- Peculiarities

- Installation of duct air exchange systems

- Basic rules for duct design

- Features of the installation of plastic boxes

- Installation of supply and exhaust ventilation with recuperation

- Installation diagrams

- Natural

- Forced

- mixed

- Project composition

- Optimal scheme

- Tasks to be solved in the design

- Low noise and vibration

- Climate control and energy saving

- Integration

- Promising technologies

- Ergonomics

- Aesthetics

- Scope of use and general installation information

- Designing ventilation in the house

- Ventilation: design consists of several stages

- The composition of the project documentation

- Device nuances

- Types of ventilation systems

- Connecting blocks

- Drainage

- Freon circulation system

- rolling

- Port connection

Peculiarities

Ventilation designers deal with seemingly "weightless", but with a very capricious substance - air. If for the development of the project of electrical wiring, plumbing and other communications, an increase in the volume of the building only increases the quantitative complexity of the work, then with ventilation it is not so. On an area of 1000 sq. qualitatively new problems arise. In addition, it is necessary to analyze from the very beginning where it is possible to use the natural course of air, and where it is necessary to help it.In some cases, fans are indispensable.

Another caveat: you need to consider the location of the ventilation. If the building has one floor - this is one situation, but in multi-tiered buildings the situation is different. The preparation of projects for such buildings as:

- residential buildings;

- industrial premises (with a breakdown by industry);

- medical institutions;

- educational organizations;

- hotels and so on.

Installation of duct air exchange systems

When installing duct ventilation systems or kitchen hoods, special boxes or flexible corrugated pipes are used.

They are also needed to move air from technical rooms to a remote entrance to the ventilation shaft. You can carry out the installation of such an air duct on your own.

Basic rules for duct design

For apartments, there is no need to use metal ventilation ducts designed to pass air at high speeds and to operate at sub-zero temperatures. Plastic boxes are easy to install and easy to fit into the design of any room.

You can find many offers of plastic ducts for ventilation, differing in color, cross-sectional area, shape, method of connecting sections and method of fastening to walls and ceilings.

The presence of a large number of shaped elements allows you to create a ventilation duct of any geometry. The choice between a round and rectangular cross-sectional shape is not fundamental from a technical point of view.

The cross-sectional area should be selected in such a way that the flow velocity does not exceed 2 m/s. Otherwise, noise will occur in the channel, and the increase in resistance will lead to rapid wear of the equipment.

The size of the plastic ventilation duct for the apartment must be chosen in such a way that the air flow rate at maximum load is from 1 to 2 m/s

The size of the plastic ventilation duct for the apartment must be chosen in such a way that the air flow rate at maximum load is from 1 to 2 m/s

When designing duct geometry, it is desirable to minimize the number of turns, constrictions, and transitions that increase aerodynamic resistance to flow, generate noise, and accumulate grease and dust deposits.

Features of the installation of plastic boxes

The plastic parts of the ventilation duct are lightweight, so they do not require any special actions during fastening.

Depending on their location, installation takes place as follows:

- Inside the cabinets, the elements are fastened with clamps to the cabinet walls. Foam or foam rubber inserts are introduced into the places of passage through walls and partitions to prevent rattling during system operation.

- Above the cabinets, the elements are fixed using any holders and self-tapping screws.

- The structure is fixed to the wall and ceiling with the help of special clamps, which can be purchased for any channel size. The distance between fasteners should be no more than 1 meter.

Immediately after the installation of the ventilation duct, which will subsequently be hidden behind a stretch or suspended ceiling, it is necessary to check its operation at the maximum possible air flow. Detected problems are easier to fix immediately, while access to the system is not difficult.

It is quite simple to securely fix the elements of the plastic ventilation duct with the help of special clamps. They are not expensive, so it is better not to use independent solutions.

By smearing the joints of the elements with silicone sealant, you can get an additional guarantee of the tightness of the structural joints.

For these purposes, it is not necessary to use glue or “liquid nails” type compounds, since in the future it will be almost impossible to disassemble the system for maintenance or changing its configuration.

If depressurization nevertheless occurred, and to eliminate it there is no way to disassemble the air duct, then in this case it is necessary to wrap the problematic joint with self-adhesive tape to match the color of the shaped elements.

Installation of supply and exhaust ventilation with recuperation

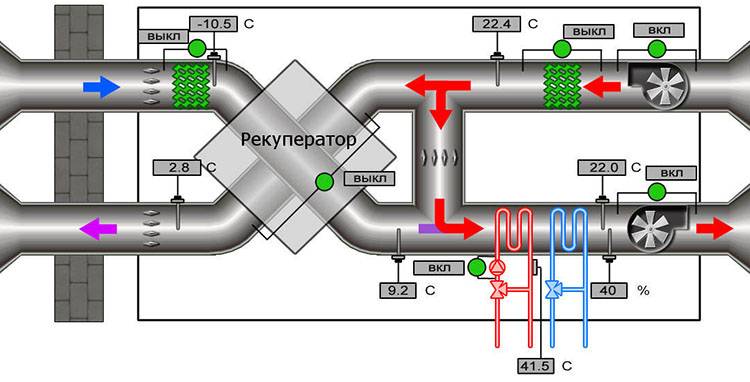

In winter, heated housing can very quickly give off warm, heated air, while a lot of energy is spent on heating the incoming cold air. Ventilation "with repayment" is a system in which a special device is installed - a heat exchanger. Thanks to its heat exchanger, the air entering from the street is heated from the outgoing warm air, without mixing with it.

If a heat exchanger is included in the ventilation circuit, the inlet and outlet channels must converge and run in parallel in the device case.

Recuperator in the ventilation system

It is not advised to place the heat exchanger above living rooms. It is better to place it in the corridor or utility room.

You need to take into account in which position it is advised to install a particular model. Sometimes appliances need to be installed only vertically, or only flat.

If the design of the heat exchanger provides for the collection of moisture, it should be located only in a warm room. Drainage is done at an angle to the nearest sewer riser.

Pay attention to recuperators with cellulose cassettes. Such devices are not so prone to icing, do not require drain installation

In addition, having been absorbed into the cellulose walls, moisture enters the incoming flow channel and moistens it. Thus, the recuperator becomes a bit of a humidifier.

Installation diagrams

The choice of ventilation systems depends on several parameters, including the building materials of the walls and ceilings of the building, the area of the room. An important factor is the degree of purity of the outdoor air; with high levels of pollution, there is no reason to pump it into the house. One of the criteria influencing the choice is cost. The ventilation project should take into account the financial capabilities of the residents, but not be contrary to common sense, otherwise, saving on trifles, you can get big problems in the future.

According to the principle of operation, three types of ventilation can be distinguished:

- natural;

- forced;

- supply and exhaust or mixed.

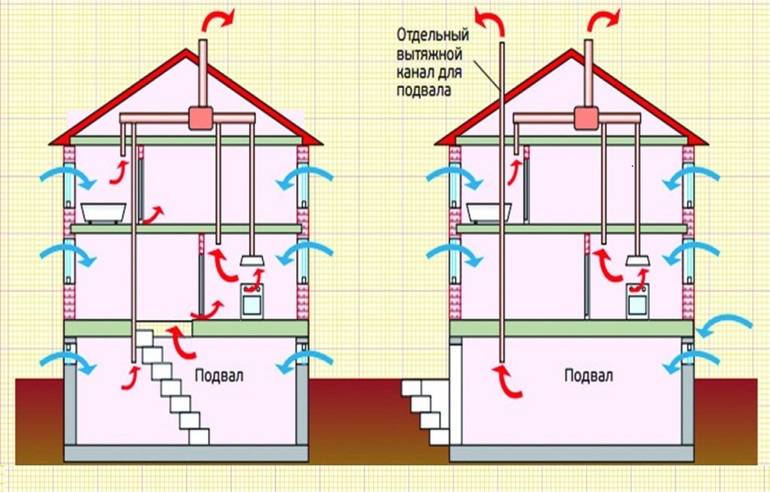

Natural

This type of ventilation works autonomously due to changes in temperature and pressure. Most often used in apartment buildings, where ventilation shafts are installed along the entire building. In each room in the bathrooms and the kitchen, special channels are equipped that bring the exhaust air outside. Air vents were previously supposed to be air inlets, so we often hear that the room needs to be ventilated. Air also enters through cracks in the wooden frames. Unfortunately, today plastic window blocks are more often installed than they violate the natural circulation of air flows. In this case, it is necessary to provide additional supply ventilation or open windows more often.

The advantages of this type of systems include autonomous operation, low cost of installation and further maintenance, ensuring the movement of natural air flows, more suitable for normal human life.

Forced

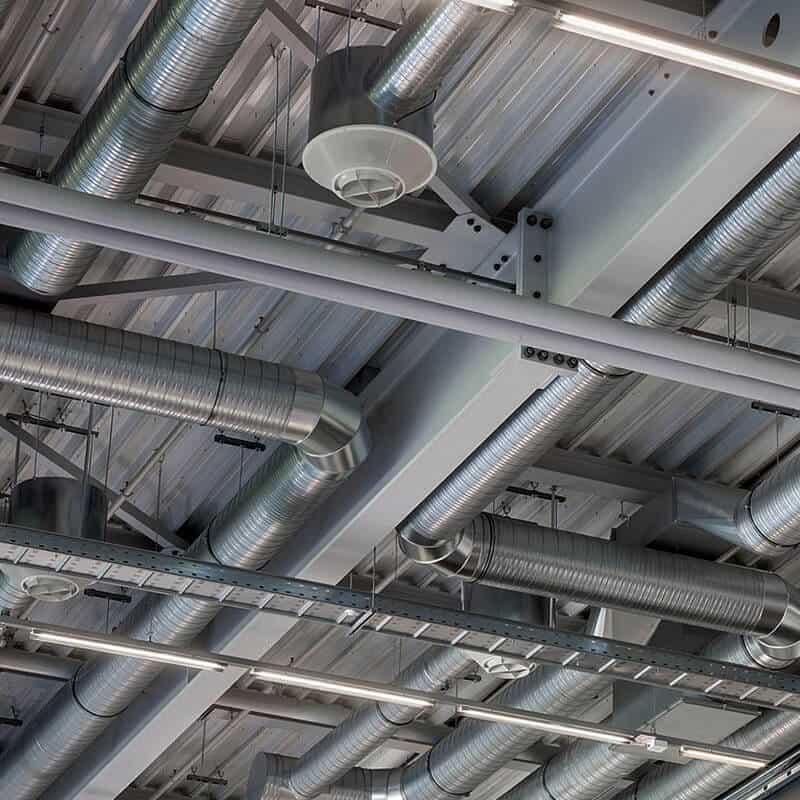

The operation of the system is carried out by special electric fans that pull the exhaust air and evaporation out through the ventilation ducts.

Forced ventilation is more often installed in rooms with a massive crowd of people: production sites, shopping centers, gyms, airports and train stations, classrooms and institute auditoriums.

The advantages of this type of construction are that they are completely independent of the weather outside the window, the purification of the air in the room is due to the filter system, in addition, you can change the temperature of the air flow.

As disadvantages, experts identify the following factors.

- High price at every stage of work, from the cost of the equipment itself to installation and maintenance.

- Since the parts of the system cannot be constantly cleaned, and during operation a large amount of dust and dirt settles on them, they themselves are often breeding grounds for fungi and bacteria. As a result, respiratory diseases in residents are possible: asthma or allergies. To date, special disinfecting complexes have been developed for forced ventilation, they increase its cost, but the effect is actually insignificant.

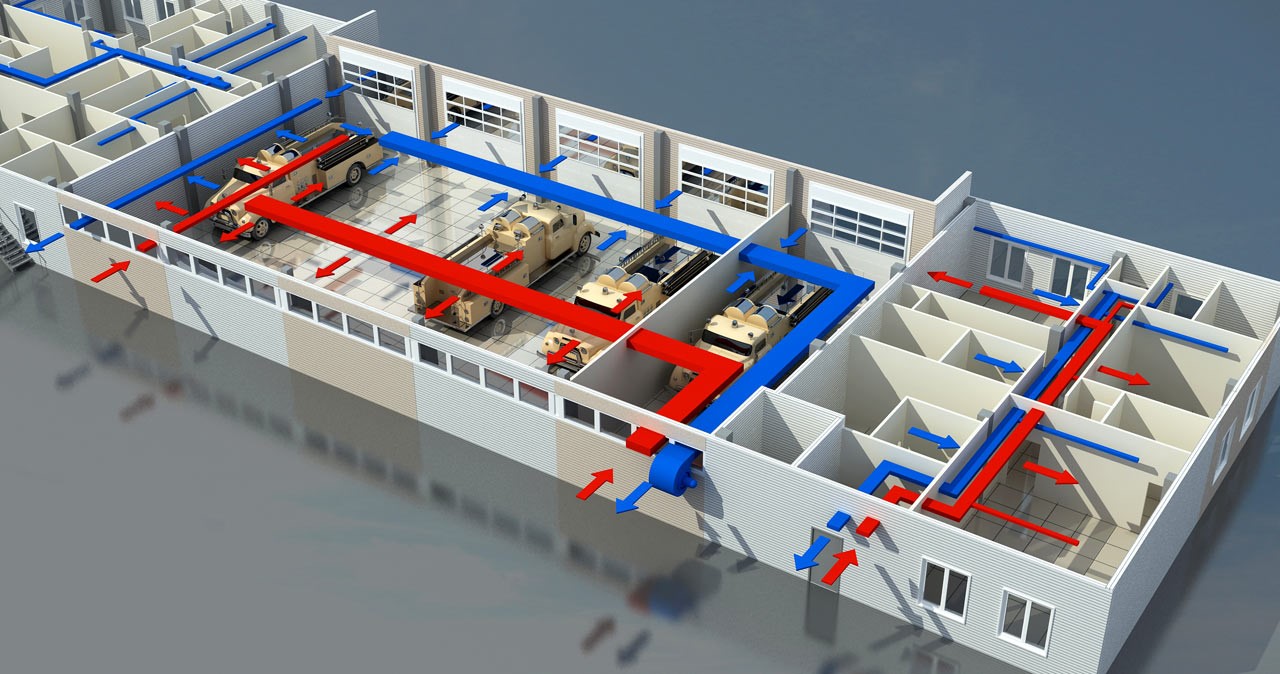

mixed

In this case, natural and forced components are involved in the movement of air flows. Through some openings, air enters the house due to the difference in pressure, through other channels it is removed with the help of fans.

Project composition

- development of a general scheme: general data and equipment characteristics

- calculation of heat gains and air exchange parameters

- explanatory note and feasibility study

- drawings with elements applied to them

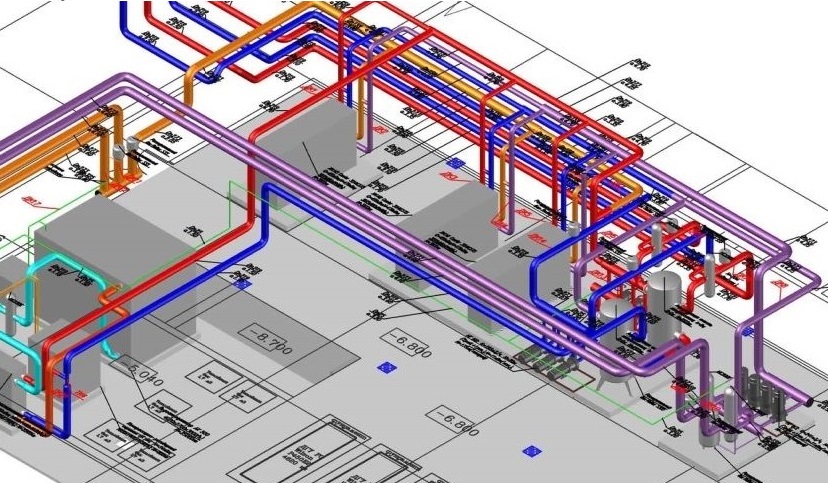

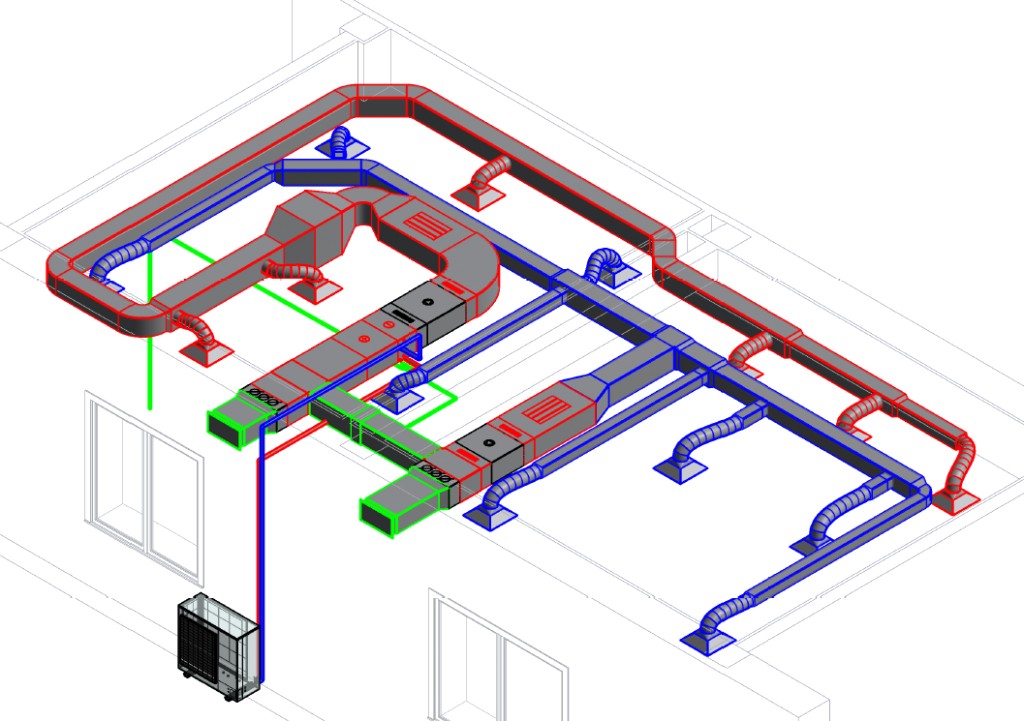

- axonometric diagrams of ventilation and air conditioning

- ventilation equipment specifications

- equipment selection program results and specification

When selecting equipment, computer programs for selecting equipment are used, provided by manufacturing companies, which allows you to select equipment with the best price-quality ratio, as well as ensure flexibility and manufacturability of implementation.

Optimal scheme

There are many schemes and methods for installing a ventilation system in a house. They are selected taking into account the interior decoration, area and other features of the building.

The optimal option should comply with the drafted terms of reference, and also take into account a number of recommendations:

- No extra nodes. The hood should have a minimum number of elements and parts that can fail at the slightest impact.

- Ease of maintenance and repair. Ventilation must be placed in such a way that the master can service it at any time and repair or replace parts.

- Ease of use. The daily operation of the system should be understandable to the owners of the premises, who have neither the skills nor experience in such a matter.

- Backup solutions. In the event of a breakdown of the main components in the building, there should be backup solutions.

- Invisibility in the interior. When designing a ventilation system, it is necessary to take into account the aesthetic part of the work.Any nodes and components of ventilation should not spoil the overall concept of the interior style.

Tasks to be solved in the design

When designing ventilation in the premises of a country house, cottage or any other object, the company's specialists solve the following main tasks:

- First of all, air exchange is calculated for rooms in which an air ventilation system is provided.

- The second task of designing a ventilation system is to carry out an aerodynamic calculation, as a result of which the total air flow is determined, the cross-sectional dimensions of the air ducts are selected according to the selection criteria, and, based on this, the pressure losses in the air duct system are calculated.

- The third task of the design is to carry out an acoustic calculation - the calculation of the sound pressure at the outlet of the air distribution device.

- On the basis of aerodynamic calculations, a detailed and final selection of ventilation equipment is also carried out, the locations of ventilation units and air duct routes are determined.

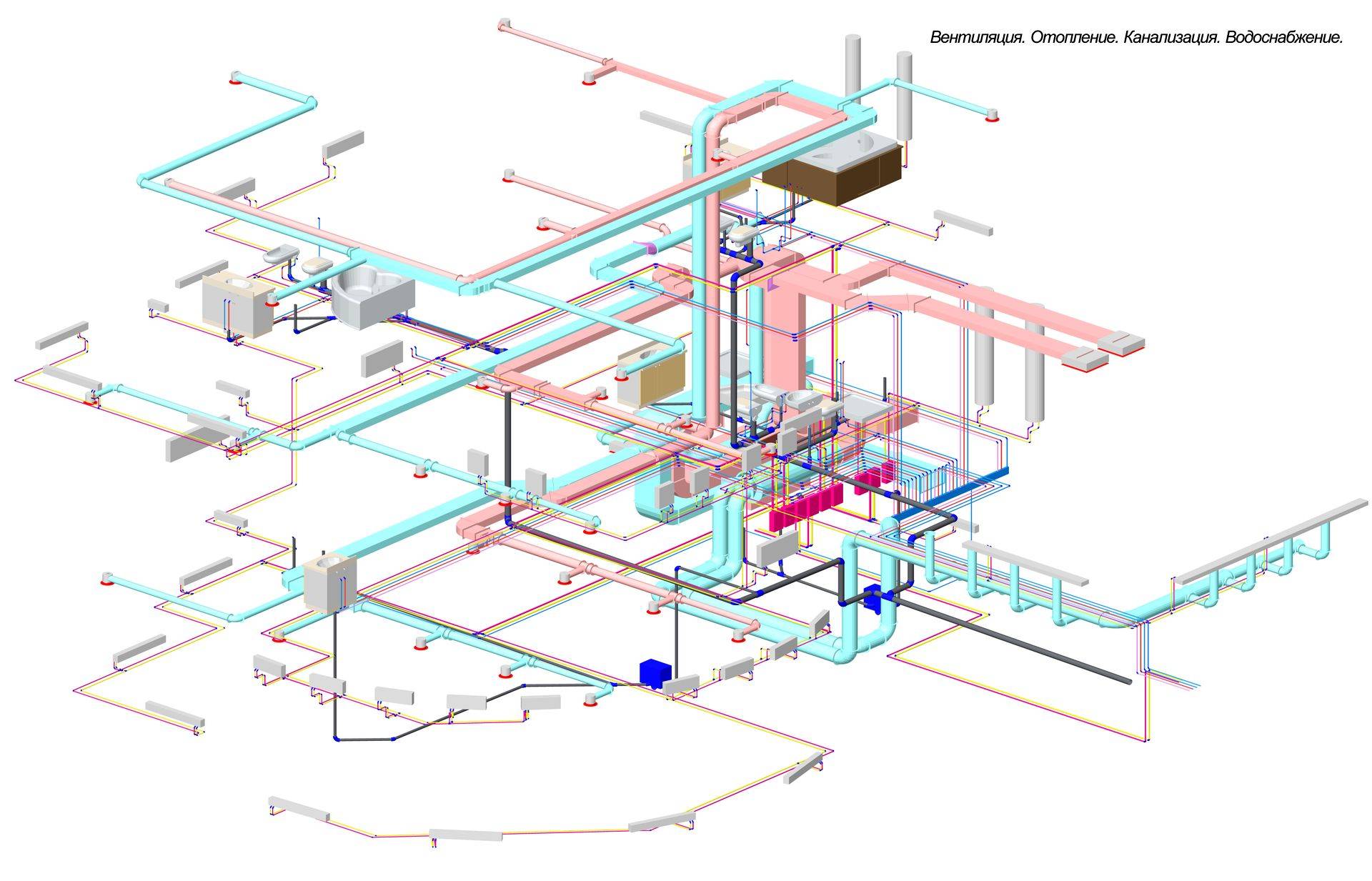

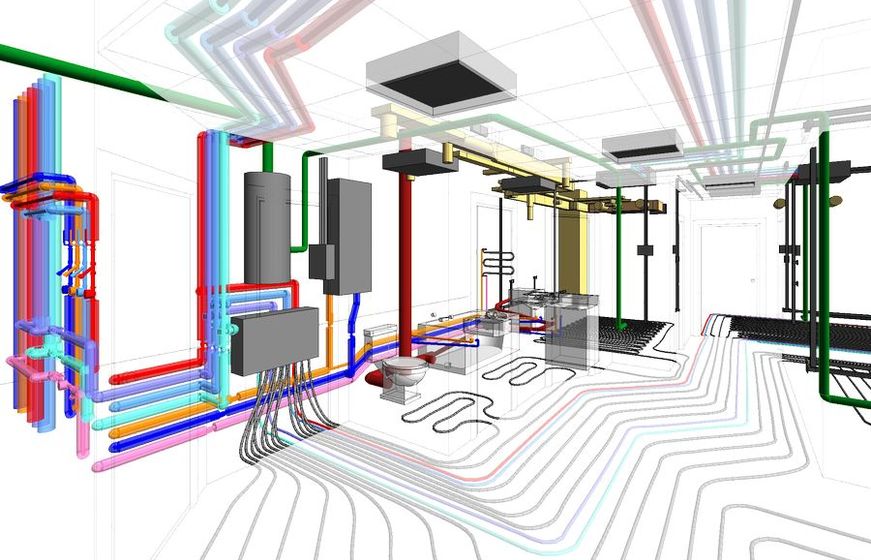

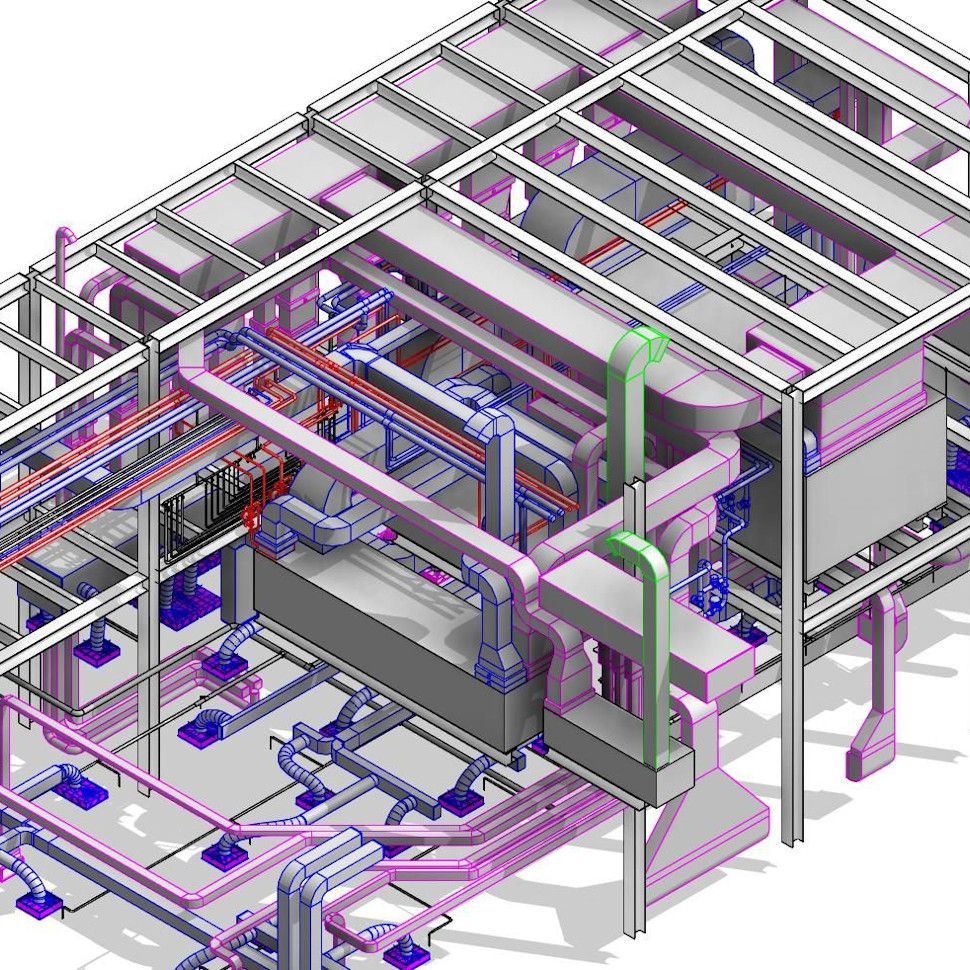

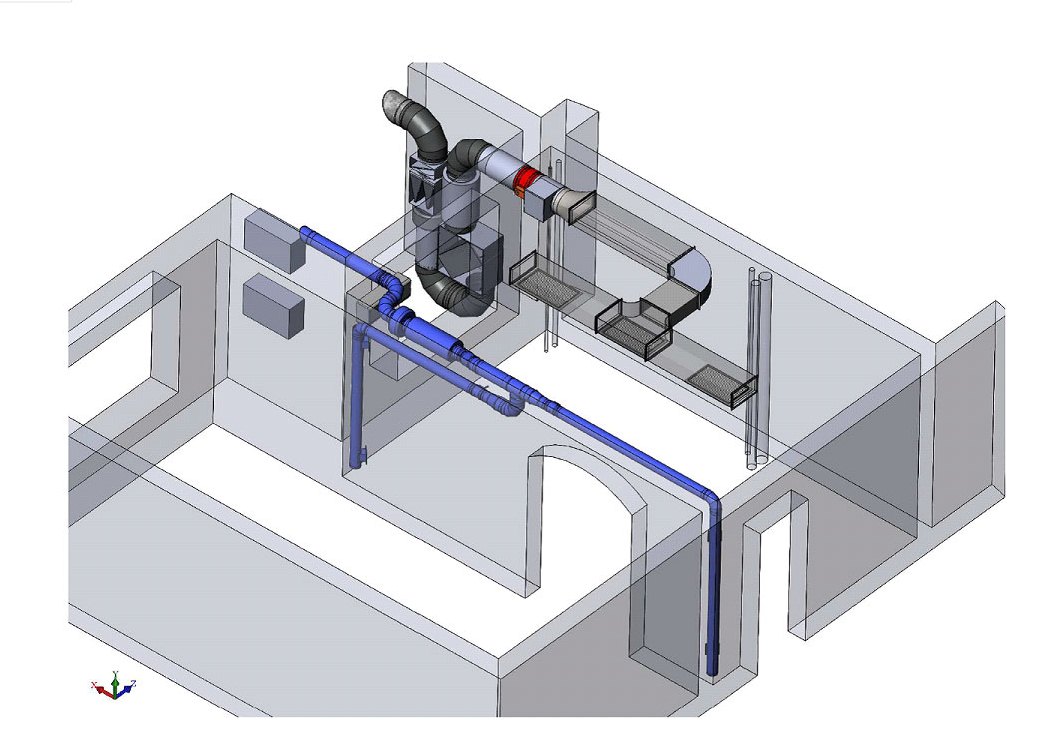

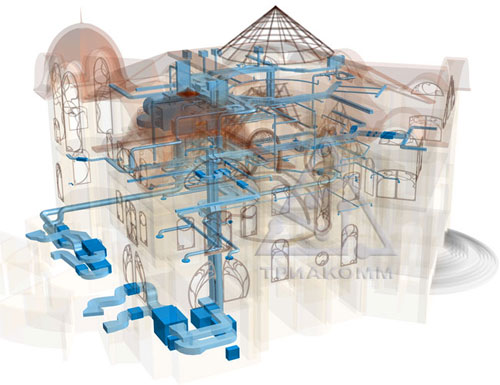

Approximately this is how the designed ventilation system of the building looks like

Approximately this is how the designed ventilation system of the building looks like

Low noise and vibration

The ventilation system obtained as a result of these calculations is checked for compliance with the requirements of regulatory and technical documentation for the limit values of noise and vibration. In case of non-compliance with the requirements, measures are provided to reduce them to the required value.

Climate control and energy saving

The ventilation created according to our projects performs not only the task of providing a given air exchange in the premises, but also allows climate control in the building, and also takes into account the operation of heating and air conditioning systems.The ability to integrate ventilation with these climate systems, as well as with the power supply system, laid down at the design stage, can significantly reduce the energy consumption of the entire building.

Integration

Our experts in the process of designing ventilation achieve its correct integration with other engineering systems to ensure the coordinated operation of the entire complex of climatic and other engineering systems. The designed system can operate under the control of the "Smart Home" system. As a result, you get a modern controlled ventilation system with climate control function.

The video below demonstrates an example of a preliminary system design supply and exhaust ventilation, or rather, the climate system in a private cottage, including:

- climate control functions

- ventilation and heating functions with floor convectors,

- elements of integration with the heating and cooling system,

- the video shows the location of the main engineering equipment, air duct routes and other utilities on the basement and 1st floors of the cottage, as well as the installation site of the Swegon Gold supply and exhaust ventilation unit.

Promising technologies

This motto - "We work with technologies that will become standards in the future" - is not an empty phrase for us. During the design process, our company offers customers only modern technological solutions that will be relevant throughout the life of the ventilation system.

We pay special attention to the use of energy-saving technologies.For 90% of the developed facilities, our company has applied energy-efficient ventilation air handling units ventilation

Ergonomics

The ventilation systems created by our company are very ergonomic - during the design, ventilation control devices are located in easily accessible places, which makes it easy to control the indoor climate.

Aesthetics

In addition to meeting the requirements for ergonomics, when designing ventilation systems, our specialists also comply with the requirements of designers and architects for aesthetics, so that diffusers and other end devices of the ventilation system fit seamlessly into the design of any room in your house, cottage, apartment or office.

In the design process, the personal wishes of the customer must be taken into account.

Scope of use and general installation information

-

The instructions set out the requirements for the launch, adjustment and use of ventilation systems for already operating and commissioning facilities;

- Ventilation units are necessary to create certain temperature, humidity, dust content in accordance with the requirements of sanitary services;

- For each zone of the enterprise (working, auxiliary, technical), the parameters of temperature, air velocity and humidity are set in accordance with the rules for the technical operation of ventilation systems;

- Temperature and humidity indicators are set based on the minimum summer outdoor temperature of +25 degrees. In the operating instructions for the equipment, it is necessary to indicate the optimal values \u200b\u200bof temperature and humidity for a particular enterprise;

- The amount of supply air depends on the volume of the hall and is determined on the basis of SNiP 2-33-75 and the operating instructions for the equipment.

Designing ventilation in the house

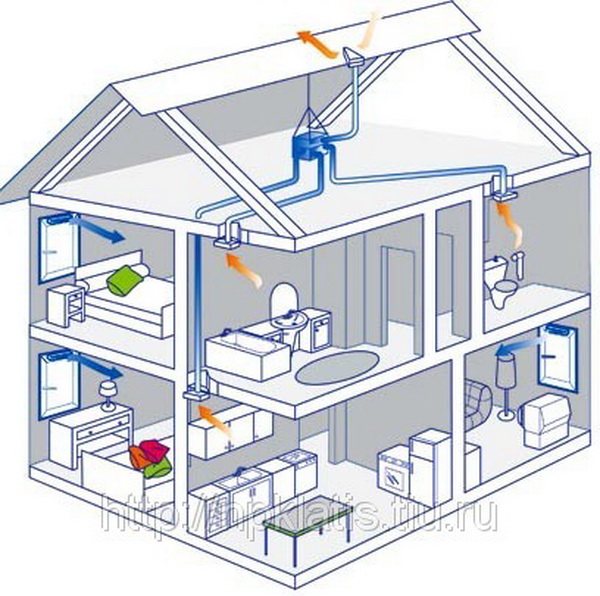

Designing exhaust ventilation or any other is, first of all, a competent arrangement of air ducts. The project is drawn up at the design stage of the house itself and is an integral part of the overall project. Therefore, ventilation ducts, especially exhaust ducts, are laid immediately at the stage of building a house.

First of all, the main risers are laid in the kitchen, in the bathroom and toilet, boiler room and other rooms specified above. Installation is carried out from the basement, that is, the ventilation pipe is laid in the foundation of the house and brought to the basement with the help of a branch. That is, it is installed at the stage of pouring concrete mortar. This, of course, is not a strict requirement, because there are many options for construction, it's just the simplest option.

At the design stage, it is necessary to take into account the volume of air exchange, due to which the sections of the ventilation pipes are selected. This is an important point on which the efficiency of the entire system depends. Be sure to take into account the performance of the fans and their installation location.

Ventilation: design consists of several stages

The calculation takes into account the specifics of the building and individual rooms in it

The calculation takes into account the specifics of the building and individual rooms in it

- Inspection of the building where the system will be installed, or familiarization with its plan. Finding out the volume and purpose of the room, taking into account the number of people and the time they spend in the room, the presence of household electrical appliances, determining the level of humidity, air aerodynamics. Based on the data obtained, the preparation of technical specifications;

- Calculation of the intensity of air exchange, calculation of acoustic and aerodynamic indicators.

- Calculation of the suitable power of the necessary equipment for ventilation. Calculation of compression and cross-section of the air duct, its size and type.

- Designing a ventilation system, taking into account its separation using special valves in different areas

- Selection of materials required for installation, as well as working tools. Determination of places for installation of all structural details and laying of the air line;

- Selection and accounting of materials for heat and noise insulation of the system.

- Approval of the plan in accordance with fire, sanitary and construction and architectural requirements.

The composition of the project documentation

Upon completion of the work, the customer receives a finished project, which includes the following documents:

- Project cover and title page;

- Required licenses and certificates for design and installation work;

- Terms of reference for the creation of a ventilation system;

- Explanatory note:

- Main technical solutions for ventilation systems:

- Heat consumption and installation electric power of ventilation equipment;

- Characteristics of the ventilation system (dimensions, energy consumption, etc.);

- Table of calculations of air exchange in rooms;

- Calculation of the main equipment for ventilation using software products of the equipment manufacturer;

- Layout of the main ventilation equipment in the ventilation chambers;

- Scheme of placement of air distributors and consoles;

- Layout of air ducts, ventilation lines and other elements;

- Specification of ventilation equipment;

- Axonometric diagrams of the ventilation system.

The development of project documentation is carried out in computer-aided design systems - we provide a copy of the project in electronic form to the customer.

Device nuances

Any ventilation involves the inflow and outflow of air, its movement and exchange inside the room. The outlet of the exhaust air from the premises is organized by installing special openings in the roof or walls with access to the street. By their nature, they should be done during the construction of the building before the fine finishing of the walls. The air duct box is usually rigid, transitions between elements and turns are often made in the form of a corrugated aluminum pipe. The entire structure is hidden under the final finishing of the house, leaving only holes covered with protective bars. In production, the ventilation complex is left open in case of unforeseen breakdowns or maintenance of individual elements.

The hood in the apartment of a multi-storey building is usually already done, if necessary, adjustments can be made in the form of additional fans in the bathroom or in the kitchen. As for the exhaust ventilation in a private house or at work, then you have to act from scratch, which involves the installation of air ducts and the removal of the hood through the roof. In this case, you will need to insulate the part of the duct that will pass through rooms where there is no heating. This will prevent the formation of condensate, respectively, will protect the pipes from dampness.

If it is planned to make a ventilation outlet on the roof, then it is necessary to provide for its thermal and hydroprotection, as well as the installation of a deflector, which will increase traction and serve as protection from precipitation.

Types of ventilation systems

Before starting the installation of the system, it is necessary to determine its type. The choice of a particular option depends on the purpose of the hood and the characteristics of the room.

The ventilation system is:

- Supply and exhaust. The most popular option recommended for standard living spaces and large production halls. Equipped with several degrees of filtration that prevent the penetration of street odors and dust. Installation and installation of supply and exhaust ventilation is not an easy, but quite solvable task.

- supply. Provides only air flow (its output is carried out in a natural way). It is represented by a conventional fan or an expensive installation that performs several tasks at the same time (supply, heating, etc.).

- Exhaust. It implies the installation of powerful fans, the strength of which depends on the parameters of the room. Designed for rooms with a high degree of humidity and temperature (for example, for the kitchen).

The choice of a specific type of ventilation, the installation of which is planned to be done by one's own hands, depends on several factors: the quality of the environment, the design of the house, and the financial solvency of the owner. In certain situations, it is possible to balance the microclimate only when using additional installations, which means that only a combined ventilation system will provide the best effect.

Connecting blocks

Here, in general, there are no special secrets. The communications stretched through the hole in the wall are connected to the appropriate connectors. There are no problems with connecting the cable - connect wires of the same color to the terminals that are already connected to them. In this case, you can't really go wrong.

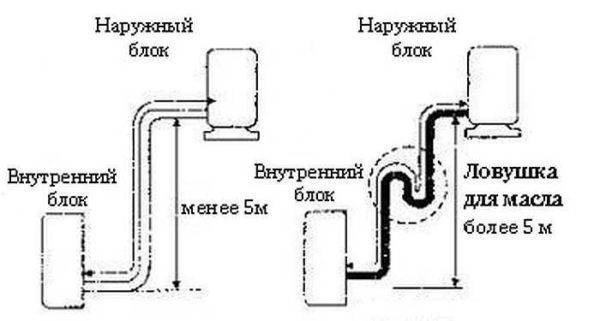

If the height difference in the installation of blocks exceeds 5 meters, it is necessary to make a loop to catch the oil (we lay copper pipes in this way) dissolved in freon. If the drop is lower, we do not make any loops.

Laying the route between the indoor and outdoor unit of the split system

Drainage

There are two ways to divert drainage from the split system - into the sewer or just outside, outside the window. The second method is more common with us, although it is not very correct.

This is the drain outlet of the indoor unit (handy)

Connecting the drain tube is also easy. A corrugated hose is easily pulled onto the outlet of the drainage system of the indoor unit (a tube with a plastic tip at the bottom of the unit). To keep it secure, you can tighten the connection with a clamp.

The same is the case with the drainage from the outdoor unit. Exit it at the bottom. Often they leave everything as it is, and the water just drips down, but it's probably better to also put on a drainage hose and take moisture away from the walls.

Outdoor Unit Drainage

If not a hose is used, but a polymer pipe, it will be necessary to select an adapter that will allow you to connect the outlet of the air conditioner and the tube. You will have to watch on the spot, because situations are different.

When laying a drain pipe, it is better to avoid sharp turns and certainly not to allow sagging - condensation will accumulate in these places, which is not good at all. As has been said more than once, the tube is laid out with a slope. Optimal - 3 mm per 1 meter, minimum - 1 mm per meter. Throughout it is fixed to the wall, at least every meter.

Freon circulation system

It is somewhat more difficult with connecting copper pipes. They are carefully laid out along the walls, avoiding kinks and creases.For bending, it is better to use a pipe bender, but you can get by with a spring one. In this case, sharp turns should also be avoided, but in order not to bend the tubes.

The ports on the outdoor unit look like this. Same on the inside.

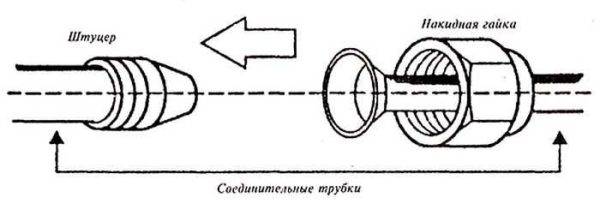

From the beginning, we connect the tubes in the indoor unit. On it, we twist the nuts from the ports. As the nuts loosen, a hiss is heard. It's nitrogen coming out. This is normal - nitrogen is pumped in at the factory so that the insides do not oxidize. When the hissing stops, take out the plugs, remove the nut, put it on the tube, and then start rolling.

rolling

First, remove the plugs from the pipes and check the edge. It should be smooth, round, without burrs. If the section is not round during cutting, use a calibrator. This is a small device that can be found in the forehead shop. It is inserted into the pipe, scrolled, aligning the section.

The edges of the tubes are carefully aligned for 5 cm, after the edges are flared so that you can connect to input/output blocks, creating a closed system. The correct execution of this part of the installation is very important, since the freon circulation system must be airtight. Then refueling the air conditioner will not be needed soon.

Expanding copper pipes for air conditioning installation

When flaring, hold the pipe with the hole down. Again, so that copper particles do not get inside, but spill out onto the floor. In the holder, it is clamped so that it sticks out 2 mm outward. That's right, no more, no less. We clamp the tube, put the flaring cone, twist it, applying solid efforts (the tube is thick-walled). The flaring is finished when the cone goes no further. We repeat the operation on the other side, then with the other tube.

This is what the result should be

If you have not rolled pipes before, it is better to practice on unnecessary pieces. The edge should be smooth, with a clear continuous border.

Port connection

We connect the flared edge of the pipe to the corresponding outlet, tighten the nut. No additional gaskets, sealants and the like should be used (forbidden). For this, they take special tubes made of high-quality copper so that they provide sealing without additional funds.

Connection principle of copper tube with air conditioner port

You need to make a serious effort - about 60-70 kg. Only in this case, the copper will flatten out, compress the fitting, the connection will become almost monolithic and accurately sealed.

The same operation is repeated with all four outputs.