fresh air from the street enters the combustion chamber of the apparatus through the gap between the outer and inner pipes.

This design allows you to make the exhaust pipe shorter and increase the efficiency of the device. In addition, a column with such a chimney option will not burn out oxygen in the room air, which usually happens with an open combustion chamber.

Having opted for a turbocharged column, you do not need to take care of sufficient ventilation of the room, but it is important to pay attention to the choice of chimney diameter. It is necessary that its diameter is not less than the outlet pipe of the column

Installation Requirements

Ceramic pipes are made in separate sections for further assembly. Therefore, when buying, you need to consider several important factors. Among them are the following:

- type of heating equipment;

- fuel used;

- dimensions of the room in which the boiler will be installed;

- diameter of pipes recommended by the manufacturer of the heating device;

- the shape and dimensions of the roof, the place where the chimney exits.

All these conditions must be announced to specialists in the sale of ceramic pipes in order to receive qualified assistance in selecting the type of product for the chimney and calculating the required dimensions.

The chimney can be installed both indoors and outdoors, adjoining the wall of the building. This type of installation is suitable for the location of the boiler room in a separate room.

It is worth considering that the impressive weight of a structure made of ceramics requires a reliable foundation. Such chimney systems are not recommended for installation on ordinary ceilings. The surface of the base must be flat and without slopes. The foundation is erected by the standard method using concrete grade M250 and higher. After the maturation of the building material, it is covered with double rolled waterproofing, which protects the channel for the removal of combustion products from high humidity.

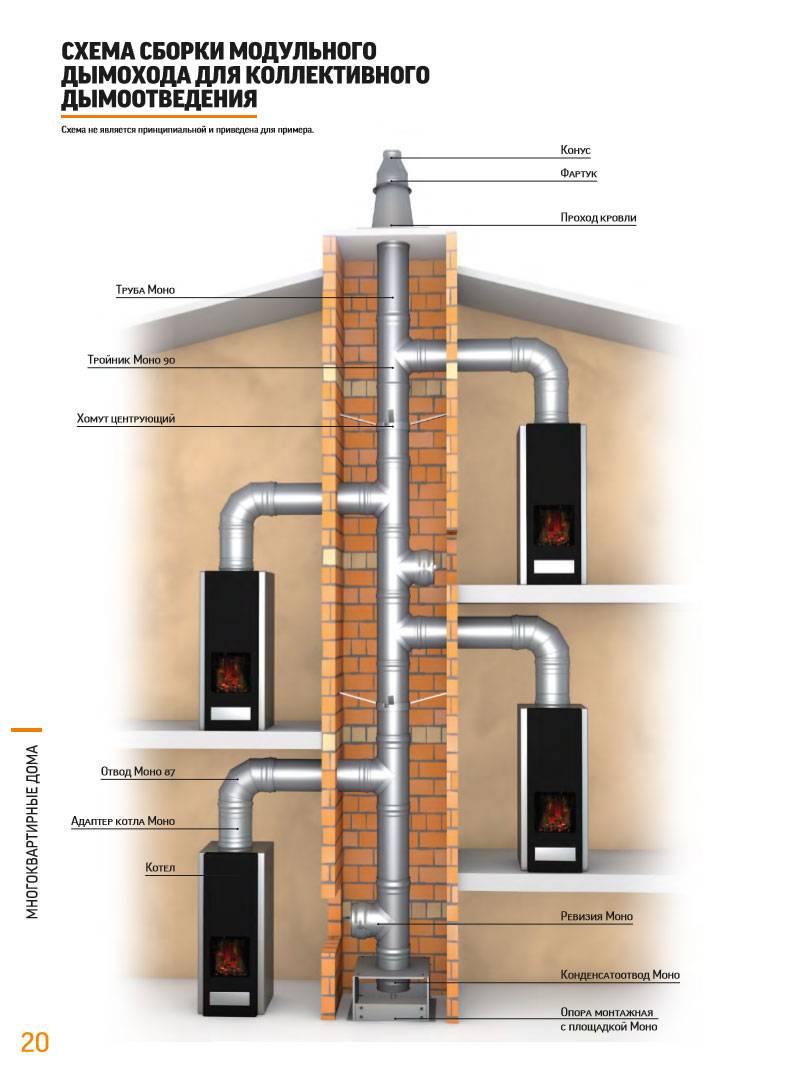

The design capabilities of ceramic pipes make it possible to bring several channels to the chimney from different sources of heating within the same building. The main thing is to provide for the presence of a ventilation grill and a section for collecting condensate in the lower part of the entire structure.

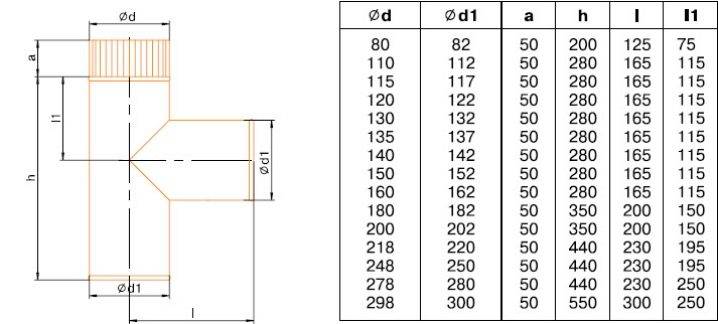

Channels to the chimney are usually connected using tees. They are also useful for installing a cleaning door.

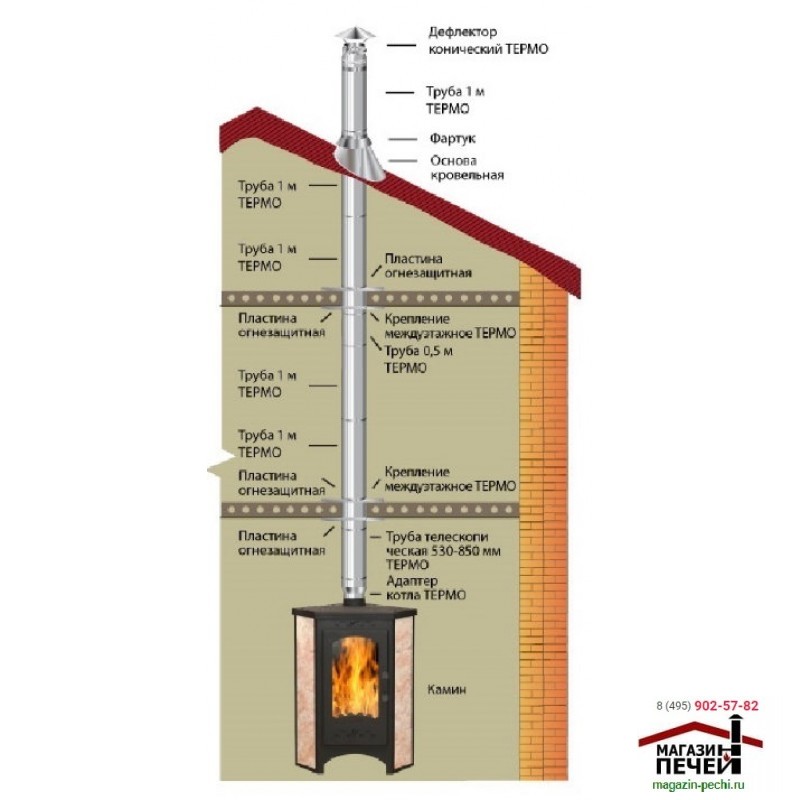

When installing the system, you need to take care of the thermal insulation of pipe sections passing through unheated zones or ceilings. You can also install segments of sandwich pipes. In areas of products for the smoke channel, passing in heated places, thermal insulation is optional. Uninsulated parts of pipes are located at a distance of at least 60 cm from flammable objects.

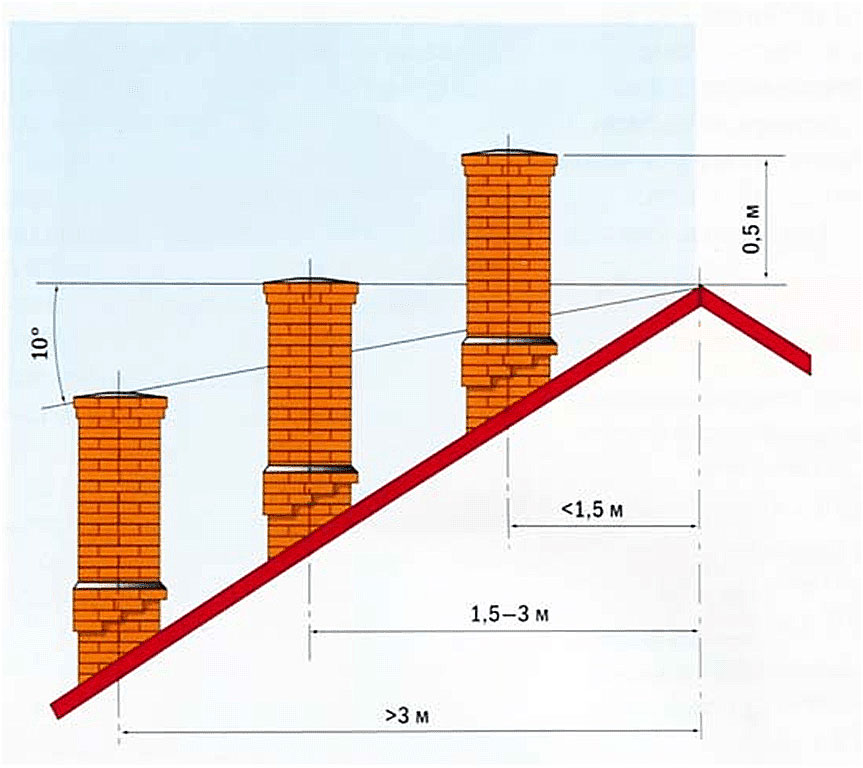

In the device of the chimney system, it is worth paying attention to the height of the cylindrical product located above the roof surface. There is an erroneous opinion that traction increases with pipe lengthening, but in fact there should be a measure in everything. If the ceramic product is too long, under the influence of aerodynamics, combustion products will settle on its walls.

To calculate this process, you can not do without special knowledge

If the ceramic product is too long, under the influence of aerodynamics, combustion products will settle on its walls. To calculate this process, one cannot do without special knowledge.

The top of the pipe is decorated with a cap - an element that protects the chimney from debris and precipitation. It is recommended to give preference to a product of the correct conical shape, since it affects the aerodynamics of the exhaust gases.

Details of the chimney system are installed using a special solution prepared from a liquid and a dry mixture. When mixing, you should strictly follow the instructions, and during operation, do not allow the drying solution to be diluted with water. The mass is applied with an ordinary trowel or with a construction gun. The seams are rubbed to remove excess mortar.

If in the future it becomes necessary to create holes for the removal of pipes, you can use the grinder for sawing blocks.

Before installing the chimney system, it is important to study the plan of the house, consider the location of the joints between the elements in order to prevent the seams from getting into the ceiling. It is required to take into account the sequence of parts of the system, as well as calculate the dimensions of the required pipes

A free-standing product without a sandwich box must be fixed to stable structures using clamps installed every 1-1.2 meters, and the area above the roof should be strengthened with wire braces.

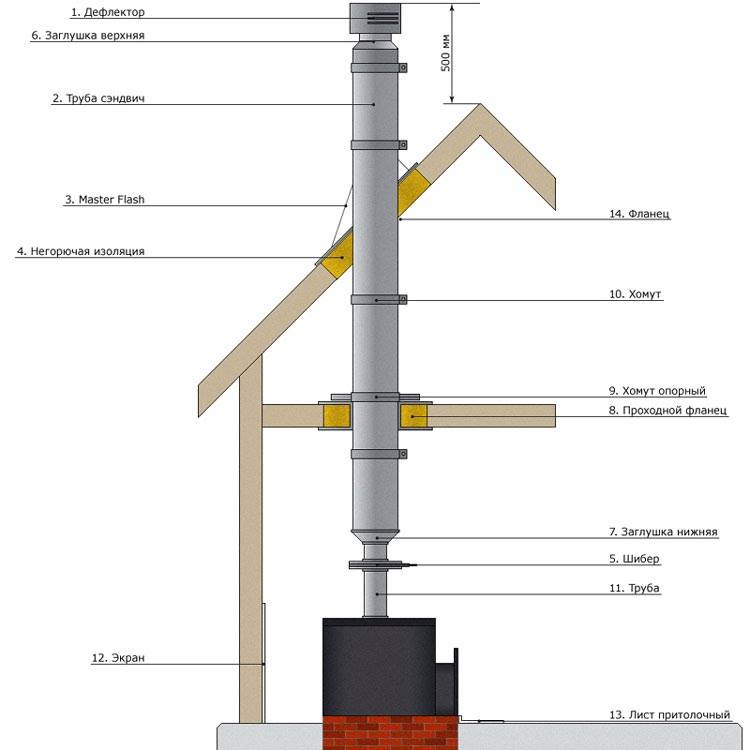

Mounting

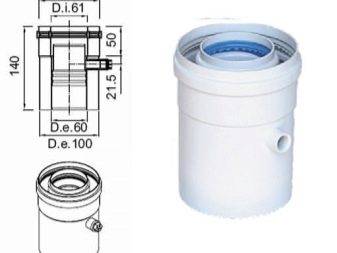

When installing a coaxial system with your own hands, you need to do a number of preparatory work. In particular, it is worthwhile to carefully calculate the dimensions, prepare the holes in the wall and provide for a slight slope of the pipe. A slope of 2-3 degrees will allow the resulting condensate to drain.Next, you need to bring the chimney through the wall of the house. It is quite simple, the main thing is to comply with all the requirements of regulatory documents.

Then you can proceed to the installation of coaxial equipment to the boiler. To do this, you must use a special connection adapter. Then a tee with a condensate collector is installed, after which the chimney structure is led out through the wall.

In some cases, during installation it is necessary to increase the length of the coaxial chimney pipe. For this, swivel couplings are used, which fasten the joints between the pipes. It should be noted that it is not recommended to seal the pipes with silicone. It may not withstand high temperatures. It is also recommended to minimize the number of pipe turns so that the thrust of the structure is higher.

Many users of this type of chimney are faced with the problem of icing of the removed pipe. If this happened and there is ice on the pipe, then most likely the installation of the system was carried out incorrectly. To avoid the appearance of icicles on the pipe, you can use a special nozzle. Such an anti-icing device will eliminate the problem of ice on the pipe. In particular, when using this type of chimney in collective systems, the use of a nozzle is a must.

To protect the pipe from wind blowing, it is necessary to calculate in advance where the chimney will be installed. Here it is necessary to take into account the structure of the building. Also, a special wind protection and a diaphragm are used for this.

If there is no self-confidence, then you should contact specialists who will help you properly install the coaxial chimney.Otherwise, gross miscalculations can be made, due to which the system will work inefficiently.

Among the most common mistakes during installation, the following should be highlighted:

- Gross errors in the calculation. It is necessary to carry out measurements and calculations strictly in accordance with established regulatory legal acts.

- Violation of fire safety standards. For such systems, clearances must be provided to reduce the level of fire hazard. If such requirements are not met, the consequences can be very deplorable.

- Incorrect connection to the heating equipment.

- Error in the choice of material. It was said above that chimney systems can be made of stainless steel or plastic. When choosing, the individual characteristics of the heating system should be taken into account so that the material can withstand the required temperatures.

Coaxial chimney for gas boiler

As mentioned above, a coaxial chimney is a double-circuit pipe. Its principle of operation is based on the influx of clean air masses through the distance between the pipes, and the removal of carbon monoxide through the inner pipe. Using a coaxial hood for gas water heaters in an apartment will help bypass the public ventilation duct, bringing combustion products through pipe to the street, and avoid a situation with a loss of boiler efficiency, which may occur when the ventilation duct is clogged.

For this system, a pipe with a diameter of 11 centimeters is used. Often, for greater traction, fans with sensors are installed. This allows you to achieve high performance gas boiler at any time of the year.

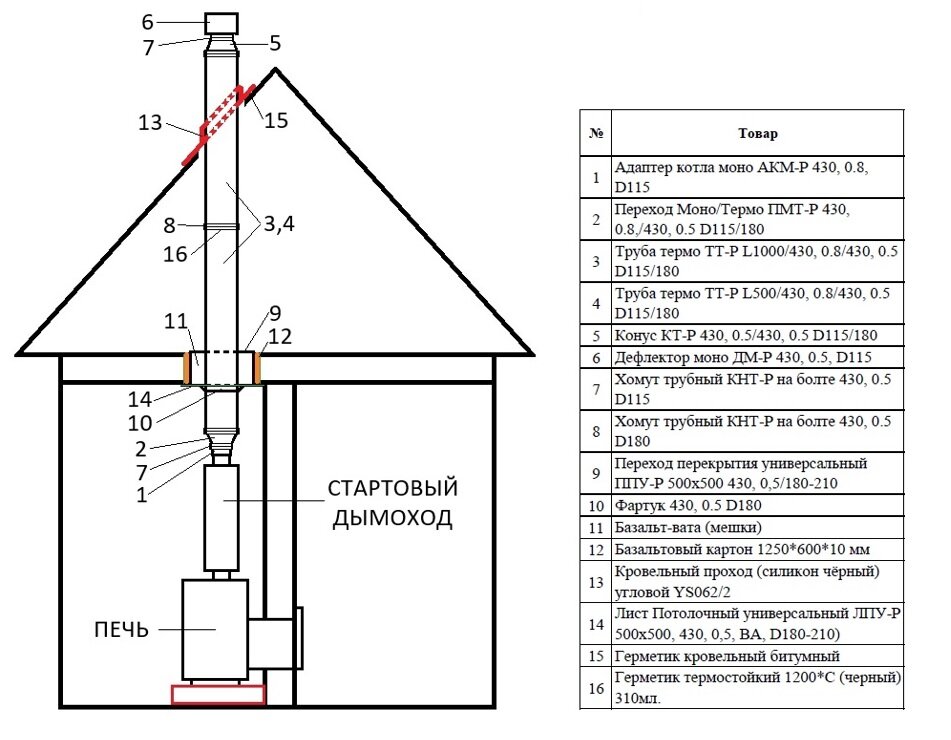

Step-by-step instructions for building a smoke exhaust system

The ventilation of the room must be taken into account for the commissioning of the equipment.In the absence of air exchange, forced turbo exhaust is required. Without it, the commissioning of a gas boiler is impossible. We will look at how the hood for a gas boiler is installed in a private house using the example of a coaxial chimney. The length of the pipe from the boiler room to the street for this type of hood does not exceed two meters.

- Getting started, make sure that the installation of the gas boiler complies with the rules and regulations approved by the inspection organizations in order to avoid redoing the entire power unit.

- Choose a suitable material for the hood, taking into account the parameters of the gas outlet: gas boiler inlet = pipe diameter.

- Calculating the power of the fans and their number, taking into account how long the hood is, the number of knees in its structure, and the position in space relative to the horizon, at what height the exhaust pipe is located in the room.

- Do not forget about the features of budget equipment, indicated in the data sheet.

- All materials used in the work must be refractory and resistant to corrosion.

- After making sure that all the parts are intact, we proceed to the assembly. We attach the chimney elbow to the gas boiler nozzle using a tee.

- To build up a coaxial pipe and connect all its parts, special crimp clamps and refractory sealants are used.

- Turbo exhaust is used if there are more than two bends in the pipeline geometry. This helps to maintain the efficiency of the gas boiler. The fan and all sensors are installed after installation of the supply pipe.

- Installing a coaxial pipe outside a building is no different from installing a conventional sandwich chimney.

We recommend that you read: How to choose and install a ventilation grill for a window sill

outside the building

Having laid the line for the exhaust device in the house, the design of the hood for the gas boiler goes outside.

- As soon as the pipe has been brought out into the street through a hole in the wall, it must be closed with special metal plates. The remaining space between the pipe and the wall is filled with mineral wool.

- Now install the tee. The lower hole is closed with a plug with an inspection to clean the pipe.

- We increase the chimney to the desired length by connecting the parts using a special sealant and clamps with gaskets. As the pipe grows, we attach it to special brackets.

- We install a protective cone at the top of the chimney and additionally fasten it to stretch marks in those places.

- If the chimney structure was not covered with special paint at the factory, this can be done at home. This is done to protect the metal from environmental influences.

See how to connect a gas water heater to a chimney system and how to collect it, you can on the video.

Inside the house

Inside the house, the installation of a coaxial chimney, in detail, with comments, was described above. The only step left for you to take is to connect the two pipes, street and room, by extension. For additional insulation, the use of special metal tape is recommended.

I would like to note an important advantage of a coaxial chimney - this is the absence of additional holes in the roof or wall of your home

Features for installation in an apartment

To connect a standard gas water heater in a city apartment, the house must have a stationary channel for smoke removal.In most modern buildings, such ventilation ducts are laid in the walls, so bringing a chimney to them from a column is not a problem. However, in many buildings of the last century there are no such channels, so it will not be possible to install an ordinary column in them. In this case, you can opt for a turbocharged model.

Other features of installing a chimney in apartments are the following nuances:

- The chimney inside must be smooth and without any constrictions.

- Most often it is installed vertically. No more than 3 bends are allowed.

- The pipe must be well sealed to prevent combustion products from entering the living quarters.

How to check and adjust the draft in the chimney of a gas boiler

Thrust is a reduction in pressure at the place where the fuel is burned. The pressure reduction occurs due to the removal of combustion products through the smoke channel. Speaking within the framework of this article, the draft forces fresh air to enter the combustion chamber, where there is a reduced pressure that occurs due to the fact that the products of combustion of the gas are removed to the outside.

The presence of draft indicates that the chimney is designed and installed correctly, and the equipment is working properly. Lack of draft may be a direct or indirect confirmation of the need for preventive maintenance or repair of equipment and the smoke exhaust system.

The speed of the air flow in the chimney can be measured with a special device - an anemometer.

To check the level of traction, the following methods are used:

- visual inspection - in the room where the heating equipment is located, there should be no smoke;

- use of improvised means, for example, a sheet of paper. It is brought to the viewing hole. If there is traction, then the sheet will deviate towards the hole;

- measurement with a special device - anemometer. It is used to control the air speed.

For traction control, it is better to use the latter method, since only it will show the exact value. When measuring natural draft, the flue gas velocity should be in the range of 6–10 m/s. The value is taken from SP 41-104-2000 "Design of autonomous heat supply sources".

If this does not help, then the only way out is to replace the chimney with a preliminary calculation of the cross section of the chimney. At the same time, it is desirable to minimize the number of rotary elements or even remove them altogether.

Why does the boiler blow out and how to fix it

The main reason why the burner blows out in the boiler is the backdraft effect that occurs due to problems with the chimney.

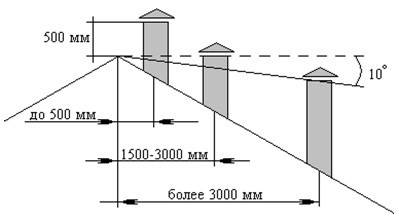

Before proceeding with any measures, you should check the height of the chimney above the level of the ridge and the presence of an installed deflector, which allows you to reduce the penetration of wind flows into the chimney. If the pipe device is not made according to the rules, then after the steps described below, you will need to build up the pipe and install a deflector.

Sometimes, in order to increase traction, you need to clean the chimney of soot.

In order to solve the problem with blowing the boiler, you will need to do the following:

- First of all, it is necessary to check the level of draft in the pipe. For better use an anemometer. If it was not possible to find it, then with the boiler running, you need to lean the paper against the outlet of the chimney. If the sheet is attracted to the chimney, then there should be no problems with draft.

- If it was found that the blowing is due to a loss of natural draft, then it will be necessary to check the chimney connection points. For this, a thermal imager is used. If the pipe passes air, then the device will show a strong temperature difference between the main pipe and the junction of the two modules.

- If the chimney is assembled correctly, then it is necessary to clean the smoke channel using a cable with a nozzle. The diameter of the nozzle is selected according to the section of the chimney pipe. An inspection hole at the bottom of the chimney is used to clean soot, tar and other combustion products.

- After performing these simple steps, you will need to check the level of traction again. If the natural draft has not improved, then it is necessary to carry out work to correct the height of the chimney and install a deflector. During installation, a heat-resistant sealant and crimp collars are used.

In cases where the work described above did not work, you should contact the gas service to check the gas equipment. Perhaps the problems with blowing are associated with ultra-sensitive automation.

Video: how to check draft in a gas boiler

Compliance with regulatory requirements is a guarantee that during the operation of the chimney there will be no emergency situations. This is especially true for vertical chimneys, when it will take a lot of time to correct the mistakes made during their installation.

Boiler structures and chimney outlet

Structurally, a gas boiler is a device consisting of a gas burner, to which gas is supplied through the nozzles, and a heat exchanger, which is heated by the energy obtained during the combustion of gas. The gas burner is located in the combustion chamber.The movement of heat occurs with the help of a circulation pump.

In addition, modern types of gas boilers are equipped with various self-diagnosis and automation modules that allow the equipment to be used offline.

When choosing a chimney, pay attention to the type of combustion chamber of the boiler. It is from its design that the method of taking in the air necessary for the combustion of gas will depend, and as a result, the optimal type of chimney

Different types of chimneys are suitable for different types of combustion chamber

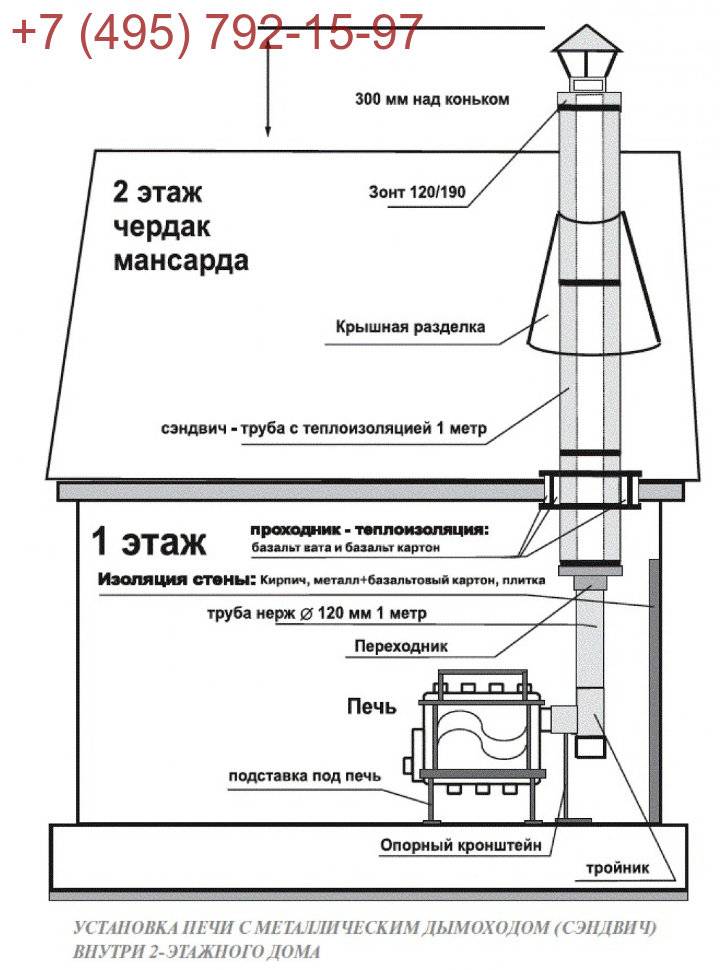

The combustion chamber for gas boilers is of two types:

- open - provides natural traction. The air is taken from the room where the heating equipment is installed. The removal of combustion products is carried out by means of natural draft using a chimney with an exit through the roof;

- closed - provides forced draft. The intake of air for combustion of fuel occurs from the street. In rare cases, air can be taken from a special room equipped with forced ventilation. For the simultaneous removal of flue gases and intake of fresh air, a coaxial type chimney is used, which is led out through the nearest load-bearing wall.

Knowing the type of combustion chamber, you can easily select or make a chimney that is suitable for the design. In the first case, when the boiler is equipped with an open combustion chamber, a conventional thin-walled or insulated chimney is used.

For boilers with a closed combustion chamber, a coaxial chimney is used, which is a structure consisting of pipes of different diameters. A pipe with a smaller cross section is fixed inside a pipe with a larger diameter by means of special racks.Through the inner channel, carbon dioxide and other combustion products are removed, and through the gap between the outer and inner pipes, fresh air enters the closed combustion chamber.

Methods for installing chimneys

According to the method of installation, chimneys are divided into:

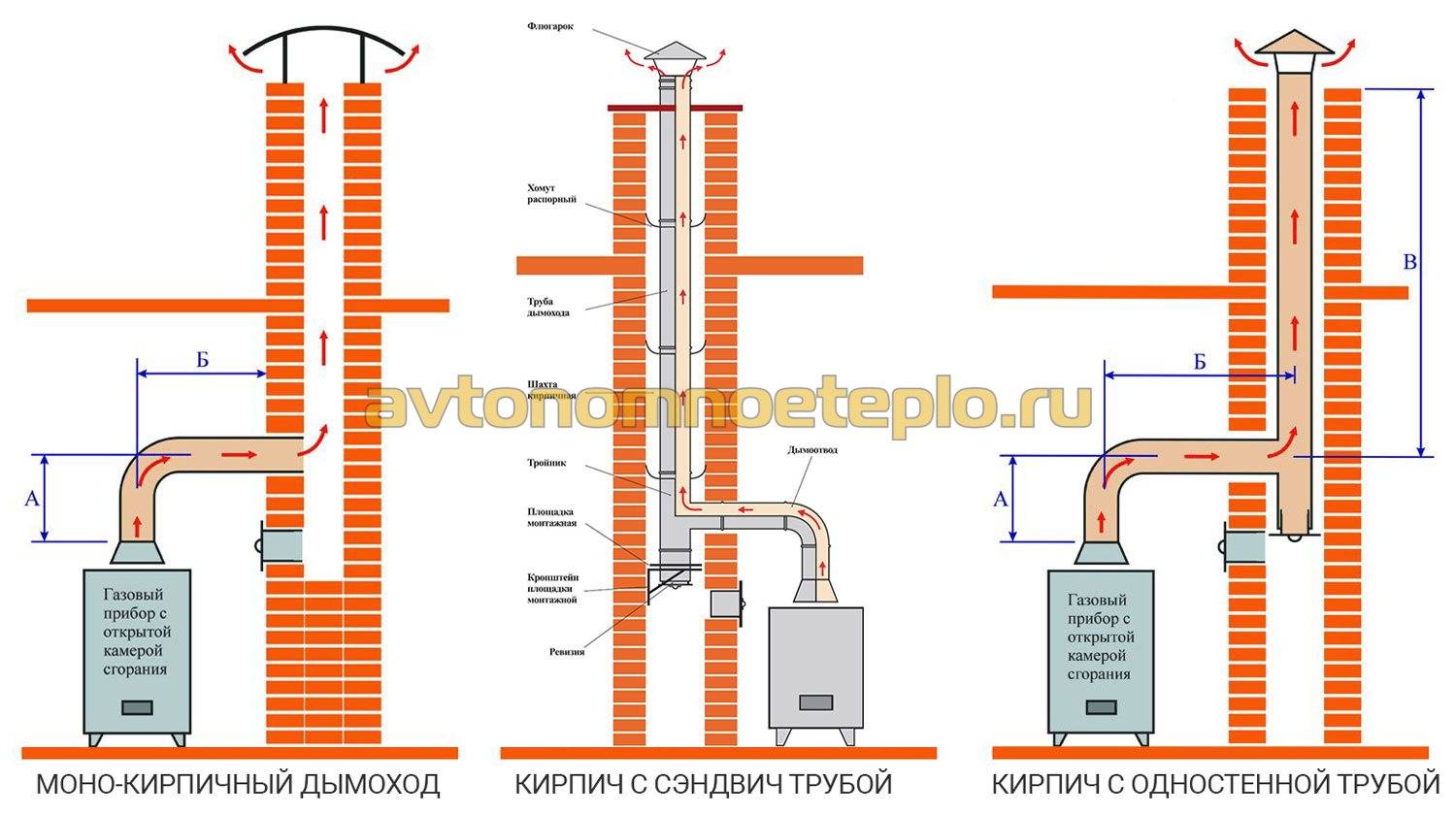

- internal - chimneys made of metal, brick or ceramics. They are both single-walled and insulated double-walled structures. Arranged vertically upwards. Perhaps the presence of several knees with an offset of 30o;

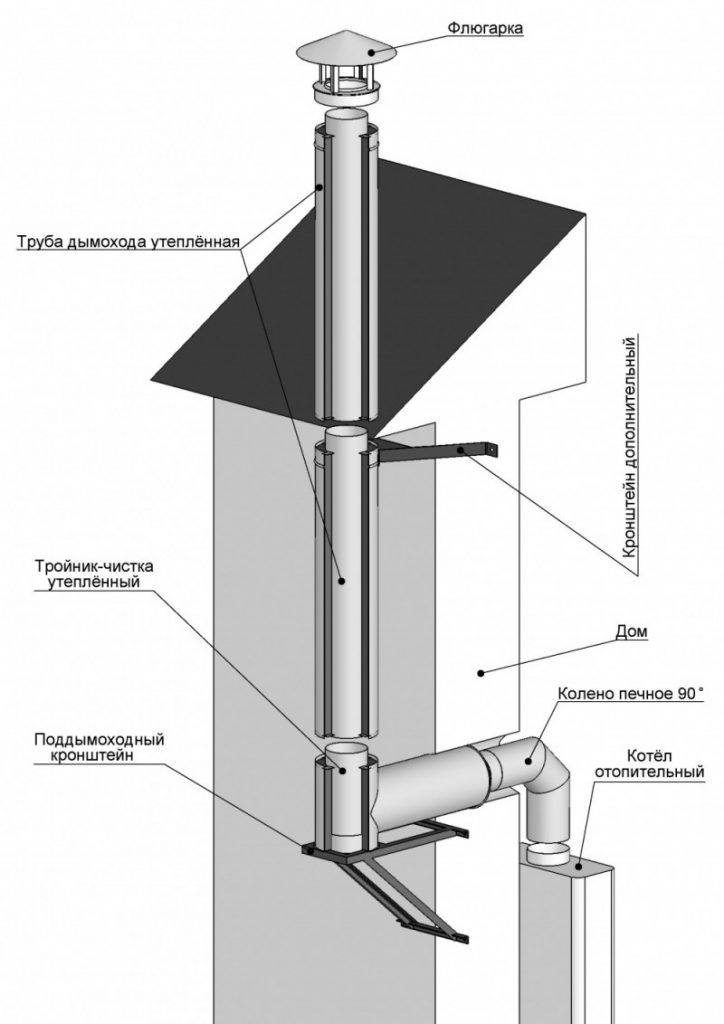

- outdoor - coaxial or sandwich chimneys. They are also located vertically upwards, but the chimney is brought out horizontally through the load-bearing wall. After the pipe is removed, a 90° swivel elbow and support brackets are installed to allow installation in the desired direction.

The chimney can be led outside through the wall in the immediate vicinity of the boiler or in the traditional way through the roof

When choosing a chimney device, the dimensions of the building in which the equipment is located should be taken into account. For small buildings, it is more advisable to use external chimneys, as they allow you to bring the chimney outside the room.

In other cases, one should build on personal capabilities. If space permits and it is possible to perform high-quality insulation in the places where the pipe passes through the floors, then an internal chimney will be the best solution. Especially if the structure is lined with brick or protected by a ceramic box.