- Construction stages

- Video description

- How to choose the best place for a septic tank

- Pit preparation

- Installation of rings and sewer pipes

- Sealing and waterproofing

- Manhole installation and backfill

- How does the septic tank start up

- What rules must be observed when maintaining a septic tank

- Requirements for septic tanks for summer cottages

- How to make a device with your own hands

- Stages and features of installation work

- Pit arrangement

- Mounting

- Supply of sewer pipes

- Ventilation system device

- Sealing joints between rings and pipes

- Installation of floors and backfill

- Do-it-yourself concrete septic tank

- Design

- Excavation

- formwork

- Pouring solution

- overlap

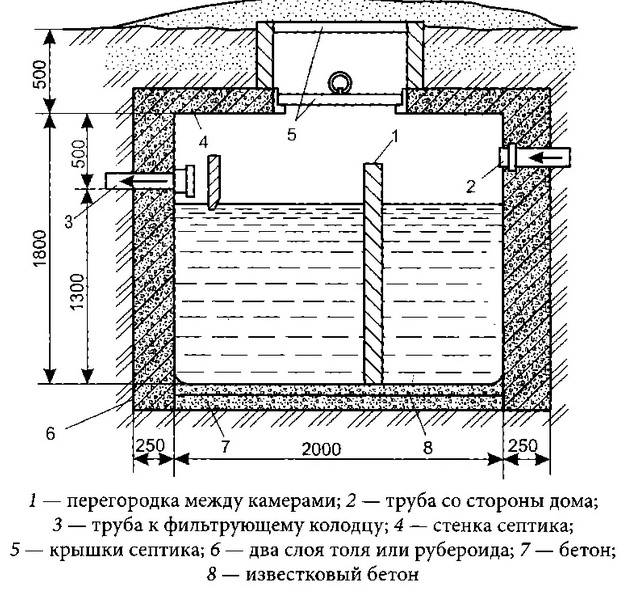

- The device of a simple septic tank

- Installation ↑

- digging a hole

- Formwork erection

- Concrete works

- Overlapping a septic tank

- Installation Tips

- The device of a single-chamber septic tank

- Consider the device of a reinforced concrete septic tank

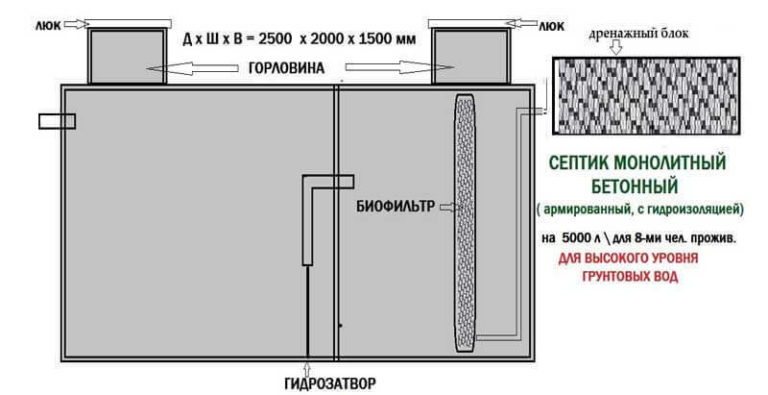

- The device of monolithic septic tanks

- Creating a concrete septic tank with your own hands

Construction stages

Installation is carried out in the following order:

- A place is selected, an installation scheme is built, and the parameters of the septic tank are calculated.

- A hole is being dug.

- Rings are installed, pipes are connected.

- Sealing and waterproofing works are underway.

- Covers are installed.

- Backfilling is underway.

Video description

The order of work and the installation of a septic tank from concrete rings on the video:

How to choose the best place for a septic tank

The structure is mounted above the groundwater level. The best location is at the maximum distance from the house (at least 7 meters, but not more than 20, so as not to increase the cost of pipeline construction). It is logical to have a septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving the tanker-vacuum truck is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage truck does not need to drive into the yard, and the hoses will not roll on the beds or paths (otherwise, when the hose is rolled up, the waste can get into the garden).

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of rings and their waterproofing. The bottom is covered with rubble and concreted.

Preparing a pit for a septic tank from concrete rings

Installation of rings and sewer pipes

Rings for a septic tank are installed using lifting equipment, which saves a lot of time (when compared with manual installation). Fixation of the seams is provided with cement mortar, metal ties (brackets, plates) are additionally placed.

The crucial moment is the process of installing rings

Sealing and waterproofing

Sealing the seams of the septic tank from concrete rings is carried out on both sides of the structure. For this, cement and coating protective solutions are used. Inside the well, you can install ready-made plastic cylinders. Such additional costs will make the system 100% hermetic.

In the process of waterproofing concrete rings for a septic tank, the joints are treated with liquid glass, mastic based on bitumen or polymer, concrete mix. To prevent freezing (and destruction) of the structure in winter, it is recommended to insulate it with a layer of polystyrene foam.

Sealing joints and waterproofing a septic tank from concrete rings

Manhole installation and backfill

The wells are covered with concrete slabs, with holes for manholes. In the first two wells, ventilation is necessary to remove methane (gas appears as a result of the vital activity of anaerobic bacteria). To backfill the installed floors, use the soil taken out of the pit (backfill).

Backfilling of finished wells

How does the septic tank start up

In order for the system to begin to function effectively, the erected septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- A new septic tank is filled with wastewater and defended for 10-14 days. Then it is loaded with sludge from an operating anaerobic septic tank (2 buckets per cubic meter).

- You can buy ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes that are intended for other treatment systems).

Ready to run septic tank from the rings

What rules must be observed when maintaining a septic tank

There are simple rules that support the quality of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (and preferably in 2-3 years), bottom heavy fats are cleaned.The volume of sludge must not exceed 25% of the volume of the tank. During cleaning, part of the sludge is left to restore the microflora.

- Quality of work. Effluent at the outlet of the system must be cleaned by 70%. Analysis of wastewater in the laboratory will determine the acidity index, which will allow you to know the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after enhanced ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (wet environment).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

Requirements for septic tanks for summer cottages

All country septic tanks must meet certain requirements:

- The design of the septic tank is calculated taking into account the principle of multi-stage cleaning in two or three chambers in series. The first capacity of the septic tank for giving is used to accumulate the separation of waste into fractions. Solid waste sinks to the bottom, while liquid and light fractions sink to the top. This water enters the second chamber, where it is further purified from organic matter. In the filter well, water is additionally purified and then discharged into the soil.

- All chambers, except for the one where the drains are brought out, are as tight as possible.

How to make a device with your own hands

In addition to the above tips, there are many more recommendations that are especially important to consider during construction, since only this will help to do the installation correctly, efficiently and without violating technology.When installing rings, you must follow the safety rules

When installing rings, you must follow the safety rules

Namely:

Pouring is carried out using concrete of exactly such grades as B15 and higher. For mixing, you need to follow the proportion for 1 m3: crushed stone - 1200 kg, sand - 600 kg, cement - 400 kg, water - 200 l, superplasticizer C3 - 5 l.

Before concreting the bottom, a sand cushion is laid at the very bottom of the pit. The sand is laid in a layer of 20 cm. Next, you need to make reinforcement, for which a special mesh is used. The mesh is taken the one for the manufacture of which reinforcement with a rod diameter of 10 mm was used. The optimal cell size is 20x20 cm.

Concrete is laid above the surface of the reinforcement by at least 3 cm, and it is possible to proceed with the subsequent arrangement of the walls only after 2 weeks, so that the base is frozen as firmly as possible.

The walls should be no more than 20 cm thick, and the thickness of the partition between the chambers should be 15 cm.

When equipping a rectangular septic tank, it is worth considering that high pressure will be exerted on it, so you need to increase stability with a degree of soil resistance. For this, reinforcement is carried out not only of the bottom, but also of the walls.

In order to compact concrete during laying, it is necessary to use a deep manual vibrator, since the usual bayonet method will not give the desired result in the form of maximum level compaction.

Formwork should be assembled from edged boards, which will be cheaper and more convenient.

The pouring of the walls should be completed at one time, however, if this is not possible, then before starting to pour the next layer, the first one must be covered with Penerat.This allows you to make the adhesion between the layers at the highest level and eliminate the formation of a gap at the junction.

Once the walls are filled, you need to wait at least 14 days, after which the formwork is removed.

The structure is inspected for integrity, and if no defects are found, then work continues, and if there are any, it is necessary to grout with cement mortar and apply a waterproofing layer using special mastic.

Next, it remains to make the roof of the septic tank, for which the formwork is assembled from the boards

It is important to remember that concrete has a considerable weight, and therefore the spans between the boards are supplemented with props. This must be done every 1.5 m.

The ceiling is reinforced in the same way as other parts of the tank, but reinforcement with a rod thickness of 12 mm is used here.

The minimum amount of concrete on top is applied at 3 cm.

Before filling up the container that will be used for sewage, you need to wait 3 weeks, remove the props and cover with a layer of polyethylene for the drying period of the concrete.

The work requires a considerable investment of time and effort, but in the end you can get a high-quality concrete septic tank. If you want to equip it in a private house, and with your own hands, then the concrete and reinforced concrete option is what you need. Such designs are thoughtful, comfortable, and most importantly - durable, stable and strong.

Stages and features of installation work

The main stages of installation work in the construction of a septic tank from concrete rings:

- arrangement of the pit;

- installation of concrete rings;

- supply of sewer pipes;

- device of the ventilation system;

- joint sealing;

- installation of ceilings and backfilling.

Pit arrangement

Excavation work can be carried out using special equipment or manually. When building a new house, it is better to dig a pit with an excavator. But at the same time, one nuance should be taken into account: when digging a pit with a bucket, a pit is obtained, the shape and dimensions of which are much larger than those required by a septic tank made of concrete rings. It will not be easy to lower products weighing 400 kg or more into such a pit on your own. Therefore, you will have to use the services of a crane. Digging by hand takes much more time, but allows you to make a foundation pit exactly in size.

Concrete rings with a bottom should be installed in the pit first, i.e. - bottom

The bottom of the pit must be concreted to prevent the penetration of untreated sewage into the soil. If the septic tank is made of concrete rings and its device involves the use of special products with a bottom, then the bottom of the pit does not need to be concreted.

If a three-chamber version is being constructed from concrete rings for a bathhouse or a house, then in the third filter well a pillow of gravel and sand 50 cm thick is made. At the stage of digging a pit, trenches are made for pipes connecting the tanks and leaving the house. A layer of sand 10 cm thick is covered at the bottom of the trenches.

Mounting

Since the concrete elements are quite heavy, a truck crane or a homemade winch is used to install them in the pit. You can use another method - the sequential installation of rings with digging, but this method is very labor-intensive. In addition, it is rather inconvenient to concrete the bottom of the septic tank, in which the rings are already installed.

After installation, the rings must be fastened together with a cement-sand mortar. Additionally, they can be fastened with metal brackets.

This precaution will prevent the formation of cracks in the rings during seasonal ground movements.

Supply of sewer pipes

Holes for pipes are punched in the mounted rings. The pipe transporting wastewater to the first well is placed at a slight angle. The pipe that connects the first and second wells should be 20 cm lower than the previous one, and the pipe supplying the treated effluents to the filter well should be installed another 20 cm lower.

Ventilation system device

To ensure ventilation of the septic tank, it is necessary to connect the sewer pipe to the ventilation riser, which goes to the roof of the building. The riser pipe in diameter must be no less than the pipe transporting domestic wastewater to the septic tank.

If the ventilation pipe is made smaller than the sewer pipe, then the drains will create a “piston” effect, and this leads to the disappearance of the water seal in the siphons of plumbing fixtures. As a result, sewage odors begin to penetrate into the room.

Therefore, it is very important to build a septic tank from concrete rings, the ventilation of which will perform two main tasks as efficiently as possible:

- to exclude rarefaction of air in sewer pipes;

- eliminate unpleasant odors from sewer lines and wells.

Sealing joints between rings and pipes

Ordinary concrete, contrary to popular belief, does not hold water. A septic tank made of concrete rings is no exception.

The waterproofing of the internal and external surfaces of the septic tank must be carried out very carefully. To do this, use a solution of liquid glass, bituminous mastic or well-proven polymer mastics.The best results when deciding how to properly make a septic tank from concrete rings with the best waterproofing are given by a concrete solution with special additives.

Installation of floors and backfill

Mounted sewer wells are covered with concrete slabs, in which holes are made for the installation of hatches. After installing the plates, the septic tank is backfilled. To do this, use the soil taken out of the pit. Upon completion of backfilling, the septic tank is completely ready for operation.

Do-it-yourself concrete septic tank

Like any other construction work, making a concrete septic tank with your own hands is carried out in several stages:

- design;

- location determination;

- excavation;

- strengthening of reinforcement and waterproofing, construction of formwork;

- the process of pouring concrete;

- overlapping.

Each stage is carried out in this sequence, so we will analyze them in more detail.

Design

Calculate the power of the system, the volume of the first chamber. Decide how many of them should be, determine the location of the treatment system.

Excavation

Figure 4. Pit for a concrete septic tank First you need to dig a pit. The process can be significantly facilitated and accelerated if you organize the rental of an excavator. The walls of the pit and its bottom are leveled and compacted. When digging a pit, do not forget to prepare trenches in which pipes are to be laid.

formwork

To prevent the penetration of runoff into the ground, it is required to cover the surface of the pit with waterproofing material. Then the bottom of the pit is backfilled with sand. Fittings are mounted on the sand from old pipes, wire, scrap metal. Concrete is poured onto this structure, which should completely hide it.The solution must contain a plasticizer (liquid glass) to increase the water resistance of concrete.

After the screed has hardened at the bottom, they begin to build formwork around the perimeter of the pit. Any material is suitable for it: plywood, boards, OSB sheets. In order to save money, it is recommended to perform sliding type formwork. First, a low structure is built, which is raised as the concrete hardens. To cast a partition between the sections, the formwork is built on both sides of the pit. Both parts are fixed with spacers to level the high pressure of concrete on the walls.

Pouring solution

Figure 5. Concrete septic tank with formwork It is more convenient to order a ready-made mortar from the enterprise in order to speed up the work. But more often it is prepared independently: sand is mixed with cement inside the container, and then fine-grained gravel is added to the solution. It is advisable to pour an additional plasticizer into the solution.

It is more convenient to pour the formwork in layers to eliminate the formation of air voids in the monolithic structure. The thickness of each layer is made such that it does not exceed half a meter. It is recommended to use a construction vibrator for concrete compaction. The height of the partition should be 15 cm below the level of the walls.

The formwork is removed after the concrete has hardened. Performing the procedure, closely inspect the inner surface of the container. In the presence of any potholes, they are immediately covered with a solution. It is recommended to cover the inner surface with coating waterproofing in order to eliminate the possibility of leakage of drains through the walls as much as possible.At the same time, this procedure will increase the resistance of concrete to aggressive environments.

overlap

Figure 6. Covering a concrete septic tank The top cover of the structure is of particular importance. It must be strong enough to withstand ground pressure. Such an overlap is made according to a certain method:

- The perimeter of the walls is filled with metal corners, they are welded together to form a single frame. In the center, above the partition, it is recommended to weld a channel that provides additional rigidity. Each of the chambers must have a frame that will serve as the location of the hatch, allowing you to periodically clean the container. Be sure to install pipes in the ceiling through which gases will be removed from the septic tank.

- Boards are laid over the corners, covering them with roofing material. A layer of reinforcement is placed on top of it, then the solution is poured. To keep the hatches intact, formwork is made of boards around them.

- The manhole openings are covered with bricks to prevent the risk of their deformation due to the weight of the soil. The resulting boxes are covered with plank lids covered with roofing material. The rest of the floor surface is covered with expanded clay soil to significantly lighten the load.

When pouring walls, holes must be made in them through which pipes will be inserted. To do this, sections of large pipes are mounted in the formwork, through which it will be possible to push the necessary pipelines. An insulator of any material is laid between concrete and pipes.

The device of a simple septic tank

A septic tank is a tank, a rectangular or round well, through which sewage flows very slowly, which makes it possible for sediment to fall. Such a precipitate is not removed until it rots (six months, a year).The process of decay is accompanied by fermentation and the release of gases. They lift sediment particles up, forming a crust (sometimes 0.5 m thick).

The body of the septic tank can be made of concrete or plastic, but must be airtight.

The septic tank is easy to use. The settling well can be cleaned 1-2 times a year. After that, a small amount of sediment should remain in it for the experience of the newcomer.

You can find recommendations for building a septic tank without pumping (cleaning), but this is complete nonsense - the septic tank should be regularly cleaned at least once a year. This is a sanitary requirement. You are building a domestic sewer, not a plant for microbiological weapons of mass destruction.

The simplest septic tank on the estate is a single-chamber septic tank. It can be easily built by hand. It may be round in plan. It is assembled from reinforced concrete rings with a diameter of 1.0 m. The well cover is collapsible. It is necessary to provide for natural ventilation in the form of a steel pipe, which must be covered with Kuzbaslak.

The capacity of the septic tank must be at least three times the wastewater flow.

With a flow rate of up to 0.5 m3 per day, a single-chamber septic tank has the following dimensions:

- required capacity - 1.5 m3;

- diameter of reinforced concrete rings - 1.0 m;

- the total depth of the well is 2.95 m.

It is recommended to plaster the inside of the septic tank with a cement mortar (1: 2) 1.5 cm thick with grout.

The tray of the pipe entering the septic tank should be located 0.05 m above the liquid level in it, and the exit pipe - 0.02 m below this level (Fig. 1).

Installation ↑

The installation of a septic tank made of concrete, depending on the option chosen, differs in the type of work.

To equip a monolithic two-chamber structure with your own hands, you must adhere to the following rules:

- compound. Do not use concrete grade below B15. The optimal mixture will be the following composition: cement - 400 kg, liquid additive superplasticizer C-3 - 5 l, sand - 600 kg, water - 200 l, crushed stone - 1200 kg;

- dimensions. The thickness of the walls and the base of the product is from 20 cm, the thickness of the partitions is 15 cm;

- distance. From the reinforcement bar to the concrete surface should be 3 cm;

- additional reinforcement. It is necessary if the pit is rectangular in shape.

The procedure for installing a septic tank with your own hands is as follows:

For a family of 6-8 people, a Topas 8 septic tank is quite suitable. Find out how much it will cost from the article: Topas 8. How to hide pipes in the toilet behind plastic panels, see the photo in the article.

digging a hole

The dimensions of the pit are calculated on the basis that a volume of 1.5 m3 is enough for a family of 3-4 people. Prepare it with an ordinary shovel in the shape of a rectangle or square. Works on average last from 1 to 2 days. The bottom and walls of the pit must be even;

excavation

Formwork erection

To reduce material costs, the sliding formwork method can be used. To do this, it is installed only on half of the structure. After curing the first part, it is rearranged to the second. This method also allows more even placement of concrete in the inter-form space.

The following materials will be required for work:

- as chipboard boards;

- pieces of plastic pipes that may remain after the installation of a sewage system coming from the house;

- reinforcing bars;

- for the rigidity of the shields, pieces of wooden beams.

When creating a sealed structure, at this stage it is necessary to fill the base and leave it to harden for several days.

concrete base of the pit

After preparing the necessary materials, you need to proceed to the construction of the formwork:

- carry out the installation of shields, which are fixed to each other with the help of wooden beams;

- prepare holes for drainage. To do this, every 30 cm holes are cut out in the formwork equal in diameter to pipe trimmings. They should be driven into the ground by 5 cm so that they do not come off when the structure is poured with concrete;

- pipes that go from the house are carried through the formwork into the pit.

formwork

Concrete works

Before pouring the solution, it is necessary to install reinforcing elements in it to enhance the strength of the structure.

Next, you need to perform the following actions:

- pour the mortar into the first part of the pit, and then wait for it to harden for 2 days;

- get the formwork and rearrange it in the second compartment;

- pour the solution into the second chamber and wait for complete solidification.

walls Next, you should proceed to dividing the structure into two compartments, equal in volume: for cleaning wastewater and lowering them through the filtering bottom into the soil. As a material for the wall, bricks, stones, concrete blocks are used.

At this stage, it is important to observe the height of the hole. It should be lower by 0.5 m compared to the input

Overlapping a septic tank

Move on to the next step after 2 weeks. This is done in order to give the structure strength to withstand heavy loads. If small cracks have formed on the walls, then they can be rubbed with concrete mortar.

The order of work on the overlap:

- have channels for laying floors on them;

- install shields from boards with sides that create the boundaries of the hatch openings. They are arranged in such a way that through the manhole it is possible to get into both parts of the septic tank;

- mount pipes: ventilation supply and output;

ceilings and installation of ventilation pipes

- lay reinforcement to enhance the strength of the structure;

- poured with cement mortar.

ceilings with cement mortar At this stage, the installation of a monolithic concrete septic tank is completed. It turns out practical equipment that is suitable as a sewer system for a private house.

hatches

For the installation of concrete factory septic tanks, a pit should also be prepared. Its dimensions and installation conditions can be found in the instructions for the equipment. The finished structure is connected to the sewer, given that all pipes must be laid at a slope of 2%.

Installation Tips

- To prevent freezing of the well, its chambers should be insulated.

- It is desirable to mount ventilation pipes on each of the containers.

- To increase the strength of the structure, concrete rings can be connected with metal brackets.

- When building a septic tank, it is best to rent special equipment that will lay concrete rings in dug holes. For the same reason, excavation work must be carried out in advance before laying the chambers.

- When blocking each of the wells, care must be taken to create covers with hatches that allow you to monitor the condition of the septic tanks.

Thus, the construction of a septic structure from concrete rings will solve the problem with the sewerage of private houses.This design will handle large volumes of waste while preventing soil contamination.

The device of a single-chamber septic tank

This type of sump consists of a pit in which walls are made of concrete rings or monolithic concrete. The bottom should be monolithic or consist of layers of sand and gravel. Water enters the pit, after two days the heavy elements settle to the bottom. Gases exit through a special hole, and water is pumped out. Silt is formed at the bottom, which is removed by a special pump. The size of the drain pit depends on the number of people living in the house. The disadvantage of such a septic tank is the rapid occupancy.

A septic tank with one chamber usually requires pumping out waste with special equipment

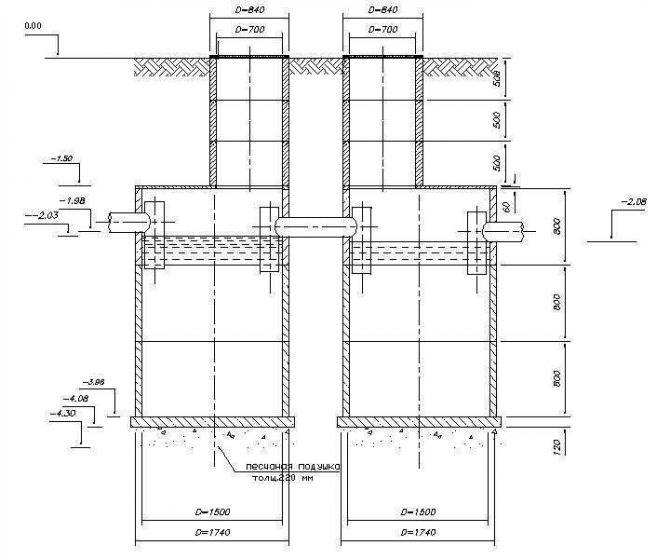

Consider the device of a reinforced concrete septic tank

The base of a concrete septic tank is made of monolithic concrete or a finished reinforced concrete slab laid on a layer of well-compacted rubble. Two reinforced concrete rings with a diameter of 1 m are laid on the base, in the form of a well. In the upper ring, inlet and outlet holes are provided, into which tees are mounted, with a diameter of 10 cm. The inlet is arranged above the outlet by about 5 - 10 cm.

From above, the septic tank well is covered with a reinforced concrete floor slab with a hatch on which a wooden cover is provided. Above the hatch, another reinforced concrete ring is installed, but already with a diameter of 0.7 m, on which, at ground level, the last support ring is mounted. The reinforced concrete septic tank is covered from above with a cast-iron or wooden hatch. From the lower well, mounted strictly above the tee, there is a ventilation riser, which is a pipe with a diameter of 8 cm.

The total depth of a reinforced concrete septic tank is approximately 2.7 - 3 m.Running brackets are mounted on the inner surface of the well, allowing a person to go down for cleaning. Around the upper hatch, at a distance of at least 1 m in a circle, the terrain is cemented.

During the installation of reinforced concrete septic tanks, tight sealing of the joints is provided. If the area is characterized by a high level of groundwater, the rings and slabs are additionally coated with hot bitumen from the outside. All external sinuses around the rings are carefully filled and rammed during the installation of structures.

The device of monolithic septic tanks

As a rule, such structures have a rectangular or square section. First, the soil is excavated to the desired depth, the walls are thoroughly cleaned and the earthen base is rammed. Then the prepared surface is backfilled with gravel to a thickness of about 20 cm, which also needs to be well compacted. A concrete screed is laid on a gravel cushion, at least 10 cm thick.

To perform further pouring work, formwork is installed from wooden, well-polished panels. It is advisable to beat them with plastic, tin or waterproof plywood (more about plywood can be found here http://usadba.guru/fanera/). To prevent concrete from sticking to the formwork, the panels should be lubricated with machine or vegetable oil, grease or any other similar material.

The construction of a monolithic septic tank is a much longer process than installation from finished reinforced concrete products, since, before pouring the next volume, you have to wait several days for the previous one to harden. Some advantage of monolithic structures is that no backfilling of the sinuses with soil is required.

For monolithic works, only high-quality building material is used: cement not lower than M400 or Portland cement. Gravel and sand should not contain organic or clay impurities. The concrete mass should be made of the same composition and plasticity during the entire scope of work.

Creating a concrete septic tank with your own hands

To carry out work on the installation of a concrete septic tank in the country on your own is a project, although not simple, but quite feasible. First you need to decide on the size of the structure. The volume of the septic tank should be such that its permanently filled part is equal to three times the daily inflow of liquid. The size of the above-described design of prefabricated reinforced concrete rings will be quite sufficient for a family of 4-5 people.

The septic tank should be located no closer than 5 m from a residential building. Since it will be necessary to pump out the accumulated sediment with a sewage machine, it is necessary to provide a convenient access road to the structure.

Having decided on the material for the manufacture of the structure, you must first perform a fairly large amount of excavation work - dig a hole 3 m deep and 1.5 m in diameter. Then installation work will follow, for the production of which special equipment will be required. During the installation process, one should not forget about the complete sealing of all cracks and joints, for which it is recommended to make ebbs from cement or use tarred rags.

Popular articles:

Choosing an inexpensive septic tank for a summer residence, device and turnkey installation Fiberglass (fiberglass) septic tanks, is it worth buying? What is better than a Tank or Topas (Topaz) septic tank? causes and remedies