- What fittings are on the market

- Compression fittings

- Press fittings

- Capillary

- Do-it-yourself installation of copper pipes for water supply and heating systems

- Fitting count

- Assembly

- The nuances of working with copper pipes

- Pipe processing and welding requirements

- On the interaction of copper with other metals

- Invalid Errors

- Options for joining pipes made of copper

- Welding joint

- Flaring connection

- Press connection method

- Thread type connections

- Purpose of brake pipes

- Methods for connecting copper pipes

- Secrets of soldering with a gas torch

- Connection with compression fittings

What fittings are on the market

Do-it-yourself installation of copper pipes is considered a simple task. Viega solder fittings must be used when connecting these piping products.

Currently, 3 types of fittings are used:

- compression;

- press fittings;

- capillary.

To install press fittings, you need to use a set of pliers with different diameters and different shapes.

Compression fittings

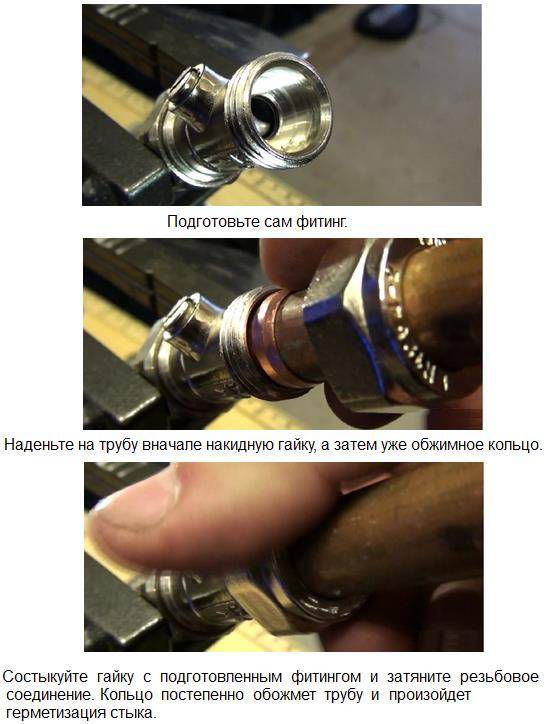

Compression fittings for copper pipes have a ring that is used when crimping. This part maintains reliable sealing of copper tubes. Such copper fittings must be tightened using a specific wrench and nuts.

Also, fittings for copper pipes for pressing can be of 2 types:

- Type A. Used in the construction of land pipelines, which is made of semi-solid copper;

- Type B. Such crimp fittings for copper pipes are used in the construction of various communications - underground and above ground. In this case, soft tubes are used.

As a result, the installation of compression fittings is simple and convenient. In this case, you do not need to use heating and use special equipment.

Press fittings

When using a press fitting, the fact that copper gives pipes high plasticity follows.

Press fittings are susceptible to deformation, which can appear on the pipeline under external influence. These products, used in crimping tubes, are considered the most reliable.

The docking of copper tubes is done in this way: first, such copper products are inserted into the press fitting, and then it is tightly crimped with special press tongs.

Thanks to the use of such technology, a reliable connection is created.

Capillary

Capillary copper fittings are soldered connectors. Docking of tubes from these parts is done in the construction of solder.

The solder is a wire that is made of copper and is placed under the threads of the capillary fitting.

The installation of such a part is done in this way:

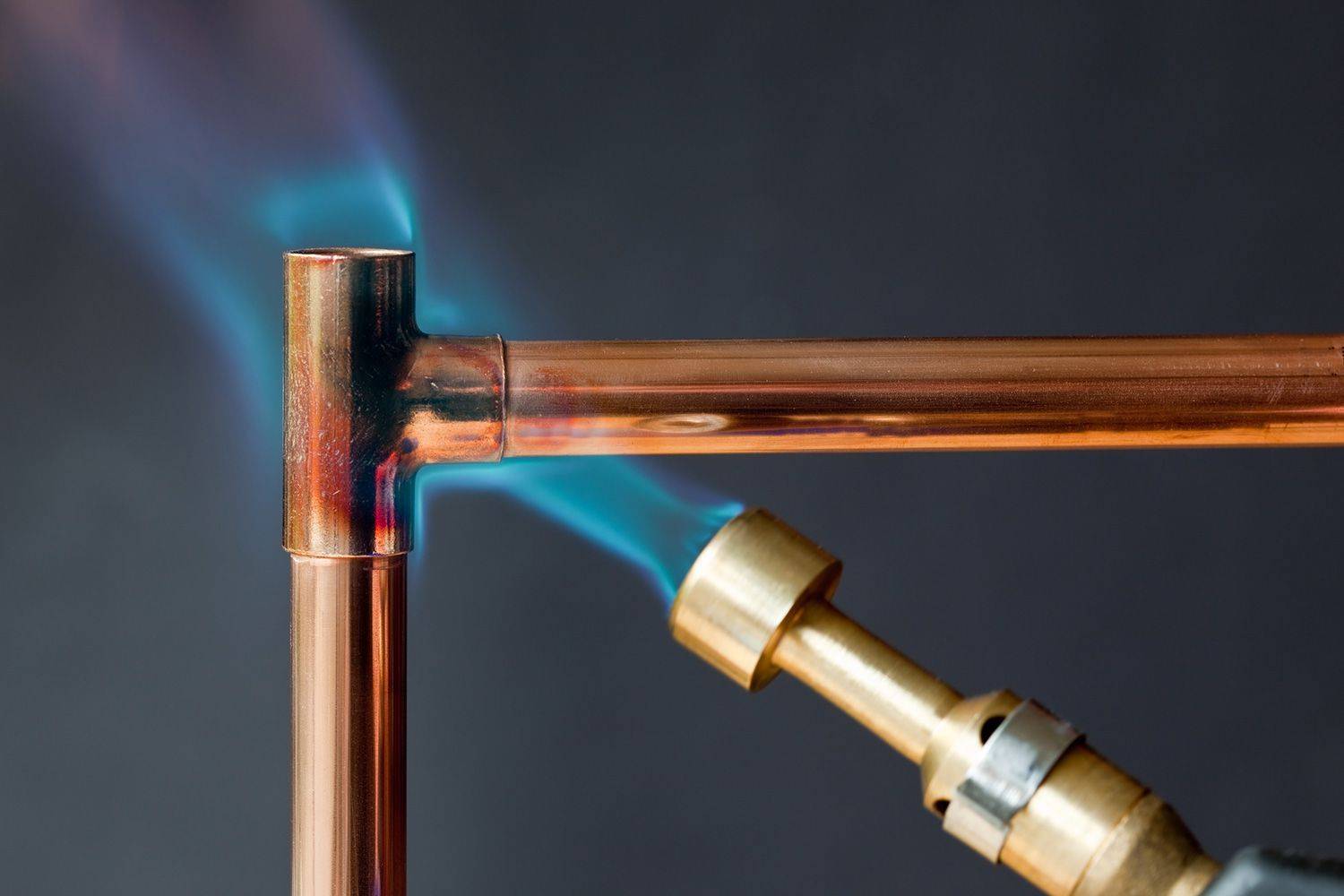

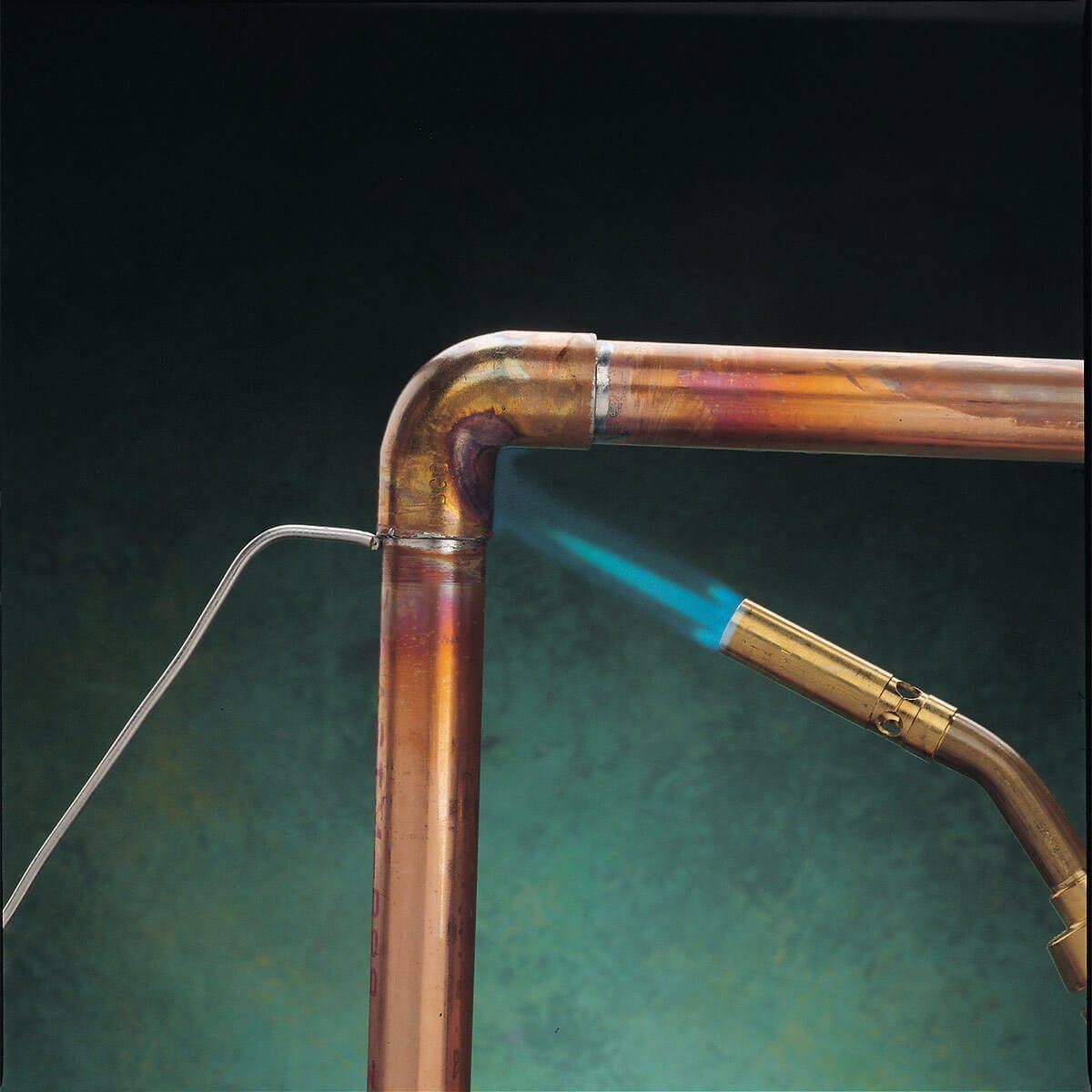

- a fitting is installed on the tube, which is pre-coated with flux;

- then the connecting element is heated with a burner. In this case, all parts of the pipe should be well warmed up so that the solder is completely melted and all the joints of such products are impregnated with it;

- after the copper product has cooled down, remove excess solder from it using sandpaper.

The main advantage of capillary fittings is the ability to quickly install without the use of heaters or a burner. They are installed on objects where the burner cannot be used, as well as in a tank or tank.

The connection of such fittings is considered more reliable than that made using compression elements.

When laying pipelines throughout the house, several pipes should be installed. In this case, a copper pipe expander should be used, which has a low cost.

Also, when installing such tubes, you can save a lot if copper pipes are flanged - making a coupling and fittings for soldering with your own hands. In this case, you can make copper fittings for soldering using tools such as a beader and pipe expander.

In order to make soldered copper fittings yourself, you can purchase a set of copper pipe expanders - manually operated or electric.

Also, when laying such pipeline elements, a copper tube roller is used. With this tool, metal is rolled around a roller of a specific size. By moving adjustable rollers to unregulated ones, the required diameter of the part is selected.

Rolling copper tubes makes it possible to create a workpiece of the required shape from ductile metals or plastic materials.

WATCH VIDEO

The cost of such tubes depends on the section, wall thickness, grade of copper and other factors. The average price for copper pipes and fittings starts from 415 rubles / kg. By footage - from 200 rubles / m. P.

Fittings cost 25 - 986 rubles / piece.

Do-it-yourself installation of copper pipes for water supply and heating systems

- Before installation, it is necessary to cut the pipes into segments of the required length.

- It is better to cut pipes for heating with a pipe cutter or a hacksaw.

- The inner surface of pipelines must be free of burrs and metal chips. To complete this task, you will need a file and scraper.

- The cut point must be leveled, especially in cases where the cutting was carried out with a hacksaw for metal, which slightly deforms the pipe.

- You can bend the tubular product manually or using a special tool.

- If the heating system has curved sections of a particularly complex shape, it is recommended to use a pipe bender. Such a bend will protect the material from unwanted creases, which can subsequently become a place of corrosion.

- Products should be bent with the minimum allowable radius.

- The bending radius when performing work with a pipe cutter must be at least 3.5 times the diameter of the pipeline. If pipes are bent by hand, a bending radius of at least 8 diameters should be performed.

Heating system with copper pipes

The connection of elements of the copper heating system is carried out in two already known ways:

- Crimp fittings;

- soldering method.

Due to the fact that copper can be easily bent, installation is simple and requires a small number of fittings. However, it is necessary to remember some rules for combining materials in the heating system.

If the use of aluminum radiators cannot be avoided, the transition must be made through a steel pipe. This will help to avoid the onset of corrosion when joining copper and aluminum. As for radiators made of other materials, such as steel or cast iron, there are no such problems.

Installation of copper pipes is a process that can be carried out in different ways. There are several options for connecting such products, which include assembly, welding and soldering. It is allowed to use fittings from other manufacturers, which in certain cases can reduce financial costs.

Fitting count

In order to carry out the installation of copper pipelines, fittings are required. They can be either crimped or soldered. In the first case, the connection will be detachable, in the second - one-piece.

The choice of fittings will also affect the fastening of all elements.

Assembly

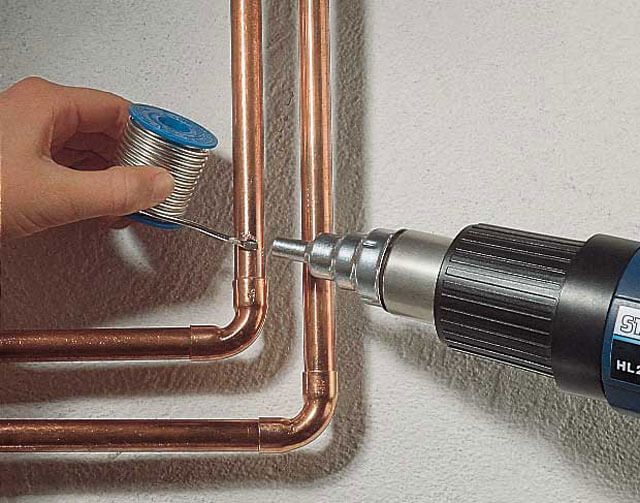

After counting the required number of fittings, pipe assembly begins. To begin with, the edges of the products are covered with a thin layer of flux. The procedure is necessary in order to prevent the oxidation process, which necessarily occurs when the elements are heated. This processing method prevents foreign substances from depositing on the joint that adversely affect strength.

The ends of the pipes crimped by the fittings are clamped with the help of special tongs. It is this pressure that causes fixation.

The nuances of working with copper pipes

To perform the installation of internal pipelines in the house, you can choose a pipe made of plastic, metal-plastic or stainless steel. But only an analogue made of copper is able to serve without problems and overhaul for more than half a century.

Properly installed copper piping systems in practice work properly throughout the entire period of operation, which is assigned to a cottage or apartment building.

Copper pipes are not afraid of long-term thermal loads, chlorine and ultraviolet.When freezing, they do not crack, and when the temperature of the internal environment (water, sewage, gas) changes, they do not change their geometry. Unlike plastic counterparts, copper pipelines do not sag. This plastic is subject to expansion at high temperatures, with copper this does not happen by definition.

Pipe copper products have two drawbacks - the high price and the softness of the metal. However, the high cost of the material pays off with a long service life. And so that the walls of the pipes are not damaged from the inside by erosion, filters must be installed in the system. If there is no pollution in the form of solid particles in the water, then there will be no problems with the destruction of pipelines.

Pipe processing and welding requirements

When working with copper pipes, the following rules must be observed:

- When mounting cold water or hot water pipes by soldering, the use of lead solder should be excluded - lead is too toxic.

- The water flow rate must be no higher than 2 m / s, otherwise the smallest particles of sand or other solid matter will gradually begin to destroy the pipe walls.

- When using fluxes, after completion of installation, the pipeline system must be flushed without fail - the flux is an aggressive substance and will contribute to the corrosion of copper pipe walls.

- When soldering, overheating of the junction should not be allowed - this can lead not only to the formation of a leaky joint, but also to loss of strength of the copper product.

- Pipe transitions from copper to other metals (steel and aluminum) are recommended to be performed using brass or bronze adapter fittings - otherwise steel and aluminum pipes will quickly begin to corrode.

- Burrs (metal deposits) and burrs at the cutting points must be removed - their presence leads to the formation of turbulent eddies in the water flow, which contributes to erosion and a reduction in the operational life of the copper pipeline.

- When preparing copper pipes for connection, it is strictly forbidden to use abrasives - their particles left after installation inside will lead to damage to the metal and the formation of a fistula.

If in the plumbing or heating system in the house, in addition to copper, there are also pipes or elements made of other metals, then the water flow should go from them to copper, and not vice versa. The flow of water from copper to steel, zinc or aluminum will lead to rapid electrochemical corrosion of pipeline sections from the latter.

Due to the ductility and strength of the metal, copper pipes are easily cut and bent. The pipeline can be rotated either by using a pipe bender or by using fittings. And for branching and connecting with various devices, there are many parts made of heat-resistant plastics, brass, stainless steel and bronze.

On the interaction of copper with other metals

In most private houses, household water pipes are assembled from steel and aluminum pipes. In heating systems, there are also radiators made of steel or aluminum. Incorrect insertion into such a wiring of copper pipes is fraught with considerable problems.

The most optimal installation option is the use of pipes and devices exclusively from copper and its alloys. Now you can easily find bimetallic aluminum-copper radiators, as well as the corresponding fittings and valves. Combining different metals is only in extreme cases.

If the combination is unavoidable, then copper should be the last in the chain of pipeline elements. It is impossible to rid it of the ability to conduct electric current. And in the presence of even a weak current, this metal creates galvanic couples with steel, aluminum and zinc, which inevitably leads to their premature corrosion. When installing a water supply system, it is imperative to insert bronze adapters between them.

Another potential problem is the oxygen in the water. The higher its content, the faster the pipes corrode. This applies to pipelines both from the same metal, and made from different ones.

Often, cottage owners make a serious mistake by often changing the coolant in the heating system. This only leads to the addition of completely unnecessary portions of oxygen. It is best not to change the water completely, but to add it when the need arises.

Invalid Errors

The reason for the poor-quality connection of two parts is most often haste, so you need to remember to control the edges of the product for the absence of foreign small objects that may form after cutting.

When applying the flux, it is important to try not to miss even the slightest surface area, because any defect can cause poor contact. If any part of the surface is slightly heated, this will lead to a weak fusion of the two metals. Overheating can burn the flux and form scale or oxide at the soldering site, which affects its reliability.

Overheating can burn the flux and form scale or oxide at the soldering site, which affects its reliability.

If any part of the surface is slightly heated, this will lead to a weak fusion of the two metals. Overheating can burn the flux and form scale or oxide at the soldering site, which affects its reliability.

Options for joining pipes made of copper

When assembling heating, various installation methods are used. So, the docking of copper pipes is carried out by a collapsible and non-collapsible method. In the first case, flanges, threaded fasteners, fittings are used, which are fixed automatically. When designing a non-separable heating system, pressing, soldering and welding are used.

Welding joint

Let's take a look at the process of welding copper pipes. This docking technique is applied to pipes with a diameter of 108 mm or more. The wall thickness of the heating material must be at least 1.5 mm. To carry out welding work, in this case, it is only necessary to butt, while the proper temperature should be 1084 degrees. It is worth adding that this option for installing heating is not recommended to be done by hand.

To date, builders use several types of welding:

- Gas welding using oxy-acetylene type burners.

- Welding with consumable electrodes, performed in an inert gas environment - argon or helium.

- Welding in which non-consumable electrodes are used.

In most cases, the arc welding method is used to join copper elements. If the pipes that are planned to be used to assemble the pipeline are made of pure copper, then it is necessary to use non-fusible tungsten electrodes in an argon, nitrogen or helium environment. When welding copper elements, the process must be fast.This will prevent the formation of various oxidations on the metal base of the pipe.

Welding joint of copper pipes

To give strength to such a connection, upon completion of the docking work, it is recommended to carry out additional forging of the resulting joints.

Flaring connection

It happens that the use of welding torches during the installation of heating systems creates some inconvenience. In this case, it is recommended to resort to flaring copper pipe joints. This installation method will turn out to be detachable, which will play a positive role in the event of a forced heating assembly.

An operation of this kind will require the obligatory presence of a flaring device. We will try to describe in detail how to connect heating pipes by flaring:

- to begin with, the tip of the pipe is cleaned in order to remove from its surface the scuffs and burrs formed during the sawing of the material;

- a coupling is fixed on the pipe;

- then the pipe is inserted into a clamping device, with the help of which further expansion is performed;

- then you should begin to tighten the screw of the tool until the angle of the end of the pipe reaches 45 degrees;

- after the pipe area is ready for connection, a coupling should be brought to it and the nuts should be tightened.

You can learn more about the process in the video below.

Press connection method

In addition to all of the above methods for installing heating pipes, there is also a pressing technique. To join the copper elements in this case, it is necessary to insert the previously prepared end of the pipe into the coupling until it stops. After this, the use of a hydraulic or manual press will be required, through which the pipes will be fixed.

If the heating is planned to be assembled from thick-walled pipes, press fittings with special compression sleeves will be required. These elements make it possible to compress pipes and fittings for heating from the inside, while external seals will provide excellent tightness of the structure.

Thread type connections

Unfortunately, it is impossible to find copper pipes with threaded connections on the market, and therefore it is customary to use fittings that have a union nut to join parts of a heating system.

For joining copper pipes with pipes made of other materials, bronze or brass threaded fittings are used. Their use eliminates the possibility of galvanic corrosion. In the event that the pipes differ in diameter, resort to the help of special expanders.

Considering the types of seals used today for copper heating systems, there are two types of threaded connections:

- Consolidations of conical type ("American"). These elements are recommended for heating installation in conditions of high temperature indicators.

- Flat type connections. Such materials include in their design seals made of polymeric materials of various colors. Gaskets are painted in different colors to indicate the temperatures at which you can work with such elements.

Connection diagram for copper pipes

Purpose of brake pipes

Any hydraulic system needs lines through which fluid is supplied to the working mechanisms. The braking system of a car is no exception, but it has its own characteristics.They are connected both with the design of the brakes and the technical characteristics of the working fluid used, to which very stringent requirements are imposed:

- it should not boil at temperatures exceeding 200 degrees;

- do not lose fluidity in forty-degree frost;

- not be aggressive to the rubber parts of the brake system;

- not lead to corrosion.

The last point is especially important for brake pipes, which are an integral part of the vehicle of a modern car. Consider the principle of operation of a typical braking system.

The vehicle stop algorithm is associated with the following actions:

- the driver, if necessary, to reduce the speed of the car until it stops completely, presses the brake pedal with the appropriate effort;

- the pedal rod directly acts on the piston of the brake master cylinder, bringing it into action;

- the piston, moving in the cylinder, acts on the brake fluid, creating a certain phenomenon;

- liquid, the compressibility of which is close to zero, moves along the highway and acts on the brake cylinders located on each of the wheels;

- The pistons transmit the momentum to the brake pads, which, pressing against the discs, create a braking force, slowing down the rotation of the wheels.

In this chain, the brake pipes are an integral part of the hydraulic line through which the working fluid moves. Their task is to prevent leakage of the TJ, therefore the quality of their connection with other elements of the brake system is of particular importance. For this, a technological operation called flaring is used.

Its essence lies in the deformation of the end section of the tube in such a way as to uniformly increase its diameter (the opposite operation, which consists in narrowing the diameter of the tube tip, is called rolling). Flaring is needed in order to ensure the most tight connection of the tubes to each other or the tube to the manifold.

Since, as we have already noted, the brake pipes are subject to mechanical stress, they can get damaged, causing the system to depressurize - in this case, an immediate operation is required to replace them. Normal wear and tear is the more common reason for replacing this brake system component.

The procedure for expanding the tube itself consists of three stages:

- determination of the required gap between the tube sheet and the tip of the tube;

- flaring of both tubes and tube sheets;

- removal of the damping load from the inner walls of the tube.

The deformation technology requires that the metal of the brake tube is subjected to the so-called plastic deformation, and the metal of the grille is subjected to elastic deformation. To ensure this condition, the grating is made of a harder metal, which allows, after the completion of the expansion stage, the tube grate to completely “grasp” the tube.

Ensuring the required tightness of such a connection is carried out by applying the contact pressure method formed between the outer surfaces of the contacting parts. In some cases, the technology for connecting flared pipe ends involves the use of welding - this method is called combined.

In the factory, flaring is carried out using a special machine equipped with a hydraulic, pneumatic or electric type drive, which provides for the possibility of controlling the rotation speed. It is up to the drive to ensure the required reliability of the connection.

When replacing brake pipes, flaring is carried out using a special tool that can be purchased at an auto shop.

Methods for connecting copper pipes

In practice, one of two methods of assembling copper pipelines is used - by soldering or mechanical crimping.

Secrets of soldering with a gas torch

When choosing a soldering method for mounting the system, the following must be taken into account: all connections made in this way are one-piece. Soldering provides a high percentage of tightness assurance, but imposes some maintenance restrictions. It is often impossible to upgrade the system without additional complexity.

So, if it is necessary to change some part of the water supply (heating system), for example, due to the introduction of new equipment, difficulties may arise. You will have to use the gas burner and soldering technique again just to be able to introduce a coupling, tee or other part into the system.

Therefore, solder joints are used in hidden plumbing projects immured in walls or under floors.

The soldering process is inextricably linked with the operation of a gas burner (open fire and combustion products). Therefore, this technique is not always suitable for installation, especially in rooms where a fine finish was previously performed.

Step by step installation process soldering:

- Two pipes are cut to size.The end area is cleaned from burrs.

- The end part of one of the pipes is expanded with a calibrator - a bell is made.

- With a metal brush and sandpaper, clean the soldering points to a shine.

- Cleaned surfaces are treated with a flux solution.

- The processed parts are inserted one into the other.

- The junction is heated with a burner to the melting point of the solder (350-500ºС).

- The end of the solder rod touches the lower edge of the socket.

Under the influence of high temperature, the solder melts and rushes into the gap between the walls of the nozzle and the socket due to the capillary effect created by the flux fumes. This results in a neat and high-quality solder joint. This is just one example of pipe-in-pipe soldering.

Soldering with fittings and other elements is carried out in the same way.

Step-by-step instructions for soldering copper pipes, as well as the technical nuances of the work, are given in this article.

Connection with compression fittings

It is much easier and easier to do the installation of copper pipes with your own hands, if you use another widespread technology - mechanical crimping. To create a connection of copper pipes in this case, special fittings are used.

Approximately the same elements are used in working with polypropylene pipes. But for copper, they make a slightly different design of the crimp ring - one-piece, without a cut.

Compression fittings are made of brass. Judging by the degree of plasticity of materials, these values for copper and brass are almost the same.

An important feature of the brass-copper pair bond is the almost complete absence of galvanic coupling between the materials.

This factor guarantees the purity of the connection during operation - the absence of oxides, corrosion, etc.

The situation is quite different with aluminum. This metal, unlike brass, is galvanically bonded to copper. Under conditions when tap water is saturated with salts, that is, it is an active electrolyte, a favorable environment for the occurrence of an electrochemical reaction is formed.

Under the influence of such a reaction, aluminum is destroyed. Therefore, a direct connection of copper pipes and aluminum radiators (or other aluminum appliances) is undesirable. Steel transitions should be used, for example.

Mounting the fitting by crimping:

- The end area of the pipe is deburred.

- A nut, a ferrule, a fitting is put on the end of the pipe.

- With a wrench for the desired size, the fitting is held in one position.

- With the second wrench, the nut is screwed onto the thread of the fitting.

The tightness of the connection is achieved due to the uniform pressing of the crimp ring along the diameter of the copper pipe. It is not recommended to use extreme force when tightening the nut. From the place of the initial stop, it is enough to stretch the nut 1-2 turns.

The advantages of using press connectors are that they can be disassembled and reassembled if necessary. But at the same time, the quality of sealing of such joints is influenced by changes in the temperature of the external and internal environment.

Often, due to temperature changes, crimp connections leak. Such a defect is eliminated simply and quickly - by tightening the union nut.

However, for hidden installation of a water supply system, the method of crimping collet joints of copper pipes is clearly not suitable.