- Internal or external laying

- Laying scheme

- Benefits of using polypropylene in heating systems

- Water supply system design

- Wiring for plumbing

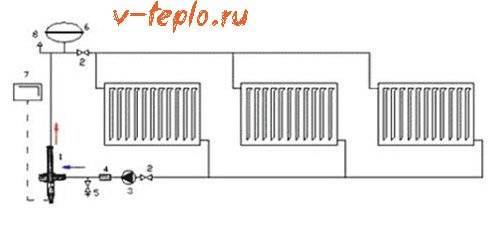

- Wiring for the heating system

- Checking the quality of joints

- Installation of pipes in a private house

- The most common mistakes and how to avoid them

- Connection principle

- What will be required in the work

- Prices for the installation of water supply from polypropylene pipes

- Accessories for polypropylene pipes

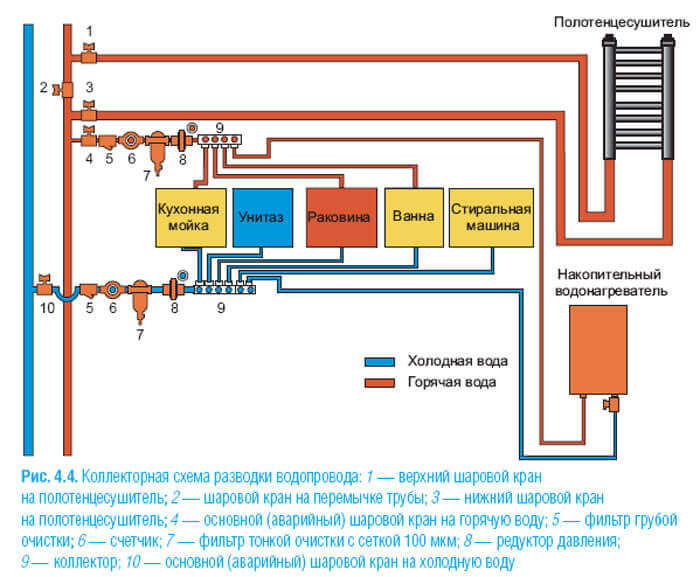

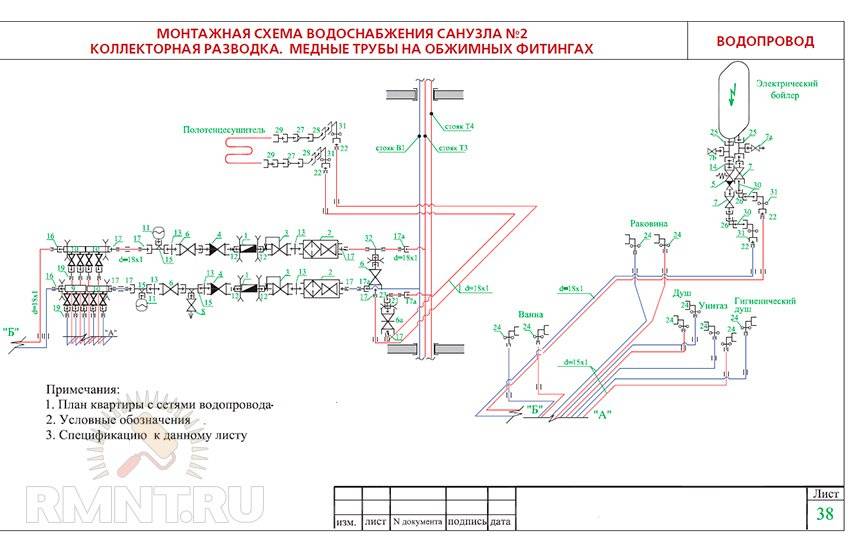

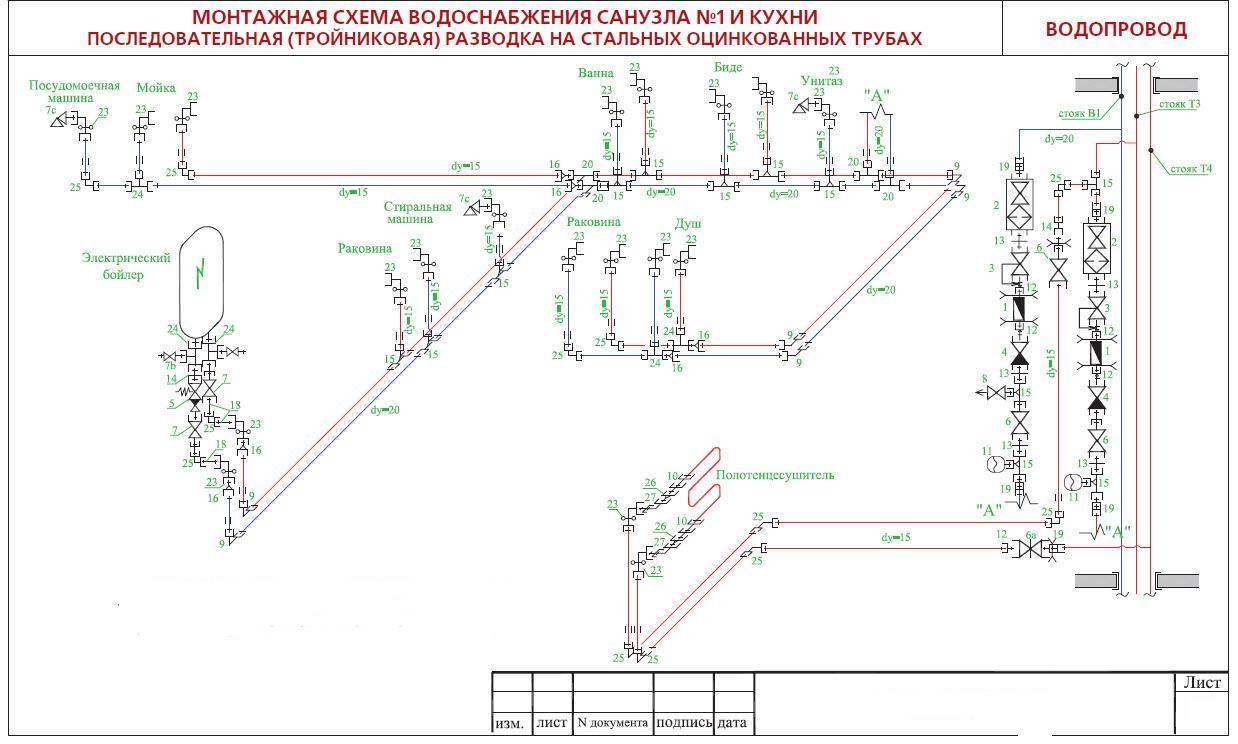

- Plumbing scheme

- Plumbing in private homes

- PP pipe manufacturers

- Possible or not

Internal or external laying

One of the advantages of polypropylene plumbing is that it can be easily embedded in walls and floors. This material does not corrode, does not react with any materials, and does not conduct stray currents. In general, if the connection is made correctly, pipes can be hidden into the wall or into the floor without any problems. The whole catch is to make a quality connection.

Polypropylene plumbing can be hidden in walls or in the floor

To make sure that the assembled system does not leak, it is checked - pressure testing is carried out. There are special devices for this. They connect, pump water, increase pressure.Under this pressure, the water supply is left for several days. If no leaks were found, then at operating pressure everything will work for a long time and without problems.

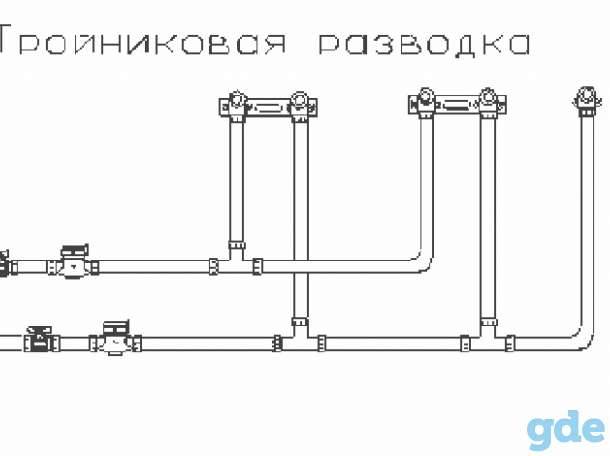

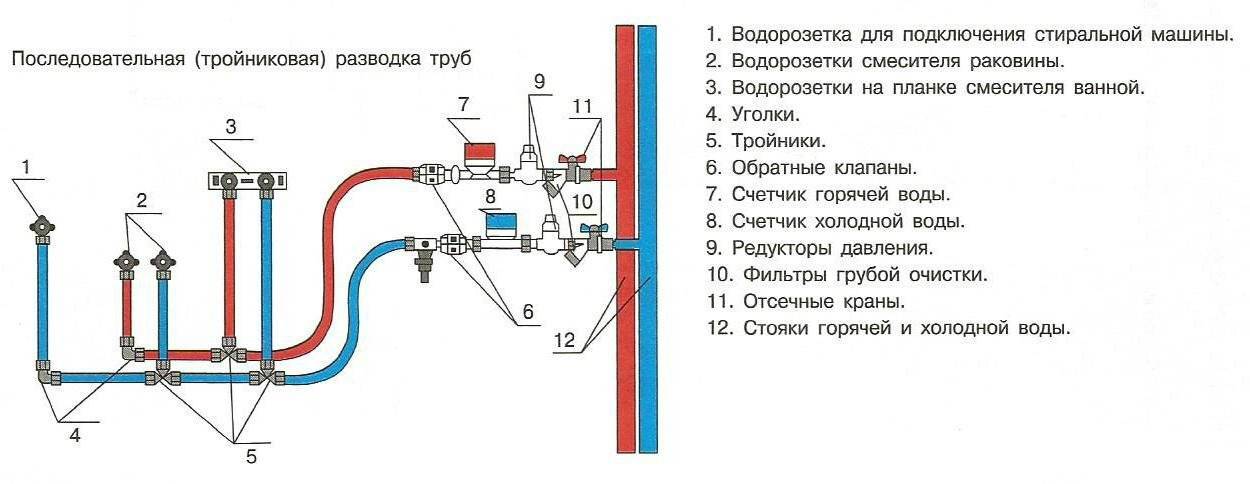

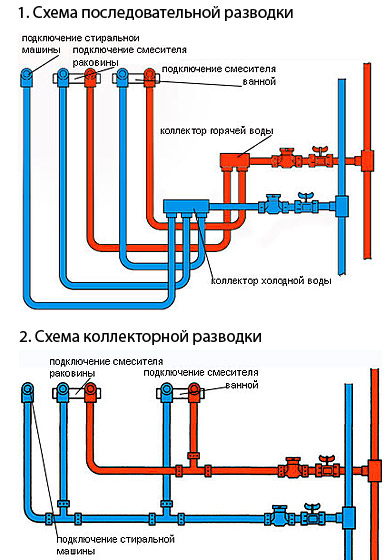

Laying scheme

- consistent;

- parallel.

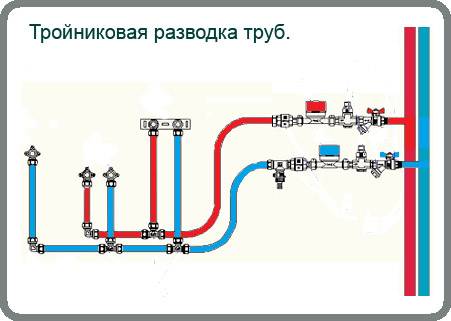

Serial connection is carried out at one point with a branch from the main pipe, using tees for pipeline branches. This is the most economical system, but when several consumers are connected at the same time, a sharp decrease in the water pressure in the network is possible.

The wiring diagram is drawn up taking into account all changes made during the work, and must contain accurate information about the pipeline. During the construction of a residential building, the plumbing piping scheme is included in the overall design of the building.

The diagram shows:

- laying pipes for cold and hot water supply;

- drains and safety valves;

- location of control devices;

- fittings special;

- point of input for analysis of water from a centralized conduit;

- spare conduit scheme;

- water inlet and outlet.

You may also be interested in an article about doing piping in the bathroom with your own hands.

Read an article about the features of the collector wiring of water supply pipes in an apartment here.

Benefits of using polypropylene in heating systems

There are many such advantages:

- Easy installation. As already mentioned, even one person with a soldering iron can handle it, while a welder is required to install steel pipes.

- Heating with plastic pipes will cost you many times cheaper.

- This material is not subject to corrosion, so it can last up to fifty years.

- Its use has a positive effect on the heat transfer of the system.

- Such pipes do not “overgrow”, that is, salts are not deposited on their inner surface.

- Finally, polypropylene, although flexible, is also very strong, so it can be used at high pressures or temperatures.

Pipe selection video

All this contributes to the fact that heating systems using polypropylene pipes are increasingly common today.

Which pipes should be used for heating systems?

When choosing pipes made of polypropylene, it is necessary to compare the features of your future heating with the conditions under which this or that material can be used. For heating systems, it is desirable to use the following brands of pipes:

- PN25.

- PN20.

The fact is that they perfectly tolerate the coolant temperature of ninety degrees, and for some time (albeit limited) withstand an unexpected jump to one hundred degrees. Such pipes must be used under conditions where the pressure will not exceed 25 and 20, respectively, atmospheres. But if you choose between these options, then, of course, for heating systems it is better to choose a reinforced pipe PN25.

Read also how to connect a thermostat to a heating system

Why is that? The fact is that its design has a foil that significantly increases the strength of the product. So it will be less deformed due to thermal expansion.

The main thing is a competent project

If your plans include the installation of heating from polypropylene pipes on your own, then the first thing to do is to draw up the right project. It is extremely difficult to do this without the appropriate education, so let the experts do it.

Everything is explained by the fact that there are a lot of factors affecting the operation of heating, and an ignorant person can hardly take all of them into account. Here they are:. Correct selection of diameter

Correct selection of diameter

It is worth remembering that there are pipes of different diameters in the system, which makes it possible to obtain the most efficient circulation of the heat carrier.

The number of heating devices, as well as their location, will play an important role in the temperature.

The angles of inclination of plastic pipes must be normalized, which is especially important in systems with natural circulation. Although, if you look, and in the case of forced circulation, this is also important.

The temperature and pressure of the coolant also largely depend on the marking of the pipes. The best option is reinforced pipes made of polypropylene.

The best option is reinforced pipes made of polypropylene.

Important! Before drawing up a project, it is necessary to take into account all the features of the room, to find out whether it is possible to install one or another heating system in it. Based on this, you should draw up a project. This project should include the following:

This project should include the following:

- Drawing of the boiler piping.

- All pipe diameters used.

- Nuances of fastening and installation of all heating devices.

- Information about pipe inclination angles.

If you are planning to install a heating system in a greenhouse, see the instructions here

It is for this project that further installation of heating from polypropylene pipes should be carried out. It will look something like this.

In addition, it is worth adding that there are two types of plastic pipe installation schemes:

- With bottom spill. There is a special pump that distills water.The advantage of such a system is that it can be used even in houses with two or more floors. Moreover, the diameter of the pipes here may be smaller, and the wiring diagram does not play any role at all.

- With an overflow, in which the coolant moves on its own, driven by the difference in temperature. This system is very common in the private sectors. It is characterized by simplicity and convenience, it does not need pumps or other additional equipment, so there will be no special costs.

Water supply system design

The basis for creating a normally functioning water supply system is a well-made project. To do this, a thorough measurement of all premises in which pipelines are planned is carried out. Based on these measurements and the location of the plumbing, a plumbing scheme is made. It should be tied to the building plan and executed in an appropriate scale.

During the design process, you need to determine:

- Number of consumers;

- Length and diameter of pipe openings;

- Number of connections and bends of the pipeline;

- The required number of adapters, splitters and other connecting elements;

- The possibility of placing sections of the pipeline inside the walls and under the floor;

- Locations of connections and the ability to provide unhindered access to them;

- The location and size of all possible obstacles and options for bypassing them.

- All sizes in one table.

When drawing up a project, it should be taken into account that the number of bends and connections should be minimal, since bends affect the loss of water pressure in the pipes, and there is a risk of leaks at the joints of pipeline sections. Pipes should also be located away from heat sources, since plastic pipes are subject to deformation under the influence of high temperature.

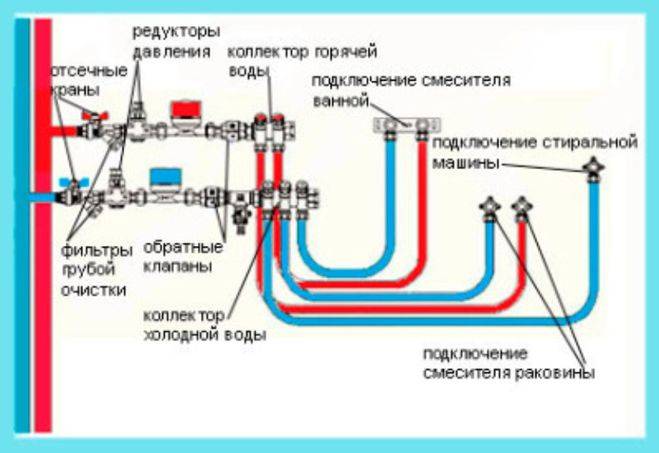

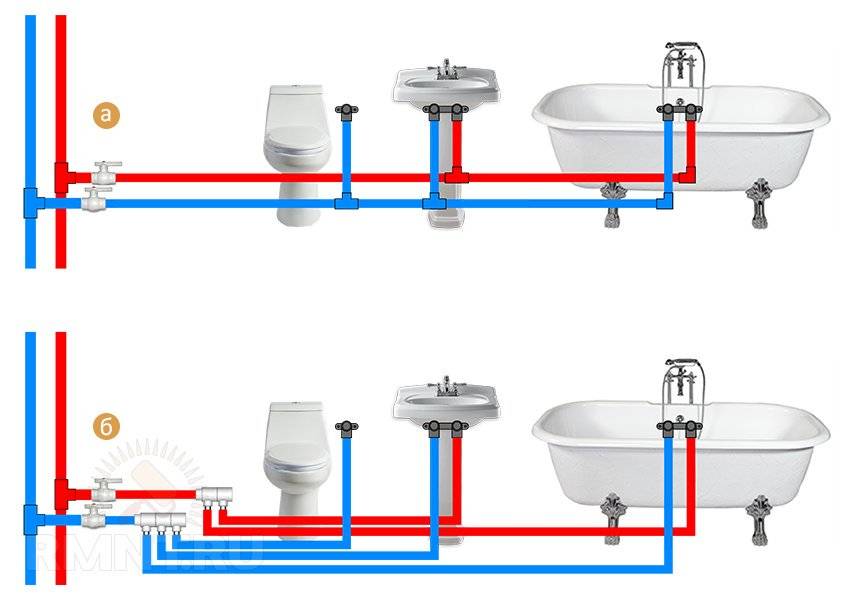

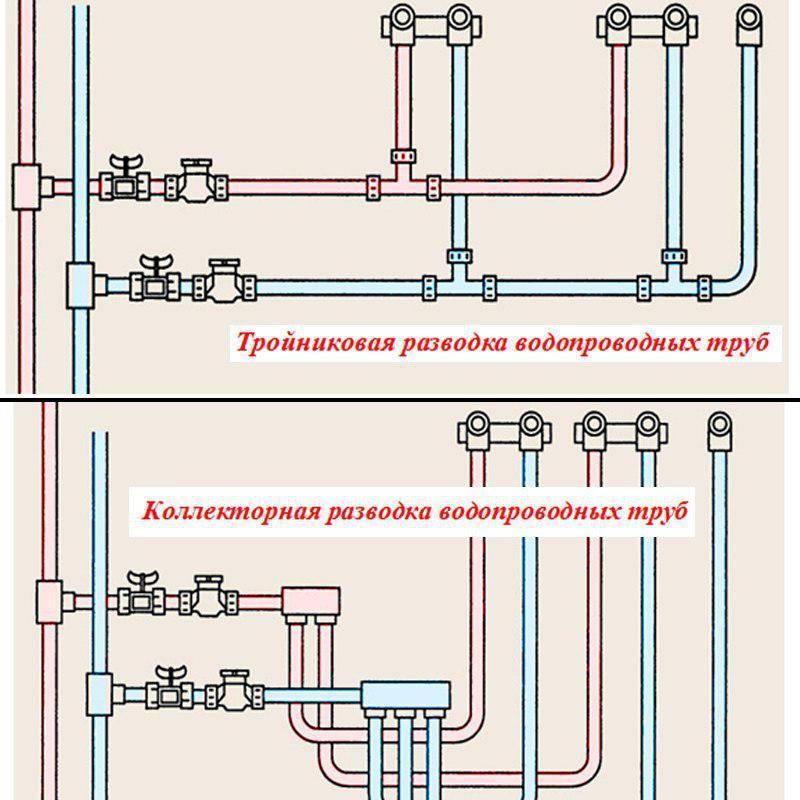

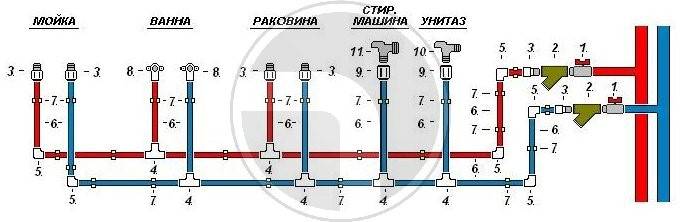

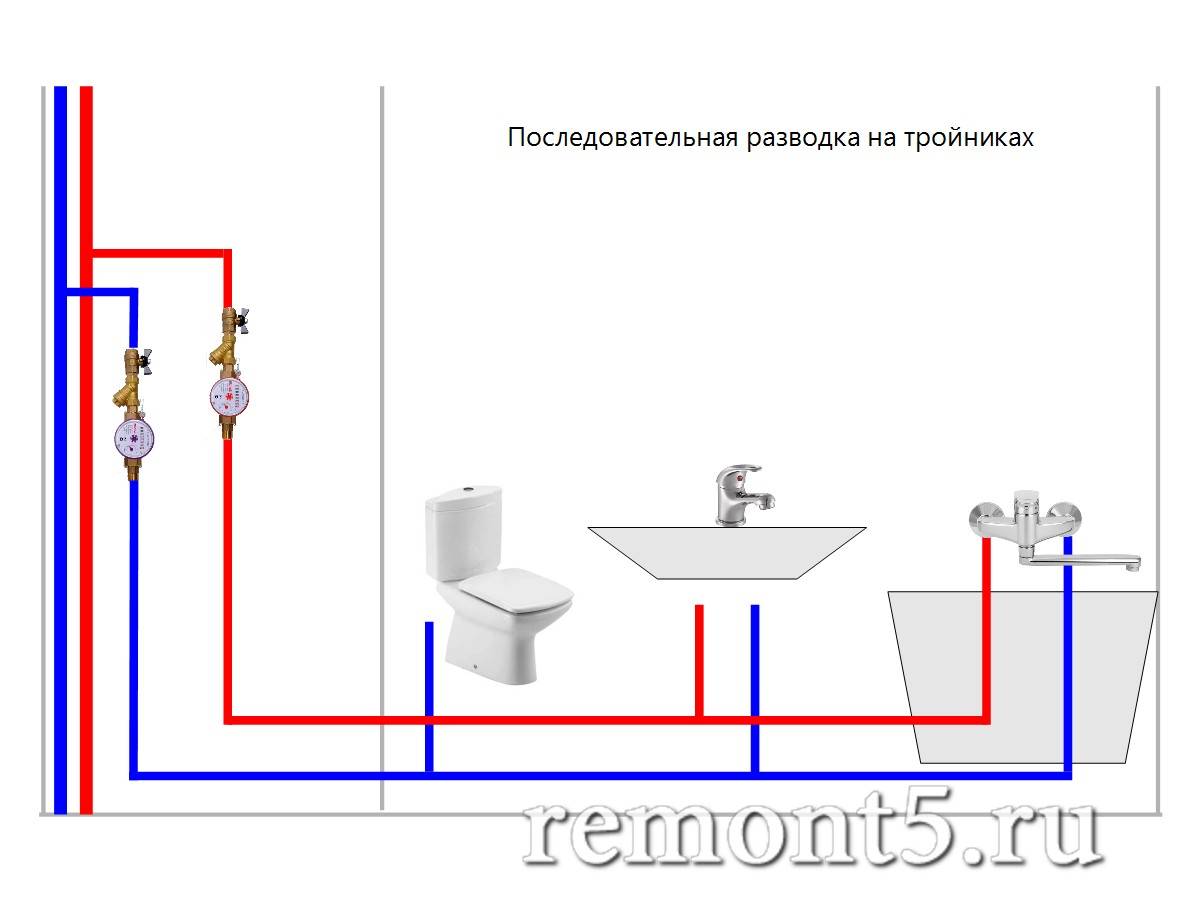

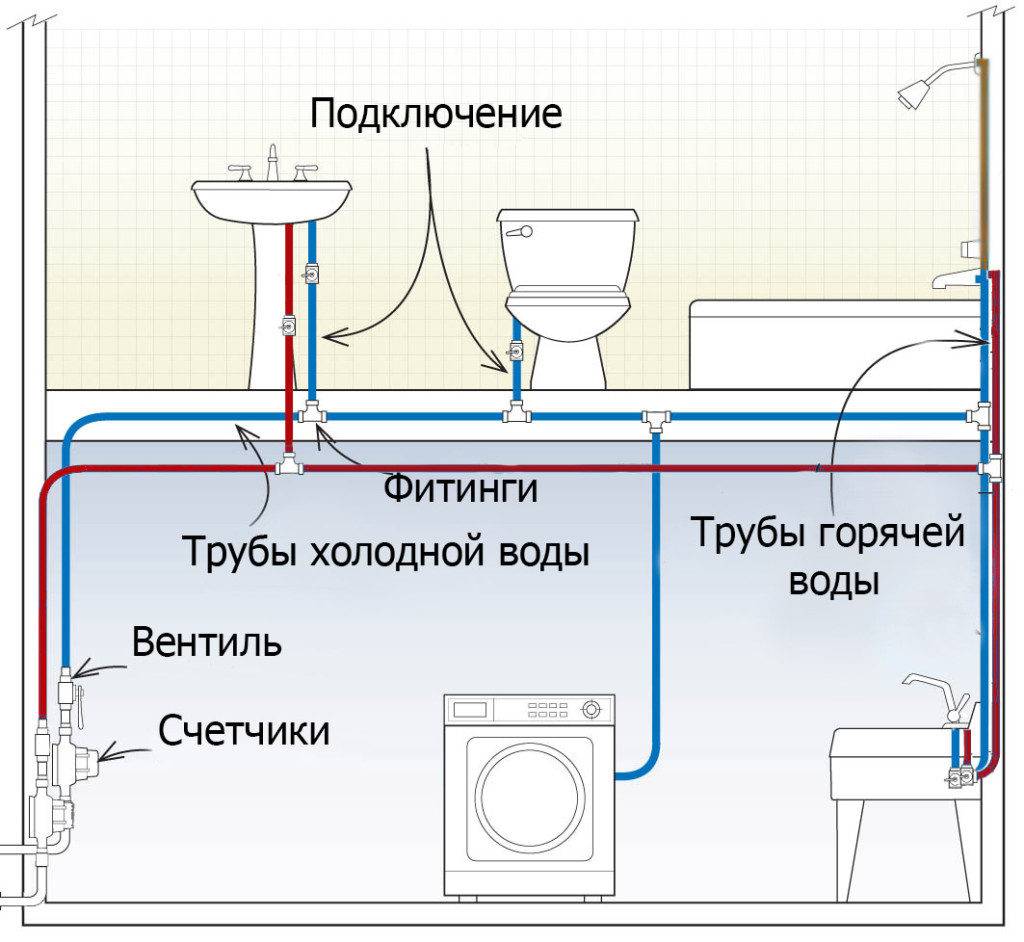

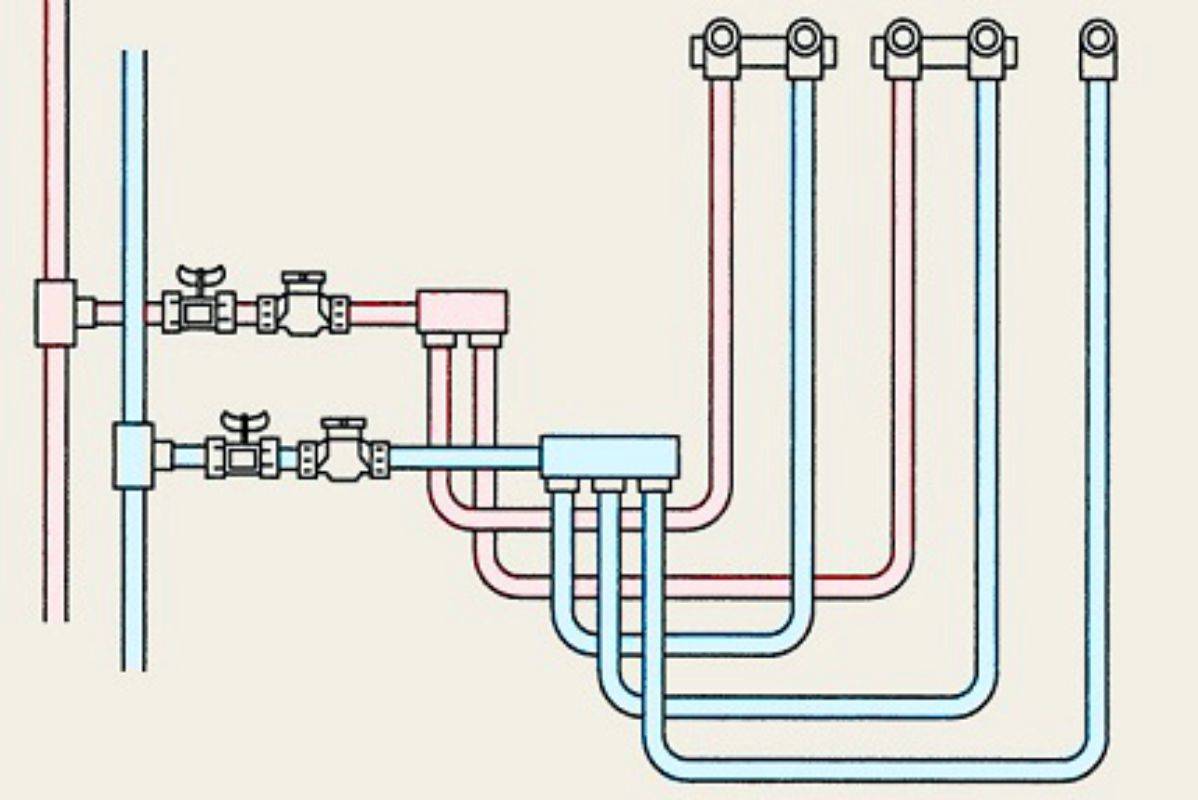

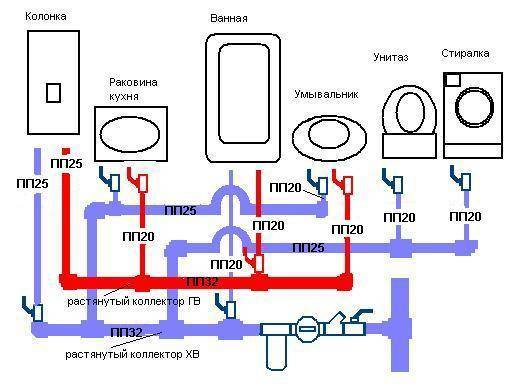

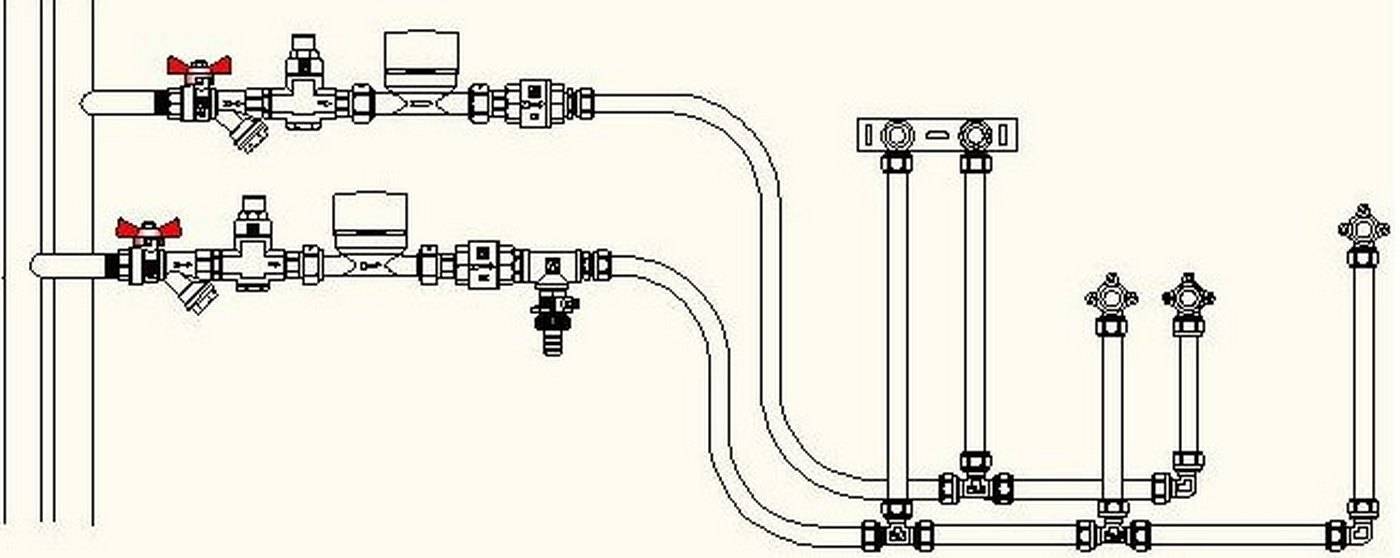

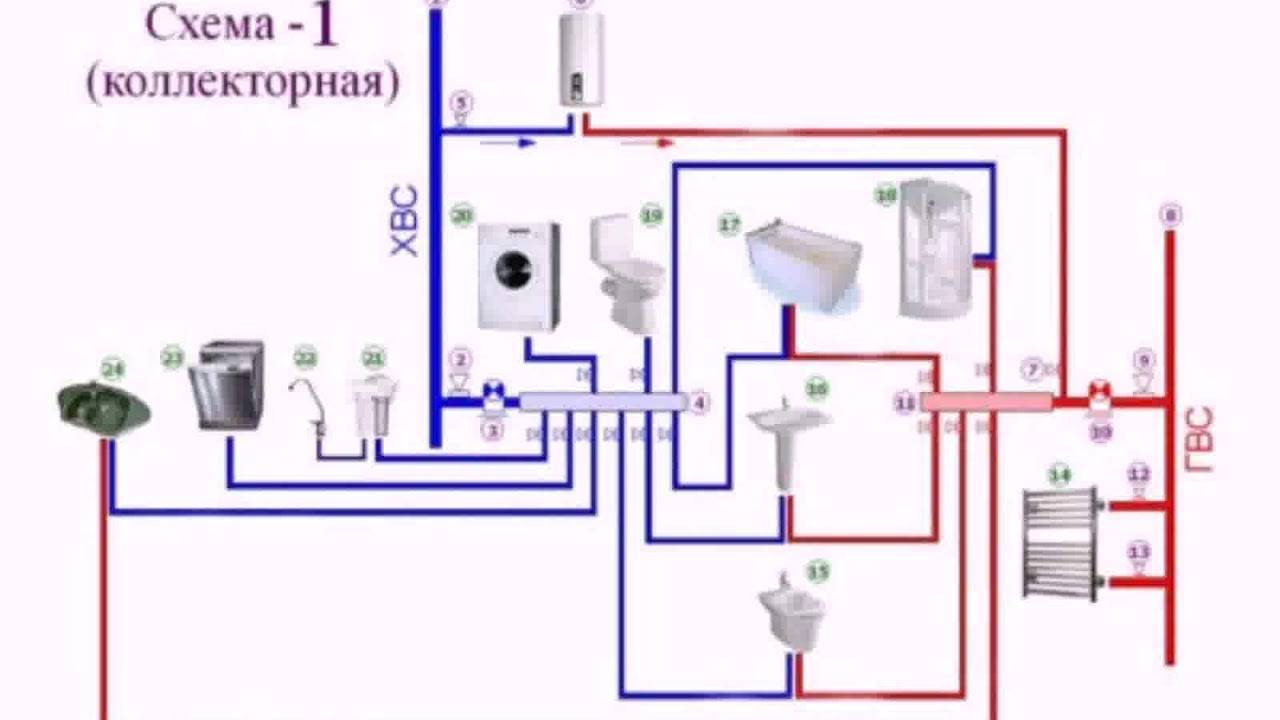

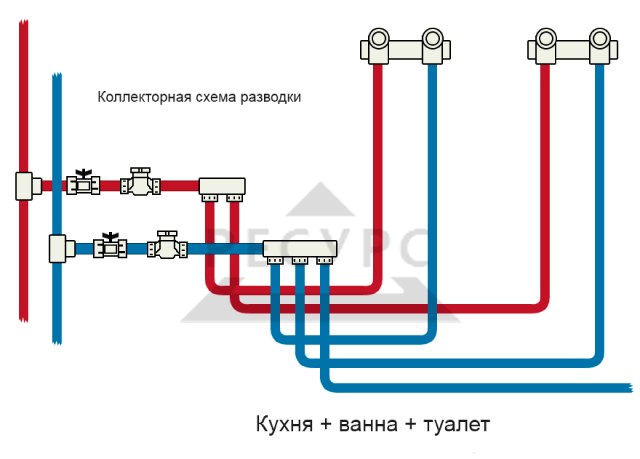

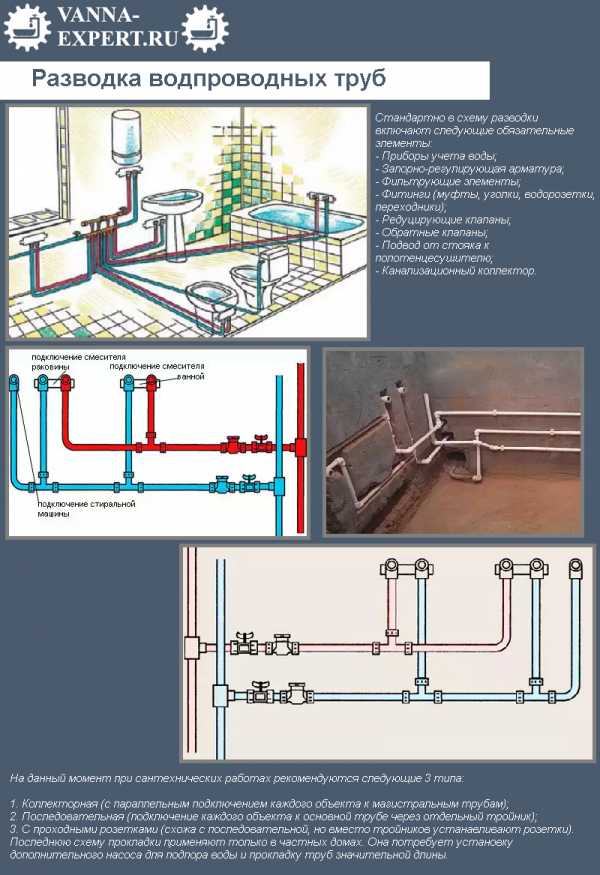

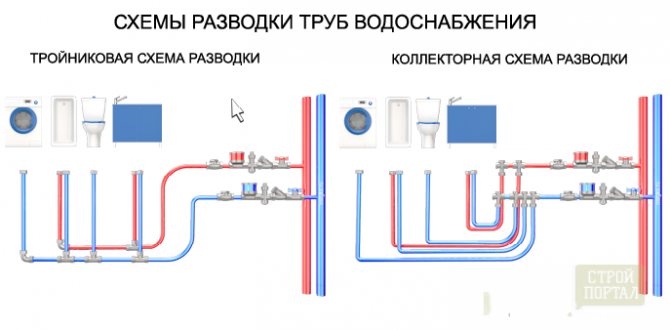

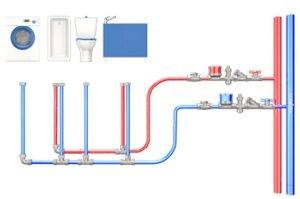

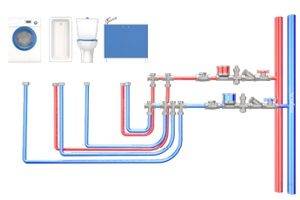

Wiring for plumbing

There are two fundamentally different in design and principle of operation of the organization of the water supply system. Each of them has its own positive and negative qualities and requires a different amount of materials.

- The first option for piping is a tee or serial way of placing connecting elements. With such a wiring diagram, a separate pipeline branches off to each consumer by installing splitters from a common main pipe.

- The installation of such a system requires fewer materials, but the farther the consumer is from the beginning of the water supply, the less water pressure is created in this area. This is most felt when a large number of plumbing fixtures are in use at the same time.

- In the second option, a special design is mounted at a certain point in the system, which makes it possible to direct a separate line to each consumer. This node is called a collector, and this wiring method is called a collector.

- With this method of building a water supply system, the pressure in all areas is almost the same. But for such wiring options, it is necessary to spend more pipes, which significantly increases the cost of the water supply.

The most suitable wiring option should be chosen based on the number of consumers, the size of the premises and the budget allocated for the construction of the water supply system. To save materials, you can mount the collector not at the beginning of the system, but closer to the consumers.

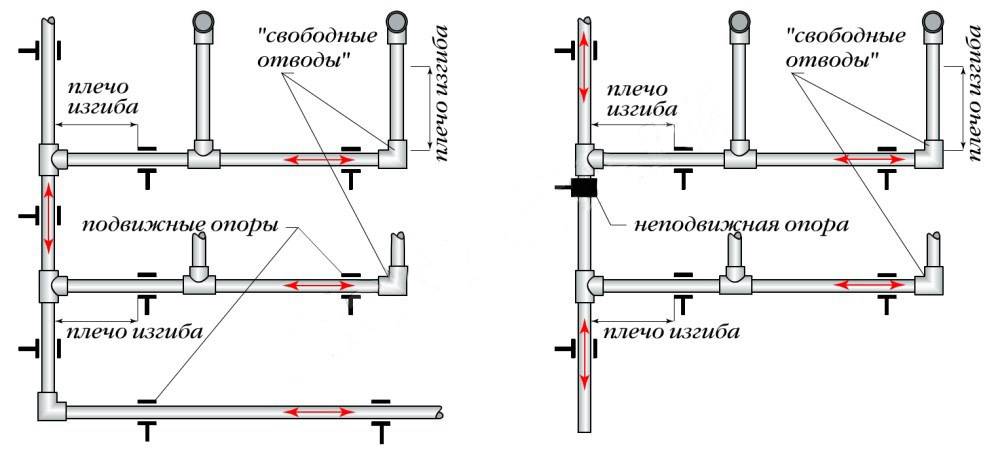

Wiring for the heating system

When designing a heating system, all the features of the premises, the number of pipes and connectors are also taken into account, and a detailed scale diagram of the entire system is drawn up, indicating the location of the heating radiators. It should be remembered that only those pipes are suitable for hot water supply and heating systems that are designed for an increased temperature of the liquid inside the pipe.

Connection of heating radiators can be carried out from below or from the side and be single-pipe and two-pipe.

Checking the quality of joints

Before operation, the water supply system is checked for leaks by subjecting it to a pressure 1.5 times higher than the nominal one, but not lower than 0.15 MPa. At the same time, the system is filled with water and the pressure is increased to the required level using a car pump. The indicators are controlled by a pressure gauge with a division of 0.01 MPa. During the test, joints and connections are checked for leakage. If necessary, the problematic joint is cut out and new elements are installed, after which the control process is repeated from the beginning. If the size of the new elements is not enough, then the pipeline is extended using a pipe segment of the required size and a pair of couplings.

Installation of pipes in a private house

The layout of the water supply network in a private house can be done on its own, especially when using plastic pipes.Depending on the type of products used, the plumbing system is assembled in the following ways:

- Welded or by means of threaded connections - for steel pipelines. Stainless pipes in most cases are connected by means of threaded fittings.

- By soldering. This method is suitable for copper piping and some polymer products.

- By crimping press. This method is used when assembling a metal-plastic pipeline.

The most common mistakes and how to avoid them

Most often, those who do such work for the first time overheat the parts being welded. This comes from the desire to “weld reliably, because I do it for myself”, and as a result, a curved joint and a narrowed hole on the inner surface of the pipe.

The installation of a water supply system does not tolerate fuss, here, as in the saying: measure seven times, cut one. Inaccuracies in the markup greatly affect the result.

- In order to make plumbing at the lowest cost and alterations, first make knots for hard-to-reach places, fit them to the joined structures and devices, and fix them. When you achieve the desired result, you can dismantle everything from the fasteners and from the devices, and then weld it with the remaining straight sections.

- Before starting soldering, prepare the premises: remove all unnecessary. Read the instruction manual for the welding machine and follow it.

- During operation, remember that the welding machine heats up very strongly (260-270 gr.). You need to work with closed hands (in a robe with long sleeves) and gloves.

- The most important advice is to follow safety precautions, work carefully and only with a serviceable tool.

Connection principle

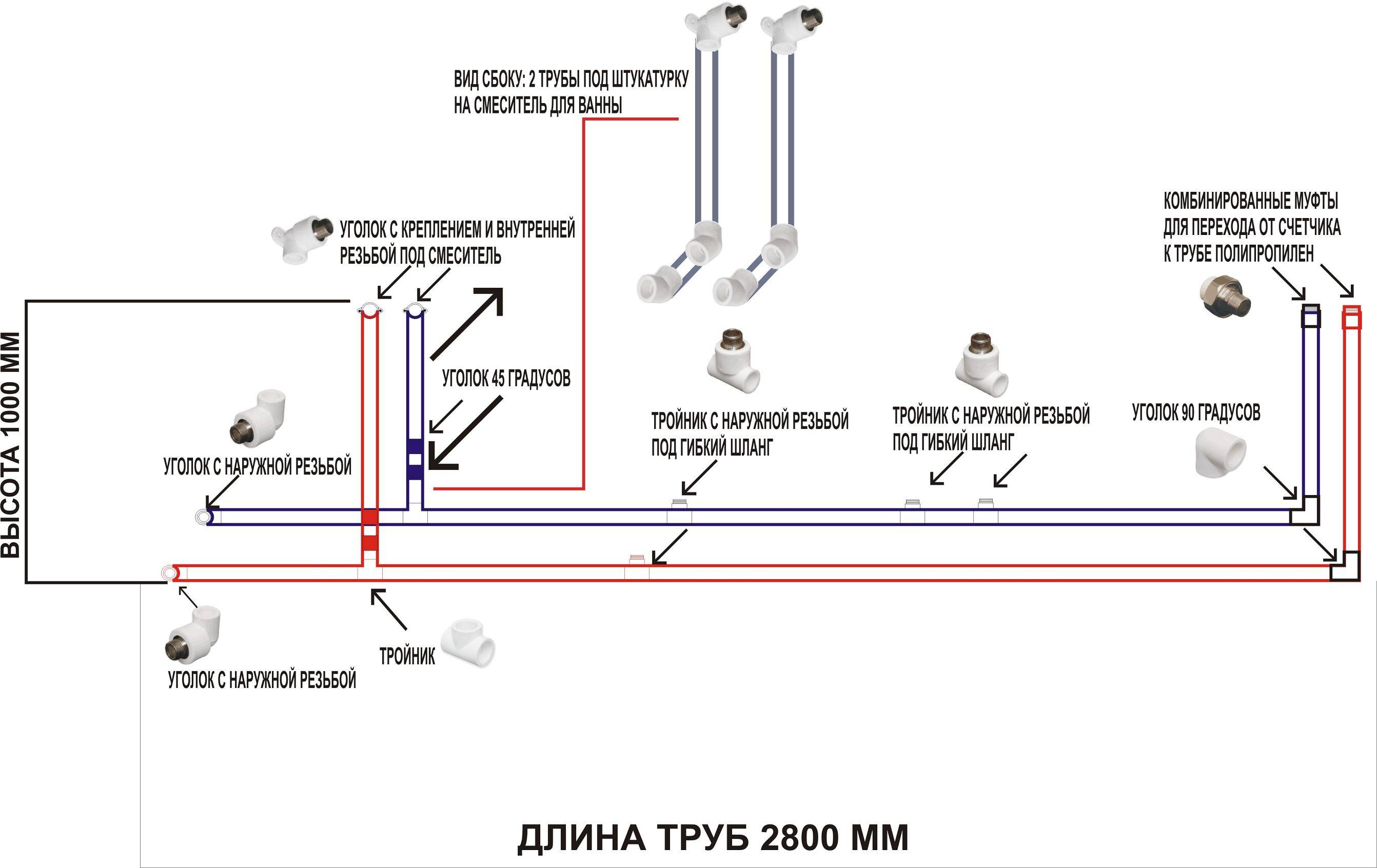

Polypropylene pipes have a lot of advantages, but one of the disadvantages is that they do not bend. Therefore, when installing a water supply system from polypropylene pipes, fittings are used for all branches and turns. These are special elements - tees, angles, adapters, couplings, etc. There are also taps, compensators, bypasses and other elements of the system, also made of polypropylene.

Polypropylene fittings

All these elements with pipes are connected by soldering. The material of both connected parts is heated until melted, then joined. As a result, the connection is monolithic, so the reliability of the polypropylene plumbing is very high. Read more about soldering and the necessary tools for this, read here.

To connect with other materials (metal), to switch to household appliances or plumbing fixtures, there are special fittings. On the one hand, they are completely polypropylene, on the other, they have a metal thread. The size of the thread and its type is selected according to the type of connected device.

What will be required in the work

Plumbing installation equipment:

- welding machine for plastic pipes with nozzles;

- electric jigsaw or ordinary hacksaw for metal;

- perforator;

-

klupp - a special device for threading;

- Bulgarian;

- marker;

- corners and self-tapping screws for fastening to walls.

Necessary materials:

- PP pipes;

- fittings, detachable or non-detachable;

- tees;

- couplings;

- corners (for installation of inclined sections of the highway).

The ambient temperature during operation must be at least +5ᵒС.All parts are checked for defects, cleaned of dirt, and directly during welding / installation are located away from open sources of fire.

Prices for the installation of water supply from polypropylene pipes

The photo shows a hidden wiring of polypropylene pipes

It is not difficult to mount a water supply system from polypropylene pipes with your own hands, especially since the manufacturers have done everything to facilitate the assembly of the structure. However, if the installation is performed by inexperienced users, there will be no confidence in the quality of the work performed. In the absence of experienced specialists among relatives and friends, you can turn to professional plumbers.

When calculating the cost of installing a water supply system from polypropylene pipes, it is necessary to take into account all the nuances of the work. Prices are determined by the following factors:

- Type of polypropylene pipes. Products with an outer braid are more expensive due to the need to remove the outer layer at the soldering point.

- To weld the pieces, a soldering iron is used, which should be held motionless in a predetermined place. If the conditions are difficult, the master will need an assistant, the price of the work will be higher, because. he will also have to pay.

- The complexity of the developed water supply project and non-standard wishes of the customer.

- The number of floors of the house, its area, an unusual design.

- The number of plumbing fixtures and mechanisms to which water must be supplied, and their location in the house.

- When installing polypropylene pipes, it is necessary to pay for the drilling of technological holes in the wall for laying the route.

- If the customer saved on the cost of the material and bought low-quality workpieces, the master will spend more time on their installation, so he will increase the prices for his services.

The tables below show the cost of individual operations during the installation of polypropylene pipes.

The price of installation of polypropylene pipes in Ukraine:

| Job Title | Terms | unit of measurement | Price, UAH. |

| Installation of the route d 20-32 mm | p.m. | 15-40 | |

| Soldering of fittings (corner, coupling) d 20-32 mm | PCS. | 10-20 | |

| Soldering fittings (tee) d 20-32 mm | PCS. | 20-25 | |

| Pipe connection to plumbing fixtures | Depending on the type of equipment | dot | From 160 |

| Pipe fastening | dot | From 12 | |

| Ball valve installation | Depending on the diameter | dot | From 30 |

| Chasing to hide pipes in the wall | depending on wall material | m.p. | 70-150 |

The price of installation of polypropylene pipes in Russia:

| Job Title | Terms | unit of measurement | price, rub. |

| Installation of the track d 20-32 mm | p.m. | 250-300 | |

| Soldering of fittings (corner, coupling) d 20-32 mm | PCS. | 100-150 | |

| Soldering fittings (tee) d 20-32 mm | PCS. | 150-200 | |

| Pipe connection to plumbing fixtures | Depending on the type of equipment | dot | From 300 |

| Pipe fastening | dot | From 80 | |

| Ball valve installation | Depending on the diameter | dot | From 150 |

| Chasing to hide pipes in the wall | depending on wall material | m.p. | 350-800 |

How to make a water pipe from polypropylene pipes - look at the video:

It is not difficult to assemble a water pipe from polypropylene pipes with your own hands. To do this, you should learn how to use a soldering machine to connect workpieces. In addition, you will need knowledge of the requirements of SNiP for water pipes, which should be strictly followed during installation work.

Accessories for polypropylene pipes

For the installation of water pipes from plastic pipes, various components are used. Their assortment is very extensive and amounts to dozens of positions in the price lists of manufacturers.Details differ in shape, size and purpose. Consider the most common types of such elements.

A large number of components are available for polypropylene pipes.

When buying them, it is important to choose parts from the same manufacturer as the pipes. Couplings

The simplest connecting piece. The shape resembles a small barrel, the inner diameter of the hole of which exactly matches the cross section of the connected pipes. The element is designed to connect two pipe sections

Couplings. The simplest connecting piece. The shape resembles a small barrel, the inner diameter of the hole of which exactly matches the cross section of the connected pipes. The element is designed to connect two pipe sections.

Adapters. These parts are designed to connect pipes of different diameters. Outwardly, they are very similar to couplings, but their main difference is that the inner diameter of the two opposite ends of the element is different.

Adapters are selected according to the diameter of the pipes to be connected and come in various sizes. Parts are produced with internal or external threads, designed to switch to threaded connections.

corners. As you know, polypropylene pipes cannot be bent. Therefore, in order to perform the rotations required during installation, the manufacturer produces special connecting parts bent at an angle of 90° and 45°.

Corners can end with holes for pipes or have threads, both internal and external. For example, such parts are used for mounting a mixer. Moreover, they can be both double and single.

Some home craftsmen argue that there is no need to complicate and use corners. After all, polypropylene is plastic and can be bent.They heat the pipe to softening temperature and bend it the way they want.

Indeed, it is very easy to bend a part, but you need to understand that unpleasant changes occur in it: the wall on the outside of the bend becomes thinner. This will significantly reduce the life of the pipe and lead to its breakthrough.

The shut-off ball valve made of polypropylene is installed in the water supply system by soldering

Crosses and tees. This is the name of the elements designed to connect three or four pipes at the same time, which is often required for the installation of a water supply system. They are produced in a variety of variations: with different hole diameters, with fittings for pipes of other types, for example, for metal-plastic or copper, with internal and external threads of various sizes.

Contours. This is the name of specially molded bends that are used to circle the pipe around some small obstacle. At the same time, it is desirable that the distance from the pipeline to the wall be minimal. The bypass is welded into the gap in the section of the water supply so that the pipe sections lying before and after it are straight.

In addition to these components, other items are also available. Among them are plugs used to block unnecessary branches of the water supply system, special ball valves for polypropylene pipelines.

To fix the pipes to the wall, special clips are used, which are selected according to the diameter of the part. Can be single or double. Experts advise choosing pipes and components from the same manufacturer. So there will be fewer problems during installation, and the system will turn out to be of better quality.

For PP pipes of all sizes, a wide range of fittings is produced, allowing you to quickly install a plastic circuit and, if necessary, connect it to metal branches

Plumbing scheme

The plumbing layout in a private house can be implemented in one of two ways: by connecting plumbing fixtures in series to the water supply system or by connecting them to a collector. A series-connected water supply scheme is most often used in small houses with a relatively small number of plumbing fixtures.

Using such a scheme for connecting a water supply to a private house with a fairly large number of water consumers is not the best solution, since when several consumers are turned on at the same time, the water pressure in the house's water supply system will decrease significantly.

In this case, the solution, which is to conduct water supply using pipes of a larger diameter, will not help either. The scheme of the water supply system of a private house with a serial connection of consumers to the water supply is shown in the photo:

The house water supply scheme, which implies a collector connection, is more difficult in terms of installation, however, with such a system, there are no problems with water pressure in the water supply system of a private house. Therefore, most often in large private houses, the plumbing is carried out precisely according to the collector scheme.

Of course, with a significant removal of the consumer from the pumping station of the water supply system, a slight decrease in the pressure level will take place. However, in comparison with the sequential installation of a water supply system in a private house, such a pressure drop will be insignificant.At the same time, the diameter of the pipes used in order to conduct water supply can be the minimum allowable.

For clarity, we suggest you watch a video in which the question of how to make the plumbing in a private house yourself is considered in detail:

In this case, the best solution is to turn to experienced professionals involved in water supply and plumbing. Of course, their work has a certain price, but on the other hand, you will have a guarantee that all the wiring and all the connections in the water supply at home are really done correctly, efficiently and reliably.

Plumbing in private homes

- Prepared pipes are laid in the house, starting from water consumers.

- The pipes are connected to the consuming point with an adapter so that a tap can be installed to shut off the water.

- Pipes are laid to the collector. It is advisable not to pass pipes through walls, as well as partitions, and if this has to be done, enclose them in glasses.

For easier repairs, place pipes 20-25 mm from wall surfaces. When installing drain taps, create a slight slope in their direction. Pipes are attached to the walls with special clips, installing them on straight sections every 1.5-2 meters, as well as in all corner joints. Fittings, as well as tees, are used to combine pipes at angles.

When connecting pipes to the collector, shut-off valves are always installed (it is needed for repairs and the possibility of turning off water consumption).

PP pipe manufacturers

To install a polypropylene water supply system, it is better to use high-quality pipes from manufacturers who have already managed to positively recommend themselves. These include Ekoplast, Kalde, Rilsa, and so on.The use of low-quality products is fraught with consequences.

Calde

When heated, pipes will melt longer than expected, and their diameter may not fit the nozzle. If the end of the product enters the nozzle too freely, then a high-quality connection is unlikely to work.

To prevent this from happening, a small segment is bought and soldered to the fitting. This will allow you to draw the right conclusions regarding the purchase of PP pipes from an unknown manufacturer.

Possible or not

First, let's talk about where polypropylene can be used, and where it is better to prefer other materials:

- In cold water supply systems, it can be used without restrictions;

- In hot water systems with an autonomous source of thermal energy for heating water (boiler, gas column, double-circuit boiler, etc.), its installation is also quite acceptable: polypropylene pipes for water supply perfectly tolerate long-term operating temperatures up to 70 degrees;

The connection to the boiler is mounted with polypropylene

DHW system connected to closed heating system (without coolant withdrawal) through a common heat exchanger for them, it can also be diluted with polypropylene: the temperature in it does not go beyond the maximum 90 degrees for plastic, and the pressure is always equal to the pressure in cold water;

Water supply is diluted with corrugated stainless steel

The instruction is associated with a high probability of water hammer in such systems, as well as the fact that the water temperature in the supply line of the heating main can reach 150 degrees.If hot water supply at the peak of cold weather is not switched to the return line for any reason, polypropylene pipes for water supply systems will end their career ahead of schedule with the most unpleasant consequences for the homeowner and his riser neighbors.

Apartment flooded in a neighbor's accident