- Metal-plastic pipe

- Reinforced polypropylene pipes - ideal for heating systems

- Pipe structure

- Made of metal-plastic

- Made of polypropylene

- Selection of pipes for water supply

- Comparison of metal-plastic and polypropylene systems

- Working temperature

- Price

- Mounting

- Leading manufacturers

- Cross-linked polyethylene

- Polypropylene or metal-plastic, which is better Pipes and plumbing

- Types of connection for metal-plastic products

- Comparison of pipes made of polypropylene and metal-plastic

- Polypropylene pipes

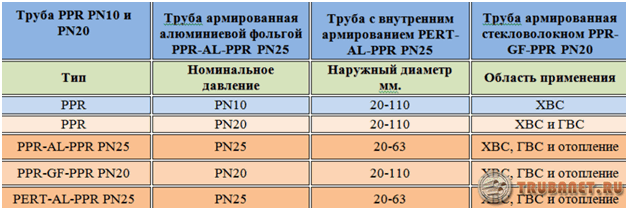

- Types of pipes

- Steel pipes

- Copper pipes

- Stainless corrugated pipes

- Polymer

- Polyethylene cross-linked

- Polypropylene

- PVC pipes

- Metal-plastic pipes

Metal-plastic pipe

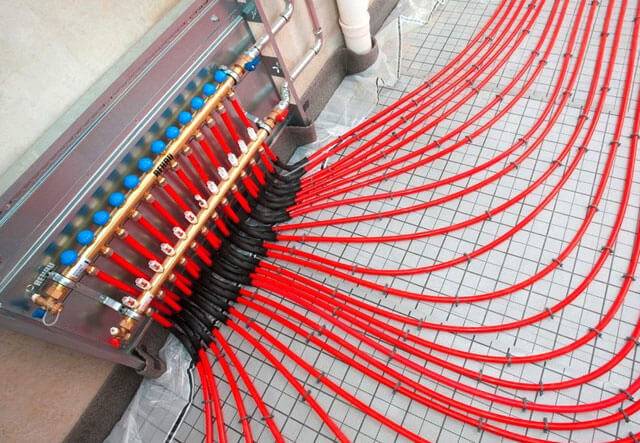

Metal-plastic pipes in the floor are a common way of arranging a warm floor. This material has several advantages:

- A combination of flexibility and strength.

- The ability to maintain a curved shape.

- A light weight.

Metal-plastic pipes for underfloor heating are a composite material (they consist of glued layers of plastic and metal). The metal-plastic pipe has three layers: polyethylene on the outside, polyethylene on the side of the inner cavity and aluminum foil in the middle.Aluminum provides thermal conductivity and is an oxygen barrier, while plastic protects the pipe from the outside and from the inside. It prevents the formation of internal deposits in the pipe cavity and protects the foil from external pressure.

The connection of the three layers with each other is made with an adhesive mixture.

It is important to know that plastic and metal have different coefficients of thermal expansion. And the adhesive composition must compensate for the difference in the change in linear and volumetric dimensions when the pipe is heated (during the passage of hot water).

Scheme of a metal-plastic pipe - Photo 08

Floor made of metal-plastic pipes - Photo 09

It is the adhesive composition that ensures the durability of the metal-plastic. With low quality glue, the pipe is stratified into separate layers of aluminum and polyethylene.

The quality of the adhesive is reflected in the price of the pipe. The better the glue, the more durable the pipe and the higher its cost. The price of one meter of a metal-plastic pipe varies from 35 to 70 rubles. per meter, this is the most inexpensive type of pipe for installing a warm water floor.

Recommendations: do not buy cheap metal-plastic pipes for underfloor heating. Focus on the indicator of the warranty service life, it should be more than 50 years.

A warm floor made of metal-plastic will heat your room for a long time, provided that a high-quality pipe is laid.

Reinforced polypropylene pipes - ideal for heating systems

Among the variety of polypropylene consumables, only some products can be used for heating systems. When asked which polypropylene pipes are best for heating, the answer is unequivocal. The best choice is reinforced polypropylene consumables.

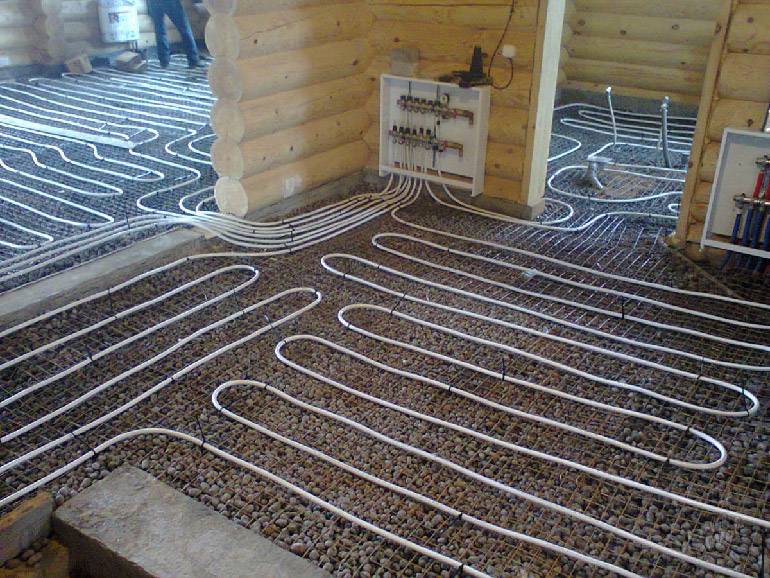

Ordinary polypropylene pipes are not able to withstand high temperatures normally. Such a line will sag due to thermal elongation and lose its attractiveness. Such products, of the smallest diameter, are suitable for the installation of low-temperature heating systems. Warm water floors with such consumables will serve for a long time and reliably. Due to the fact that in these heating systems the heating temperature of the coolant is not high, thermal elongation does not play such a critical role. In addition, the water circuit is most often walled up in a concrete screed and is less susceptible to deformation.

The remaining products manufactured and offered for sale have various applications, while reinforced products are designed mainly for hot water systems and heating. The heating circuit for a single-circuit or double-circuit heating scheme will have the best performance in all respects if it is made of reinforced polypropylene. Its marking is PPR-AL-PPR or PPR-FB-PPR, where R means random copolymer, and AL and FB reinforcing components, aluminum or fiberglass

Therefore, when buying, you should pay attention to all the inscriptions, symbols and numbers that are printed on polypropylene pipes for heating

The random copolymer has a high degree of crystallization, therefore, due to the inclusion of this compound in the polymer composition, polypropylene of high strength and stability is formed. It is this synthetic compound that is the base for the manufacture of water heating pipes. Additional reinforcement only improves the performance of consumables. It is easy to work with such pipes directly on the site, and the installation of a pipeline from PPR pipes does not require the use of special tools.

The random copolymer has a high degree of crystallization, therefore, due to the inclusion of this compound in the polymer composition, polypropylene of high strength and stability is formed. It is this synthetic compound that is the base for the manufacture of water heating pipes. Additional reinforcement only improves the performance of consumables. It is easy to work with such pipes directly on the site, and the installation of a pipeline from PPR pipes does not require the use of special tools.

In a practical plane, we can say that polypropylene pipes are used almost everywhere where there is a need to provide water or other liquids. However, multilayer products are intended for the heating circuit.

In all other cases, when a coolant with an elevated heating temperature is used, polybutene or are used. Layers in synthetic channels are either solid or perforated, i.e. in the form of a sieve, with round holes. All this is done with only one goal, to reduce the effect of high temperature on polypropylene, to reduce thermal expansion.

For example, by comparing the coefficients of thermal expansion of a conventional, homogeneous material and a pipe with an aluminum layer or fiberglass.

In the first case, the thermal expansion values will be 0.15%, while for reinforced products these figures are only 0.03%. Between pipes reinforced with aluminum foil and fiberglass, the difference is small, only 5-6%. So, both are good consumables.

The only difference is that when installing the pipeline, aluminum-reinforced products must be cleaned. For these purposes, a shaver is used. Otherwise, a strong connection of individual pipe fragments cannot be achieved. The aluminum layer in the places of future soldering is removed to a depth of 1-2 mm.

Pipe structure

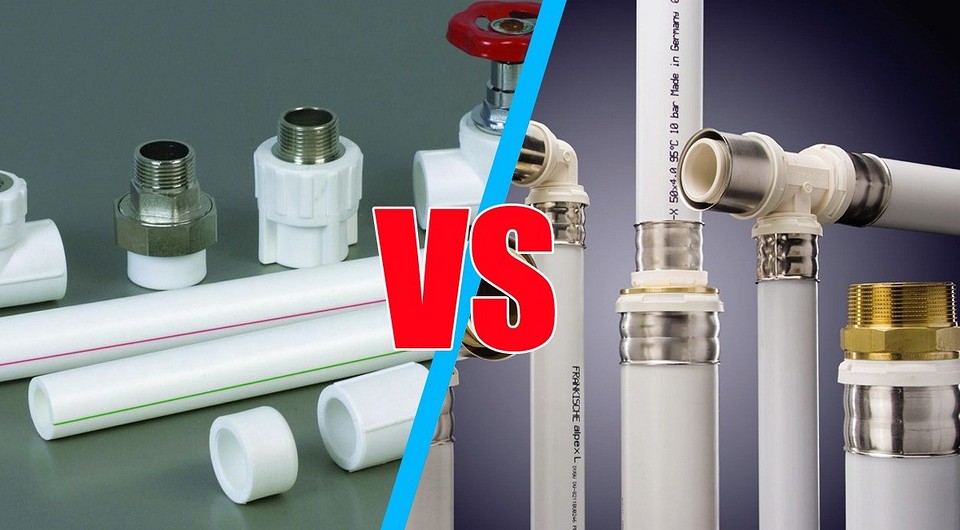

The competition of polypropylene and metal-plastic pipes is based on the similarity of the material, many of their characteristics also coincide.They differ in structure and operating conditions, as well as in the method of installation and service life.

Made of metal-plastic

Metal-plastic pipes (MP) have a three-layer structure:

- inside they are covered with very smooth cross-linked polyethylene;

- the outer layer is a protective polyethylene;

- in the middle - an aluminum layer with a thickness of 0.2 to 1 mm, which reduces thermal expansion.

The diameter of products ranges from 10 to 63 mm on the inside. They bend perfectly (bend diameter 80-500 mm), have more weight than polypropylene (PP), can be covered with perspiration. Cheap products from unknown manufacturers often delaminate at the folds during water hammer. The service life of metal-plastic in hot water conditions is 25 years, and for a cold branch - 50 years.

When choosing any pipes, it is better to give preference to well-known manufacturers.

Made of polypropylene

Polypropylene products are of two types:

- single-layer is a monolith;

- three-layer - a thin layer of perforated foil or fiberglass soldered between the layers of polypropylene.

The size of pipes for domestic use is 10–40 mm, but products up to 1600 mm are produced. The service life of PP for cold water supply is 100 years, and for hot and heating - 50 years. These pipes do not bend, are sold in straight lengths up to 3 m and are not covered with condensate, but they have a higher coefficient of thermal expansion and elongation.

Polypropylene pipes do not bend, so special connections must be used to arrange turns

Selection of pipes for water supply

Polypropylene piping components are a practical and relatively inexpensive option for laying plumbing in homes.

To supply cold water, a simple version of polypropylene pipes without special layers that reinforce the element is suitable. These are inexpensive single-layer pipes without reinforcement. Feel free to choose them.

PPH single-layer pipe made of solid homopropylene, durable, withstands heating up to 60 ° C, higher temperatures are not recommended

PPB is a single-layer pipe made of flexible block copolymer, resistant to defrosting.

PPR single layer random copolymer pipe, more durable and resistant to temperature rise, recovers after defrosting.

They differ in diameter - from 20 to 40 mm, and shell thickness - from 1.9 to 6.7 mm. The thickness of the sheath is indicated by the parameter PN10 or PN20. These parameters affect the hydrodynamic properties of the system and the throughput of the water supply. Pipes ⌀ 32 mm are connected to the central water supply, ⌀ 16 - 25 mm is enough for internal communications.

For hot water supply, it is possible to choose the connection of single-layer inexpensive polypropylene pipes:

- PPR, PPRC from a copolymer of propylene and ethylene - coolant t less than 70 gr.С

- PPS - made of special polypropylene - heating not more than 95g.C

However, for greater reliability, it is worth using reinforced pipes. Experts recommend pipes reinforced with fiberglass:

PPR-FB-PPR - propylene, laminated with glass fiber

PPR/PPR-GF/PPR is a three-layer pipe, internally and externally made of polypropylene, the middle layer is made of a composite material in which glass fiber is distributed in a polypropylene matrix. A colored intermediate layer on a light background is a distinctive external feature of these pipes.

They are produced, for example, by the Italian-Chinese company Valtec and the Russian company Kontur. They are superior to aluminum-coated options in a number of ways, they are easier to install, do not need to be cleaned during assembly, they do not swell during operation and do not collapse from the inside.

Meanwhile, aluminum pipes are impermeable or almost impermeable to oxygen.

This is an important property, since oxygen, saturating the coolant with bubbles in water, creates the so-called cavitation processes in all metal components of the water supply system. They destroy the walls of pumps, valves and other parts

Comparison of metal-plastic and polypropylene systems

The final choice in favor of a particular material should be based on a comprehensive assessment. Here it is impossible to say unambiguously what is better and what is worse.

Working temperature

Metal-plastic pipes withstand high temperatures and pressures, which is especially important for heating. However, with differences in these parameters, the fittings begin to leak.

Properly mounted polypropylene pipes are a single monolith and do not leak. However, they have a smaller operating range. And if there is a risk of running superheated water into the hot water supply or heating system, it is better not to use them.

Price

The cost comparison also looks ambiguous. Metal-plastic itself is cheaper than polypropylene, but all connecting parts will cost two to three times more. The high cost of fittings can be partly offset by the relative flexibility of the piping.

Mounting

Requirements for installation and spatial orientation of polypropylene pipes are more stringent. The condition of coaxiality between the pipe and the fitting must be strictly observed.

If the parts to be joined are not fixed correctly, it is possible to correct their relative position after melting only within 3-4 seconds. During this time, the frozen material does not have time to seize and harden.

The indisputable advantage of the metal-layer, due to which it is very often preferred, is the undemanding to the presence of special tools. In the simplest case, all work can be done with two keys and a hacksaw, which is in the arsenal of almost any master.

Leading manufacturers

The main task of any heating heating system is to create comfortable conditions in the room during the cold season.

Navigating brands and trademarks of polypropylene products is difficult even for specialists. To simplify a little the difficult choice of the right material and not make a mistake in the chosen product, we offer a top list of the best manufacturers of propylene heating pipes:

- The first place belongs to European brands. An example is the German brands Aquatherm (Aquaterm). Wefatherm (Vefatherm). Rehau (Rehau), whose products are of excellent quality and perfect manufacturing technology. The only drawback of this product is the high price.

- The second place is occupied by Czech manufacturers. Many experts note the quality of EKOPLASTIK brand products. This company was the first to launch the production of polypropylene pipes reinforced with basalt fibers, capable of competing with the best German brands in terms of quality and lower price.

- The third place belongs to the well-known Turkish companies Tebo and Kalde, which produce products of average quality and affordable price.Heating systems assembled from pipes and fittings of these brands are designed for an average service life of up to 50 years and, from a practical point of view, have no complaints.

The budget segment is represented by a line of the best Russian manufacturers PRO AQUA (Pro Aqua) and RVC, as well as the Chinese brand BLUE OCEAN. Firms have gained a good reputation and produce products of normal quality with an affordable price.

In order not to make a mistake in choosing polypropylene pipes and not to buy a fake of a well-known brand, you should carefully read the company logo on the official website, check the accuracy of the company name

It is necessary to pay attention to the evenness and smoothness of the surface, check in practice the coincidence of the connecting fittings with the pipeline

Cross-linked polyethylene

Thanks to modern technologies, such a seemingly fragile material as polyethylene has been made suitable for the production of pipes. In ordinary polyethylene, hydrocarbon molecules are not connected in any way, but in a new material (PEX, or cross-linked polyethylene), hydrocarbon molecules are connected through the interaction of hydrogen and carbon atoms. Additional high pressure treatment makes the material even more durable

The production of cross-linked pipes for underfloor heating has become widespread only recently, although the technology itself was developed about 40 years ago. The new material has characteristics that are not inherent in its predecessor. In particular, cross-linked propylene for underfloor heating is characterized by high mechanical strength, that is, it is not afraid of scratches and does not wear out, and is resistant to temperature fluctuations.Mainly, the technique and the degree of its crosslinking affect the properties of the material.

When deciding which cross-linked polyethylene to choose for a warm floor, you should pay attention to the material with a degree of cross-linking of 65-80%. This indicator will affect the strength and durability of products, but at the same time, their price will also increase.

True, the extra costs at the installation stage will pay off in the future due to the reliability and long service life of the pipes.

With a low degree of crosslinking, polyethylene will quickly lose its original qualities, crack under the influence of external factors and require replacement. However, no less significant is the method of creating molecular bonds.

There are 4 types of stitching:

- peroxide;

- silane;

- nitric;

- radiation.

When choosing which pipe to make a warm floor from, take a closer look at its marking. The highest quality is PEX-a, although it is the most expensive. But pipes with the PEX-b marking, sewn by the silane method, are in high demand. They have a relatively low price along with good performance properties.

This material has other advantages, in particular:

- The ability to fully work at temperatures from 0 ℃ to 95 ℃.

- Cross-linked polyethylene begins to melt only at a temperature of 150 ℃, and it burns at 400 ℃, so it can be successfully used in underfloor heating systems.

- The so-called "molecular memory" is inherent in pipes made of cross-linked polyethylene, that is, after increasing the temperature of the material, any possible deformations are smoothed out, and the products themselves take on their original shape.

- The good resistance of products made of cross-linked polyethylene to pressure drops in heating systems is another argument in their favor at the time of deciding which pipe to take for a warm floor. Depending on the characteristics, such pipes can maintain a pressure of 4-10 atmospheres.

- PEX pipes are characterized by good ductility, so even with repeated bending in the same place, they do not break.

- Cross-linked polyethylene is biologically and chemically stable. This means that bacteria and fungus do not multiply on the inner surface of the pipes, and the material itself does not react with an aggressive environment and does not corrode.

- The chemical composition of cross-linked polyethylene is absolutely safe. It does not emit toxins, and at the time of combustion it decomposes into carbon dioxide and water.

The recommended operating temperatures for XLPE pipes are 0-95 ℃, but for a short time the range can expand to -50 - +150 ℃, and the material will not burst and remain strong. However, such increased loads lead to a reduction in the service life of the material.

Some users confuse heat resistant polyethylene pipes with PEX products. It is not correct. Indeed, heat-resistant polyethylene is able to function at high temperature values, however, in all other qualities, it lags far behind crosslinked. PEX pipes are able to resist aggressive external factors much longer, but their price is higher. And their installation does not require sophisticated equipment and is available to every consumer.

So, if you are in doubt about which pipes are needed for underfloor heating, you can safely stop at products made of cross-linked polyethylene.Moreover, their characteristics make it possible to use such pipes even for radiator heating and hot water supply. The only limitation is to minimize the impact of direct sunlight on the material, although it is not relevant for a warm floor.

In order not to damage the outer anti-diffusion layer on the pipes, their transportation and installation should be carried out very carefully. Violation of the integrity of the protective coating will lead to a decrease in the durability of the pipe due to the ingress of oxygen into the structure of the material.

Polypropylene or metal-plastic, which is better Pipes and plumbing

- Metal-plastic pipes

- Types of connection for metal-plastic products

- Polypropylene pipes

- Advantages of polypropylene products

- Connection types for polypropylene products

- Comparison of pipes made of polypropylene and metal-plastic

Gradually, polypropylene and metal-plastic pipes replaced the usual cast-iron and metal pipes in the heating system. Their popularity among consumers is explained by a long service life, high reliability, ease of installation and practicality in use.

Heating scheme with plastic pipes: 1. Copper tube wrapped around the stove exhaust; 2. Metal pipe; 3. Expansion tank with a valve for bleeding air; 4. Plastic pipes for heating; 5. Radiator.

During the construction of a house, as well as during the overhaul of an apartment, it is advisable to use high-quality heating heating systems, but today there is a large supply of materials on the construction market. In such a variety of goods it is quite difficult to decide and make the right choice. Which heating pipes to choose, which is better: metal-plastic or polypropylene?

Types of connection for metal-plastic products

- detachable fittings, which are also divided into threaded or collet fittings. Detachable fittings allow multiple disconnection of the system from the device or other fitting, so these fittings are the most expensive;

- conditionally detachable fittings, that is, compression. Compression fittings are very difficult to disengage. If there is a need for undocking, then another replacement of the ferrule will be required. Disconnection of the fitting is carried out only in a serious situation, in case of emergency;

- one-piece or press-fitting. This type of connection cannot be dismantled, since the pipes are pressed into them completely, without the possibility of separation in the future.

Scheme of a pipe made of plastic material.

The first two types of connection of metal-plastic products have a threaded connection, therefore, access to the connection point should be provided for preventive maintenance during the operation of the system.

Since the connection with a press fitting is permanent, it is more practical to immediately close it under the monolith.

The only drawback of metal-plastic heating pipes is that they are not resistant to ultraviolet rays. It is recommended to protect metal-plastic and products from it from direct sunlight, mechanical damage and exposure to open flame and possible sparks. Therefore, manufacturers provide a hidden protective gasket in the metal-plastic heating system.

Comparison of pipes made of polypropylene and metal-plastic

A visual diagram of a metal-plastic pipe for heating.

Today, polypropylene and products made from it are in great demand due to a number of advantages compared to metal-plastic products. First of all, polypropylene pipes differ in the way they are connected.

So, thermal welding makes it possible to create a monolithic joint, which in structure becomes the same as the product itself.

For welding, a welding machine is used, or, as it is also called, a soldering iron.

Metal-plastic pipes are connected without welding, using a press fitting, in which case a special tool is required. And in the way of a compression fitting, this work can be done with a simple wrench. But the connection itself is already obtained non-monolithic. At the same time, metal-plastic can be bent if necessary, and when connecting polypropylene, tees and corners are used.

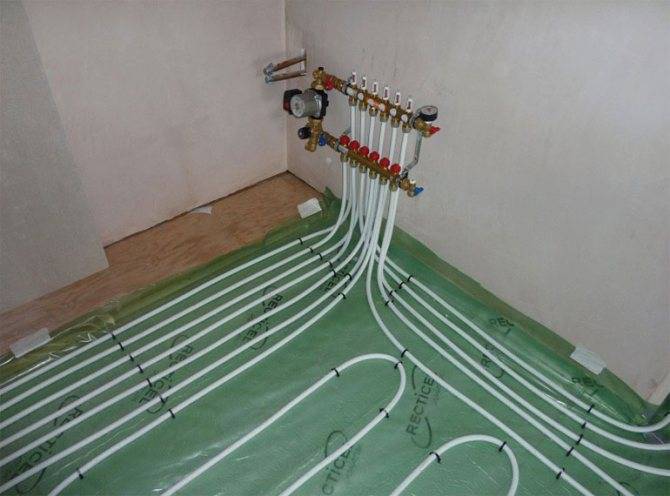

In terms of reliability, polypropylene is the leader, because its connections can be concreted into walls and floors.

Polypropylene pipes

Polypropylene pipe (PN marking) is available in the following types:

Thus, a warm floor made of polypropylene pipes can be made exclusively of two types - PN20 or PN25.

Polypropylene pipe of the third type

Distinctive features of pipes made of polypropylene are:

Polypropylene pipe reinforced with aluminum foil

The disadvantages of this type of pipe are:

low temperature level. The manufacturers state that the pipe can withstand temperatures up to 95ºС, but at the same time, the value at 80ºС is optimal. Reducing the recommended temperature regime leads to the need to install additional equipment; installation difficulty.

As a rule, pipes are produced in small lengths.To connect individual pipes into a whole water circuit, welding is required. This reduces the service life of the finished structure.

In addition, polypropylene pipes are characterized by low elasticity. It is impossible to bend them into a small radius; a high degree of expansion when exposed to temperature.

When using pipes for hot water supply, special expansion joints are installed on the surface, but in the manufacture of a water floor, the installation of expansion joints is not possible, which leads to a decrease in the service life of products.

Types of pipes

The water circuit is the main part of the water floor design. The choice of material from which the pipes are made will determine how long the floor will last.

Consider the most popular options, paying special attention to the metal-plastic version

Steel pipes

It would seem that this is a fairly popular option. Reliable, strong, endowed with a long service life. However, this type is categorically not compatible with the underfloor heating system.

Steel pipes for underfloor heating

The steel is quite heavy, and together with the rest of the elements, including the coolant and the concrete screed, this will create tremendous pressure on the floor slabs.

The use of steel pipes is allowed only for connecting the boiler room and the distribution manifold cabinet, but in no case for laying the circuit.

Copper pipes

Still not ideal, despite the pros. Copper heats up well and gives off heat, does not corrode, copper products are ductile and very durable, and are not afraid of temperature changes. But for the installation of this copper circuit, special equipment and skills are required, and the price is very high for the material.

Stainless corrugated pipes

They have a number of qualities acceptable for installation. Products are flexible, durable, do not corrode, resistant to aggressive environments, and such pipes are connected much easier than other types. They can not boast only very high prices.

Polymer

Good choice for installation. Products serve from 20 to 35 years, are resistant to adverse environments, are made of environmentally friendly materials, do not transmit noise, and also have an increased ability to pass water.

Inferiority of products in the use of a large number of elements in the composition. It includes: polyethylene, PVC, chlorinated PVC, reinforced aluminum PVC, polybutene.

The components create a temperature maximum of 95°C, which is not good for underfloor heating. To regulate the heating, you will have to install automatic control equipment.

Polyethylene cross-linked

Polyethylene materials are most suitable for underfloor heating systems. Strong, reliable, very flexible. UV-resistant, do not deform due to exposure to aggressive substances. Equipped with a sound-absorbing surface.

Assembling a polyethylene pipeline will not be a problem. The connection can be one-piece and detachable. Detachable are fastened with brass fittings, one-piece are connected by fittings and special couplings.

Polypropylene

They are considered a good option along with polyethylene. They have a set of qualities approximately similar to the previous types, and are additionally endowed with heat resistance.

However, the material is unstable to ultraviolet, short-lived at the junction with metal pipes.

In addition, it is allowed to connect them only at positive temperatures, and they are connected by welding.This is also considered a disadvantage, since most people simply will not be able to competently weld the circuit.

PVC pipes

Endowed with a low maximum heating limit of 75°C. Such a mark is not suitable for a warm floor, therefore the material is reinforced by chlorination, which is unacceptable, since when heated, vapors that are caustic to the human body will be released. In addition to chlorination, reinforcement is used to also increase heat resistance. There are 2 types of reinforced PVC pipes:

- reinforced aluminum housing is located in the middle of the structure;

- reinforcement frames the second layer after the outer one;

Metal-plastic pipes

One of the leading options for laying the contour of the water floor along with polyethylene and polypropylene. Excellent heat transfer with high-quality space heating is supported by a service life of up to 45-50 years. In addition to this product are endowed with:

- simple installation;

- lack of corrosion;

- resistance to temperatures;

- small price;

- smooth inner surface;

- increased strength;

Minuses:

- during installation, you need to use a special type of fitting;

- connections can be destroyed due to a layer of scale;

- possible delamination of the pipe contour.

Metal pipes for underfloor heating

![[instruction] do-it-yourself toilet installation | video](https://fix.housecope.com/wp-content/uploads/e/0/5/e05c3aaa569c15a65a76abf551b1139c.jpg)