- Types and design features of roof fans

- for hood

- To eliminate smoke

- Discharges smoke horizontally

- Axial fan

- Diagonal

- Radial

- Installation procedure for industrial axial fans

- Purpose and features of the choice of smoke exhaust fans for roofs

- Application area

- Types of fans: how to choose?

- Recommendations for installation and fastening

- Features of roof fans

- Axial fans can be installed in several ways:

- Wall and window installation of axial fans

- Installation of axial fans on the ceiling

- Installing an axial fan in a duct

- Ventilation pipe passage assembly

- 2 The right choice of power is a guarantee of safety and optimal consumption of resources

- 2.1 Installation of smoke exhaust fans: what you need to know

- 1 Main types of roof fans

- Conclusions and useful video on the topic

Types and design features of roof fans

Ventilation roof systems can be classified according to their purpose.

for hood

The device includes an electric motor, an automatic regulator and mechanisms that reduce the vibration of the device.

In addition, roof-type exhaust fans are equipped with a deflector to protect against precipitation and thermal sensors that protect against overheating.

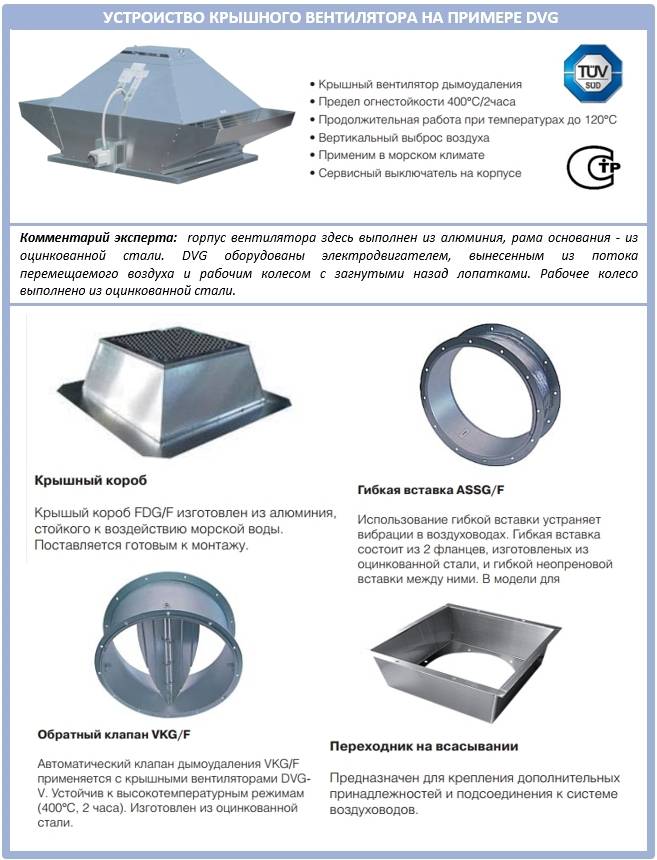

To eliminate smoke

Most often, roof ventilation systems are used for this.

The smoke exhaust device is of two types:

It discharges the air stream with combustion products vertically. Devices with this design are installed if there is a need to get rid of gases with harmful impurities, from smoke and combustion products.

The fan must be installed horizontally so that the axis of rotation is vertical. This type of device must be protected from moisture entering the housing.

To do this, you can use a protective cap or a waterproof coating.

Discharges smoke horizontally

But most models of ventilation systems with smoke exhaust for roofs operate in two modes:

- emergency (automatically turns on when sensors are triggered in case of fire, gas leaks, etc.);

- standard (the fan performs the function of airing the room).

Ventilation devices can also be divided into types according to the device.

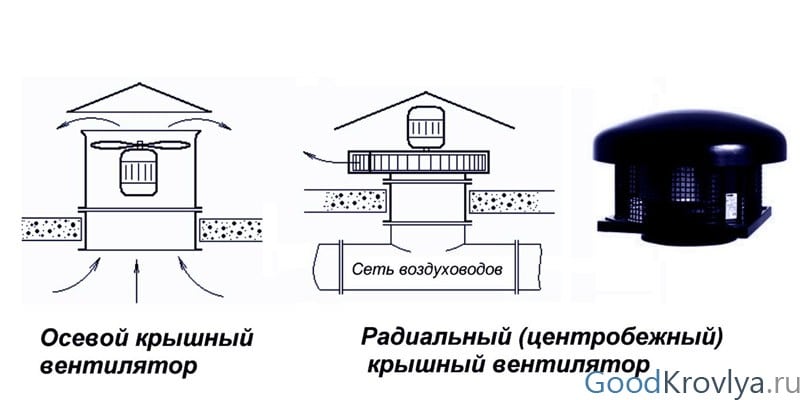

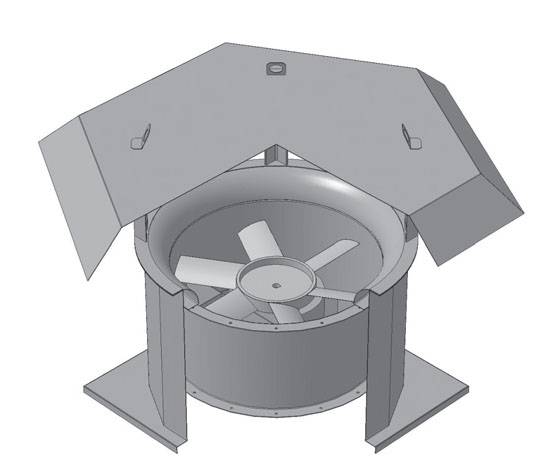

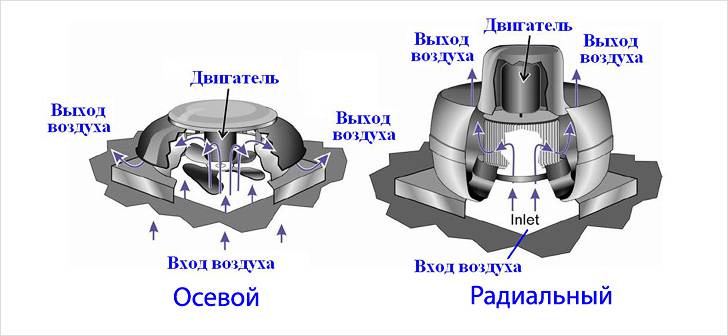

Axial fan

This type of ventilation equipment is the most common. For the operation of the device, it is not necessary to install a structure of air ducts.

An axial system is a propeller with blades in a protective housing that rotates around an axis. The basis of the device is an electric motor that controls the movement of the blades.

During the operation of the device, a zone of low pressure is created, while stagnant air is drawn out of the room.

Axial fans are most often made of high-strength steel, which is not affected by moisture and has anti-corrosion properties. The impeller of the mechanism is made of aluminum alloy.

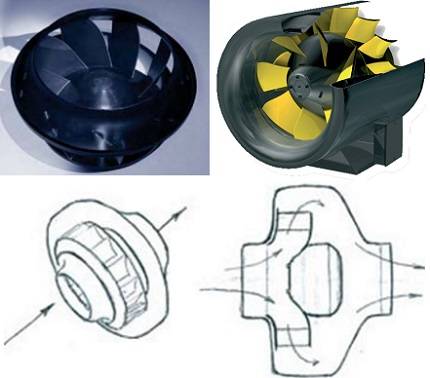

Diagonal

This view is an improved version of the axial fan.It consists of a robust housing in which the impeller with blades is located.

Due to their shape, the device takes in air along the axis, and outputs it diagonally.

Thanks to this, the fan is practically silent and has a high performance.

Radial

The fan is made of high strength material that is resistant to corrosion and chemical attack. This design can be used in rooms with chemically aggressive substances and high humidity.

A distinctive feature of the device is that its curved blades have a special aerodynamic shape. Air is removed due to the centrifugal force generated during their rotation.

Radial fans are very powerful, they vibrate and make a lot of noise during operation. For this reason, they are much more often used in industrial premises than in residential ones.

A fan with a two- or three-speed motor adjusts the performance on its own, depending on the season and general conditions. It is mainly used for smoke extraction and as part of a general ventilation system.

Automated models independently regulate the speed of rotation of the motor, based on the performance of sensors, using installed programs. Such devices can significantly reduce energy consumption.

For additional protection of devices from atmospheric precipitation, when installed on the roof, protective caps are used.

It is important to choose and install this element correctly, as its location can change the pressure produced by the impeller and increase the performance of the device.

Installation procedure for industrial axial fans

The axial type exhaust device is designed to supply a significant amount of air with low aerodynamic resistance of the air network. The axial fan consists of a wheel and blades fixed on the hub. The wheel is mounted directly on the electric motor of the axial fan. When rotating, it captures air flows, pulls and moves it in an axial direction. Axial fans can operate in reverse mode, i.e. for exhaust and supply. Compared to radial and diametral ones, axial ones have a higher efficiency. Ventilation units are supplied as part of exhaust or supply units, as well as independently. By appointment there are general, household, special. General purpose are used to move air in clean or lightly polluted systems. Special value for air containing aggressive impurities. These are smoke exhaust fans, mine fans, cooling towers, etc. Examples of domestic use of the simplest type of axial fan include exhaust units for bathrooms, sanitary facilities, as well as a regular table fan. As already noted, the ventilation unit consists of a sleeve, an impeller, a motor and blades . The wheels are made of plastic or metal, the blades are made of sheet metal or by casting, the bushings are welded or cast. Explosion-proof fans are made of dissimilar metals: steel and brass. The blades are attached to the sleeve with rods or welding. The number of blades depends on the size of the unit and can reach up to 50 pieces. Ventilation units are selected according to total pressure nomograms taken from manufacturers' catalogs.The fan number should be determined in such a way that the values of the total network pressure and air flow correspond to the maximum efficiency.

Purpose and features of the choice of smoke exhaust fans for roofs

Modern premises are distinguished by the presence of all kinds of artificial materials, which, despite their practicality and aesthetics, can pose a real danger to humans during combustion. Moreover, we are not even talking about the fire itself, but about smoke and fumes, which do not contain harmful emissions in small quantities.

The issue of preventing the accumulation of smoke is vital today. Rooftop smoke exhaust fans are considered an effective solution to the problem. Mostly such equipment is installed in buildings with an increased likelihood of fire, for example, shopping and entertainment centers, industrial enterprises and others. Functionally, in any extreme situation, say, in case of fire, the device quickly removes smoke, gases and other harmful components contained in the air of the room. A roof fan for a private house is also used to remove smoke when using household heating equipment, for example, gas boilers, stoves, etc.

Typically, installation is carried out in exhaust systems, where they can work as an air conditioner, as well as in a fire ventilation system. However, there are cases when roof smoke exhaust fans start functioning only in the event of a fire.

Application area

Most often, roof smoke exhaust fans are installed in industrial enterprises, large public buildings, sports and shopping centers and other premises where there is a risk of fire.

They are designed to quickly remove smoke, gases and other harmful substances in the indoor air during a fire or other extreme situations. In private houses, fans can be used to remove smoke from household stoves, fireplaces, when using gas boilers.

The remote control roof fan is mounted in exhaust systems, where it can work as an air conditioner, as well as in fire ventilation systems. Sometimes the system may be at rest and only fire when a fire occurs.

Types of fans: how to choose?

There are several types and types of smoke removal systems:

- axial;

- diagonal;

- centrifugal.

An axial fan is a design in which several blades mounted on an axis rotate at a certain speed. This is the most widely used unit today, because it is simple in itself, both technically and in maintenance of this type. The advantages of this type of fan for smoke removal include its high efficiency.

types of roof fans

Diagonal fans are advanced axial fans. The design of the blades in this form is distinguished by its shape, due to which the incoming smoke goes in an axial direction, is discharged diagonally outward.

Centrifugal or radial fans, according to the principle of operation, resemble the two previous types. But there are design features that distinguish them from other types. The air in this type of smoke exhaust fan is sucked in by centrifugal force, which is formed by the rotation of the specially shaped blades.

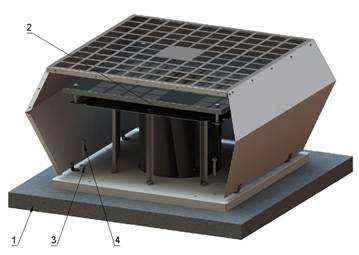

1 - mounting surface, 2 - fan, 3 - lock washer (4 pcs), 4 - screw (8x50mm)

As you can see, all devices work according to the same principle - they suck in air with smoke from the room and remove it to the atmosphere. But the presence of various design features makes it possible to distinguish them according to a number of technical parameters.

The choice of one or another roof exhaust fan is influenced by various factors - the characteristics of the premises, the existing roof air conditioning and ventilation systems, power, roofing and the entire roof system, and much more.

The fan, like any electrical appliance, is selected according to several parameters:

- reliability;

- power;

- simple installation;

- duration of operation.

First of all, they pay attention to power, because a strong unit is able to quickly clean the air in the room, thereby possibly saving more than one life. The choice depends on the ease of installation of roof fans, on the tasks assigned to him and on other factors.

There are quite a few well-known players in the ventilation equipment market

How to choose the best option in terms of price-quality ratio? Market experts advise paying attention to the products of the Swedish company SystemAir. This company is recognized as the undisputed leader in the field of ventilation in Europe, Asia and even in the Americas

SystemAir roof fans are presented in a wide range on the Russian market and are able to meet the needs of any customer, both in terms of power, design features and scope.

Recommendations for installation and fastening

You can install the ventilation outlet on the roof with your own hands.The installation location of the pipe should be chosen in such a way that, if possible, it passes through the attic without turns. At the same time, it cannot cross the rafters, and even more so the ridge run.

The best option is when the outlet of the ventilation pipe is directly above the internal riser of the ventilation shaft or air duct. If this is not possible, a corrugated pipe can be used for the connection.

The pipe must be connected to the riser strictly vertically

The pipe must be connected to the riser strictly vertically

When placing pipes or an exhaust duct, the smallest permissible distance from the supply air intake must be taken into account:

- horizontally - 10m;

- vertically - at least 6m.

The height of the ventilation pipe is determined as follows:

- if it is located near the ridge, the final opening of the hood should rise half a meter above the ridge;

- if from one and a half to three meters remains to the ridge, the hole should be flush with it;

- if the pipe is further than three meters from the ridge, the hole is displayed along the side of the angle of 10 degrees to the horizon with the top on the roof ridge;

- if the ventilation outlet is located next to the chimney, the length of the pipes must be the same;

- on a flat roof, the height of the pipe is calculated according to a special table, but it should not be lower than 50cm.

When installing a pipe on a pitched roof, the ventilation outlet should be placed as close as possible to the highest point of the roof - the ridge. In this case, the largest part of the pipe will be located in the attic or attic space, it will be protected from strong temperature changes and gusts of wind.

The height of the ventilation pipe to the roof is selected depending on the distance from the ridge. These conditions must be observed so that the exit does not end up in the backwater zone.

The height of the ventilation pipe to the roof is selected depending on the distance from the ridge. These conditions must be observed so that the exit does not end up in the backwater zone.

For a flat roof, the main role is played by the geometry of the duct, which should be located directly under the exhaust pipe so that the air can freely go outside.

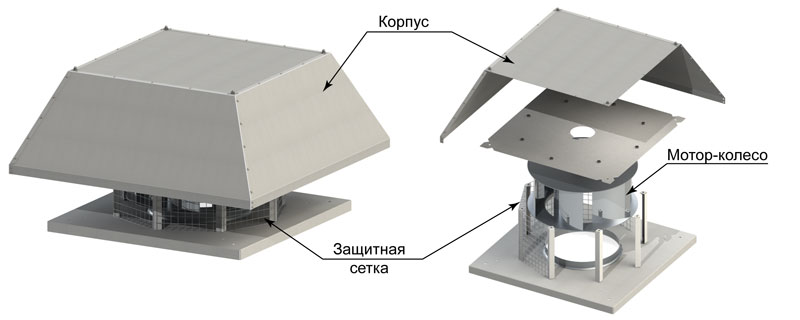

Features of roof fans

Another element of the ventilation system is the roof fan. With the help of these devices, exhausted polluted air is removed from the premises.

They are mainly designed to work in general ventilation systems without ventilation ducts, but are also used with air ducts. The main advantage of roof fans is that their use allows to reduce the required length of air ducts.

In regions with low and medium wind load, you can install an original and effective weather vane-deflector. It will make the system work even with slight wind blows

In regions with low and medium wind load, you can install an original and effective weather vane-deflector. It will make the system work even with slight wind blows

Variants of roof fans differ in dimensions, power, performance, sound pressure level.

The following common types can be distinguished:

- axial airborne spacers are installed on industrial buildings;

- KROV can be used in private homes;

- VKRM and VKR are connected to air ducts.

What are the advantages of roof fans:

- installation does not require a separate room;

- simple maintenance;

- in models with hinged housings, access to the main parts is facilitated.

When choosing a roof fan, you need to pay attention to the performance of the model, the material of the case, the method of power supply, and the noise generated. If there is no draft in the exhaust duct, a roof fan is a good solution

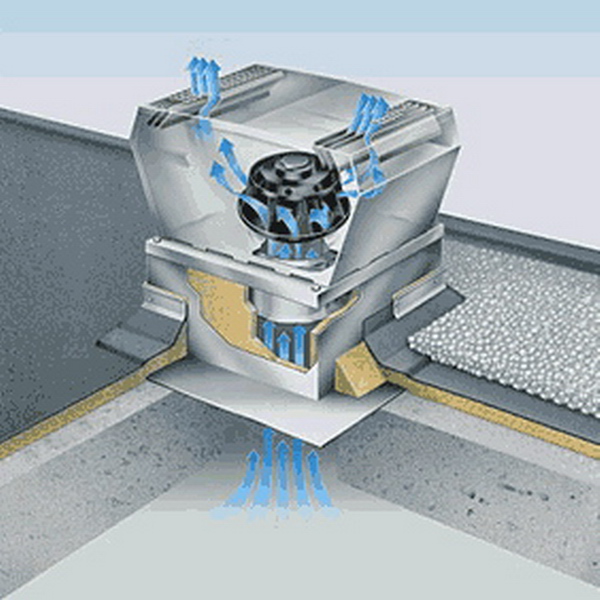

When using models with vertical discharge, air is thrown upwards, sometimes up to several meters in height

If there is no draft in the exhaust duct, a roof fan is a good solution. When using models with vertical discharge, air is thrown upwards, sometimes up to several meters in height

If there is no draft in the exhaust duct, a roof fan is a good solution. When using models with vertical discharge, air is thrown upwards, sometimes up to several meters in height

Most products are manufactured as centrifugal or axial:

- An axial fan is used to pump low-pressure air masses. Gas moving through the rotor does not change direction, moving along the axis of the engine.

- The centrifugal fan is equipped with special blades that distribute the air to the sides, which moves further towards the outlet.

Types of roof fans are divided according to the direction of emission. Horizontal discharge fans are installed where the exhaust air is not polluted and there is no risk of it mixing with the fresh air entering the house.

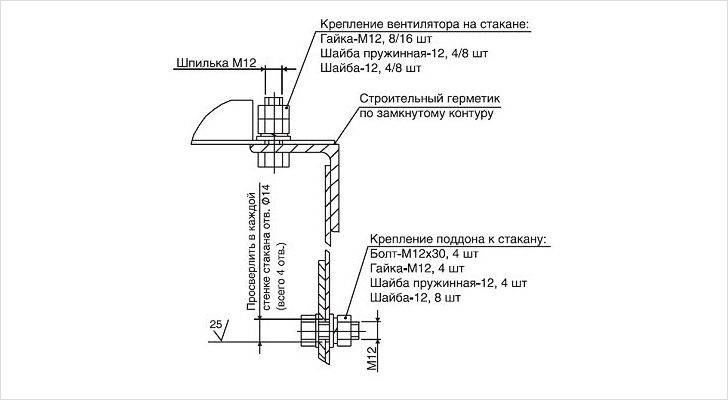

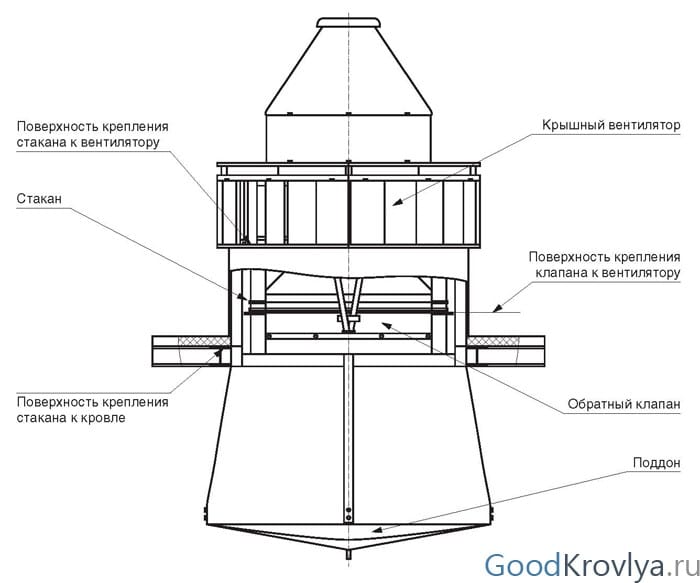

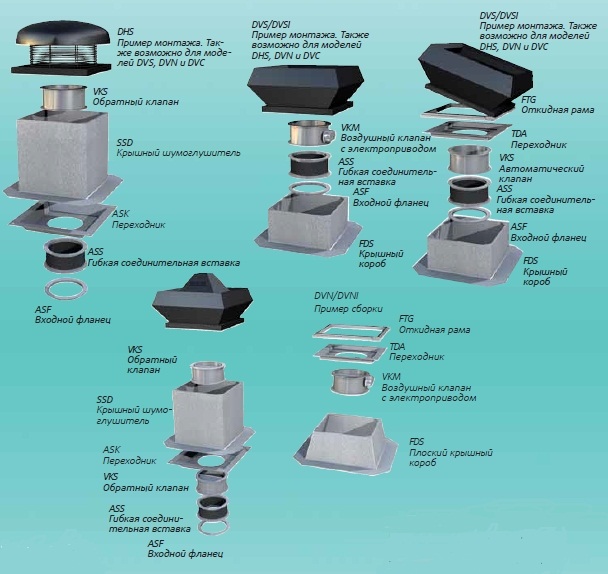

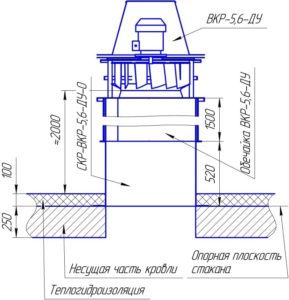

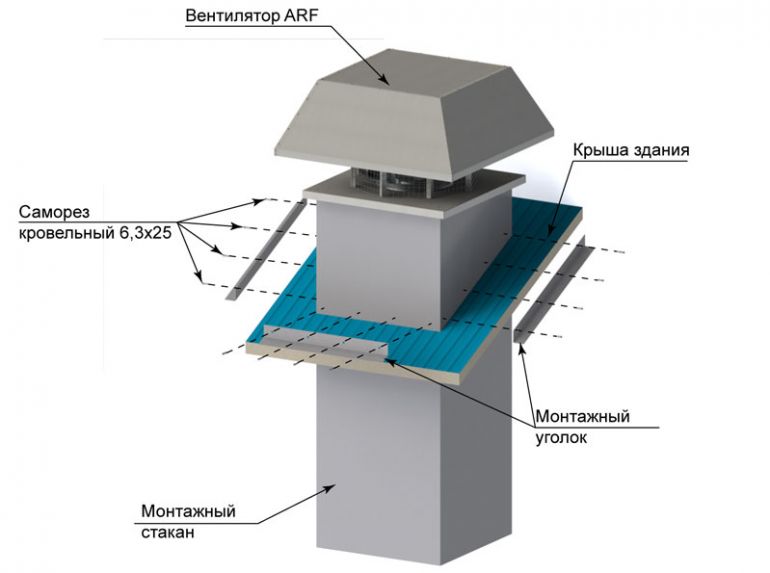

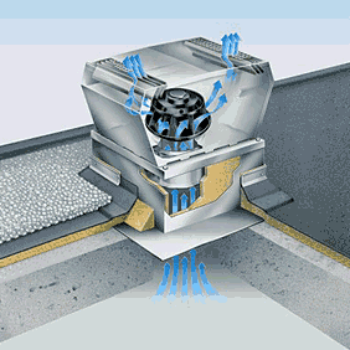

Roof fans can be installed on different types of roofs. The technology of the passage unit in a hard roof is simple. A technological opening is cut in the ceiling, and a brick foundation for the fan is built on the ventilation shaft.

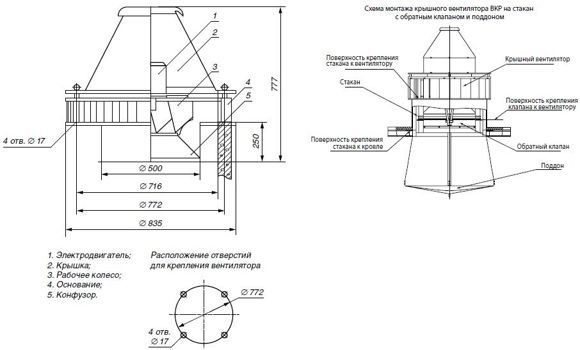

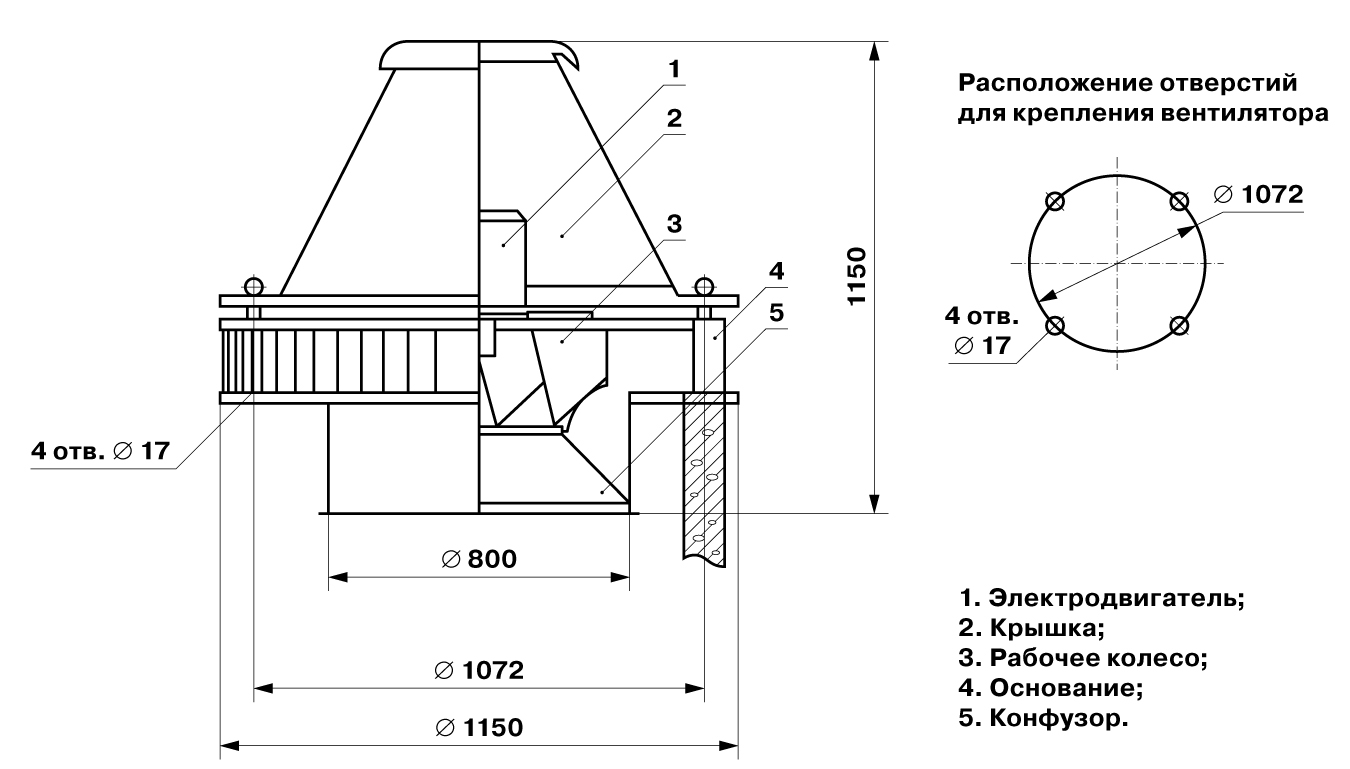

To simplify installation work, special glasses are used, which are sometimes supplied complete with fans. The glasses have holes on the mounting flanges and are attached to the roof with anchor bolts. The fan and the glass are connected by bolted flanges.

Between the flanges there should be a rubber gasket for greater tightness. The glass during installation must be set strictly vertically. The fan on the glass is mounted on a horizontal level. After installation, possible gaps are eliminated with a sealant.Then a steel apron is installed.

Axial fans can be installed in several ways:

- wall or window;

- ceiling;

- in the channel.

Wall and window installation of axial fans

When installing ventilation in the production room, axial units are installed at a height of more than 2 meters. To lift the unit to the required height, hoisting mechanisms and winches are used. The equipment is mounted in an opening made in advance and framed with a metal corner in a window or wall, and fixed with bolts. The dimensions of the openings must correspond to the dimensions of the impeller diameter. Large-section fans are mounted on brackets or a support frame, which reduces the load on the wall and ensures the reliability of the structure. Rubber pads with a thickness of at least 7 mm are laid on the frame to reduce vibration and noise from operating equipment. The fan is attached to the bracket or frame with anchor bolts, which are tightened with locknuts. This is required to protect the system from precipitation, birds and debris.

Installation of axial fans on the ceiling

This installation method is often used when installing a domestic axial fan in kitchens, bathrooms and toilets. Axial exhaust devices remain operational in any position, the main thing is to install them in accordance with the indicated direction of air flow. They are mounted in suspended or stretch ceilings.One end of the air duct is connected to the fan and fixed with mounting tape, and the other end is connected to the ventilation duct. Installation of axial units on the ceiling is practically not used in industrial premises. An exception is the installation of rooftop units, whose design includes an axial fan. They are delivered fully assembled and have a so-called mounting box. The fans are fixed to a reinforced concrete cup in the roof, which should be provided for at the design stage. The glass is installed at the factory during the manufacture of roofing. When installing a roof axial fan, the tightness of the joints between the roof and the glass must be ensured. A valve is mounted under the fan from the side of the room; when the fan is off, it closes and prevents backflows of air.

Installing an axial fan in a duct

The air ducts of the ventilation network, in which the ventilation unit is installed, are required to maintain a straight section in front of the inlet or outlet. The section must have a length of at least 3 dimensions of the duct sections. This is necessary to equalize the air flow. Failure to comply with this condition will lead to a decrease in the aerodynamic characteristics of the unit. Work on the installation of axial fans for special purposes is carried out according to the requirements of technical standards and state standards. Here are the basic rules for the installation of axial ventilation units for any installation method.

- install axial fans in such a way as to ensure safe maintenance, convenient repair;

- installation of the installation is carried out only after assembly and a complete check of performance;

- with a duct arrangement in the duct, a hatch for electrical connections and monitoring of work should be provided;

- the parameters of the electrical network must correspond to the characteristics of the fan;

- power supply connection must be carried out in accordance with the diagram attached to the equipment and design solutions;

- devices must be grounded.

Work with the equipment is carried out only by qualified workers who have all the necessary permits.

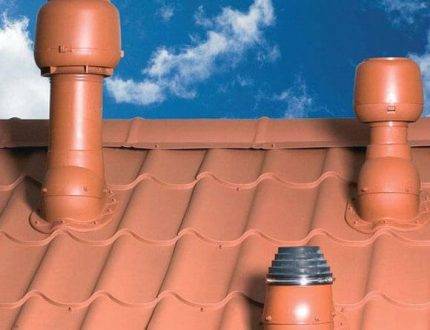

Ventilation pipe passage assembly

A roof vent is a pipe made of metal or plastic that fits into a hole in the roof. The pipe is fixed in a metal cup. After its installation, the hole is sealed and insulated from the outside and from the inside. From below, an air duct is joined to the node, and a deflector is installed from above.

It is more convenient to use a ready-made factory fitting for mounting the ventilation pipe passage. Manufacturers of ventilation systems offer many models that differ in design, shape and color. For each type of roof, their own types of ventilation pipes have been developed.

Galvanized steel pipes wrapped in a layer of polypropylene are in the greatest demand. In the lower part of such a product there is a seal, and on top there is a cap with a deflector.

It is impossible to combine the outlets of the air ducts into one, otherwise, in the event of adverse weather conditions, as a result of reverse draft, unpleasant odors will spread throughout the house

It is impossible to combine the outlets of the air ducts into one, otherwise, in the event of adverse weather conditions, as a result of reverse draft, unpleasant odors will spread throughout the house

Installation features of the ventilation pipe passage assembly depend on a number of factors:

- from the type of roof - complex or flat, single or gable;

- from roofing material - metal or ceramic tiles, corrugated board, soft tiles, etc.;

- from the corner of the pitched roof.

The sealing and insulation of the roof at the installation site of the passage element must be carefully performed. If this is not done, moisture will enter the thermal insulation layer of the roofing pie and the room through the junction of the pipe with the coating, which will cause the destruction of structures.

The junction of the ventilation pipe with the roof must be carefully sealed. Sealing is done by applying a water-repellent material to the passage and applying silicone sealant under the ventilation outlet flange

The junction of the ventilation pipe with the roof must be carefully sealed. Sealing is done by applying a water-repellent material to the passage and applying silicone sealant under the ventilation outlet flange

What are the main requirements for the passage node:

- pipe outlets must be strictly vertical so that the air does not encounter obstacles when moving up;

- for each air duct - from the kitchen hood, from the sewer riser, from the bathrooms there must be a separate exit to the roof;

- the best option is that the exhaust outlets pass close to the ridge edge of the roof, but so that the run is not disturbed and the entire rafter system based on it is not weakened;

- the selected fittings must ensure the unhindered movement of air masses and tightness.

The main element of the passage assembly is the outlet - a fitting: a branch pipe with a flexible metal base, made in the form of a flange. It is pressed against the roofing, giving relief to the roof on which it is mounted. During the installation process, the geometry of the roofing materials used is achieved and the node is impeccably sealed.

On sale you can find different types of shaped products that facilitate and speed up the installation of a ventilation outlet to the roof. Can be purchased separately - outlet for exhaust, separately - for sewerage, etc.

Roof penetration: proper installation will ensure complete tightness of the roofing pie

Roof penetration: proper installation will ensure complete tightness of the roofing pie

There are several types of pass-through elements:

- Valveless / with valve. Valveless models are great for arranging ventilation outlets in a private house. Valves are more suitable for industrial buildings.

- With insulation / without insulation. In cold regions, it is better to choose a ventilation outlet with thermal insulation. Moreover, insulation is necessary if the pipe is placed close to the eaves. In regions with warm winters, the option without insulation will suffice.

- With manual and auto control. The choice depends on the budget of the design. Products with a cable for adjusting air circulation are very popular with owners of private houses.

For a ventilation penetration device, you cannot buy a similar part for a chimney, since they implement fire protection that is unnecessary for ventilation outlets.

2 The right choice of power is a guarantee of safety and optimal consumption of resources

In general, when choosing the power of a fan, one must proceed from the indicators of their operation in normal and emergency modes, as well as the volume of the premises. Choosing too much roof ventilation will result in unnecessary energy wastage, and a weak system will be unable to help in an emergency.

For residential buildings, for example, axial roof fans are ideal, due to the relatively moderate power requirements, and also because of the ease of installation of the glass for them. This type of fan is also available in the Veza product range.

Vkrn fans can also be an excellent choice for residential buildings and office premises, which, due to the special shape of the blades, provide a low noise level. And the design features of these systems allow you to place mounting sleeves close to each other, increasing the number of fans and their combined power.

Forms and types of roof fans

Industrial plants and large production halls require more powerful roof ventilation. Here, radial shelter systems, or VKRN, will come to the rescue, capable of providing the necessary level of air circulation in normal mode, and having high emergency mode capacities.

The quality of the system should be one of the first places. For those who value reliability, Systemair roof fans should take a closer look as they are the epitome of durability and reliability. Not inferior to them in quality and shelter systems, domestic production.

Also, when choosing a roof ventilation system, one must proceed from the installation features of each type, as well as the installation principle. We will talk about them in the next section.

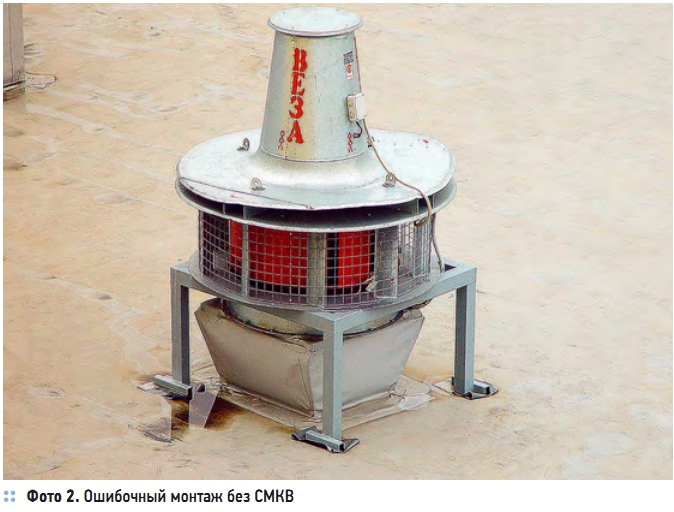

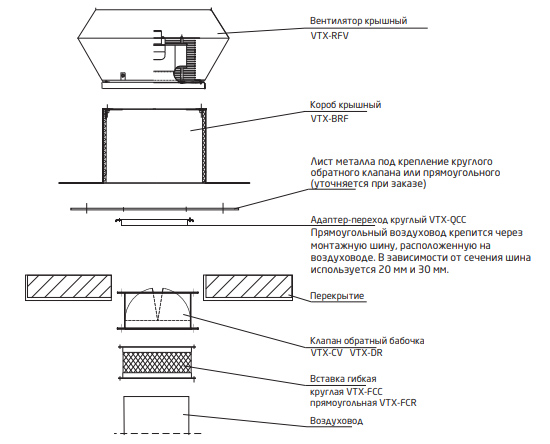

2.1 Installation of smoke exhaust fans: what you need to know

Depending on the principle of installation in the air conditioning system and chimney, roof fans are divided into the following types:

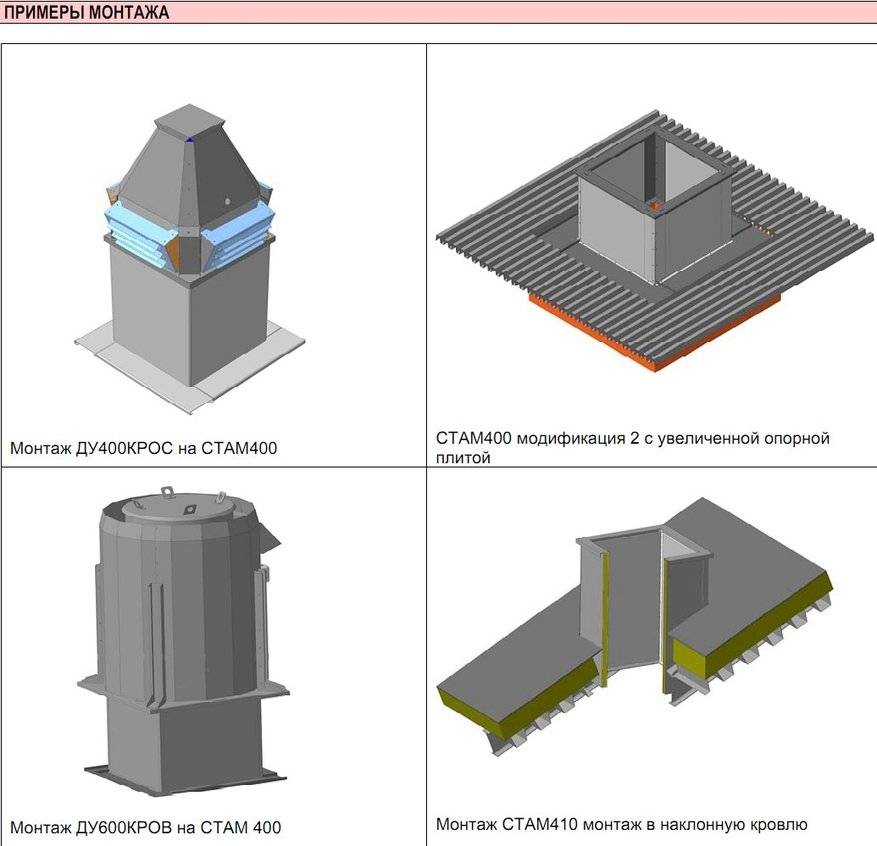

- Channel. This type is mounted at the outlet of a ventilation duct running through a building or at the top of a ventilation shaft.

- Channelless. They are installed on the roofs of single-level large premises, such as production workshops, gyms, retail areas.

- Universal. Having the ability to be installed on any of the systems. An example of such roof fans is the krovdu system.

This should also be taken into account when choosing a ventilation and chimney system. The right choice will ensure maximum functionality, and high efficiency in the event of an emergency.

Installation steps for roof ventilation

By choosing the right type of roof ventilation, based on the required power ratings, features of mounting on the roof, as well as the principle of operation of the device, you can install roof fans.

Roof fan in the production room

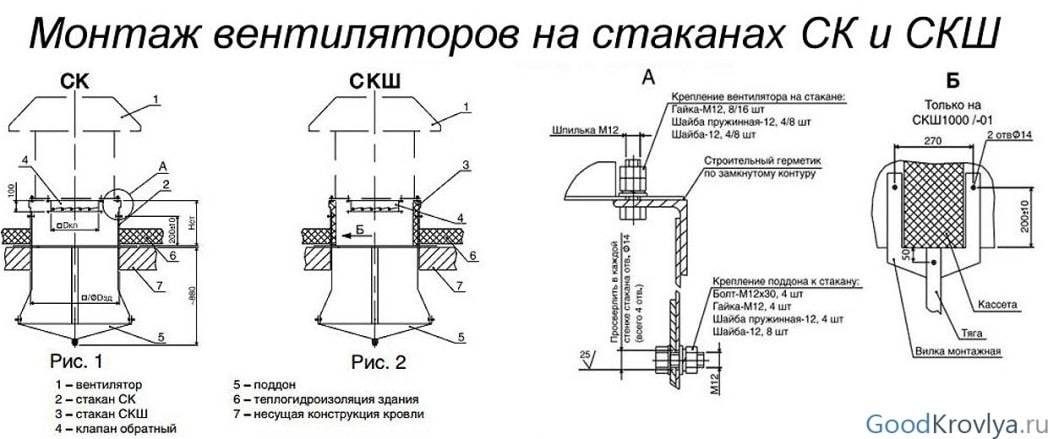

Installation of a roof fan is carried out in several stages:

- Preparation of a hole in the roof for the installation of the system. This type of work can be done according to the principle of roof cutting of the chimney;

- Installation of a glass under the fan. It should be noted that the glass must be mounted exclusively vertically. You should also take into account possible loads on the roof during the operation of the system;

- Next, a roof fan tray is installed. It is attached to the glass;

- Attaching a check valve. In this procedure, the fan is suspended using a special tool. In order to avoid distortion, it is strictly forbidden to lower the fan while connecting the check valve;

- Installation of a fan with a check valve in a glass;

- Completion of installation work. At this stage, all gaps are closed with sealant. To exclude the possibility of roof leakage at the installation sites of the system, it is advisable to make an additional cement screed around the glass and lay waterproofing.

Proper implementation of all stages of installation, as well as the correct choice of the type of roof ventilation, will allow you to be sure of the high-quality operation of the system, as well as that it will not let you down in a critical situation.

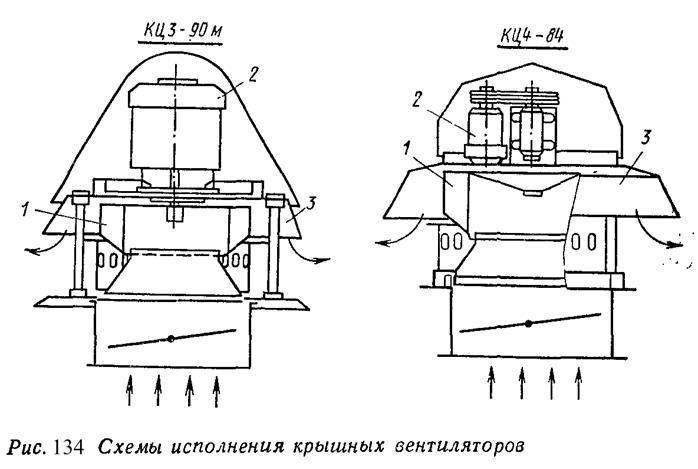

1 Main types of roof fans

Types of roof exhaust systems are distinguished by the principle of operation of the fans. There are three main types:

Axial. The most common type, characterized by simplicity of design and affordable price. Among the range of proposals, one can single out a roof fan by the roof, manufactured by the Veza company, as an excellent option for quality products at a relatively low price.

Air flow through the roof fan

- Diagonal. It has a specific shape of the blades, as a result of which the intake air enters parallel to the fan axis, and at the exit from it - at an angle of 45 degrees. A striking example of the quality of mechanisms of this type can be called systemair roof fans.

- Radial (centrifugal). This type of fan is equipped with a rotor consisting of helical blades. The air flow in such fans enters the rotor, where the blades give it rotational motion, and the air, due to centrifugal force, exits through the opening of the fan spiral casing. In this case, the outlet air flow is at right angles to the inlet. This type of roof fans is widely used in industrial facilities. In the product range of the Veza company, this type of fans is also widely represented, among which, for example, the Vkrndu system line can be distinguished.

The decision to choose the type of roof ventilation should be made based on the volume of the room, installation features at the facility, as well as the required fan power.

Characteristics of devices: performance, operating modes, features of different types

Roof ventilation has only two modes of operation:

- Conditioning mode.In this case, the roof ventilation operates at minimum power, facilitating air circulation in the room.

- Emergency mode. The mode in which the roof ventilation operates at full capacity, for the fastest possible cleansing of the room from hazardous gases or combustion products. Depending on the type, the emergency mode can be activated manually, or automatically, thanks to the sensors built into the fan. Preference should be given, of course, to Vkrn automatic fan systems manufactured by Veza, because the human factor in an emergency can play a negative role.

Design of axial and radial roof fans

For clarity, let's consider the difference in performance of one of the models of roof ventilation VKRH, manufactured by Veza: in normal mode, this system provides a performance of about 2300 cubic meters of air per hour.

When the emergency mode is turned on, the fan of this model is capable of pumping out up to 130 thousand cubic meters per hour, providing a quick cleaning of the object, or pumping air out of the room, which leaves little chance of a fire when the inlet ventilation is closed.

Conclusions and useful video on the topic

Large manufacturers of ventilation systems produce video instructions for installation on the roof and fastening of supply and exhaust units, shaped elements, aerators, deflectors:

The arrangement of the exit through the roof to the roof of the ventilation pipe of the house must be approached especially carefully. Indeed, in natural ventilation systems, the presence of traction in the system depends on the state of this node.

Do not allow the pipe to flood with rain or ice

Therefore, much attention is paid to sealing the assembly itself and installing additional protective parts. Similarly, installation of supply devices is carried out.