- Pipes for a pumping station in the country

- What could be the consequences: narrowing the diameter of the heating pipe

- Heating system calculation example

- Thermal power calculation

- Diameter definition

- Features of heating systems with natural circulation

- Installation of suction and discharge pipelines

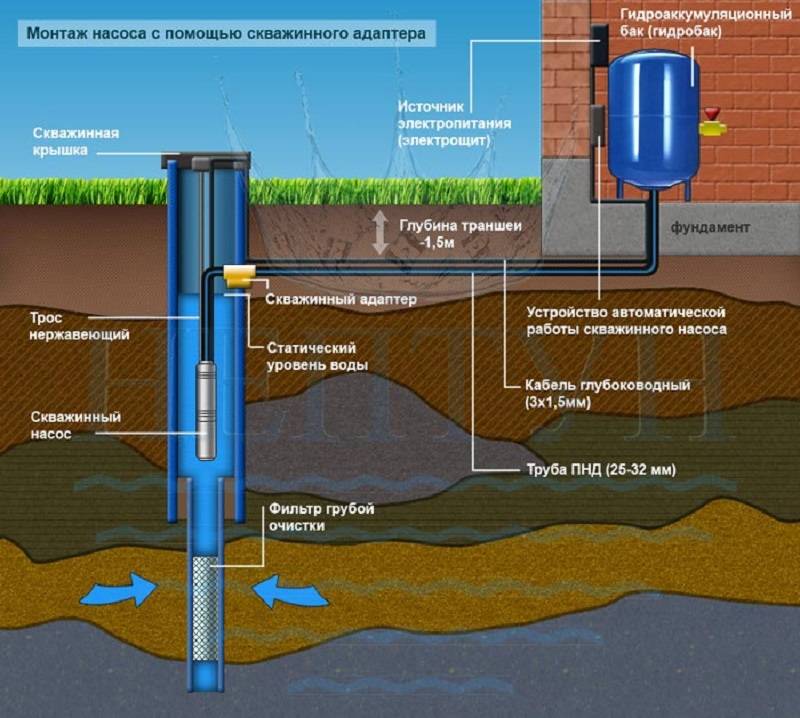

- How is the installation of water pipes

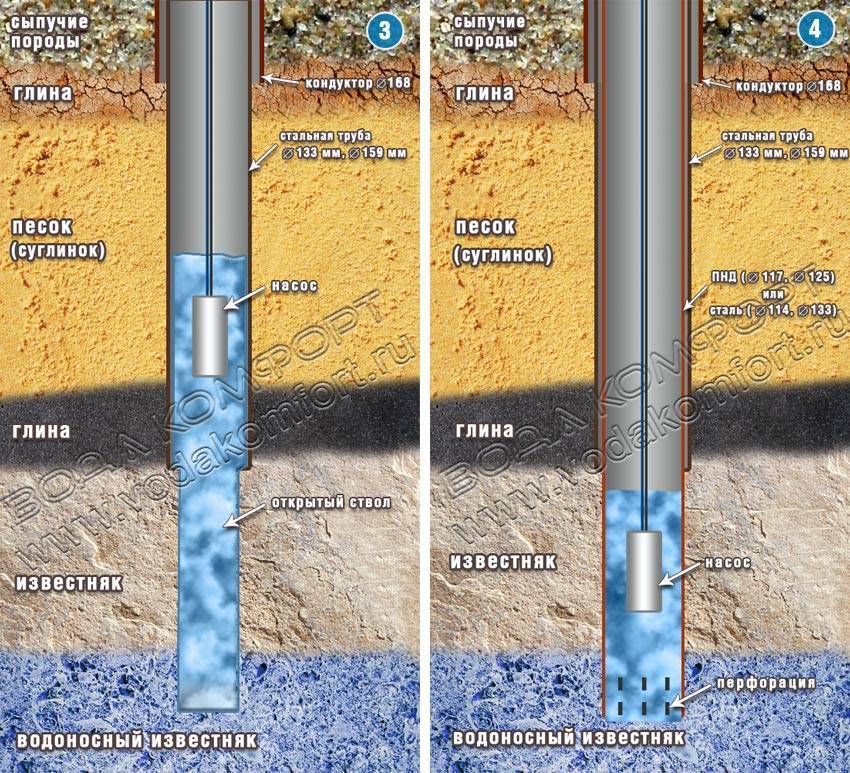

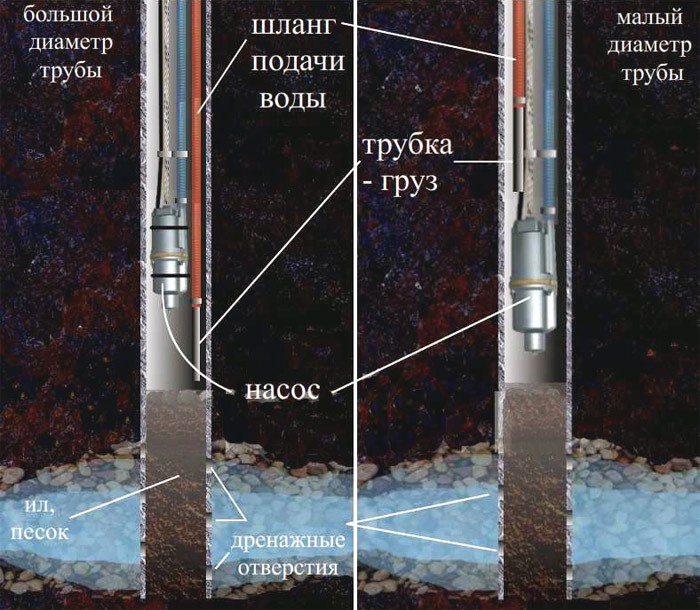

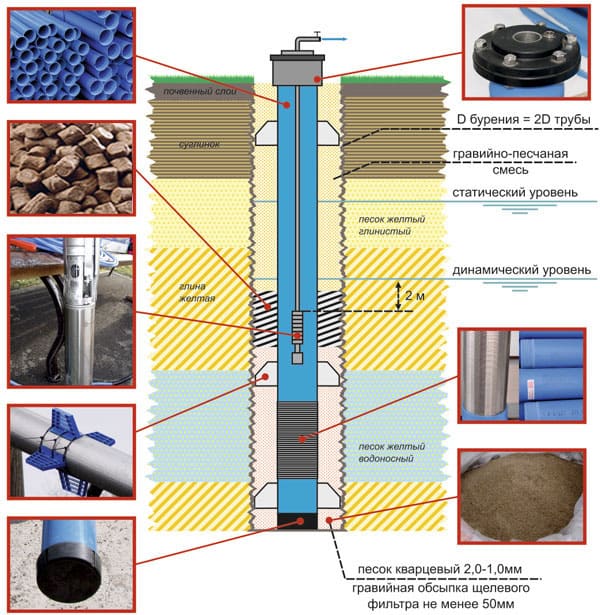

- Casing size selection

- Thoroughly and reliably

- Pump types

- About connecting a polypropylene pipe to a pumping station

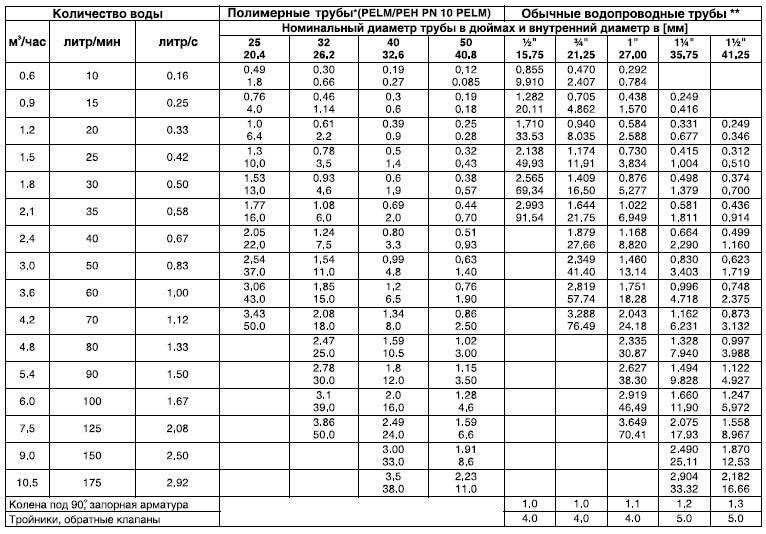

- Data: how to calculate the diameter of a pipe for heating

- Installation

- Types of deep pumps by diameter

- Suction pipe diameter for pumping station

Pipes for a pumping station in the country

The pipes used for the pumping station in the country have the same requirements as for other options for using the hydrophore

It is worth paying attention to the diameter of the pipe. However, the calculation rules are common for all stations that we have analyzed above.

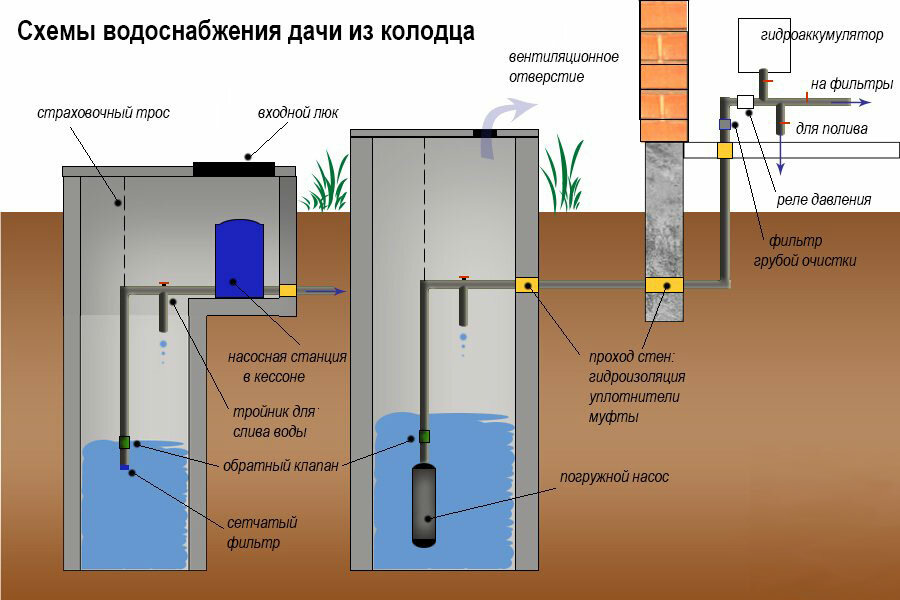

But the choice of a hydrophore for a summer residence should be discussed separately. To ensure your life in the country with an autonomous and reliable water supply at any time of the year, you need to automatically supply water to any point of water consumption. This is precisely why a pumping station is needed, which will be able to provide sufficient pressure in the water supply system under any conditions, even when the pump is turned off.The main thing is to choose the optimal equipment and properly mount it on your own summer cottage.

Where is it better to install a pumping station in the country? Let's name three main options for placing a hydrophore:

- in the immediate vicinity of a well or well;

- in one of the business premises;

- directly in the residential building.

When choosing a hydrophore (pumping station) for a summer residence, you should pay attention to such characteristics as:

- engine power;

- generated water pressure;

- hydrophore performance.

Many stations are equipped with safety devices that look like sensors that can turn off the device in case of overheating or the so-called "dry mode" when there is no water in the system.

This increases the cost of the station, but will ensure its safer use in the country. The kit usually has a check valve and a water filter. If they are not available, be sure to buy them and install them in the hydrophore circuit.

What could be the consequences: narrowing the diameter of the heating pipe

Narrowing the pipe diameter is highly undesirable. When wiring around the house, it is recommended to use the same size - you should not increase or decrease it. A possible exception would be only a large length of the circulation circuit. But in this case, you need to be careful.

Many experts do not recommend narrowing the diameter of the pipes, as this can adversely affect the entire heating system.

Many experts do not recommend narrowing the diameter of the pipes, as this can adversely affect the entire heating system.

But why does the size narrow when replacing a steel pipe with a plastic one? Everything is simple here: with the same inner diameter, the outer diameter of the plastic pipes themselves is larger. This means that the holes in the walls and ceilings will have to be expanded, moreover, seriously - from 25 to 32 mm. But for this you will need a special tool.Therefore, it is easier to pass thinner pipes into these holes.

But in the same situation, it turns out that the residents who made such a replacement of pipes, automatically "stole" from their neighbors in this riser about 40% of the heat and water passing through the pipes. Therefore, it should be understood that the thickness of the pipes, arbitrarily replaced in a thermal system, is not a matter of a private decision, this cannot be done. If steel pipes are replaced with plastic ones, you will have to expand the holes in the ceilings, whatever one may say.

There is another option in this situation. When replacing risers in old holes, it is possible to skip new segments of steel pipes of the same diameter, their length will be 50-60 cm (this depends on such a parameter as the thickness of the ceiling). And then they are connected by couplings with plastic pipes. This option is quite acceptable.

Heating system calculation example

As a rule, a simplified calculation is performed based on such parameters as the volume of the room, the level of its insulation, the flow rate of the coolant and the temperature difference in the inlet and outlet pipelines.

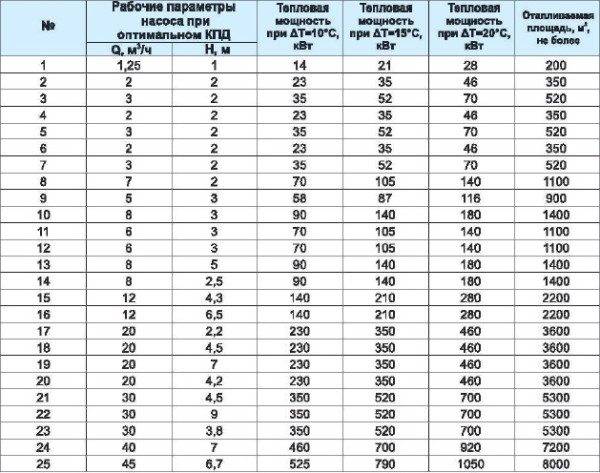

The diameter of the pipe for heating with forced circulation is determined in the following sequence:

the total amount of heat that needs to be supplied to the room is determined (thermal power, kW), you can also focus on tabular data;

The value of heat output depending on the temperature difference and pump power

given the speed of water movement, the optimal D is determined.

Thermal power calculation

A standard room with dimensions of 4.8x5.0x3.0m will serve as an example. Heating circuit with forced circulation, it is necessary to calculate the diameters of the heating pipes for wiring around the apartment. The basic calculation formula looks like this:

The following notation is used in the formula:

- V is the volume of the room. In the example, it is 3.8 ∙ 4.0 ∙ 3.0 = 45.6 m 3;

- Δt is the difference between the temperature outside and inside. In the example, 53ᵒС is accepted;

Minimum monthly temperatures for some cities

K is a special coefficient that determines the degree of insulation of the building. In general, its value ranges from 0.6-0.9 (efficient thermal insulation is used, the floor and roof are insulated, at least double-glazed windows are installed) to 3-4 (buildings without thermal insulation, for example, change houses). The example uses an intermediate option - the apartment has standard thermal insulation (K = 1.0 - 1.9), accepted K = 1.1.

The total thermal power should be 45.6 ∙ 53 ∙ 1.1 / 860 = 3.09 kW.

You can use tabular data.

Heat flow table

Diameter definition

The diameter of the heating pipes is determined by the formula

Where designations are used:

- Δt is the temperature difference of the coolant in the supply and discharge pipelines. Given that water is supplied at a temperature of about 90-95ᵒС, and it has time to cool down to 65-70ᵒС, the temperature difference can be taken equal to 20ᵒС;

- v is the speed of water movement. It is undesirable that it exceeds the value of 1.5 m/s, and the minimum allowable threshold is 0.25 m/s. It is recommended to stop at an intermediate speed value of 0.8 - 1.3 m / s.

Note! Incorrect choice of pipe diameter for heating can lead to a drop in speed below the minimum threshold, which in turn will cause the formation of air pockets. As a result, the efficiency of work will become zero.

The value of Din in the example will be √354∙(0.86∙3.09/20)/1.3 = 36.18 mm

If you pay attention to the standard dimensions, for example, of a PP pipeline, it is clear that there is simply no such Din. In this case, simply select the nearest diameter of the propylene pipes for heating

In this example, you can choose PN25 with an ID of 33.2 mm, this will lead to a slight increase in the speed of the coolant, but it will still remain within acceptable limits.

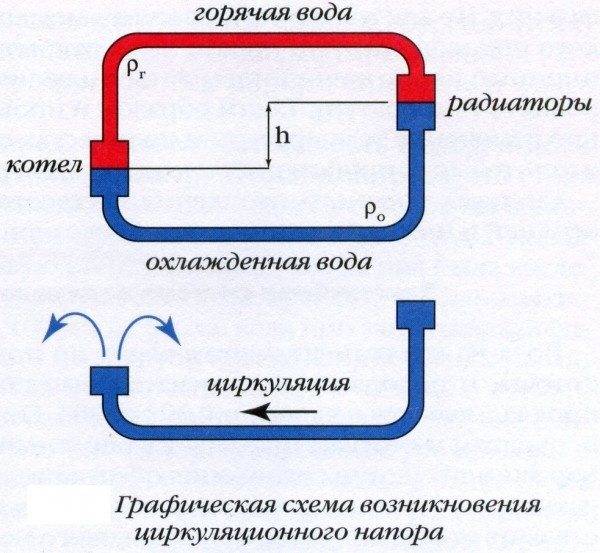

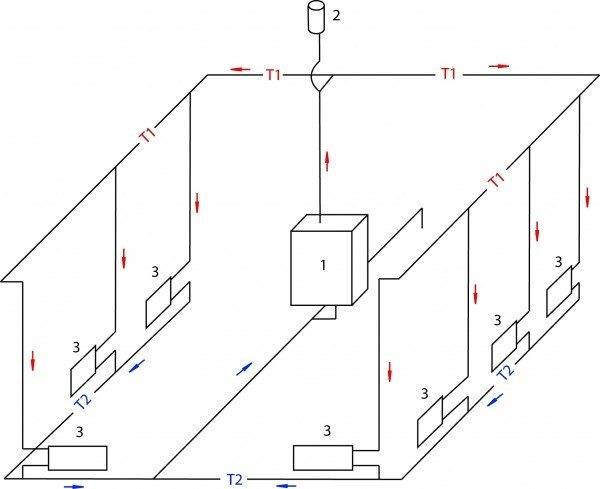

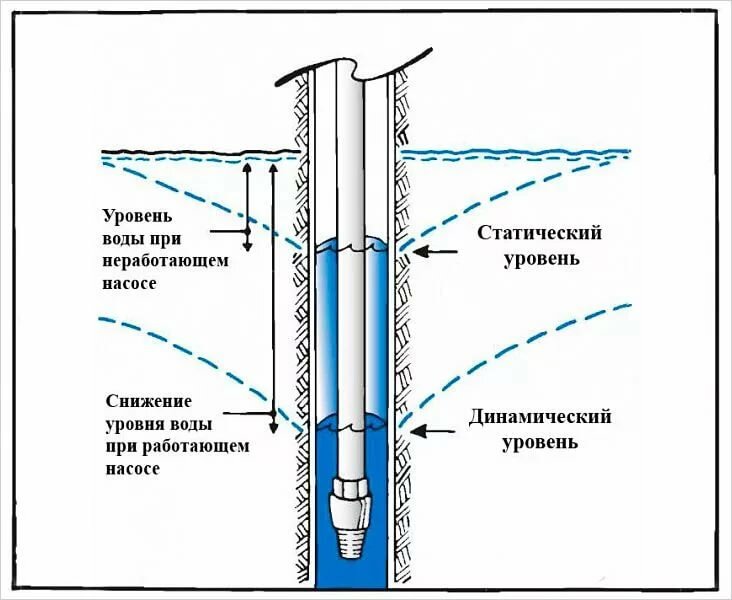

Features of heating systems with natural circulation

Their main difference is that they do not use a circulation pump to create pressure. The liquid moves by gravity, after heating it is forced upward, then passes through the radiators, cools down and returns to the boiler.

The diagram shows the principle of circulation pressure.

Compared to systems with forced circulation, the diameter of pipes for heating with natural circulation must be larger. The basis of calculation in this case is that the circulation pressure exceeded friction losses and local resistance.

Example of natural circulation wiring

In order not to calculate the value of the circulation pressure each time, there are special tables compiled for different temperature differences. For example, if the length of the pipeline from the boiler to the radiator is 4.0 m, and the temperature difference is 20ᵒС (70ᵒС in the outlet and 90ᵒС in the supply), then the circulation pressure will be 488 Pa. Based on this, the coolant velocity is selected by changing D.

When performing calculations with your own hands, a verification calculation is also required.That is, the calculations are carried out in the reverse order, the purpose of the check is to establish whether the friction losses and local resistances exceed the circulation pressure.

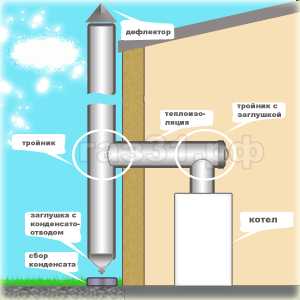

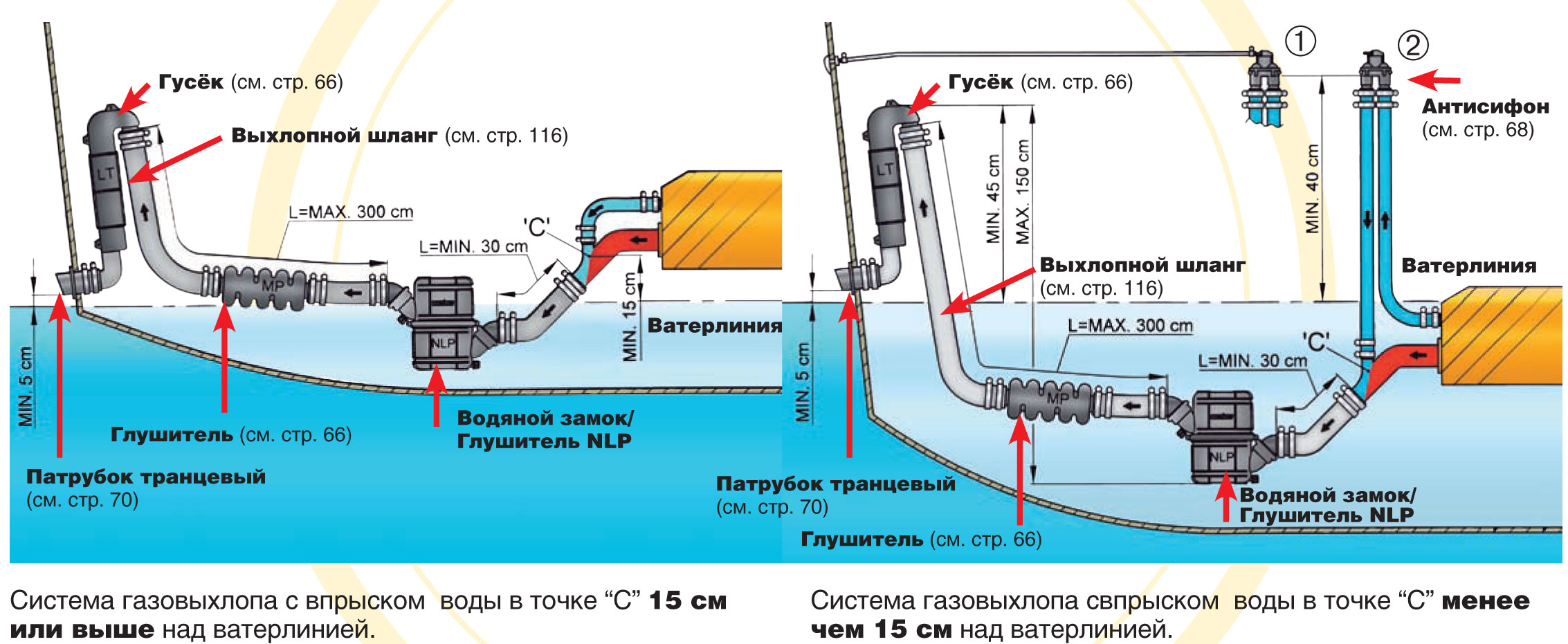

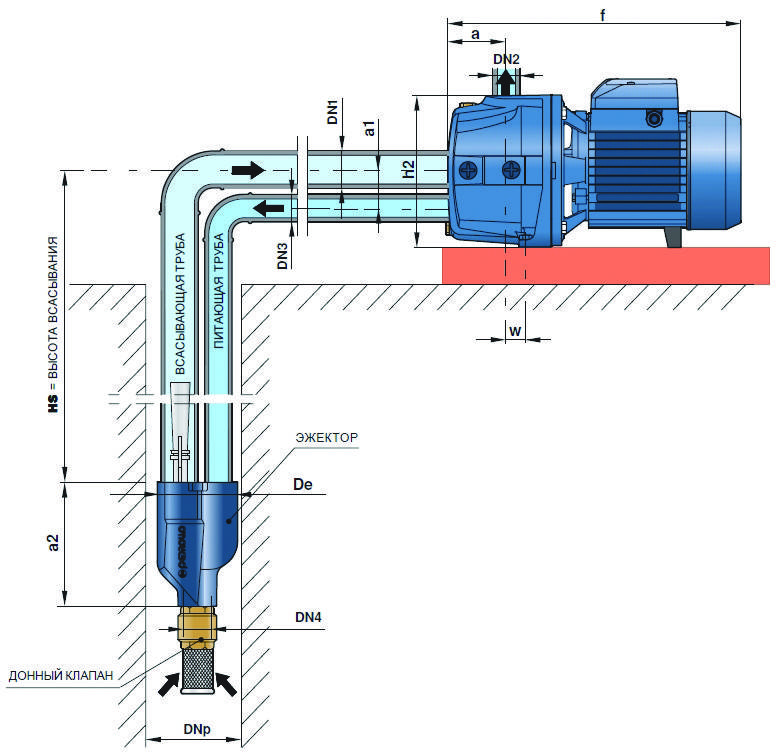

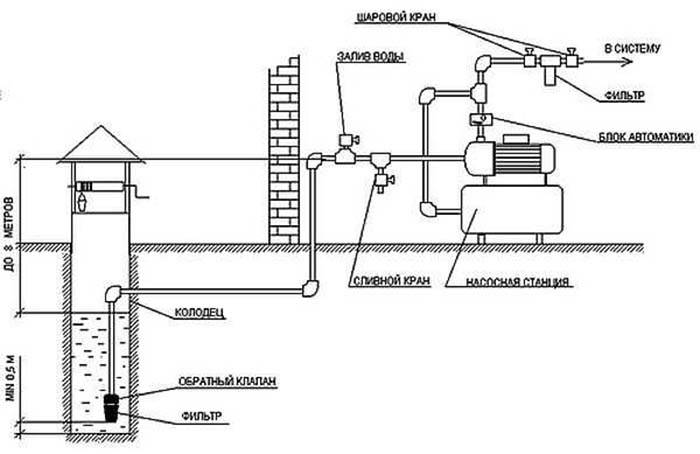

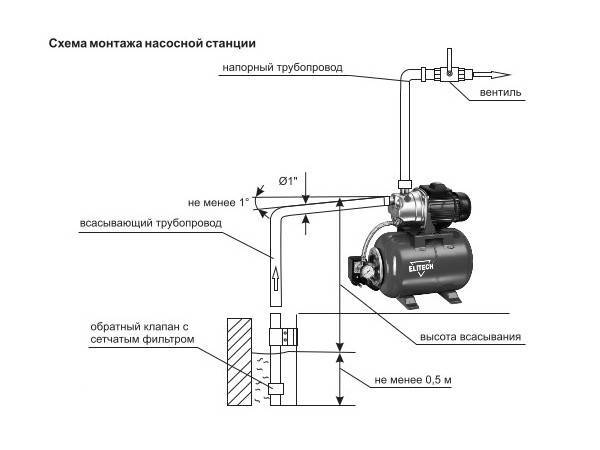

Installation of suction and discharge pipelines

The suction pipeline is arranged from metal pipes for flange or socket connections.

For normal operation of the suction pipeline, the tightness of all its connections is necessary. The pipe joints must be very tight, to prevent air from entering the suction pipe, since even minor leaks can cause the pump to fail. Flange joints are connected on rubber gaskets, which are placed centrally to the pipe holes. During installation, do not correct the distortion of the flanges by tightening the bolts, as this may deform the pump.

The suction line passing through the trench is laid from the pump to the reservoir along the shortest distance, with a minimum number of turns, at a depth of 0.1-0.2 m below the freezing soil.

The horizontal length of the suction pipes is not recommended to be more than 30 m. Laying is carried out with a smooth, slight rise to the pump and without kinks in which air pockets could form.

The total vertical suction height should not exceed 4-6 m.

The suction elbow must not be connected directly to the suction port of a centrifugal pump or to the cylinder coupling of a piston pump.

To avoid excessive resistance when water enters the pump, a pipe 200-300 mm long is installed between the elbow and the pump.

The inlet valve, designed to prevent water from flowing out when filling or stopping the pump, must stand 0.4-0.5 m from the bottom with its lower part.This is done in order to prevent it from being sucked in by sand and silt.

The inlet valve must be immersed in water for at least 0.4-0.5 m, counting from the lowest water level to the grate inlets. If water is taken from an open source of shallow depth, then a receiving well of sufficient depth should be arranged. In this case, it must be taken into account that the receiving well will be subject to soil drifts. Therefore, the depth of the intake well should be 0.5-1 m greater than the immersion depth of the lower part of the pump intake valve.

The discharge pipeline starts from the transition box or from the pressure pipe of the centrifugal pump and ends in the water reservoir. The length of the discharge pipeline horizontally can be greater or less and depends on the discharge height that the engine is able to overcome. In practical calculations, 100 m of horizontal injection is approximately equal to 1 m of vertical injection.

The diameter of the discharge pipes must not be less than the diameter of the discharge opening of the adapter box of the piston pump or the discharge pipe of the centrifugal pump.

A check valve and an air cap are mounted on the discharge pipeline coming from the piston pump. The latter serves both to absorb hydraulic shocks that occur during the operation of a piston pump, and to equalize the speed of water movement in the discharge pipeline.

The size of the air cap on the discharge pipeline should be equal to 10-15 times the volume of one pump of water, and the diameter of the cap should be approximately 2.5 piston diameters with a cap height 1.8-3.5 times greater than the diameter of the cap .

A gauge glass is installed to indicate the water level in the air cap, and a pressure gauge is used to determine the pressure.

The normal volume of air in the hood during pump operation is approximately two-thirds of the volume of the entire hood.

Injection pipes are laid in trenches in a straight line with a rise towards the water tank. When approaching a water pressure structure, the pipeline must create a smooth transition of water into a vertical plane (to the riser), for which connection with the riser is made using a special elbow.

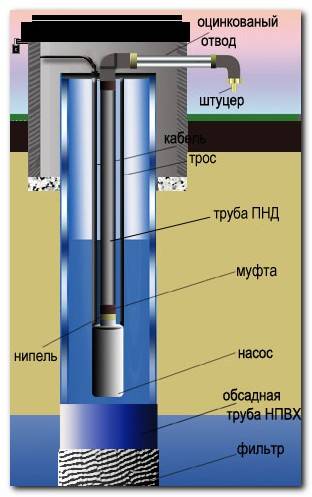

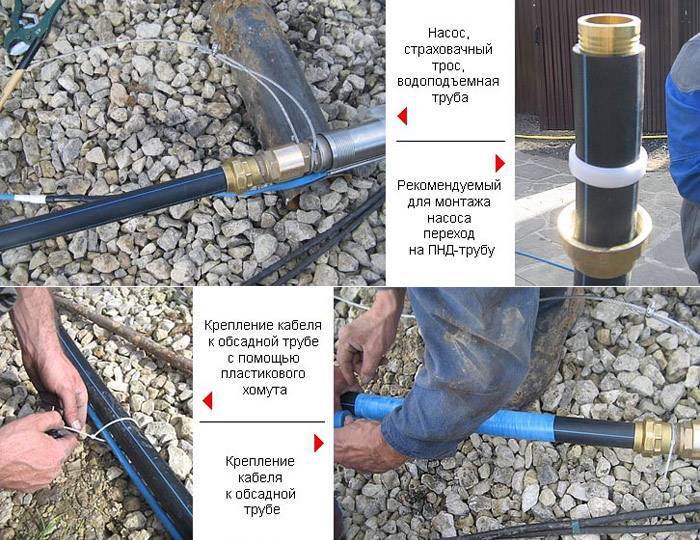

How is the installation of water pipes

It is immediately worth noting that it is most convenient to immediately install both the pump and the pipes. In this case, all the necessary calculations should be done in advance, otherwise you may encounter a lot of difficulties. The descent of the pump into the well should be smooth. Moreover, if the preliminary preparation is not carried out correctly, then you can not receive enough water, which is required to provide the house. The lack of pressure will affect the comfort of residents. As a result, they will have to choose between doing laundry, using the shower, or watering the garden. Simultaneous side procedures will become impossible.

Modern pumps are most often equipped with a flanged or threaded version for connecting a pipe. Although sometimes a coupling type of connection is also used. Experts recommend first attaching the water-lifting element on one side, and only after that proceed with the installation of the second part of the pipe. Lowering the structure to the ground is strongly discouraged. This can cause damage to important components or displacement of certain parts.

Casing size selection

Quite often, decisions on laying another type of well structure are made when drilling a hole. During the deepening process, it may be necessary to use pipes of various widths to create a more reliable and efficient water supply system. This is what leads to the fact that when forming the structure, pipes of various diameters are used, due to which the initial width of the downhole equipment column expands or narrows.

Some well drilling companies initially offer narrow passes to their customers, which makes for a better deal in a competitive market. And in some cases, the owner of the facility himself decides on a reduced cross-section of the well, since it is cheaper

It is important to understand that the productivity of the well does not depend entirely on the width of the pipe, since to a large extent it is determined by the technical parameters of the filter components and the ability of the rocks to produce water.

In any of the options, it is very important that there is a gap between the casing and the casing of the pumping equipment, which allows you to quickly and easily dismantle the pump along with the pipe and other parts. Most often, specialized documentation indicates that pumping equipment should be no less than 10 millimeters thinner than the inner diameter of the pipe

This minimizes damage from axial displacements, welding seams, compression of the pipe under ground pressure, and other unpleasant factors.

That is why it is recommended to choose so that the gap is more than 10 mm.

Thoroughly and reliably

When deciding which pump station pipes to use, you can pay attention to metal-plastic options. They have several advantages over rubber hoses:

- do not deform and do not change their qualities with temperature changes;

- sure to withstand the required pressure;

- have greater mechanical strength;

- they are significantly more hygienic and more suitable for contact with drinking water.

True, for the installation of metal-plastic, special skills will be required, but not at all complicated. Pieces of pipe of the required diameter are interconnected using fittings tightened with ordinary wrenches.

However, when laying a water pipe, it must be remembered that it will work not only thanks to the correct choice of pipes. Other factors must also be taken into account. Pipes should be laid below the freezing level of the soil. And also provide the desired slope - from the pump to the well, and not vice versa.

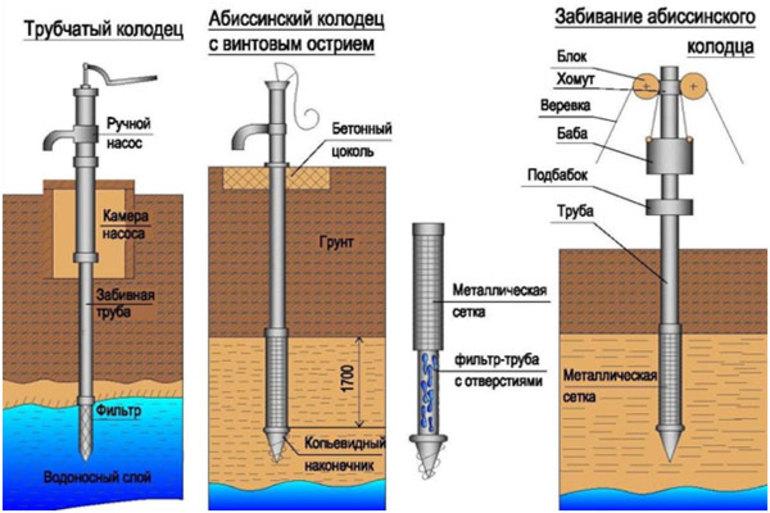

Pump types

The requirements for pipes depend on which pump will be used to lift the liquid and move it through the water supply system. Therefore, before choosing one or another option, it is necessary to clarify which pump is used or will only be installed on the site. In total, there are 2 main types of pump for a well. It can be manual or mechanical. Each type can be further divided into subclasses.

The requirements for pipes depend on which pump will be used to lift the liquid and move it through the water supply system. Therefore, before choosing one or another option, it is necessary to clarify which pump is used or will only be installed on the site. In total, there are 2 main types of pump for a well. It can be manual or mechanical. Each type can be further divided into subclasses.

Hand pumps can have a piston or hose system. The latter option, as a rule, is used when it is necessary to lift water from a depth of more than 7 m. Piston - it is more convenient to use in shallow wells.

As part of the hose pump there is a pump cylinder, which must be fixed at the very bottom of the plumbing system. The kit includes hoses equipped with a piston and a mechanism with a manual drive. It must be placed on top of the well.

Piston pumps differ slightly from hose pumps. But there are still installation features. Such a device must be fixed at the end of the riser pipe. It is for this reason that piston pumps are not recommended for use where the depth of the well exceeds 7 m.

Mechanical devices are more complex, but easy to use. This group is also divided into several types. Mechanical pumps can be gear, centrifugal and electromagnetic.

Centrifugal are considered the best option for simple cottages or small houses. Small water pipes are connected to them, but this is quite enough for domestic use. Such devices are considered relatively inexpensive. They are rust resistant as they are made of stainless steel. In addition, centrifugal pumps can be equipped with several useful add-ons. For example, they often use a protection system from switching on in the absence of water. This helps protect the device from damage and premature wear.

Feature of electromagnetic well pumps is that they last a very long time. There are no rubbing parts that can wear out over time. During installation, such a pump can be immersed directly in water.

Hydraulic pumps are quite powerful and can be used to supply large quantities of water. But for its smooth operation, electricity is needed.If there is no light in the house, then, accordingly, the water will turn off. This is not always convenient, since in some settlements, and especially in rural areas, power outages are not uncommon.

About connecting a polypropylene pipe to a pumping station

Situations when it is necessary to connect a polypropylene pipe to a pumping station, most often there can be two:

- At the initial connection of a new station;

- When replacing old metal pipes with new HDPE pipes.

In any case, to connect to the central water supply, you must perform the following sequence of actions:

The first step is to block the flow of water at the point of connection to the central water supply.

Next, we prepare the pumping station. The main thing when setting up a pumping unit is to choose the right pressure in the system. To adjust the equipment, a small amount of water (about 2 liters) is poured into a special hole on the pump unit. Now you need to open the valve and measure the pressure in the system at which the pump turns off and on.

If the pressure at which the device operates is not within the specified limits, the device must be adjusted. This is very easy to do:

- The pressure cover opens on the pressure switch.

- To adjust the cut-off pressure of the device, a screw with the designation "DR" is used. It should be rotated in the direction of decreasing or increasing, depending on the results.

- To adjust the switching pressure, turn the screw marked "P".

- After adjustment, the cover on the relay is put in place.

So the sequence of actions when connecting a polypropylene pipe to a pumping station:

- First we assemble the ejector.As a rule, this is a monolithic cast-iron assembly with three outlets.

- At the lower outlet of the ejector, we mount a coarse filter made of propylene mesh.

- At the top of the cast-iron structure is a plastic bell. It is necessary to put on it a drive with a diameter of 32 mm.

- Next, you need to assemble the squeegee according to the diameter of the pipeline. Usually two parts with adapters are enough for this.

- A bronze coupling is installed at the outlet of this spur. With it, a connection to a polyethylene pipe will be made.

Use couplings to connect the ejector to the water supply.

Before lowering the second end of the polypropylene pipe, it must be passed through the knee at a right angle. Foam is used to seal the space. After that, the pipe can be connected to the adapter, and it, in turn, must be connected to the outside of the water supply system.

Now you can lower the ejector into the well. The immersion depth must be determined in advance, taking into account the mark on the top of the housing. The lid is fixed to the body with reinforced sanitary adhesive tape.

Data: how to calculate the diameter of a pipe for heating

To calculate the diameter of the pipeline, you will need the following data: these are the total heat loss of the dwelling, the length of the pipeline, and the calculation of the power of the radiators of each room, as well as the wiring method. Divorce can be single-pipe, two-pipe, have forced or natural ventilation.

Also pay attention to the marking of copper and polypropylene pipes of outer diameter. The internal can be calculated by subtracting the wall thickness

For metal-plastic and steel pipes, the internal size is affixed when marking.

Unfortunately, it is impossible to accurately calculate the cross section of pipes. One way or another, you will have to choose from a couple of options. This point should be clarified: a certain amount of heat must be delivered to the radiators, while achieving uniform heating of the batteries. If we are talking about systems with forced ventilation, then this is done using pipes, a pump and the coolant itself. All that is needed is to drive the required amount of coolant for a certain time period.

It turns out that you can choose pipes of smaller diameter, and supply the coolant at a higher speed. You can also make a choice in favor of pipes of a larger cross section, but reduce the intensity of the coolant supply. The first option is preferred.

Installation

Features of installing pipes and pumps largely depend on the type of well. In some cases, the installation of conventional devices will be very difficult. In such situations, it is allowed to use flexible hoses that can replace water pipes. The main thing is that these elements are strong enough and safe for humans. In no case should they release harmful chemical compounds into the water. In addition, it is worth making sure that the pipes are reliable enough, and all fasteners are of high quality. Otherwise, the plumbing will have to be repaired immediately after its first use.

Experts strongly recommend that only those options that have been designed and manufactured for this purpose be used as lifting pipes. Do not take nylon hoses or fire pipes, as they will quickly fail and may even ruin the pump.As a result, you will have to spend money on purchasing a new set of expensive equipment.

Types of deep pumps by diameter

Most often, for the installation of pumping equipment intended for autonomous water supply, 3- and 4-inch products are offered, which have a diameter of 76 mm and 101 mm, respectively. 4" pumps are more common and come in a wide variety of models, while 3mm pumps are less popular. In terms of configuration, reliability and technical parameters, thin pumping equipment is in no way inferior to analogues with a diameter of more than 100 mm. However, they are several times lighter and 30% longer.

When choosing borehole pumps, it is necessary to be guided not only by the diameter, but also by other important technical characteristics that can satisfy the needs of the facility:

- performance;

- immersion depth;

- pressure;

- pollution resistance;

- maximum pressure;

- principle of operation;

- suction system, etc.

The choice of pump should be carried out with a combination of all these factors, which will help to choose the most suitable model for a particular object.

CNP manufactures the highest quality industrial pumps that are not intended for installation in private homes. Our equipment is used in industrial facilities and other specialized buildings. Pumps are characterized by increased reliability and performance, which allows you to meet the needs of any free-standing objects.

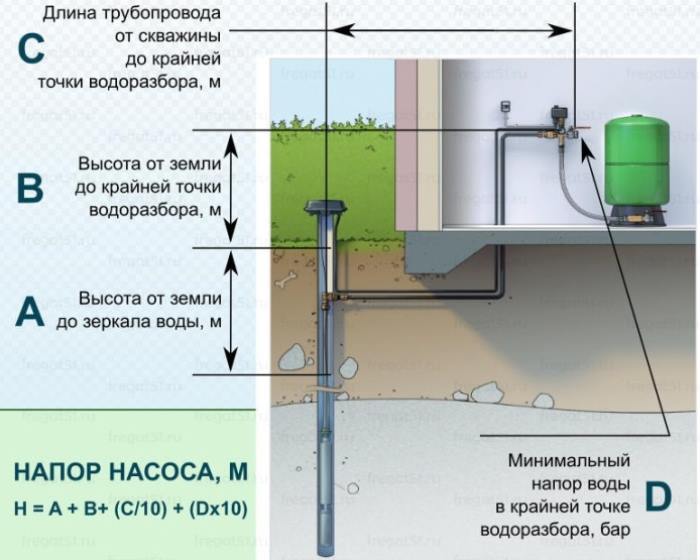

Suction pipe diameter for pumping station

Many parameters of the pumping station itself affect the parameters of the intake pipe. Therefore, it would not be correct to unambiguously recommend a specific diameter.An inch pipe is often used. In any case, a pipe less than 1″ cannot be placed on the suction line.

When using a pumping station to increase the pressure in the network, excess pressure is already applied to the suction pipe, the pump does not suck water up to itself, so the diameter of the supply pipe is not so critical. Suction pipe diameter 1″ is approximately 25 mm inner diameter, usually 32 mm outer (for plastic).

The pump is usually made of metal and is designed to transfer some of the energy to the water. And since it is made of iron and is made in such a way that, for example, 1 cube of water per hour can be raised by 100 meters, it doesn’t matter to him which section of this hundred meters to stand on, either suck this cube from a depth of 100 meters, or push it away from you to a height of 100 meters , or suck in 50 and then push 50. He is made of iron and does not care, his task is 1 cube, 1 hour, 100 meters.

But there is such a thing as atmospheric pressure. And it is it that does not allow water to be sucked in by a value greater than itself. In general, even if we create an absolute vacuum, water will not rise to this vacuum to a height greater than 10.2 meters (theoretically), in practice, the suction height is limited to 7.5-9 meters.

But there is such a thing as atmospheric pressure. And it is it that does not allow water to be sucked in by a value greater than itself. In general, even if we create an absolute vacuum, water will not rise to this vacuum to a height greater than 10.2 meters (theoretically), in practice, the suction height is limited to 7.5-9 meters.

So, a well pump could stand on any part of a 100-meter column, but atmospheric pressure limits its run to the first 9 meters

When installing the pump, it is very important to stay within these 9 meters. And this despite the fact that we still have 90 meters left

Water experiences a friction force that prevents it from rising and, therefore, reduces this same 9-meter section even more. And this force just depends on the diameter of the pipe, the roughness of its walls, the amount of water that you will try to pump through the pipe section.Therefore, the suction pipe (water intake pipe for the pumping station) is made larger, smoother and straighter.

![Installation of suction and discharge pipelines [1951 Rogozhkin n.s. - mechanization of water supply for livestock farms]](https://fix.housecope.com/wp-content/uploads/d/9/c/d9c5d2c20baf1f728beaa71138c30632.jpeg)

![Installation of suction and discharge pipelines [1951 Rogozhkin n.s. - mechanization of water supply for livestock farms]](https://fix.housecope.com/wp-content/uploads/f/5/3/f535f63708c905167dd242ea5f9b2a15.jpeg)

![Installation of suction and discharge pipelines [1951 Rogozhkin n.s. - mechanization of water supply for livestock farms]](https://fix.housecope.com/wp-content/uploads/5/7/8/578a12c686d79d0fc1fd1626c4d25018.jpeg)