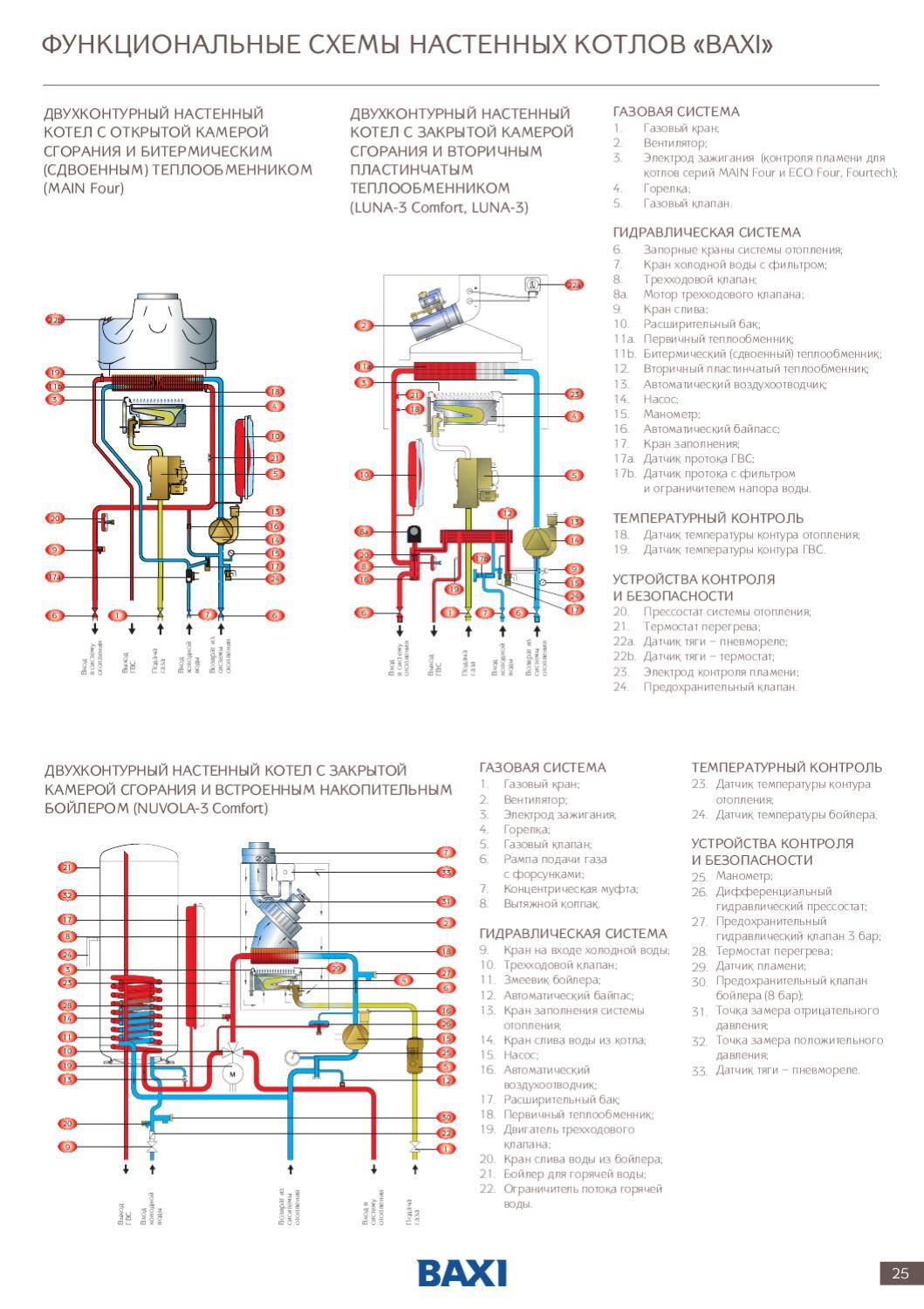

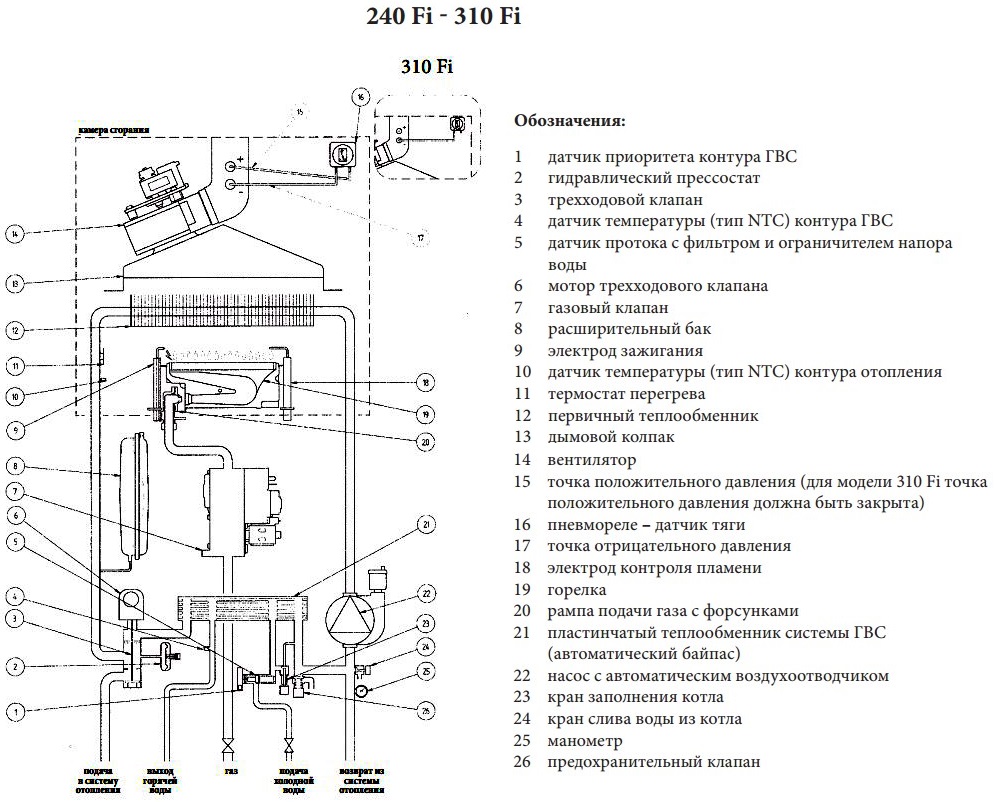

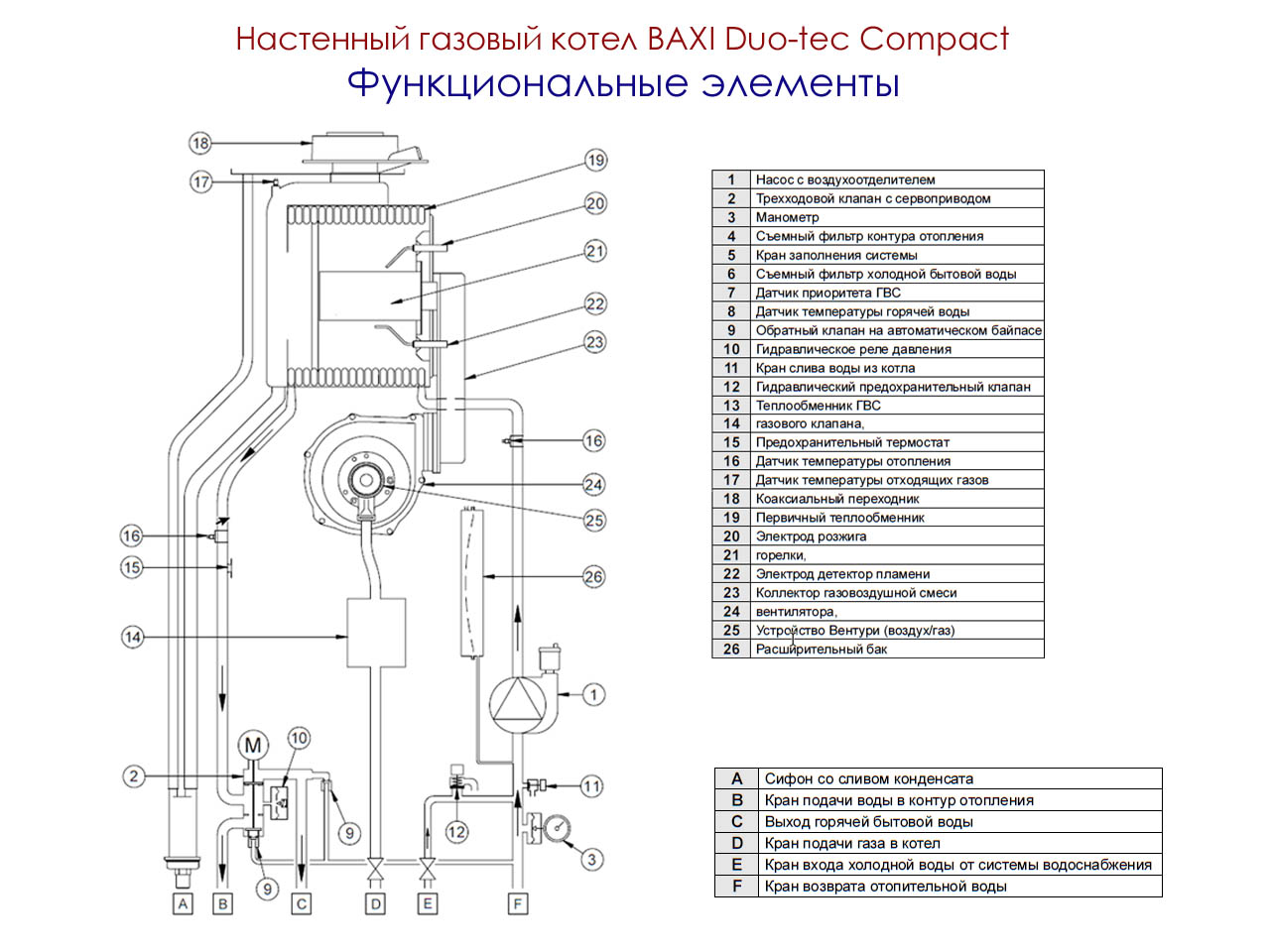

- Device and main elements

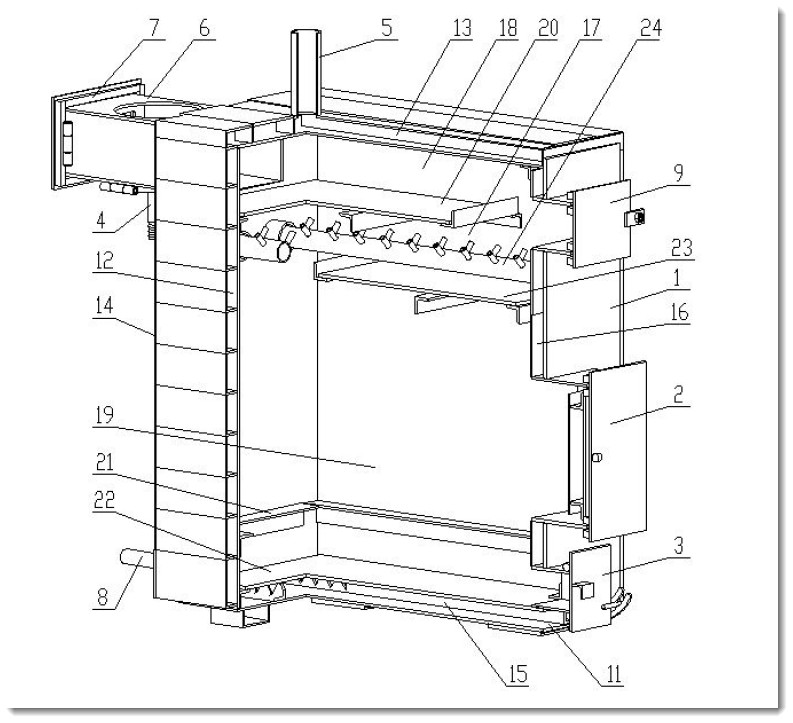

- Gas burner device

- heat exchanger

- Automation system

- Operating principle

- Principle of operation

- Installation location

- Malfunctions and error codes of the Baxi gas boiler

- Advantages of Baxi boilers and equipment

- Main nodes and principle of operation

- Power Requirements

- Pressure setting

- Recommendations for reducing operating costs

- Boiler self-cleaning

- Kinds

- Conclusion

- Menu for displaying information about the operation of the Baxi boiler on the display

- BAXI Main Four |Baxi Eco Four | BAXI Four Tech:

- BAXI Main 5:

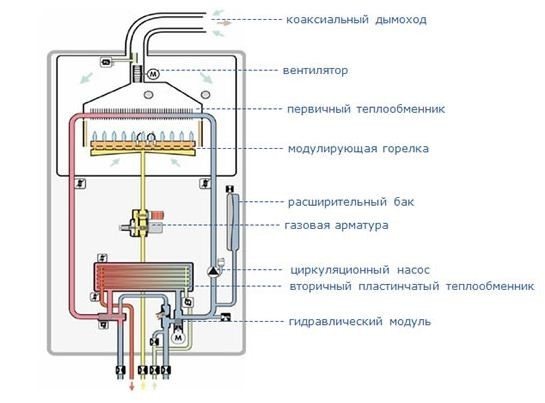

Device and main elements

In terms of their design, TM Baksi units are not much different from other gas boilers. They consist of several components.

Gas burner device

This node contains several elements:

- Gas burner: the most affordable models are equipped with a burner with a constant output, the more expensive - with step regulation. To maintain a constant temperature in the room, the automation system has to periodically extinguish such burners, and then ignite them again. In the most expensive Baksi boilers, modulating burners are installed, the power of which is smoothly regulated. Such burners operate constantly and in the most optimal mode, so the set temperature is maintained with high accuracy.

- Combined gas valve: allows or blocks the gas supply to the burner, depending on the signals from the automation devices.

- Ignition unit: consists of an electronic circuit and an electrode. This unit converts the mains voltage supplied to it into high-frequency high-voltage pulses that are applied to the electrode. As a result, a spark flares up between the electrode and the burner (in some models, between two electrodes), igniting the gas-air mixture on the burner.

The combustion chamber of TM Baksi boilers is closed, that is, air is taken into it from the street. The only exception is the Luna-3 Comfort 240i, which has an open chamber.

The branch pipe for connecting the gas supply line is located in the middle between the branch pipes for connecting the heating system.

heat exchanger

The latter are more efficient due to their high thermal conductivity.

The successful design of the heat exchanger allows you to assimilate 90.8% of the heat generated in the combustion chamber (for some models, the efficiency is slightly less - 88.7%).

In addition to the main heat exchanger, the Baksi heater may contain another one designed for preparing hot water. Such boilers are called double-circuit. Some models, for example, Baksi Ecofor 24, can heat water in an external boiler.

A mesh filter is installed at the inlet to the heat exchanger.

Automation system

All units of this brand use volatile automation. The total power consumption of the boiler, depending on the model, is 135 or 165 watts. For most models, for example, Luna-3, Eco-3, Slim, Nuvola, the automation is weather-dependent.

This means that in addition to the timer and room thermostat, you can connect an outdoor temperature sensor to it.Accounting for weather conditions allows the system to timely switch the boiler to the optimal mode, which makes the heating system more economical.

The wall-mounted model Luna-3 Comfort (3rd generation boiler) uses a temperature sensor instead of a room thermostat.

The insides of the Luna boiler

Analyzing the information coming from it and from the outdoor temperature sensor, this boiler itself calculates the dependence of the coolant temperature on the air temperature outside. This property is called self-adaptation.

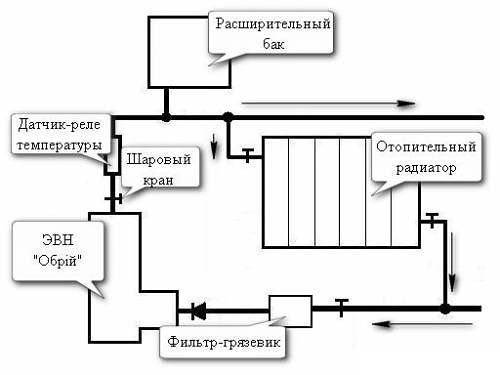

Operating principle

The operation of the boiler is to heat the coolant entering the primary heat exchanger using a circulation pump. At the outlet, the hot RH passes through a three-way valve, where it is mixed in a predetermined proportion with a colder return flow, as a result of which the coolant temperature acquires the desired value and is sent to the heating system.

Hot water is heated in an indirect secondary heat exchanger. The source of heat for it is hot RH, which has not yet entered the three-way valve.

The operation of all nodes is constantly monitored by a system of sensors that transmit a signal to the control board.

When changing the nominal mode, the display shows an error code related to a specific unit or part of the boiler.

Principle of operation

A control board is installed inside the boiler, which controls all the actions of the units of the unit. It has special contacts, which are connected by default with a special jumper. They are used to connect the thermostat.

While the jumper is in place, the operation of the system is subject to its own logic - the temperature of the coolant is set, the boiler heats up the RH to the set parameters and turns off when they are reached until the water cools down to the lower limit.

When connecting the thermostat, the jumper is removed. The device is included in the gap, so all control of the boiler is transferred to it. The process of work becomes more even, frequent starts and stops of heating stop. The air temperature changes more smoothly.

This method of control gives a more successful effect, allowing you to reduce gas consumption and save a lot on heating.

There are many design options for room thermostats. For Baxi boilers, it is possible to use any of them, which is very convenient for users.

All types of thermostats can be divided according to individual features:

Installation location

At the place of installation, all thermostats can be divided into indoor and outdoor (outdoor). The former are mounted indoors, the latter are placed outside and monitor the state of external weather and temperature conditions.

Most owners prefer to control the indoor conditions of the premises, as they have a greater influence on the microclimate of the home. Outdoor devices are suitable for residents of the southern regions, where the thermal insulation of the walls is not so effective.

Malfunctions and error codes of the Baxi gas boiler

The microprocessor control and monitoring system of a modern gas boiler detects a malfunction and displays an error code indicating a particular malfunction in the operation of the boiler units and assemblies.

Error code on the display of the BAXI gas boiler. The backlight of the display flashes synchronously with the displayed fault code.

Error code on the display of the BAXI gas boiler. The backlight of the display flashes synchronously with the displayed fault code.

The boiler control system reacts differently to the occurrence of a malfunction. Depending on the possible consequences of the malfunction:

-

- The operation of the boiler is immediately blocked in an emergency. The boiler is turned off.Error codes: E01, E02, E04, E07, E25, E27, E40, E41, E42, E43, E50, E62, E65. It is required to eliminate the malfunction and restart the boiler using the "R" button (keep pressed for at least 2 seconds).

- The operation of the boiler stops abnormally, but is not blocked. After the problem is eliminated, the boiler will automatically continue to work with the previous user settings.

- There are errors - warnings that do not require immediate attention, in which the operation of the boiler does not stop.

Advantages of Baxi boilers and equipment

The BAXI brand is owned by BDR Thermea, a major European manufacturer of domestic and industrial heat and power equipment.

The units are equipped with auxiliary devices of the brand of the same name: a circulation pump for modifications with forced movement of the coolant, a blower fan in closed-type furnaces and a safety group.

They provide the output of the unit to the factory operating parameters and have advantages in layout, compared with devices that are assembled with a complete set from different manufacturers.

The main advantages of BAXI boilers:

- high thermal efficiency, efficiency up to 92%;

- wide power range from 14 to 80 kW;

- environmental Safety;

- refers to energy efficient equipment;

- ample opportunities for setting thermal conditions and automatic maintenance of the specified operating parameters.

The latest modifications are available with a powerful self-diagnosis system, frost protection and antibacterial protection.

Integrated weather-dependent automation ensures sanitary living conditions in the house, while guaranteeing the low cost of generated thermal energy for heating and hot water needs.

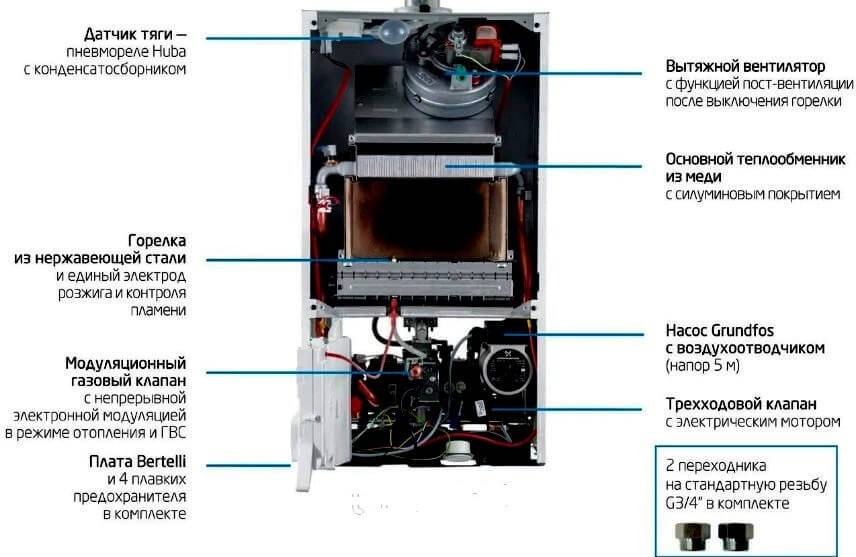

Main nodes and principle of operation

The line of Baksi gas boilers includes a number of models that differ in volume, type of installation, and functionality. At the same time, the principle of their work is generally similar.

The most popular boiler models:

- Baxi Luna (Baksi Luna).

- Baxi Slim (Baxi Slim).

- Baxi Main four (Baxi Mine for).

- Baxi Main 24 fi (Baxi Main 24 fi.

- Baxi Nuvola (Baxi Nuvola).

- Baxi EKO four (Baxi Ecofor, Baksi Ecofor).

Gas boiler baxi luna-3 1.310 - price and where to buy

Baxi Luna (Baxi Luna)

According to the type of installation, gas boilers are divided into wall and floor.

The wall heater is fixed with the help of special brackets in any convenient place, which makes wall models very popular. Chambers with a closed combustion chamber, such as the Baxi Main 24 fi, have increased efficiency and environmental friendliness in a small size.

The volume of coolant in the heat exchanger depends on the model, in the most powerful it reaches 80 liters. In terms of functionality, models can be single-circuit - for heating, or double-circuit - in addition to the heating system, they also feed the DHW circuit.

They can work both on natural main gas and on liquefied gas from cylinders, which makes it possible to install them in non-gasified areas. The boilers are completely volatile and require connection to an alternating voltage network.

The principle of operation of gas heating equipment:

- The sensors analyze the temperature in the room, and when the minimum value is reached, they give a signal to turn on the circulation pump.

- The pump turns on, creating a vacuum in the return pipe, while the heated water enters the heating system.

- The microprocessor gives a signal to ignite the burner at low power, it gradually increases, and the coolant heats up to the temperature set by the user.

- Further, the boiler operates in modulation mode - it maintains the temperature within the specified limits, turning on when it decreases.

At any of these stages, a malfunction may occur, which the boiler notifies with the help of coded errors.

Possible malfunctions of the boiler Baxi Main for, Baxi Main 24 fi, Baxi Eco for:

- the burner goes out immediately after switching on or during heating (error codes e01, e04);

- ignition of the boiler is not possible;

- overheating occurs (error code e02);

- the water pressure in the system drops (error code e10);

- extraneous noise is heard in the work;

- pops occur in the combustion chamber;

- the coolant does not heat up to the set temperature;

- one of the sensors fails (various error codes may appear).

The most common causes of the appearance of certain malfunctions, according to service center specialists, can be:

- improper installation of the heating system;

- errors when connecting the boiler to the mains;

- water ingress onto the board, into the burner or into the electrical part of the boiler;

- low quality of network water or other heat carrier;

- a sharp drop in gas pressure;

- the voltage drops or increases unacceptably in the network.

The resulting malfunctions can be easily eliminated by adjusting the boiler, but sometimes it is necessary to call a specialist to replace parts of the boiler.

If you are not sure about your skills in setting up gas equipment, it is better to contact a service center. Incorrect repairs can lead to a complete failure of the boiler!

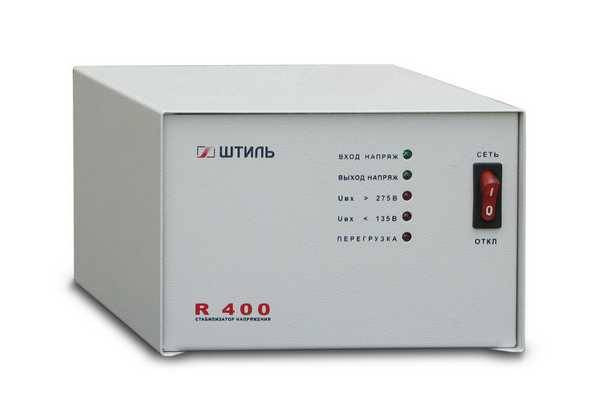

Power Requirements

Requires the installation of a voltage stabilizer - automation does not tolerate surges.In addition, for the normal operation of automation, a sinusoid close to the ideal is required, which is far from always present in our electrical networks. Therefore, instead of a stabilizer (or together with it), it is necessary to install an inverter, the output of which will be a stable frequency of 50 Hz (which our networks also cannot boast of) and a sinusoid close to ideal. The problem can also be solved by an uninterruptible on-line class. In this case, you will not only supply the required voltage, but also ensure the operation of the boiler for some not very long time during a power outage. To make volatility even less can connect batteries to the UPS.

For Baksi boilers, both the shape of the pulses and the stability of the characteristics are important.

But that's not all the power requirements. It is also necessary to provide for protection against impulse currents - SPDs are needed that will protect against sudden drops when powerful equipment is turned on in the neighborhood or during a thunderstorm. Although, as experience shows, during a thunderstorm the only thing that can save your boiler is a plug pulled out of the socket, and even then only with proper grounding - there have been cases when the potential “punched” the automation through a gas pipe. In order to prevent such a situation, all metal pipelines entering the house must have dielectric inserts.

Mains voltage stabilizer

Pressure setting

A fill valve is used to raise the pressure, and a bleed valve is used to release the pressure.

The optimal value is considered to be the range of 0.7-1 mbar. Usually, Baxi boilers maintain the desired value on their own, but sometimes failures occur.If there is a constant drop that does not disappear after the system is recharged, then somewhere there is an OM leak.

This could mean either leaking piping or radiators, underfloor heating systems or other external elements.

Often the problem occurs due to a malfunctioning drain valve. An abnormal increase in pressure may be due to a malfunction or an open make-up valve or damage to the expansion tank membrane.

Recommendations for reducing operating costs

If all operational settings are made in accordance with the tabular data given by the manufacturer, then the equipment will consume energy very economically, generating the necessary heat in the volume required by the owners.

For this you should:

For systems with radiators or thermosiphons, select the temperature of the coolant at the outlet of the boiler +60ºС. It is worth increasing it only if, during the operation of the unit, comfortable heat in the room was not received.

Regulate temperature conditions in accordance with the manufacturer's instructions and the purpose of the room. For heating bedrooms and other rarely visited rooms, the heating temperature can be selected below the average.

Do not exceed the temperature background recommended by the manufacturers of the heating devices included in the circuit.

Use a room and outdoor temperature sensor that detects an increase / decrease in temperature. The thermostat connected to them will independently start / stop the boiler as needed.

Set the temperature of the coolant by the hour using a timer. At night, for example, it can be lowered by 3-5 ºС.

It should be remembered that by increasing the temperature in the treated room by only 1º, we immediately increase costs by approximately 6%.

In order not to constantly change the temperature settings of the coolant in the autumn-spring difficult period, it is better to install an outdoor temperature sensor. If a suitable model does not come across or there is no money to buy the original, you can build such a home-made device:

From For the construction of an outdoor sensor that reads the outside temperature, you can buy a conventional NTC thermistor. In the example, B57861-S-65-18 is used for 10 kOhm 103 A40 with an error of 1%. The device is installed in a plastic case from headphones to protect against atmospheric phenomena and wrapped in foil to prevent heating by the sun. In order to bring the sensor outside, a hole must be drilled in the wall next to the boiler. The thermistor is connected to the boiler with a twisted pair cable. Using the graph presented by the Baxi corporation, you need to adjust the coolant temperature according to the graph that displays its optimal values for different thermometer readings. The sensor is fixed on the outside of the main wall. It is advisable for him to find a place not directly illuminated by the sun. From the side of the room, the hole drilled for the cable is slightly foamed or covered with a plastic plug. Step 1: Assembling a home-made outdoor sensor.

In case of a long absence, it is better to disconnect the boiler from the power supply, but at the same time, the frost protection system should not be turned off. It is turned off only for the summer period, during which the heating function is abandoned, completely turning off the single-circuit model and transferring the double-circuit version to the supply of hot water.

In order to save on heating, do not cover the radiators with screens and heavy curtains. They will disrupt the normal air circulation and force the boiler to work at full capacity for no apparent reason.

Also, the equipment manufacturer does not recommend micro-ventilation in the premises, keeping the transoms constantly ajar. It is better to open the window wide open and ventilate it with a “volley” than to artificially lower the readings of the room temperature sensor for a long time. It has been proven in practice that it is more economical.

When using the water preparation function, it is better to initially select a temperature that is comfortable for use, without counting on mixing hot and cold water in the mixer. Believe me, thanks to this solution, the thermal energy generated by the generator will not be wasted. In addition, limescale will not settle on the inner walls.

Boiler self-cleaning

It is necessary to drain the water, unscrew the tap on the right. If the situation allows, it is better to get rid of the water in the heating system. The Zhel device will help: it cleans the system. We connect the device to the Baxi pipes. We remove the cover of the device, fill in the cleaning liquid. Turn on the device Zhel. We work for several hours: we change the direction of the washing liquid. After two hours of cleaning, turn off the device, turn off the tap. When the liquid goes into the device, remove the hoses. We carry out connecting operations of the boiler and heating system. The described procedure will prolong the operation of the boiler, remove scale, and prevent blockages.

We clean the secondary heat exchanger

Again he resorts to the device for washing. We perform connection operations, turn on Jelly. We close the gas valve, open the valve that supplies hot water.Turn off the cleaning device. The fluid will travel along the short circuit of the system.

Before choosing a model and installing the boiler, it is better to listen to a specialist. Baksi boilers have many advantages, but, like all equipment, they are not eternal, the strength indicators of the devices are not ideal. We assessed the scale of breakdowns, described the main steps necessary for self-repair. We hope that you will not regret your purchase and your boiler will create a warm atmosphere for a long time. And if breakdowns occur, let them be minor and quickly eliminated. It is good when, with a minimum set of tools and in a short period, the trouble is eliminated and a warm atmosphere reigns in the house again.

If you think that you can install and connect a gas boiler yourself, you are mistaken. Even if you carefully study the instructions for the Baksi double-circuit wall-mounted gas boiler, purchase the necessary tools, then no one will give you permission to perform such work

It is important to know that the installation, and even more so the connection of gas equipment, should be carried out only by experienced craftsmen who are able to do everything in compliance with the requirements and rules.

Upon completion of all work, the master will without fail perform the first start of the Baxi gas boiler, which will allow you to check the quality of the work performed. If everything is in order, the equipment is put into operation. Despite the fact that the installation and connection of gas boilers is carried out by a specialist, you should know how to properly install wall and floor heating boilers, as well as carefully study the device of the Baxi gas boiler - this will allow you to properly operate the equipment in the future.

Kinds

The company produces equipment with various capabilities.

The assortment includes:

- Floor and wall views.

- Single and double circuit.

- Turbocharged and atmospheric (with a closed or open burner).

- Cast iron, copper and stainless steel heat exchangers with different capabilities and efficiency.

Such an abundance of options allows users to choose the optimal installation that meets the needs of a given room.

IMPORTANT!

Baksi boilers are initially manufactured with the expectation of working on natural gas, but at any time they can be reconfigured to liquefied gas, for which it is necessary to change the gas burner nozzles.

Conclusion

Double-circuit gas units Baxi Luna 3 are distinguished by reliability and high build quality.

Despite some complaints about the design and high cost, boilers of this series are deservedly popular and in high demand among users.

The presence of many useful functions and protection options allows you to ensure reliable and stable operation of the boiler.

Special preparation for work in Russian conditions makes it possible to maintain quality even in the event of pressure interruptions or other deviations from the nominal values.

Stability and resistance to external loads make it possible to provide a high-quality microclimate, coziness and comfort in the house.

Menu for displaying information about the operation of the Baxi boiler on the display

On the display of the Baxi boiler, in the information menu, the designation of the first line A00 is alternately replaced by the value of the parameter of this line - 35 ºС.

To display the menu of information about the operation of the boiler on the display located on the front panel of the boiler, press the "i" button for at least 6 seconds.

The "INFO" function is activated and the first line of the information menu "A00" appears on the display, which is replaced by the display of the parameter - temperature.

To move through the lines of the information menu, press the buttons (crane +/-).

BAXI Main Four |Baxi Eco Four | BAXI Four Tech:

Line A00: actual value (ºС) of domestic hot water temperature (DHW system);

Line A01: value (ºС) of the outdoor temperature (with a connected outdoor temperature sensor);

Line A02: Instantaneous value (%) of the gas valve control signal;

Line A03: value (%) of power (MAX R);

Line A04: set value (ºС) of the temperature at the supply to the heating system;

Line A05: current value (ºС) of the water temperature at the supply to the heating system;

Line A06: set value (ºС) for domestic hot water temperature;

Line A07: Flame level % value (0 - 100%);

Line A08: current value (l/min x 10) of domestic hot water consumption;

Line A09: the last error detected in the operation of the boiler.

BAXI Main 5:

A00: current value of the heating water supply temperature (°C);

A01: current domestic hot water temperature (°C);

A02: current value of the outside temperature, in °C (with connected outside temperature sensor);

A03: flue gas temperature current value (°C);

A04: instantaneous value of gas valve control signal (%);

A05: power indicator, in % (MAX CH);

A06: heating water temperature set point (°C);

A07: domestic hot water temperature setpoint (°C);

A08: last boiler malfunction;

A09: not used; A10: not used.

The “INFO” function remains active for 3 minutes.To exit this mode before this time, press the “i” button for at least 5 seconds or turn off the power supply to the boiler.