- Do-it-yourself installation of metal-plastic pipes

- The nuances of mounting and soldering pipes of all diameters

- Do-it-yourself step-by-step work in 7 steps

- What is needed for soldering copper pipes

- Options for joining pipes made of copper

- Welding joint

- Flaring connection

- Press connection method

- Thread type connections

- Limitations when using copper pipes

- Installation instructions with fittings

- Mounting

- What is a push-in fitting?

- Types of push-in fittings

- Advantages and disadvantages

- Copper pipes

- ELITE company is a distributor of copper pipe manufacturing companies

- Their advantages and disadvantages

Do-it-yourself installation of metal-plastic pipes

Pipe cutting is carried out with metal shears or a special hacksaw. Cutters are used for cutting small and medium diameter metal-plastic, and are widely used in professional installation. Scissors are a simpler household appliance, they can also be bought in the budget price category, the main thing is that there is a comfortable and balanced handle, and the blades themselves are sharp, made of high-quality metal. The cutters are equipped with an internal calibrator, which allows not only cutting metal-plastic, but also restoring the deformed shape of the edges.

In addition to special tools, when installing a system of metal-plastic pipes, the use of more versatile devices is required: a measuring tape, keys of the right size, a beveler, grinding emery, an expander, provided that press fitting connections are used.

The plumbing system made of plastic and metal is not only durable and practical, but also easy to install. The process is available for execution even by a person who does not have the necessary knowledge. Having a set of the simplest tools, you can do basic installation work efficiently and with decent cost savings if you follow simple installation rules.

Plastic in combination with metal is a good tandem, but it is also “afraid” of aggressive mechanical and ultraviolet effects, this must be taken into account when laying them open. If it is intended to install a closed type, then it is necessary to provide for the presence of hatches for access to compression type fittings. The heating system can also consist of MP pipes, but in this case it is worth paying special attention to checking the integrity of all elements and observing the condition of the most durable connection of all elements. Do not use sharp objects when unpacking new elements of the system, even a micro-scratch can seriously damage the entire system. Metal supports and hangers used for pipe installation must be equipped with soft gaskets, this will help to avoid mechanical damage to the plastic surface.

As a wardrobe begins with a hanger, so the installation of metal-plastic pipes begins with the selection and fastening of ball valves

This element is extremely important for the entire system, you should not save on it and buy Chinese budget counterparts.A high-quality faucet must withstand up to 60 atmospheres and high temperatures

In the event of a leak, it is the faucet that is able to stop the flow of water in the shortest possible time. If at the right time the tap does not cope with its direct task, the plumbing system is in danger of serious damage.

As a wardrobe begins with a hanger, so the installation of metal-plastic pipes begins with the selection and fastening of ball valves

This element is extremely important for the entire system, you should not save on it and buy Chinese budget counterparts. A high-quality faucet must withstand up to 60 atmospheres and high temperatures

In the event of a leak, it is the faucet that is able to stop the flow of water in the shortest possible time. If at the right time the tap does not cope with its direct task, the plumbing system is in danger of serious damage.

If the entire system is installed from scratch, then it will include the installation of cleaning filters, meters, a pressure reducer, a manifold for piping throughout the area. Pipes are recommended to be mounted together with filters, this will prevent technical debris from entering the system.

Read also:

The nuances of mounting and soldering pipes of all diameters

Copper pipes and fittings for plumbing are connected by threading or soldering, the first method is considered simpler and more accessible to non-professionals. Work begins with drawing up a wiring diagram and counting the footage; in the absence of experience, it is recommended to provide a margin of 3-5 m.

Do-it-yourself step-by-step work in 7 steps

Do-it-yourself copper plumbing with threaded connections is assembled in the following sequence:

- Pipe cutting.

- File cleaning of burrs in the cut area, on pipes with PVC insulation, the insulating layer is cleaned.

- Chamfer removal.

- Putting a union nut and a ferrule on the pipe.

- Preparing the fitting, mating it with the nut and tightening the connection (first by hand, then with a wrench).

- Connection of steel pipes (if necessary) using transition fittings, mandatory sealing of threaded connections.

- Leak test.

Copper pipes and fittings for plumbing must be properly installed.

Checking the condition of the joints and correct installation

The assembly of a copper water pipe using press fittings is considered quite reliable, the quality of sealing depends on the strength of the twist. It is recommended to use special pneumatic or hydraulic pliers for this operation. The disadvantage of this method is the deterioration of the appearance of the water pipe at the joints, if the appearance plays a decisive role, then the sections should be connected by soldering.

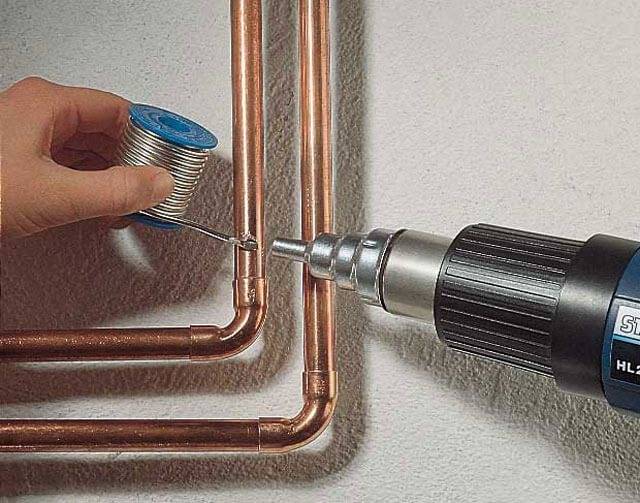

Soldering is considered the most reliable way to connect copper pipes. The sequence of actions is almost the same as the assembly with press fittings: the pipes are cut and carefully protected from burrs

It is important to wipe the products from dust and residues of the oxide film (inside and outside). Then a flux is applied to the outer surface of the pipe, a fitting is inserted with a mandatory gap, the joint area is evenly heated with a burner or blowtorch, when choosing the second option, overheating should be avoided. To check that the desired temperature has been reached, it is enough to lightly touch the solder, if it melts, then the area has already warmed up

After that, the solder is inserted into the left gap and the seam is sealed

To check that the desired temperature has been reached, it is enough to lightly touch the solder, if it melts, then the area has already warmed up. After that, the solder is inserted into the left gap and the seam is sealed.

An important nuance of soldering: during heating and connection, the section of the future pipeline must remain motionless. Any efforts and movements are allowed only after the solidification of the solder. At the end of the assembly, the system must be washed from flux residues.

WATCH VIDEO

Heated products are easy to bend; special springs are used to give the desired shape while maintaining the section. The optimal equipment for producing bent elements is a special pipe bender; its purchase is advisable for large volumes of work. The sections assembled by soldering the system look neater than those bent when threaded. But, despite the obvious advantages and reliability of this method, soldering is not carried out in explosive places due to open flames. Fire safety measures are mandatory. Copper pipes and plumbing fittings are widely used in construction.

What is needed for soldering copper pipes

Soldering copper pipes, which is not difficult to do with your own hands, does not require expensive equipment and any special materials. In order to properly implement it, you will need the following devices.

A burner, due to which the solder and the pipe section where they will be connected will be heated. As a rule, propane gas is supplied to such a burner, the pressure of which is regulated by a welding reducer.

Special tool for cutting copper pipes. Since products made of this metal are very soft, they should be cut gently enough so as not to wrinkle the walls. Pipe cutters of various models are offered on the modern market, differing both in their functionality and technical capabilities.

The design of individual models of such devices, which is important, allows them to be used even for work in hard-to-reach places.

A pipe expander is a device that allows you to expand the diameter of a copper pipe, which is necessary in order to better solder. In various systems mounted from copper pipes, elements of the same section are used, and in order to connect them qualitatively, it is necessary to slightly increase the diameter of one of the connected elements. It is this problem that such a device as a pipe expander solves.

It is this problem that such a device as a pipe expander solves.

Copper pipe flaring kit

Device for chamfering the ends of copper pipes. After trimming, burrs remain on the ends of the parts, which can interfere with obtaining a high-quality and reliable connection. To remove them and give the ends of the pipes the required configuration, a beveler is used before soldering. There are two main types of chamfering devices on the market today: placed in a round body and made in the form of a pencil. More convenient to use, but also more expensive, are round devices that can process soft copper pipes with a diameter of not more than 36 mm.

To properly prepare copper pipes for soldering, it is necessary to remove all impurities and oxides from their surface. For these purposes, brushes and brushes are used, the bristles of which are made of steel wire.

Brazing of copper pipes is usually performed with hard solder, which can be high and low temperature.High-temperature solder is a copper wire containing about 6% phosphorus in its composition. Such a wire melts at a temperature of 700 degrees, while for its low-temperature type (tin wire), 350 degrees is enough.

The technology of soldering copper pipes involves the use of special fluxes and pastes that perform a protective function. Such fluxes not only protect the formed seam from the formation of air bubbles in it, but also significantly improve the adhesion of the solder to the pipe material.

In addition to flux, solder and other basic elements, additional tools will be needed to solder copper pipes, which can be found in every workshop or garage. To solder or weld copper products, additionally prepare:

- regular marker;

- roulette;

- building level;

- a small brush with stiff bristles;

- a hammer.

Before starting work, it is also important to decide how to solder copper pipes. There can be two main options: brazing copper (less commonly used) and using soft solder. When resolving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder

So, hard solders are used for soldering elements of refrigeration units and air conditioners. In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

When solving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder. So, hard solders are used for soldering elements of refrigeration units and air conditioners.

In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

Brushes for stripping the inner surface of a copper pipe before soldering

Options for joining pipes made of copper

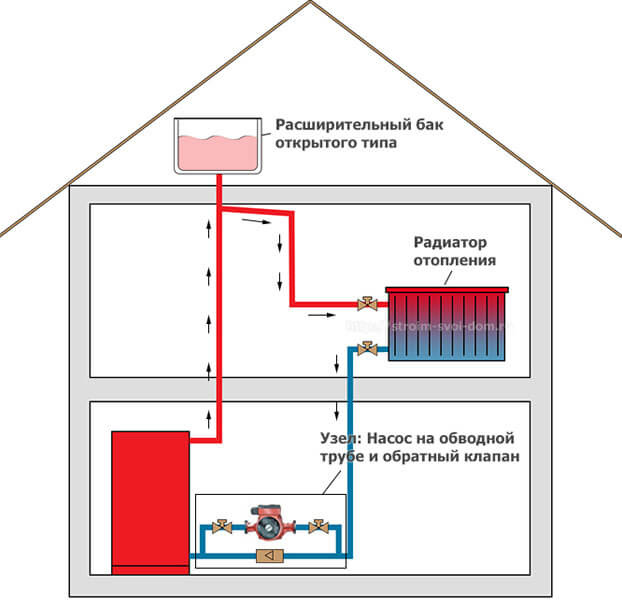

When assembling heating, various installation methods are used. So, the docking of copper pipes is carried out by a collapsible and non-collapsible method. In the first case, flanges, threaded fasteners, fittings are used, which are fixed automatically. When designing a non-separable heating system, pressing, soldering and welding are used.

Welding joint

Let's take a look at the process of welding copper pipes. This docking technique is applied to pipes with a diameter of 108 mm or more. The wall thickness of the heating material must be at least 1.5 mm. To carry out welding work, in this case, it is only necessary to butt, while the proper temperature should be 1084 degrees. It is worth adding that this option for installing heating is not recommended to be done by hand.

To date, builders use several types of welding:

- Gas welding using oxy-acetylene type burners.

- Welding with consumable electrodes, performed in an inert gas environment - argon or helium.

- Welding in which non-consumable electrodes are used.

In most cases, the arc welding method is used to join copper elements. If the pipes that are planned to be used to assemble the pipeline are made of pure copper, then it is necessary to use non-fusible tungsten electrodes in an argon, nitrogen or helium environment.When welding copper elements, the process must be fast. This will prevent the formation of various oxidations on the metal base of the pipe.

Welding joint of copper pipes

To give strength to such a connection, upon completion of the docking work, it is recommended to carry out additional forging of the resulting joints.

Flaring connection

It happens that the use of welding torches during the installation of heating systems creates some inconvenience. In this case, it is recommended to resort to flaring copper pipe joints. This installation method will turn out to be detachable, which will play a positive role in the event of a forced heating assembly.

An operation of this kind will require the obligatory presence of a flaring device. We will try to describe in detail how to connect heating pipes by flaring:

- to begin with, the tip of the pipe is cleaned in order to remove from its surface the scuffs and burrs formed during the sawing of the material;

- a coupling is fixed on the pipe;

- then the pipe is inserted into a clamping device, with the help of which further expansion is performed;

- then you should begin to tighten the screw of the tool until the angle of the end of the pipe reaches 45 degrees;

- after the pipe area is ready for connection, a coupling should be brought to it and the nuts should be tightened.

You can learn more about the process in the video below.

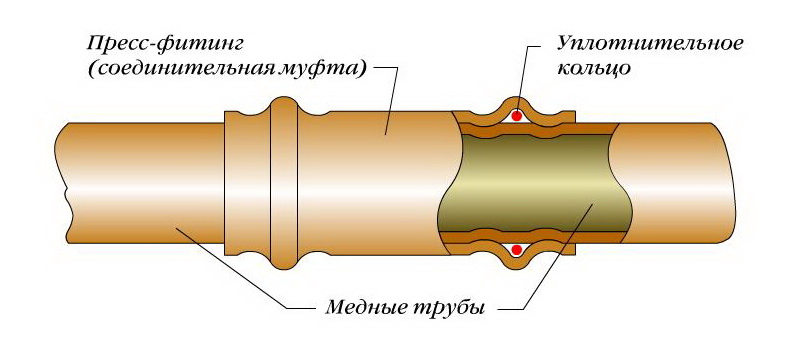

Press connection method

In addition to all of the above methods for installing heating pipes, there is also a pressing technique. To join the copper elements in this case, it is necessary to insert the previously prepared end of the pipe into the coupling until it stops.After this, the use of a hydraulic or manual press will be required, through which the pipes will be fixed.

If the heating is planned to be assembled from thick-walled pipes, press fittings with special compression sleeves will be required. These elements make it possible to compress pipes and fittings for heating from the inside, while external seals will provide excellent tightness of the structure.

Thread type connections

Unfortunately, it is impossible to find copper pipes with threaded connections on the market, and therefore it is customary to use fittings that have a union nut to join parts of a heating system.

For joining copper pipes with pipes made of other materials, bronze or brass threaded fittings are used. Their use eliminates the possibility of galvanic corrosion. In the event that the pipes differ in diameter, resort to the help of special expanders.

Considering the types of seals used today for copper heating systems, there are two types of threaded connections:

- Consolidations of conical type ("American"). These elements are recommended for heating installation in conditions of high temperature indicators.

- Flat type connections. Such materials include in their design seals made of polymeric materials of various colors. Gaskets are painted in different colors to indicate the temperatures at which you can work with such elements.

Connection diagram for copper pipes

Limitations when using copper pipes

Despite the many advantages that copper pipes have, there are certain limitations to their use. These limitations are due to the following characteristics of this metal.

Copper is a very soft and ductile metal, so the fluid flow velocity through pipes made of this material should not exceed 2 m/s.

If the water that flows through the water supply systems contains solid particles of contaminants that mechanically act on the walls of the pipes, this can cause gradual washing out of the metal (erosion) and a significant reduction in the life of the water supply system. That is why, in order to ensure the reliable operation of copper pipelines, it is necessary that the water for them undergo preliminary purification from impurities.

An oxide film that forms on the inner walls of copper pipes and provides them with even more reliable protection can only form when the hardness of the water in contact with them is 1.42–3.42 mg / l, and the pH is 6.0–9, 0. If this requirement is neglected, then the oxide film (patina) on the surface of copper pipes will be constantly destroyed and restored, which will eventually lead to a gradual decrease in the thickness of their walls and premature wear.

If the water transported through copper pipes will be further used for food or drinking purposes, then lead-based solders cannot be used for their installation.

Given the fact that the average life of copper water pipes is 50 years, they should be installed in such a way as not to reduce it in any way. So, it is not allowed: to twist the pipes, to make creases when they are bent, to edit jams on them more than once.

Fittings for copper pipes

- When soldering pipes, it is also necessary to monitor the temperature of their heating, since overheating can lead to a decrease in the strength of the material and its rupture at the junction.

- After the installation of the fittings, it is necessary to remove the used flux from the inside of the water supply system, for which the flushing method is used. Such a flux, being a chemically aggressive substance, can lead to the development of corrosion processes in the pipeline.

- After copper pipes and connecting fittings (in the direction of water flow), elements made of zinc, steel and aluminum cannot be used in water supply systems, this can lead to the active development of corrosion processes. If the use of such elements is necessary, then passive anodes attached to the system will help prevent their corrosion.

- Fittings that are used to connect a copper pipe to a water supply element made of another metal should be made of brass, bronze or stainless steel, this will avoid corrosion of these elements.

However, even these limitations, which can be considered insignificant, do not reduce the popularity of copper pipes, which are considered the best material for arranging water supply systems.

Installation instructions with fittings

There are two types of compression fittings - the so-called pressing and compression fittings. They create completely different connections, so before starting work, you need to decide what kind of connections you would like to see: one-piece or conditionally detachable.

Pressing elements are similar to solder fittings, but have shallow grooves along the edges with sealing gaskets. With the help of special press tongs, which have a set of nozzles for different diameters, crimping is performed.As a result, it creates a sealed one-piece connection that cannot be repaired, and in the event of an accident it can only be replaced.

In the store you can see the same parts at first glance, but they differ in characteristics (composition, wall thickness, etc.). Heating fittings are marked with green markings

Pressing creates a strong, reliable connection of parts, while maintaining the geometry of the pipes and does not deform the connecting elements. There is a nuance of pressing "soft" copper products: before the operation, a support sleeve is inserted into the pipe, which resists deformation of the pliable material

The pressing process is simple and does not take much time. From the tool you need a standard set for cutting and processing pipes, as well as pressing tongs with the desired nozzle.

Image gallery

Photo from

Connecting elements must be selected according to the size of the pipe, which is often indicated in inches. Also, do not forget about the marking so as not to accidentally use a fitting for gas or cold water

For a strong connection, no additional lubricants or solutions are required. We simply put the fitting on the pipe and set it in the desired position with light movements.

It is necessary to accurately indicate the place of attachment, so with the help of a marker we mark the border of the connection - just circle the part around the circumference

We insert the connected parts into the pliers, carefully clamp and press. We make sure that the parts do not disperse - marking helps with this

Step 1 - Choosing a Brass or Copper Fitting

Step 2 - connecting a copper pipe and a fitting (corner, cross, adapter)

Step 3 - marking the installation site of the fitting

Step 4 - pressing with special press tongs

Pressing is considered a reliable method. If you plan to insulate copper pipes, then you can use insulating tubes that are easy to put on even on curved structures. After pressing, the finished heating network can be masked in strobes, covered with decorative trim and poured with a screed.

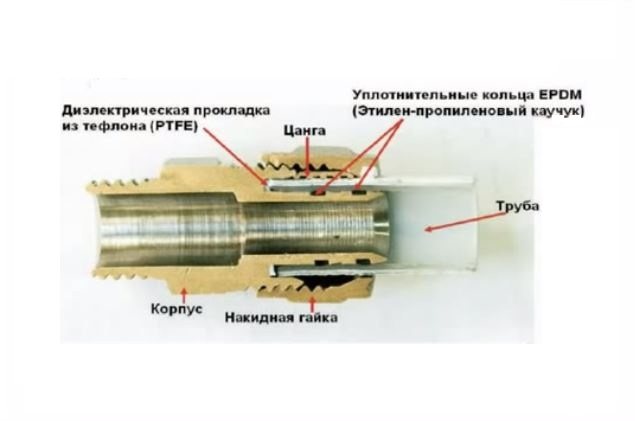

The second type of fitting is compression. They differ in design and installation process.

A compression fitting for copper pipes is a prefabricated device consisting of three parts: a brass or copper body, a ferrule, which is also called a collet, and a nut

The crimping order is as follows:

- a nut is freely thrown onto the prepared end of the pipe;

- then the collet is put on;

- lastly, the fitting body is put on until it stops;

- the nut is screwed by hand along the thread, while simultaneously pressing the split ring;

- the connection is tightened with an adjustable or sized wrench.

In the process of compression crimping, the cutting ring tightly wraps around the pipe, creating a strong and tight connection. The nut can loosen over time, so pipelines with this type of installation must be serviced regularly. The connections are conditionally detachable, since they can be disassembled, however, if necessary, a fragment with a clamped ring will have to be removed and a new fitting installed.

Mounting

Installation of copper pipelines is carried out using special connections - fittings or using welding. Through press or collapsible fittings, the pipes are firmly joined to the elements of the heating system, however, welding is most often used.When installing annealed copper pipes in places where it is necessary, they can be bent so that the total number of joints and joints is reduced. For this, a pipe bender is used, thanks to which it is possible to obtain the necessary slope without compromising the overall patency of the system.

Installation of compression fittings does not require special equipment: the pipe is simply inserted into the groove until it stops, and then it is tightly screwed with a nut, while the material itself should be pressed against the fitting body. In order to achieve maximum fit and complete sealing, two keys must be used. That's all the equipment you'll need. However, one should not forget about the specifics of crimp fasteners, which involves complete control of tightness - such systems periodically begin to "drip", which is why the joints should not be walled up, access to the pipes should be open.

Press fittings are installed using special press machines, this is a rather expensive installation option, however, the connection is strong and reliable, but one-piece. Experts note that capillary soldering is considered the most universal method of installing copper pipelines; this method allows you to connect pipe segments of the same diameter to each other. To do this, flaring is performed at one of the ends, that is, its diameter is slightly increased, this allows you to insert one pipe into another.

The joint is cleaned with a special sponge or a metal brush, and then the joined surfaces are covered with flux - this is a special composition that provides maximum adhesion of the metal to the solder.Pipes treated in this way are sequentially inserted into each other so that the gap between them does not exceed a fraction of a millimeter. Next, the solder is heated with a welded torch, and when the material reaches the melting temperature, all the gaps that have arisen are poured with the molten composition.

After the seam is filled, it must be cooled, for this you can lower the joint into the water, or you can simply leave it in the open air. In general, this process, like repair, is quite simple, however, it requires accuracy, thoroughness and compliance with safety regulations. Copper pipes are aesthetically pleasing, but sometimes users paint such products so that the piping matches the overall concept of the interior.

It is very important that the paint used for this meets the following conditions:

- the coating should not change color under the influence of high temperature;

- paint must reliably protect against any type of external influences;

- even minimal peeling is unacceptable.

It is advisable to coat the pipes with a primer before applying the paint, experts recommend using a lead-red lead composition. Keep in mind that the paint does not absorb into copper, so you need to spread it very carefully with a brush. And even in this case, a more or less even coverage can be achieved only after 2-3 layers. However, you can also use paint from a spray can, it lays down much more evenly.

How to connect copper pipes with your own hands, see the following video.

What is a push-in fitting?

To understand this issue, you need to understand the definition of two terms: collet and fitting.

There is an abundance of fittings on the market from different materials: plastic, copper, steel, etc.

Mounting a push-in fitting on a plastic pipe (sectional view)

They can be used both for simple connection of two pipes of the same diameter, and as adapters between pipes of different diameters, different materials (for example, the transition from copper pipes to metal-plastic pipes), serve as tees, crosses, corners, plugs, etc.

Thanks to the collet fixation of the fitting, such a connection does not require special knowledge, tools or large physical costs. But at the same time, the connections produced by this method are tight and durable.

- collet fittings can be used in the installation of pipelines transporting hot and cold water, gases, oils, chemical media;

- the temperature of the transported medium must not exceed 175ºC;

- allowable pressure does not exceed 1.6 MPa;

- the inner diameter of clamp connectors for plastic, metal-plastic or copper pipes on the construction market varies from 8 to 100 mm;

- push-in fitting can be straight, angle, tee, cross, etc.

Types of push-in fittings

- straight push-in fitting or coupling. This type is used to connect pipe segments of the same diameter from the same material;

- a transition fitting is required if necessary to connect pipes of different diameters or to transition between pipes of different materials (for example, connecting metal-plastic and metal pipes);

Types of push-in fittings (elbow, tee, coupling, wall mount)

- a corner or outlet connector is used to arrange corners and turns from 45 to 120 degrees;

- crosspiece - an element that allows the distribution of the flow in two directions;

- a tee is used if a one-way branch from the flow is necessary;

- the fitting serves as an adapter from the pipe to the hose;

- a plug is needed to shut off the flow at the end of the pipeline.

Advantages and disadvantages

The push-in fitting is the most popular connecting element. This is due to a number of its undeniable advantages:

- affordable cost;

- wide model range;

- the presence in the assortment of any specialized stores;

- ease of installation work that every consumer can handle;

- the possibility of installation by improvised means without the purchase of any special equipment;

- tightness and high reliability of joints of metal-plastic, plastic or copper pipes;

- durability;

- the possibility of reusing connecting elements. Thanks to this, push-in fittings are convenient to use even in temporary structures;

No special tools are required to install push-in fittings. However, there are some disadvantages:

from time to time, the collet clamp weakens, so there is a need to periodically tighten the clamping nut;

a consequence of the first drawback is a categorical ban on immuring collet connectors into walls

They should always be available for preventive maintenance and repair;

installation of collet fittings, although it does not require special knowledge and skills, however, requires intelligence and caution. They must be tightened sensitively so that the collet or nut does not crack (this is especially true for plastic connectors).

Copper pipes

ELITE company is a distributor of copper pipe manufacturing companies

The ELITE company offers you high-quality copper pipes of the best European manufacturers, with a copper content of 99.9%, which have undeniable advantages in comparison with steel or plastic pipes. All offered brands of copper pipes for refrigeration, air conditioning, heating, drinking cold and hot water supply are certified according to European EN standards and have certificates of compliance with GOST, as well as a sanitary and epidemiological conclusion.

Copper pipes

ELITE company is a supplier of copper pipes.

ELITE company offers you the entire line of copper pipes from the best European manufacturers Feinrohren S.P.A. (Italy) and Cupori OY (Finland). Feinrohren and Cupori produce copper pipes for air conditioning and refrigeration systems, as well as sanitary copper pipes for heating and water supply. Feinrohren and Cupori copper pipe has a copper content of 99.9% and complies with EN 12735-1 and EN 1057 standards.

Copper pipe is the best solution

The materials used worldwide for laying pipelines are: plastic (PE-polyethylene, PP-polypropylene, PVC-polyvinylchloride), metal-plastic, steel and copper. Copper tubes, in comparison with other materials, have the following advantages:

- copper pipes are more plastic - they bend easily, do not break, which ensures ease of installation;

- do not rust - corrosion products do not enter the pipe - this is important for drinking water supply and refrigeration systems, and there is no decrease in throughput over time;

- there is no limitation on temperature and pressure, moving through the pipes of the medium;

- the service life is equal to the service life of the building;

These qualities make copper pipes versatile for use in various systems.From a technical and economic point of view, the use of copper pipes in all engineering systems is beneficial.

Elita supplies annealed copper pipes for air conditioning and refrigeration. Copper pipes are cleaned, purged and sealed to ensure a high level of internal surface cleanliness.

The pipe is supplied with plugs at the ends, individually vacuum-packed in coils. The entire range of pipe diameters is available in the warehouses of ELITE:

The advantage of annealed copper pipe is that it does not form carbon deposits when soldered, which prevents a decrease in the rate of passage of the refrigerant. This reduces the risk of compressor failure.

Contact Elita managers to buy annealed copper pipes for air conditioning.

Unannealed copper pipes

Elita supplies Unannealed copper tubes in whips, which are in inches (¼ to 4 1/8) in accordance with EN 12735-1 (ASTMB280), and metric tubes (diameters from 10mm to 108mm) in whips, EN1057.

Unannealed copper pipes are supplied in sections (whips) - 5m. Unannealed copper pipes are subjected to 25 cleaning of the inner surface, at the ends of the pipes they have plugs that prevent dust from entering. Each whip is marked. Elite company individually packs each order in its warehouses.

Buying copper products in Elite, you get the following benefits:

- Warehouse program - all tube diameters are always in stock;

- Warehouses throughout Russia provide you with the speed of delivery of copper pipes to the facility;

- Qualification of employees - insurance against errors in the selection of copper products.

Their advantages and disadvantages

The main misconceptions by which buyers refuse to purchase them include:

- comparative high cost of materials;

- installation complexity (requires soldering joints).

However, these pipes have a number of advantages:

- high quality material;

- has a high coefficient of thermal conductivity (it applies specifically to non-insulated samples);

- ease of expansion;

- does not corrode and does not react to temperature changes;

- good for soldering;

- withstands high pressure;

- are reliable with their plasticity.

- when buying non-insulated pipes, it can be noted that their price is lower than plastic or steel samples of the same diameter;

- welding for the connection is not expensive;

- it is possible to make wiring of any kind due to the wide variety of copper fittings;

- heating can last more than 50 years without repair;

- plastic material at high pressures can be deformed without rupture;

- can work effectively at temperatures up to + 250°C.

Therefore, it is quite justified that the price of copper products is correspondingly high. In addition to the pricing policy, consumers avoid using such pipes and fittings because they are worried about the complexity and correctness of their installation (soldering).