- 1 Copper pipes for water supply - technological features and advantages

- Connection methods

- Mounting

- How to solder copper pipes, step by step instructions

- Connection preparation

- Flux application

- Soldering

- Varieties of copper products

- By appointment

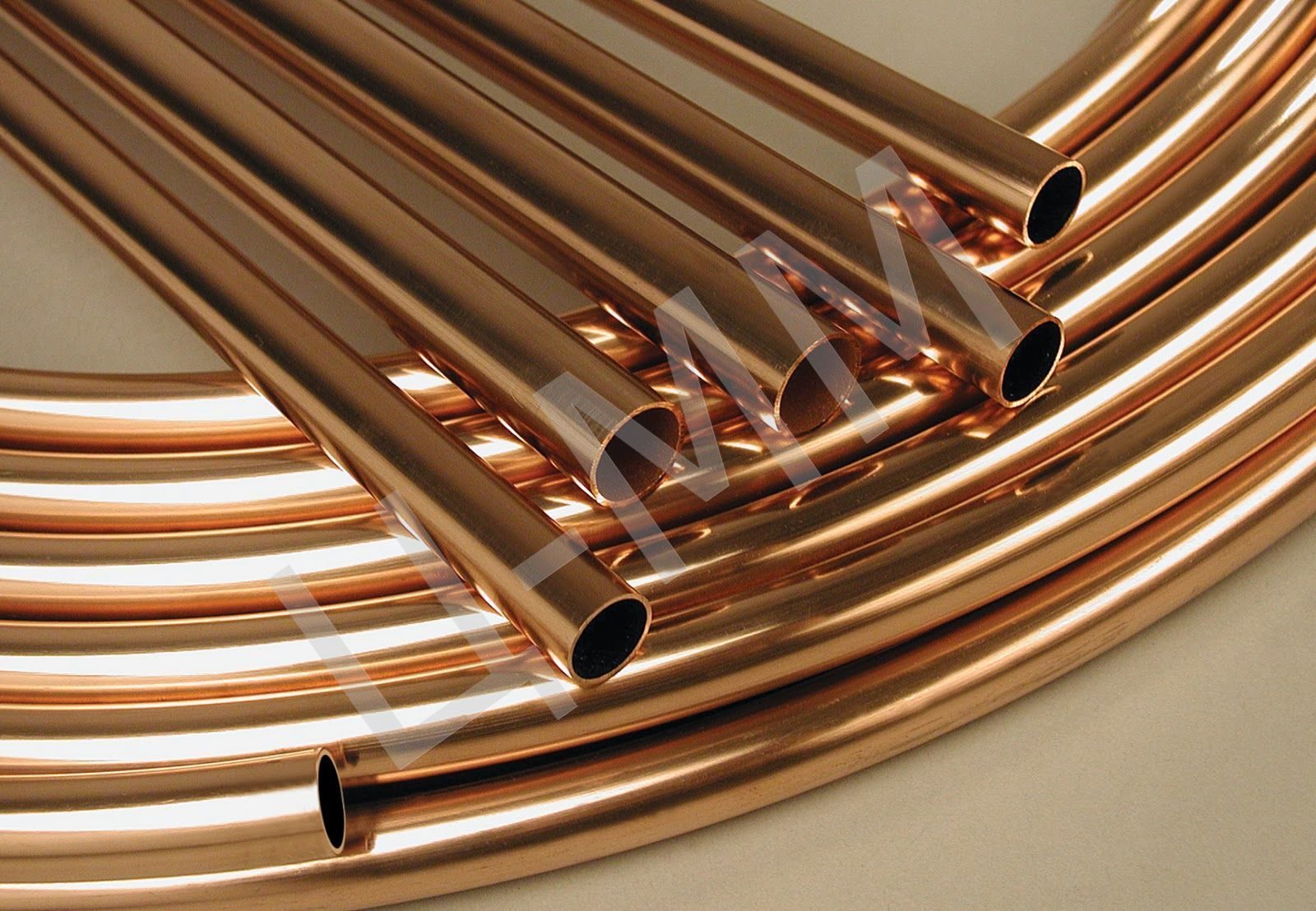

- According to the manufacturing method

- By section shape

- According to the degree of hardness

- Winding types

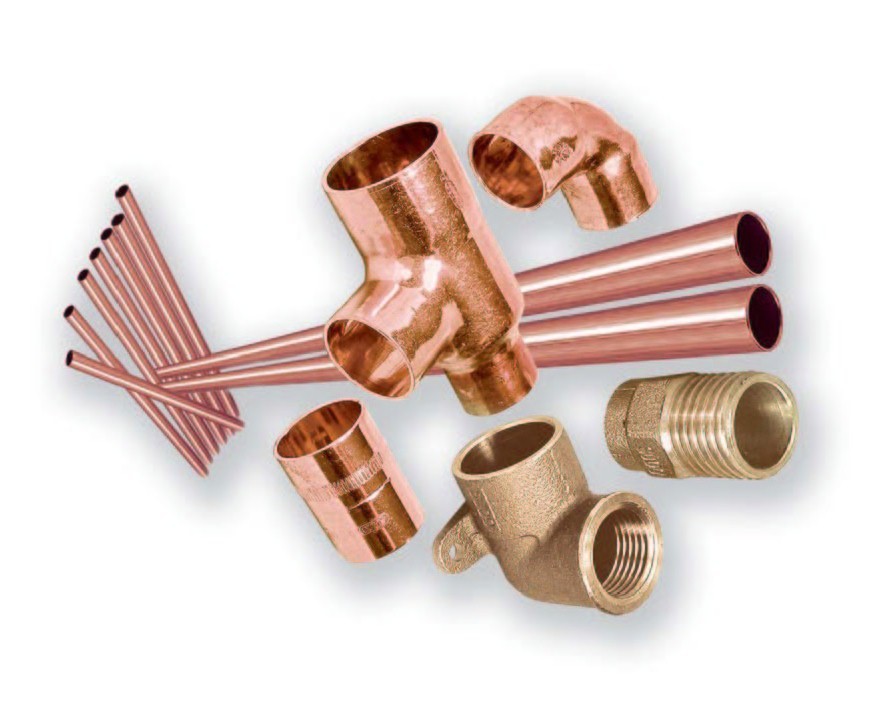

- What fittings are on the market?

- Option #1 - compression elements

- Option #2 - capillary fittings

- Option #3 - press fittings

- Types of fitting products

- The nuances of mounting and soldering pipes of all diameters

- Do-it-yourself step-by-step work in 7 steps

- Specifications

- Pipe classification

- Regulatory requirements

- Installation of copper pipes for water supply

- Necessary tools and materials

- Work progress

- Mounting Features

1 Copper pipes for water supply - technological features and advantages

First of all, copper pipes for plumbing attractive for their strength. Solid products with a diameter of 12 mm, having a wall thickness of only 1 mm, are designed for a working pressure of 100 bar at a temperature of 250 °C. Copper pipeline on fittings, assembled by hard soldering, withstands maximum loads of more than 500 atm and temperatures up to 600 °C. Many materials become brittle as the temperature drops.Copper is an exception - the strength and ductility of this metal increase with decreasing temperature.

This property ensures the admissibility of repeated freezing and thawing of copper pipes (depending on the hardness of the products up to 3 times). Even if an accident occurs, it is only in one place, unlike steel pipelines, in which the gust spreads throughout the pipe. Therefore, the elimination of the consequences of freezing copper products is not difficult, and the steel system must be completely replaced.

Copper pipes are easy to machine and very technologically advanced in any part of the installation: when passing holes, bending around corners and other obstacles, installing equipment, mounting a branch on an already finished pipeline. For all work, a simple mechanized and manual tool is needed.

Copper systems are universal - fittings and pipes of the same standard are used for all types of utilities. This ensures the use of a single installation method and the same equipment. The most common and most reliable method of joining copper pipes is capillary soldering. The soldering width, even with small diameters, is not less than 7 mm and gives the installation strength higher than that of known connection methods, including any type of welding.

During the tests, there was always a break in the body of the pipe, and the tightness of the joints, including the serviced ones, was never broken. Capillary soldering allows quick and easy assembly. Its advantages are especially evident when compared to welding, which requires greater precision and care when working with plastic pipes, or bulky equipment in the case of steel systems.

In addition to connections of high durability and reliability (pressing, soldering, welding), there are also those that do not require special skills and tools - using fittings for quick installation in case of accidents, as well as in non-pressure systems (self-locking, compression, and so on). This provides efficiency and flexibility in the work of the installer. It is forbidden to thread copper pipes, but combination fittings allow a simple transition to threading by pressing or soldering.

Due to the plasticity of copper, it is possible, using a mechanized or manual expander, to connect pipes by capillary soldering without the use of fittings. This makes it possible (in some cases significantly) to reduce the cost of the system during its installation. The fitting method of connection provides guaranteed stability of parameters and reliability of the system.

It is permissible to embed a copper pipeline in walls and floors, if products are used in insulation, corrugated pipe, shell, where thermal expansion is provided due to fluctuations in the temperature of the supplied water, or mounted in a box. Serviced connections must not be monolithic without providing access to them. When laid open, copper pipes are very aesthetically pleasing, can be painted, but require an arrangement that prevents the risk of accidental damage.

Connection methods

Installation of these products can be done in two ways: by threaded connection or by soldering. Copper and alloys formed on its basis can be joined by both high-temperature and low-temperature soldering.

For water supply systems, low-temperature soldering is mainly used using various solders, with the exception of lead-tin.They contain a large proportion of lead, which cannot be used. for soldering drinking water pipelines. For the assembly of such systems, it is better to choose tin-copper or silver-containing solders. They create a seam of good quality and meet all the requirements for strength, reliability and durability of plumbing systems. As a flux, you can take rosin - vaseline paste, which includes rosin, zinc chloride and technical vaseline. It has an easy-to-apply paste-like consistency.

Mounting

Installation of copper pipelines is carried out using special connections - fittings or using welding. Through press or collapsible fittings, the pipes are firmly joined to the elements of the heating system, however, welding is most often used. When installing annealed copper pipes in places where it is necessary, they can be bent so that the total number of joints and joints is reduced. For this, a pipe bender is used, thanks to which it is possible to obtain the necessary slope without compromising the overall patency of the system.

Installation of compression fittings does not require special equipment: the pipe is simply inserted into the groove until it stops, and then it is tightly screwed with a nut, while the material itself should be pressed against the fitting body. In order to achieve maximum fit and complete sealing, two keys must be used. That's all the equipment you'll need. However, one should not forget about the specifics of crimp fasteners, which involves complete control of tightness - such systems periodically begin to "drip", which is why the joints should not be walled up, access to the pipes should be open.

Press fittings are installed using special press machines, this is a rather expensive installation option, however, the connection is strong and reliable, but one-piece. Experts note that capillary soldering is considered the most universal method of installing copper pipelines; this method allows you to connect pipe segments of the same diameter to each other. To do this, flaring is performed at one of the ends, that is, its diameter is slightly increased, this allows you to insert one pipe into another.

The joint is cleaned with a special sponge or a metal brush, and then the joined surfaces are covered with flux - this is a special composition that provides maximum adhesion of the metal to the solder. Pipes treated in this way are sequentially inserted into each other so that the gap between them does not exceed a fraction of a millimeter. Next, the solder is heated with a welded torch, and when the material reaches the melting temperature, all the gaps that have arisen are poured with the molten composition.

After the seam is filled, it must be cooled, for this you can lower the joint into the water, or you can simply leave it in the open air. In general, this process, like repair, is quite simple, however, it requires accuracy, thoroughness and compliance with safety regulations. Copper pipes are aesthetically pleasing, but sometimes users paint such products so that the piping matches the overall concept of the interior.

It is very important that the paint used for this meets the following conditions:

- the coating should not change color under the influence of high temperature;

- paint must reliably protect against any type of external influences;

- even minimal peeling is unacceptable.

It is advisable to coat the pipes with a primer before applying the paint, experts recommend using a lead-red lead composition. Keep in mind that the paint does not absorb into copper, so you need to spread it very carefully with a brush. And even in this case, a more or less even coverage can be achieved only after 2-3 layers. However, you can also use paint from a spray can, it lays down much more evenly.

How to connect copper pipes with your own hands, see the following video.

How to solder copper pipes, step by step instructions

Step-by-step work allows you to get high-quality connections. When performing the process, you do not need to rush, you must follow all the rules and recommendations.

Connection preparation

At the first stage, the necessary parts of the required dimensions are prepared. For cutting, a pipe cutter is used, which must be located strictly perpendicular to the pipeline. First, the pipe is clamped in the tool bracket between the blade and the support rollers.

The cutter rotates once or twice around the segment to be cut.

The cutter rotates once or twice around the segment to be cut.

Then the screw mechanism is tightened. After that, the cutting process is repeated. Such actions are carried out until the final cutting of the pipe occurs.

To prepare parts of the required size, you can also use a hacksaw with a metal blade. However, it is not always possible to perform an even cut with such a tool. Moreover, when using a hacksaw, a lot of metal filings are formed.

Therefore, you have to pay great attention so that they do not get into the system.After all, sawdust can cause damage to expensive equipment or congestion in engineering communications.

The pipe cutter allows you to get a straight cut. Then burrs are removed from the end of the pipe.

The pipe cutter allows you to get a straight cut. Then burrs are removed from the end of the pipe. The inner surface of the product is cleaned and degreased. The same actions are performed with the second segment.

The inner surface of the product is cleaned and degreased. The same actions are performed with the second segment.

At the next stage, a pipe expander or rolling is used. It allows you to increase the diameter of one of the segments so that the parts can be connected. The gap between them must be 0.02-0.4 mm. At smaller values, the solder will not be able to seep into it, and at larger sizes, there will be no capillary effect.

Flux application

The flux is applied in an even layer in a minimum amount on the outer surface of the product that is inserted into the connected segment.

The operation is performed with a brush. It may be included in the reagent kit.

The operation is performed with a brush. It may be included in the reagent kit.

In its absence, a paint brush is used. It is necessary to use a tool that does not leave fibers.

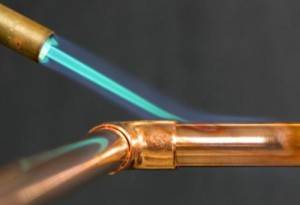

Soldering

The process begins with the connection of pipeline parts. It is performed after using the flux.

There should be no foreign matter on the moistened surface.

There should be no foreign matter on the moistened surface.

When the pipe and fitting are connected, the last element rotates until it is completely put on the pipeline segment. This action also allows the flux to be distributed throughout the area to be joined. If a consumable comes out of the gap between the parts, it is removed with a napkin or cloth, as it is an aggressive composition of chemical origin.

The low-temperature soldering process begins with the burner turning on. Its flame is directed to the place to be joined and constantly moves along the joint for its uniform heating.After heating the parts, solder is applied to the gap between them. The consumable will begin to melt if the junction has been sufficiently heated. At this point, the torch must be removed from the joint because the consumable will fill the gap. Soft solder does not need to be specially heated. The melting of the consumable material occurs under the influence of heat from the heated parts.

Soft soldering of copper pipes

Soft soldering of copper pipes

Connections of pipeline elements are made with constant control of copper heating. Metal must not be overheated! If this rule is not followed, the flux will be destroyed. Therefore, oxides are not removed from the parts. As a result, the quality of the seams is reduced.

Hard soldering begins with uniform and rapid heating of the parts to be joined. It is carried out using a flame of bright blue color of moderate intensity.

Solder is applied to the joint when the elements are heated to a temperature of 750°C. It reaches the desired value when the copper becomes a dark cherry color. For better melting of the solder, it can be additionally heated with a torch.

After the seam has cooled, the joint is wiped with a cloth to remove flux residues. Otherwise, the substance may cause the destruction of copper. If solder has formed on the surface of the pipeline, it is removed with sandpaper.

Varieties of copper products

At the moment, there are several varieties of copper tubes. Below are the main ones.

By appointment

The following tubes are used for their intended purpose:

- for furniture - made of chrome - 25 mm;

- for commercial equipment - an oval product - 25 mm;

- in the manufacture of furniture supports - 50 mm (bar);

- for the kitchen room - 50 and 26 mm (railing and bar).

In the manufacture of furniture, furniture chrome-plated pipe is used. It is used in the main furniture structure - as a metal bar. Unlike round, it has a rectangular cross section. The most commonly used profile is 40*100, 40*80, 50*50.

It is installed only on a flat surface, and also used in repairs and in car factories - when creating a strong frame.

According to the manufacturing method

Depending on the manufacturing method, such copper tubes are used as:

Unannealed copper piping. It is made of pure metal using stamping.

It has high tensile strength. In this case, the metal becomes less ductile, after which there are some restrictions on the use of such a tube.

Annealed copper pipes are plastic, this quality facilitates the installation process

Annealed copper pipe. It goes through a special processing technology. It is heated to 700 degrees Celsius and then cooled down. In this case, the pipeline elements become less strong, but more flexible.

In addition, they stretch well - before breaking, their length increases by 1.5 times.

Annealed piping products are softer, so their installation is faster and easier.

By section shape

By section shape allocate:

- round water pipes;

- pipeline elements having the shape of a rectangle. They are used to create conductors in the stator winding of electrical equipment, which is cooled by a liquid method.

The dimensions of copper pipes can be determined by the outer diameter, which is 12–267 mm. In this case, any pipe size has a certain wall thickness equal to 0.6–3 mm.

When conducting gas to houses, pipes are used that have a thickness equal to 1 mm at least.

When installing plumbing, in many cases a copper plumbing pipe is used, which has such sizes as: 12, 15, 18, 22 by 1 mm, 28, 35, 42 by 1.5 mm and 52 by 2 mm.

According to the degree of hardness

According to the degree of hardness, copper tubes are used, such as:

Soft. The designation is M or W. They are able to withstand expansion without cracking and tearing when the outer diameter expands by 25%.

Such pipeline products are used when a heating system is being created or pipelines are being laid for the water supply of consumers. At the same time, a beam distribution of the piping to plumbing and heating devices is made.

Soft pipeline elements in most cases are used in the construction and repair of water pipes. Their connection is considered the simplest - docking can be done without the use of additional equipment.

Copper pipes can withstand the high temperature of the liquids transported through them

Semi-solid. They have the following designations - P or NN. Such pipeline products are able to withstand expansion with a diameter increase of 15%.

When they are installed, heating is used to connect the tubes without the use of fittings. For bending or unbending semi-solid products, a pipe bender for copper pipes is used.

Solid. They are designated by the following letters - T or H. When they are installed, distribution is done only during heating. In order to bend the pipe, use a pipe bender.

The last 2 types of copper products are used in the construction of various highways.

Also, such parts are used in the construction of a pipeline, which should have increased mechanical strength.

The sealing of such tubes is considered an important process. After all, their undocking can occur at any time - for example, when the sealant is depleted. In the event of such a situation, it will be necessary to completely redo the joints.

Winding types

Manufacturers use different types of windings for copper pipes:

- FUM tape. This tape is used in all types of threaded connections;

- curing sealant for plumbing. Such material is used both at various enterprises and in everyday life;

- homemade sealant for plumbing. The pipes that are installed in the houses of the 1940s do not leak.

Also, this method can be applied if it is necessary to make heating from copper pipes.

If red lead is not available, then ordinary PF paint should be used.

Sealing when working with fluid-conducting systems is mandatory

What fittings are on the market?

Copper pipelines are quite simple and easy to install. This is due to the presence of a large number of types of connections and fittings for them, which makes it possible to perform systems of complex configuration. When carrying out installation work, bulky special equipment is not required. Connections in copper pipelines are considered the most reliable elements. Depending on the connection method used, there are several types of fittings.

Option #1 - compression elements

The parts are equipped with a special compression ring, which ensures the tightness of the connection and secures the fitting to the pipe. The element is tightened by hand using a union nut and wrench. The main advantage of compression parts is ease of installation.No special equipment or heating required. With this method, you can mount the pipeline in the most inaccessible places. Installation labor costs are low, and the resulting system is quite durable and tight. Compression fittings also have disadvantages. They are not designed for high pressure, they need to be periodically checked and tightened. It is impossible to concrete such details.

Theoretically, compression elements provide a collapsible connection. However, practice shows that after the first disassembly and assembly, the reliability of the assembly decreases sharply and it has to be changed. There are two types of compression fittings. They are marked with the letters A and B.

- Parts A are used for above-ground pipelines made of semi-solid grades of copper.

- Parts B are used for arranging ground and underground communications from pipes made from semi-hard and soft grades of metal.

Installation of parts of both types is carried out according to a similar scheme.

The diagram shows a compression fitting device. It is easy to install, but gives a weak connection that needs regular monitoring.

Option #2 - capillary fittings

Brazed copper fittings are called capillary fittings. They connect pipes with solder, that is, copper, tin or silver wire, located under the internal thread of the part. During installation, the fitting is put on the pipe, which is pre-coated with flux. The joint area is heated with a torch until the metal solder melts and fills a small gap between the fitting and the pipe. After that, the parts are allowed to cool. After that, external cleaning is carried out using a special tool. The pipe is ready for use.

The process of soldering a fitting involves the use of solder, which, when melted, fills the gap between the parts.

The advantage of this connection method can be considered high reliability. The maximum operating pressure of the assembly is 40 bar at a system temperature of 150°C. The capillary method gives a very even and neat seam, the minimum amount of solder is used during the work, the cost of installation work is quite affordable. The relative disadvantages of the method include the mandatory presence of a burner and the need for a certain qualification and experience for the person who will be involved in the installation.

Option #3 - press fittings

The principle of operation of parts is based on the use of the plasticity of copper and its susceptibility to deformations that are created under mechanical stress. To obtain such a connection, the pipe, which is previously inserted into the press fitting, is crimped with press tongs. Minimum crimping force 32 kN. This allows you to create a one-piece strong connection. A sealing ring is laid along the contour of the press fitting, which ensures tightness of the connection. The connecting part can rotate, tightness and strength do not suffer from this. Structurally, press fittings differ in parts with a double and single contour of deformation compression.

The main advantage of these elements is the possibility of quick installation without the use of electric heaters or an open flame. They are installed at facilities where the use of burners with an open flame is prohibited, as well as inside various tanks, tanks and containers. The resulting connection is stronger than that made with compression parts.The disadvantages of the elements include a higher cost than solder fittings, and the need to use special equipment during installation - hydraulic or electric presses with a set of tongs of different profiles and diameters.

For installing press fittings you will need to use an electric or hydraulic press with a set of tongs of different diameters and shapes

Types of fitting products

Connecting elements made of metal and plastic are manufactured in the same modifications as steel and plastic products:

- Straight couplers. The simplest type of product for connecting two pipes of the same diameter.

- Transition couplings. Products used to connect pipes of different section sizes.

- Squares. Fittings that allow you to connect two pipes at right angles.

- Branches. Products that allow you to change the relative position of pipes from 45 to 120 °.

- Crosses. Connectors designed to connect four pipes at an angle of 90°.

- Tees. Fittings connecting three pieces of pipe, one of which is installed perpendicular to the other two.

- Plugs. Products designed to close the end section of a pipe. They have an internal or external thread for screwing into a pipe.

- Nipples. Fittings, which are products with external threads at both ends, with the help of which they are connected to other sections of the pipeline.

- Futorki. Products used to connect pipes to measuring instruments. They have an internal thread on one end and an external thread on the other.

- Fittings. Elements that allow for connecting a pipe to process equipment (boiler, boiler, filter, heat exchanger, collector).

- Drives.Used to increase the length of the pipe using an internal or external thread.

- Americans. Products resembling spurs with a union nut. They can be straight and angular, allowing you to change the direction of movement of the connected pipes.

All listed types of fittings have a thread - external, internal or combined. In addition to them, there are also one-piece connecting elements, as well as products connected by welding or capillary soldering.

The connecting elements from the list above are the most popular types of fittings that are used in the installation of pipelines. When installing more complex and highly specialized engineering systems, other special fittings can be used - locknuts, barrels, extensions and other elements.

The nuances of mounting and soldering pipes of all diameters

Copper pipes and fittings for plumbing are connected by threading or soldering, the first method is considered simpler and more accessible to non-professionals. Work begins with drawing up a wiring diagram and counting the footage; in the absence of experience, it is recommended to provide a margin of 3-5 m.

Do-it-yourself step-by-step work in 7 steps

Do-it-yourself copper plumbing with threaded connections is assembled in the following sequence:

- Pipe cutting.

- File cleaning of burrs in the cut area, on pipes with PVC insulation, the insulating layer is cleaned.

- Chamfer removal.

- Putting a union nut and a ferrule on the pipe.

- Preparing the fitting, mating it with the nut and tightening the connection (first by hand, then with a wrench).

- Connection of steel pipes (if necessary) using transition fittings, mandatory sealing of threaded connections.

- Leak test.

Copper pipes and fittings for plumbing must be properly installed.

Checking the condition of the joints and correct installation

The assembly of a copper water pipe using press fittings is considered quite reliable, the quality of sealing depends on the strength of the twist. It is recommended to use special pneumatic or hydraulic pliers for this operation. The disadvantage of this method is the deterioration of the appearance of the water pipe at the joints, if the appearance plays a decisive role, then the sections should be connected by soldering.

Soldering is considered the most reliable way to connect copper pipes. The sequence of actions is almost the same as the assembly with press fittings: the pipes are cut and carefully protected from burrs

It is important to wipe the products from dust and residues of the oxide film (inside and outside). Then a flux is applied to the outer surface of the pipe, a fitting is inserted with a mandatory gap, the joint area is evenly heated with a burner or blowtorch, when choosing the second option, overheating should be avoided. To check that the desired temperature has been reached, it is enough to lightly touch the solder, if it melts, then the area has already warmed up

After that, the solder is inserted into the left gap and the seam is sealed

To check that the desired temperature has been reached, it is enough to lightly touch the solder, if it melts, then the area has already warmed up. After that, the solder is inserted into the left gap and the seam is sealed.

An important nuance of soldering: during heating and connection, the section of the future pipeline must remain motionless. Any efforts and movements are allowed only after the solidification of the solder.At the end of the assembly, the system must be washed from flux residues.

WATCH VIDEO

Heated products are easy to bend; special springs are used to give the desired shape while maintaining the section. The optimal equipment for producing bent elements is a special pipe bender; its purchase is advisable for large volumes of work. The sections assembled by soldering the system look neater than those bent when threaded. But, despite the obvious advantages and reliability of this method, soldering is not carried out in explosive places due to open flames. Fire safety measures are mandatory. Copper pipes and plumbing fittings are widely used in construction.

Specifications

The grade of non-ferrous metal has a significant impact on the technical characteristics of rolled pipe from this material. Basically, copper water pipes are made of pure copper. In the production of rolled products, alloys of this metal are also used. They contain alloying components in a small amount.

The percentage of specific impurities in copper affects the operating conditions, mechanical and technological properties of pipes. The elasticity and strength of non-ferrous metal increases with the addition of zinc, lead, iron and tin.

The resistance of the alloy to corrosion is increased with the help of phosphorus. The mechanical resistance of copper is increased by beryllium and aluminum. Rolled steel manufacturers use manganese to reduce the impact of unwanted impurities on the material.

Pipe classification

Copper pipes vary in diameter. The throughput of communication depends on the size of the section. The standard range of pipe diameters ranges from 1/4″ to 2″.Inside the dwelling, pipelines of the following sizes are mainly used:

- 1/2″ - for shower and bath;

- 3/8″ - for kitchen faucet and washbasin;

- 1/4″ - for the toilet, bidet and ice maker connection.

Copper plumbing pipe in the shower.

Copper plumbing pipe in the shower.

Manufacturers produce two types of copper pipe:

- Annealed products are soft products that have been treated with a high temperature of 550-650 °C. Annealing lasts 60-90 minutes, then the heated workpieces gradually cool down. The process makes it possible to obtain flexible pipes that are resistant to high pressure, sudden temperature changes and humid environments.

- Unannealed products are rigid products with higher strength but less elasticity.

It is possible to buy rolled products in special insulation with a PVC sheath. Condensation does not form on the surface of this type of product.

Produced copper pipes also differ in wall thickness. The area of use of the rolled product depends on the parameter, since this characteristic affects the highest working pressure in the system.

Thick-walled products with the letter "K" are used for input and in fire protection networks. Often products with thick walls are laid in the ground. Compression fittings are often used to connect individual sections of such pipe rolling.

Thin-walled products with the letter "M" are used to create household networks, but have a large number of restrictions. Most often, when installing plumbing systems, pipes marked "L" are used.

Regulatory requirements

Products with thick walls, produced by pressing and using cold deformation, must comply with the specifications reflected in GOST 617-2006.Drawn thin-walled pipe is manufactured in accordance with GOST 11383-75.

Well-known and responsible manufacturers produce high-precision products. Its characteristics correspond to GOST 26877-2008. During the production of copper pipes, alloys and primary copper are used, in accordance with the requirements of GOST 859-2001.

Installation of copper pipes for water supply

Before starting work, you need to draw up a diagram of the future plumbing structure and, on its basis, calculate the footage of rolled pipe and the number of connecting elements (press couplings, tees, bends, adapters, etc.).

Necessary tools and materials

To perform the installation of pipe rolled copper alloy, you need to prepare a set of tools, consisting of:

- Hacksaws for metal or pipe cutter.

- Pliers.

- Manual calibrator.

- Wrenches or a gas burner (for heating the pipe section when connecting parts by soldering).

- File.

For joining pipe sections, depending on the selected connection method, the following materials will be required:

- Fitting.

- FUM - tape for sealing joints of detachable fittings.

- Solder and flux (in the case of soldering products).

Precautionary measures

Soldering copper products is carried out when they are heated to high temperatures, so when working it is necessary to wear protective clothing and use a fire shield. It is necessary to remove rubber or plastic braids from the parts to be joined in the contact zone. The valve to be installed must be unscrewed so that the sealing rings do not melt.

When soldering copper products in an already installed pipeline system, all shut-off valves should be opened so that the pressure level in the pipes does not exceed the permissible values due to the heating of some sections.

Work progress

Docking of pipe segments using fittings is performed in the following sequence:

- Cut pipe sections to the required size.

- If the water supply is assembled from copper pipes with PVC insulation, then this layer should be removed at the ends of the products.

- Clean the cut line with a burr file.

- Remove bevel.

- Put on the prepared part alternately the union nut and the compression ring.

- Connect the fitting to the nut and tighten the threads first by hand and then with a wrench.

- In places where a transition fitting is being installed from a copper pipe to a steel pipe, the tightness of the joints is ensured by the use of FUM - tape.

When connecting pipes by soldering with your own hands, you must follow the precautions described above and have certain skills. The preparation process and the soldering itself includes the following steps:

- Cutting the required lengths of pipes with a pipe cutter or a hacksaw.

- Removal of the heat-insulating layer (if any) and the resulting burrs at their ends.

- Removal of the oxide film in the soldering zone with a fine abrasive sandpaper.

- Fitting sanding.

- Lubrication of the outer surface of parts with flux.

- Inserting the end of the pipe into the fitting in such a way that a gap of no more than 0.4 mm remains between the parts.

- Warming up the contact zone of the gas burner elements (pictured below).

- Inserting solder into the gap between the fitting and the end of the copper pipe.

- Solder seam.

- Flushing the system from flux particles.

The process of soldering copper pipe rolled products can be viewed on the video:

Mounting Features

Mounting by soldering forms one-piece connections that do not need maintenance and are considered the most reliable in operation. But in order to solder copper plumbing, you must have sufficient experience in this type of work and relevant knowledge. Beginners can use the following recommendations:

- Cleaning copper products should not be done with abrasive cleaners, coarse sandpaper or a wire brush, as they will scratch the copper. Deep scratches on the surface interfere with the solder joint.

- Flux is a fairly aggressive substance with high chemical activity. Apply it in a thin layer using a brush. If there are excesses on the surface, at the end of the process of joining the parts, then they must be removed immediately.

- The contact zone should be warmed up sufficiently, but not excessively, so as to prevent the metal from melting. The solder itself should not be heated. It should be applied to the heated surface of the part - if it starts to melt, then you can start soldering.

- Pipes must be bent in such a way as to prevent creases and twisting.

- Installation of copper products should be carried out in front of aluminum or steel sections in the direction of water flow in order to prevent rapid corrosion of the latter.

- For the transition from copper pipes to sections of other metals, it is recommended to use fittings made of brass, bronze or stainless steel.