- How does a geyser work?

- Causes of gas column pops

- Not cleaned ash pan of the boiler

- How to prevent explosion of gas equipment?

- Typical problems of double-circuit boilers

- What other reasons are there for fading?

- Membrane, obsolete

- Ignition system and piezo element

- The shower turns on - the column goes out

- Flow water heater device

- How does a geyser work?

- Can a modern gas boiler / column explode

- Non-volatile boiler goes out

- Column does not turn on

- Insufficient pressure

- Faulty ignition system

- Dirty wick

- Radiator leak

- How to troubleshoot?

- Boiler safety group defective

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

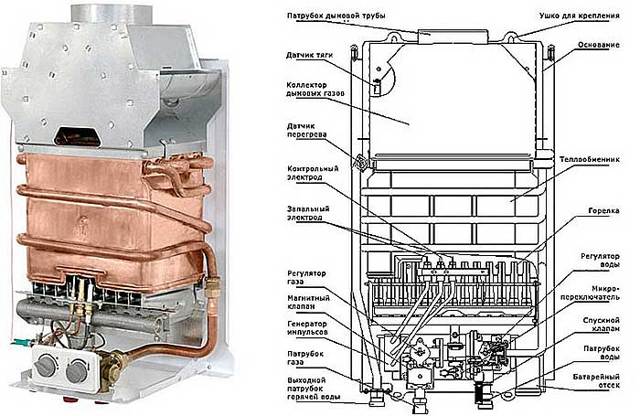

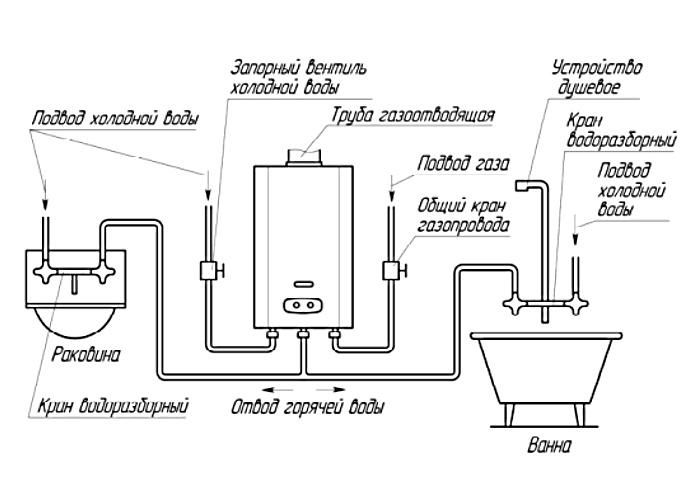

How does a geyser work?

Two main elements are responsible for heating water in the column:

- gas-burner;

- the heat exchanger, which is located above it, is a spiral tube through which heated water passes.

The rest of the device of the gas apparatus consists of the following nodes:

- Ignition. In the "prehistoric" Soviet models, this role was played by a wick or igniter, which was lit with a match. Now the piezoelectric element is responsible for this, which requires the user only to press a certain button.

- Water and gas device.Its elements are a gas valve and a membrane installed in the water supply. When you turn on the water, it starts moving through the column. Due to the water flow, the membrane opens the gas valve, due to which gas is supplied to the burner.

- Safety automation includes a solenoid valve to which sensors are connected to monitor the smooth operation of the device. If any problems are detected, the sensors instantly close the valve, and the column stops working. If we are talking about devices with igniters, then a thermocouple is also connected to the valve, heated by a flame. When the burner goes out, it fires.

Causes of gas column pops

For automatic geysers:

• malfunction of electric ignition.

The automatic column has electric ignition from an electric discharge. A spark is formed from it, which ignites the gas on the main burner. This spark should be between the glow plug and the main burner. If the electric candle is faulty, then an electric discharge may occur at the end of the burner or on the lead wire at the bottom of the candle, so the gas column pops, as the spark appears out of place and when it ignites the gas, it has time to accumulate inside the combustion chamber.

• weak electric ignition discharge.

In a column with an automatic type of ignition, batteries are installed. If they sit down, then the discharge on the glow plug becomes weak, and the gas supply to the burner remains the same. The result is a strong bang.

For geysers with piezo ignition:

• the wick burns to the side.

When the pilot wick is clogged with dirt and dust, the flame may burn weakly or away from the burner.In this case, the fire does not reach the combustion chamber and gas pop occurs.

For any geysers:

• The appearance of pops may be the result of a long operation of the device without its maintenance, which includes a detailed inspection, thorough cleaning, preventive maintenance, adjustment of all parts of the equipment. If maintenance is carried out on time, annually, many problems can be avoided.

Not cleaned ash pan of the boiler

The deposition of soot in the ash pan can also lead to a soot explosion. Therefore, this place in the boiler must be constantly monitored and soot removed in time. It is necessary to take into account the fact that the amount of soot in the ash pan (as well as in the chimney) depends on the quality of the fuel burned. Wet and tarry wood will form more soot than dry and clean wood. Burning any kind of plastic in the furnace also leads to increased soot formation.

Since ancient times, the stove has been the main source of domestic heat. One of the modern and effective means of creating heat in a room today are heating devices for a water heating system. They are mainly used in cottages and mansions for heating houses with a large area. They are especially intensively exploited during the onset of frost. And this, in turn, leads to an increase in the number of fires in this period. So, only in January 2020, there were 2 cases of explosion of heating boilers in the Yurginsky district. This suggests that it is necessary to remember about safety measures, rules for using and caring for heating devices. First of all, the state of the apparatus must be constantly monitored. It is necessary to clean the ash chamber in a timely manner

Attention should be paid to the valves of the smoke channels: they must be opened before starting a fire. Do not use the heating device for cooking purposes.

There are other heat sources for this. The following malfunctions can lead to the explosion of the boiler and subsequent fire: 1. Lack of water leading to overheating of the boiler walls. If there is not enough water in the boiler, the walls overheat, since the heat of hot gases, designed for heating and evaporating water, is not removed. The desire to replenish the lost water in the boiler by immediately supplying it only accelerates the explosion of the boiler, since the water, falling on the overheated walls, instantly evaporates and a pressure exceeding the calculated pressure arises in the boiler. 2. Exceeding the allowable pressure in the boiler. This is possible due to the formation of an air lock in the heating system or freezing of water in one of the sections of the system. 3. Deposition of scale, causing burnout of the walls. The deposition of water scale on the inner walls of the boiler and due to its untimely cleaning leads to overheating of the boiler walls and a decrease in its strength. 4. Corrosion of the metal of the walls and seams. As a result of corrosion, the mechanical strength of the metal of the boiler walls decreases, and bulges form. With a further increase in pressure in the boiler, cracks appear in the places of bulges, and the boiler explodes. In addition, explosions are possible as a result of defects in the metal, welding and riveting seams, changes in the structure of the metal of the walls during operation (temperature changes, chemical effects of water and steam), violations of the strength of the metal due to improper boiler manufacturing technology.To ensure normal operating conditions, heating devices are equipped with safety devices, fittings, automation devices, safety valves, water level indicators, pressure gauges, thermometers. To prevent the heating device from causing a tragedy, do not forget to follow the safety rules! Take care of yourself and your loved ones!

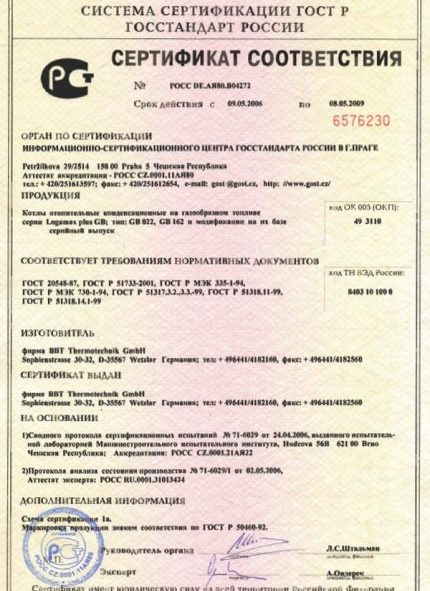

How to prevent explosion of gas equipment?

To protect your home and prevent the occurrence of emergencies, it is recommended to purchase gas equipment in specialized stores.

All technical devices, including gas water heaters, are certified by the State Standard of Russia. Without this permission, gas appliances are not allowed to be used in everyday life.

In a specialized store, when buying, you are required to provide a "certificate of conformity". If the equipment is not of domestic production, it is worth asking if the column has been tested and certified in Russia. Look at the data sheet of the wall-mounted gas boiler, find out what security systems it is equipped with.

The purchase of a flowing gas water heater at specialized points is a guarantee of quality. In addition, you can later contact the center in case of a malfunction of the device and the need to replace it if a factory defect is detected.

To prevent breakdowns, inspection of the device by gas workers is recommended to be carried out annually. You should also study the instructions of the purchased device, which indicates under what conditions the device can operate, how operate it correctly. The connection should be trusted only to the masters from the gas service with which the contract has been concluded.

Components and parts must be regularly cleaned of soot and debris. If problems are observed during ignition or malfunctions are found (the column pops), call the wizard. Any technique, even potentially dangerous, with proper use and constant monitoring of functionality will not cause trouble and will not lead to sad consequences.

Typical problems of double-circuit boilers

Double-circuit modifications of gas boilers designed for the preparation of coolant and hot water can also fade for all the reasons described above. But if there are no signs of the above breakdowns, perhaps the problem is caused by the specific features of the unit.

These include those that arise due to the operation of the water overheating protection system, namely:

- mixing hot and cold running water;

- thinning of the walls of the reducer membrane.

In the instructions for boilers with an additional heat exchanger for hot water, they usually warn that two taps cannot be opened at the same time. It is better to initially select the most suitable temperature for heating domestic hot water in the settings.

The fact is that when cold water is turned on, the consumption of hot water decreases, and heat is generated in the same mode, overheating the heat exchanger. Due to overheating, automation is triggered, which shuts off the gas supply and blocks the operation of the boiler.

The reasons why the DHW boiler goes out are much more due to the features of its design. The problem is solved quite simply: to avoid overheating, choose a comfortable water temperature by changing the regulator on the control panel

If the operation takes place according to the instructions, and the bypass unit is still turned off, you need to change the gasket of the water unit. She's probably worn out.

What other reasons are there for fading?

Failure of the geyser can provoke these elements.

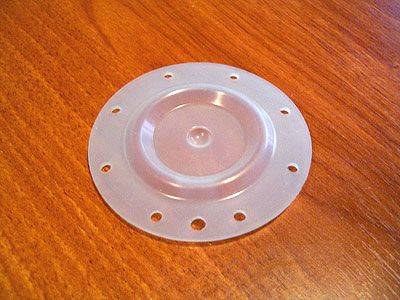

Membrane, obsolete

The polymeric material from which the membranes are made has sufficient elasticity, but after many years of operation, it disappears, and the element becomes rigid, and the appearance of cracks or lime deposits in it is not excluded. Such defects will not allow the geyser to work regardless of how the tap is open. Therefore, it is worth removing and inspecting the membrane: if its condition is apprehensive, this element should be replaced as soon as possible.

Ignition system and piezo element

In devices that do not have an igniter, its functions are performed by electronic ignition, where batteries generate a spark. Perhaps the fault lies with them, since they are not always able to work for a whole year. In other gas water heaters, a piezoelectric element, driven by a water turbine, is responsible for generating a spark. Such an ignition system will not help if the water pressure is low.

The usual igniter is also threatened with clogging, it is easy to determine this by the yellow color of the flame. If the burner ignites with a loud pop, this is your case. After cleaning the element, everything returns to normal.

The shower turns on - the column goes out

If the water heater turns off only when the shower is turned on, then this is entirely his fault. The reasons may be:

- The strainer in the shower head is clogged.

- When the watering can is clogged, the water pressure decreases. You can try to open it. If the column starts to work, the reason is found.

- The inner rubber tube of the hose is twisted, because of this, the flow of water is blocked.

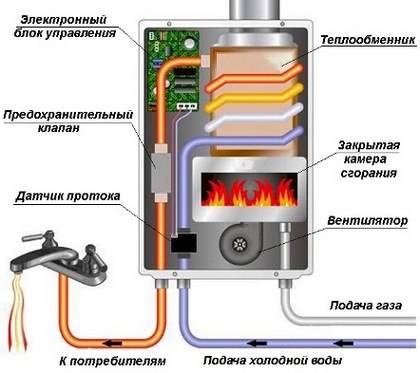

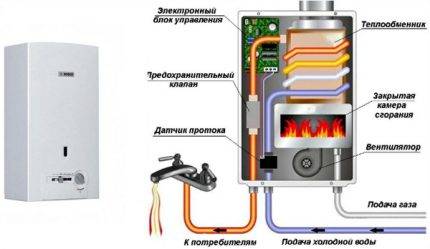

Flow water heater device

The geyser is able to instantly change the temperature of the water, which is heated in a direct-flow pattern. There is no tank in this equipment. The device has a plate heat exchanger, most often made of copper.

A water pipe runs through it. Gas burners are located below. The heat exchanger plates are heated by the combustion gas and in turn heat the water tube.

For safety reasons, new models of gas water heaters are equipped with automation that controls the draft in the chimney and the flame. In the event of a malfunction, the gas supply is interrupted automatically

For safety reasons, new models of gas water heaters are equipped with automation that controls the draft in the chimney and the flame. In the event of a malfunction, the gas supply is interrupted automatically

At the top of the device is the exhaust gas collector. In it, the combustion products of blue fuel are accumulated and redirected to the chimney. On the body of gas boilers there are regulators, with the help of which the water pressure and gas supply are adjusted. Thanks to them, the temperature of heating water is set individually.

The recommended temperature indicators are not higher than 42-50°C. A higher temperature leads to active deposition of salts on the heater parts. As a result, excessive heating of the geyser body occurs, and very hot water flows from the tap.

How does a geyser work?

To understand whether there is any threat from extraneous sounds emitted by the speaker, you need to consider all possible causes. If the column is old, then there will likely be more options. In addition, each model of water heating equipment may have its own characteristics. But still, the principle of their work is similar.Therefore, first you need to figure out how the gas column works and whether it is possible to fix the problem yourself.

Any modern water heater consists of a rectangular box and a supply of gas and water to it. Cold water enters the device and passes through the radiator compartment, where it is heated with a special burner.

As soon as you open a hot tap, a valve opens in the device, which is designed to supply gas to the system. It enters the combustion chamber through a special ignition burner and the process of direct heating of the heat exchange element through which the water passes begins.

Carbon monoxide, which is produced after the combustion of natural gas, is discharged to the street through the chimney. Withdrawal is carried out naturally or forcibly (turbocharged speakers).

To determine and eliminate the cause of a malfunction in a geyser, it is necessary to study its structure and the principle of operation of all elements of the device

To determine and eliminate the cause of a malfunction in a geyser, it is necessary to study its structure and the principle of operation of all elements of the device

In cases where there is no chimney, and its construction is not possible, a turbocharged type of water heater is used. The removal of combustion products is carried out using an additional fan installed in the device. All exhaust gases are forcibly removed to the street through a coaxial pipe. The design of this chimney also provides for the intake of fresh air necessary for combustion from the outside. Such water heater models are made with a closed combustion chamber.

In all geysers, emergency shutdown systems are provided. As soon as the system detects some kind of malfunction, the water heater will stop working.

Automatic protection works under the following conditions:

- weak draft in the ventilation passage or chimney;

- weak fire in the burner, which heats the heat exchanger;

- when the water pressure decreases, the system automatically shuts off;

- with excessive heating of the copper heat exchanger.

Let's take a closer look at the causes of malfunctions in the operation of a gas water heater.

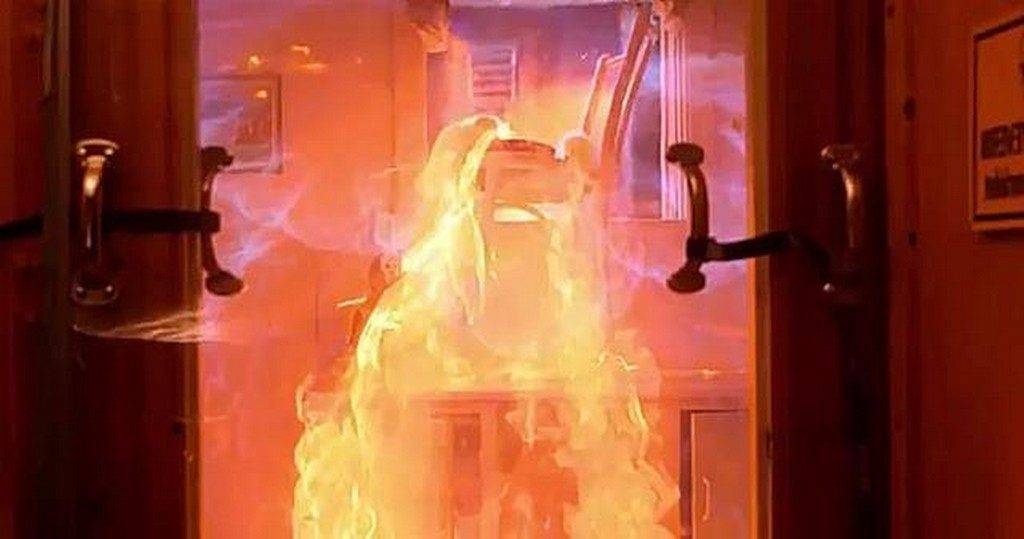

Can a modern gas boiler / column explode

Theoretically, for the technique to explode, the following reasons are necessary:

- An empty pipe is heated without heat carrier.

- The water in the radiator does not circulate, but stands and boils to critical temperatures.

Both that, and another is impossible because even in the cheapest columns of "Economy class" the security system is installed. Empty pipes will not heat up, because until you open the mixer to supply water, the burner will not start. And as soon as you close it, the heating will stop.

Heating temperature, liquid flow rate are controlled by special sensors. All models are equipped with these sensors:

Thermal sensor. Monitors temperature rise. As soon as the water heats up to the set value, it gives a signal to the main module and it turns off the heating.

- flow sensor. Fixes the speed of pressure in the pipes.

- Flexible diaphragm. Serves to open the gas valve. If the pressure in the line is sufficient, then the membrane is bent and the fuel enters the burner. As soon as the pressure decreases, the membrane returns to its original position and the gas supply stops.

- Ionization sensor. If the flame in the burner goes out, the sensor gives a signal to turn off the equipment.

- Removal product sensor. Reacts to the lack of draft in the chimney.Ideally, the smoke should exit normally through the smoke shaft. If this does not happen, protection is triggered. Did you hear that it smells like burning? Then check the chimney. In case of blockage, the mine is cleaned.

Danger arises when technology gets out of control. What experts recommend doing to avoid accidents:

- Buy heating equipment only in specialized stores. Get a warranty so that in the event of a breakdown, contact the service center.

- Trust the connection to specialists.

- Once a year, carry out breakdown prevention and maintenance. Clean components and parts from scale, soot and blockages.

- If problems are observed during ignition (the column bangs, claps), be sure to contact the master.

Any technique can be dangerous if used incorrectly. Control the operation of your devices, then you do not have to deal with the consequences.

Non-volatile boiler goes out

Conventional atmospheric gas boilers also have a number of features that lead to trouble in the form of burner damping.

- When trying to ignite the boiler, the igniter goes out immediately after the gas supply valve button is released. In this case, it is worth sinning for a malfunction of the thermocouple, which heats up from the wick and maintains the solenoid valve in the open state.

- Even the ignition of the burner and igniter does not occur. Most often, this is a weak contact in the electrical circuit between the automation unit and the draft sensor. It is worth cleaning the contacts with fine sandpaper and stretching their connections.

- Weak wick burning or unstable twitching yellow flame. The reason for this is a clogged gas supply nozzle, namely jets or a strainer, or both at the same time.Solving the problem by cleaning and blowing the listed elements.

Let's sum up a little. There are a lot of reasons why a gas boiler goes out. If this still happened, I recommend that you first try to establish the cause yourself, and not call the gas service. After all, everyone wants to make money. It is easy for an experienced gasman to breed an amateur (owner) for money. And the reason may not be in the boiler at all.

Column does not turn on

If the geyser does not turn on, it is not always necessary to call the masters. There are a number of malfunctions in the geyser that the user is able to repair on their own.

Insufficient pressure

The automation of the system blocks the gas supply in case of insufficient water pressure. You can estimate the pressure by simply opening the water taps. If it is small or completely absent, then the emergency shutdown in the geyser is not due to a breakdown of the device.

In the case of normal pressure in the tap, it is worth looking for reasons in the water heating system. As a rule, a decrease in pressure is a consequence of filter contamination or membrane failure.

Coarse filter

To correct the sources of breakdown, due to which the wick of the gas column goes out, the owner will have to:

- clean or change the filtration system;

- put a new membrane partition for the water unit;

- clean the pipeline.

Faulty ignition system

Depending on the models, there are three types of ignition: electric ignition (in modern versions), an igniter, which has a small constant flame, a hydraulic turbine - from pressure.

The electric ignition is powered by built-in batteries. According to the manufacturers, they are enough for about a year.But as practice shows, the service life of such batteries is less. For example, in the Bosch geyser models W 10 KB or WR 10-2 B, there is an LED on the front panel that indicates the state of the batteries. Also, this type of ignition is equipped with a range of gas water heaters Neva Lux. If necessary, old batteries are replaced with new ones.

In the case of a hydroturbine type of ignition, for example, as in the Bosch WRD 13-2 G or WRD 10-2 G, a malfunction may occur due to the lack of water pressure on which it is based.

Dirty wick

This problem is typical for columns with an igniter - very often it can become contaminated with dust. As a result, the fire becomes very weak and turns yellow.

This problem leads to the fact that the column either cannot be ignited at all, or it will start working after a large influx of gas. In this case, cotton will be heard first.

You can easily clean the part with your own hands. To do this, you will need to prepare all the necessary tools - screwdrivers and wrenches. After that, perform the following sequence of work.

- Unscrew all bolts, remove the cover, dismantle the housing.

- Remove interfering tubes - on the draft sensor and on the gas supply to the wick.

- Completely disassemble the entire structure by unscrewing the remaining screws.

- Clean and blow through all the parts, assemble the case back. After everything is assembled, you need to check the operation of the column. If the flame ignites the first time and glows blue when burning, then the cleaning is done correctly.

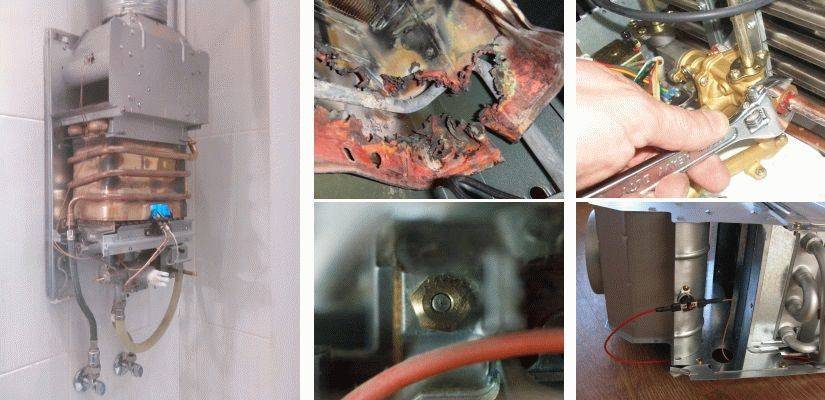

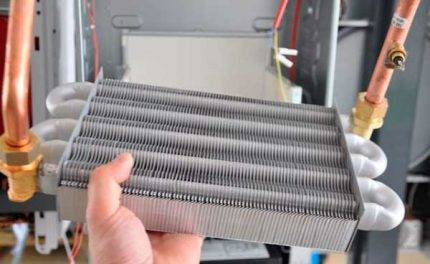

Radiator leak

Hot water appears thanks to the existing heat exchanger.The heat exchanger radiator is metal pipes and plates located close to each other. The plates are in direct contact with the fire, due to which soot appears on them during operation.

The signs of soot accumulation are:

- The flame is yellow;

- When burning, the fire deviates to the side and heats the body (the flame should strive upwards);

- Soot falls off the gas column;

- Even when operating at full power, there is a slight heating of the water.

To remove soot, you will need to remove the casing by unscrewing the bolts (latches) that secure it.

After the assembly is removed, it must be washed by putting it in a container of water for several hours to deoxidize the soot. This will facilitate washing the space between the heat exchanger plates. For high-quality cleaning, it is recommended to use running water, a brush with a long bristle and detergents. After drying, the radiator is put in place.

Green spots on the heat exchanger indicate the presence of cracks and holes.

If the geyser is leaking due to the failure of the heat exchanger radiator, then the actions should be as follows:

- Water pipes must be closed to prevent water from entering the gas column. After that, the hoses are disconnected and the remaining water is drained. The remaining liquid in the coil is removed by a pump or vacuum cleaner, you can try to blow the water out with your mouth using a hose. This must be done, since the remaining moisture takes on heat during the soldering process, and it will not be possible to heat the metal to the desired temperature.

- Damaged areas (they are green) will need to be cleaned with sandpaper and degreased with a solvent, and then wiped dry.

- Crushed rosin or an aspirin tablet should be sprinkled on the work surface. Rosin and aspirin will serve as solder here.

- With a soldering iron with a power of at least 100 W (since they will have to work at a temperature of 180 degrees), it is necessary to increase the solder to a height of approximately two millimeters. If the soldering is loose, this means that the working surface is not warm enough. You can additionally heat up the soldering place with an iron or another soldering iron.

- You will need to solder each through damage in this way.

- After the soldering work is completed, it is necessary to wait until the working surface has completely cooled down and assemble the geyser.

- Before full operation, the equipment is launched in a test mode.

If the geyser is leaking, but no leaks are visible on the radiator, then perhaps they are located where it is turned to the body. In this case, it will be necessary to remove the heat exchanger from the housing, for which you will have to disassemble the entire column. Before starting the procedure, it is advisable to familiarize yourself with the diagram in the passport, since this is a rather time-consuming process and knowing the device of a particular model will simplify the work.

Soldering damage to pipes can only be used as a temporary measure to eliminate the cause of the geyser leak, since the repaired surface remains vulnerable. The best option for troubleshooting, due to which water drips from the column, is to replace worn elements with new ones.

How to troubleshoot?

If the body of the geyser is heated due to contamination in the communications, then they should be cleaned. To do this, you need to check the inlet and outlet hoses of the water supply, the axle box faucet and the faucet cartridges.The hoses are cleaned under running water.

To clean pipes, you can use reverse current or seek help from a master

To clean pipes, you can use reverse current or seek help from a master

In case of incorrect installation of the regulator, it is necessary to transfer the operation of the water heater to summer mode. The initial temperature of the water at the outlet is affected by the temperature index of the liquid at the inlet. For example, the device heats water up to +35°C.

In summer, the inlet water temperature is +15°C. Therefore, at the outlet, the liquid will warm up to +50°C. In winter, when the inlet water temperature is lower, this figure also decreases.

Boiler safety group defective

Boiler safety group

The installation of a safety group for solid fuel boilers is mandatory, as it helps to avoid exceeding the permissible pressure in the heating system, keeps it (pressure) at the proper level, and also vents the system in time. Recall that the operating pressure in the heating system must be between 1 and 2 bar.

Structurally, the security group consists of three elements: manometer

,safety valve andair vent a. Failure of one of these elements can lead to an increase in pressure in the boiler. And yet, it is strictly forbidden to install shut-off valves between the boiler and the safety group.

Conclusions and useful video on the topic

How the gas column works: the principle of operation of the device:

How to correct the position of the flame adjustment sensor:

Analysis of two non-obvious reasons why the geyser can turn on and immediately go out:

How to diagnose a malfunction by removing the heater cover:

p> The main problems with the attenuation of the heater are listed. In most cases, they do not depend on the instrument model or manufacturer.Some you can handle on your own. But if you are not sure about this, it is advisable to contact a service center or gas service.

Do you want to talk about your personal experience in diagnosing the cause of column attenuation and how to repair it yourself? Or do you have questions that we have not covered in this material? Write your comments, participate in the discussion - the feedback form is located below.

Conclusions and useful video on the topic

Search for the cause and solutions of the column attenuation problem can be found here:

Column attenuation is a symptom of an internal malfunction or a misuse of the instrument. It is necessary to correctly find out the cause of the problem, after which a significant part of the described breakdowns can be eliminated on your own. But to solve complex problems, you will have to contact the service center.

Do you have questions when looking for the cause of speaker attenuation? Ask them under this article - our experts and site visitors will try to help you.

Or maybe you want to tell other users about the problems that arose with your column during operation, and their successful solution? Share your experience, leave recommendations in the block below.