- Calculations

- By number of people

- By room area

- By air exchange rate

- What is a check valve for?

- Optimal scheme

- Distance between fasteners

- Recommendations for installation and fastening

- Financial expenses

- Mistakes when installing a kitchen hood

- Calculation algorithm

- Calculation of cross-sectional area and diameter

- Calculation of pressure loss on resistance

- Assembly instructions - all numbers and performance

- Specialized premises

- Duct design and requirements

- Examples

- Installation of supply and exhaust ventilation with recuperation

- Conclusions and useful video on the topic

Calculations

By number of people

In an apartment building, when constructing a ventilation system, it is necessary to calculate the correct parameters and take into account the number of people who live there. You can do this in a private version or order such calculations in specialized firms. When holding an event, it is necessary to take into account the general scheme of the network, the area of \u200b\u200bthe premises, their purpose and the number of inhabitants

It is also important to consider the amount of air exchange. It is measured in cubic meters.

After that, it is necessary to calculate the speed of air movement, which should be 1 m / s.

By room area

Based on the above parameters, experts calculate by drawing up diagrams, which makes it possible to identify the optimal cross-section of the main for certain structures, depending on their area. For example, an air duct with a round section of a box with a diameter of 150 mm or a rectangular one - 200 mm will be optimal for a ventilation system for an industrial premises with a volume of 300 square meters.

By air exchange rate

When laying and constructing an air duct, it is also necessary to take into account the frequency of air exchange and isolate communications, which will help prevent condensation in the network and will become an important component for the smooth operation of the highway. Sometimes additional soundproofing of the duct may be required to ensure that sufficient air is supplied to the structure. In order for the system to function for a long time and smoothly, it is necessary to periodically clean the channels

Often this is done without dismantling communications

In order for the system to function for a long time and smoothly, it is necessary to periodically clean the channels. Often this is done without dismantling communications.

What is a check valve for?

The main function of the valve is to pass air in only one direction, and close immediately if a reverse flow occurs. It is implemented quite simply: the flow area is blocked by a damper rotating on a transverse axis inside the channel. The second option: the passage is closed with thin polymer petals.

Before outlining the scope of valves, we recall an important point: most domestic ventilation systems work in a natural way. The draft of a vertical pipe or shaft creates a vacuum and sucks out air, a fresh influx compensates for the losses.When is a check valve used?

- When connecting a kitchen hood to the shaft outlet. To maintain natural air exchange when the fan is off, the ventilation duct is connected to a tee with a return device.

- If forced emission is organized using a horizontal duct laid through the wall. After the fan stops, the valve will not allow cold air from outside to enter the room.

- In systems of supply and exhaust ventilation with forced impulse - for distribution of flows.

- When it is necessary to eliminate the mistakes of designers or installers of ventilation systems at the lowest cost.

A grill with a ventilation valve helps a lot from blowing wind on the upper floors of high-rise buildings. Another case: the end of the exhaust pipe is not raised high enough above the roof of a country house or is poorly protected from the wind. But the inflow is still needed, otherwise a weak draft will not open the valve flap.

Optimal scheme

There are many schemes and methods for installing a ventilation system in a house. They are selected taking into account the interior decoration, area and other features of the building.

The optimal option should comply with the drafted terms of reference, and also take into account a number of recommendations:

- No extra nodes. The hood should have a minimum number of elements and parts that can fail at the slightest impact.

- Ease of maintenance and repair. Ventilation must be placed in such a way that the master can service it at any time and repair or replace parts.

- Ease of use. The daily operation of the system should be understandable to the owners of the premises, who have neither the skills nor experience in such a matter.

- Backup solutions.In the event of a breakdown of the main components in the building, there should be backup solutions.

- Invisibility in the interior. When designing a ventilation system, it is necessary to take into account the aesthetic part of the work. Any nodes and components of ventilation should not spoil the overall concept of the interior style.

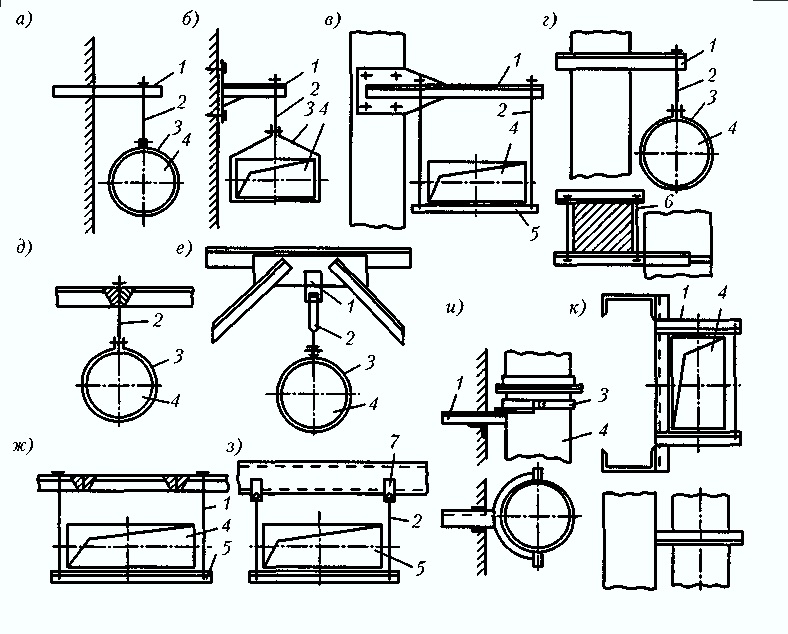

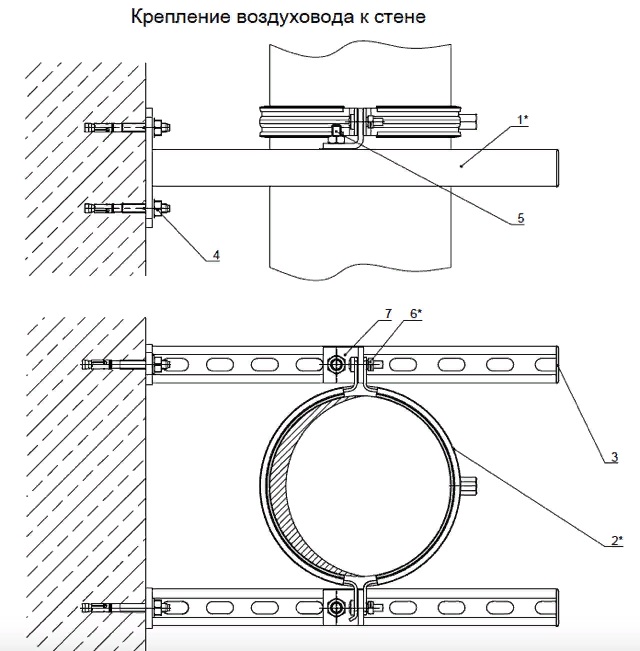

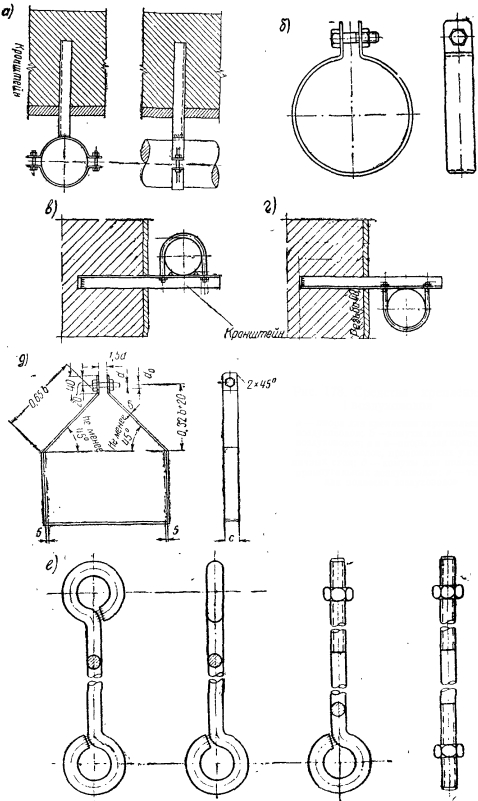

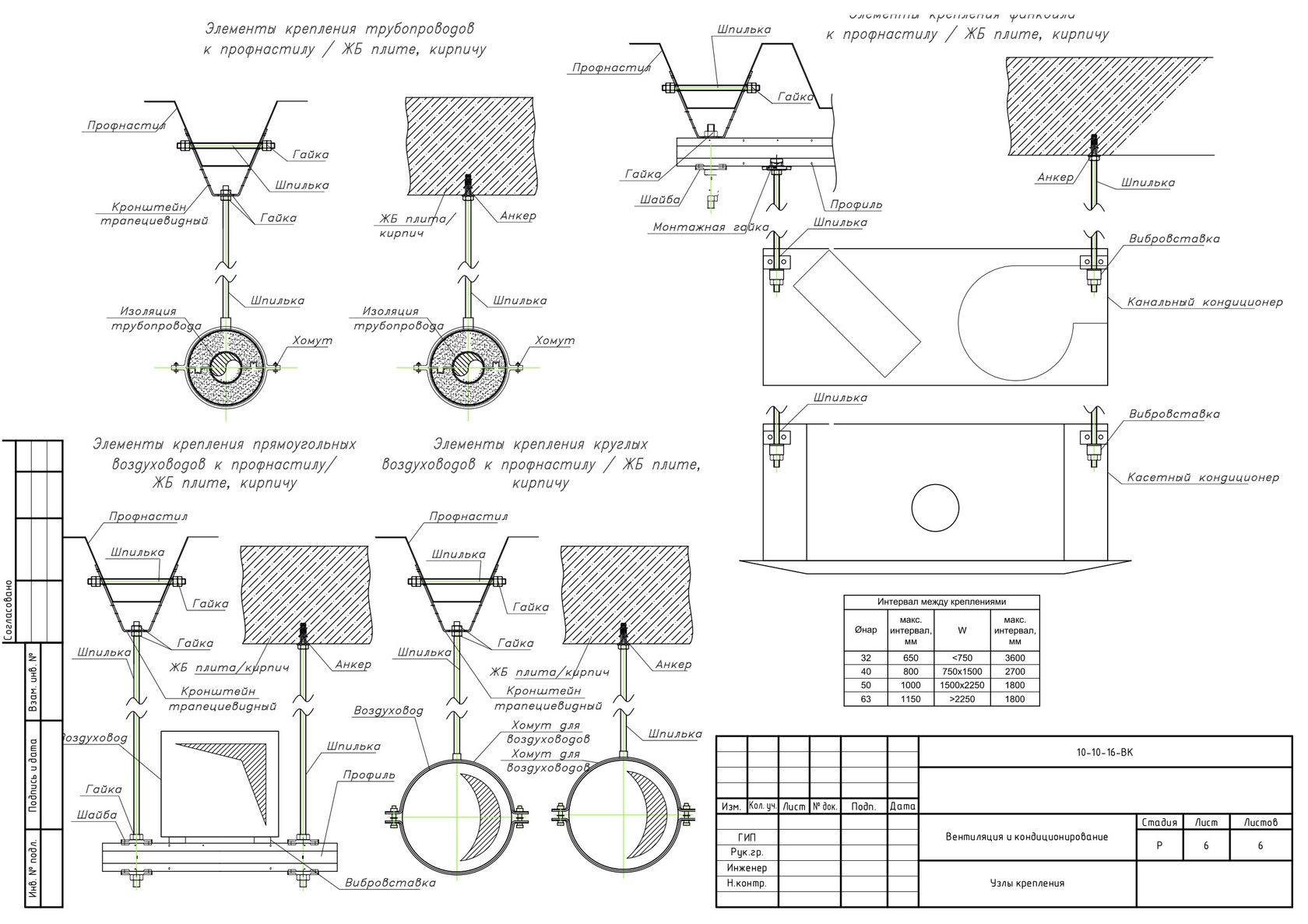

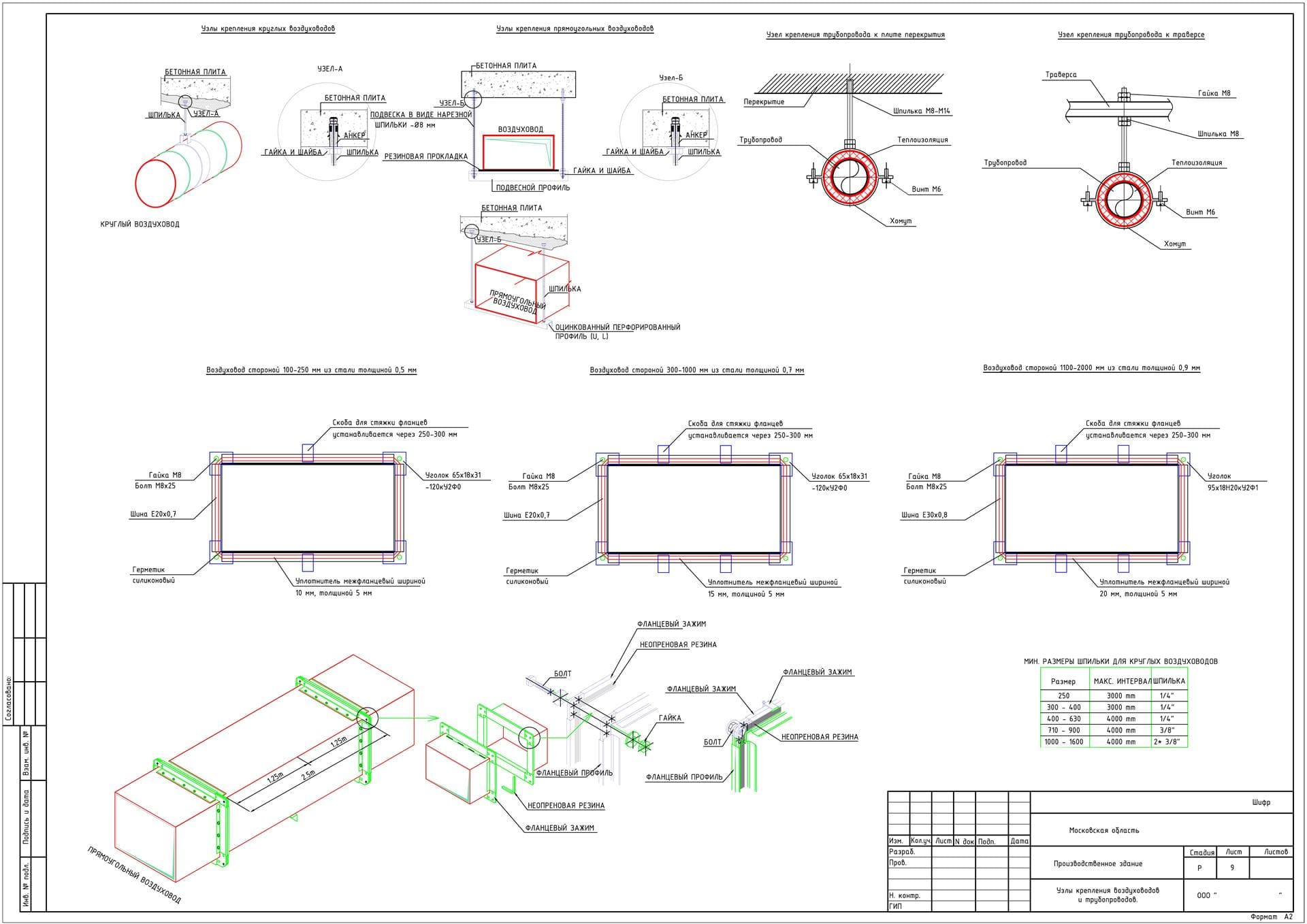

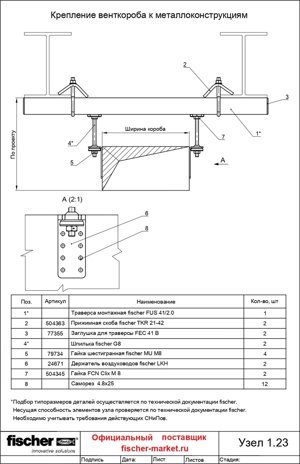

Distance between fasteners

SP 60.13330 and SP 73.13330.2012 indicate how to calculate the fastening of square and round air ducts. The recommendations of equipment manufacturers, prescribed in the instructions, are also taken into account. To get the correct result, you need to know the length of the ducts and the allowable distance between the fasteners.

Fasteners for horizontal non-insulated metal flangeless air ducts are installed at a distance of no more than 4 meters from each other. This requirement applies equally to supports, hangers, clamps.

The rule applies to rectangular and round air ducts, in which the diameter or largest side does not exceed 40 cm. For air ducts with a rectangular cross section or a diameter of more than 40 cm, the distance between the fasteners is reduced to 3 meters.

Horizontal metal non-insulated air ducts on a flange connection with a diameter or larger side up to 2 meters are mounted with a step of no more than 6 meters between fasteners. Flange mounting is not permitted. The maximum distance between the fixings of vertical metal ducts is 4.5 meters.

When designing even the simplest kitchen hood, gaps are left between the surface of the duct and walls, ceilings, other communications and interior items

To connect the main sections of air ducts, flexible air ducts made of a polymer film can be used as fittings. In some cases, they serve as the main elements for building a ventilation line.

For their fastening of flexible polymer air ducts, steel wire rings are used. The diameter of the wire should be within 3-4 mm, and the diameter of the ring itself should be 10 percent larger than the diameter of the duct. The step between the rings is no more than 2 meters.

With this type of installation, a carrier cable is pulled along the duct, to which the rings are attached. The cable itself is attached to building structures in increments of 20 to 30 meters. The flexible duct must be tensioned so that sagging does not form between the rings, which reduces the pressure in the system.

Recommendations for installation and fastening

You can install the ventilation outlet on the roof with your own hands. The installation location of the pipe should be chosen in such a way that, if possible, it passes through the attic without turns. At the same time, it cannot cross the rafters, and even more so the ridge run.

The best option is when the outlet of the ventilation pipe is directly above the internal riser of the ventilation shaft or air duct. If this is not possible, a corrugated pipe can be used for the connection.

The pipe must be connected to the riser strictly vertically

When placing pipes or an exhaust duct, the smallest permissible distance from the supply air intake must be taken into account:

- horizontally - 10m;

- vertically - at least 6m.

The height of the ventilation pipe is determined as follows:

- if it is located near the ridge, the final opening of the hood should rise half a meter above the ridge;

- if from one and a half to three meters remains to the ridge, the hole should be flush with it;

- if the pipe is further than three meters from the ridge, the hole is displayed along the side of the angle of 10 degrees to the horizon with the top on the roof ridge;

- if the ventilation outlet is located next to the chimney, the length of the pipes must be the same;

- on a flat roof, the height of the pipe is calculated according to a special table, but it should not be lower than 50cm.

When installing a pipe on a pitched roof, the ventilation outlet should be placed as close as possible to the highest point of the roof - the ridge. In this case, the largest part of the pipe will be located in the attic or attic space, it will be protected from strong temperature changes and gusts of wind.

The height of the ventilation pipe to the roof is selected depending on the distance from the ridge. These conditions must be observed so that the exit does not end up in the backwater zone.

For a flat roof, the main role is played by the geometry of the duct, which should be located directly under the exhaust pipe so that the air can freely go outside.

Financial expenses

Design and installation of ventilation systems are impossible without financial costs. The services of a professional master will cost more. The final amount of expenses depends on a number of conditions:

- Room area.

- Its intended purpose.

- The number of residents.

- The location of housing in relation to the cardinal points.

- The size and number of window openings.

Evaluation of the listed parameters allows you to navigate the choice of equipment for self-installation of ventilation.For example, the approximate cost of work for a two-room apartment with a minimum number of medium-sized windows facing the north side is 40 thousand rubles.

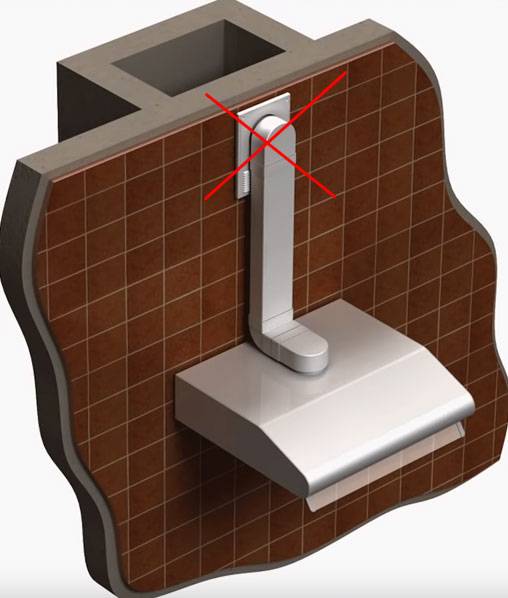

Mistakes when installing a kitchen hood

1

Some, of course, leave a grate for the natural movement of air, but at the same time manage to block it anyway with the air duct itself.

2

The recommended dimensions for round air ducts are d=125mm. For rectangular - 204 * 60mm.

3

In most cases, this is prohibited by the rules. Further on the text will be given specific points.

Of course, you can lay a separate box along the facade straight to the roof. But is it worth it? Although in restaurants and cafes located on the first floors of high-rise buildings, this solution is widely used.

By the way, the ban on air outlet through the wall does not apply to private houses, but only to high-rise buildings.

4

First of all, it will affect the noise. Although, of course, the turns themselves are not the greatest evil. And sometimes you can't do without them.

It is the turns that go one after the other, without accelerating sections, that are dangerous.

5

Remember that a capacity of 200-300 m3 / h is quite enough for the high-quality removal of all odors, with a minimum load on the ventilation of the house.

6

The installation height directly depends on what kind of stove you have - gas or induction cooking.

7

Believe me, sometimes this design has to be disassembled.

8

Why this is a mistake, and when it is still possible to do so, is discussed further.

9

As a result, connecting it at random, through carrying and extension cords. Keep in mind that it is not, after all, a portable appliance, such as a fan, heater, or mobile air conditioner.

This means that the wiring under it must be done stationary and wisely.

10

It must be cut and installed in compliance with the appropriate angles and inclinations. Otherwise, it will work through time.

In general, the installation of the hood can be divided into two main stages. First, it is its connection to electricity. The second is the air duct device and everything connected with it.

Let's look at each of them separately.

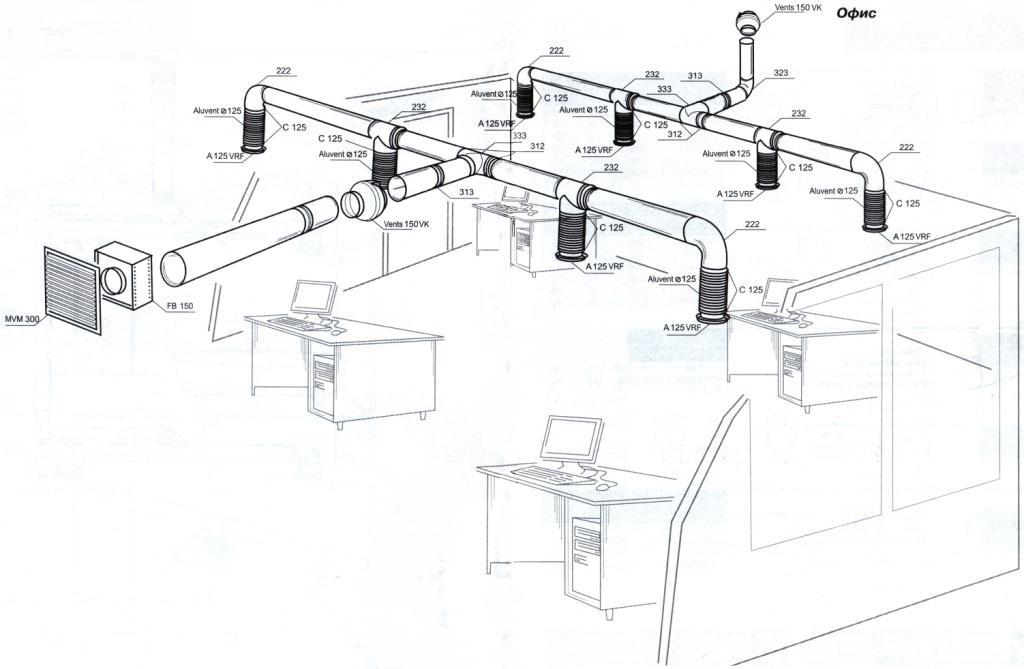

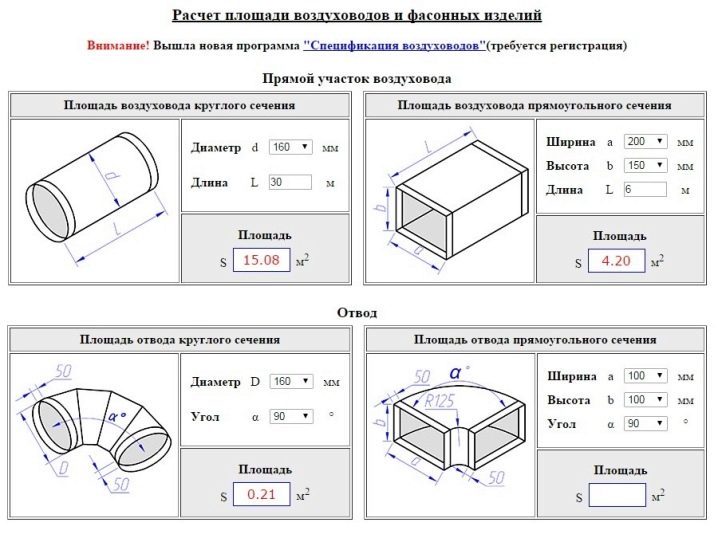

Calculation algorithm

When designing, setting up or modifying an existing ventilation system, duct calculations are required. This is necessary in order to correctly determine its parameters, taking into account the optimal characteristics of performance and noise in actual conditions.

When performing calculations, the results of measuring the flow rate and air velocity in the air duct are of great importance.

Air consumption - the volume of air mass entering the ventilation system per unit of time. As a rule, this indicator is measured in m³ / h.

Movement speed is a value that shows how fast air moves in the ventilation system. This indicator is measured in m/s.

If these two indicators are known, the area of circular and rectangular sections, as well as the pressure required to overcome local resistance or friction, can be calculated.

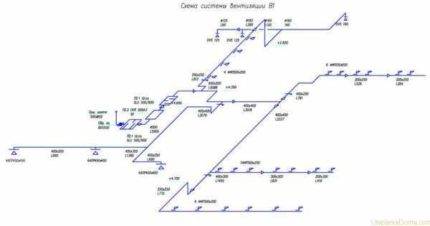

When drawing up a diagram, you need to choose the angle of view from that facade of the building, which is located in the lower part of the layout. Air ducts are displayed as solid thick lines

When drawing up a diagram, you need to choose the angle of view from that facade of the building, which is located in the lower part of the layout. Air ducts are displayed as solid thick lines

The most commonly used calculation algorithm is:

- Drawing up an axonometric diagram in which all elements are listed.

- Based on this scheme, the length of each channel is calculated.

- The air flow is measured.

- The flow rate and pressure in each section of the system is determined.

- Friction losses are calculated.

- Using the required coefficient, the pressure loss is calculated when overcoming local resistance.

When performing calculations on each section of the air distribution network, different results are obtained. All data must be equalized using diaphragms with the branch of the greatest resistance.

Calculation of cross-sectional area and diameter

The correct calculation of the area of circular and rectangular sections is very important. An unsuitable section size will not allow for the desired air balance.

Too large a duct will take up a lot of space and reduce the effective area of the room. If the channel size is too small, drafts will occur as the flow pressure increases.

In order to calculate the required cross-sectional area (S), you need to know the values \u200b\u200bof the flow rate and air velocity.

For calculations, the following formula is used:

S=L/3600*V,

while L is the air flow rate (m³/h), and V is its speed (m/s);

Using the following formula, you can calculate the duct diameter (D):

D = 1000*√(4*S/π), where

S - cross-sectional area (m²);

π - 3.14.

If it is planned to install rectangular rather than round ducts, instead of the diameter, determine the required length / width of the air duct.

All obtained values are compared with GOST standards and products are selected that are closest in diameter or cross-sectional area

All obtained values are compared with GOST standards and products are selected that are closest in diameter or cross-sectional area

When choosing such an air duct, an approximate cross section is taken into account. The principle used is a*b ≈ S, where a is the length, b is the width, and S is the sectional area.

According to the regulations, the ratio of width and length should not exceed 1:3.You should also refer to the standard size table provided by the manufacturer.

The most common dimensions of rectangular ducts are: minimum dimensions - 0.1 m x 0.15 m, maximum - 2 m x 2 m. The advantage of round ducts is that they have less resistance and, accordingly, create less noise during operation.

Calculation of pressure loss on resistance

As air moves through the line, resistance is created. To overcome it, the air handling unit fan creates pressure, which is measured in Pascals (Pa).

Pressure loss can be reduced by increasing the cross section of the duct. In this case, approximately the same flow rate in the network can be provided.

Pressure loss can be reduced by increasing the cross section of the duct. In this case, approximately the same flow rate in the network can be provided.

In order to select a suitable air handling unit with a fan of the required capacity, it is necessary to calculate the pressure loss to overcome local resistance.

This formula applies:

P=R*L+Ei*V2*Y/2, where

R is the specific pressure loss due to friction in a certain section of the duct;

L is the length of the section (m);

Еi is the total coefficient of local loss;

V is the air speed (m/s);

Y – air density (kg/m3).

The R values are determined by the standards. Also, this indicator can be calculated.

If the duct is round, the friction pressure loss (R) is calculated as follows:

R = (X*D/B) * (V*V*Y)/2g, where

X - coefficient. friction resistance;

L - length (m);

D – diameter (m);

V is the air speed (m/s) and Y is its density (kg/m³);

g - 9.8 m / s².

If the section is not round, but rectangular, it is necessary to substitute an alternative diameter in the formula, equal to D \u003d 2AB / (A + B), where A and B are the sides.

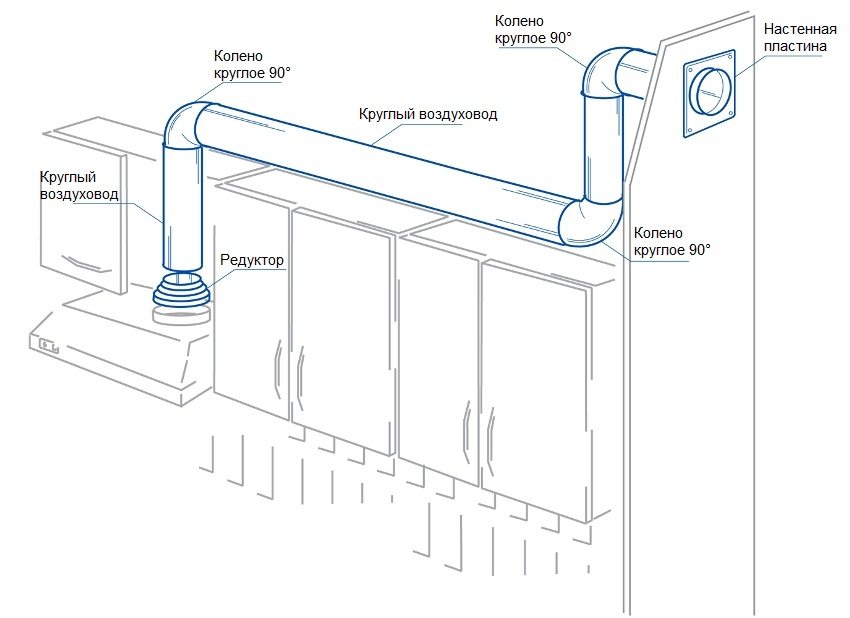

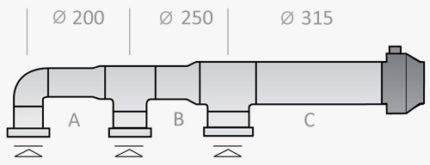

Assembly instructions - all numbers and performance

How is it all put together in practice? For capacities up to 300 m3 / h (low speeds of most hoods), a d-125mm pipe is enough. On the device itself, the outlet can be large.

For example, for 650 m3 / h you will need a d-150mm pipe. However, you are unlikely to find such plastic pipes, and if you use the next standard size d-160mm, then this will turn out to be a huge and clumsy structure that spoils the entire interior and kitchen design.

Moreover, you will have to hammer a factory ventilation duct hole in the wall, expanding it.

Therefore, in most cases, the optimal diameter of 125 mm is chosen. And you don't need more.

Forced capacity of standard channels and shafts with dimensions of 100 * 150mm - 400 m3 / h.

An air flow of more than 450 m3 / h will simply not fit in there (it was tested in practice), even if it is written on your hood - 1200 m3 / h!

Remember also that it is impossible to overestimate the diameter of the duct compared to the outlet pipe on the hood. Otherwise, the vibration and noise will be so strong that the structure will have to be glued again every month.

The connection of different diameters is done using special adapters.

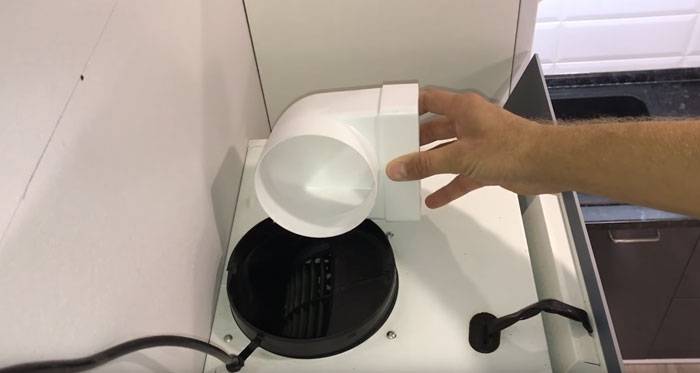

Let's start assembling. At the beginning, install the adapter on the hood and connect a vertical section to it.

To improve its sound insulation, it makes sense to get confused and stick a heat-sound insulating material 5 mm thick on top.

They also do not hurt to glue the decorative casing from the inside and the noisiest part - the adapter. It is there that the greatest turbulence is observed.

Next, use 90-degree elbows and other straight sections of duct as needed to eventually exit towards the hole in the wall.

All this is glued together with silicone, no superglues. There should be no cracks anywhere.

We get to the trio. A valve is installed in it from the side of the room.

Be aware that this is a gravity acting valve! It opens not due to the flow of air, but due to its own weight.

It has one half heavier than the other and at the same time it is set at a slight angle of 2 degrees.

Specialized premises

Features of the manufacture of ventilation directly depend on the functions and specifics of the room where it will be installed. If the natural type cannot provide effective air exchange, a forced one will have to be installed. This variety is suitable for specialized rooms such as bathroom, kitchen and toilet.

When installing important components of the future system, you need to be guided by certain requirements:

Kitchen exhaust units should handle as much free space as possible above the hob, but not overlap the exhaust grille on top of the wall.

To reduce electricity consumption while the bathroom fan is running, it must be connected to a light switch. In this case, the device will start only when a person stays in the room.

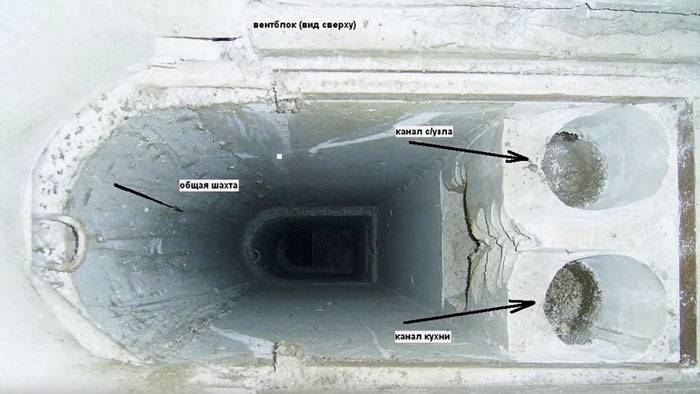

The ventilation of the bathroom is equipped with a special box, which is connected to a common shaft, and check valves are installed on the fans. Thus, the air flows from the toilet and the bathroom will not mix.

Bathroom models should be as reliable and resistant to high humidity as possible.

Experts advise using devices fixed in a polypropylene or acrylic case.

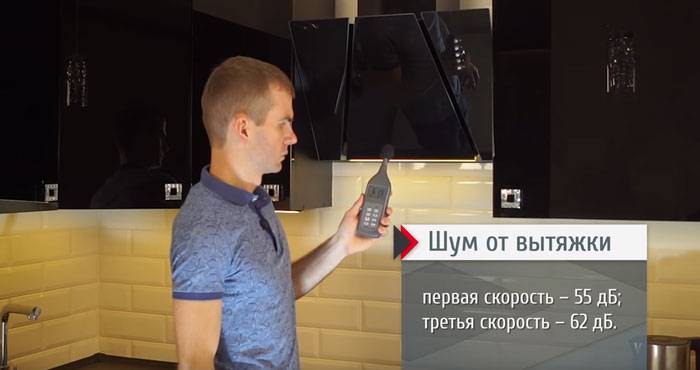

When buying a silent fan, it is important to understand that such devices are much quieter, but they consume a lot of electrical energy.

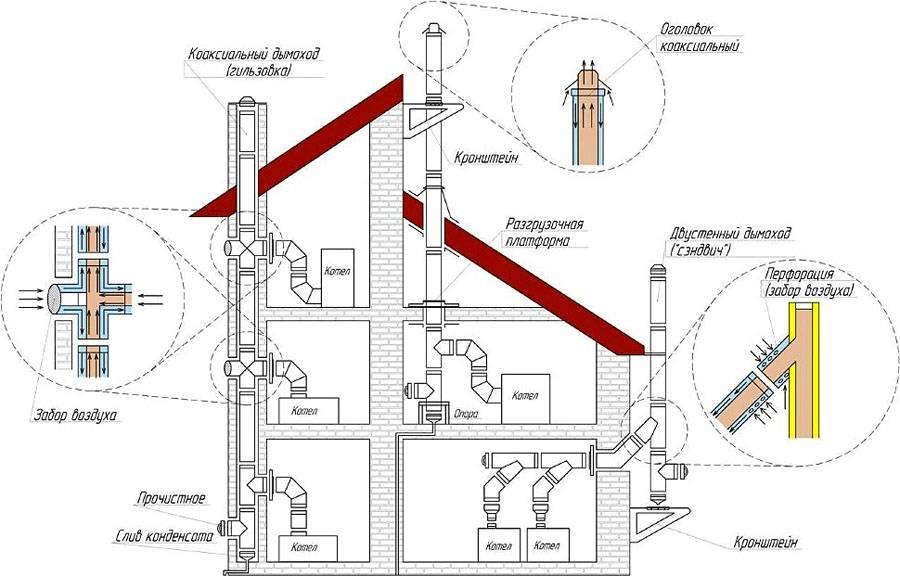

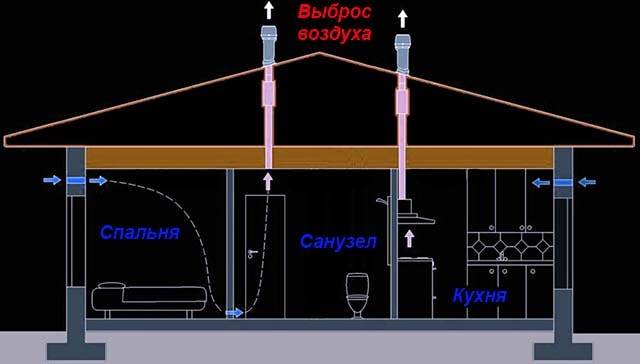

Duct design and requirements

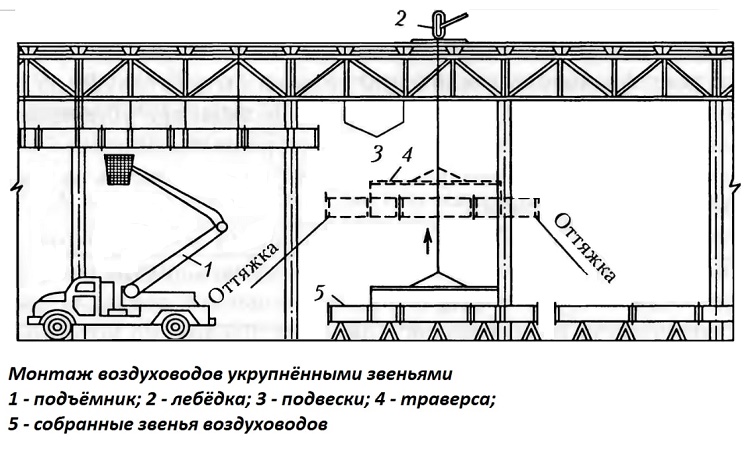

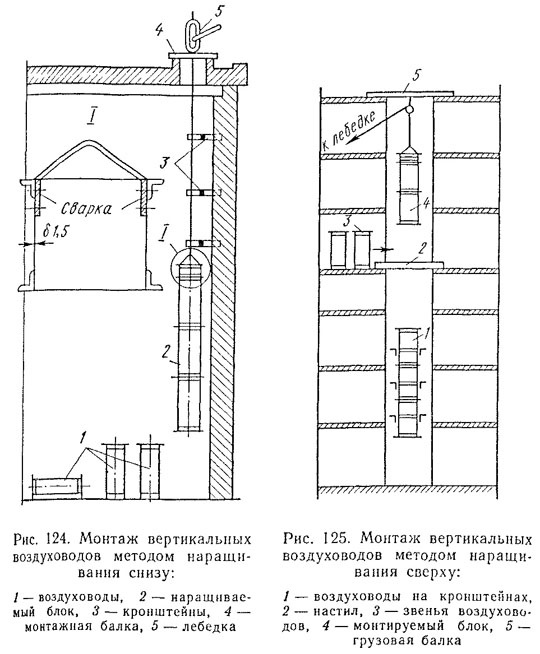

The movement of air flows inside the building and outside is carried out through vertical and horizontal ventilation ducts. Installation of ventilation pipes is carried out according to the design marks indicated in the working drawings. Installation rules are given in the regulatory collections SP 73.13330.2016 and SP 60.13330.2016.

Ventilation ducts can be laid out inside the main walls or located in the premises of the house under the ceiling or along the walls. Often, circumstances dictate the design of air ducts outside the building.

It happens that the laying of air ducts is carried out outside the building. The prerequisites for such a decision are mainly related to the conversion of residential facilities into commercial or industrial

Separation of channels by functionality:

- supply - through them fresh air enters the house;

- exhaust - to remove polluted air masses.

With natural ventilation in a private house, all exhaust ducts can pass in one shaft. For this room with high humidity, unstable temperature and characteristic vaporization, from which the used air is removed, the designers try to place them next to each other.

There are a number of requirements for ventilation ducts:

- tightness;

- noiselessness;

- compactness, location in hidden parts of the house;

- strength, durability.

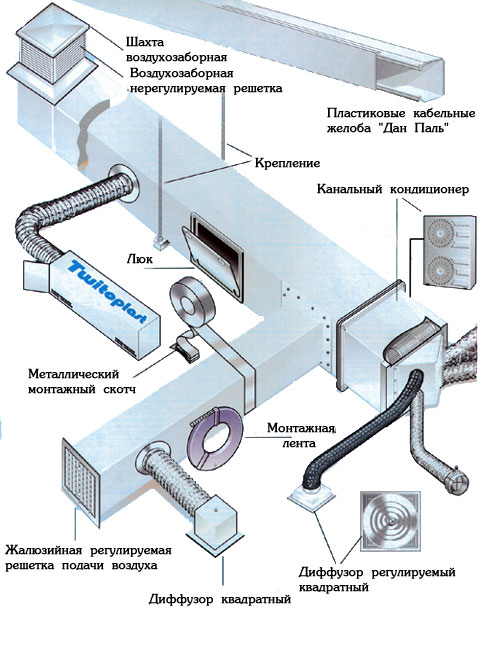

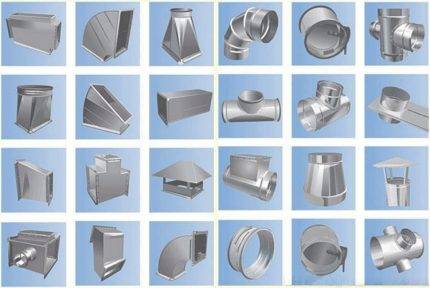

During installation, a spatial structure of air ducts is created from individual standard parts. For its construction, in addition to rectilinear elements, additional shaped parts are used.

The elbow is used to rotate the channel by 90 degrees. Tee and cross are designed to create branches from the main. Umbrellas prevent debris and precipitation from entering the pipe. The nipple connects all the parts together

The elbow is used to rotate the channel by 90 degrees. Tee and cross are designed to create branches from the main. Umbrellas prevent debris and precipitation from entering the pipe. The nipple connects all the parts together

According to the external configuration, round and rectangular air ducts are used. Pipes with cylindrical shapes have optimal data for the unhindered movement of air masses. Rectangular boxes allow you to save free space, they are easy to hide behind false walls and false ceilings.

Air ducts are rigid and flexible. Rigid highways are made in both round and rectangular versions according to VSN 353-86, TU-36-736-93.

For the hard version, materials are used:

- cold-rolled galvanized steel - 0.5 - 1.0 mm;

- hot-rolled sheet steel - 0.5 - 1.0 mm;

- polymers - 1.0 - 1.5 mm.

For wet rooms, air ducts made of plastic or stainless steel with a thickness of 1.5 - 2.0 mm are suitable. In chemically active zones, pipes made of metal-plastic, aluminum and its alloys are used.

Flexible channels are made in the form of pipes made of soft material. They are often used as convenient inserts for connecting rigid ducts to ventilation equipment.

On the cross section, the multilayer structure of the flexible insulated channel is clearly visible: a soft shell, a reinforcing plastic or metal frame. Obedience to pipes is given by materials: aluminum foil, polyester, silicone, textiles, rubber

Curved ventilation ducts are suitable for moving air at low speed and pressure.

In residential buildings, PVC ventilation pipes with high heat and sound insulation properties are often installed.

Typical PVC parts are connected using:

- one-piece contacts - butt welding or welded sleeves;

- detachable elements - flanges, couplings, sockets.

Fixings to PVC air ducts are used both suspended and supporting.

Thermal insulation protects ventilation ducts from condensation. This mainly applies to industrial and unheated premises. For private houses and offices, thermal insulation is used when insulating ventilation in the attic. Soundproofing of pipes is carried out in living rooms.

Be sure to ground the metal ventilation pipes to remove the accumulated static voltage.

Examples

Schematic diagram for installation in country houses and in the country - ventilation with natural air circulation. It is suitable for brick and wooden buildings, as well as structures made of expanded clay concrete. As a rule, the design of just such a scheme prevails in the construction of apartment buildings. If you have purchased an apartment in Khrushchev, then be guided by the fact that there will be natural ventilation.

Natural air exchange is based on the phenomenon of the pressure difference of the air column. The ventilation system is easy to install and operate, does not depend on the availability of electricity, does not require the installation of expensive equipment. However, the system is affected by weather conditions, in particular wind, and temperature, since natural circulation requires that the temperature inside the room is higher than outside. Otherwise, air movement stops.

In the age of developing technology, many use forced ventilation. It can be partially automated, when the equipment is used only to force air into the building, or, conversely, to remove fumes to the outside, or fully mechanized, which involves the use of fans at both stages.

Since the ventilation shaft in the kitchen usually has a larger diameter, all flows rush to it. In windy weather, this powerful channel can “overturn” the smaller one in the bathroom, forming a reverse draft, that is, a cold wind will begin to blow from the toilet. In this case, a competent installation of forced ventilation is necessary.

A ventilation system is also required on a glazed balcony or landscaped loggia. There are several options for its arrangement. First of all, it is natural due to the opening of windows, but during the cold period it is not always convenient. Some window manufacturing companies build ventilation holes in them, with the help of which micro-ventilation is carried out. More often, the owners install a hood, which ensures the removal of condensate.

The supply and exhaust circuit is necessary for ventilation in a room without windows, for example, a pantry. In particular, for security reasons, many technical premises require to be equipped with a forced system (garages, boiler rooms, boiler rooms, warehouses).

The ventilation complex in the case of a mixed scheme is a system of pipes, some of which draw in air from the outside, others take the exhaust air outside the building. The inflow is provided by a convector, which additionally heats, filters and disinfects the flow from the street with ultraviolet light.In order to prevent the forced air from expelling heat from the room during the cold period, a special heat exchanger was developed - a heat exchanger, which is designed to use the temperature of the outgoing stream to heat the incoming one.

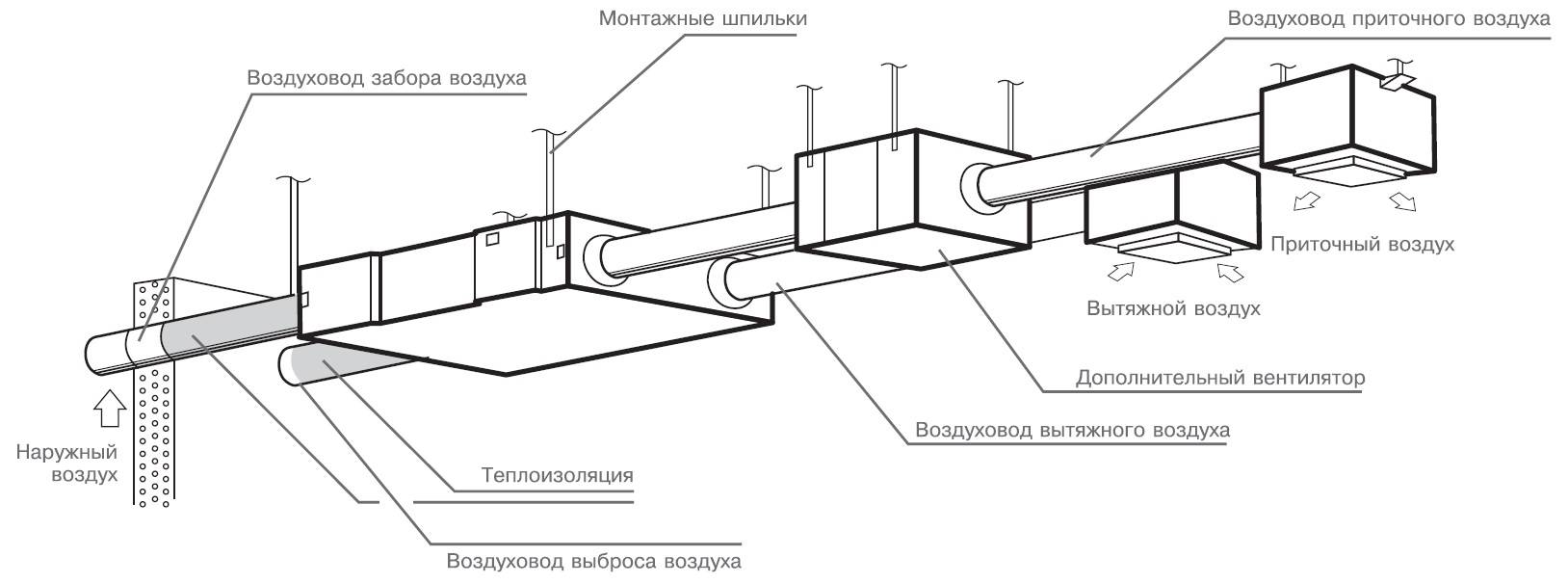

Installation of supply and exhaust ventilation with recuperation

In winter, heated housing can very quickly give off warm, heated air, while a lot of energy is spent on heating the incoming cold air. Ventilation "with repayment" is a system in which a special device is installed - a heat exchanger. Thanks to its heat exchanger, the air entering from the street is heated from the outgoing warm air, without mixing with it.

If a heat exchanger is included in the ventilation circuit, the inlet and outlet channels must converge and run in parallel in the device case.

Recuperator in the ventilation system

It is not advised to place the heat exchanger above living rooms. It is better to place it in the corridor or utility room.

You need to take into account in which position it is advised to install a particular model. Sometimes appliances need to be installed only vertically, or only flat.

If the design of the heat exchanger provides for the collection of moisture, it should be located only in a warm room. Drainage is done at an angle to the nearest sewer riser.

Pay attention to recuperators with cellulose cassettes. Such devices are not so prone to icing, do not require drain installation

In addition, having been absorbed into the cellulose walls, moisture enters the incoming flow channel and moistens it. Thus, the recuperator becomes a bit of a humidifier.

Conclusions and useful video on the topic

Video #1 About the device of natural ventilation in a private house:

Video #2A visual aid on the purpose and use of a brick ventilation duct in a country house:

Video #3 How to make the laying of ventilation ducts from solid bricks:

Video #4 Detailed recommendations on the rules for arranging ventilation in a private house:

Video #5 About the system of ventilation ducts made of flexible plastic pipes in a country cottage:

Having studied the features of choosing a ventilation system, you can choose the most appropriate option for your private home. And whether it is worth equipping ventilation ducts on your own or is it better to invite a team of specialists, it completely depends on the complexity of the chosen system, the area of \u200b\u200bthe house and personal skills.

If you have suggestions or interesting information on the installation of ventilation ducts, you know how to effectively modernize ventilation, please write comments. To place them after the text of the article there is a block. Here you can ask questions and point out shortcomings.