- Design features

- Advantages of metal-plastic pipes

- Do-it-yourself installation of metal-plastic pipes

- Do-it-yourself installation of metal-plastic pipes: where to start

- What is the peculiarity of propylene pipes used in heating systems

- Bending of metal-plastic

- Mounting

- The device of metal-plastic pipes

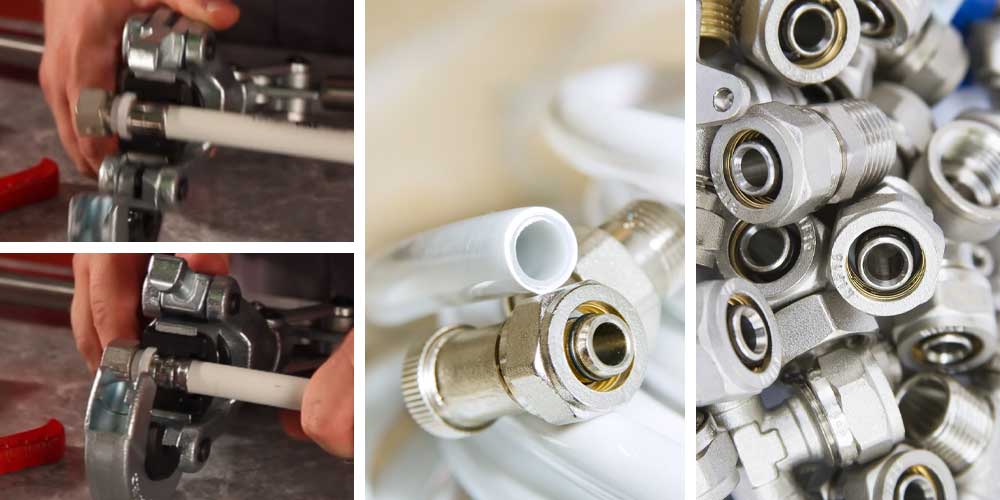

- Methods for connecting and installing metal-plastic pipes

- push fittings

- Compression connection

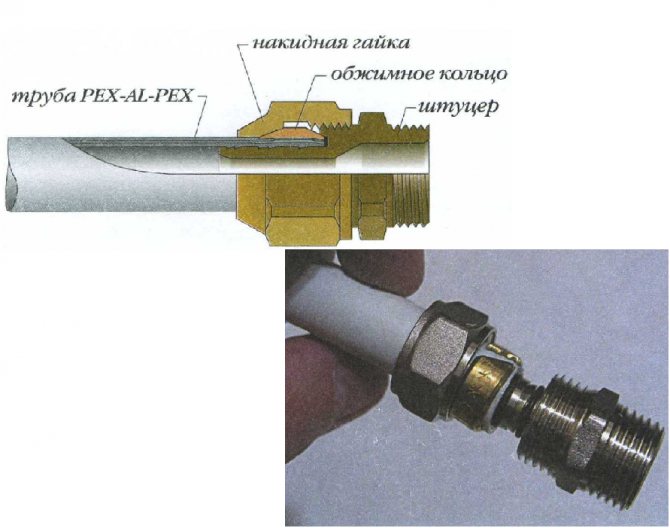

- Push-in fitting

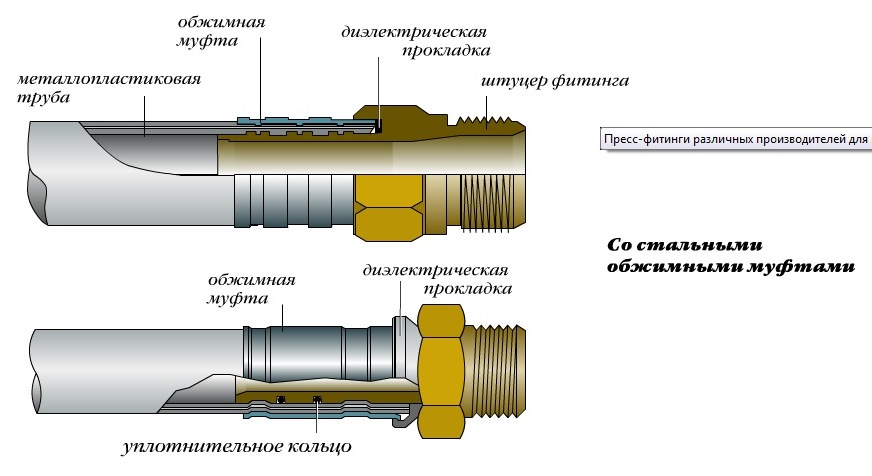

- Press fitting

- Sliding fittings

- Pressure testing of the plumbing system

Design features

Metal-plastic pipes have a multilayer structure, which consists of 5 separate layers that perform different functional tasks:

- outer and inner layer made of polyethylene;

- intermediate reinforcing layer of aluminum foil;

- aluminum and PE sheaths are bonded with two layers of high temperature resistant adhesive.

For the manufacture of metal-plastic products, two types of polyethylene can be used - PEX (cross-linked polyethylene) and PE-RT (thermal stabilized polyethylene).These modifications of PE differ in manufacturing technology, in practice, the differences between them are that PEX is more resistant to deformation during long-term heating, which makes PEX pipes the preferred choice for arranging underfloor heating and hot water systems.

The foil sheath lying between the inner and outer PE layers provides zero vapor permeability of the pipes, which, in turn, minimizes problems with corrosion of heating devices (boilers, radiators) due to the penetration of oxygen coolant into the interior.

Metal-plastic pipes can be used in the following systems:

- cold and hot water supply;

- radiator heating;

- warm floor;

- pipelines for gas supply.

The temperature maximum of operation of metal-plastic products is +90 degrees, they are able to withstand the pressure of the working environment up to 20 MPa.

Tool for cutting metal-plastic pipes

Metal-polymer pipes are produced in the range of diameters 16-53 mm. Products with a diameter of more than 40 mm are practically not found in domestic use, while segments up to 32 mm are most in demand. The cheapest and most used are metal-plastic pipes 16 and 20 mm, the cost of connecting fittings for which is minimal.

The wall thickness can be from 2 to 3.5 mm, the maximum bending radius is 80 mm (when bending manually) and 40 mm (using a pipe bender).

Advantages of metal-plastic pipes

The advantages of metal-plastic products that distinguish them from polymer analogues include:

- Ideally smooth walls (roughness coefficient 0.006), which guarantees the noiselessness of the water supply and the absence of problems with patency even after a long time of operation.

- Full resistance to corrosion and chemically aggressive substances.

- High mechanical strength, resistance to bending and tensile loads, crack resistance.

- Minimum weight, low cost of the pipes themselves and connecting elements, the pipeline is extremely easy to install with your own hands.

- Products are easily bent and due to the aluminum layer perfectly keep the given shape.

- Durability - the service life of products exceeds 50 years, and maintainability.

- Aesthetic appearance - after laying the pipeline does not need to be painted.

Among the shortcomings, we note the tendency of the material to linear expansion. To prevent the problems associated with it, the installation of metal-plastic pipes must be carried out in compliance with a number of rules, namely:

rigid fasteners cannot be used for fixation, since when the expanding line is clamped, the stress in the material increases greatly, sliding clips must be used; it is important to observe a step between the clips of 40-60 cm, which does not allow the pipeline to sag between the fasteners. In general, in terms of the combination of performance, pipes made of metal-plastic are superior not only to metal, but also to most polymer analogues.

In general, in terms of the combination of performance, pipes made of metal-plastic are superior not only to metal pipes, but also to most polymer analogues.

Do-it-yourself installation of metal-plastic pipes

Pipe cutting is carried out with metal shears or a special hacksaw. Cutters are used for cutting small and medium diameter metal-plastic, and are widely used in professional installation.Scissors are a simpler household appliance, they can also be bought in the budget price category, the main thing is that there is a comfortable and balanced handle, and the blades themselves are sharp, made of high-quality metal. The cutters are equipped with an internal calibrator, which allows not only cutting metal-plastic, but also restoring the deformed shape of the edges.

In addition to special tools, when installing a system of metal-plastic pipes, the use of more versatile devices is required: a measuring tape, keys of the right size, a beveler, grinding emery, an expander, provided that press fitting connections are used.

The plumbing system made of plastic and metal is not only durable and practical, but also easy to install. The process is available for execution even by a person who does not have the necessary knowledge. Having a set of the simplest tools, you can do basic installation work efficiently and with decent cost savings if you follow simple installation rules.

Plastic in combination with metal is a good tandem, but it is also “afraid” of aggressive mechanical and ultraviolet effects, this must be taken into account when laying them open.

If it is intended to install a closed type, then it is necessary to provide for the presence of hatches for access to compression type fittings.

The heating system can also consist of MP pipes, but in this case it is worth paying special attention to checking the integrity of all elements and observing the condition of the most durable connection of all elements. Do not use sharp objects when unpacking new elements of the system, even a micro-scratch can seriously damage the entire system.

Metal supports and hangers used for pipe installation must be equipped with soft gaskets, this will help to avoid mechanical damage to the plastic surface.

As a wardrobe begins with a hanger, so the installation of metal-plastic pipes begins with the selection and fastening of ball valves

This element is extremely important for the entire system, you should not save on it and buy Chinese budget counterparts

A high-quality faucet must withstand up to 60 atmospheres and high temperatures

As a wardrobe begins with a hanger, so the installation of metal-plastic pipes begins with the selection and fastening of ball valves

This element is extremely important for the entire system, you should not save on it and buy Chinese budget counterparts. A high-quality faucet must withstand up to 60 atmospheres and high temperatures. In the event of a leak, it is the faucet that is able to stop the flow of water in the shortest possible time.

If at the right time the tap does not cope with its direct task, the plumbing system is in danger of serious damage.

In the event of a leak, it is the faucet that is able to stop the flow of water in the shortest possible time. If at the right time the tap does not cope with its direct task, the plumbing system is in danger of serious damage.

As a wardrobe begins with a hanger, so the installation of metal-plastic pipes begins with the selection and fastening of ball valves

This element is extremely important for the entire system, you should not save on it and buy Chinese budget counterparts. A high-quality faucet must withstand up to 60 atmospheres and high temperatures.In the event of a leak, it is the faucet that is able to stop the flow of water in the shortest possible time.

If at the right time the tap does not cope with its direct task, the plumbing system is in danger of serious damage.

In the event of a leak, it is the faucet that is able to stop the flow of water in the shortest possible time. If at the right time the tap does not cope with its direct task, the plumbing system is in danger of serious damage.

If the entire system is installed from scratch, then it will include the installation of cleaning filters, meters, a pressure reducer, a manifold for piping throughout the area. Pipes are recommended to be mounted together with filters, this will prevent technical debris from entering the system.

Read also:

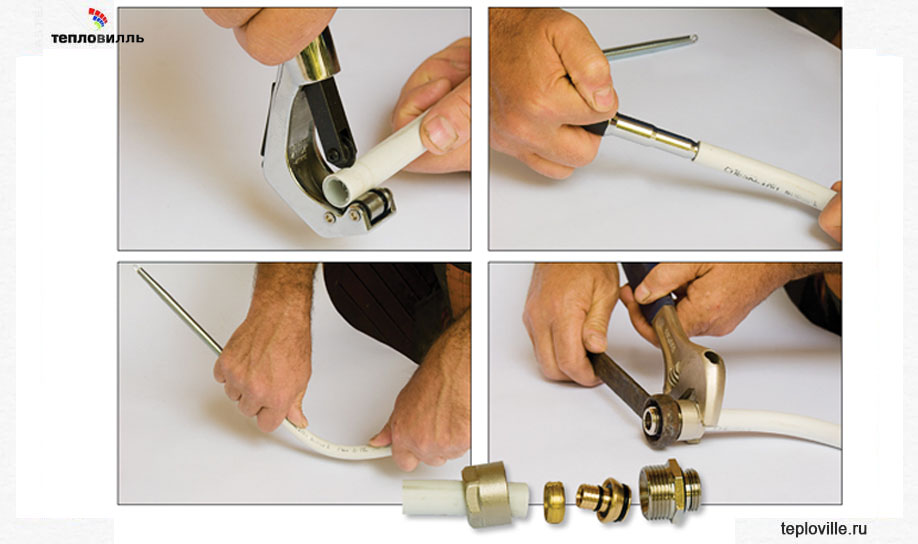

Do-it-yourself installation of metal-plastic pipes: where to start

Let's start learning how to work with metal-plastic pipes by learning how to cut them correctly. The fact is that this type of pipe itself is a relatively soft material - incorrect or inaccurate pressure with scissors can simply flatten the end of the pipe. A deformed pipe, even if it is straightened, is compressed much worse, therefore, the likelihood of leakage increases.

Do-it-yourself installation of metal-plastic pipes - trimming

The process of cutting metal-plastic pipes looks something like this: first, with light pressure, you need to make a small incision on half the diameter of the pipe, after which, turning the scissors in a circle, we cut the pipe to the end. In this way, a smooth and uncreased edge of the pipe is obtained.

Device for fitting metal-plastic pipes

High-quality installation is impossible without the correct connection of the pipe with the fitting. To understand the principle of their connection, it is necessary to study the design of the compression fitting.It consists of three parts - a body (on one side of which either a threaded connection or a fitting is provided, and on the other there is a fitting with ring rubber seals), a compression nut and a cone ring. It is these three elements that ensure the tightness of the connection. Such a connector works quite simply - as the nut is tightened, the compression ring squeezes the pipe, forcing it tightly and with effort to fit the fitting with a rubber seal.

How to connect metal-plastic pipes photo

Now about the direct connection of the pipe and fitting. To begin with, it is necessary to put a nut on the end of the pipe to be connected and then tighten the brass compression ring after it. In different models of metal-plastic pipes, the compression ring can be made in different ways - some manufacturers make it a cone, while others make it straight with large chamfers. Those with chamfers can be installed on either side, and those made with a cone are put on the pipe with the thin side from the fitting.

Put on? Now, the evenly cut edge needs to be calibrated. As a rule, the inner diameter of metal-plastic pipes is slightly smaller than the fitting fitting - this is done in order to achieve a high crimp density. In the normal state, pulling the pipe onto the fitting is quite difficult. We insert the gauge into the inner hole of the pipe and, turning it in different directions, immerse it a couple of centimeters deep. Some craftsmen use the handle of an adjustable wrench instead of a calibrator - this is wrong and can lead to unpleasant consequences in the form of deformation of the end of the pipe and, as a result, leakage of the connection.

Work with metal-plastic pipes - calibration

Having lightly moistened the fitting fitting with water, we put a pipe on it.It is necessary to pull it to the very end, until the pipe rests against a small white ring. If you do not insert the pipe completely, the chances that it will be torn off during operation increase several times. At this stage, you should check the evenness of the cut - if the pipe rested against the white ring evenly from all sides, then everything is in order. If there is a gap of more than a millimeter on either side, then it is better to remove the pipe and cut its end again, since such a docking can lead to a leak.

Connection of a metal-plastic pipe and a fitting photo

If everything is connected normally, then you can move the nut as close to the fitting as possible and use adjustable wrenches to tighten with all force until a characteristic squeak or squeak appears. Do not be afraid to pull - if the fitting is of high quality, then the nut will withstand any load. If it pops, that's even better. You will get rid of low-quality spare parts, the operation of which could lead to a flood.

How to crimp a metal-plastic pipe fitting

Here, in principle, is the entire installation of metal-plastic pipes with your own hands. Difficult? As for me, there is nothing easier. Well, you judge for yourself - someone will support my opinion, but for someone this work will seem impossible.

The author of the article is Yuri Panovsky

What is the peculiarity of propylene pipes used in heating systems

Since the advent of propylene on the heating equipment market, the process of organizing intra-house communications has become much simpler and cheaper. Unlike metal pipes, a pipeline made of polypropylene consumables is 3-5 times cheaper.Moreover, due to the affordable cost of products, it is already possible not to save on the length of communication lines. Previously, it was the factor of the high cost of consumables that was the main reason that heating in the house was done to a minimum, with significant technological and design limitations.

The laying of heating circuit pipes using propylene products allows you to equip a full-fledged home heating, which can heat all residential premises. The low cost of propylene consumables is the result of the low cost of the manufacturing process. However, this is not all the advantages that polymer consumables have. Let's dwell on some other important aspects. For example, polypropylene pipes are:

- resistance to high temperatures;

- good resistance to mechanical stress;

- resistance to corrosion processes;

- high performance;

- long service life;

- environmental Safety.

Of all the above, it is especially worth highlighting the thermal stability of polypropylene. The material begins to change its structure and shape only at very high temperatures. Upon reaching the mark of 1400C, the plasticity of the material increases. Polypropylene easily changes shape. At around 1750C, polypropylene begins to melt. This feature of the substance is key for its industrial use. In heating systems, the temperature of the coolant can reach a maximum of 950C, which is consistent with the technological parameters of polypropylene products.

The addition of certain stabilizers to the composition of polymers makes propylene pipes resistant to corrosion, aggressive environments, and dynamic loads. Due to these components, the service life of propylene pipelines is significantly increased.

Polypropylene has high water resistance, which allows the use of pipes made of this material, laying liquid communications, including plumbing and heating circuits.

Despite the mass of positive properties and characteristics, polypropylene pipes have one drawback, which, if the laying technology is not followed, can negatively affect the condition of the highway. This is a high coefficient of thermal expansion. This aspect must be taken into account when choosing consumables for the heating circuit.

Thanks to such qualities and properties of polymers, polypropylene pipes have become an excellent alternative to the use of metal consumables and metal-plastic products. The only condition that will allow you to make the most of all the positive qualities of polypropylene pipes is the correct installation of heating.

Bending of metal-plastic

The advantage of the material is the ability to give the pipeline the desired bend, which means that the number of connectors will be less. Plastic threads are bent when laying the "warm floor" system, if a turn is needed in laying the line through the living space. The bending process is carried out in 4 ways:

- manually;

- professional spring;

- building hair dryer;

- with pipe bender tool.

Only an experienced specialist can bend manually. Otherwise, you can bend too much and the plastic will burst.

A professional spring is bought for bending a metal-plastic structure. It is bought according to the parameters of the pipe, since it is inserted inside this structure. With a spring, it is easier to make a bending angle, as a result there are no defects on the surface of the pipeline.

The stream of hot air of the building hair dryer is directed to the metal-plastic. It becomes pliable and easily bends in the right direction. The warm plastic flexes easily without the use of force.

If there is little experience in working with metal-plastic pipes, then it is recommended to use a crossbow pipe bender. A product of any size is bent: the desired bending angle is set, plastic is inserted, the handles are brought together. The tool will help even an inexperienced person to cope.

The connection of metal-plastic pipes is carried out if old ones are replaced with new ones or the main is being repaired. You can handle the work yourself. Installation will be easy if metal-plastic material is chosen for laying. The advantage of this choice is obvious: the pipeline is not painted, the material does not rust, even the long structure is not heavy, the material bends in the right direction.

The water supply line or heating system will last for more than one year, provided that it is not exposed to high temperatures (its deformation occurs) or vice versa, low temperatures (the pipeline freezes at temperatures below 0).

Options for connecting pipes made of metal-plastic are easy to implement. They differ in the possibility of disassembling the structure.

Mounting

Do-it-yourself installation of metal-plastic pipes is a rather entertaining and even creative process. Now that the valves have been changed, turn off the water supply and proceed with the installation.Install a coarse filter and a fine filter behind the valve (optional).

They differ in the size of the filter cell. Many people neglect the fine filter, and in vain. It is he who retains small particles of scale from pipes, which, getting into expensive ceramic mixers, can damage the smooth surface of ceramic plates.

In addition, it is he who stops the “little thing” that accumulates in the filter on the faucet spout and reduces the water pressure.

Next, install the counters, if you use them, and proceed with the wiring.

If there are many consumers in the apartment that are connected to the water in parallel, then use the collector.

This device is good in that it provides all consumers with the same pressure, and a separate tap can be mounted on each branch.

A little lower we can see metal-plastic pipes installation video clearly. It is useful to know the internal structure of a metal-plastic pipe.

The device of metal-plastic pipes

Combined pipes made of metal and polymers consist of five layers. The outer and inner layers are made of cross-linked polyethylene, with an aluminum shell between them. Layers of polyethylene and aluminum are held together by bonding adhesive layers.

This design provides metal-plastic pipes with a number of advantages:

- polymer layers have high corrosion resistance, providing aluminum with protection from moisture and aggressive environments;

- the aluminum layer provides easy installation of metal-plastic pipes with your own hands, thanks to the ability to maintain the shape that was given to the pipe.

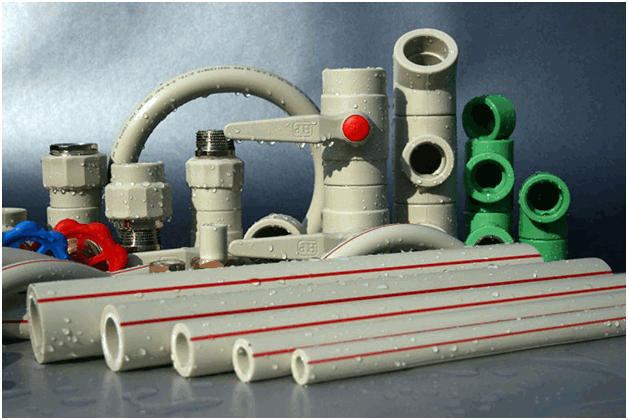

The diameters of metal-plastic pipes vary between 16-32 mm. Installation of certain types of such pipes can only be carried out using fittings of the manufacturer of the same name, and some are universal in this regard and allow the use of any fittings.

Methods for connecting and installing metal-plastic pipes

Fittings are used to connect individual parts of a metal-plastic pipeline. This part consists of a fitting, a split ring, a nut. They come in a variety of shapes and sizes, connecting pipes of the same or different diameters. Main types of fittings:

- push fittings;

- compression;

- collet;

- sliding;

- press fitting.

Each of the structures deserves a separate description.

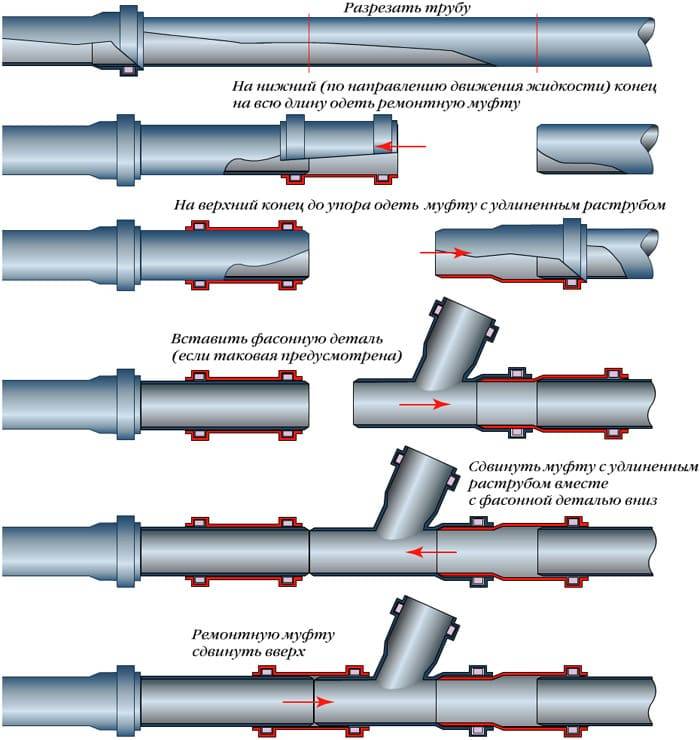

push fittings

Made of PPSU polyethylene, which is characterized by high mechanical strength, resistance to low temperatures, long-term operation. These connectors are used in cold and hot water pipelines, floor heating systems and other types of heating.

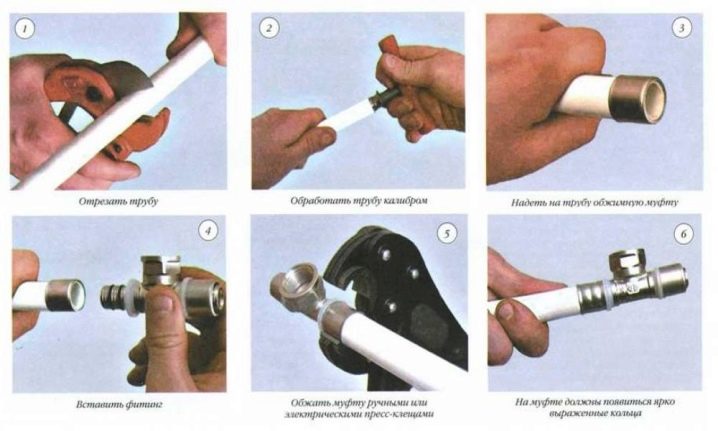

During installation, perform the following work:

- Cut the required sections.

- Calibrate the ends of the pipes.

- Remove burrs, chamfer.

- The fitting is mounted on the pipe to the control hole in its body.

- On the reverse side, insert the second section of the pipeline.

After assembling the assembly, the connection is fixed with a crimp ring.

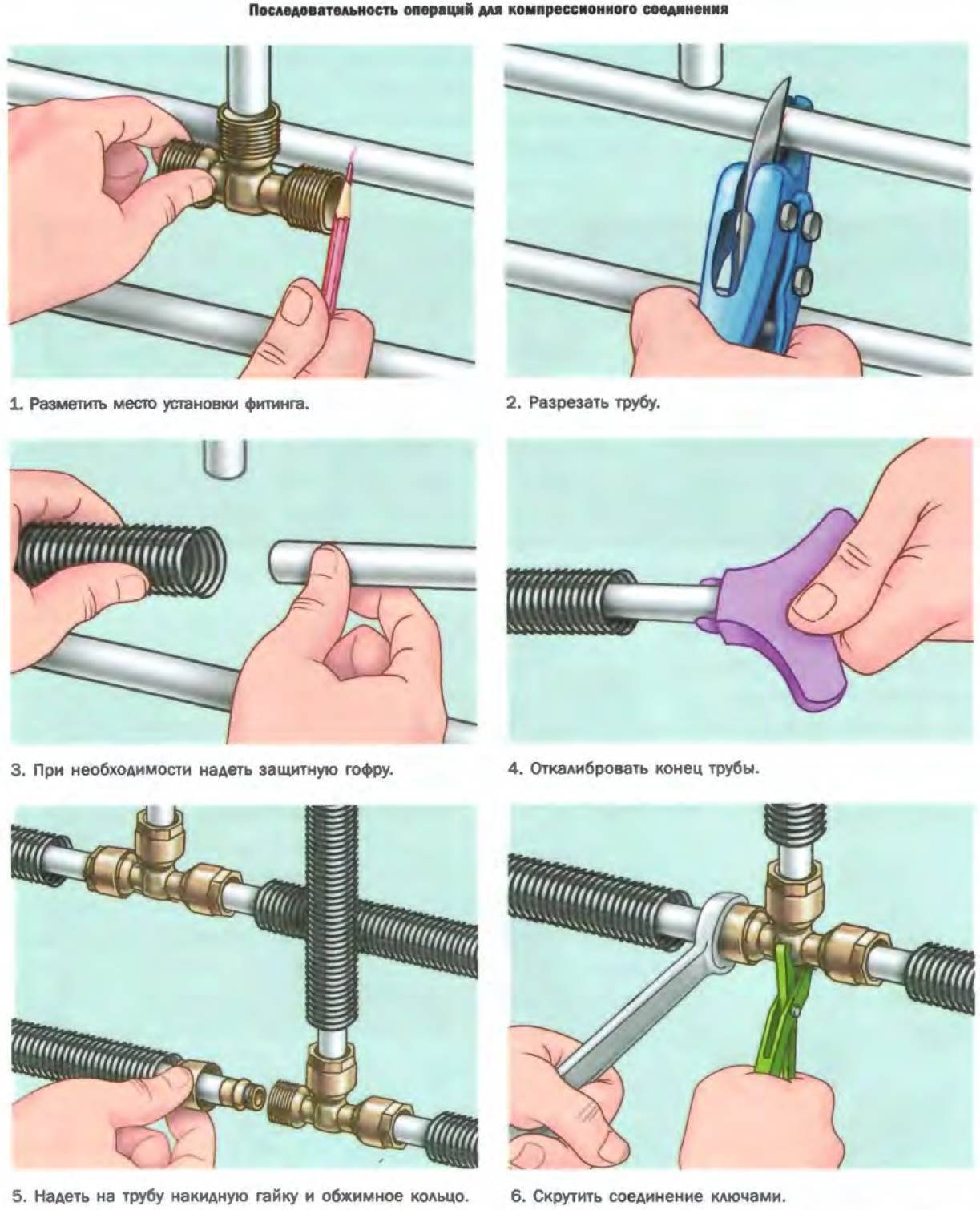

Compression connection

It is the easiest when assembling pipelines. Before starting work, cut segments of the desired length, clean the edges, cut the chamfer. The edge must be perpendicular to the axis of the pipe.Next, perform the following steps:

- A union nut is put on the pipe, a split ring is put on it.

- The fitting is moistened with water, a pipe is put on it, resting its edge against the protruding collar.

- Tighten the nut by hand until it stops.

- Fasten the connection with a key, while 1-2 turns of the thread should be visible.

It should be remembered that overtightening the nut, as well as under tightening it, leads to a leaky connection.

Push-in fitting

Such elements are used when connecting products made of different materials and different diameters. When joining elements made of metal and metal-plastic, the threaded part of the fitting must correspond to the diameter of the metal pipeline.

Connection using a push-in fitting is carried out as follows:

- tow or other soft insulation is wound on a steel pipe;

- a fitting is put on it;

- a washer with a nut is put on the end of the metal-plastic element.

The joint is fixed by screwing the nut onto the body. Clamp the mount with a special, so-called gas key.

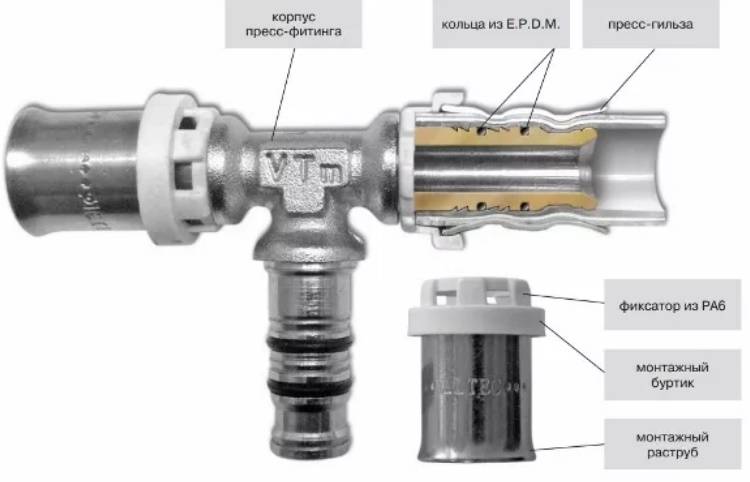

Press fitting

The design includes a body and a crimp sleeve. The preparation of the pipe section is the same as for the previous connections, the further assembly order is as follows:

- put a sleeve on a piece of pipe;

- a gasket is screwed onto the threaded part;

- insert a fitting into the pipe, bringing it to the hole on its body;

- then use pliers with pads of the right size;

- the pliers are shifted to the extreme part, the handles are squeezed, the part is crimped.

As a result of this operation, two circular depressions of the same depth are formed on the surface of the sleeve. Press fittings withstand a pressure of 10 atm, which is quite enough for internal pipelines of low-rise buildings.

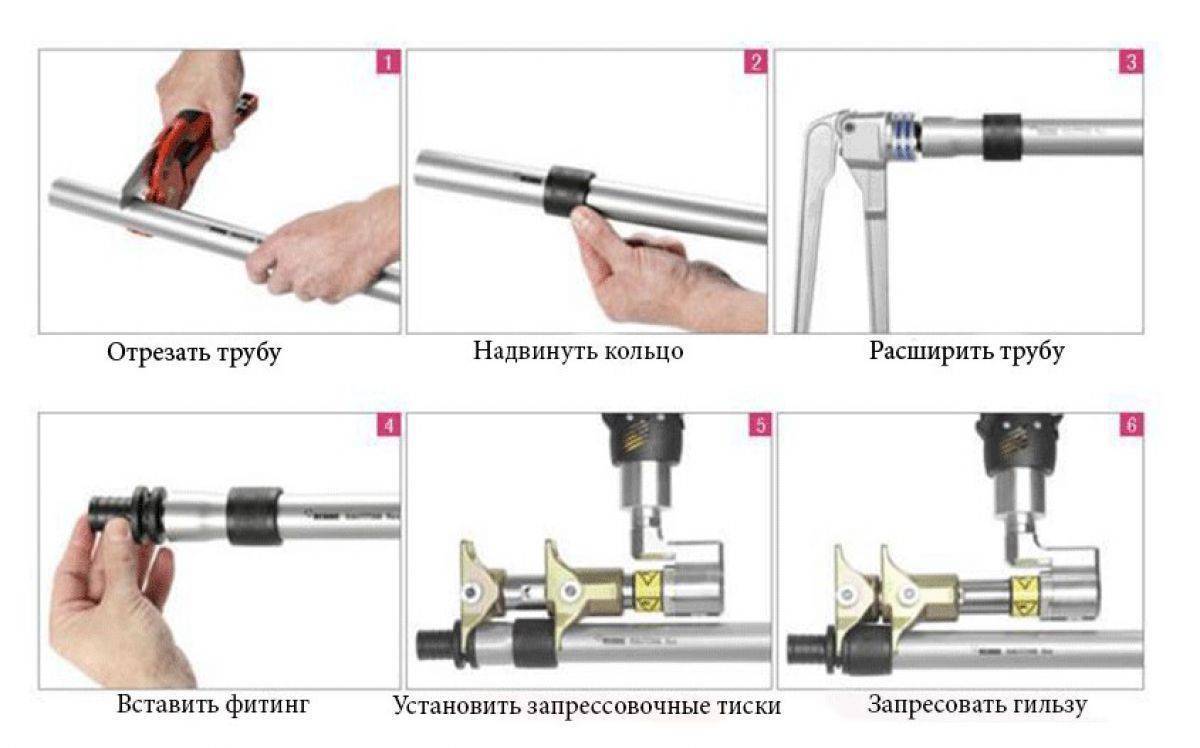

Sliding fittings

This connector consists of a fitting and a sliding plastic sleeve. She puts on the pipe with an interference fit, compressing it. An expander is used to expand the pipe. The procedure is as follows:

- A plastic sleeve is put on one of the pipes.

- The second section of the pipe is expanded with an expander.

- Insert the fitting until it stops.

- Push the sleeve onto the fitting and press it in.

The tightness of the joint is ensured by the ability of polypropylene to return to its original state due to its elasticity.

Pressure testing of the plumbing system

When the installation of a water pipe from metal-plastic pipes is completed, it is necessary to check it for leaks using the pressure test process:

- It is necessary to close the test area filled with water to seal it (using taps / valves).

- Connect a pump to the connection pipe of one of the taps (manual, low-power is suitable for a home water supply system).

- Using a pressure pump, pump water into the selected area at a pressure greater than the calculated working pressure, then turn off the pump, record the pressure gauge readings.

- Keep the system under pressure for a while - at least half an hour.

- Then compare the current pressure gauge readings with the original value. If the two values are different - something went wrong, there is a leak.

Pipe crimping pump

If you have an open gasket, the problem area can be visually detected. After troubleshooting, you will have to re-pressurize.

HelpfulUseless