- Performance and scope

- Advantages of ordering products in our store

- Diameters of metal-plastic pipes and characteristics, tables with parameters

- Composition of metal-plastic pipes

- Characteristics of metal-plastic pipes

- Dimensions of pipes made of metal-plastic

- The choice of metal-plastic products

- Features of metal-polymer pipes

- Manufacturing technology

- Advantages over metal products

- Purpose and marking of products

- Connection methods

- Composition and production

- Production process

- Scope of MP products

- Dimensions of metal-plastic pipes

- Performance characteristics

- Varieties of structures made of metal-plastic

- Dimensions and diameters

- What temperature can a metal-plastic pipe withstand

- What pressure can a metal-plastic pipe withstand

Performance and scope

The structure and technical characteristics of the metal-plastic led to a number of strengths of the composite highway. The positive aspects of operation include:

- anti-corrosion - the inner surface is not covered with rust and does not silt;

- good throughput due to low hydraulic resistance of the pipeline;

- chemical inertness to most toxic substances and aggressive environments;

- flexibility, which allows minimizing the amount of corner reinforcement during installation of the line;

- gas tightness - elements of the pipeline system (radiators, boilers, pumping equipment) are protected from the harmful effects of oxygen;

- noise absorption - quiet transportation of liquid along engineering communications;

- wear resistance, ease of use and no need for additional maintenance.

Pipes are light in weight, so they are easy to transport and install. Additional advantages: aesthetics, affordable cost and virtually waste-free use.

Docking the pipeline with press fittings ensures a tight, reliable connection of the line - this allows you to perform hidden laying of the pipeline and perform concrete pouring

Along with the positive aspects of the metal-layer, there are also disadvantages:

- Thermal expansion difference. Plastic "adjusts" to changes in water temperature faster than aluminum. This difference negatively affects the material - over time, the butt joints weaken, and the risk of leakage increases.

- bending requirements. Multiple bending/extension or one-time bending in excess of the norm can lead to deformation of the layers of metal-plastic moldings.

- Susceptibility to UV rays. The polymer outer layer with prolonged exposure to ultraviolet loses its protective properties.

Installation of the metal-polymer pipeline takes place by means of crimp fittings.

When using low-quality products and non-compliance with the installation technology, delamination of the metal-layer structure and cracking of the outer plastic layer are possible

These deformations can be the result of freezing of the coolant in the pipe.Solution to the problem: insulation of the main at the installation stage or replacement of the transported water in the heating system with anti-freeze.

The operational properties of metal-polymer pipes allow them to be used in private, industrial construction and other areas of management.

Main applications:

- communications of water supply systems;

- supply of aggressive liquids, gas in agriculture and industrial facilities;

- arrangement of insulated "water floors", including for heating the soil in greenhouses;

- insulation of electrical cables and wires.

Reinforcement made of metal-plastic composite is widely used in the construction of ventilation, air conditioning and irrigation systems from wells.

Provided that the “inner sleeve” of the pipe is made of food-grade plastic, it is permissible to use a metal-polymer pipeline for supplying drinking water

Operating restrictions:

- premises belonging, according to fire safety standards, to category “G” - substances are located, the processing of which is accompanied by heat release or the appearance of sparks;

- buildings with heat sources if their heating temperature exceeds 150°C;

- centralized heating with "insertion" of the elevator unit;

- when supplying a hot coolant with a working pressure of 10 bar.

Metal-plastic components are not recommended to be introduced into open-type engineering highways. Temperature fluctuations and operation in frost will lead to the destruction of the pipeline.

Advantages of ordering products in our store

- Wide range of pipes. You can order products of the desired length and optimal diameter from us. Production is delivered in bays. This simplifies the process of transportation and use.

- Sophisticated feedback system.All questions about the quality of the proposed pipes, their characteristics, you can ask our specialists. Managers will talk about the features of the products. Experts will help you quickly make a choice in favor of those pipes that are able to successfully solve all the tasks.

- The possibility of exchanging goods of inadequate quality.

- Fast dispatch approval and order confirmation. Sale of all production is carried out by us on conditions, convenient for clients.

- Prompt delivery in Moscow and other cities.

Contact us! Specialists will answer all questions regarding the sale of pipes and their return.

The advantages of metal-polymer (metal-plastic) pipes are the absence of corrosion, resistance to overgrowing, aggressive building mixtures, strength, smooth inner surface, convenient transportation, technological, economical installation, impermeability to gas molecules, relatively small thermal linear elongation. Metal-plastic pipes VALTEC are widely used in the installation of water supply systems, heating, cooling of buildings, transportation of various technological media, including food.

The crosslinking of the polyethylene of the inner, outer layers of the proposed metal-polymer pipes is carried out using the organosilane method (PEX-b). The inner (working) layer has a degree of crosslinking of 65%, the outer (protective) layer of PEX has a degree of crosslinking of 55%. Such a constructive solution makes the pipe more flexible. The metal layer is butt-welded from pure aluminum foil with a thickness of 0.25–0.4 mm (for different sizes). The aluminum of the middle layer is welded by the TIG method, while the strength of the weld exceeds the strength of the aluminum layer itself.The strength of the adhesive bond of the layers is 70 N/10 mm, while the standard is 50 N/10 mm. Multiple temperature drops will not cause delamination of the metal polymer.

Metal-plastic pipes VALTEC PEX-AL-PEX can be used in radiator heating (5th class of operation, GOST 32415-2013). Compliance with passport operating conditions guarantees a 50-year service life of the product. The warranty period for VALTEC PEX-AL-PEX pipes is 10 years.

Metal-polymer pipes are a great combination of metal and plastic products.

They have proven themselves as a material for cold and hot water supply, heating, underfloor heating systems, and transportation of process fluids. Subject to all recommendations for installation and use, their service life can be up to 50 years.

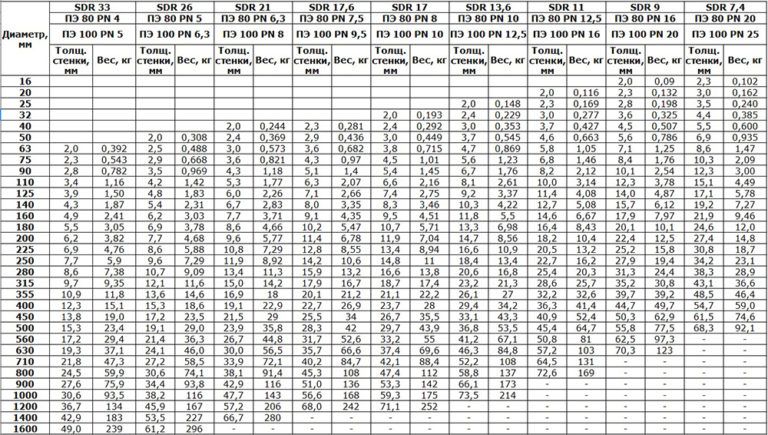

Diameters of metal-plastic pipes and characteristics, tables with parameters

Nowadays, repair work is not complete without the use of metal-plastic pipes. The strength and reliability of structures made of these multilayer products has been proven over the years. It is only necessary to correctly select the diameters of metal-plastic pipes so that there are no emergencies.

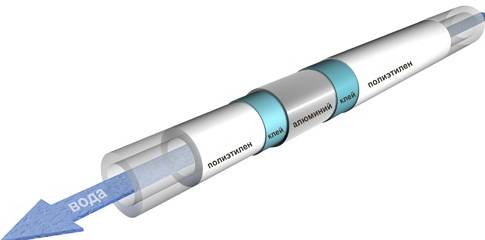

Composition of metal-plastic pipes

Metal-plastic products consist of several layers (Fig. 1):

- The top layer is cross-linked polyethylene;

- Intermediate layer - aluminum;

- The inner layer is cross-linked polyethylene.

Between these layers there are also adhesive layers. Cross-linked polyethylene is a pressed material that is highly durable.The outer layer is treated with additional chemicals for greater durability, and the inner layer is made of food-grade plastic. The aluminum inner layer is needed for protection and durability.

Rice. 1 Layers of metal-plastic tube

Rice. 1 Layers of metal-plastic tube

Characteristics of metal-plastic pipes

One of the main parameters is the inner diameter of metal-plastic pipes. This characteristic means the throughput of the pipe. You need to know it for sure when choosing other components, for example, fittings (Fig. 2).

Rice. 2 Fittings for metal-plastic structures

Rice. 2 Fittings for metal-plastic structures

The next important factor when choosing metal-plastic pipes is their outer size. Also an important indicator of the size of metal-plastic pipes is the wall thickness of the pipe. It can be from 2 to 3.5 mm. You can see the size ratio in the table.

Weight of 1 weather meter, grams

The volume of liquid in 1 linear meter, liters

Dimensions of pipes made of metal-plastic

This is a branch pipe with an outer diameter of 16 mm, a wall thickness of 2 mm, and an inner diameter of 12 mm. The aluminum words in this tube are 0.2mm thick. Such a pipe is the most relevant for arranging a heating system and a water circuit in houses. That is, such products are used for draining water to mixers, for counters, etc. Fittings for this diameter are cheaper than others. 1 linear meter of a pipe made of metal-plastic 16 * 12 mm is equal to 115 g.

The outer dimension becomes 20 mm, the wall thickness dimension becomes 2 mm, the inner diameter becomes 16 mm. The thickness of the aluminum layer becomes 0.25 mm. Such metal-plastic pipes are often used for arranging underfloor heating. They are also used for water supply, if the pressure is poor and the structure is long enough.A branch pipe with a cross section of 20 mm can withstand a pressure of 10 bar.

Such a pipe made of metal-plastic has an outer diameter of 26 mm, an inner section of 20 mm, and a wall thickness of 3 mm. This pipe is used for arranging the riser and the underfloor heating system. In a private house, autonomous systems are often equipped, such as heating and water supply. When arranging an autonomous heating system, it must be taken into account that pressure jumps often occur, so this diameter of a metal-plastic product is ideal.

The outer section becomes 32 mm, the inner section 26 mm with a thickness of 3 mm. This size of the product allows it to be installed as a riser. If such a pipe is installed as the main pipeline, then the system must have a low pressure indicator. Due to their sufficiently large throughput, they ensure the passage of a large volume of liquid without interruption.

The outer section of this metal-plastic pipe is 40 mm, the inner diameter becomes 32 mm, and the wall thickness is 3.9 mm. Such pipes are used to install long heating lines in industrial and residential buildings. Also, this size of a metal-plastic product is needed for installing central heating and air conditioning.

The outer section of such a pipe is 50 mm, the inner section becomes 40 mm, the wall thickness is 4 mm. These pipes made of metal-plastic have a sufficiently large permeability, therefore, with their help, technological pipeline systems are mounted for heating and water supply of industrial facilities.

There are pipe options with an even larger diameter - up to 63 mm, but they are not used for residential heating systems and have a narrow focus.

The choice of metal-plastic products

When choosing, the following parameters of metal-plastic pipes should be taken into account:

Wall thickness;

Internal patency and external section;

Weight, because in some cases it is important to know the weight of the heating system, etc.;

Thermal conductivity indicators;

Indicators of maximum and minimum temperature;

Permissible bending radius;

Life time.

As a rule, all parameters given in the table are standard, slight deviations are possible. It depends on the manufacturer.

Features of metal-polymer pipes

Manufacturing technology

The technology for the manufacture of pipe products from metal polymers involves several stages:

- The inner shell is extruded from a special device (extruder).

- On top of the shell, using a special adhesive layer, a carrier layer of aluminum foil is applied, which is welded along the seam by laser butt or overlap.

- An extruded outer shell is glued onto the aluminum layer.

- All layers are pressed simultaneously.

The outer layer of the pipe protects aluminum from oxygen and moisture. The aluminum foil ensures the strength of the product, and the inner layer is designed to protect the product from the effects of the working environment and the formation of condensate.

Manufacturing technology

Advantages over metal products

Thanks to this technology, metal-polymer multilayer pipes obtain physical and mechanical characteristics, due to which they are significantly superior to metal pipes. First of all it is:

- resistance to corrosion and aggressive environment;

- good heat resistance;

- ease of installation;

- preservation of the geometric shape after bending;

- resistance against internal deposits;

- high throughput, etc.

Purpose and marking of products

Metal-polymer pipes are used for laying water pipes, heating and sewerage systems. They are also quite suitable for gas.

For a clear, unambiguous classification of products, international marking of metal-plastic pipes has been adopted. The main purpose of applying information is to convey to the buyer a maximum of useful data about the product.

The following instruction will help you understand the marking, revealing the main encoding:

- Type of plastic used for the manufacture:

- PEX-AL-PEX - cross-linked polyethylene;

- PERT-AL-PERT - heat-resistant polyethylene;

- PE-AL-PE - plain polyethylene;

- PP-AL-PP - polypropylene.

- Products made of cross-linked polyethylene in the abbreviation may contain letters that indicate how the material is cross-linked (a-pyroxide, b-silane, c-electronic).

- Product diameter and thickness (minimum) of the wall. The value is entered in millimeters or inches.

The following ratios can be used for recalculation: 16.0 mm - 3/8″; 20.0 mm - 1/2″; 25.0 mm - 3/4″; 63.0 mm - 2.0″; 90.0 mm - 3.0″; 110.0 mm - 4.0 "; 125.0 mm - 5.0″. Other values can be found using a converter.

- The nominal (working) pressure for which the pipe is designed. If the working pressure is observed, metal-polymer pipes can withstand more than 50 years of operation without deformation and other violations of technical characteristics.

- Maximum pressure. Actual parameter for piping products designed to transport a working medium with a high temperature.

- Information about the working medium that can be transported through pipes.

- Batch number and production date.

The manufacturer recommends that, when laying the pipeline, provide access to reading the marking information, which will be useful when repairing or inspecting sections of the pipeline.

Product labeling example

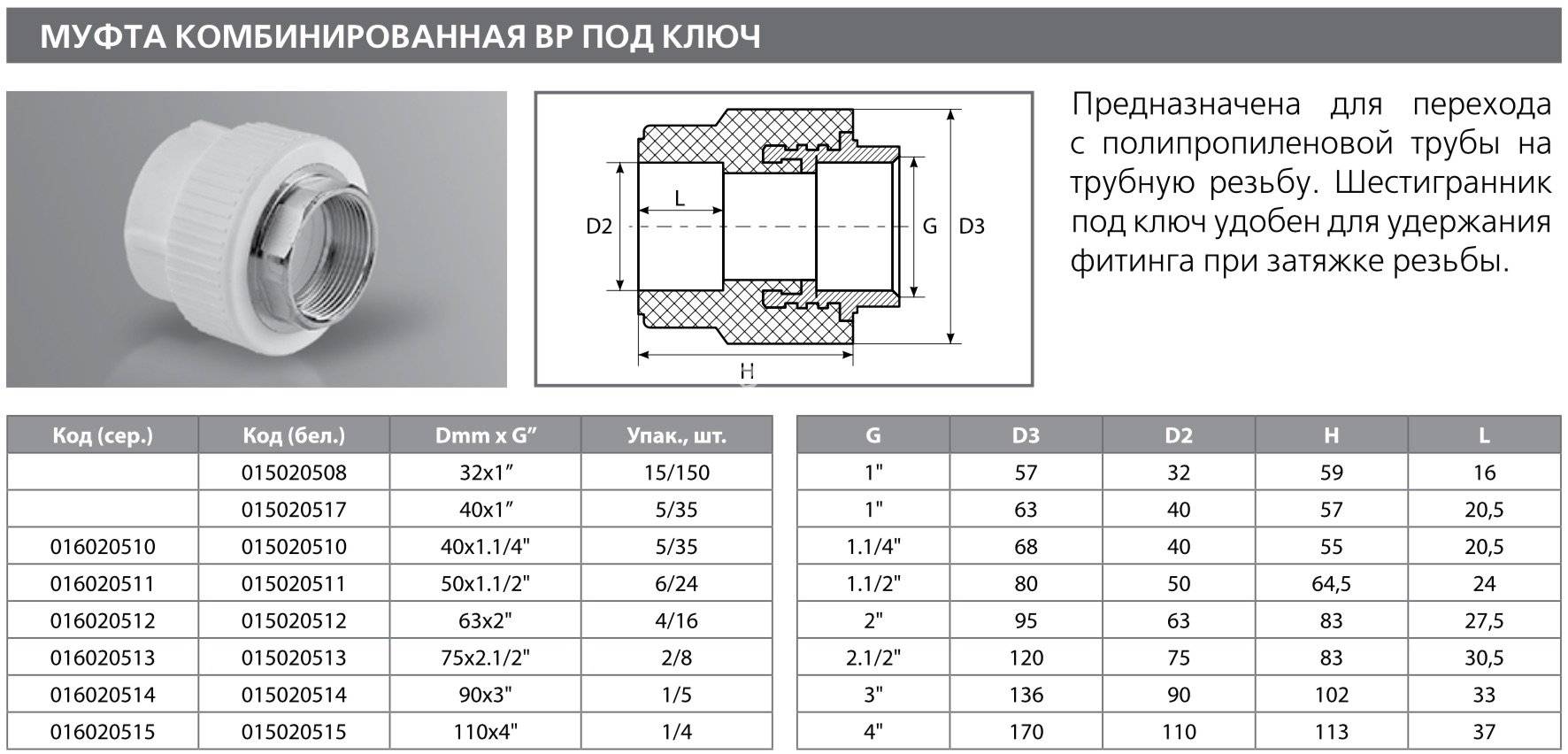

Connection methods

The use of metal-plastic pipes for laying pipelines requires solving problems with connecting products to each other or fitting products.

To ensure reliable connecting nodes, the following are used:

- Threaded fittings with sealing split ring.

- Press fittings.

Threaded fittings are easier to install and require no special tools. However, this type of connecting unit is the main disadvantage of metal-polymer products, since the connections lose their tightness over time and require constant monitoring and tightening.

The connecting nodes formed with the help of press fittings are more reliable, however, they are one-piece and a special press tool is required for their organization.

Composition and production

For household purposes, products are produced in accordance with GOST R 53630-2009.

The standard is intended for the manufacture of pressure multilayer pipes with a circular cross section, which are intended for the transport of water, including drinking water, and for the installation of water supply and heat supply.

MPT consist of several layers of plastic, metal and special glue:

- layer - internal, is in constant contact with the liquid, plastic;

- adhesive layer;

- barrier layer, rolled aluminum or fiberglass;

- adhesive layer;

- layer - outer, exposed to the external environment, plastic.

The adhesive composition consists of composites based on thermoplastic polymers with adhesion to layers and a melting point of 120 degrees. Plastic components for the inner layer are produced on the basis of the following polymers:

- cross-linked polyethylene, with a strength of 8 MPa or more (what tool will you need to buy for pipe installation);

- polyethylene with increased heat resistance and strength from 8 MPa;

- polypropylene with a strength of 8 MPa;

- polybutene with a strength of 12.5 MPa.

The metal layer is made from thin aluminum or fiberglass tape. The outer layer is polymers with low oxygen permeability.

The production of MPT is a complex high-tech process.

Molten polymers are evenly fed into the molding mechanisms, where the layers are glued together. At the same time, pipes are formed along the outer and inner diameters.

At the exit, the product enters the cooling tanks, after which it is cut or wound into coils.

The use of polymers and metal made it possible to use the advantages of each material, achieving combination of useful characteristics from pipes.

Polymer layers protect the aluminum reinforcing layer from corrosive processes. Metal makes products flexible, increasing fracture strength.

Thanks to this combination, the pipes withstand the temperature of hot water without changing their technical characteristics (read about the use of cold welding for pipes under pressure in this article.).

Production process

The characteristics of metal-plastic pipes that allow their use in many areas are not known to everyone. First of all, you need to know how these pipes are produced in order to be able to choose quality products.

Metal-plastic pipes consist of two layers of polyethylene PE-X crosslinked at the molecular level and a layer of thin aluminum laid between them. The layers are connected by means of a special adhesive composition, which each manufacturer has its own.

It is aluminum that gives the pipe sufficient strength, and polyethylene flexibility.

An aluminum tape of small thickness is welded from two semicircular fragments along the length using the "overlap" or "butt" method. Welding is carried out by ultrasound. After that, a layer of polyethylene is applied inside the pipe and on top using special glue.

Further, the pipes are marked and wound into coils, which in this form go on sale.

The design of metal-plastic pipes in the context is as follows:

- outer polyethylene;

- adhesive composition;

- aluminium foil;

- glue;

- inner polyethylene.

This design allows you to normalize the linear expansion of metal and polyethylene. The white color of the outer coating is a good solution for an attractive appearance of pipelines, excluding their permanent painting.

On the one hand, the inner and outer layer of polyethylene provides a smooth inner surface, on which various suspensions and scale do not settle. On the other hand, the protective layer of polyethylene protects the aluminum foil from the formation of galvanic processes when joined to the metal parts of pipelines, eliminates the risk of condensation, which significantly increases the service life of metal-plastic pipes.

The structural layer of a metal-plastic pipe, which has incorporated all the positive properties of aluminum and polyethylene, makes it possible to widely use this modern material in water supply, sewerage, air conditioning systems and others for 50 years.

The design of the metal-plastic pipe

Scope of MP products

In addition to the installation of pipelines for water supply, heating and sewerage systems in housing construction, metal-plastic pipes can be used:

- for transporting compressed air;

- in air conditioning systems;

- when installing high voltage electrical networks, as protection against force fields;

- in industry and agriculture in the construction of various pipelines transporting liquid and gaseous substances.

However, there are certain restrictions on the use of metal-plastic pipes. They are not recommended for use:

- in centralized heating systems, if there are elevator nodes;

- for fire safety purposes, plastic pipes are not used if the room has category "G";

- for high pressure pipelines (over 10 bar), if the diameter of the metal-plastic pipe is not large enough;

- near heat sources, if the temperature of thermal radiation exceeds 150 degrees.

Dimensions of metal-plastic pipes

Manufacturers produce pipes from metal-plastic of different diameters in the range of 16 - 63 mm. A pipe is selected for the device of a particular design according to the outer diameter.

Manufacturers produce pipes from metal-plastic of different diameters in the range of 16 - 63 mm. A pipe is selected for the device of a particular design according to the outer diameter.

For the installation of a water supply system in private houses or apartments, metal-plastic pipes are best suited, the outer diameters of which are 16-26 mm.

If the house has a large water supply network, an abundance of household and plumbing fixtures, pipes with a diameter of 32 or 40 mm are used. In this case, the main line is arranged from pipes of a larger diameter, and the connection to the devices is carried out by pipes of a smaller diameter.

Metal-plastic pipes supplied in coils can be 50-200 m long.

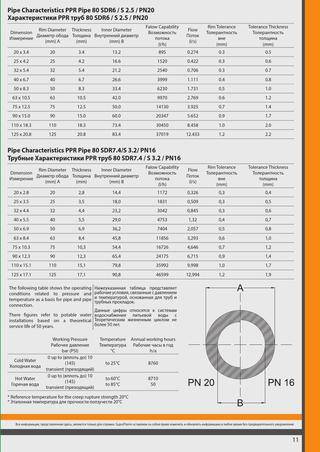

Performance characteristics

To figure out which material is better for a metal-plastic pipe or a variety of polyethylene, it is better to immediately compare the technical characteristics of each type:

| Characteristics | MP pipes | Polypropylene products | PVC structures |

| Max pressure | 15 atmospheres | 30 atmospheres | 120 atmospheres |

| pressure to work | 10 atmospheres | From 16 to 25 atmospheres, depending on the selected diameter | 100 atmospheres |

| Maximum temperature | 120 °С | 120 °C, at 140 °C the material begins to melt | 165 °С, begins to melt at 200 °С |

| constant temperature | 95 °С | From 40 to 95 degrees depending on the selected diameter | 78 °С |

| Thermal conductivity | 0.45 W/mK | 0.15 W/mK | 0.13 to 1.63 |

| Life time | 50 years | 10 to 50 years, depending on operating temperature and pressure | 50 years |

Varieties of structures made of metal-plastic

- Metal-plastic pipes reinforced with aluminum foil - during production, first the foil sheets are welded together by ultrasonic welding, then, using an adhesive (natural or synthetic), the manufacturer connects two layers of cross-linked polyethylene and an aluminum layer, which makes them more flexible, but less durable and with a lower index temperature stability.

- MP products reinforced with a rigid mesh frame - since not only different metals can act as the central link, but also forms that are different in the way they are made (mesh, wire, strips), the technology of each type will be different. The technological process of production is as follows - when stretching the longitudinal reinforcement from plastic, a transverse winding of the metal frame occurs, which is welded to the surface of the inner layer of the future product using a special electrode. Further, the structure is again filled with a melt of the upper layer of plastic. This method of production occurs without gluing with various types of adhesives, which increases the duration of the service life.

In comparison with other types of polyethylene structures, metal-plastic structures serve without constant repairs.

Dimensions and diameters

The most commonly used diameters of metal-plastic pipes are from 16 to 26 mm. However, the manufacturer produces fittings with a larger diameter - up to 63 mm.

When choosing the right size of a metal-plastic product, it is necessary to be guided by the future place of operation, so metal-plastic pipes with an inner diameter of 16 mm and 20 mm are better suited for plumbing (16 mm pipes are used for taps to plumbing).

To build large heating or plumbing distributions for residential buildings, metal-plastic pipes with a size of up to 40 mm can be used, but structures with an outer diameter of 63 mm are used in industrial, metal and oil industries.

The dimensions of MP products can tell about their capabilities, which often differ from each other precisely depending on the diameter. Table of sizes and specifications:

| Diameter (outer layer) | 16 | 20 | 26 | 32 | 40 |

| Inner diameter | 12 | 16 | 20 | 26 | 33 |

| Wall thickness, in mm | 2 | 2 | 3 | 3 | 3,5 |

| Weight of 1 meter, in kg | 0,12 | 0,17 | 0,3 | 0,37 | 0,463 |

The parameters of 16 mm fittings and the price for it often allow craftsmen to use this variety without fear in residential premises and apartment buildings.

Metal-plastic products with a diameter of up to 40 mm can be found on sale in coils (coils) from 50 to 200 meters long.

What temperature can a metal-plastic pipe withstand

The wall thickness and the selected reinforced composition of the finished fittings determine what temperature the metal-plastic pipes can withstand. The normal temperature for operation will be 60-95 degrees, however, with pressure and temperature drops, the MP design will be able to cope with a temperature of 120 degrees.

At a temperature of 140 degrees, the walls and fittings for MP structures melt, which leads to deformation of products and the formation of leaks.

The heat output of a metal-plastic pipe of 0.45 W / mK is a decisive factor when choosing products for creating underfloor heating.

What pressure can a metal-plastic pipe withstand

Since low-pressure polyethylene is used in the production of products, MP pipes can withstand pressure up to 15 atmospheres, the main working pressure is 10 atmospheres.

When building plumbing or heating structures in private homes, the pressure can drop to 7-8 bar. With this indicator in apartment buildings, wall breaks are possible.

Such indicators allow the use of metal-plastic structures in the extraction of metals at great depths, since they can withstand the pressure of several layers of earth rocks.