- Insulation of a wooden house with foam plastic from the outside: material characteristics and installation

- What is foam and how to mount it

- What is foam and how to mount it

- Conclusion

- How to insulate a wooden house with foam plastic

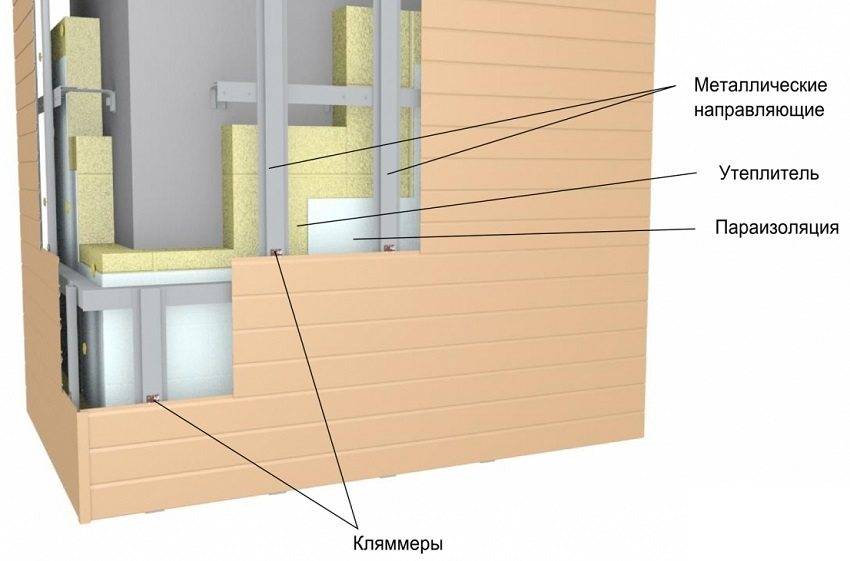

- Features of a hinged facade

- As a result - what other options can be considered

- What is better foam or foam?

- Which foam to choose

- Stages of warming a wooden house

- Foundation preparation

- Lathing device

- Insulation mount

- Foam cladding

- Characteristics of penoplex

- Types of extruded polystyrene foam

- Advantages

- Styrofoam insulation of a wooden house: wonderful myths and harsh reality

- A little about fire safety

- It's all about vapor permeability

- Styrofoam insulation outside

- Conclusion

- The better to insulate a wooden house - foam or foam

- Benefits of outdoor insulation

- Selection of suitable materials for work

- The easiest way to reduce thermal conductivity

- How to apply polyurethane foam correctly

- Materials for insulating the walls of a house from a bar

- How and how to insulate a house from a bar

- vapor barrier

- Installing the frame for thermal insulation

- Laying thermal insulation

- Waterproofing

- Second frame layer

- outer skin

Insulation of a wooden house with foam plastic from the outside: material characteristics and installation

Of course, the question of whether it is possible to insulate a wooden house with foam plastic will cause controversy, in view of the flammability of the latter, but there is an iron counterargument about this - the tree also burns, and besides, it is even better. As you can see, this parameter cannot be considered as decisive, but otherwise this heat insulator is quite suitable for a building of this type.

Insulation of a wooden house with polystyrene foam for siding

What is foam and how to mount it

Styrofoam characteristics

Is polystyrene harmful as a heater).

What is foam and how to mount it

Styrofoam characteristics

Styrofoam is not toxic, but when it ignites, it releases phenols, and at temperatures above 75⁰C, it begins to degrade, but in residential buildings, such a threat can only come from heating appliances. Also, the instructions for use indicate that such material is afraid of alcohols, acetones, benzene and dichloroethane.

Advice. Due to the weak resistance of polystyrene to an active chemical environment, when insulating a house with your own hands, you need to be especially attentive to the purpose of the insulated room. If these are technical buildings (garage, shed), then such a thermal insulator must be very well closed for contact with paints, varnishes, gasoline, and the like.

Installation of insulation

Penoplex insulation, just like other materials, has a number of advantages with a large tail of disadvantages, which appear under certain conditions of use of the insulation. The panels are made of gas-filled polystyrene foam, laid in the desired shape. The main volume of the resulting product is occupied by gas, so it is a poor conductor of heat and is able to dampen sound vibrations.

- Due to the closed cellular structure, the material has very low water absorption, so, depending on the density, in one day the sheet can gain from 2% to 3% of moisture from the total mass. The density of the foam, which is used to insulate walls, floors and ceilings, can be 15 kg / cm 2 or 25 kg / cm 2 - the degree of “flowability” of the panels during cutting and their price will depend on this.

- Styrofoam is not toxic, but when it ignites, it releases phenols, and at temperatures above 75⁰C, it begins to degrade, but in residential buildings, such a threat can only come from heating appliances. Also, the instructions for use indicate that such material is afraid of alcohols, acetones, benzene and dichloroethane.

Advice. Due to the weak resistance of polystyrene to an active chemical environment, when insulating a house with your own hands, you need to be especially attentive to the purpose of the insulated room. If these are technical buildings (garage, shed), then such a thermal insulator must be very well closed for contact with paints, varnishes, gasoline, and the like.

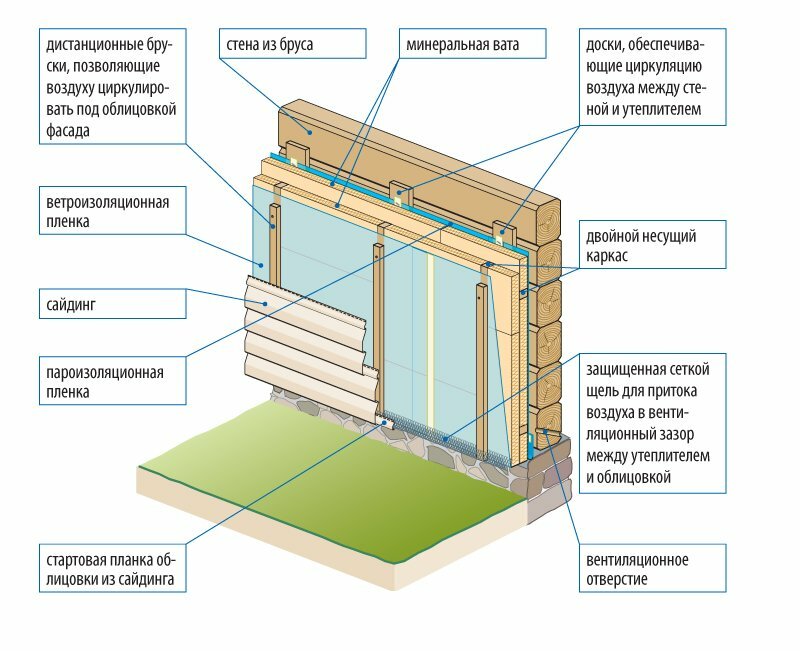

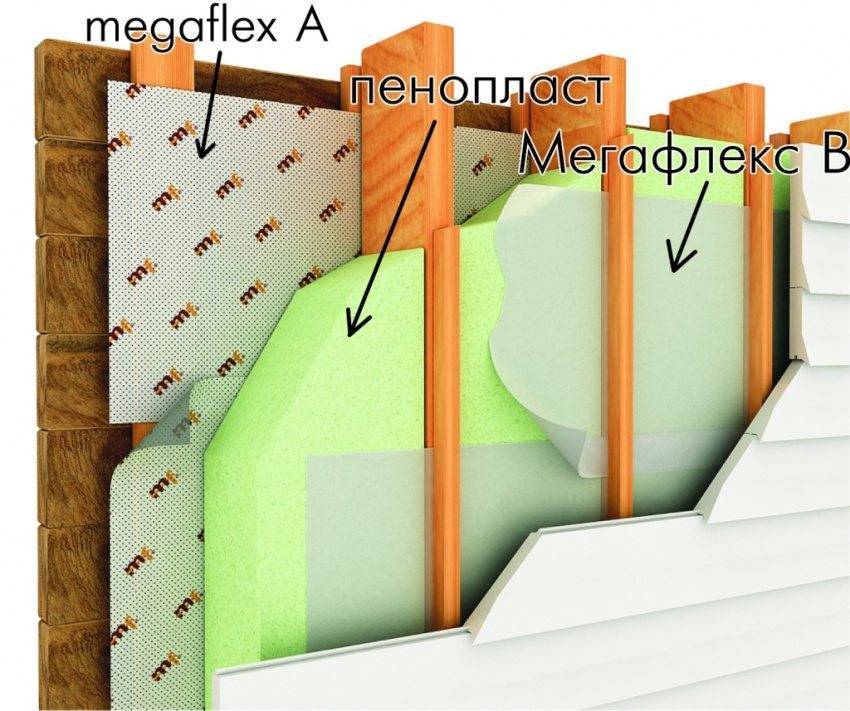

U-shaped suspension is used as a bracket

- Now let's look at how to insulate a wooden house with a ventilated facade with foam plastic without using branded frames. However, both the essence and the design itself in this case practically do not differ from the factory kit, but it all costs much less. As brackets, we use tape U-shaped suspensions, on which we then fix the rails or metal profiles.

- The consoles are screwed to the wall in those places where the profile of the crate should be, observing the desired step (for cladding) and a distance of 40-50 cm from each other.After all the brackets are screwed to the wall, you can proceed with the installation of the foam. A small footnote should be made here - perhaps, due to certain technical needs of the wall structure, a hydrobarrier will need to be placed under the consoles - the wall will breathe inside the house.

Wall insulation with facade ventilation

Now the panels just need to be threaded through the consoles - the principle of such installation is clearly visible in the schematic diagram above. Here you no longer need to cut the sheets, with the exception of the corner ones, but still, try to stack them so that there are no holes left.

Conclusion

In a similar way, the warming of the loggia or balcony also occurs, only there are slightly different scales. It is also possible to install foam under putty, but given that our house is wooden, we did not consider this method as unnecessary.

How to insulate a wooden house with foam plastic

If desired, you can find examples of using foam to insulate wooden house outside. Moreover, there is a technology that does not impair the "breathing" properties of the walls and the level of comfort, which is ensured by natural gas exchange between the premises and the street. This is achieved by creating a ventilated gap between the insulation and the wall. Moreover, in this case it does not matter what the walls are made of - from a bar or a log.

In order not to impair the "breathing" properties of a wooden house, a ventilated gap must be created between the foam and the wall

In our video, we will look at how polystyrene is produced, is polystyrene harmful and where is it used?

What happens if it is wrong to insulate with polystyrene - in the video:

Features of a hinged facade

In this case, the requirements for the peel strength of the insulation surface are not as high as for the "wet facade", so the density of the mats can be less than 125 kg/m³, but higher than 80 kg/m³.

There are ready-made systems of hinged facades with their own fastening subsystem, a set of panels and fasteners. The only drawback of such systems is the need for individual adjustment to the specific geometry of the house and walls. As a rule, these systems are designed for houses made of brick or building blocks, and aluminum sandwich panels, artificial stone, porcelain stoneware are used as cladding.

For facing wooden houses, imitation of timber, block house, planken, siding are usually used. That is, those materials that are more in line with the aesthetics of a wooden house.

If you want to change the decorative qualities of a wooden house, you can use facade panels made of artificial stone when cladding

The most common practice is the manufacture of lathing from a wooden beam - it is easy to adapt to the surface of the walls, it is easier to fix, it does not change size with temperature changes and does not serve as a "cold bridge".

Wooden crate is the easiest option

The only drawback of wooden structures is low resistance to moisture. Therefore, both the elements of the crate and the finishing panels made of natural wood must be treated with an antiseptic before installation.

As a result - what other options can be considered

The article described only the two most common ways to insulate a wooden house from the outside.What is better in your case and other options should be discussed with the developer, who knows the local conditions. The use of eco-wool has not yet become widespread, although the technology is quite simple - mounting the crate to the wall, applying a “wet” insulation (mixed with glue) to the surface with the help of special equipment, sheathing with facade panels along the crate. Brick cladding on flexible connections follows the same rules as for a stone house, with the only restriction on the choice of insulation - the use of only mineral wool.

Despite the apparent simplicity of the whole process, when installing any type of insulation, there are a sufficient number of pitfalls that must be taken into account so that all the work is not done in vain. If there is no experience, then it is always better to invite a professional, especially since self-respecting developers perform all work under the contract and give a guarantee.

What is better foam or foam?

Many private traders are interested in the question of whether it is possible to insulate the walls outside a wooden house with foam plastic. Sometimes it is confused with polystyrene, believing that they are one and the same.

In fact, these are completely different materials and this is manifested in their properties:

- Penoplex, unlike polystyrene, has sufficient strength, as it is formed by heating, during which its components are fused into a single dense mass.

- The same applies to thermal insulation properties. Where a foam plate 8-10 cm thick is required, 3-4 cm is enough for foam plastic. This property is used when insulating houses in the Far North.

- It does not burn well, unlike its “brother”, but when ignited, it melts, releasing toxic and extremely caustic smoke.

This material, like polystyrene, does not pass steam well, so you should think carefully about how to get moisture out of the premises to the outside if foam is chosen for work. Warming a wooden house from the outside with this material requires additional costs for conducting ventilation ducts from the premises to the outside.

Which foam to choose

It has been proven that the density does not significantly affect the thermal conductivity, so a material with a low density, for example, PSB-S-15, should be preferred.

This material has the following characteristics:

- Weighs little.

- The compressive strength is up to 10% and 0.05 MPa when deformed. This means that the insulation will be resistant to kinks.

- The thermal conductivity is not higher than 0.042 W/mK, which is not much higher than other materials with a higher density.

- Affordable price.

This material will be an acceptable option to insulate the house from the outside with foam.

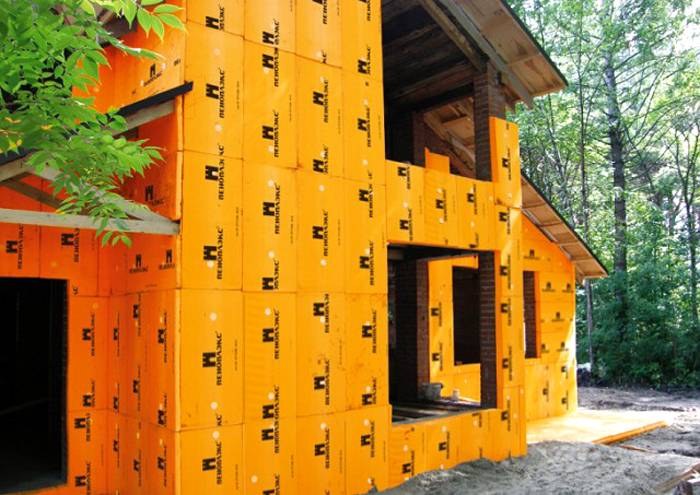

Stages of warming a wooden house

How to insulate a wooden house outside with penoplex with your own hands? It is important for the owner to remember some features of just such insulation in order, on the one hand, not to pay extra money, and on the other hand, to do everything taking into account the characteristics of the wooden facade as a base. Important! Before you start decorating your wooden house with foam, it is important to know that many experts do not recommend this method of insulation, because due to the lack of vapor permeability, the wooden walls stop "breathing"

Important! Before you start decorating your wooden house with foam plastic, it is important to know that many experts do not recommend this method of insulation, because due to the lack of vapor permeability, the wooden walls stop “breathing”.It is recommended to use vapor-permeable mineral wool, but such material is usually more expensive.

Despite this circumstance, many homeowners continue to insulate with styrofoam, and claim that the performance of the house has not been affected.

It is recommended to use vapor-permeable mineral wool, but such material is usually more expensive. Despite this circumstance, many homeowners continue to insulate with styrofoam, and claim that the performance of the house has not been affected.

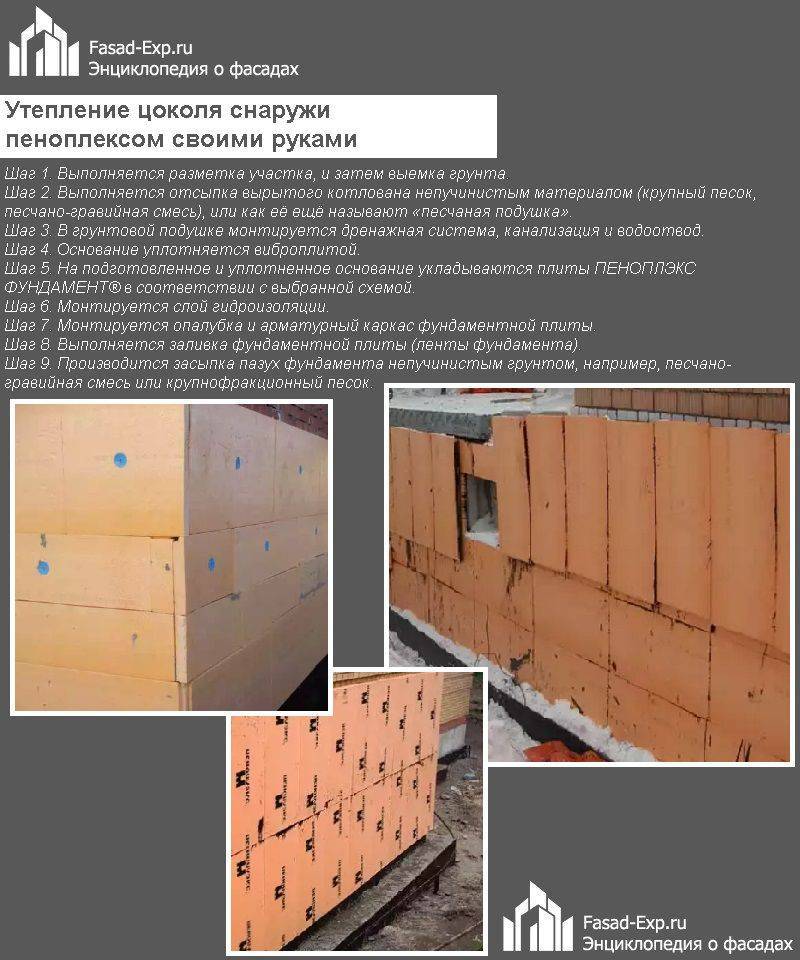

Foundation preparation

- We carefully examine the surface of the walls and, if there are even small cracks, we close them with tow or dry moss;

- We check the plane of the surface of the facade, if there are significant protrusions, it is better to remove them;

- We impregnate the logs with flame retardants and antiseptics, which will protect against decay and make it difficult to burn.

After completing these procedures, the surface of the walls is ready for further do-it-yourself work.

Lathing device

Many builders neglect this stage of work, and indeed, the lathing of the walls outside can be omitted, but only if they are made of logs, not beams, and not using frame technology.

The crate is made, as a rule, from a bar 25 x 50 or 50 x 50, but it can also be made from a metal mounting profile. You need to mount it on the walls with high quality, making sure that an absolutely flat mounting surface is formed - the foam boards are very rigid and in case of irregularities, they will not fit snugly.Given the dimensions of the insulation boards - 1200 x 600 mm, the vertical and horizontal guides must be positioned in such a way that squares of 600 x 600 mm are formed - for better reliability, or 1200 x 600 mm - this is also allowed.

Many then install a vapor barrier membrane on the crate, but this is superfluous - extruded polystyrene foam itself is an excellent vapor barrier and is not afraid of moisture.

Insulation mount

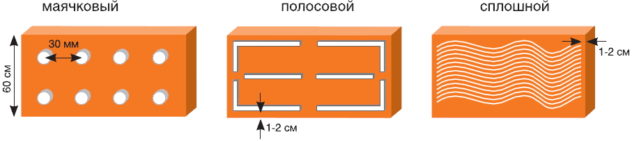

After installing the guides, you can proceed with the installation of the penoplex with your own hands. This is done using self-tapping screws and a special, two-component adhesive. Ordinary inexpensive glue is not suitable for a wooden facade - this is an unstable base, the slightest movement of which in the direction of expansion or contraction will lead to deformation and peeling of the insulation. That is why an adhesive composition with special polymer additives is used, which allow it to maintain elasticity after drying.

After the owner has fixed the insulation on the outside of the crate of the facade, you can start finishing the walls.

Foam cladding

There are a lot of options on how to proceed further to make your home beautiful. It remains to choose the one that is suitable for cost and labor intensity - and finish insulating the house from the outside. Since after the installation of foam boards in two layers, the surface of the facade has become very hard, you can decorate it with your own hands under the plaster. Briefly about the stages of plastering walls outside:

- We apply the first layer of the same elastic adhesive solution to the insulation boards;

- We sink a reinforcing mesh made of durable fiberglass into it;

- We apply a second layer of glue, making sure that the mesh is completely recessed;

- After the surface has dried, apply a leveling plaster - smooth or textured, white or colored.

You can go further (if the owner of the house is willing to pay) and purchase a complete system of hinged ventilated facade with artificial or natural stone cladding, fiber cement or composite boards, etc. After that, your house will become a pearl of local architecture.

Characteristics of penoplex

This is the name of extruded polystyrene foam. It is the most productive heat insulator due to its qualities:

- low moisture absorption, its cellular structure practically does not absorb water;

- high thermal efficiency allows the use of a smaller thickness of the insulating layer;

- fire safety, expanded polystyrene does not burn and does not emit toxic substances;

- ease of installation;

- good strength and resistance to mechanical stress;

- resistance to the formation of fungi and mold.

Types of extruded polystyrene foam

Penoplex can have a different density, its value is in the range of 25.0–45.0 kg / m³. Depending on this indicator, the material has a different purpose and is divided into five types:

- the first - for the roof (28.0–33.0 kg / m³);

- the second - for the foundation (29 kg / m³);

- the third - for walls (25 kg / m³);

- the fourth is universal (25.0–35.0 kg/m³);

- fifth - industrial (45.0 kg / m³).

Each of them has its own purpose depending on the name. The universal option has collected all the best indicators, so it can be used for any part of a wooden building.

Industrial foam has the highest strength.It is used for arranging roads and insulating industrial pipelines.

Advantages

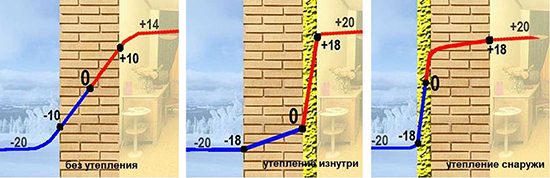

If you place a thermal insulation layer inside the house, the dew point will shift. This indicator determines the temperature value below which condensation occurs. The dew point in this case moves inside the room. This means that humidity will increase, the walls will begin to “sweat” and mold will form. Internal insulation reduces the space of the room.

Even a small thickness of insulation can significantly reduce the quadrature, because for the thermal insulation of a wooden building you will need to equip the crate. Another factor is the deterioration of the internal microclimate. The use of even modern thermal insulation materials will not allow the tree to “breathe”. Insulation from the outside eliminates all of the above factors.

Styrofoam insulation of a wooden house: wonderful myths and harsh reality

The most common question on insulation is whether it is possible to insulate a wooden house with foam plastic from the outside? In order to correctly answer it, you need to delve a little into the jungle of thermal physics.

A little about fire safety

Insulation of a wooden house with foam plastic from the outside is warned to be done on the basis of fire safety: the first polystyrene foam burned, releasing poisonous smoke. However, now the production of materials for facade insulation has been established (they have the letter F in the marking), capable of self-extinguishing within 1 second. Therefore, fears about the fire hazard became groundless.

It's all about vapor permeability

So that the wood of the walls does not rot after insulation, it is required that the “dew point” - the point where water vapor turns into water, does not fall on the surface or body of the wooden wall. If this happens, the tree will rot. That is, after making a calculation using a calculator, the walls of a house in the Moscow region have a design:

- A bar made of pine or spruce wood, across the fibers - 250 mm.

- Insulation - polystyrene concrete slab PPS FG15–80 mm.

- Moisture-windproof membrane - 0.1 mm.

- Air layer - 40 mm.

- Cladding with a planquet (like a ventilated facade).

We get that the wall meets all the heat engineering requirements, and it has no conditions for the formation of condensate. No condensate - no rotting, which means that insulation with polystyrene foam, followed by finishing with a plank or clapboard, walls of this design are possible.

The second option: we have a house in the Moscow region from logs Ø 250 mm, insulated according to the plaster system:

- Pine or spruce log working thickness - 150 mm.

- Air closed layer (due to the rounding of the log) -50 mm.

- Insulation - polystyrene concrete PPS F 20–50 mm.

- Finishing layer - mineral plaster - 8 mm.

In this case, 100% humidity inside the structure and rotting of the wall is inevitable. This can be prevented only by increasing the thickness of the insulation.

As can be seen from these calculation examples, external insulation of a wooden house with polystyrene foam is possible, but it requires a balanced approach, and a thermal insulation thickness of 50 mm for a log cabin Ø 250 mm with a working thickness of 150 mm is clearly not enough if you want your house to stand for more than 5-8 years old. A person who claims the opposite is a myth-maker.

In terms of functionality, foam insulation works better with subsequent cladding with a ventilated facade system, rather than with plaster systems. This is due to the fact that the layers of materials, as they approach the outside air, should have greater vapor permeability.

The vapor permeability of moisture-windproof membranes is higher than the adhesive and finishing layers of plaster materials, and the air gap and cladding give a 100% release of water vapor.

Styrofoam insulation outside

So how to insulate a wooden house with foam plastic in order to live a long comfortable life in it?

It is necessary to follow fairly simple rules, without trying to save on the necessary:

- Before performing work, make a thermal calculation to make sure that the thickness of the insulation is sufficient and that the dew point is not in the wooden wall.

- Carefully prepare the wall - clean it of dust, dirt, rot, moss, treat it with flame retardant and fungicide, check and repair all joints and grooves.

- Carry out work with minimal air humidity, in good weather; in case of possible precipitation, cover the wall with polyethylene.

- Observe the technology for performing insulation in accordance with the recommendations of the manufacturer of materials.

Insulation work does not require special skills and is available to any homeowner. All that is required is the ability to use a building level, a stapler and a drill.

Insulation with crates is the easiest option. Boards 40 mm thick, with a width equal to the thickness of the insulation, are attached to the wall along the entire height of the facade. The distance between them is equal to the width and length of the foam board minus 5 mm. Plates are installed by surprise, without gaps.If necessary, the seams are filled with scraps of insulation or mounting foam. Plates are fixed with anchors, at least 5 pcs. on the stove.

The moisture-windproof membrane is mounted from the bottom up with gaps of 10-15 cm between the sheets using wooden bars 40x40 to the boards of the crate with special nails.

Perform the finishing lining, attaching it to the bars.

Conclusion

Despite the low price of the insulation itself, it costs money to perform thermal insulation at home, and not small ones. Doing the work yourself will save a significant amount, but let this be the only reason to save. Only high-quality materials and the phased implementation of all work will make it possible to insulate a wooden house from the outside, and make life in it comfortable - and this is a harsh reality.

The better to insulate a wooden house - foam or foam

Surprisingly, almost 50% of the funds spent on heating the house and maintaining the optimum temperature in it during the cool season could easily be saved - just a one-time warming is enough. The most popular method for increasing the thermal insulation of a wooden house is insulation from the outside. Most often, such practical and inexpensive materials as polystyrene foam and foam plastic are used for this.

Benefits of outdoor insulation

This technology has a number of significant advantages compared to the use of the same materials inside. Among the most respectful, it is worth noting the following:

- Deciding to insulate the house from the outside, you can avoid reducing the internal space,

- Preservation of wooden structures for a longer period, due to protection from the action of adverse harmful factors, such as high humidity, mold, being under constant direct exposure to sunlight.

- Contact between residents and natural wood is not disturbed, which ensures comfort while being inside.

Selection of suitable materials for work

Undertaking to increase the thermal insulation of a wooden house, one should be guided by the fact that the raw materials chosen for this task are wear-resistant, do not have a harmful effect on health and, if possible, are not excessively expensive in price.

To date, all these requests are best met by synthetic materials - foam plastic and foam plastic.

Their main positive characteristics:

- A light weight,

- They maintain heat well inside the house due to the low level of thermal conductivity,

- Quick and easy to install,

- Virtually no absorption of water and steam,

- Decent degree of strength

- environmental friendliness,

- Long service life.

- Resistant to temperature fluctuations.

- Detailed review and comparison of heat insulators

Despite the fact that both materials described above have good parameters in order to qualitatively insulate a wooden house from the outside, there are still some differences between them. It should immediately be noted that penoplex is a more modern and improved substance, but its cost will be an order of magnitude higher. A more detailed analysis is presented in the table:

Conclusion: In order to insulate a house, it will take up to two times more foam, but its cost is much lower, which makes this process more economical. The time of its use is up to three times shorter, however, one should take into account the intensity of the action of adverse factors from the external environment, if their number is minimized, the durability can be extended.

The easiest way to reduce thermal conductivity

For this purpose, foam is used. But before that, you need to carry out thorough preparatory work. Sequential steps to achieve the best result:

- Leveling the surface to avoid the formation of voids, which over time can subject the material to brittleness.

- Removing a layer of paint and applying a layer of primer to the wall.

- Installation of slopes for window sills outside. Finished ebbs are attached to the window itself, the protrusion should be about 5 cm.

- Directly sticking foam.

- Three days later, blocks of used raw materials are nailed to the wall of the house.

- All joints are carefully treated with construction foam.

- Covering with a thin layer of glue, after which the next layer of insulation can be laid.

- Another application of the adhesive composition on top of which the reinforcing mesh is attached.

- After about a day, the protective layer is covered, and then leveling, priming and the final turn - decorative work.

How to apply polyurethane foam correctly

Or, in other words, penoplex can be used for insulation outside by two basic methods:

- According to the principle of pouring - a traditional process in which the plane of the house is evenly covered with layers. In this case, it is necessary to create a special crate in advance, into which the insulation will be mounted,

- The method of special spraying is a modernized technology with which the substance can be applied to any surface, regardless of its structure.

The better to insulate a wooden house - foam or foam What is better to use when insulating a wooden house - foam plastic or foam plastic. Comparative characteristics of materials, their pros and cons.

Materials for insulating the walls of a house from a bar

To insulate the walls of a log house, you can use various modern heat-insulating materials. A house made of timber is insulated:

- fiberglass

- Mineral wool slabs

- Basalt mats

- Expanded polystyrene and other materials

Each of these heaters has its own distinctive properties.

But when choosing a material for a heat-insulating system for a wooden house, you need to pay attention to whether this type of heat insulator meets the basic requirements

Heaters for external insulation of houses made of timber should have:

- High heat-shielding properties.

- Fire resistance.

- Moisture resistant.

- Non-hygroscopic.

- The ability to prevent heat transfer between the room and the external environment.

- Ecological safety.

Excellent conditions for insulation and will not allow condensation to accumulate

How and how to insulate a house from a bar

The most popular material for warming log houses is mineral wool. This material is light enough not to create additional load on the structural elements of the building.

The cost of mineral wool is not high, it keeps the heat in the house well, but, most importantly, mineral wool is not a combustible insulation. Due to its softness, elasticity, mineral wool is easy to install and does not form cold bridges.

In addition, it is resistant to thermal deformations of the walls.

Warming can be done under a block house, or you can sheathe the walls of the house with plastic siding from the outside. Installation of a thermal insulation system using mineral wool consists of several stages:

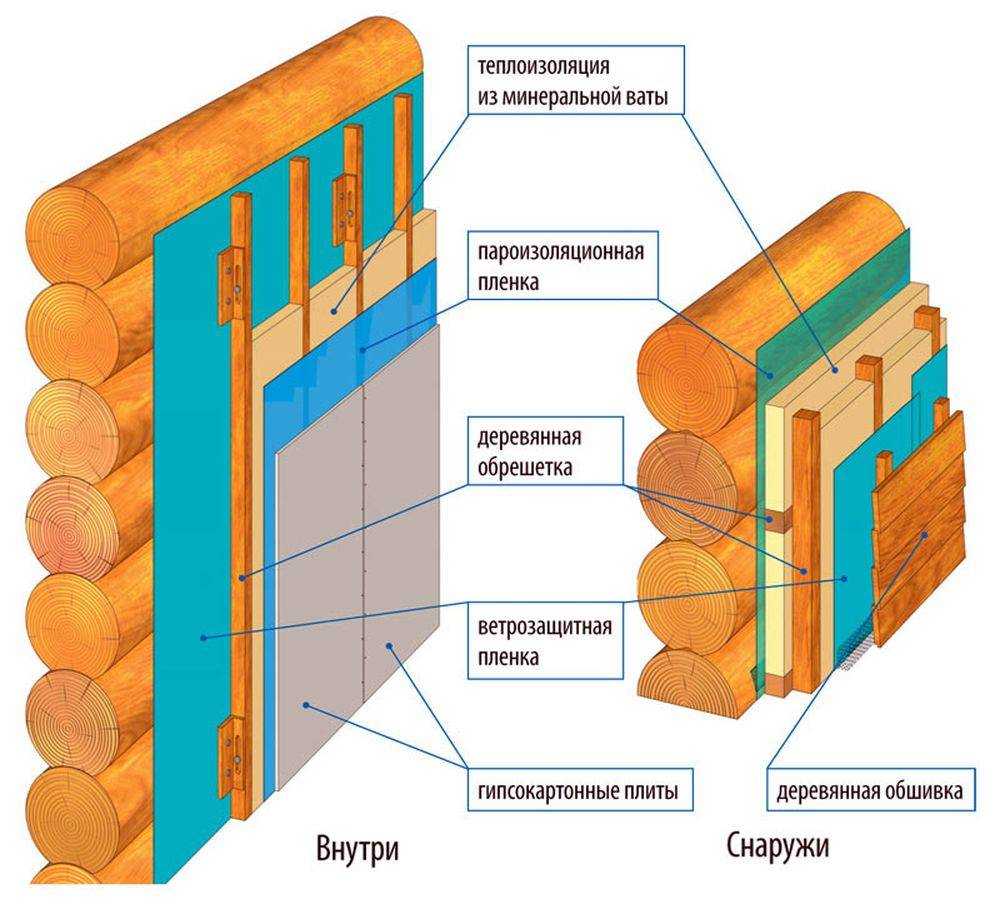

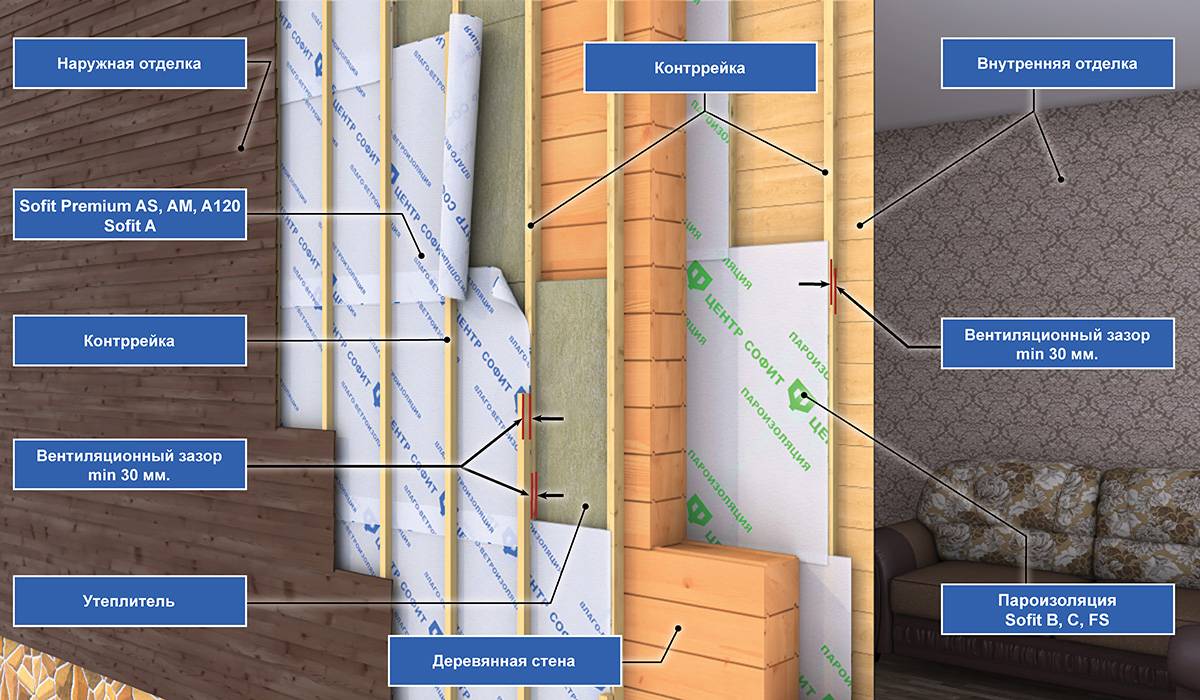

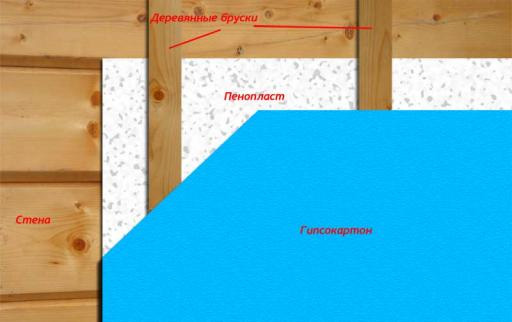

vapor barrier

Installation of the thermal insulation system of a wooden house begins with a vapor barrier device. To do this, you can use aluminum foil, plastic film, a special vapor barrier film and roofing felt. Vapor barrier provides ventilation of the facade under the film.

Vertical slats 2.5 cm thick are stuffed onto the walls, at a distance of 1 meter from one another. Further, a vapor barrier layer is stuffed onto the laid rails on the entire surface of the wall. Holes (20 mm in diameter) are made between the base rails at the top and bottom for ventilation. The presence of a ventilated layer between the vapor barrier and the wall will prevent moisture from accumulating under the film, which could lead to rotting of the wooden wall. The vapor barrier is fastened with nails or staples, the attachment points are sealed with adhesive tape to protect them from water ingress.

Installing the frame for thermal insulation

For the frame, take boards 100 mm wide and 40-50 mm thick. On the wall, the boards are stuffed vertically on the edge. The distance between the boards should be less than the width of the insulation by one to two centimeters.

The beam is attached to the facade of the house with self-tapping screws. When installing a beam, you need to control its position with a level or plumb line. If the crate is unevenly mounted, the installation of the facing material at the final stage of thermal insulation work will be of poor quality.

To install the thermal insulation system of a timber house, it is necessary to install a frame

Laying thermal insulation

Between the boards of the frame, the mineral wool slabs are installed as close as possible to each other so that there are no gaps. Mineral wool 50 mm thick is laid in two layers. They use semi-rigid, elastic, slabs with a density of 80 - 120 kg / m3, they are easily held between the frame boards, without slipping without additional fastening.

Laying insulation between the bars of the frame

Waterproofing

Having finished laying the thermal insulation, it is necessary to lay a waterproofing film, which should allow steam to pass through, but at the same time retain water. The film is laid on the thermal insulation, nailed with staples or nails of the frame. When joining the film, 5-10 cm of overlap is left, the joints are sealed with self-adhesive tape.

Second frame layer

Laths are stuffed onto the thermal insulation frame over the waterproofing (50 mm wide and 2.5 - 3 cm thick). This is necessary in order to ensure free circulation of air between the sheathing and the vapor barrier, which will dry the condensate that appears on the waterproofing layer. The resulting space is closed from below with a dense metal mesh, from the penetration of insects and rodents into it.

outer skin

The outer skin performs mainly a decorative function. Therefore, what will be the facing material does not matter much. It can be wooden lining, and plastic siding or any other material.