- Hydraulic gun in a parallel connection system

- Benefits of a Dual Boiler System

- The feasibility of using automatic and manual switching between two boilers

- Pellet and electric boiler

- Boilers for diesel fuel and electricity

- Combination of electric boiler and wood burning

- Combination of gas and electric boilers

- Two-pipe connection diagram with a boiler

- Installation of gas equipment

- How to connect two double-circuit boilers for hot water?

- Two boilers in one heating system: schemes

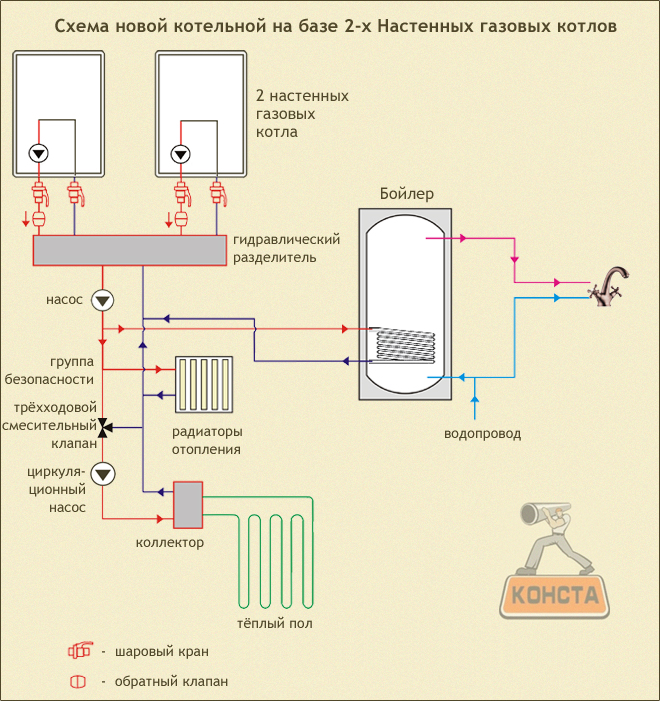

- How to connect two wall-mounted gas boilers to one radiator circuit?

- How to connect two wall-mounted gas boilers to several circuits?

- Parallel and serial connection of boilers

- Parallel connection

- Serial connection

- Requirements for the room and air exchange

- Arrangement of a heating system with a heat accumulator

- Installation of a heating boiler in the attic

- Installation of radiators

- There are several types of radiator wiring

- Piping schemes for boiler types

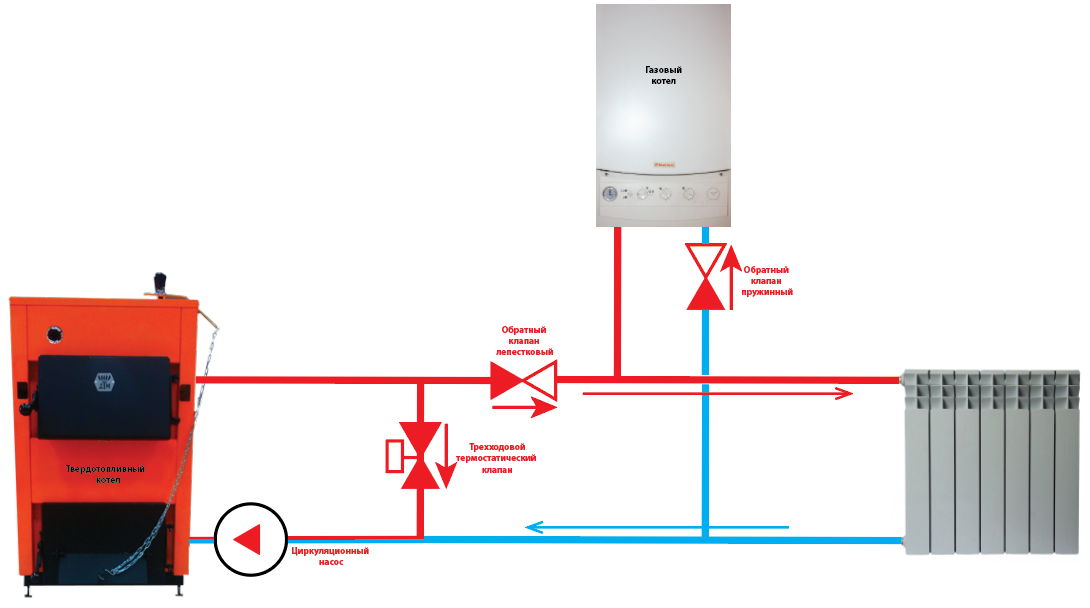

- Connection of a gas and floor standing solid fuel boiler

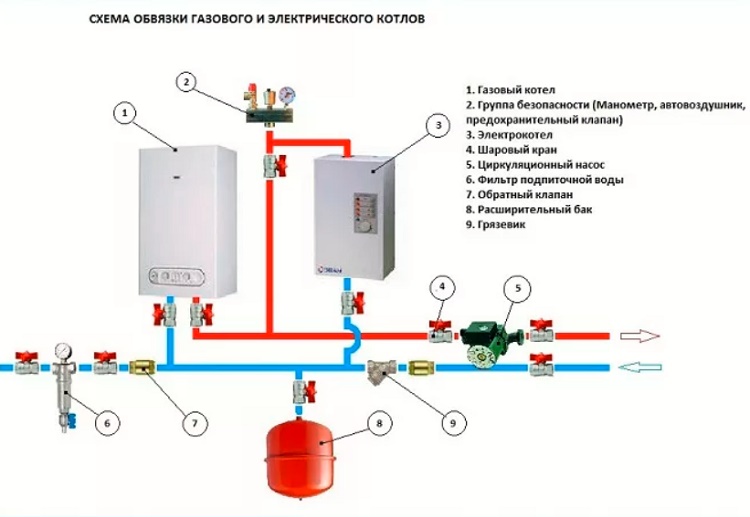

- Electric and gas

- Connecting a solid fuel and electric boiler

- Features of installing a gas boiler

- Installation

- Chimney arrangement

- Connection to the heating system and water supply

- Connection to the gas line

- Network connection

- Conclusions and useful video on the topic

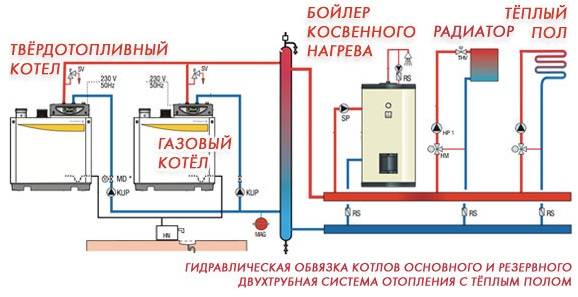

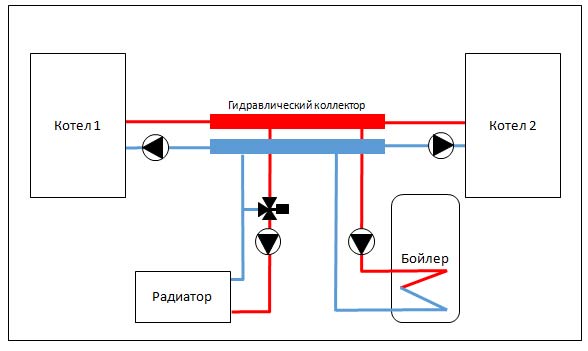

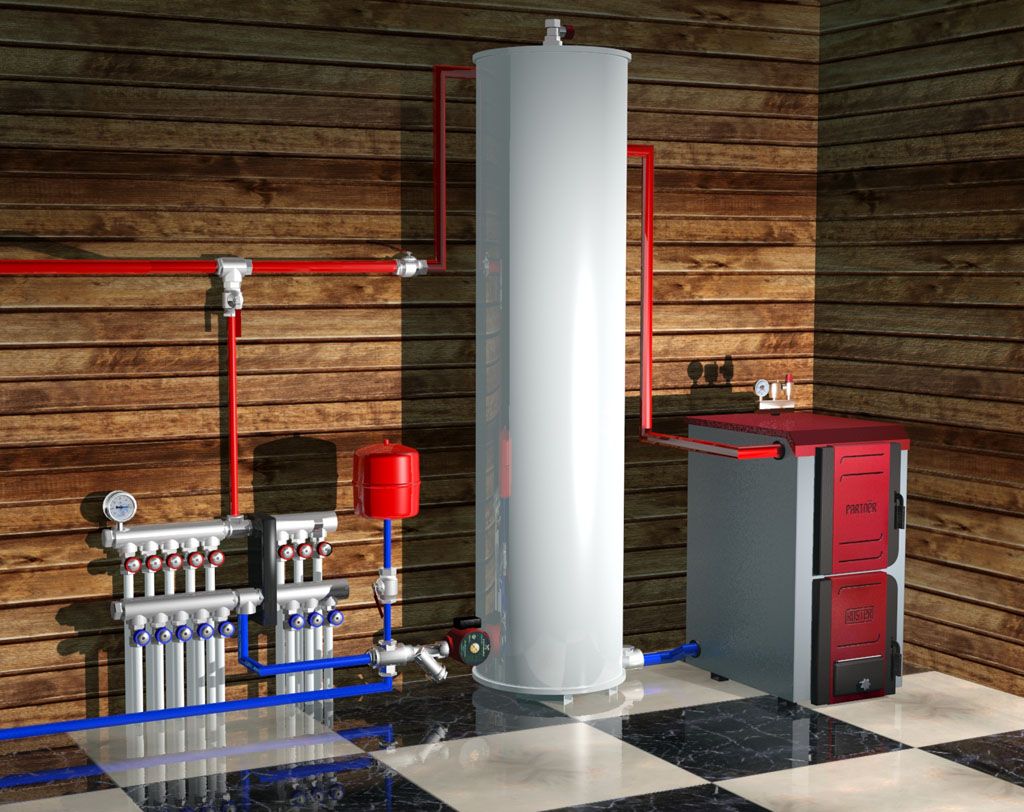

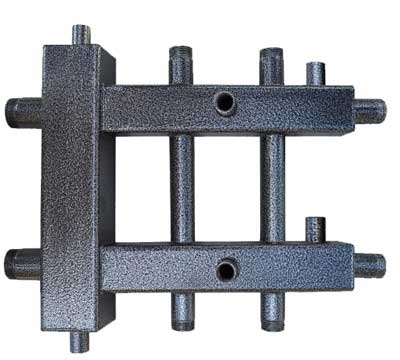

Hydraulic gun in a parallel connection system

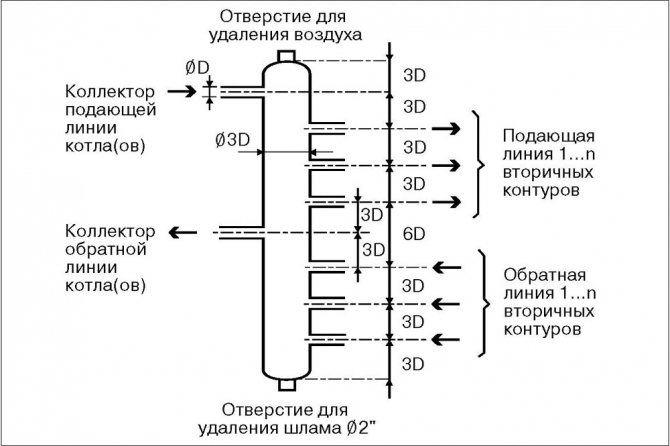

A hydraulic arrow is a device that provides hydraulic decoupling of flows supplied to individual circuits of the heating system. It plays the role of a buffer tank that receives the flow of coolant heated by boilers and distributes it to consumers in an extensive system.

Often, the volume of coolant required for them varies, the speed of movement of heated water and its pressure differ. And in the situation under consideration, the movement of heated water from each of the boilers also stimulates its own circulation pump.

When a powerful pump is turned on, an uneven distribution of the coolant along the circuits occurs. So, the task of the hydraulic arrow is to equalize this pressure. Due to the fact that there is virtually no hydraulic resistance inside it, it will freely accept and distribute the coolant flows from both boilers.

Let's figure out if it is really necessary in a parallel system for connecting 2 boilers, especially since if you buy and install a hydraulic separator with the help of a master, and not with your own hands, the total amount will unpleasantly surprise you.

The device is a piece of pipe with nozzles, hollow or with filter meshes to remove bubbles and filter out incoming contaminants. It can be placed in any position, but more often vertically, equipping an air vent on top and a shut-off valve for cleaning from below. A hydraulic arrow is installed between the boiler and heating circuits

In the classic connection scheme, a hydraulic separator is usually not required, since the conflict of 2-3 pumps can be leveled without this device.Accordingly, if you have 2 boilers used exclusively as a backup and there are no more than 3-4 pumps in the system, there is no special need for it.

But if there are more circuits with forced circulation or heating boilers work simultaneously on power - it is best to mount this device. Again, it is not known whether you will use the second boiler permanently or only in standby mode, so it is better to play it safe.

Benefits of a Dual Boiler System

The main positive aspect of installing two boilers in one heating system is the continuous support of heat in the room. A gas boiler is convenient in that it does not need to be constantly serviced. But in case of emergency shutdown or in order to save money, a wood-burning boiler will become an indispensable heating supplement.

The heating system of two boilers allows you to significantly increase the level of comfort. The advantages of a dual thermal device include:

- choice of the main type of fuel;

- the ability to control the entire heating system;

- increasing the operating time of the equipment.

Connecting two boilers to one heating system is the best solution for heating buildings of any size. Such a solution will allow you to continuously keep warm in the house for many years.

The feasibility of using automatic and manual switching between two boilers

Consider the following five options with different units in conjunction with an electric boiler, which is in reserve and must turn on at the right time:

- Gas + Electric

- Firewood + Electric

- LPG + Electro

- Solar + Electro

- Pellet (granular) + Electro

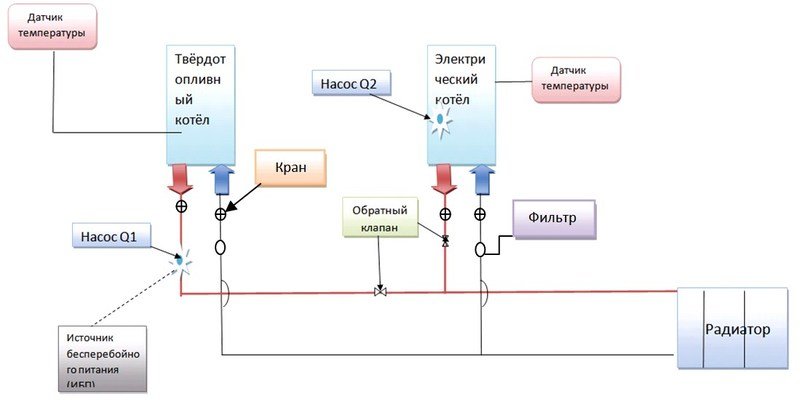

Pellet and electric boiler

The combination of connecting two boilers - a pellet boiler and an electric boiler - is best suited for automatic switching on and manual switching is also allowed.

The pellet boiler may stop due to the fact that it has run out of fuel pellets. It got dirty and wasn't cleaned. The electric must be ready to turn on instead of the stopped boiler. This is only possible with automatic connection. Manual connection in this option is only suitable if you permanently live in a house where such a heating system is installed.

Boilers for diesel fuel and electricity

If you live in a house with such a system for connecting two heating boilers, a manual connection is quite suitable for you. The electric boiler will work as an emergency in case the boilers fail for some reason. Not just stopped, but broken and in need of repair. It is also possible to switch on automatically as a function of the time. The electric boiler can work in pairs with liquefied gas and a solar boiler at a nightly rate. Due to the fact that the night rate is cheaper for 1 kW / hour than 1 liter of diesel fuel.

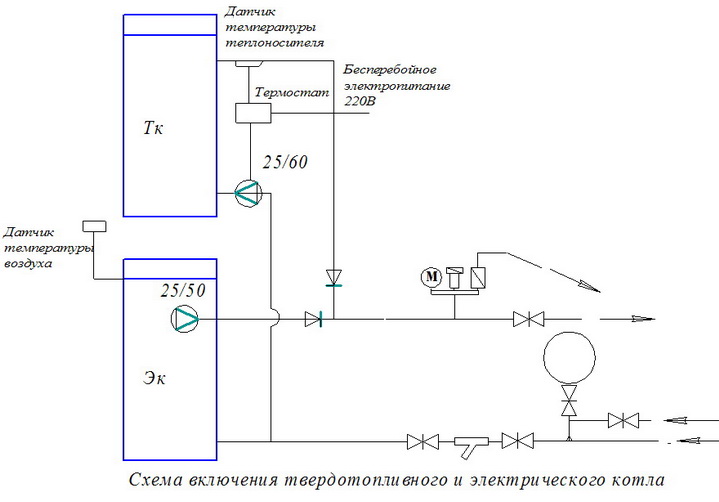

Combination of electric boiler and wood burning

This combination of connecting two boilers is more suitable for automatic connection and less for manual connection. The wood burning boiler is used as the main one. It heats the room during the day, and the electric turns on to heat it up at night. Or in the case of a long stay in the house - an electric boiler maintains the temperature so as not to freeze the house. Manual is also possible to save electricity.The electric boiler will turn on manually when you leave and turn off when you return and start heating the house with a wood-fired boiler.

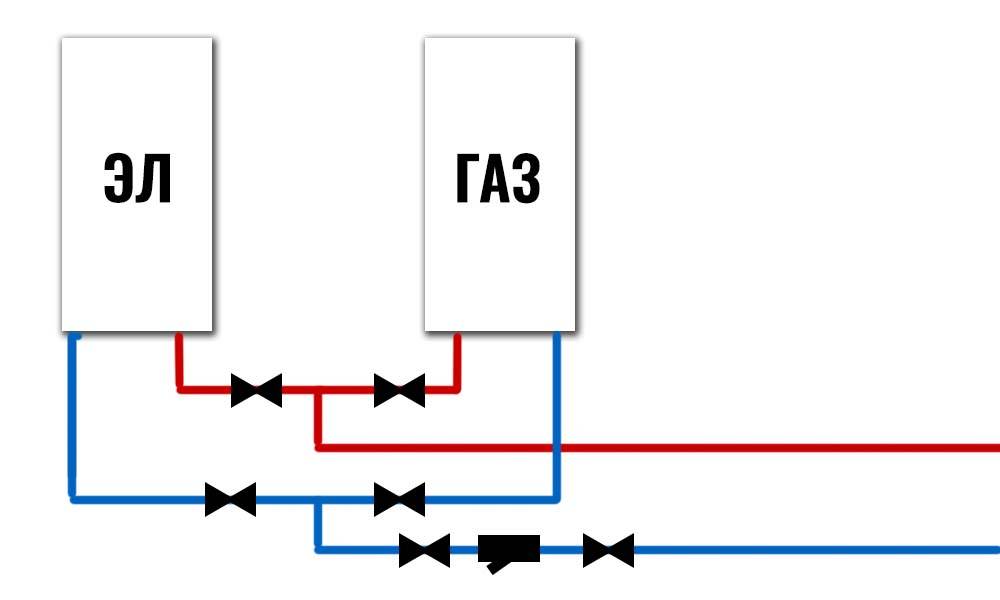

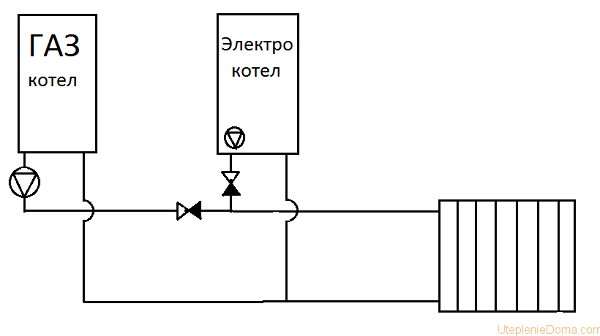

Combination of gas and electric boilers

In this combination of connecting two boilers, the electric boiler can act both as a backup and as a main one. In this situation, a manual connection scheme is more suitable than an automatic one. The gas boiler is a proven and reliable unit that can work for a long time without breakdowns. In parallel, it is not advisable to connect an electric boiler to the system for safety net in automatic mode. In the event of a gas boiler failure, you can always turn on the second unit manually.

Read also:

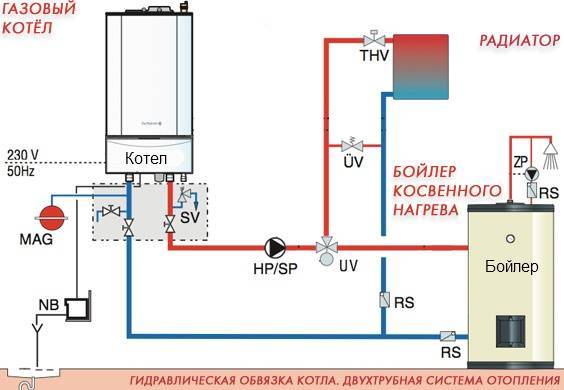

Two-pipe connection diagram with a boiler

Connection of a double-circuit gas boiler.

A two-pipe scheme can be used to connect the heating system. The coolant here will move up along one separate line, after which it will return back to the boiler along a completely different one. In such a system, as a rule, forced circulation of the coolant is used, i.e., the installation of a circulation pump is required. But on the other hand, the system warms up much faster, it loses less heat when transported to radiators.

Such a decrease in heat loss is due to the fact that for each radiator it is possible to install a special heat regulator, while the rest of the components of the entire system do not suffer any damage. The installation of this system with a boiler is very different from a single-pipe system, for which the installation of regulators is simply impossible. An example of such a boiler connection scheme is shown in fig. 3.For installation, according to this scheme with a boiler, you can use different types of pipes, radiators, everything warms up evenly and correctly.

Scheme of connecting a gas double-circuit boiler directly.

The connection of the system with the boiler is carried out in several ways, one of them involves the supply of coolant to and from the radiator from one side of the equipment. On the other, ordinary plugs are placed, the return pipe goes from below, while the coolant enters from above. But if the radiator has more than 15 sections, then such a scheme is not used due to large heat losses. In this case, a connection scheme is used when the coolant is supplied from below on different sides of the equipment. This method is effective when all pipes of the heating system are laid under the floor, exits are organized only at the places where heating radiators are installed. But there are also disadvantages: the coolant may not completely warm up the radiator from the bottom to the top, so cast-iron radiators are not used, preference is given to panel ones, which are best heated.

When the lower connection scheme is performed, it is also necessary to provide for an emergency shutdown from the coolant supply. This avoids leaks in the event of a malfunction of the entire heating system. If all conditions are met correctly, then heat loss will be minimized, they will be approximately equal to 2%.

Connecting the heating boiler and performing the entire wiring of the house system is an important and complex process. It is necessary to strictly follow all the norms and recommendations, having previously calculated which elements should be included in the connection diagram, what type of wiring for heating you want to choose.

Installation of gas equipment

When a dual-circuit heating system is installed, the scheme must be followed exactly - only in this case the equipment will work correctly and efficiently.

The body of the heating unit must not be adjacent to the wall, and it must not be installed in niches.

- electrical;

- hydraulic;

- gas.

End fittings are required to connect the equipment to the heating system. On the left, hot water enters the batteries, and on the right, the cooled water returns for heating. Thus, connecting a double-circuit heating boiler is quite simple, you just need to follow the recommendations of specialists.

A coarse filter must be installed on the return pipe pipe - this is necessary in order to protect the boiler from debris and rust that will accumulate in the pipes. If it is not installed, then the service life of the equipment will be significantly reduced. Screw the filter to the pipe in the direction of the arrow to the boiler.

Water supply and return pipes are equipped with taps, with the help of which, in the event of a breakdown of the heat unit, water can be shut off. If this is not done, then before starting the repair, the coolant will have to be drained from the heating system, and this will take time. The water supply circuit is connected in much the same way; a filter is placed on the cold water supply to prevent debris from clogging the device. To cut off the contour of the pipeline, it is also necessary to install cranes.

When wiring a double-circuit heating boiler, several conditions must be observed. Before starting the system, you need to make sure that the cold and hot water taps have not been mixed up.An error in this can lead to sad consequences - even an explosion of a gas boiler, so you should not take the connection of equipment lightly.

Next, an expansion tank is installed. It is needed to compensate for the expansion of the heating system due to increased pressure. The volume of the tank should be approximately equal to 10% of the amount of coolant in the entire system. Most often, the tank is installed between the boiler and the circulation pump, but it can also be placed in another place where it will not interfere. It will also come in handy if the pressure drops in a double-circuit boiler.

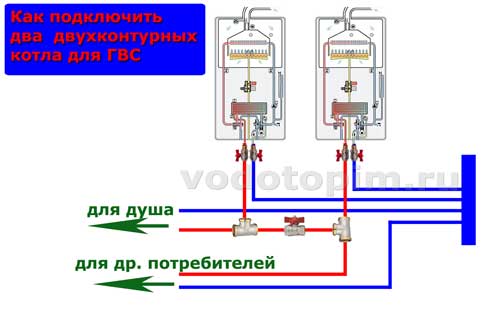

How to connect two double-circuit boilers for hot water?

Well, and another option, where two boilers in one system work on hot water. In such a scheme, it is most correct to make one boiler heat water for one consumer group, for example, for a shower; the second is for everyone else:

Then the person taking a shower will be spared the troubles experienced when there is only one wall-mounted boiler: when opening and closing other hot water taps at the same time (for example, in the kitchen), there will be no temperature jumps in the shower room.

Pay attention to the diagram for the presence of a ball valve between the hot circuits. This is in case of repair / maintenance / replacement of one of the boilers, when the remaining one will heat water for all consumers

Only after repairing you need to remember to open the tap.

Well, it seems that he said everything about two boilers in one system.

Two boilers in one heating system: schemes

Boilers can be single or double circuit. Regardless of the type, two boilers in one system are connected in parallel.

Obviously, single-circuit boilers are installed when they think of heating water with an indirect heating boiler ...

How to connect two wall-mounted gas boilers to one radiator circuit?

So, in the diagram there are two boilers in one system with one branch of radiators:

The main thing - pay attention to the piping of the boilers. And radiator wiring can be different

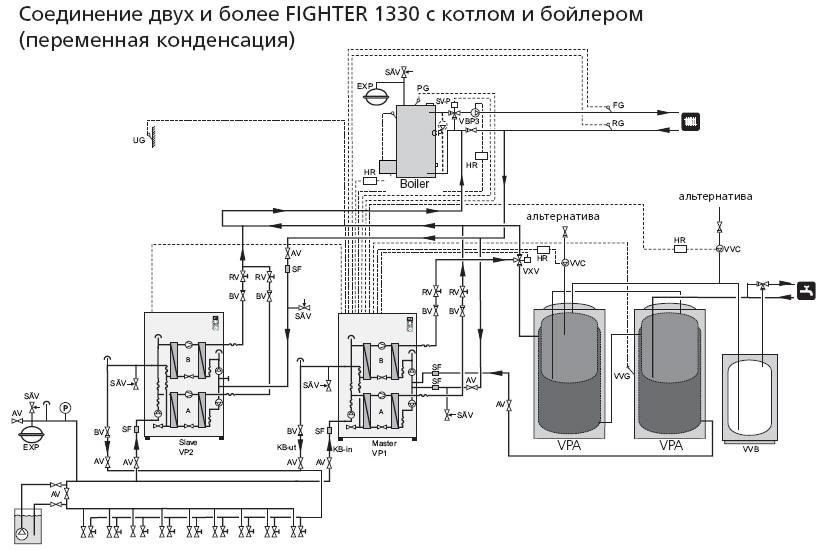

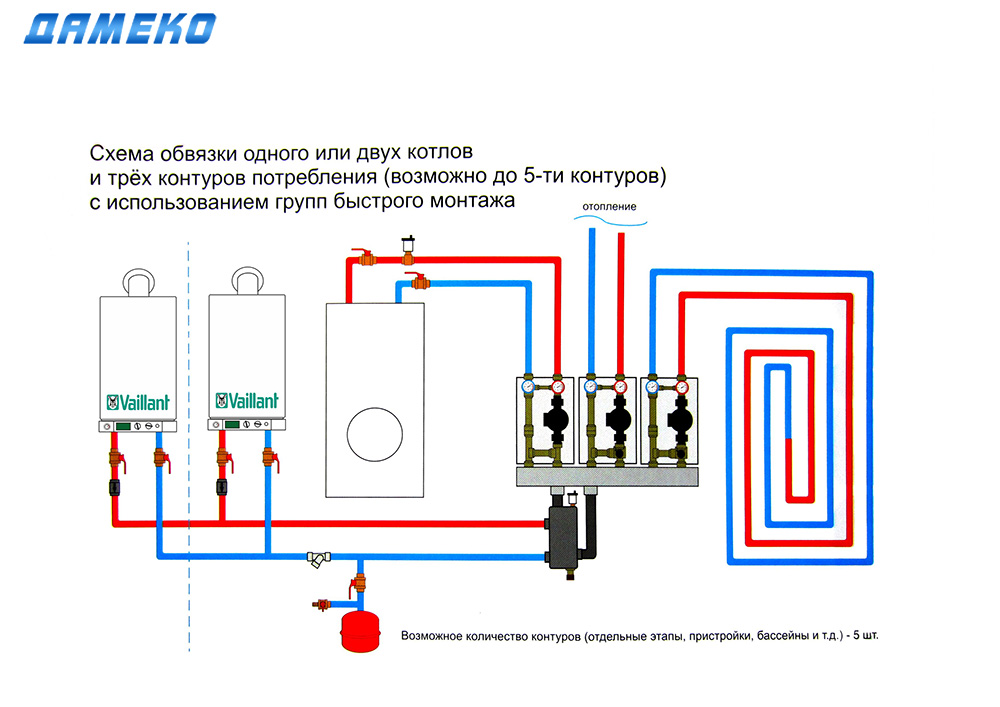

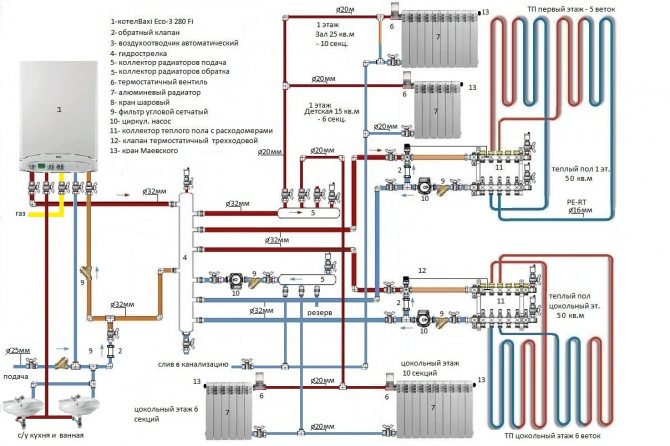

How to connect two wall-mounted gas boilers to several circuits?

For several circuits, we connect two boilers in one system as follows:

We connect boilers with radiator branches through a hydraulic arrow and a collector. The collector can be assembled from separate parts - tees, adapters, couplings, spurs, nipples ... and connected to a separately purchased hydraulic gun. Or, to simplify and speed up assembly, you can purchase this contraption:

And don't sweat it.

Please note: in the piping of the boilers, in comparison with the first scheme, an addition has appeared - check valves for each boiler. Also: instead of radiators, you can connect branches of a water-heated floor to the outlets of the collector, as here, or an indirect heating boiler, and everything will work

Also: instead of radiators, you can connect branches of a water-heated floor to the outlets of the collector, as here, or an indirect heating boiler, and everything will work.

Since the system is large, the volume of expansion tanks in the boilers may not be enough, this must be checked and, if necessary, connected tanks from the outside. The volume of the tank of EACH boiler must be at least 15% of the volume of the entire system for water and 20% for anti-freeze. This is in case one of the boilers has to be turned off.

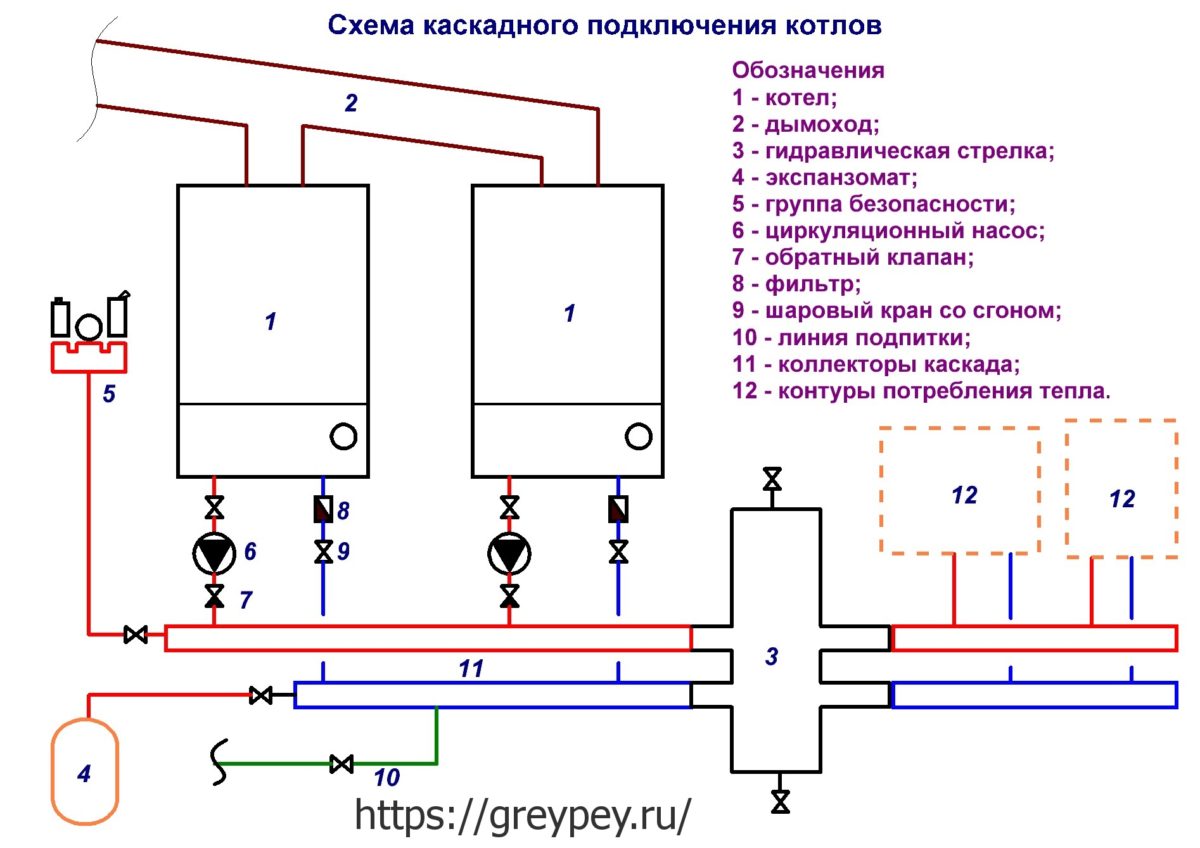

Parallel and serial connection of boilers

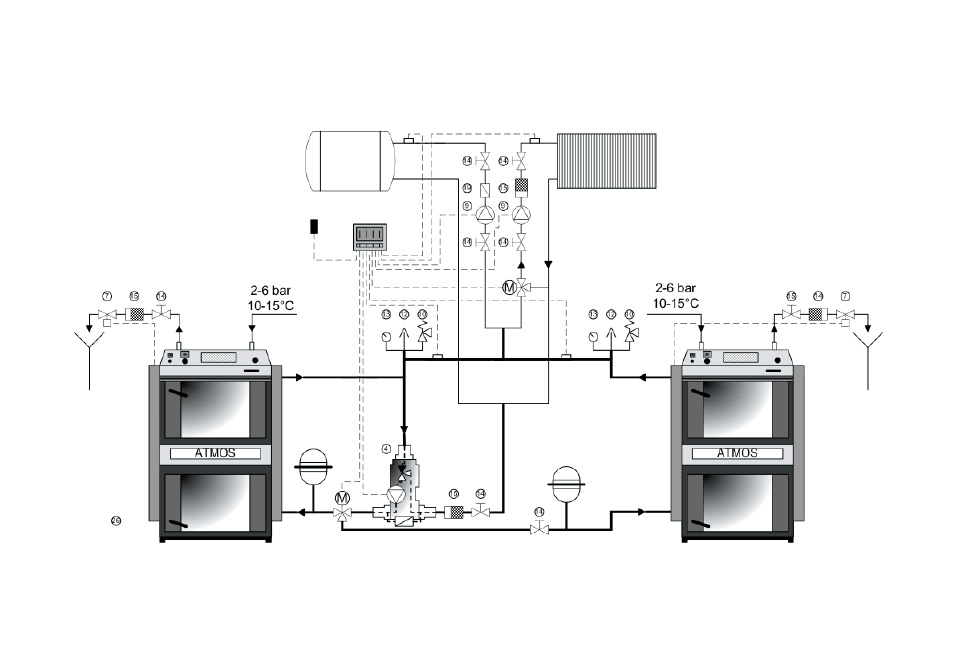

When planning a heating system of two and three boilers, it is important to take into account the position of the main and connecting elements.And the point is not only ease of operation and space saving, but also the ability to repair local areas, preventive maintenance and obtain a technically safe operation of the heating system. The choice of parallel or serial connection, the creation of technical diagrams allow you to carefully consider all the nuances of installing equipment and additional elements, the length and number of pipes, their laying and places for wall chasing

The choice of parallel or serial connection, the creation of technical diagrams allow you to carefully consider all the nuances of installing equipment and additional elements, the length and number of pipes, their laying and places for wall chasing.

Parallel connection

Parallel connection is used to connect gas and solid fuel boilers with a volume of more than 50 liters. This choice is justified, first of all, by saving the coolant and reducing the load on the system.

Tip: before calculating the saved finances, it is necessary to take into account the high cost of such systems and the installation, in combination with an electric boiler, of additional equipment for the circuit: shutoff valves, expansion tank - safety group.

Note that a parallel type system can operate in two modes: manual and automatic, in contrast to the sequential one. In order for the system to work only in manual mode, it is necessary to install shut-off valves / ball valves or a By-Pass mortise system.

To organize automatic work electric with gas or solid fuel the boiler will require a servo drive and an additional thermostat, a three-way zone valve to be able to switch the heating circuit from one boiler to another.This connection option is appropriate for the ratio of the total volume of the system coolant per 1 kW of boiler power.

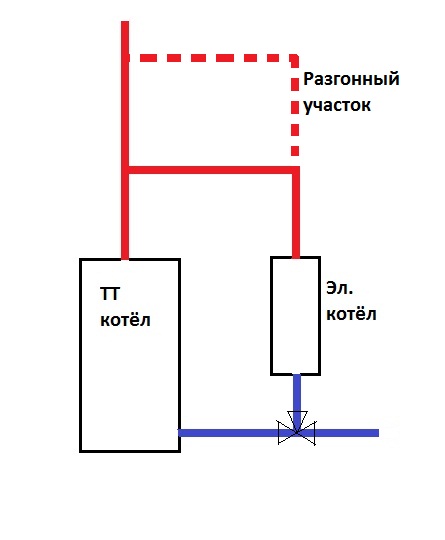

Serial connection

The expediency of serial connection is justified if an expansion tank and a safety group built into the gas boiler are used. In this situation, you can connect the heating system with the least difficulty.

In order to save on components and increase functionality, when connecting an electronic boiler paired with solid fuel or gas, it is required to take into account the volume of the tank capacity. Connection is recommended for sizes up to 50 liters.

The electric boiler can be connected before and after the gas boiler, depending on the convenience and physical possibility of inserting the system. It is recommended to make a tie-in, taking into account the fact that the circulation pump will be located on the "return" of both one and the second boiler. If a circulation pump is used in a gas boiler, then the best option would be to insert an electric boiler first, and then a gas one.

Important: the use of a safety group and an expansion tank when connecting the heating system of a gas and electric boiler is a key point when tie-in to an existing circuit.

Summing up, we can say that each of the schemes has the right to exist and has proven its effectiveness. And yet, what to choose and how to properly organize the linkage of boilers in a pair: in series or in parallel? The answer will vary depending on your individual requirements:

- physical possibilities of the room for the installation of two boilers;

- well-thought-out ventilation and sewerage system;

- the ratio of thermal and energy parameters;

- choice of fuel type;

- the possibility of control and prevention of the heating system;

- financial component when buying boilers and additional elements.

Requirements for the room and air exchange

To ensure normal air exchange in the room during the operation of the boiler, it will be necessary to equip an effective natural ventilation system that provides a 3-fold hourly air exchange of the room.

When calculating the supply ventilation, the volume of air required for the combustion process is added to this indicator, the value of which is taken from the passport data.

It is important to take care of ventilation in the room with the boiler

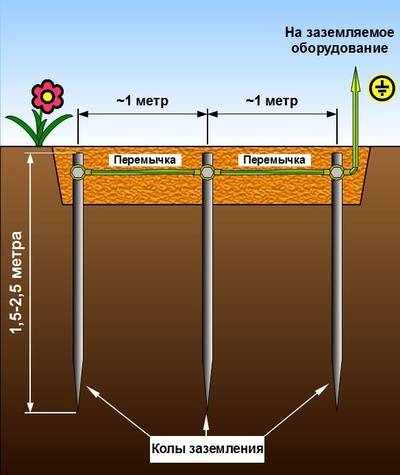

Basic requirements for the room where the boiler will be installed:

- The smallest height of the room is 2.0 m, cubic capacity is 7.5 m3. In the case when two or more boilers are installed, the dimensions change by 2.5 m and 13.5 m3, respectively.

- It is not allowed to install heaters in basements, bathrooms, bathrooms, and corridors, as well as in rooms without vents.

- The walls of the boiler room must be protected with fire-resistant materials or special heat-resistant panels.

- Glazing is carried out from the ratio of 10 m3 of room - 0.3 m2 of windows.

- The room is equipped with a protective earth circuit.

- The cross section of the chimney must correspond to the power of the boiler unit, and in diameter correspond to the flue pipe at the outlet of the boiler.

- For maintenance of the unit, there must be free passages: the front of the boiler - from 1.25 m, on the sides from 0.7 m.

- When placing the flue, the maximum distance from the vertical flue to the boiler is maintained - no more than 3.0 m.

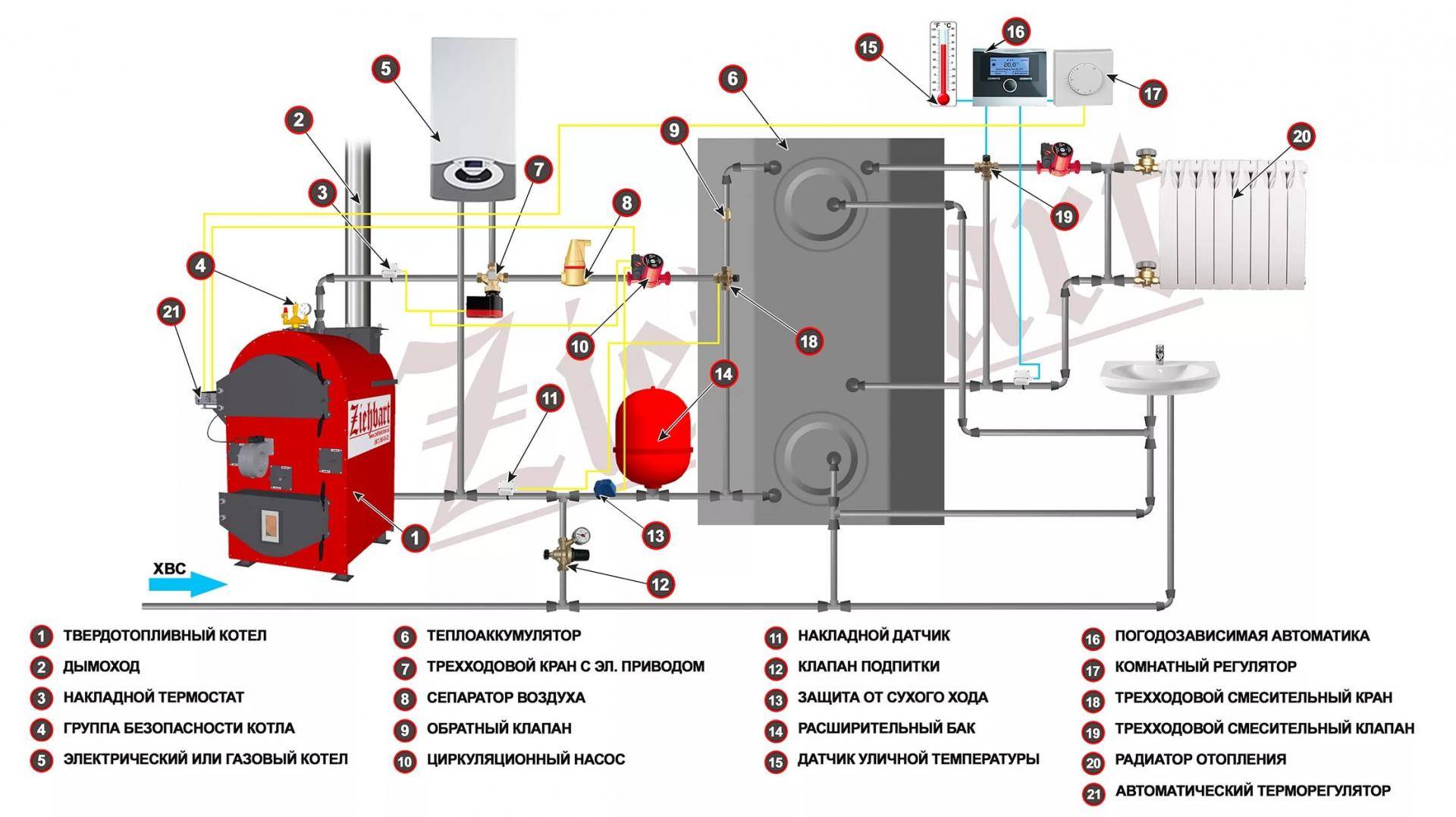

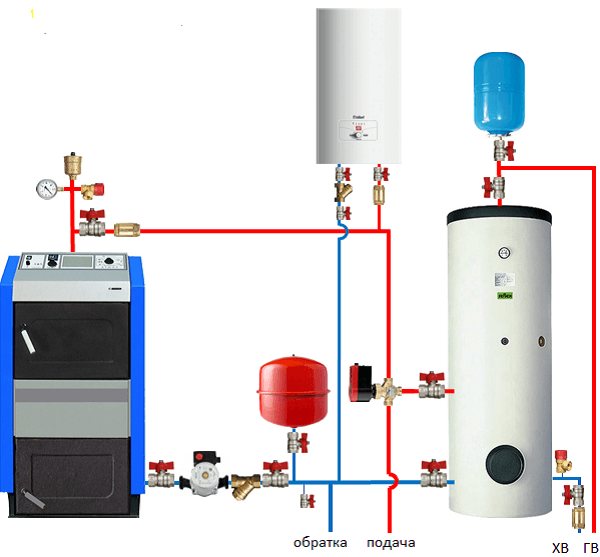

Arrangement of a heating system with a heat accumulator

The use of such an element in a scheme with two boilers in one heating system has several features, depending on the installed units:

- The heat accumulator, gas boiler and heating devices form a single closed system.

- Solid fuel boilers, working on wood, pellets or coal, heat water, thermal energy is transferred to a heat accumulator. It, in turn, heats the coolant circulating in a closed heating circuit.

To independently create a heating scheme with two boilers, you must purchase the following:

- Boiler.

- Heat accumulator.

- Expansion tank of the appropriate volume.

- Hose for additional removal of the heat carrier.

- Shut-off valves in the amount of 13 pieces.

- Pump for forced circulation of the coolant in the amount of 2 pieces.

- Three-way valve.

- Water filter.

- Steel or polypropylene pipes.

Such a scheme is characterized by operation in several modes:

- Transfer of thermal energy from a solid fuel boiler by means of a heat accumulator.

- Heating water with a solid fuel boiler without using this device.

- Receiving heat from a gas boiler connected to a gas cylinder.

- Connecting two boilers at the same time.

Installation of a heating boiler in the attic

- Is it possible to install heating boilers in the attic and the second floor of the house at all? According to experts, this is not the best option, but in extreme cases, if there is no other way out, you can go for it, observing certain conditions;

- Which boiler can be installed above the first floor of the house? With a closed combustion chamber! It is much safer than the traditional one, although it costs half as much. Condensing boilers are suitable, in which the combustion chamber is always closed.In this case, there will be no risk of carbon monoxide poisoning, and the room will not cool down during the operation of the boiler;

- As for the closed combustion chamber, it is clear, but still, which boiler is ideal for installation in the attic? Wall gas, power up to 30 kW. Such boilers are compact, do not take up little space, they do not need a separate room. The specified power will be quite enough to provide heat in a cottage designed for one family, that is, relatively small. The main thing is that the wall can withstand the weight of the boiler. However, we solve this issue even in frame buildings;

- And if the boiler runs on solid or liquid fuel, not gas, can it be installed in the attic? Theoretically, yes. However, think about how you will maintain the solid fuel boiler on the top floor? You will have to constantly carry briquettes, coal and firewood up the stairs. Yes, and solid fuel boilers weigh a lot, it will be necessary to strengthen the floors. Liquid fuel boilers are noisy and emit an unpleasant odor, so they are absolutely not suitable for installation on upper floors;

- What should be the chimney if the boiler is installed in the attic or second floor? Here there can be problems. In general, the height of the chimney for a gas heating boiler should be at least four meters. Imagine if such a pipe rises above your roof. This can ruin the look of the house. You can get rid of the need to build such a high chimney if you choose a boiler with a closed combustion chamber, which has a coaxial pipe. For boilers with a power of up to 30 kW, which we recommend for installation in attics and second floors, it is possible to lead the chimney directly through the outer wall.The outlet of the pipe in this case should be located at a height of 2.5 meters from the ground, but in the case of an attic, this is not a problem. The nearest window from the chimney through the wall must be at least half a meter;

- What should be the heating system if the boiler is installed above the ground floor? Closed! This is a prerequisite. With an open heating system, when the circulation of fluid in the system occurs naturally, all heaters are located above the boiler itself. In the case of installation in the attic or second floor, this condition for the normal operation of the heating system cannot be sustained. Therefore, it becomes mandatory to install a circulation pump, which will become part of a closed heating system at home;

- Will natural ventilation be sufficient for an attic boiler? In general, yes. But for greater reliability and safety, experts advise making a non-closing hole 30 centimeters from the floor. An exhaust vent is made under the ceiling. The total area of such ventilation should be at least 200 square centimeters.

We state: a wall-mounted gas boiler with a closed combustion chamber and a circulation pump, in addition, can be safely installed and used in the attic or second floor of a private house. published

If you have any questions on this topic, ask them to specialists and readers of our project here.

Installation of radiators

The main elements of the heating system in the premises of the house are radiators. At present, many experts began to advise: do not purchase traditional cast-iron batteries, since they are heavy and much worse in properties than bimetallic alloy products.In addition, the latest products look much more aesthetically pleasing and have good heat dissipation.

There are several types of radiator wiring

The most common is the lateral one-way connection. In this case, the inlet pipe is connected to the upper branch pipe, and the outlet pipe to the lower one. Due to this, maximum heat transfer is achieved, and when connected back, the power is reduced by about 10%.

The main advantage of the bottom connection is aesthetics - in this case, both pipes are hidden behind the baseboard. The pipes are located at the bottom of the pipe and face the floor. Diagonal connection is mainly used for multi-section radiators. As a result, hot water is supplied from one side to the upper pipe, and on the other hand, it is discharged through the lower one.

Radiators are connected in two ways: in series and in parallel. When connected in parallel, water moves under pressure throughout the entire system, and if one battery breaks down, all heating is turned off until the repair is completed. When connected in parallel, radiators can be changed without turning off the heating system.

The calculation of the number of sections of the device has to be done depending on the specific situation. This largely depends on the climate of the region and the quality of home insulation. But according to the standard, 1 section of the radiator is able to heat 2 "squares" of the area if the ceiling height is not more than 2.7 m

This formula can be considered conditional, since it is important to take into account other parameters: the thickness of the walls and their material, the type and parameters of the insulation (for more details: "How to choose a heater for heating pipes and whether it is needed "), heater power, climatic features of the region.Double-circuit heating boilers should be selected taking into account the area of \u200b\u200bthe room, but the heating efficiency also depends on the area of \u200b\u200bthe house and the type of radiators

Piping schemes for boiler types

It is quite simple to tie the work of two units of the same type, but real operating conditions do not always allow this. More often, it is necessary to combine the operation of units not only with different capacities, but also with different energy carriers.

The most popular pairs of two-boiler schemes:

- gas fuel and electricity;

- gas and solid fuel;

- firewood and electricity;

- propane and electricity;

- heating oil and electricity;

- pellets and electricity.

Connection of a gas and floor standing solid fuel boiler

This is the most technically complex way of tying two boilers, since it requires the implementation of a smoke ventilation system and compliance with the dimensions of the room for the installation of large fire hazardous objects.

The development of the scheme is best entrusted to the design organization, since it must take into account all safe operation rules, both for gas and solid fuel boilers.

The optimal mode in the heating network is achieved when installing a multi-circuit system, in this case it is necessary to connect boilers with two independent circuits.

Given that solid fuel devices are practically not amenable to regulating the temperature of the coolant, an open heat supply system with the installation of an expansion tank should be used.

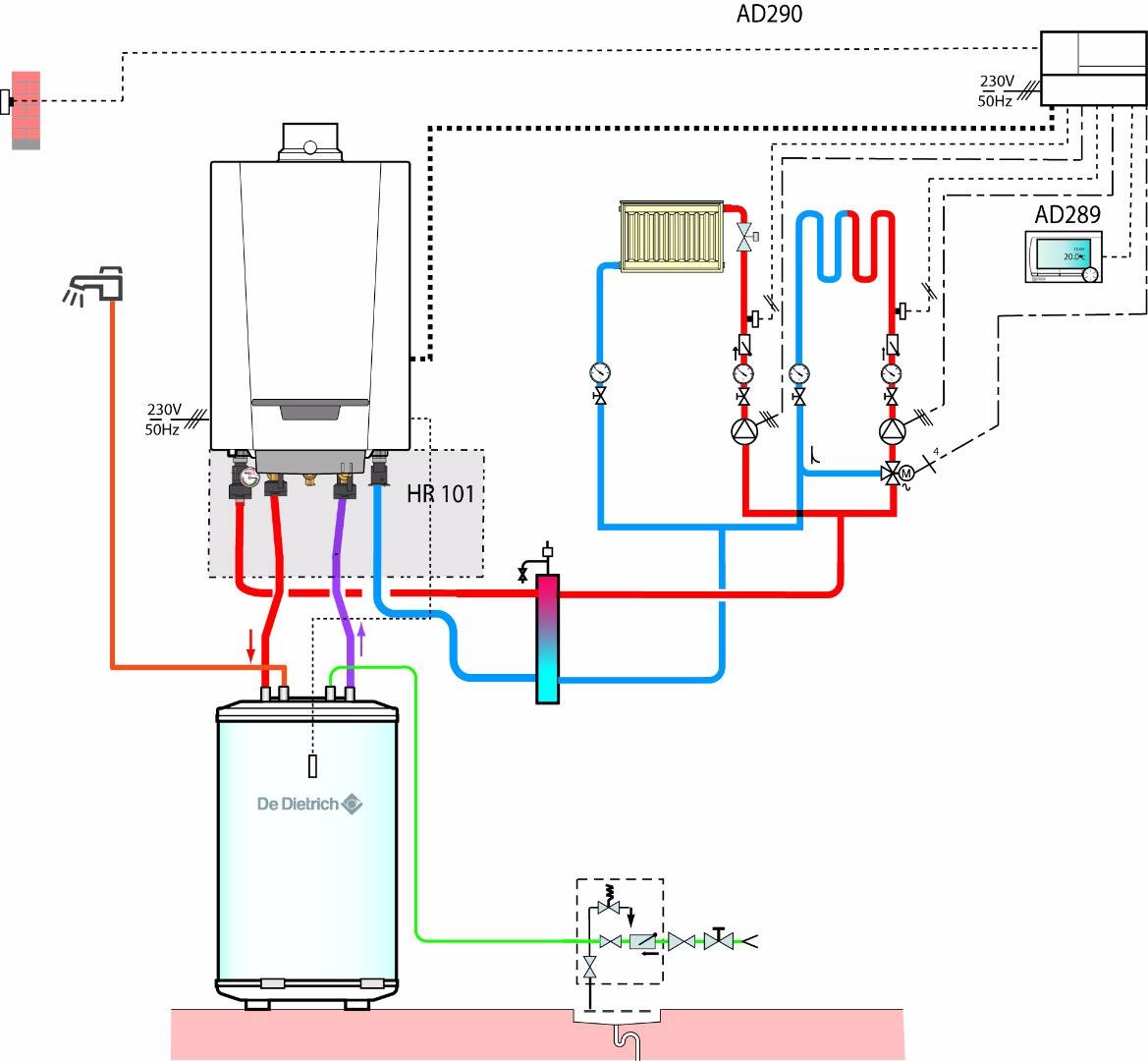

Electric and gas

Very efficient and easy to manage scheme.Combining gas and electric boilers in one heat supply system, it is possible to achieve a much greater thermal effect, and with the right combination of operating modes of the units, the scheme is more economical than traditional gas boilers.

The function of the leader in this pair, as a rule, is performed by a gas boiler unit, having the lowest cost of thermal energy. The electric boiler on diftariff electricity metering is turned on at night using the cheapest tariff.

When choosing the thermal power of the equipment, it is necessary to focus on such a boiler piping scheme. The gas unit must be more powerful, and the electric boiler must have peak power for operation at night or at peak heat consumption. There are no prohibitions on the joint operation of this pair of boilers in regulatory materials. However, when installing them, it will be necessary to coordinate the design of the boiler house from both the gas service and the energy supervision.

Connecting a solid fuel and electric boiler

Connecting a solid fuel and electric boiler is also an effective implementation of a combined heat supply source. The basic boiler is solid fuel, which is able to operate at one load for at least 8 hours. It warms up the heating object well.

After the fuel burns out and the coolant cools down to 60 C, the electric boiler is switched on in the mode of maintaining the temperature graph. For greater energy efficiency, it is desirable to have a hot water storage tank, which is heated by an electric boiler during night economy hours.

The solid fuel boiler itself is difficult to regulate due to the inertia of the combustion process; it will produce almost nominal performance until the fuel burns out.

In this case, working to heat the primary circuit in the storage tank, the heating mode will be adjusted in the secondary heating circuit from the storage tank through a three-way valve by mixing cold water from the return heat carrier with hot water from the supply line.

Features of installing a gas boiler

The connection scheme for a gas boiler begins with the choice of a place for its installation. Moreover, it should be a separate non-residential premises, which is called the boiler room. In the boiler room, it is required to equip a chimney from a pipe for exhaust gases. A prerequisite for installing a gas boiler is the installation of supply and exhaust ventilation. Its installation is carried out by making a hole under the ceiling for air to escape, and for its inflow - below 30 cm from the floor level.

Mounting floor gas boiler involves the use of the following tools:

- Welder.

- Drill and drills.

- A set of keys and screwdrivers.

- Building level.

- Roulette.

Installation

Installation of a floor gas boiler is carried out on a flat and solid surface. A concrete screed is used as a solid surface. It is unacceptable to install the unit on surfaces that ignite: board, laminate, etc.

Chimney arrangement

After placing the unit, the chimney is arranged and the subsequent check for draft is carried out. For the arrangement of the chimney, asbestos-cement or galvanized pipes are used.The best option is to use coaxial chimneys, which are a pipe-in-pipe design. Such chimneys are already insulated, so they only require installation.

When arranging an asbestos-cement chimney, it will subsequently be necessary to insulate it with mineral wool with foil. There are special chimney heaters. When the chimney is ready, you can connect the boiler to the heating system.

Connection to the heating system and water supply

Connecting a double-circuit gas boiler to the heating system differs from a single-circuit one. In the case of a single-circuit unit, it is connected only to the heating system: a discharge pipe and a return pipe. The second circuit is hot water, which is used for washing dishes or taking a shower.

Which circuit to connect initially does not matter. When connecting the second circuit (hot water supply), it is necessary to install a tap and a coarse filter at the inlet to the boiler. At the outlet (where hot water will come from), a tap is mounted, when opened, water will be supplied. It is recommended that the connection to the water supply be made as close as possible to the water supply pipe, which will ensure high pressure.

Installation of the primary circuit involves the use of the following products:

- Two check valves;

- Security group if it is absent in the unit device;

- Expansion tank.

The connection diagram for a double-circuit gas boiler is as simple as installing a single-circuit one. The only difference is when connecting the wall gas boiler and parapet. All additional devices for the wall-mounted unit are already installed inside it, so its connection to the heating system requires the installation of two valves: at the inlet and outlet.

In the case of installing a parapet gas boiler, which can also be double-circuit, you will need to separately install a circulation pump placed on the return pipe, as well as an expansion tank and other additional piping. However, doing it yourself will not be difficult, but it will only take more time.

Connection to the gas line

A flexible hose is used to connect to the gas line. You can also use a steel pipe, but this method of installation is less convenient. The supply pipe must be equipped with a tap or valve. After installation, a gas leak test is carried out.

Network connection

Before starting the unit, it must be connected to the network. To do this, use a household network with a voltage of 220 volts. As practice shows, it is recommended to connect gas boilers with electronics through voltage stabilizers. This will extend the life of the unit, because at the slightest voltage drop, the electronics fail.

Conclusions and useful video on the topic

Rules for installing heating equipment in the video:

The video explains the features of a two-pipe heating system and demonstrates different installation schemes for devices:

Features of connecting the heat accumulator to the heating system in the video:

p> If you know all the connection rules, there will be no difficulties with the installation of the circulation pump, as well as when connecting it to the power supply at home.

The most difficult task is to insert a pumping device into a steel pipeline. However, using a set of lerok for creating threads on pipes, you can independently arrange the arrangement of the pumping unit.

Do you want to supplement the information presented in the article with recommendations from personal experience? Or maybe you saw inaccuracies or errors in the reviewed material? Please write to us about it in the comments block.

Or have you successfully installed the pump and want to share your success with other users? Tell us about it, add a photo of your pump - your experience will be useful to many readers.