- Soldering polypropylene pipes

- How to choose the right pipe diameter for home heating - table and calculations

- Rules for welding pipes together

- Dimensions of polypropylene pipes

- Preparation for installation of PP pipes

- Stage 1 drafting

- Stage 2 preparation of tools

- Stage 3 selection of polypropylene fittings

- Stage 4 connection scheme selection

- Choosing polypropylene pipes

- Required data for calculation

- Advantages of polypropylene heating circuits

- Classification and design parameters

- Marking and scope

- What are the advantages of installing heating from polypropylene pipes

- Advantages and disadvantages of PP

- Conclusion

Soldering polypropylene pipes

Before starting work, you need to prepare the tools and equipment necessary for installation.

- For soldering polypropylene pipes, a special soldering iron is used. Its design is made in such a way as to simultaneously heat the inside of one element and the outside of the other. There are nozzles for each of the pipe diameters in the soldering iron kit. Each appliance is equipped with a power regulator, thanks to which you can adjust the heating temperature.

- You will also need a sharp knife, and a tool for stripping pipes, which are reinforced with foil.

- The soldering time depends on the diameter of the pipes and the ambient temperature.You can't overdo the pipes. Otherwise, melted polypropylene will create a natural barrier to the flow of water at the junction. So for a pipe with a diameter of 20 mm, the heating time is only 5 seconds, while a pipe with a diameter of 75 mm needs to be heated for about 30 seconds.

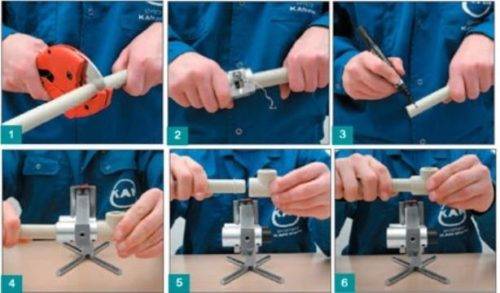

The process of soldering pipes is quite simple:

- First of all, nozzles are put on the heating part of the soldering iron, which correspond to the diameter of the pipes to be soldered.

- Then the soldering iron is turned on at a power that corresponds to the recommended for a particular type of pipe.

- Two parts are put on nozzles (one outside, the other inside) and held for the required time. In the process of dressing (pulling) the connected parts onto the nozzle, an influx is formed on the surface of polypropylene, which plays the role of a side.

- After a certain time, the parts are removed from the soldering iron and connected to each other. In order for the polypropylene to harden, it is necessary to hold them for 30 seconds.

- It is imperative to remember that when heating or connecting, in no case should the parts be rotated. Otherwise, the polypropylene will “move out” and the connection may become leaky. This is the main rule for installing plastic pipes.

- Currently, nozzle manufacturers have made a special mandrel that signals that it is time to stop heating. It just has a small hole in it. When the polypropylene is already heated, it begins to flow out through the hole. In this case, the parts are removed from the soldering iron. In this way, absolutely all polypropylene pipes are soldered, including heating pipes.

How to choose the right pipe diameter for home heating - table and calculations

It is not difficult for a professional to calculate the optimal cross-section of a pipeline. Practical experience + special tables - all this is enough to make the right decision. But what about being an ordinary homeowner?

After all, many people prefer to mount the heating circuit on their own, but at the same time they do not have a specialized engineering education. This article will be a good hint for those who need to decide on the diameter of the pipe for heating a private house.

There are several nuances that you need to pay attention to:

- Firstly, all data obtained on the basis of calculations using formulas is approximate. Various rounding values, average coefficients - all this makes a number of corrections to the final result.

- Secondly, the specifics of the operation of any heating circuit has its own characteristics, therefore, any calculations provide only indicative data, “for all cases”.

- Thirdly, pipe products are produced in a certain assortment. The same applies to diameters. The corresponding values are arranged in a certain row, with a gradation of values. Therefore, you will have to select the denomination that is closest to the calculated one.

Based on the foregoing, it is advisable to use the practical recommendations of professionals.

All Du - in "mm". In parentheses - for systems with natural circulation of the coolant.

- The common pipe of the line is 20 (25).

- Leads to batteries - 15 (20).

- With a single-pipe heating scheme - diameter 25 (32).

But these are general contour parameters that do not take into account its specifics. More accurate values are shown in the table.

Rules for welding pipes together

The procedure for connecting polypropylene pipes to each other by welding should be as follows:

- To begin with, you should put the fitting on a heating pin specially designed for this, and insert the pipe into the sleeve from the reverse side.

- After that, the parts should be kept on the soldering iron for such an amount of time that they soften sufficiently and are ready for fastening together (as a rule, this time depends on the thickness of the pipe walls). If desired, a photo with the parameters of the exposure time of products on a soldering iron can always be found from specialists in the installation of such equipment.

- Further, having removed the parts from the heater, they must be quickly and tightly connected to each other by compression.

Dimensions of polypropylene pipes

Tables of diameters and wall thicknesses of polypropylene pipes depending on the type of pipe

In general, polypropylene pipes are produced in different sections and diameters. Sections can be square, oval and round, and radii (or dimensions in cases with a square section) from 20mm to 600mm. For heating, only pipes with a round cross section are used, the diameter of which is in the range from 20mm to 40mm. These dimensions are sufficient for wiring any individual heating system.

What must be taken into account when choosing is that when marking, the outer diameter is indicated, and not the inner one. The internal is calculated. To do this, the wall thickness is subtracted from the specified value. The wall thickness depends on the type of pipe and the type of reinforcement. The table shows the wall thickness values depending on the diameter for PPR pipes used in heating PN20 and PN25.

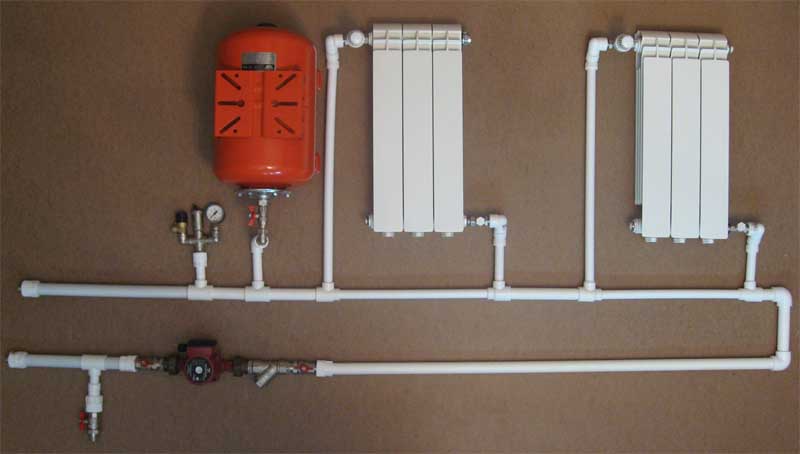

When designing a heating system with your own hands, it is necessary to correctly calculate the diameter of the pipes.To do this, you will need a heating scheme. It should indicate the power of the radiators in each room (heat load) and the value of the total heat loss of the apartment or house (actual or predicted boiler power). Based on these data and special tables, the diameter of the pipes is selected at each stage of the wiring. Details on how to choose the diameter of the pipe for heating are described here.

Preparation for installation of PP pipes

To carry out the installation of PP pipes, it is important to carefully study the scheme of the water supply and heating system, prepare a number of tools and read the step-by-step instructions. All work is carried out in several stages

All work is carried out in several stages.

Stage 1 drafting

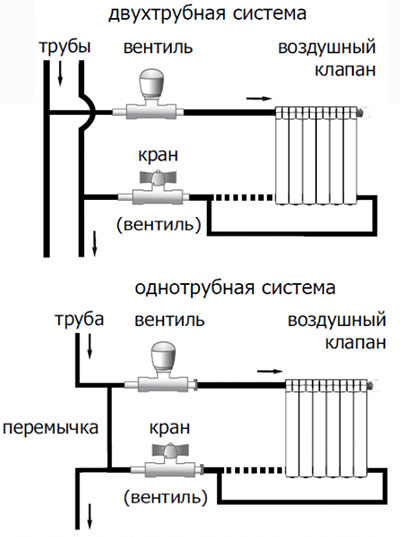

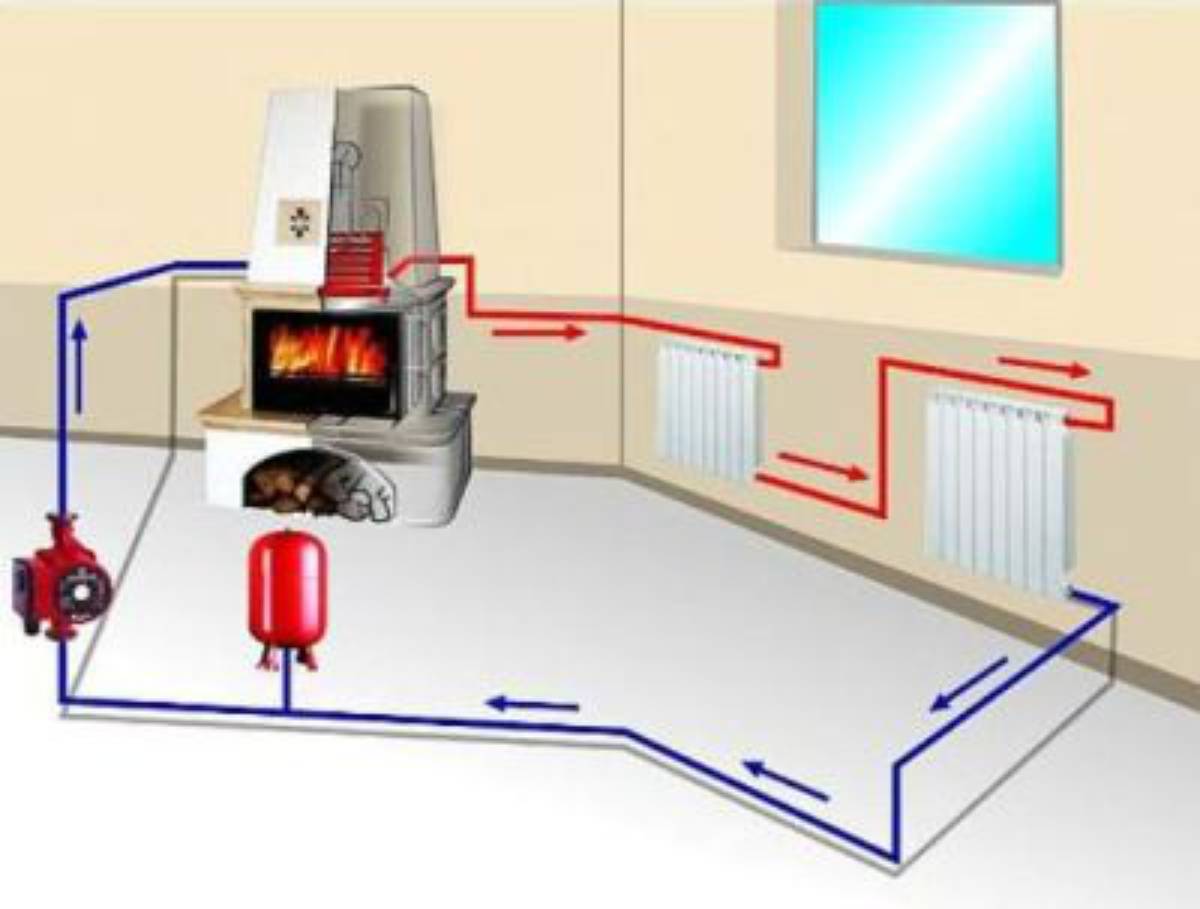

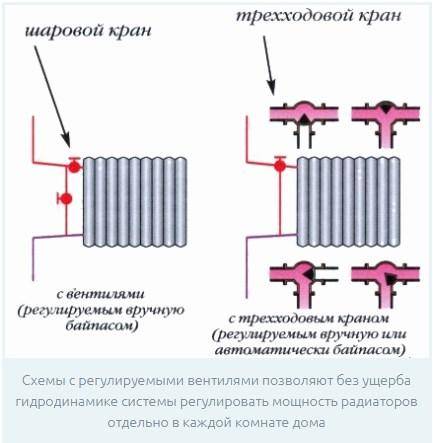

Before purchasing materials for installing pipes with your own hands, you need to draw up a diagram of their connection. To connect the batteries to the heating circuit, the following methods are used:

- Flowing.

- Installation with non-adjustable bypass.

- Installation with valves.

- With three way valve.

Even home plumbing may differ in the wiring diagram. Today, two technologies for the installation of polypropylene pipes are used:

- Parallel. It is carried out according to this principle: a collector resembling a flute is installed at the inlet of the water supply system. With it, you can create a number of taps in any convenient direction.

- Tee (considered the traditional solution).

A separate pipe is pulled from each outlet. The advantage of this system is the same level of pressure at all points of liquid analysis, and the disadvantage is the need to use a large number of pipes. At the same time, if one element is damaged, the remaining parts will work without failures.

The last scheme is called sequential and consists in laying a single pipe for all plumbing. Further from it, bends are made by means of a tee.

Stage 2 preparation of tools

Working with polypropylene pipes involves the use of a special tool. The cost of all devices will vary from 5 to 10 thousand rubles. The basic set consists of:

- Welding equipment or soldering iron for working with polypropylene.

- Scissors for cutting pipes.

- Aluminum shaver.

- Calibrator, with which it will be possible to monitor the diameter of all components.

- Parts for heating soldering elements.

| Tool photo | Name |

|---|---|

| welding machine, for work at home it is recommended to use units designed for welding PP pipes of small and medium diameter - up to 63 mm. |

| A pipe cutter is an ideal device for cutting off polypropylene. |

| Shaver - designed to remove a layer of reinforcement. |

| The trimmer is needed for high-quality pipe joining |

| Marker for marking pipes. |

| Using a building level and a pencil, draw the direction of the pipes on the wall |

| Roulette is one of the main tools in construction. |

| A degreaser is needed to remove impurities from the surfaces of welding joints. |

In addition, you need to find an adjustable wrench, a tape measure and a marker. If PPR structures and pipeline installation are implemented once, it is better to ask friends for tools or rent them.

Stage 3 selection of polypropylene fittings

To carry out the laying of a water pipe from polypropylene pipes with your own hands and combine them with home plumbing, you should purchase special PP fittings. Among them:

- Adapters.

- Nipple type taps.

- Connecting couplings.

- Tees.

- Plugs.

- Crosses.

- Ball Valves.

- Clamps.

Since the quality of the fittings may vary, it is necessary to select them taking into account the characteristics of the pipe.

Stage 4 connection scheme selection

For distributing water supply in an apartment with polypropylene, you should find a connection diagram. The specifics of soldering may differ for pipes of different diameters. Pipes of the same thickness are joined end-to-end, and different ones - using the socket method. It implies a joint of one part of the pipe into an expanded fitting.

1. Top ball valve for heated towel rail. 2. Ball valve to the jumper. 3. Bottom ball valve for heated towel rail. 4. Main faucet for hot water. 5. Filter - "Mud" 6. Counter. 7. Fine filter. 8. Pressure reducer. 9. Collector. 10. Main tap for cold water.

1. Top ball valve for heated towel rail. 2. Ball valve to the jumper. 3. Bottom ball valve for heated towel rail. 4. Main faucet for hot water. 5. Filter - "Mud" 6. Counter. 7. Fine filter. 8. Pressure reducer. 9. Collector. 10. Main tap for cold water.

The connection of PP products can be detachable or one-piece. In the first case, threaded fittings are soldered to the ends of the parts. With one-piece installation, two polypropylene structures merge.

Choosing polypropylene pipes

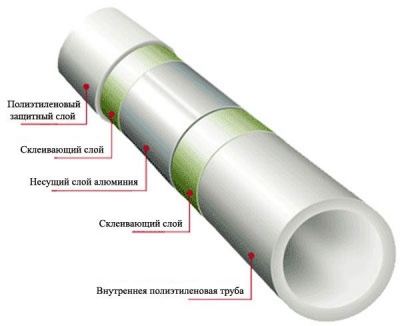

Polypropylene pipes for heating have an aluminum layer in their design, for greater resistance to high temperatures.

Ordinary plastic pipes for heating are not suitable - the high temperature of the coolant can damage them. Therefore, reinforced pipes are used in heating systems. They contain aluminum or fiberglass in their structure, which makes them stronger and more resistant to high temperatures. Such products are the best suited for use in heating systems.

When choosing pipes made of polypropylene, you need to pay attention to the manufacturer.The best option is to buy products from the most common brands, which are not so many.

Taking the products of a little-known manufacturer, you may encounter a situation where there are no suitable fittings and other accessories - if something breaks in the system or it needs to be reworked, installation and repair work may be delayed until the necessary elements are found.

For the installation of pipes, it is desirable to use one-piece fittings - they provide a strong and tight connection. Installation work is carried out using a special soldering tool.

Required data for calculation

The main task of heating pipes is to deliver heat to the heated elements (radiators) with minimal losses. From this we will build on when choosing the correct pipe diameter. for home heating. But to calculate everything correctly, you need to know:

- pipe length;

- heat loss in the building;

- element power;

- what will be the piping (natural, forced, one-pipe or two-pipe circulation).

The next item after you have all the above data on hand, you will need to sketch out a general scheme: how, what and where it will be located, what heat load each heating element will carry.

Then it will be possible to begin to calculate the desired section of the diameter of the pipe for heating the house. You should also be careful when buying:

- metal-plastic and steel pipes are marked by the size of the inner diameter, there are no problems here;

- but polypropylene and copper - according to the outer diameter.Therefore, we need to either measure the inner diameter ourselves with a caliper, or subtract the wall thickness from the outer diameter of the pipe for heating the house.

Do not forget about this, because we need exactly the "inner diameter of the pipe for heating the house" in order to calculate everything correctly.

Advantages of polypropylene heating circuits

The use of polypropylene pipes in heating is due to a lot of advantages, among which the following can be noted:

the service life of polypropylene heating pipes is from 25 to 50 years;

due to the special composition, the inner walls of such pipes are not subject to corrosion;

even at high temperatures, polypropylene is resistant to chemical influences;

the coolant in the polypropylene heating circuit does not make unpleasant noises;

the reliability of the joints of these elements allows you to equip a reliable and integral design;

performing such a procedure as soldering heating with polypropylene pipes, you will not need to use complex construction equipment, since it will be enough just to use a standard welding machine or a soldering iron;

the cost of polypropylene pipes is affordable for the average consumer;

due to the special properties of such a material, it does not allow oxygen to pass through itself, which helps protect the system from the formation of rust in it and from damage to metal parts;

the strength of polypropylene pipes is very high;

An equally important property of these products is their environmental friendliness and harmlessness for residents.

Classification and design parameters

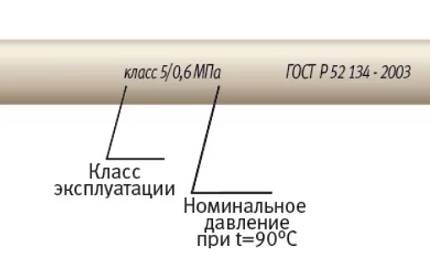

The existing GOST standards (ISO10508) establish the classification of polypropylene hoses, based on which this material can be used in certain operating conditions.

The marking of PP pipes clearly indicates the operating parameters

Taking into account this designation, it is easy and simple to choose the material for a specific configuration of the heating system. Long-length polypropylene products are divided into 4 classes (1.2, 4.5) according to typical areas of application and operating pressure values (4,6,8,10 ATI):

Long-length polypropylene products are divided into 4 classes (1.2, 4.5) according to typical areas of application and operating pressure values (4,6,8,10 ATI):

- class 1 (hot water systems up to 60°);

- class 2 (hot water systems up to 70°C);

- class 4 (floor heating and radiator systems up to 70°С);

- class 5 (radiator systems up to 90°С).

For example, polypropylene pipes are required to make a low-temperature heating system. Then, according to the designation on the outer surface of the pipes, it is possible to determine the suitable material.

For this case, hoses with the designation - Class 4/10 are quite suitable, which corresponds to the boundary temperature parameter of 70ºС and the permissible limit of the working pressure - 10 ATI.

The industry, as a rule, produces products for general purposes. An extensive classification is supported by manufactured products. In the documentation for such material, the marking of PP pipes is indicated by the standard enumeration of permissible parameters (Class 1/10, 2/10, 4/10, 5/8 bar).

Each branded product has an application class designation on the outer surface, which actually determines the operational parameters of the future home heating design.

Thus, when counting on making heating in a polypropylene house with your own hands, the main material is usually chosen by the master in direct proportion:

- from the planned operational parameters;

- from methods of heating the coolant;

- from the applied regulation system.

It is also desirable to calculate the service life of the future heating system, using the parameters:

- upper values Trab and Pwork;

- pipe wall thickness;

- outside diameter;

- safety factor;

- duration of the heating season.

On average, the life of polypropylene should be at least 40 years.

Marking and scope

It is necessary to start the installation of a water supply system from polypropylene pipes by choosing the type of pipes. They are single-layer and three-layer, they also differ in wall thickness and, accordingly, have different purposes. To make it easier to navigate, they are marked:

- PN10 - single-layer pipes designed for cold water in pipelines with low pressure. Suitable for distributing polypropylene plumbing in private homes.

- PN16 - single-layer pipes with a thicker wall. They can be used both for transporting cold water in systems with increased pressure (centralized), and for distributing the DHW system. The maximum allowable temperature is +50°C.

- PN20 - three-layer pipes with a fiberglass reinforcing layer. They can be used for the installation of a water supply system for transporting hot water, low-temperature heating systems. Maximum temperature +90°C.

- PN25 - three-layer pipes reinforced with aluminum foil. They are mainly used for heating, they can be used for hot water supply, but this is not economically feasible: these are the most expensive pipes, and their qualities for hot water supply are excessive.

By colors there are pipes made of gray and white polypropylene. This is not displayed in any way on quality, so choose according to aesthetic preferences. Some firms (mostly German) paint their products green. If the wiring is hidden - in the walls or in the floor - you won’t find anything better, since the Germans are leaders in quality.

For the installation of a water supply system from polypropylene pipes, fittings will also be required.

To make it easier to navigate by area of application, colored stripes are applied along the PPR pipes. Those that are designed for cold water are marked in blue (light blue), those for hot water and heating are marked in red, universal ones are marked in orange. Some manufacturers have different markings. They mark products for heating and hot water in red, and do not apply markings to those intended for cold.

From the above, the following conclusions can be drawn: it is better to install a water supply system from polypropylene pipes in an apartment from PN 16 for cold water and PN20 for hot water. In a private house, you can get by with PN 10 for cold water and PN 20 for hot water.

What are the advantages of installing heating from polypropylene pipes

More than twenty years of use of this type of pipe has proven the reliability of this material, and also revealed a number of advantages over metal pipes.

Installation of heating from polypropylene pipes must be carried out in accordance with clear instructions and according to a specific scheme, however, this does not prevent such pipes from remaining practical and functional at the same time.For a better understanding of the advantages of installing a heating system using polypropylene pipes, you need to look at their technical characteristics.

If we compare the heat resistance of polypropylene with other materials, we can note its high heat resistance. Polypropylene softens at 140°C, and melting begins at 170°C.

This is of particular interest in the installation of heating systems using PP pipes, since the temperature of hot water in them is usually kept at no more than 95 ° C. For systems where the temperature of hot water exceeds 105 ° C, various cooling methods are provided that prevent the coolant from boiling.

It is worth noting the high resistance of polypropylene pipes to mechanical stress and moisture absorption. In case of prolonged contact with water (for example, within half a year), polypropylene will absorb only 0.5% moisture. In the case when the temperature of the coolant will remain above 60 °C for a long time, the absorption coefficient will not exceed 2%.

To all of the above, you can add a list of other advantages of PP pipes that affect the efficiency of the heating system:

-

PP pipes serve from 50 years;

-

they are environmentally friendly and are great for installation in premises intended for permanent residence;

-

polypropylene pipes show excellent resistance to corrosion, to chemically active environments;

-

polypropylene does not pass moisture and does not conduct electricity;

-

scale does not settle in the pipe, outgrowths of deposits of the aquatic environment, smoothness and, therefore, high throughput throughout the entire service life are maintained;

-

the configuration of pipes and accessories allows for the installation of heating from PP pipes independently;

-

the low density of polypropylene pipes prevents cracking or other damage that occurs in other materials due to hot water and pressure;

-

the light weight of polypropylene pipes simplifies their installation;

-

competitive price compared to other plastic pipes: installing heating with polypropylene pipes will save a lot.

This list is a clear reason why for the installation of heating both residential and office space, the vast majority chooses polypropylene pipes.

Read the material on the topic: How to make heating in a private house: options and schemes

Advantages and disadvantages of PP

The advantages of PP pipes in the installation of internal heating and water supply are obvious and are confirmed by their undivided dominance in this area.

The properties that make this product a priority for the assembly of intra-house communications are:

- noiselessness;

- impact strength;

- ease;

- resistance to corrosion;

- durability;

- tightness of connections;

- cheapness;

- immunity of the inner walls to raids.

But polypropylene pipes also have negative sides that cause inconvenience during installation:

- lack of flexibility;

- strong relative elongation during heating;

- the need for special tools when connecting individual products.

Specialists who assemble PP pipes on a daily basis have long developed ways to compensate for these shortcomings, so there are no special alternatives to polypropylene.

Conclusion

Working with polypropylene pipes is not particularly difficult.Previously, any installation of the heating system has a ready-made scheme and thermal calculations. With the help of the drawn up scheme, you will be able not only to calculate the required number of pipes for your heating circuit, but also to correctly place the heating devices in the house.

The use of polypropylene pipes at home allows you to reinstall the radiator at any time. The presence of appropriate shut-off valves will ensure that you turn the radiators on and off at any time. However, during the installation process, certain rules and instructions should be followed.

- avoid using a combination of individual pipe fragments made of different materials during installation.

- Excessively long piping without the proper number of fasteners can sag over time. This applies to small heated objects, where there is a powerful autonomous boiler, respectively, the water in the pipeline has a high temperature.

When installing, try not to overheat the pipe, fittings and couplings. Overheating leads to poor soldering quality. Molten polypropylene boils, obscuring the internal passage of the pipe.

The main condition for the durability and quality of the pipeline of the heating system is the strength of the connections and the correct piping. Feel free to install taps and valves in front of each radiator. By installing an automation system and adjusting the heating mode, with the help of taps you can mechanically turn on and off the heating in the room.

Oleg Borisenko (Site Expert).

Indeed, the configuration of the room may require a combined connection of radiators.If the design of the radiator allows, then several radiators can be mounted in one circuit by connecting them in different ways - side, diagonal, bottom. Modern threaded fittings, as a rule, are high-quality products with consistent thread parameters. However, to ensure the tightness of threaded connections, various seals are used that differ in characteristics. The sealing material must be selected depending on the design features of the heating system and its location (concealed, open), since sealants can be designed to adjust (tighten) threaded joints, or they can be a one-time use that does not allow deformation after curing. Select a sealant for sealing threaded connections will help the material of this

- Do-it-yourself project and calculation of a brick fireplace

- How to lay and insulate heating pipes in the ground?

- Why do you need a plinth for heating pipes?

- Choosing ribbed registers, radiators and heating pipes

- How to hide a heating pipe?