- Plumbing installation

- Types of fittings for joining metal-plastic

- Crimp fittings

- Compression fittings for metal-plastic

- push fittings

- Installation of pipelines from metal-plastic pipes

- Connection methods

- Connecting pipes with press fittings

- Connection of pipes with compression fittings

- Instructions for installing metal-plastic pipelines

- Is it worth it to use metal-plastic pipes for plumbing

- Scope of application

- Advantages of pipes made of metal-plastic

- Disadvantages of metal-plastic pipes

- How is the installation of various types of fittings for metal-plastic pipes

Plumbing installation

Every engineering solution starts with a design on paper. Pipe wiring is drawn with the designation of end and stopping points (sink, faucet, battery, etc.). Accurate visual design significantly reduces financial and labor costs.

The project plan indicates the initial source of water intake. It can be a deep own well or a central water utility system. If a well is used, then in this case it will be more profitable to use a water battery - a metal or concrete hydraulic accumulator. With it, you can not drive the pump, because the water itself flows directly into the living room by gravity, and passes through the filter system.

If it is planned to insert into the central water supply system, then water meters must be included in the project. This will reduce utility bills and provide metering and control of water consumption. Cleaning filters are selected taking into account the individual characteristics of the initial composition of the water. For this reason, recommendations may vary.

Installation of pipes made of metal-plastic

The algorithm of actions for working with all types of metal-plastic pipes is the same. First, the length and number of required connecting parts - fittings are calculated. The length is measured with a rope or other improvised materials. It can be a ribbon, lace, rope and a certain amount of nails.

From the starting point where the water intake will take place, a cord or rope is pulled. In those places where there will be turns, the rope is fixed with nails. This determines the direction of the future water supply. After marking, the wiring is schematically drawn on the wall, exactly along the attached rope. You can use a washable marker for this. Only after that, the rope can be removed and measurements taken using a centimeter.

Next, you can think about the types of fittings that will be used in the installation. Any dilution of pipes should start from the water intake and end at the end point (sink, battery, etc.). From a common coil of flexible pipe, a piece is cut to the size of the next connecting element. For the installation of a water supply network, you will need installation tools:

- adjustable wrenches in the amount of two pieces;

- caliber which has a countersink;

- screwdriver;

- cutting tool for hard plastic;

- press tongs;

- a hammer;

- conductor.

Installation of metal-plastic pipes using fittings

You will also need a sufficient number of fasteners, self-tapping screws and a long tape of thin fluoroplastic film. If any tool is missing, and its price is high, then you can use the rental services. It is economical and expedient to rent professional construction tools for domestic use. This service is in great demand among the population.

The gauge will help improve the geometric section of the pipe after cutting it, and the countersink will remove notches and burrs, and chamfer. If there is no countersink in the arsenal, then it can be replaced with sandpaper. An external or internal conductor will bend the pipe in the desired direction.

The outer one is considered the most versatile, because the inner one is not very convenient if the bend needs to be done at a remote distance from the pipe cut. Press tongs can be used in combination with press fittings. Such fasteners do not require annual maintenance, unlike compression fittings. Unfortunately, many people forget about this, which contributes to the formation of leaks in such compounds. Therefore, press fittings are considered a more reliable and rational solution.

Installation of metal-plastic pipes - fastening with fittings

When buying pipes, in order to avoid unpleasant surprises, it is better to measure the stock in the amount of ten percent. The most common cross-sectional diameter is 16 millimeters. Such a pipe is capable of providing normal working water pressure.

Before making a purchase, it is advisable to pay attention to the supplier, or reviews about the store, as well as proven brands of manufacturing plants. Relying only on low cost can be fraught with short-lived use

Types of fittings for joining metal-plastic

Let's move on to the section: types of fittings for joining metal-plastic.

Compression fittings for metal-plastic pipes

The main part of these elements - the body - outwardly does not differ from those that are installed on pipelines made of other materials. Recently, fittings with plastic cases have appeared, as a rule, they are made of bronze or brass.

The difference lies in the design of the docking part, which provides a hermetic connection of the body with a metal-plastic pipe.

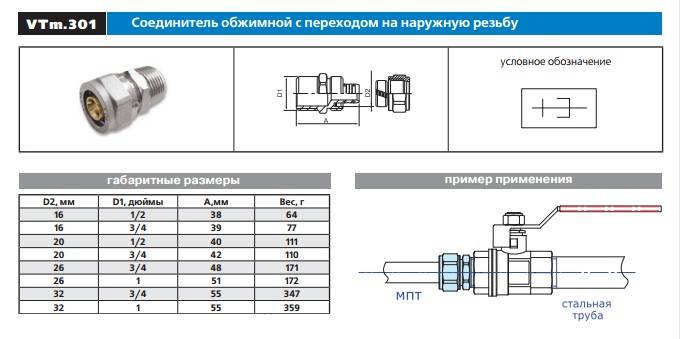

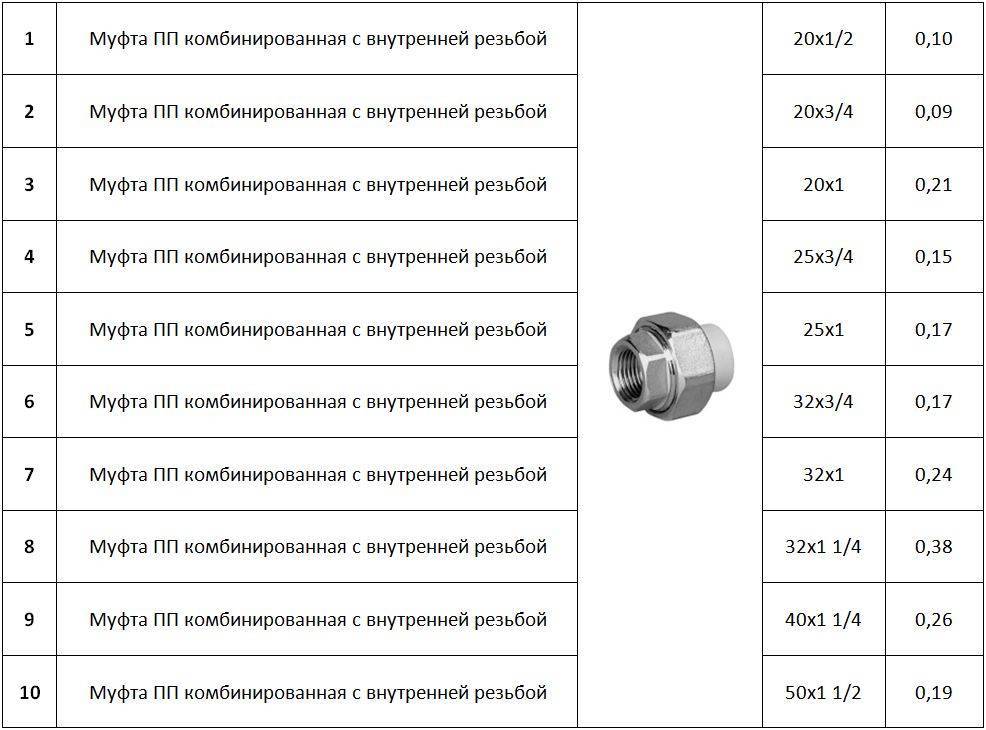

Crimp fittings

The main element of this type is a sleeve, one end of which is pressed into the body, and the other is pushed onto the outer part of the pipe. In inexpensive models of fittings, it is made of aluminum, but only stainless steel provides a good connection.

_

Element - inst. an integral part of something, an architectural, technical or mechanical component of a site, building or room, e.g. - workplace, resting place, shower, telephone booth, door, control device, handle, handrail, etc. (SNiP 35-01-2001)

The sleeve will need to be crimped with a special tool so that it fits snugly against the outer plastic layer of the pipe. The design also includes an insulating ring that prevents direct contact of the body metal with aluminum foil.

Compression fittings for metal-plastic

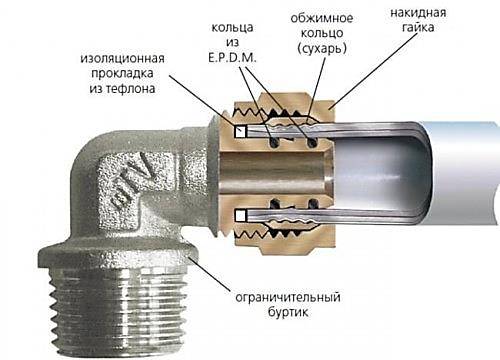

This is a more complex device that includes several elements. Its action is based on pressing the fitting to the metal-plastic pipe through a threaded connection. Its structure includes:

- Crimp ring.Provides reliable clamping to the outer plastic layer of the pipe. To do this, notches are applied on its inside.

- Gaskets. In addition to sealing the joint, they are dielectrics that prevent contact between the metal of the fitting and the aluminum foil of the pipe. They are made of polymeric materials - Teflon or fluoroplastic.

- Union. For reliable fastening inside the metal-plastic pipe, grooves are made along the circumference, on which rubber rings are put on for sealing. Made from bronze or brass. The outer part is carved.

- Cap nut. Ensuring the strength of the connection, at the same time, the metal-plastic, through the compression ring, fits snugly to the inner fitting. It is screwed onto the external thread of the fitting from the side of the pipe.

_

Device - a set of elements representing a single design (multi-contact relay, a set of transistors, a board, a block, a cabinet, a mechanism, a dividing panel, etc.). The device may not have in the product certain functional purpose. (GOST 2.701-84)

Reliability - in management, this is a property of systems to perform the functions assigned to them for a specified period of time under certain operating conditions. The N. of a system is often determined by the reliability of its least reliable link. In this connection, to improve the performance of production control systems, it is of great importance to identify bottlenecks in the administrative apparatus and to develop measures to eliminate them. Common measures for different systems to ensure the required N. are redundancy of insufficiently reliable elements, duplication, and functional redundancy.

Due to the complexity of the design, compression fittings are more expensive than compression devices.But they have undoubted advantages:

- Therefore, fittings of this type can be worn repeatedly on metal-plastic, they are collapsible elements. When reconnecting, it may be necessary to replace the seals and seals.

- For their installation, specialized crimping equipment is not allowed. To a sufficient extent, ordinary wrenches.

- No special skills are required to work with them. Anyone can create a connection.

The disadvantage of threaded contact is that over time or due to vibrations, the union nut can loosen the clamp, which will lead to leakage at the junction. But this is easily fixed with a little tightening with a wrench.

push fittings

Push connection for pipes

This even more complex design is joined to metal-plastic even without the use of tools. Therefore, fittings of this type are put on the prepared metal-plastic in a matter of seconds, the push-connection is self-clamping. you only need to cut the pipe evenly and process the chamfer with a calibrator.

To connect, the fitting is inserted into the pipe and pushed into it until it stops. For additional control, slots are provided on the outer part of the fitting. An internal click means that the clamp is made and the contact is fixed. The connection is made correctly if the outer surface of the metal-plastic pipe is visible through them.

Installation of pipelines from metal-plastic pipes

Connection methods

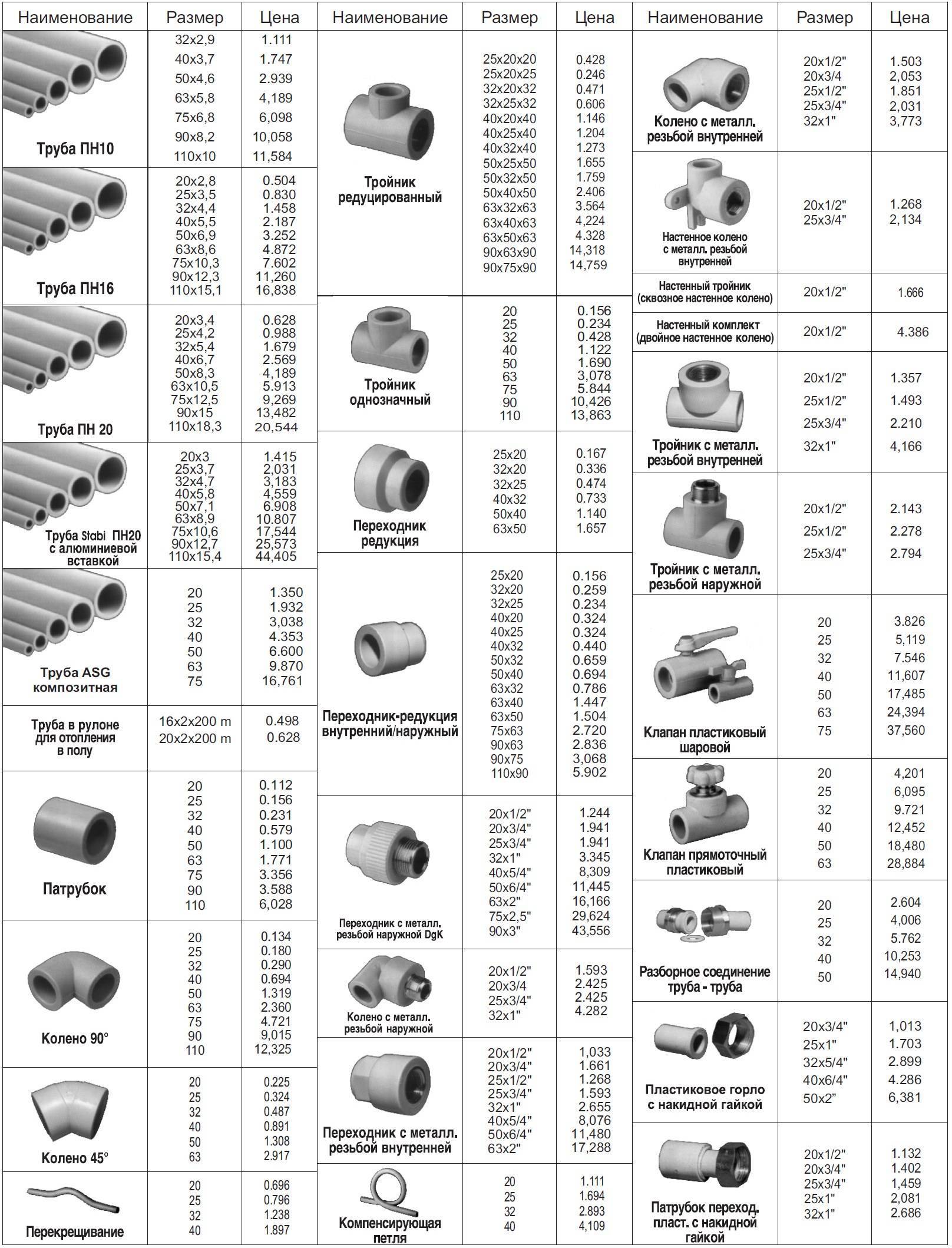

As already noted, the installation of a heating system with metal-plastic pipes is easy and does not require you to have welding equipment. The connection is made with special fittings made of metal-plastic materials, the range of which is very diverse: adapters, tees, elbows, etc.d.

Translated from English, the word “fitting” literally means “mount, adjust”, that is, fittings are connecting elements installed on sections of pipelines where pipes are joined or branched. This is a very convenient way of connecting, providing durability, high quality and reliability of heating systems. With the help of a variety of fittings, you can make a competent and qualified installation of the most complex pipe dilution schemes.

Fittings, depending on the method of fixing on pipes, are produced as glued, threaded or compression fittings. For connecting parts of metal-plastic pipeline, compression and press fittings are used.

Connecting pipes with press fittings

As a connector, press fittings are the most popular; they are used in the installation of heating, plumbing and gas supply systems. The design of these connecting nodes contains a sleeve inserted into the body, crimping is carried out with a special tool.

Press fittings provide the connection with reliability and increased tightness, while having a good appearance, and therefore the heating system from metal-plastic pipes can be laid both hidden and external. These fittings, of course, also have disadvantages. Firstly, the higher cost of products in comparison with other types, and secondly, with their help only one-piece connections are obtained that cannot be dismantled without violating their integrity.

To install press fittings on pipes, you will need a manual or electric tool - a gun, which can be purchased at specialized stores.

Press fitting technology

Connection of pipes with compression fittings

To install another type of connecting products - compression fittings, you will need the following tool:

- spanners;

- chamfer - for cleaning the ends of the connected pipes;

- pipe bender - for changing the shape of pipes;

- pipe cutter - for correcting pipe sizes.

The principle of installation of compression fittings is that the compression ring is squeezed and fixed at the junction by means of a tightening nut. Such shaped products are much cheaper and, thanks to the collapsible design, create a detachable connection, that is, they can be repeatedly used after the dismantling of the old pipeline. Regarding the negative qualities, it is worth noting the following:

- the need for periodic tightening of tightening nuts - 3-4 times a year for prevention or more often (in case of leakage from the joints);

- ensuring constant access to pipe joints - this means that it is difficult, often impossible, to hide communications with this connection method.

Technology of pipe installation with compression fittings

Instructions for installing metal-plastic pipelines

If you are laying metal-plastic pipes for heating in an apartment, make the installation taking into account several important recommendations:

- metal-plastic pipes intended for space heating must operate at a temperature of 95 ° C and at a pressure of 6.6 atm or more; to buy the right product, read the label;

- when fixing pipes on the walls, the interval between fastenings should be a maximum of 0.5 m, otherwise pipes may sag during operation, leading to a violation of the movement and circulation of the coolant;

- installation of metal-plastic pipes outside the room is undesirable, since when the heating system is defrosted, they can burst. This will lead to an emergency shutdown of the heating boiler and the need to replace the entire heating system.

Fixing the pipeline to the wall

Is it worth it to use metal-plastic pipes for plumbing

The metal-plastic water pipe is a multilayer structure, the main of which are two polyethylene (outer and inner) layers and one aluminum layer. The layers are connected to each other with a special glue. Today, metal-plastic water pipes are produced with an outer diameter of 16 to 63 mm, the most popular sizes for internal wiring are 16, 20 and 26 mm. If it is necessary to arrange external wiring for large objects, the most common diameters are 32 and 40 mm.

The metal-plastic pipe consists of 3 layers connected by an adhesive composition

In apartment buildings, it is recommended to use metal-plastic pipes with a diameter of 16 and 20 mm. From pipes of a larger diameter, the main wiring is performed, and from pipes of a smaller diameter, branches to household appliances (faucet, washing machine, toilet bowl, etc.) are made.

Scope of application

After the approval of the changes by the Ministry of Construction of the Russian Federation to SNiP 2.04.01-85, metal-plastic pipes began to be used everywhere in civil and industrial construction.They are successfully used in the organization of hot and cold water supply of multi-apartment and private houses, heating, in the reconstruction of plumbing systems, in the installation of irrigation systems, for supplying compressed air, in installations for taking water from wells and wells, for transporting various liquids, including chemical aggressive. Particularly relevant is the installation of systems made of metal-plastic pipes where it is impossible (forbidden) to use welding.

Advantages of pipes made of metal-plastic

Compared with polymer pipes, all metal-plastic pipes for water supply have a number of advantages, namely:

- low coefficient of linear expansion;

- high ability to keep the original shape;

- exceptional tightness.

Most models of metal-plastic pipes have an inner composite layer with nanosized silver particles. This improves the hygienic qualities of the pipe, since silver ions destroy harmful bacteria and prevent the deposition of various suspensions on the pipe walls. Therefore, metal-plastic pipes serve flawlessly and for a long time.

Compared with pipes made of steel, cast iron and copper, metal-plastic pipes also have a number of advantages:

- they have a lower cost;

- low operating costs (do not require maintenance and repair);

- their installation is carried out much faster (about 5 times);

- they silently convey the flow of liquid;

- they are much lighter, do not carry a significant load on building structures;

- more aesthetic;

- they are the tightest.

Elastic metal-plastic pipes withstand sub-zero temperatures, and also successfully cope with the transportation of hot (up to +90) water.They withstand water hammer and have low thermal conductivity.

With high-quality installation and careful operation, systems made of metal-plastic pipes can serve up to 50 years without the need for repair.

Disadvantages of metal-plastic pipes

With many indisputable advantages, metal-plastic pipes, like any other material, have their drawbacks. First of all, they are most susceptible to mechanical damage, especially for open communications. Even metal-plastic pipes for hot water are less resistant to high temperatures and water hammer, compared to the same metal ones.

Metal-plastic accumulates static voltage, so these pipes cannot be used for grounding.

When laying outside, metal-plastic pipes are at risk of mechanical damage, they are easy to damage even with a chopper or a shovel

Mounting units of the pipeline system made of metal-plastic during operation at low temperatures are subject to destruction.

Aging and weakening of the initial qualities of metal-plastic pipes are observed during their long-term intensive operation, especially if they are exposed to direct solar radiation or are operated at low temperatures.

How is the installation of various types of fittings for metal-plastic pipes

In translation, the word fitting means: to install, to mount. In pipelines, fittings are called connection elements at the end of pipe sections.

When installing a water supply system, the following types of fittings for metal-plastic pipes are used:

- couplings;

- adapters for threaded connection;

- tees;

- compensators;

- lap.

Professionals often use press fittings. They allow you to hermetically connect two sections of the pipe and securely fix them.

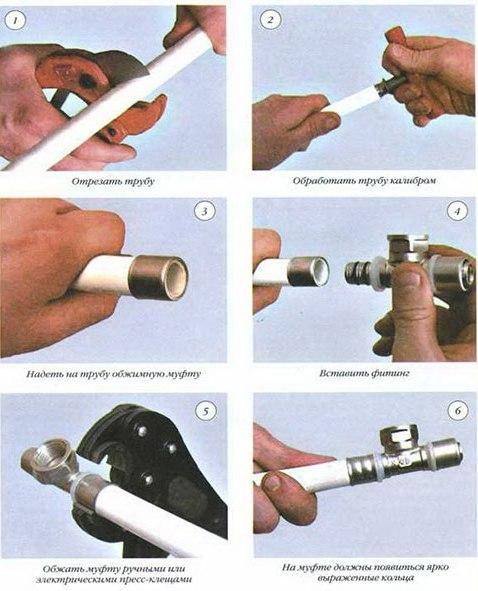

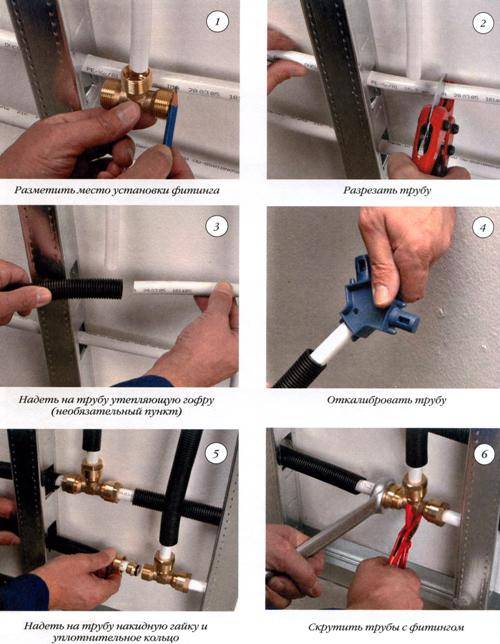

For this kind fittings use press tongs. They can significantly increase the service life of such a connection. True, in replacement if necessary fitting, it can only be cut off together with a small section of pipe and replaced with a new one. This procedure looks like this:

- the pipe is cut with special scissors;

- the end of the pipe is processed by the calibrator, the cut point is leveled and the internal chamfer is removed;

- a beveler is passed along the outer edge of the pipe;

- the sleeve is removed from the fitting and the sealing rings are inspected (for damage);

- after passing the test, the sleeve is put back in place;

- a connector fitting is inserted into the pipe;

- press tongs are placed over the sleeve and the tool handles are pressed.

One sleeve must not be crimped more than once. Therefore, if installed incorrectly, such a fitting must be replaced.

Together with press fittings, compression types of fittings are also used (they belong to collapsible types). They are a set of a union nut, bushing, rubber seals and a locking collet.

Tighten this fitting with two wrenches. You need to do this in this order:

- The pipe is pre-prepared.

- A nut is mounted on this section of the pipe, after it - a cutting ring, and then the pipe is inserted into the fitting body.

- Before tightening the nut, it is necessary to wind the FUM tape (2-3 turns from the edge of the thread, keeping the tape taut). Next, the thread is lubricated with sunflower oil for additional protection against leaks.

- The nut is turned by hand until it stops. Only after that we fix the fitting with one wrench, and with the second we tighten the nut itself.

This connection has a number of advantages:

- there is no need to use expensive equipment;

- no special knowledge and skills are needed;

- the possibility of dismantling the connection if necessary.

This type of fittings for metal-plastic pipes also has its disadvantages:

- long breaks in the use of the heating system or poor installation of the fitting can lead to loosening of the connection;

- Periodically, replacement of rubber seals is required (the frequency of their replacement is determined depending on the operating conditions of the water supply or heating system).

Due to the design features of different types of metal-plastic pipes (the difference in the properties of plastic and metal), each material in the composition of the pipe has its own expansion coefficient. Since the flowing fluid has a large temperature range, leaks occur at the joints over time. This is one of the reasons why all types of metal-plastic pipes are not mounted at a stretch.

Fasteners fix the pipe on the wall, in increments of 1 meter. The fastener is fixed with a self-tapping screw on a horizontal or vertical surface, and a pipe is inserted into it.

After installing the plumbing system, it is necessary to check it for leaks:

the mounted pipes are connected to the flexible hoses of the mixer or water heater, the integrity of the connections is visually inspected;

pay special attention to tees and other splitters (open the taps at the water intake points and slowly turn the water supply tap);

this stage of the test is best done with a partner (simultaneously with the supply of water, it is necessary to control its exit from the end points), after flushing the water supply, the end points of the water intake are closed, and the system is checked under pressure;

for clarity, you can draw a paper napkin over the joints of the system elements (to identify possible leaks).

Read the material on the topic: Types of polypropylene pipes