- Fastening methods used in everyday life

- "Hot" soldering of pipes

- "Cold" soldering methods

- Solder pastes

- Epoxy resin

- Electrical fittings

- Heating system in the apartment: instructions for its creation

- Mounting methods

- open laying

- Hidden styling

- Minuses

- Features of the installation of pipes made of polypropylene

- Important installation details

- Tool preparation

- Marking on the wall

- Mounting

- Tool types

- Welders

- Glue guns

- Pipe cutters

- Cleanups

- Conclusions and useful video on the topic

Fastening methods used in everyday life

Each apartment owner independently determines the level of installation quality he needs. Someone uses soldering, and someone uses adapters or other alternatives.

"Hot" soldering of pipes

Considering soldering as the most reliable and durable method of fastening, some private property owners use this method of installing the pipeline. In the absence of special equipment, they use a gas burner. In this case, you can save on the purchase of a soldering iron and carry out work with pipes of any diameter.

Workflow features:

- The gas burner must be selected according to the type of fuel used. The gas with the highest combustion temperature is suitable for thicker pipes.

- It is best to select pipe sections of the same diameter. This will ensure the aesthetic appearance of the engineering system, the preservation of operating parameters in all sections of the pipeline and the absence of difficulties during soldering.

- Before starting installation, it is recommended to mark (cut) the entire contour, clean the ends of the joints, and degrease with a special compound.

Installation of polypropylene pipes using a gas burner

In the course of work, the melting point of polypropylene should be taken into account. Heat adjacent parts evenly and simultaneously. So it will be possible to ensure accurate and high-quality installation of the entire circuit.

Too much heating at the place of the future joint can lead to deformation of the joint, especially at the moment of adjoining and holding for soldering.

"Cold" soldering methods

If there are not sufficient skills in the operation of heating with a gas burner, the installation method using ready-made compositions will help. There are several ways to solder plastic pipes without a soldering iron:

- using solder pastes and tapes;

- using epoxy resin;

- with electrical fittings.

Let's see what the advantage of each method is.

Solder pastes

Unlike glue, solder pastes:

- set a higher quality of docking;

- allow to reduce the time for performing operations;

- minimize the risks of non-compliance with the conditions of the technological process.

This method is suitable for inexperienced people who are interested in how to solder plastic pipes without a soldering iron and do not want to damage the parts.

This method of soldering allows you to keep the pipes in their original form without the danger of deforming them.

Soldering Paste Selection Tips:

- study the marking of the paste, the composition must be suitable for polypropylene;

- after work, the paste should not leave marks, especially on white-colored pipelines;

- the paste should stand out well from the tube and be applied to the surface, it should not be too thick and not liquid.

Epoxy resin

This option of "cold" soldering is used when there is no experience in "hot" welding. It does not require special tools. Here, as in the case of glue or paste, a simple physical property of the finished epoxy compound is used - to harden when cooled.

When docking, epoxy resin is applied to degreased, pre-cleaned surfaces. In this installation option, the pipeline is put into operation a few hours after the installation work.

Preparation of epoxy resin for the subsequent fastening of the pipeline

Electrical fittings

Manufacturers of building materials offer a wide range of fittings and connecting elements with which you can assemble the pipeline by soldering.

The manufacturing technology of electrical fittings includes equipping adapters with heating elements. After the circuit is assembled, voltage is applied to the couplings, which leads to heating of the material and soldering of the assembled joints. By default, soldering with electrical fittings is suitable for industrial environments, but can also be used for everyday use.

This method is easy to install, due to which the installation of the pipeline takes place in a short time.

Heating system in the apartment: instructions for its creation

Sometimes there are situations when it may be necessary to replace the heating pipes in the apartment.Despite the complexity of such events, subject to the rules and following a strict installation algorithm, it is quite possible to carry out this work on your own, without resorting to the help of specialists.

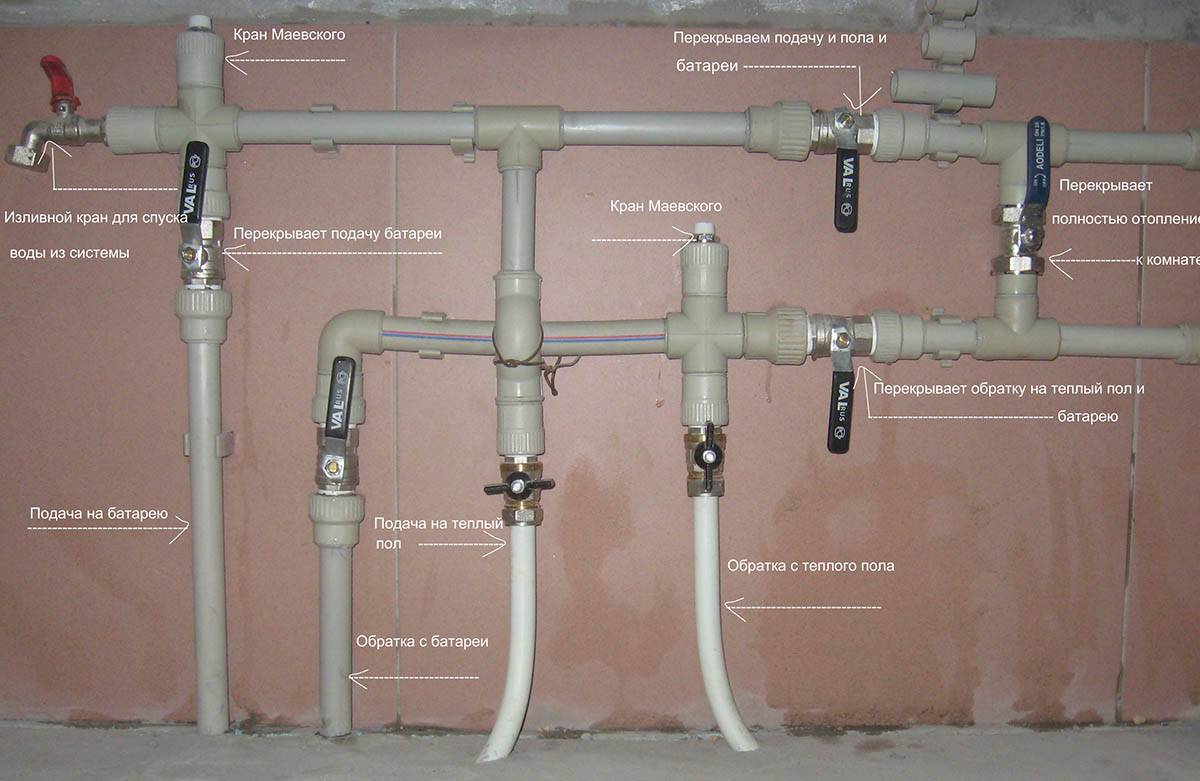

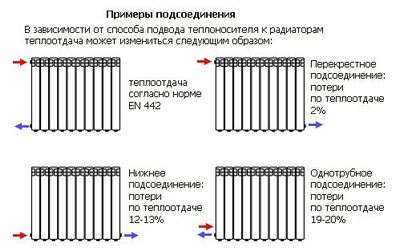

Initially, you need to consider the type of system that should eventually be installed. Not only the final cost, which is determined by the number of radiators, pipes and mounting hardware, but also the quality of heating depends on whether it will be single-pipe or two-pipe. So, when installing a two-pipe system, a large number of radiators may be required, and if more than 8 pieces are planned to be installed, pipes with a cross section of 32 mm will be optimal in this case.

Installing a single-pipe system will be cheaper, however, with this wiring configuration, it is likely that the coolant temperature in each radiator will be lower than in the previous one. To minimize this effect, it will be necessary to install thermostats to regulate the power of each of the radiators.

Mounting fittings (fittings, clamps, couplings of plugs, tees, adapters) should be selected in accordance with the selected heating scheme.

Having previously stripped the foil of aluminum-reinforced polypropylene pipes, you can begin to connect them using a special welding machine

At the same time, it is important to observe the required time interval, as a rule, different for each type of pp pipes for heating. So, for melting pipes with a cross section of 25–32 mm, 7–8 seconds will be enough.

To achieve efficient and high-quality operation of the system, it is necessary to strictly adhere to the following action plan:

Coordinate remedial measures with the relevant utilities to be able to cut off the water and carry out its discharge.

If possible, notify tenants whose apartments are located on the floor below and above

However, if it is not possible to completely replace the riser due to circumstances, you can use special adapters from cast iron to plastic pipes.

Dismantle the old communications of the heating system, observing extreme caution and accuracy. It is advisable not to neglect safety precautions and wear goggles and a respirator

The fact is that with prolonged use, cast iron becomes very brittle, and with careless or sudden movement, its fragments can get into the pipe and disrupt the movement of the coolant.

Proceed with the installation of the new system by installing new heating radiators along the specified perimeter.

Assemble polypropylene pipes and connect radiators to them (for more details: "How to connect a heating radiator to polypropylene pipes - methods used by fittings").

Check the system for integrity and tightness

In this case, attention should be paid to the fact that if the newly installed system is a two-pipe system, then when checking, the coolant must move in the opposite direction. And the pressure in the case of a test should be about 1.5 times higher than the usual initial one.

Mounting methods

The new version of the plumbing unit is a separate room where an individual design has been created. Openly laid pipes, even from polypropylene, will not become an interior decoration.Therefore, pipelines are often mounted in walls and floors.

However, not all places require a unique interior. In this case, the pipes are laid in an open way. Both methods have their own characteristics.

open laying

When pipes are mounted in an open way, access to any element of the water supply system appears. Non-walled piping in the toilet and bath is an easy system maintenance. If necessary, it is always possible to carry out repairs without violating the integrity of the interior decoration.

Polypropylene pipes in the toilet

Open laying of polypropylene pipes is easily done by hand. After all, such an installation process requires a little effort and the use of a small amount of tools.

The disadvantage of open laying is the possibility of damage to the polypropylene pipeline during other installation work or even during cleaning. However, plastic pipes need to be impacted with great force to break their integrity.

Open gasket also spoils the interior of the toilet and bathroom. In addition, people may be disturbed by the noise generated by the moving water.

To reduce the negative effects of openly laid pipes, you can install a box, for example, from drywall. Then the structure is finished with the same material that was used on the walls and / or floor.

When installing the box, it is necessary to provide a technical hatch. It will allow you to access water meters, filters, pressure gauges, ball valves and other fittings.

It is best if such elements of the system are located as compactly as possible in one place. This will allow not to create several technical hatches.

In some cases, a collapsible box is installed.This design allows access to almost the entire system. Thanks to the collapsible box, it will be possible to conveniently carry out revisions and preventive measures so that the network works trouble-free and efficiently for as long as possible.

Hidden styling

This method of mounting polypropylene pipes involves the creation of strobes in the walls. They are niches that are cut by a grinder with a special stone cutting element. In the case of gypsum partitions and walls, pipelines are laid inside the structures.

Plumbing in the bathroom from polypropylene pipes

When carrying out hidden pipe laying, it is necessary to remember the following nuances:

- It is impossible to cut special niches for pipelines in ceilings. Otherwise, the reinforcement in the hollow core slabs will be damaged. Therefore, structures will lose strength. If it is necessary to lay pipes in the floor, a screed must be performed.

- A mixture of cement and sand creates an additional load on the floors. This also reduces their strength. With a large weight, the screeds of the plate may crack.

- It is not recommended to create strobes in load-bearing walls. The implementation of special niches in the frame of the building can violate its integrity. As a result, the walls will collapse.

- It is not forbidden to make strobes in walls made of blocks and bricks. Structures made of hollow core panels must always remain intact.

If a person is not sure about the correct installation work regarding the laying of water pipes and the creation of gates, you can turn to professionals for help. Specialized companies will also help, if necessary, to prepare a redevelopment project.

Specialists will even take care of obtaining official permission to combine a bathroom with a toilet or change the configuration of the premises.

Closed laying allows you to hide the pipes in the building structures of the building. This is a significant advantage of this method. As a result, it will be possible to create a pleasant and harmonious look in the bathroom and toilet.

Minuses

The disadvantage of the hidden laying of pipelines is the inability to monitor the state of the system and carry out repairs. In the latter case, it will be necessary to violate the integrity of the finish, and in the event of a leak, even compensate for the losses of the neighbors on the lower floor.

Polypropylene pipes are connected by soldering. This method allows you to create reliable joints. Therefore, plastic pipelines are allowed to be laid in the walls. The main thing is that the welding is done with high quality.

It is recommended to perform work in accordance with GOST. The regulatory documents say that the joints of pipes cannot be walled up in walls and floors. After all, it is in such areas that leaks most often occur.

Features of the installation of pipes made of polypropylene

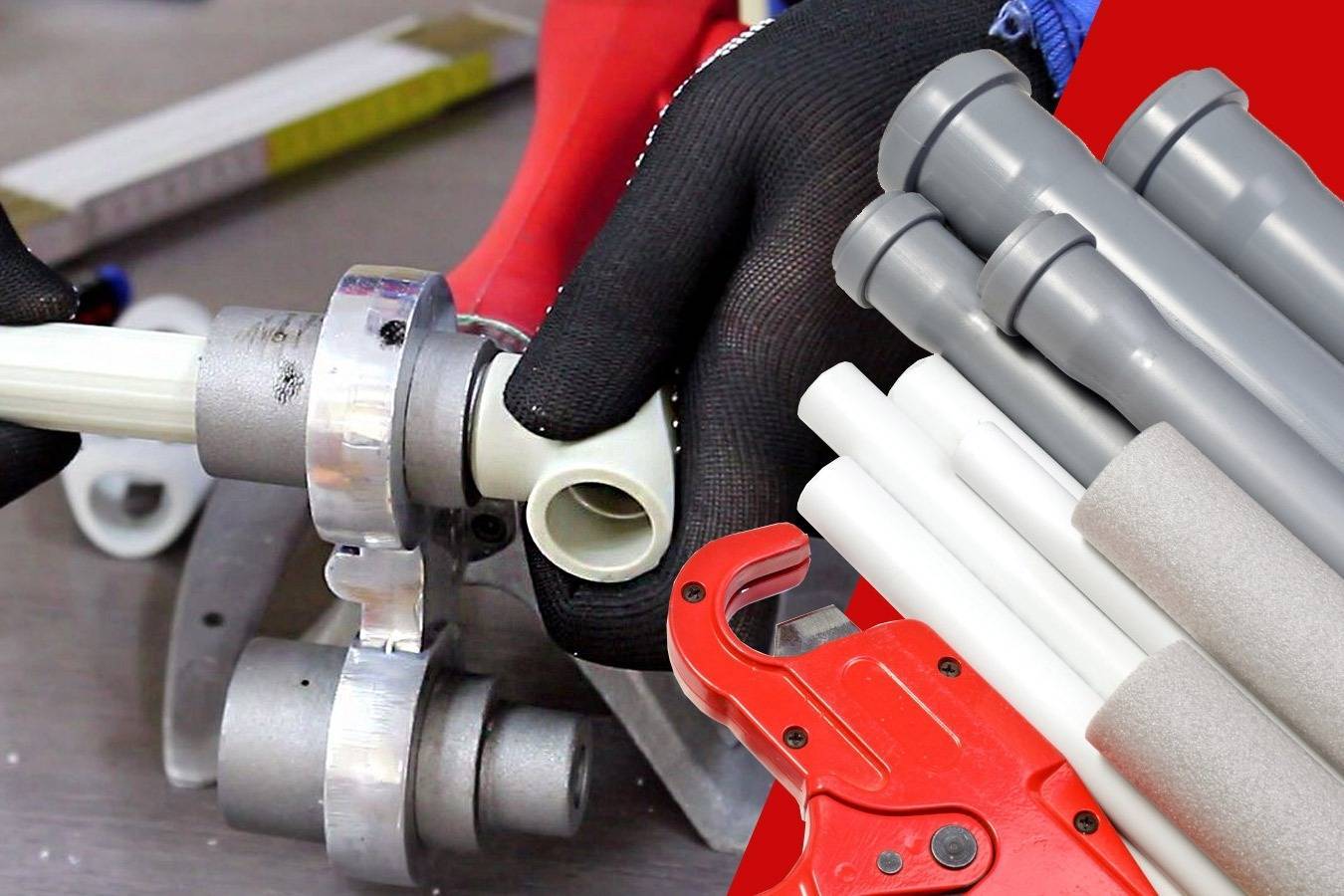

The device of a water supply system based on polypropylene pipes, as a rule, is accompanied by the purchase of a special tool and a set of elements - fittings that provide a complete installation. A special tool - a soldering iron for polypropylene pipes - can be bought or rented wiser.

The device of a water supply system from PP pipes requires compliance with a number of technical and technological nuances:

From the set of necessary tools, you will need a pipe cutter (special scissors). However, it is quite possible to trim polypropylene sleeves with a hacksaw.For measurements, you will need a construction tape measure, as well as a marker (pencil) or something similar.

An angular ruler or a protractor will not become superfluous in the assembly business. For a complete set, you also need wrenches or an adjustable wrench.

One of the main tools required for the installation of polypropylene pipes. The polypropylene pipe cutter allows fast and precise cutting. However, this tool can be replaced with a conventional hacksaw.

The process of assembling polypropylene pipes does not require any special technological actions from the plumber. But, some experience with soldering polypropylene is still needed. The complete lack of skills threatens to turn into unpleasant consequences of the operation of the water supply system in the future.

And the sequence of work, approximately, is as follows:

- The pipe of the water line is cut to size.

- The place of cut and connection is cleaned of burrs.

- The required fitting element is selected and adjusted.

- The polypropylene soldering iron is equipped with appropriate nozzles.

- Turn on the heating at the soldering station - the heating limit is 260ºС).

- Abutting elements (fitting and pipe end) are brought into contact with nozzles.

- They are heated for several seconds (4-10), depending on the wall thickness.

- They are removed from the nozzles and manually quickly connected by inserting the end of the pipe into the body of the fitting until it stops.

The peculiarity of the last action is that it must be performed quickly enough with a clear fixation of the pipe and fitting in one position. After connecting the elements, wait at least 30 seconds.This time is sufficient for hardening of the heated areas and their tight connection with each other.

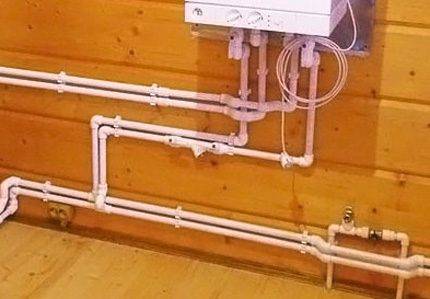

Competently performed is the installation of any type of water supply from polypropylene pipes, when the lines are drawn from plumbing fixtures to the main source of water. Pipe installation should be carried out as straight as possible, parallel to the floor or walls of the building.

If the DHW and cold water lines are located in close proximity to each other, it is recommended to install the cold water line above the DHW line.

An example of a successful installation of a water supply system based on polypropylene sleeves. Such solutions are typical for private country houses. In the conditions of city apartments, they often try to make hidden systems (hidden in the walls)

Polypropylene pipes, when compared with a metal pipe, have significantly less rigidity

Therefore, when installing polypropylene, attention should be paid to the reliable fastening of pipelines to the base. Fixing support brackets must be placed every 1.5-2 m of the pipeline line

It is desirable to build water mains taking into account the minimum loads on pipelines. It is not recommended to bend the body of a polypropylene pipe by heating the bend in order to bypass the obstacle in this way. To solve such problems, you should use special fittings - angular or bypass.

The socket connection of parts of a polypropylene pipeline is produced by welding:

Important installation details

The connection of PP pipes is carried out using threaded / non-threaded fittings. In turn, threaded products can be:

- one-piece;

- detachable.

It is worth noting that the installation is primarily affected by operating conditions.

- All polypropylene parts must be protected from fire.

-

In the case of a tie-in water meter or storage tank, it is advisable to take detachable threaded elements. However, a one-piece connection is only acceptable for flexible hoses.

- The use of deformed or dirty connectors is strictly prohibited! As well as self-cutting threads.

- Couplings are used when connecting flat sections or transitioning a pipeline to a different diameter.

- For turns, special squares are used; bending of pipes is unacceptable.

- Tees are used for branching lines.

After reviewing all the necessary information, you can get to work.

Tool preparation

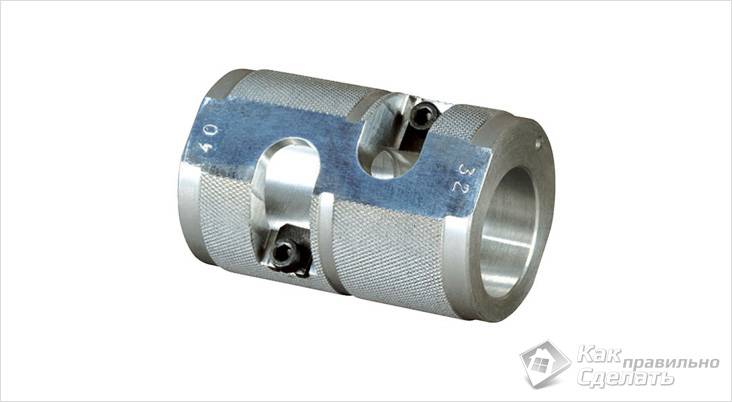

Shaver

Shaver

In addition to having all the necessary parts and materials, it is necessary to prepare all the tools to perform the installation of the pipeline.

- The most important tool for work is a soldering iron, with which couplings will be soldered. Buying this tool, you should not save. This can affect the quality of soldering and the speed of work, and the soldering iron itself can stop working very quickly. A high-quality soldering iron will not harm the Teflon coating layer of the nozzles during long work.

- For soldering, you will need nozzles for pipes. Basically, they come with a soldering iron.

- The main part of the work will be done stationary, so a stand is needed for the soldering iron.

- To cut off the desired section of the pipe, you will need special wire cutters, you can use a pipe cutter.

- The aluminum layer is removed from the pipe using a shaver.

- In order for the soldered pipe to freely enter the fitting, it will be necessary to chamfer the edge of the pipe using a beveler.

Pipes and fittings

Pipes and fittings

First visit the hardware store and buy all the necessary tools.

Marking on the wall

Installation of PP pipes for cold and hot water supply to the wall is carried out using clips or clamps.

Attention! It is very important to observe the correct distance between the points in order to avoid sagging of the structure or increase its cost due to unnecessary fasteners.

The correct step size depends on the purpose of the system and the maximum media temperature.

Comparative table of fastening pitch in centimeters relative to the diameter and temperature of the liquid

| Pipe diameter | Step at 20°C | At 50°C | At 70°C |

| 16 mm | 75 cm | 65 cm | 55 cm |

| 20 | 80 | 80 | 60 |

| 25 | 85 | 90 | 70 |

| 32 | 100 | 95 | 75 |

| 40 | 110 | 100 | 85 |

| 50 | 125 | 110 | 90 |

| 63 | 140 | 125 | 105 |

| 75 | 155 | 135 | 115 |

| 90 | 165 | 150 | 125 |

| 110 | 185 | 165 | 140 |

When marking on the wall, select the appropriate values \u200b\u200bfrom the table, getting a standard strong mount.

Mounting

Due to the fact that this material is very light and affordable, you can organize the heating of a private house, cottage or apartment from polypropylene pipes with your own hands. Before you start, you need to make a project. It is necessary to indicate the dimensions and places of connections, connection features and installation method on it. With its help, the calculation of the required materials is facilitated. You can draw it yourself or by using a special program such as AutoCAD or SolitWorks.

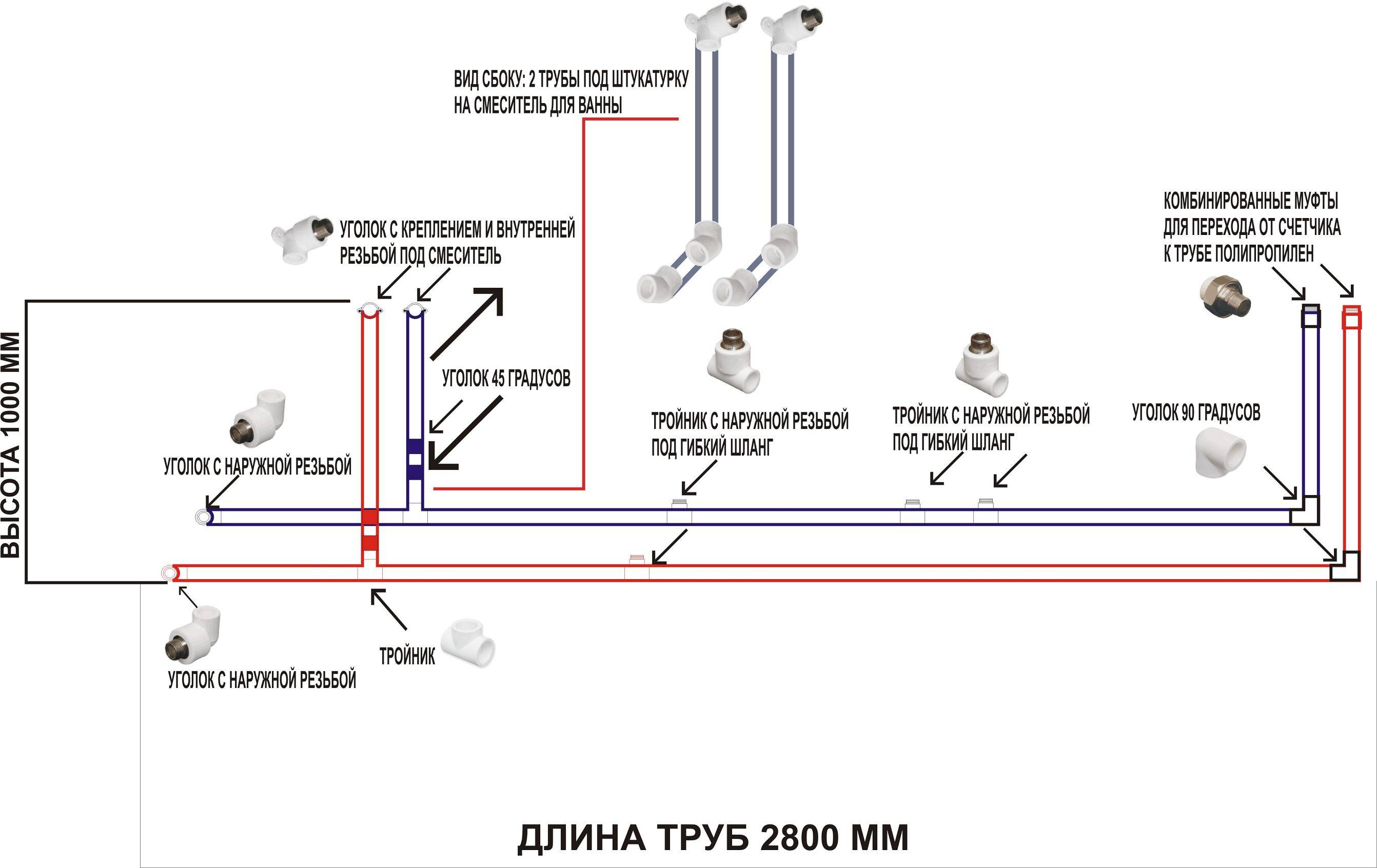

Heating scheme from polypropylene pipes

Pipe routing can be carried out according to two principles: with one pipe and with two. The first option is when only one pipe is used to supply and return water from the boiler. The second is the classic way of organizing heating. Naturally, it is easier to connect the system with this pipe yourself, but in this case you will not be able to evenly heat the housing.

Types of pipe connections

The device of the heating system when installing only plastic pipes or when they are connected to metal pipes is practically the same. You only need to choose the correct diameter when combining different materials. To do this, consult the store with the master.

Installation of polypropylene pipes in the heating system is carried out using a special welding machine for plastic, but in addition to it, you will also need connecting fittings.

How is heating soldered with polypropylene pipes:

Pipes must be cut to the required size

It is very important that the joints are even and at right angles to the floor;

After, you need to treat the sections with degreasing compounds and remove chips from their surface;

Install the pipes in the centralizer. This is a special device that will help achieve maximum geometric accuracy of the connection.

Then put fittings on the joints;

Welding is carried out only according to the instructions. Read the user manual for your inverter carefully. After, heat the device and solder. It is also possible to use electric welding couplings, in which case the installation is carried out directly in them.

The assortment of modern online and simple plumbing equipment stores allows you to choose everything for a heating system made of polypropylene pipes. In addition to fittings, special turn signals, Americans and other connections are often used. The technology of their installation similar.

If it is necessary to connect polypropylene pipes to a metal heating system, then you need to use flanges, they have a different installation scheme. They have a thread on one side - for inserting into steel pipes, and on the second - a smooth shutter for installation on plastic.

To make central heating from polypropylene pipes, you need to buy all the components, the price of which depends on the manufacturer and the type of reinforcement, below is a small rating:

To increase the efficiency and increase the operating life of the heating system, professionals recommend installing heating in a private house with their own hands using polypropylene pipes. Already after a year of operation, the efficiency of their metal counterparts decreases, all because at elevated temperatures these pipes begin to rust from the inside.

Tool types

The tool for mounting polypropylene pipes can be divided into:

- welders;

- glue guns;

- pipe cutters;

- stripping.

Welders

Welders are of two types:

- Mechanical apparatus. It is used if it is necessary to connect pipes of large diameter or a lot of effort is required to align the joints. Device:

- support frame;

- instrument block;

- hydraulic drive.

Half-ring grips are located on the left and right. Between them, for pressure distribution and alignment, inserts are installed, the inner diameter of which corresponds to the outer diameter of the pipes being welded.

Mechanical welding machine

- Manual welding machine. Serves for welding pipes of small diameter up to 125 mm. Device:

- thermostat;

- a heating plate with holes in which nozzles with a non-stick coating are installed;

- a set of nozzles for installing the elements to be welded (in pairs), the Teflon coating prevents polypropylene from sticking to the heated nozzle.

Connecting with a handheld device

Glue guns

The use of a gun simplifies the installation work. A socket connection using couplings of connecting or other elements can be made using glue for polypropylene pipes. Advantages of a hot glue gun:

- setting speed - from 1 to 3 minutes;

-

the reliability of the seam is practically not inferior to other types of connections.

Surfaces to be bonded must be free of dirt and grease.

Pipe cutters

Types of pipe cutters:

Precision scissors with a ratchet mechanism (for pipes up to 42 mm in diameter) have a steel blade with a gear rack.

Scissors for polypropylene pipes

Roller pipe cutter with ratchet mechanism. The pipe is inserted into a C-shaped recess and, when the handles are closed, it is cut off with a blade located opposite. The cutting must be carried out strictly at an angle of 90o. Deviation in the cutting process leads to deformation of the cutting line or even breakage of the scissors.

Roller pipe cutter for polypropylene pipes

- Cordless pipe cutter with a small electric motor that provides high cutting speed.

- Guillotine pipe cutter, which is used for cutting pipes of large diameter.

In the absence of a pipe cutter, you can use an ordinary hacksaw for metal or wood, but then the ends must be carefully cleaned of burrs. Also, when cutting, the pipe must not be deformed.

Cleanups

For hot water and heating systems, it is recommended to use reinforced polypropylene pipes. Pipes reinforced with fiberglass do not need to be stripped, since the mesh is located between the layers of polypropylene, it is not afraid of water and does not come into contact with the fitting. Aluminum foil used for reinforcement must be removed from the joint prior to welding. Aluminum in contact with water can cause electrochemical processes, which will lead to the destruction of the reinforcing film. In the case of external reinforcement, aluminum will interfere with the welding process of polypropylene elements. Therefore, pipes reinforced with aluminum foil need to be stripped. Types of cleaning tools:

- manual - with removable, non-removable handles or corrugation;

- drill bits.

Hand strippers and drill attachment

With small amounts of cleaning work and lack of experience, it is better to use a hand tool.

- For the outer layer, couplings with knives from the inside (material - tool steel), the so-called shavers, are used. The diameter of the tool is selected according to the diameter of the cleaned pipe. Double-sided couplings are often used, allowing work with pipes of two different diameters.

Shaver for polypropylene pipes

- For the inner layer, trimmers are used. Knives are located from the inner end. You just need to insert the pipe into the tool, turn it several times and you can weld.

Trimmer for polypropylene pipes

It is faster to remove the inner layer, because about 2 mm of foil is required to be removed. When removing the outer layer, it is necessary to remove about 2 cm.

Drill nozzle

Nozzles on a drill differ from manual strippers with a steel rod for installation in a drill, screwdriver or puncher.Serve to remove both the outer and inner reinforcing layer (the location of the knives determines the type of layer to be removed).

Conclusions and useful video on the topic

Roller #1. All about the types of polypropylene pipes:

Roller #2. Professional plumbers reveal the secrets of working with polypropylene pipes:

Roller #3. An example of incorrect pipe soldering:

Plumbing from polypropylene pipes is an excellent alternative to the traditional metal system. Many advantages make its use very attractive to homeowners, and the relative ease of installation allows even the most experienced home master to cope with the installation of such a system.

However, the advice of professionals should not be neglected. Then the new plumbing will delight with long and trouble-free operation.

Would you like to tell how you assembled a polypropylene pipeline yourself? Do you know the nuances that will be interesting and useful to site visitors? Please write comments in the block located under the text of the article.