- How to choose

- Selection Guide

- Checking the quality of purchased sandwich pipes

- Fire safety requirements for chimneys

- Operation of chimney sandwich systems

- Do-it-yourself installation of sandwich pipes

- Basic rules for installing sandwich pipes

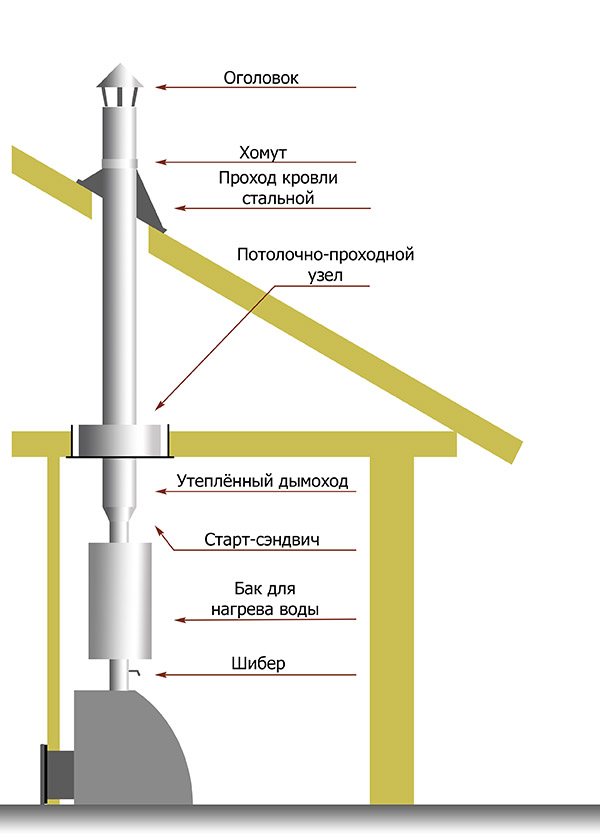

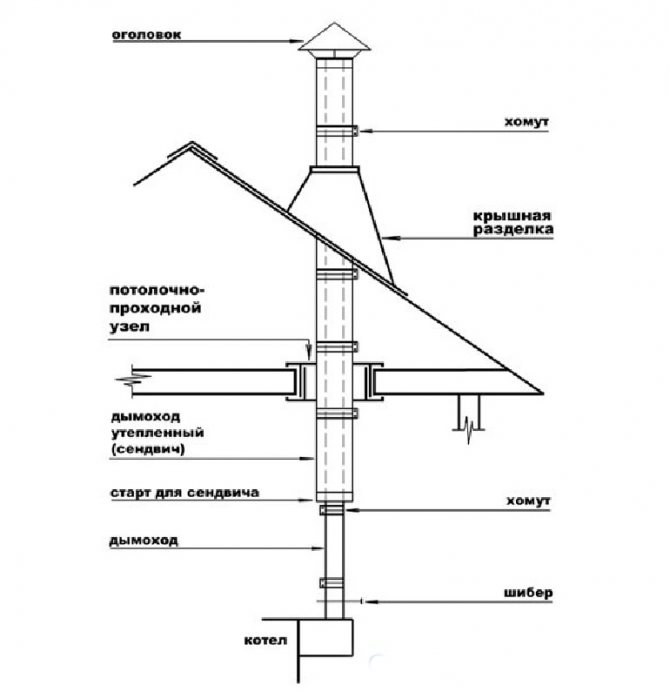

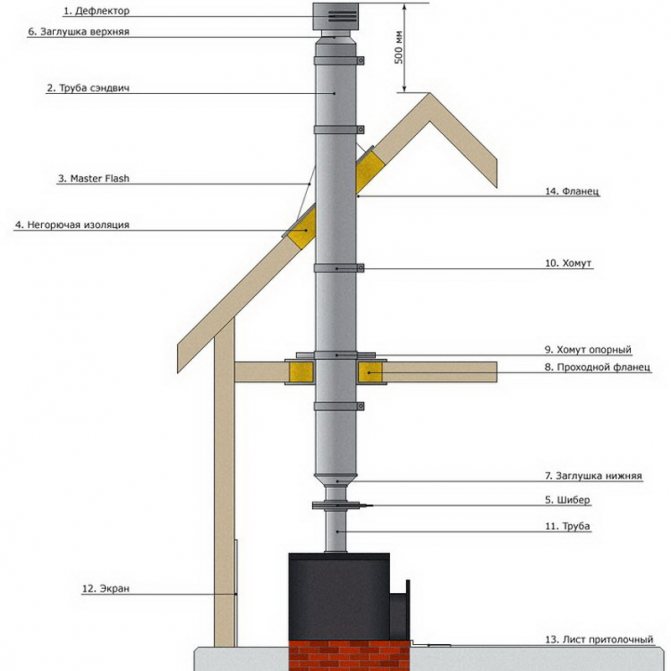

- Assembly and installation of a chimney from a sandwich pipe inside the house

- How to properly install a sandwich pipe outside the house?

- Construction and use of "sandwiches"

- We install a sandwich chimney in the bath in stages

- Stage I. We connect the elements of the chimney

- Stage II. Option 1. We pass the chimney through the wall

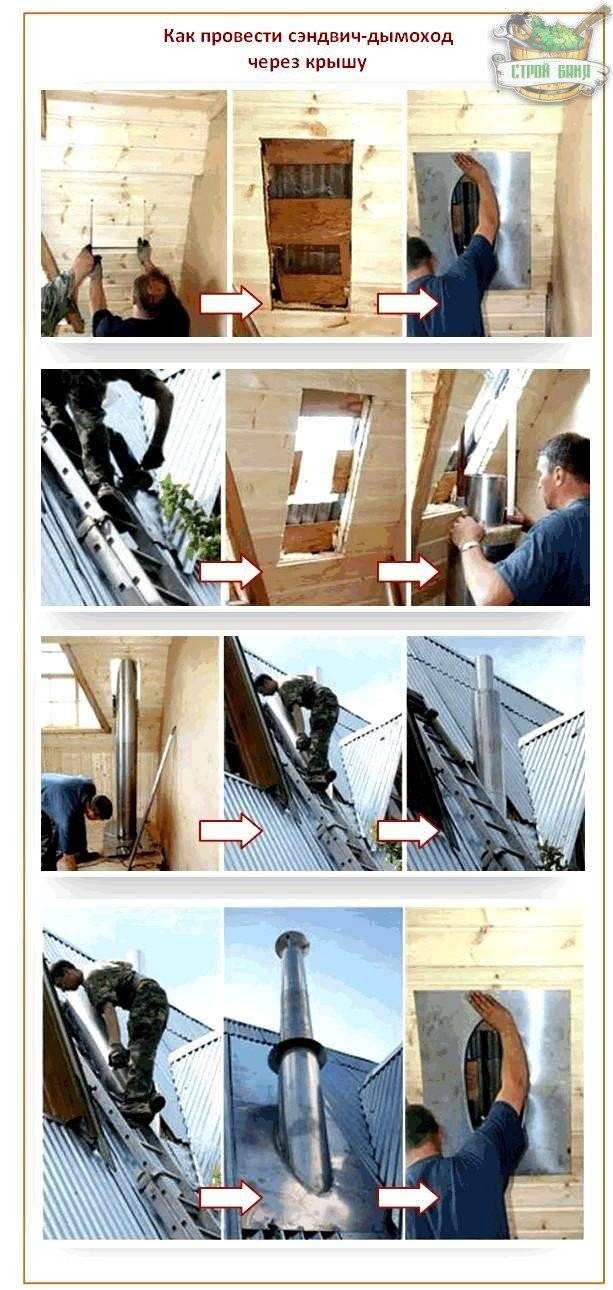

- Stage II. Option 2. We pass the chimney through the roof

- Stage III. We fix the chimney

- Stage IV. End of installation

- Sealing the chimney from the side of the street

How to choose

When choosing a sandwich pipe, you need to pay attention to the following:

- The quality of the steel from which the product is made. It affects such indicators as heat resistance and service life.

- Thermal insulation material and its density: It must withstand a heating temperature of at least 700 °C.

- The quality of the welds. For solid fuel furnaces (boilers), give preference to products with laser welding - it provides the necessary tightness of the pipes. If the seam is “rolled”, these are pipes for the chimneys of gas boilers.

The inner layer of a sandwich pipe is most often made of stainless steel, as it "accepts" the highest temperatures and is affected by condensate. If the inner pipe is made of galvanized metal, it can be used to remove combustion products from gas boilers.

For solid fuel, and even more so for baths, it is undesirable to use. In principle, it is possible, but very soon you will have to change the entire chimney. The external contour can be made of different materials - galvanized steel, stainless steel, copper, polyester, brass, etc. And again, for furnaces that do not work on solid fuels, it is better to use stainless steel, galvanizing is also acceptable. Other materials are used for chimneys more than low temperature or for device system ventilation.

The best grade of stainless steel for making inner tubes is 316 Ti, 321 and 310S are universal grades of stainless steel. Sandwiches made from them are able to withstand temperatures of 850°C, and the latter - more than 1000°C, have high heat resistance, plasticity and durability. Such elements are desirable in the chimneys of sauna stoves and for heating stoves that work on wood or coal.

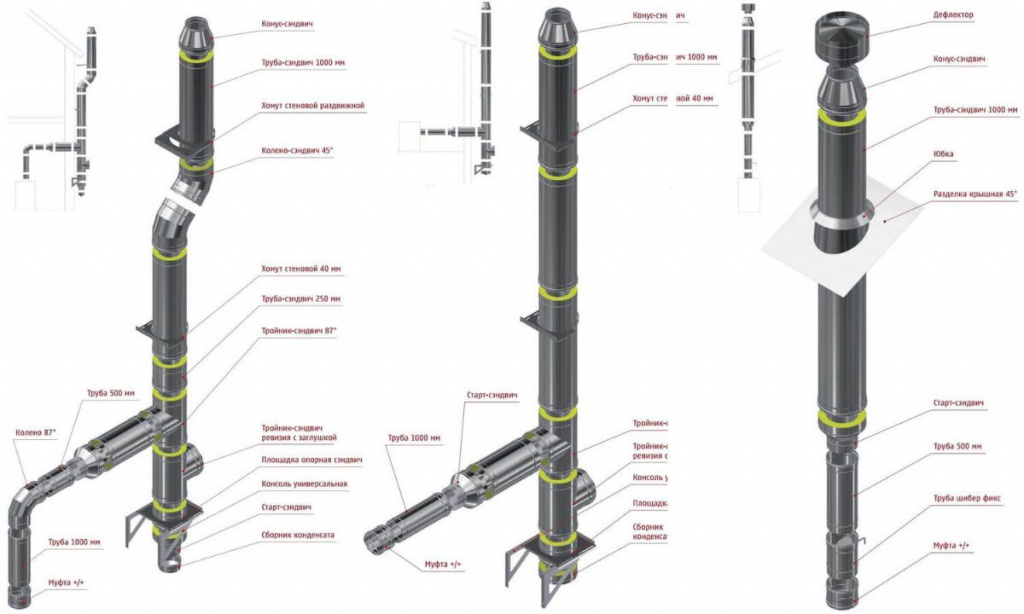

Sandwich chimneys are assembled from modular elements of various configurations

For a chimney from a sauna stove, the preferred option is both pipes made of stainless steel, but the outer casing does not have to be taken from stainless steel. The main one is the inner tube. The wall thickness in stainless steel sandwiches can be from 0.5 to 1.0 mm. For a sauna stove, they are suitable either with a thickness of 1 mm (this is made of stainless steel that is magnetized) or 0.8 mm (this is if it is not magnetized). We don’t take 0.5 mm walls into the bath - these are sandwiches for gas boilers. In baths, they burn out very quickly.

Speaking about the diameter of the chimney, they mean the cross section of the inner pipe. They are also different, but the most common in the construction of bath pipes 115x200, 120x200, 140x200, 150x220 (diameter of the inner and outer pipes in mm). The standard length of the module is 0.5 m - 1 m. Choose the internal size according to the outlet diameter smoke channel stove, and the outer one depends on the thickness of the thermal insulation.

The thickness of the insulation layer is from 25 to 60 mm. It is clear that the more the better. For sauna stoves, basalt wool should be used as thermal insulation. It's basalt. Glass wool (this is also mineral wool) cannot be taken: it can withstand up to 350 ° C. At higher temperatures, it sinters and loses its properties. In chimneys from bath stoves, temperatures are often higher and 500-600 ° C (depending on the type of furnace and intensity of combustion) is not uncommon.

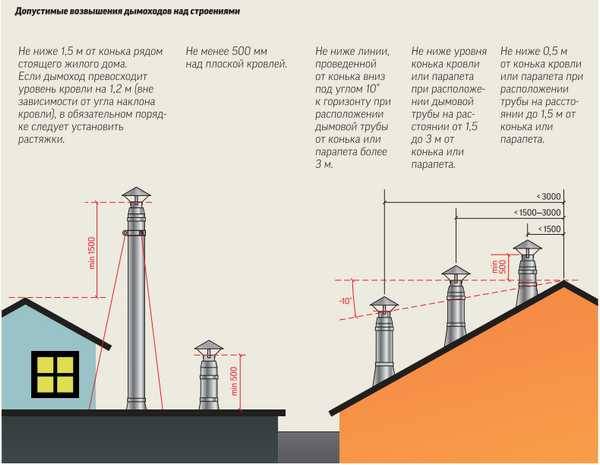

To determine the length of the chimney, the following rules must be considered:

The height of the chimney depends on where it exits through the roof

- the smoke duct must be 5 meters or more long, if less, an electric smoke exhauster must be connected;

- above a flat roof, the pipe must rise at least 50 cm;

- when the pipe is located less than 1.5 meters from the ridge, its height should be taken 500 mm above the ridge;

- when placing the chimney at a distance of 1.5–3 m from the ridge, it can be installed flush with the upper boundary of the roof, and if more than 3 meters - below its level with a slope of no more than 10 degrees;

- if buildings above the bath are located nearby or adjoin, it is necessary to bring the pipe above these extensions.

Compliance with these rules will help you accurately determine the length of the chimney. Now let's take a closer look at the features of its installation.

Selection Guide

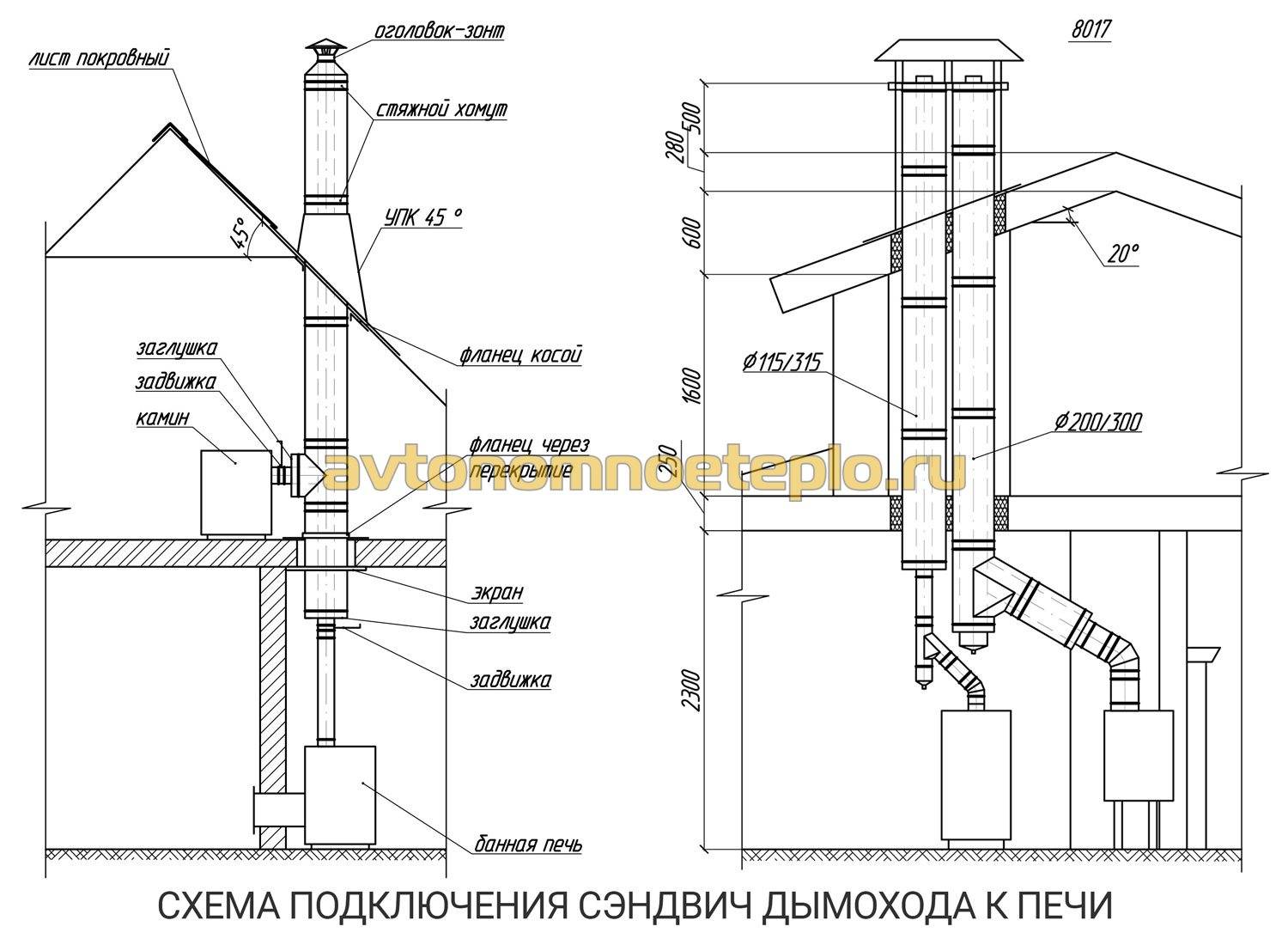

Before choosing three-layer pipes, a chimney installation diagram must be drawn. Ideally, such important parameters as the diameter and height of the chimney are calculated by specialists, but homeowners rarely turn to them for help, trying to save money and solve all issues on their own. To make the task as easy as possible for them, we will give a few recommendations in this regard.

The diameter of the pipe for chimneys can be selected according to boiler outlet. The rule is simple: the cross section of the sandwich should not be less than that of this pipe. More is allowed. As for the height, you can get a guaranteed result if you take its value at least 6 m. Moreover, the height is measured from the grate of a solid fuel boiler to the top of the pipe.

If the boiler is gas, diesel or pellet, then it is necessary to measure the height of the chimney from the burner. At the same time, it is necessary that the chimney, or rather, its cut, does not fall into the zone of wind backwater, otherwise the natural draft will be very weak. To avoid this, the following scheme is used in the calculations:

In order to reduce the resistance of the smoke channels, it is not recommended to make a large number of turns, a maximum of 3. And then, one must strive to use elbows at an angle of 45º everywhere, and not 90. The length of the horizontal section before the tie-in is no more than 1 m. Observing these recommendations, it is necessary to draw a wiring diagram and mark on it the places where the gas duct is attached to building structures.

When the scheme is ready, you can safely pick up sandwich chimneys.There are several caveats here related to the quality of the products and the presence of a large number of fakes on the market. The first moment: high-quality stainless steel alloyed with chromium does not attract a magnet at all. This fact must always be verified by taking with you a magnet wrapped in cloth. The latter is needed in order not to scratch the shiny surface of the metal during the check and not create a reason for conflict with the seller. If the magnet is even a little attracted, then you have a poor-quality product.

Pay attention to the thickness of the steel from which the chimney sandwich is made. For example, high-quality Russian-made products sold under the VOLCANO brand are made of metal 0.5 mm thick. When you come across a thinner stainless steel, know that it will burn out just as quickly, be guided by a thickness of at least 0.5 mm when choosing

When you come across a thinner stainless steel, know that it will burn out just as quickly, be guided by a thickness of at least 0.5 mm when choosing.

Well, the last. Carefully examine the tee where the horizontal section cuts. For convenience, ask the seller to attach a condensate collection unit to it. Then the opposite end of the tee, where the chimney sandwich pipe is connected, should have a socket, not a narrowing. If this is not the case, you should refuse such a purchase.

Checking the quality of purchased sandwich pipes

It will be possible to determine their reliability even upon inspection:

- Welded ones should be decorated neatly, the color should not differ from the metal itself.

- The pipe must be of the correct rounded shape.

- Check the correlation between the inside of the pipe and the outside.There should be no deviations of more than 1 mm, otherwise it will be difficult to join the sections.

- All figured components - a tee, a cap, a cap - should not have obvious joints, rough seams and other defects.

- All parts of the stove chimney must be marked. The brand, steel thickness, barcode, diameter, name are indicated.

- Packing - corrugated cardboard with branded tape. Each piece is wrapped individually.

- Laser and plasma welding is distinguished by increased reliability. It does not damage the galvanized coating, prevents corrosion at the joints.

- 2–3 mm undercooking is allowed at the end of the modules.

Fire safety requirements for chimneys

Fire Safety Rules apply to any type of smoke exhaust pipes (ceramic, brick, asbestos-cement or metal).

Incorrect connection may cause fire. This is most dangerous in wooden frame houses.

It is important to note that depending on which device is used for heating, the requirements for fastening the chimney are different. This is due to the different temperature of the raw materials for combustion:

- In natural gas condensing appliances, the operating temperature is 80 degrees, the limit is 120 degrees.

- In atmospheric gas, the operating temperature is 120 degrees, the limit is 200 degrees.

- Bath stoves can accelerate the temperature up to 700 degrees.

- Potbelly stoves, fireplace device - from 350 to 650 degrees.

- In diesel units, the indicator is 250 degrees.

- For solid fuel boilers on wood - 300 degrees. When using coal - up to 700 degrees.

It is noted that at the outlet of the gas boiler the temperature of the smoke is low, due to the significant efficiency (coefficient of performance) - from 88 to 96%.But condensate is produced, which must be removed.

Pipelines in furnaces and boilers are considered the most fire hazardous. You can learn more about the requirements and norms of the current SNiP regarding chimneys here.

Operation of chimney sandwich systems

After installing the chimney, a test fire should be carried out to check the tightness of the joints, make sure that the adjacent structures and materials do not heat up.

During the first use of the system, slight smoke and a specific smell may appear from the heating of oil residues, sealant, dust on the surface of the pipes.

Proper operation involves the timely removal of soot. When cleaning, do not use any detergents. Review of the best means and methods purges are discussed in our other article.

It is better if it is carried out by an organization that has a special license that gives the right to carry out this kind of work.

Do-it-yourself installation of sandwich pipes

The installation of the chimney must be carried out in accordance with all the rules, only then its operation will be durable and safe.

Basic rules for installing sandwich pipes

It is necessary to follow the following recommendations of experts:

- To ensure the necessary traction, the total length of the channel should be at least 5 meters.

- To seal the butt joints with your own hands, you should use materials whose operating temperature is at least 1000 degrees.

- If the height of the chimney is from one and a half meters or more, then you need to install a support mast and use extension clamps to attach it to it.

- Above a flat roof, the pipe should rise by 0.5 m.

- Every two meters the chimney must be reinforced with wall brackets.

- Pipe joints with various elements in the form of bends and tees are reinforced with clamps.

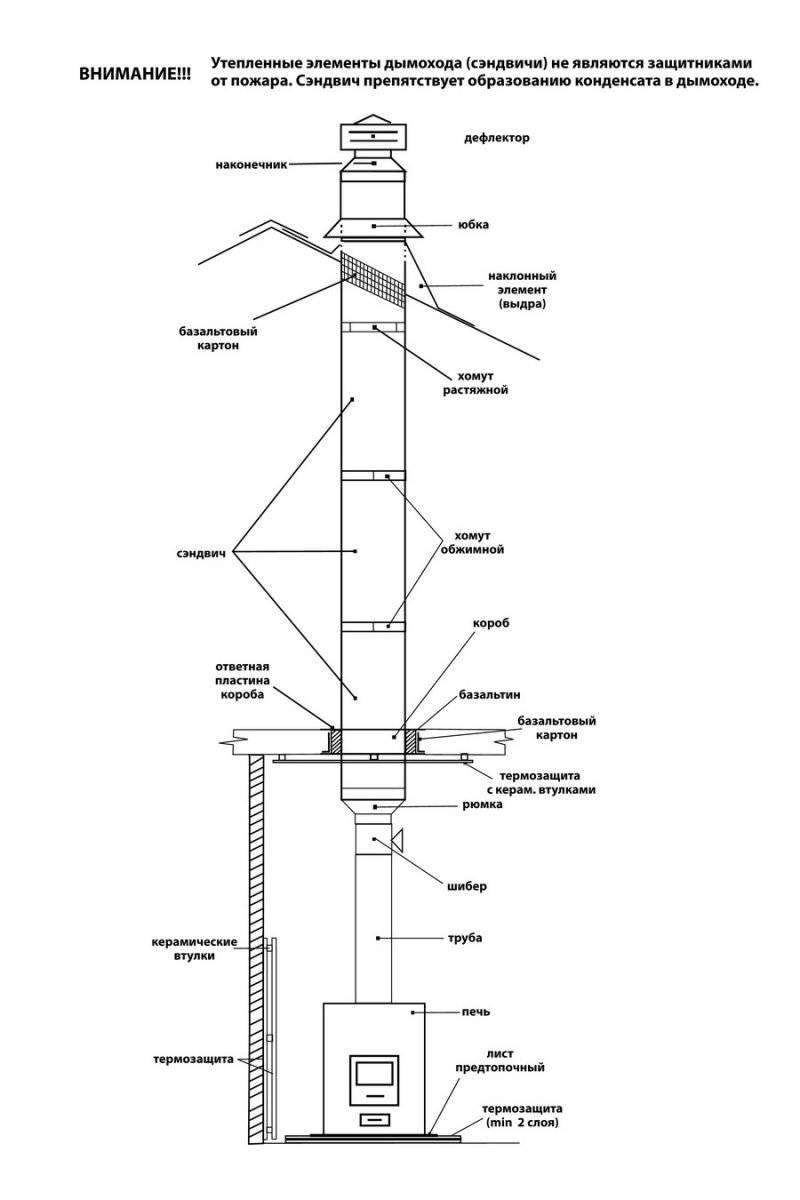

- The section of the structure coming from the furnace is not isolated.

- Ceilings, beams, walls in places where a pipe will be laid along them are insulated. In this case, a gap must remain between the surfaces and the chimney.

- For a tee, a support platform or console is installed.

- The top of the structure is protected by a deflection, a cap.

For heating to be effective, most of the chimney must be inside the room. This will reduce the temperature difference.

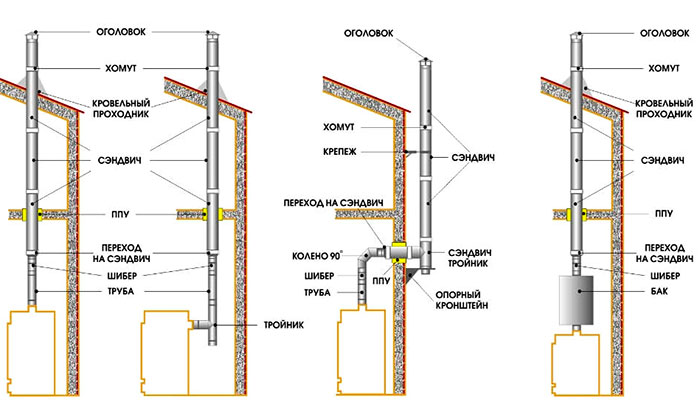

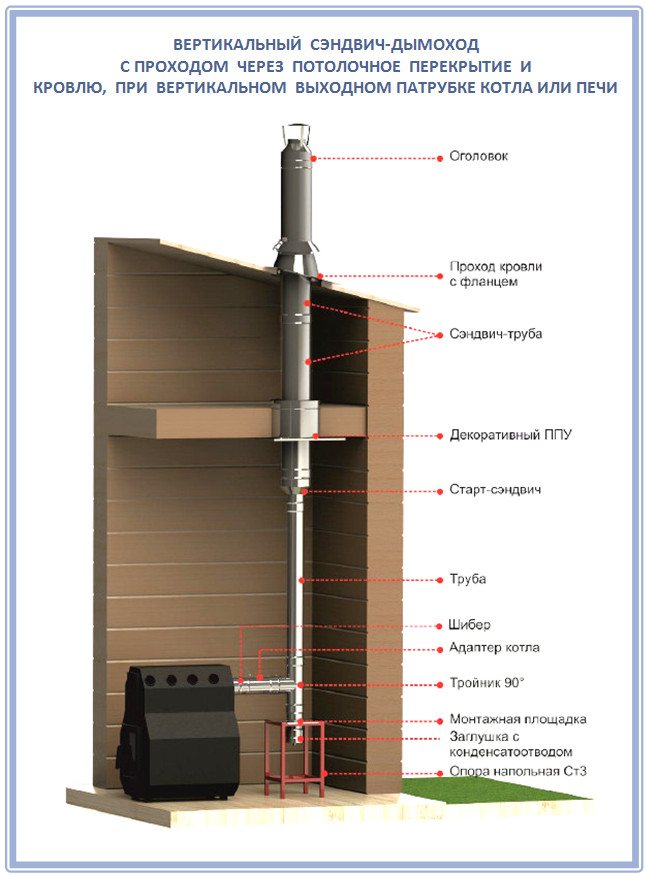

Assembly and installation of a chimney from a sandwich pipe inside the house

Installation steps:

- A coupling is installed on the chimney opening of the furnace, to which a horizontal pipe segment or a tee is attached. The element is selected depending on how the chimney will go further.

- The lower part of the tee is closed with a plug. If it is necessary to remove soot after a certain period of time, the plug is removed.

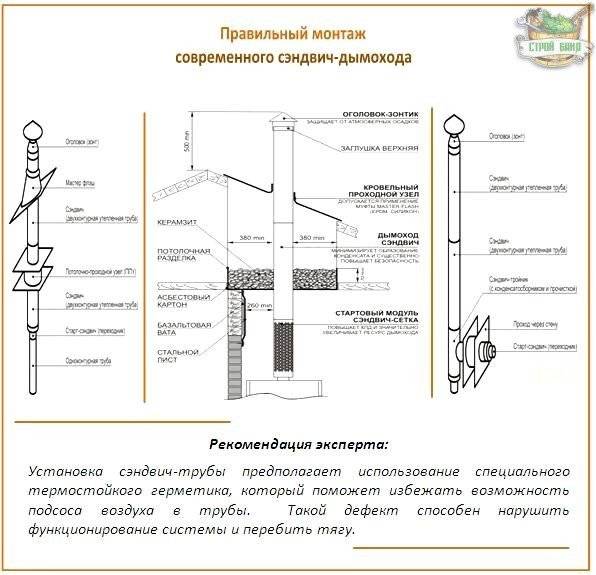

- For the passage of the sandwich pipe structure through the ceiling, a hole is made in it. An adapter pipe is installed on the vertical part of the system. From the side of the street or the attic, the pipe descends into the prepared opening and joins with the lower modules.

- The gap between the ceiling and the chimney is insulated with fire-resistant materials. You need to know that it is forbidden to join elements in places where they pass through the floor.

- On a flat roof, a square sheet of galvanized material is used to prevent moisture from escaping when snow melts or rains. It must be brought under the coating and the edges treated with sealed materials.

- On sloping roofs, a bezkilny kryza is installed - a special passage unit. This plastic element is made at a certain angle of inclination. There are universal products made of elastic materials. They are suitable for roofs with any slope.

- An umbrella head should be installed on the upper part of the structure. Its role is to protect the pipe from precipitation and small debris.

Do-it-yourself installation of a chimney from a sandwich pipe is completed. Now you can start masking the unsightly appearance left after the system. For example, plaster and paint over the ceiling.

How to properly install a sandwich pipe outside the house?

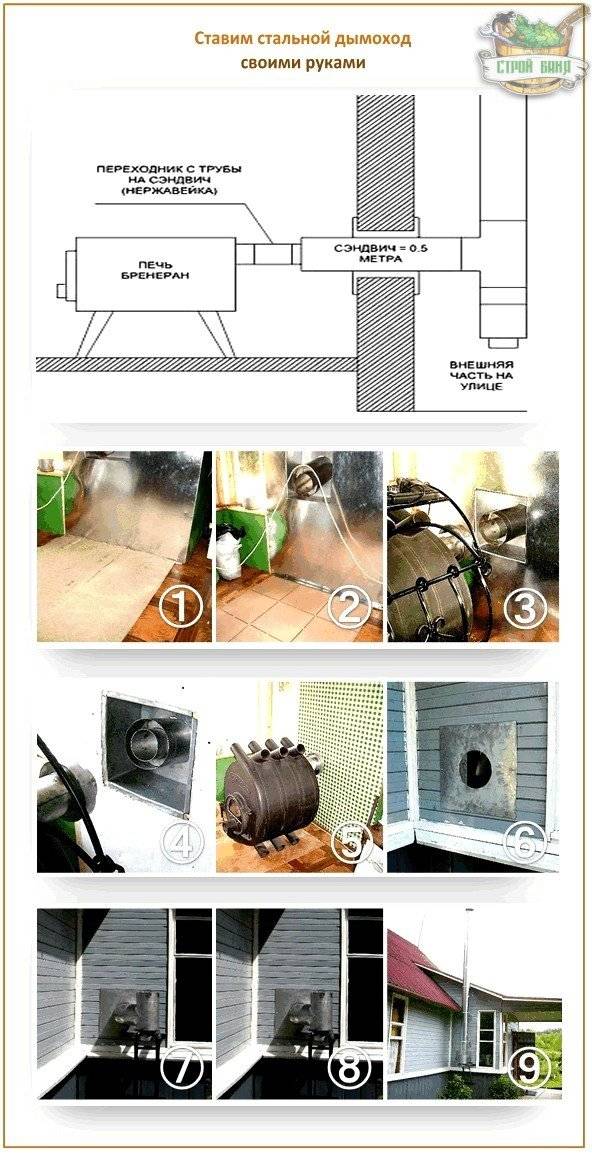

Assembly and installation of the chimney through do-it-yourself wall It is made if, due to the design features of the roof, it is impossible to make holes in it. In addition, such an installation will save the interior space of the room.

Stages of work:

- A horizontal section of pipe is installed on the starting coupling. If necessary, an elbow with an angle of rotation is used for further installation.

- A technical hole is cut in the wall through which the chimney will pass. Through it, the next element of the structure is displayed. The gaps are filled with thermal insulation material.

- A tee is put on the end of the pipe brought out, in the lower part of which there should be a blind plug. For the reliability of the system, a support console is installed.

- Brackets are attached to the outer surfaces of the walls in increments of 1.5–2 meters. The choice of fasteners and the method of installation depends entirely on what material the house is built from.

- When building up the structure, it is necessary to wear hoop rings. They are part of the bracket.

- If the pipe rises above the roof by more than one and a half meters, then for stability and strengthening of the chimney from a sandwich pipe, an extension fastener is installed.

- A head is attached to the last element of the chimney system.

Construction and use of "sandwiches"

For the organization of natural mechanical exhaust it is necessary that the air ducts meet a number of requirements.

The main ones are:

- ensuring the tightness of the ventilation system;

- the ability to maintain the required air pressure in the system;

- ensuring free passage of air inside the ventilation system;

- maintaining the necessary thermal insulation.

To ensure compliance with the requirements, depending on the climatic conditions, the type and purpose of buildings, different types of ventilation pipes are used.

The thickness of the insulation layer depends on the required operating temperature inside the ventilation system. Also, the diameter and dimensions of the pipes used affect the thickness of the thermal insulation.

The thickness of the insulation layer depends on the required operating temperature inside the ventilation system. Also, the diameter and dimensions of the pipes used affect the thickness of the thermal insulation.

Sandwich pipes are used not only for the installation of ventilation, but also for:

- private houses, where it is used as a chimney - to remove air masses from heating appliances (stoves, fireplaces, boilers);

- apartment buildings in the northern regions of the country;

- production buildings, inside which work with high heat transfer is carried out (shops for melting metals, glass production shops);

- grain storage buildings.

The necessary properties are acquired by products due to a special technology by which sandwich pipes are made. Also, due to their design, a feature of which will be discussed below, these pipes are suitable for connecting heating equipment to them. In this case, they are used as chimneys to remove smoke from the room.

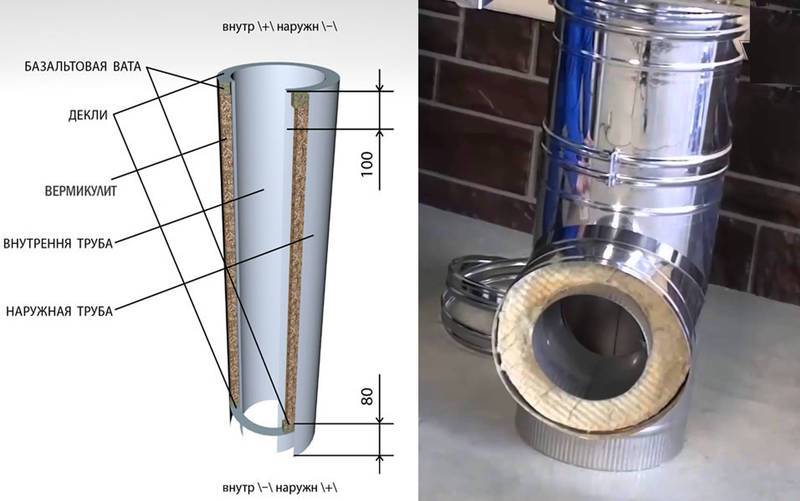

By their design, "sandwiches" consist of two pipes of different diameters, made of high-alloy stainless steel sheet. The connection between them is made using argon welding. The space formed between the two pipes is filled with a special heat-insulating material, often made on the basis of basalt, with a width of 25 to 60 millimeters.

Such a device allows you to maintain the temperature of the exhaust air inside the pipe without cooling it ahead of time. Thus, the normal draft of the air extract from the room is maintained.

It is worth noting that the basalt wool used to insulate sandwich pipes can withstand temperatures up to 1115 ° C. At the same time, it is a non-combustible substance and melts when a high temperature is reached. Therefore, it is not surprising that "sandwiches" are so popular in the construction of chimneys.

Currently, there is a fairly large selection of sandwich pipes of various diameters on the market. The uniqueness of their assembly lies in the possibility of laying pipes through hard-to-reach passages and the ability to connect sandwich pipes of various diameters to each other.

Currently, there is a fairly large selection of sandwich pipes of various diameters on the market. The uniqueness of their assembly lies in the possibility of laying pipes through hard-to-reach passages and the ability to connect sandwich pipes of various diameters to each other.

Depending on the conditions in which the sandwich pipe will be operated, a different thickness of insulation is selected.

Also, sandwich pipes can be made using steel sheets made of heat-resistant steel, which is especially important for use in places with high temperatures of air masses.

We install a sandwich chimney in the bath in stages

The installation of a sandwich pipe for a chimney itself is not difficult.Since sandwich pipes are as fireproof as possible, even a person who is very far from construction can connect and fix them correctly.

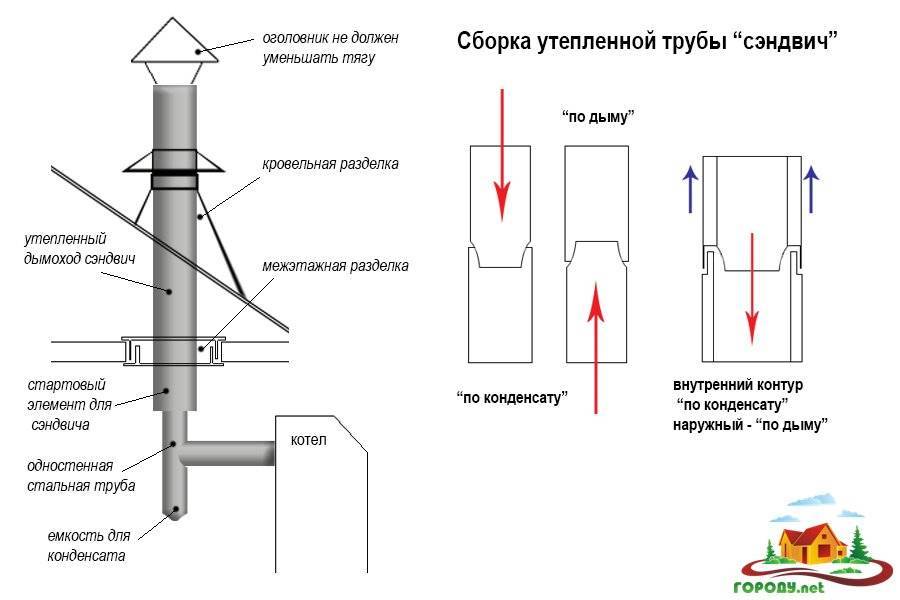

The "sandwich" chimney is mounted from the bottom up - from the stove to the roof, and the outer pipe must be "put on" the inner one. In general, there are several important points for mounting a sandwich. Let's take a closer look.

Stage I. We connect the elements of the chimney

When installing a sandwich chimney, pay attention to the fact that one of the ends of the pipe is always narrowed with a slightly smaller radius. It just needs to be inserted into the previous pipe

Due to the fact that soot almost does not accumulate in such a chimney, it is easy to remove condensate from it - and it is better to install special tees for this.

Stage II. Option 1. We pass the chimney through the wall

If the chimney will go through the wall, it will have to be disassembled and the seats under the bracket should be strengthened. Next, we assemble the outer bracket and attach two corners to it like skids - so that you can move the tee without any problems during the installation of the chimney from sandwich pipes, and nothing gets stuck.

The wall itself can be covered with plywood one centimeter thick and an asbestos sheet can be fixed with screws over its entire area. On top of that - a solid sheet of galvanized metal 2x1.20 cm. In the sheet itself, we cut a square hole for the passage and fix it with screws. Finally, we cover the bracket with metal varnish to protect it from corrosion. Next, we drill the desired hole in the adapter and put a sandwich in it.

They also use such a concept as a concession in the construction of a chimney - this is the space that we specially leave between the smoke channel and the wall.

Stage II. Option 2. We pass the chimney through the roof

When passing a sandwich pipe through the roof, you must first take a galvanized steel sheet, attach it from the inside to the hole, and bring the pipe out. Only after that we attach the sheet to the roof. If necessary, it can be additionally brought under the edge of the roof.

If the roof is made of combustible materials, it must be protected from fire. BUT for this on the chimney, which rises above wooden tiles or bitumen, we install a deflector with a spark arrestor mesh with small cells.

Stage III. We fix the chimney

We fasten all tees, elbows and other elements with clamps, and we fasten the tee with a support bracket. If the upper part of the chimney remains loose, it is better to secure it. At least the same stretch marks of 120 degrees. Here is how you additionally need to fasten the butt joints: sandwich pipes to each other - with crimp clamps, pipes with other elements, such as adapters and tees - with the same clamps, but on both sides.

Stage IV. End of installation

After assembly is completed, be sure to remove the protective film from the pipes

The optimal length of the chimney is 5-6 m from the grate of the furnace to the head - pay attention to this. And seal all seams and gaps

To do this, you will need a heat-resistant chimney sealant that is rated for temperatures of at least 1000 ° C. You need to apply it like this:

- For inner pipes - on the outer surface of the upper inner pipe.

- For external pipes - on the outer surface.

- When switching from a single-walled to a double-walled pipe - outside, around the circumference.

- When connecting a single-wall pipe and other modules - as in the last version.

When everything is ready, be sure to check the most dangerous heating zones of the chimney for temperature.And so that later cleaning the chimney is simple and easy, it necessarily provides for an audit - this is a special removable part or a hole with a door.

Installation of a sandwich chimney is very simple and easy due to the simplicity of design and light weight - if you have already decided on the project and purchased the material, feel free to roll up your sleeves!

Sealing the chimney from the side of the street

When the main construction work is completed, the protective film is removed. Check the tightness of all joints, seams, joints.

When carrying out sealing, it is important to consider such nuances:

- At the point of transition from a single-walled pipe to a sandwich, all outer edges are processed along the circumference.

- When applied to the inside of the pipes, the outer part of the upper section is coated. When processing the outer part, the principle is similar.

It is recommended to use exclusively refractory sealant that tolerates temperatures of 1000 degrees and above.

The total length of the chimney from the grate is from 6 m.