- Finding a place for a water source

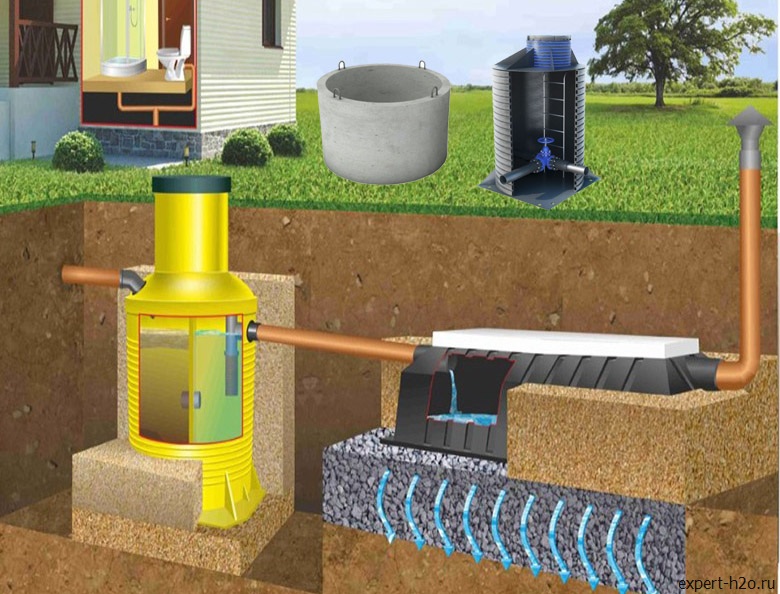

- The design and purpose of the cesspool

- Material selection

- Sizes of septic tanks and their number

- How to determine the volume of a septic tank

- Number of columns

- Material for the manufacture of pipes

- How to build a drainage tank?

- Well construction step by step

- Features of the installation of plastic wells

- Main types

Finding a place for a water source

When building a well, it is important to correctly determine the depth of the horizon of clean drinking water, calculate and purchase the required number of concrete rings, equipment for arranging the hydraulic structure itself and the water distribution system. It is also important to choose the right place and time to dig a well.

Choosing the right place for a well depends on several factors:

- Exploration data. There are many ways to search for water on the site, but nothing more reliable than geological studies of the area has yet been invented.

- Information about nearby sources. It will not be superfluous to ask the nearest neighbors how deep their wells are built, what is the quality of the water.

- Suitability of water for drinking. Be sure to take a water sample for chemical and microbiological analysis at the nearest sanitation station.Specialists will determine the concentration of chemicals and the presence of pathogenic bacteria.

- Soil type. The difficulty of digging wells, the need to use special equipment, etc. depends on this. Ultimately, all this affects the cost of the finished well. The hardest thing is to build a well on rocky soils.

- Terrain relief. The greatest difficulties arise when building a well on a hillside. The ideal option is a flat area.

- Distance from pollution sources. Wells are dug at a considerable distance from cesspools, septic tanks, compost heaps, barns. It is undesirable to place them in a lowland, where rain, melt water flows, as well as water with impurities of agricultural fertilizers.

- Degree of distance from home. The closer the source of water to the house, the more convenient.

We invite you to familiarize yourself: Do-it-yourself bituminous tile roof

At the same time, the development should be located so that it does not interfere with the passage, does not block access to outbuildings, utility rooms.

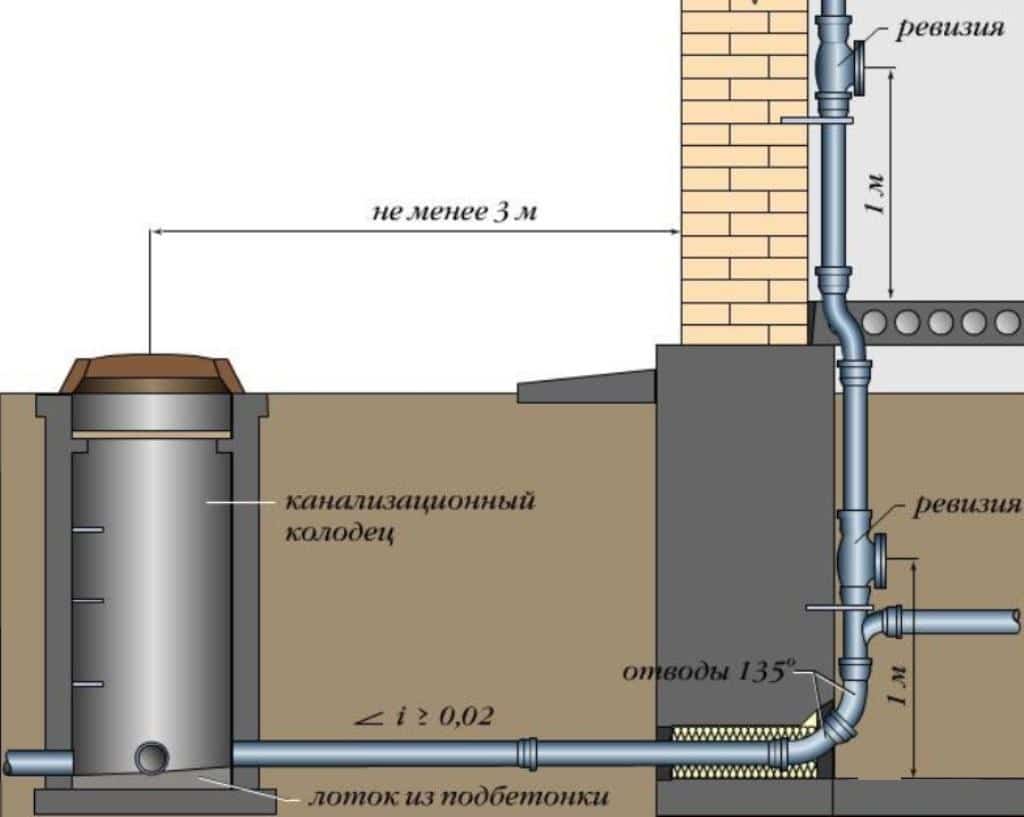

During the construction of water supply and sewerage, one should be guided by SNiP 2.04.03-85. This is necessary to prevent contamination of drinking water sources, washing away the foundations of buildings, disruption of systems

The design and purpose of the cesspool

Cesspools, like septic tanks, serve to collect sewage. But these are primitive structures that are not able to purify the liquid.

In storage tanks, waste only partially decomposes, unlike VOC, where effluents are divided into solid waste and liquid, which is further clarified and reaches a purity of 60-98%.

Image gallery

Photo from

A cesspool is the simplest variant of a storage sewerage point, which has recently been most often constructed from concrete or reinforced concrete rings.

The volume of the cesspool sewer well is calculated based on the number of people living in the house. A wide range of rings allows you to choose them for a storage device of any size

Concrete sewer wells, designed to perform the functions of a cesspool, are built by sequentially installing rings on top of each other

Rings for the construction of a sewer cesspool can be installed using construction equipment or manually

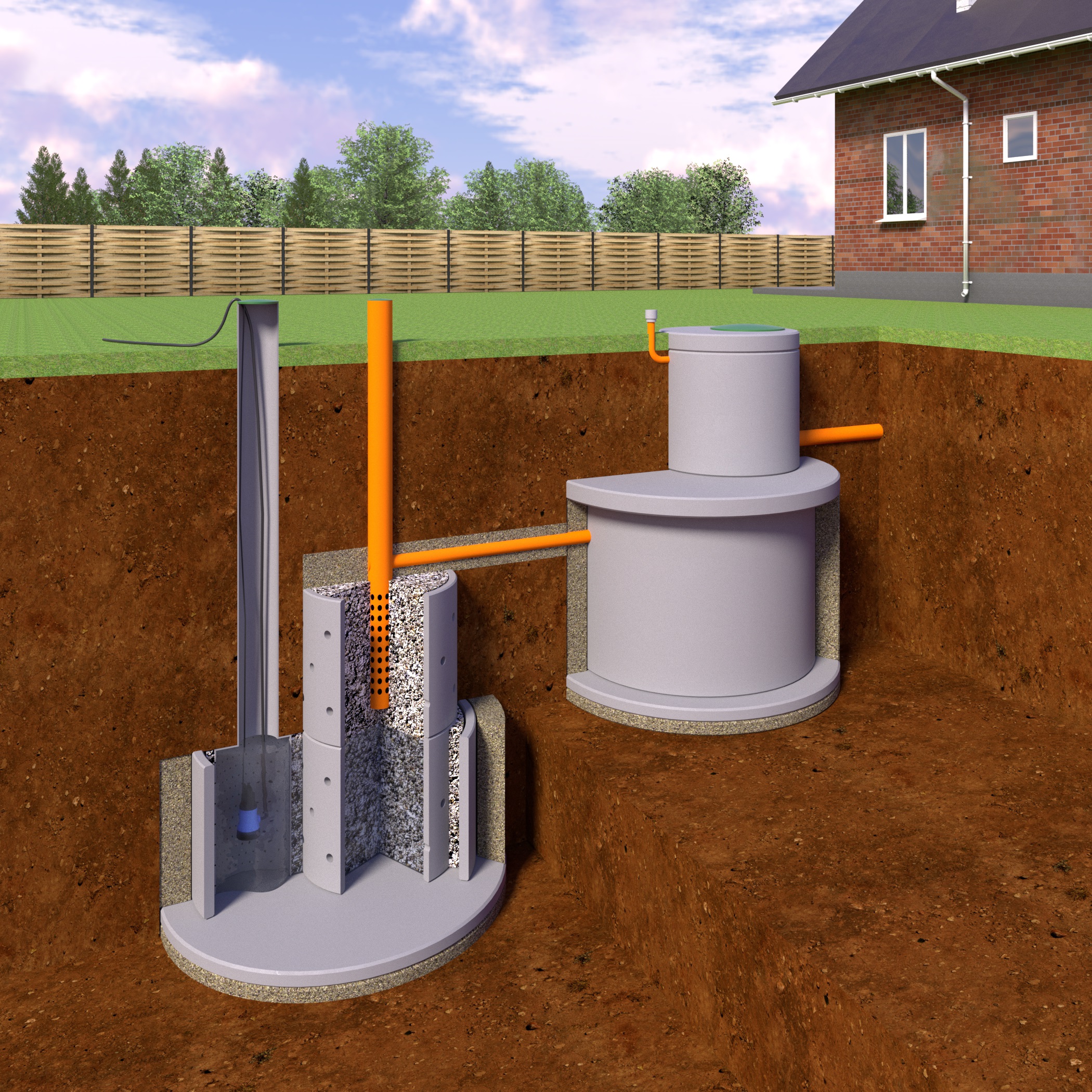

The modernized version of the cesspool involves connecting a well with a filtering bottom to it. In such a system, settled wastewater is disposed of into the ground, so that vacuum trucks are much less likely to be called.

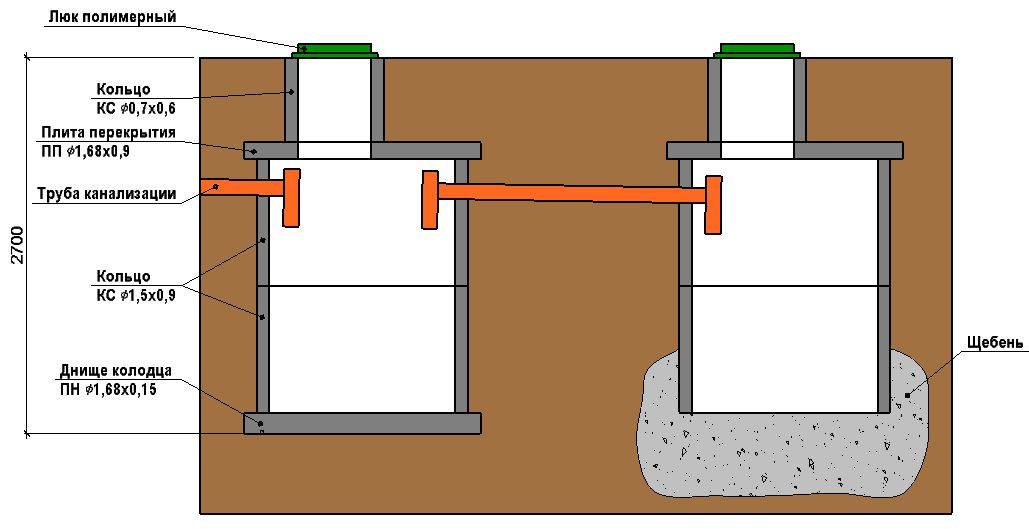

With an increase in the components of an independent sewer system, the degree of wastewater treatment increases. In such structures, the first two chambers with a sealed bottom, the third - with a filter

No matter how many separate wells the sewer system includes, each of them is supplied with its own manhole for maintenance.

Cesspools made of concrete rings are filled up to the very hatch. Only by its presence it is possible to externally determine the presence of sewer wells on the site

Cesspool of concrete rings

Sewer facility for a large family

Modular construction principle

The use of small-scale mechanization

Organization of a cesspool with overflow

Three-dimensional sewer facility

Installation of a hatch over a sewer well

Sewer wells in the suburban area

All types of cesspools can be divided into two categories:

- sealed storage containers;

- drain pits with filter bottom.

For users, 2 differences are important - the device of the bottom of the tank and the frequency of waste removal. The first type retains the entire volume of sewage, so it is emptied quite often, once every 1-2 weeks.

For the second type of pits, vacuum trucks are called less often, since the tank fills up a little more slowly. Part of the liquid seeps through a kind of filter that replaces the bottom, and enters the ground.

Scheme of the simplest cesspool. Usually it is designed in such a way that the volume of the tank is sufficient, and the drain masses do not rise above the sewer pipe.

At first glance, the second option is more acceptable, but it is only suitable for processing gray wastewater, and a number of factors must be taken into account when constructing it:

- compliance with sanitary standards;

- soil type;

- presence and location of aquifers.

If the soil in the selected area is clayey, unable to quickly absorb water, there is no point in making a filter bottom. The same with aquifers - there is a risk of contamination and violation of the ecological situation.

There are many solutions for organizing cesspools: they build structures from bricks, tires, concrete. Concrete structures and ready-made plastic containers are considered the most reliable.

Concrete tanks, created by erecting formwork and pouring, are more difficult to build than analogues from ready-made rings, which we will dwell on in more detail.

Scheme of a drain pit with a filter bottom.The air intake is removed as high as possible so that the unpleasant smell characteristic of sewer storage tanks does not disturb comfortable living

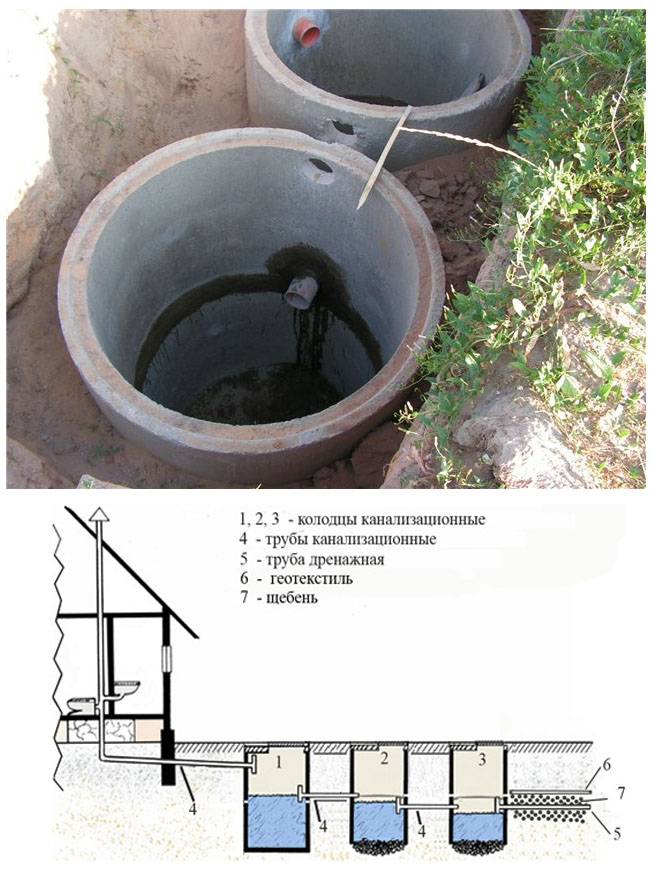

A cesspool made of cylindrical concrete blanks in finished form is a well from 2 m to 4 m deep. Rings in the amount of 2-4 pieces are placed one on top of the other, sealing the seams.

The lower element, depending on the type of pit, may be closed or completely absent. Sometimes, instead of a finished factory blank, a concrete slab is placed on the bottom.

The upper part is made in the form of a neck with a technical hatch and a tightly closed lid.

The main storage part of the tank is buried by about 1 m, since the inlet sewer pipe must be below the freezing level of the soil. The volume of the container is selected, taking into account the number of daily drains.

Material selection

Build a sewer well

hands can be from different materials. Most often choose one of the two

options:

- concrete rings. These are the finished parts

it is only necessary to install in a prepared nest and seal. However, for mounting

heavy parts will need lifting equipment. In addition, these elements

quite expensive; - brick or natural stone. It's comfortable

option that does not require the use of lifting equipment. To work with piece

materials need skills, experience.

Despite some difficulties,

most tanks are made of concrete rings. So there are several

reasons:

- standard size;

- the presence of a bottom and a lid, which greatly simplifies

mounting; - high build speed of the tank.

The only problem that

may occur when using rings - delivery and unloading. If they

drop, the walls will crack or break, the parts will be damaged. Wherein,

parts of the rings can be connected, fastened with cement mortar. For installation in

socket, you can use a conventional chain hoist suspended on a homemade

tripod. well under

sewerage in a private house, made of concrete rings, serves

long and fairly easy to repair.

Bricklaying requires effort and

time. We will have to organize the supply of material and solution into the recess, which

quite dangerous - there is a man below. If the depth of the container is small,

there will be no significant problems, but when building large tanks, it is necessary

strictly follow the safety rules.

It is especially difficult to work with natural stone. People living in regions with large reserves of this material can use it for any work. However, to fasten individual blocks, a special solution is needed, the composition of which is not known to everyone. In addition, you need experience in laying irregularly shaped elements. However, if a natural stone tank is made correctly, it can last 100 years or more.

Sizes of septic tanks and their number

In order for the drains to be effectively cleaned, they must be in the septic tank for at least 3 days. Based on this, the dimensions of the chambers are determined.

Ring septic device

How to determine the volume of a septic tank

According to the standard, the minimum volume of a septic tank chamber is three times the daily water consumption. 200-250 liters are considered per person. In total, if you have 4 people in your family, the minimum volume is 3 cubes.This is how much the storage tanks, that is, the first two chambers, should contain. The third one, the filter column, does not in any way belong to the accumulative column, therefore it is not taken into account.

It was about the regulations that are in force in Russia. In Europe, the minimum volume of a septic tank is 6 cubic meters. And many believe that such sizes are more “correct”. Effluent in large volumes stays in storage tanks longer, which means they are cleaned better. When using the native standard, in the event of the arrival of guests, it is easy to “pour” the norm. As a result, untreated effluents will end up in the filtration column, which will pollute it and the entire surrounding area. Elimination of consequences is an expensive and complicated procedure.

Even if you decide to adhere to Russian standards, if you have a bathroom, a washing machine and a dishwasher, you need to increase the volume at least by the size of the salvo discharge of all these devices (bathroom - 300 liters, washing machine and dishwasher 50 and 20 liters, all together - we will consider 400 liters or 0.4 cubic meters).

In accordance with the calculated volume, the sizes of the rings and their number are selected. The diameter of a concrete ring can be from 80 to 200 cm, sometimes there are rings with a diameter of 250 cm. Height - from 50 cm to 1 m. The table below shows the dimensions of standard reinforced concrete rings, their marking, weight and volume. In the "dimensions" column, the outer diameter, inner diameter, height are indicated through a fraction. All measurements are in millimeters.

Dimensions of standard concrete rings and their volume

When calculating, keep in mind that the actual volume of the column must be higher than the calculated one - the drains never completely fill, but rise only to the level of the installed overflow pipes.It is up to the level of these pipes that the calculated amount of drains should be placed.

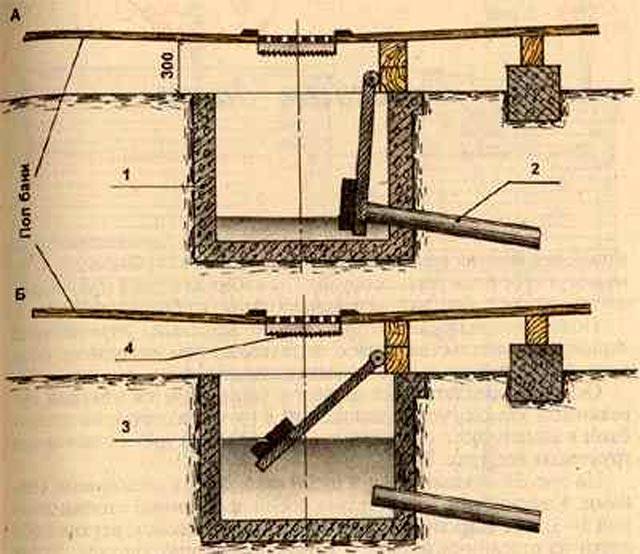

Number of columns

There can be three storage chambers in a septic tank (except for the filter column). Sometimes such a device is more practical - if it is required, for example, to install six or more rings in each of the columns. The depth of the pit in this situation is large. It is more convenient / more profitable to make three columns of four rings.

A single-chamber septic tank made of concrete rings is suitable for a small amount of wastewater

There may be a reverse option - a small volume of a septic tank is required. This happens at the dachas of periodic visits with a small number of summer residents serving it. In this case, the column can be assembled alone, dividing the rings inside with a sealed partition. and making an overflow hole at the required level.

Material for the manufacture of pipes

The correct entry into the well depends on the material that was used to make the pipes. Great demand was noted for ceramic, cast iron, asbestos-cement and plastic pipe products.

The ceramic node of the sewerage passage through the wall of the well has a long service life, is resistant to external negative factors. No special knowledge is required to perform installation work. However, ceramic pipes do not withstand mechanical stress well.

Cast iron pipes are used less often, although they have high strength and excellent corrosion resistance. Low demand is due to the large weight and rough inner surface.

Plastic is lightweight, resistant to aggressive environments, and inexpensive. The process of inserting into a sewer well is quite simple.

How to build a drainage tank?

Ready-made drainage structures for the construction of a well are distinguished by ease of installation, reliability and good quality. The main disadvantage of finished wells is their high cost, in particular, this applies to products with a diameter of 800-1000 mm. To save money, you can build such a structure yourself.

For the manufacture of a drainage structure, it is required to acquire corrugated pipes of the appropriate diameter:

- for the construction of manholes, a pipe diameter of 340 mm or 460 mm is suitable, this is enough to ensure manual cleaning of the sewer system by means of water pressure from a hose;

- to make a storage or filter tank, you will need pipes with a diameter of 575 or 695 mm;

- if there is a need to periodically penetrate inside the well for repair and maintenance work, then you need to buy pipes with a diameter of 925 mm.

In addition to plastic corrugated pipes, you also need to buy rubber seals of a suitable diameter, a hatch and plastic for the bottom device.

During the assembly and installation of the storage facility, a certain sequence should be observed:

- holes are cut in the well for connecting pipes and installing rubber seals;

- the bottom of the well is mounted. Experts recommend treating the bottom of the structure with bituminous mastic, so the bottom of the well will be protected from leaks;

- using crushed stone and sand, you need to make a base in a drainage ditch, after which it is poured with cement;

- a finished structure is installed on the prepared bottom.To prevent the risk of leakage of the structure, it is recommended to coat the places where the drainage pipes are connected with bituminous mastic;

- the tank is filled with crushed stone and sand, after which the tamping and laying of the base for the hatch device is carried out. The hatch is placed in a pre-prepared cement frame.

Well construction step by step

When all the materials have already been purchased and prepared, you can proceed with the installation work:

- First, the pipe must be cut to length, while taking into account the depth of the drainage well.

- It is necessary to cut holes for connecting pipes, retreating 50 cm from the bottom edge of the pipe. Rubber cuffs are inserted into these holes.

- The bottom of the well is fixed, while the docking site must be treated with a bitumen-based sealant.

- To install the well, you need to prepare a pit in advance, at the bottom of which cement mortar is poured.

- The structure can only be installed after the cement has completely hardened, after which drainage pipes are connected to it.

- The space formed between the walls of the pit and the structure must be covered with sand and gravel.

- A hatch is placed on top of the installed tank.

Features of the installation of plastic wells

As a rule, ready-made plastic structures are not cheap, so you won’t be able to save much. The only thing you can do is to buy individual elements of the required size and diameter yourself. So, you need to prepare:

- corrugated pipe of the appropriate diameter;

- plastic for bottom device;

- rubber seals. For the installation of a storage or filtration well, a pipe with a diameter of 695 or 575 mm is required.

During installation drainage well hands, it is important to adhere to a certain algorithm:

- the corrugated pipe must be cut, taking into account the depth of the well. Next, it is required to make holes in it for connecting perforated pipes, which are connected using rubber seals;

- a ditch is dug, on the bottom of which a layer of gravel with sand is laid. After that, the structure is poured with cement mortar and covered with geotextile material;

- at the next stage, the bottom is installed, which is connected to the pipe, while the docking place must be treated with bituminous mastic;

- now it is possible to bring drainage pipes to the structure, and the joints should also be coated with a sealing compound;

- it is imperative to install a pump that will ensure the pumping of the collected water;

- the voids formed around the well must be covered with fine-grained gravel;

- at the last stage of work, the roof is mounted.

Main types

There are several types of sewer filtering structures that operate on a similar principle, but differ in scope.

- The drainage type of the well is used as an addition to a complex drain system - an underground perforated pipeline. The well serves to drain water from buildings and land, and also filters silt and sand, allowing the water to be purified for draining, for example, into a reservoir.

- To clean the septic tank, an additional filtration well is used, which has a thick filtration cushion (at least 60 cm, preferably 1 meter) from several layers: sand, crushed stone, broken brick, waste slag.

- For open sewers. Such wells are also called viewing wells. The owners get the opportunity to visually control the degree of filling of the well.The filter material is located at the bottom. In the case of a rapid filling of the well, its contents can be pumped out with a pump.