- Applications

- Types of copper pipes

- What is needed for soldering copper pipes

- No. 11. Heating pipe diameter

- Methods for connecting copper pipes

- Welding

- Connection of copper pipes with exhaust fittings.

- Rolling

- Compression fitting

- Press fitting

- Soldering copper pipes

- Limitations when using copper pipes

- Methods for connecting copper pipelines

- How to simplify the installation of heating

- Capillary soldering

- No. 6. Copper pipes for heating

- Variety of copper products

- Production

- Method #2: Grooving (Roll Groove)

- Preparing and making a knurled groove connection

- Testing the complete knurled system

- No. 7. Polypropylene pipes for heating

- Comparative price overview

- Kinds

- Specifications

Applications

There are several situations when it is better to choose this material:

- The current option for installing a heating system from copper pipes is to connect to a solid fuel boiler. This is due to the fact that such systems are subjected to prolonged exposure to high temperatures (over 100 degrees Celsius).

- Compared to other materials, copper is better if it has a complex shape.

- Installation will be 100% justified if the owner of the house has enough funds, he wants to get the highest durability indicator.

Considering other options, you need to pay attention to plastic or stainless steel.

Types of copper pipes

Such products vary in size and cross section and are of the following types:

- Copper annealed pipe. To acquire softness, such products are subjected to heat treatment. This simplifies their installation.

- Copper not annealed pipes. These are straight segments from 1 to 5 m long.

The cross section of pipes can be classic and rectangular. The latter are used in the creation of conductors for stator windings, which are cooled by means of liquids. Their manufacture is complex and the cost is higher than conventional ones. The most popular diameter of copper pipes for water supply is from 10 to 23 mm, for drain systems - from 30 to 45 mm.

What is needed for soldering copper pipes

Soldering copper pipes, which is not difficult to do with your own hands, does not require expensive equipment and any special materials. In order to properly implement it, you will need the following devices.

A burner, due to which the solder and the pipe section where they will be connected will be heated. As a rule, propane gas is supplied to such a burner, the pressure of which is regulated by a welding reducer.

Special tool for cutting copper pipes. Since products made of this metal are very soft, they should be cut gently enough so as not to wrinkle the walls. Pipe cutters of various models are offered on the modern market, differing both in their functionality and technical capabilities.

The design of individual models of such devices, which is important, allows them to be used even for work in hard-to-reach places.

A pipe expander is a device that allows you to expand the diameter of a copper pipe, which is necessary in order to better solder. In various systems mounted from copper pipes, elements of the same section are used, and in order to connect them qualitatively, it is necessary to slightly increase the diameter of one of the connected elements. It is this problem that such a device as a pipe expander solves.

It is this problem that such a device as a pipe expander solves.

Copper pipe flaring kit

Device for chamfering the ends of copper pipes. After trimming, burrs remain on the ends of the parts, which can interfere with obtaining a high-quality and reliable connection. To remove them and give the ends of the pipes the required configuration, a beveler is used before soldering. There are two main types of chamfering devices on the market today: placed in a round body and made in the form of a pencil. More convenient to use, but also more expensive, are round devices that can process soft copper pipes with a diameter of not more than 36 mm.

To properly prepare copper pipes for soldering, it is necessary to remove all impurities and oxides from their surface. For these purposes, brushes and brushes are used, the bristles of which are made of steel wire.

Brazing of copper pipes is usually performed with hard solder, which can be high and low temperature. High-temperature solder is a copper wire containing about 6% phosphorus in its composition. Such a wire melts at a temperature of 700 degrees, while for its low-temperature type (tin wire), 350 degrees is enough.

The technology of soldering copper pipes involves the use of special fluxes and pastes that perform a protective function. Such fluxes not only protect the formed seam from the formation of air bubbles in it, but also significantly improve the adhesion of the solder to the pipe material.

In addition to flux, solder and other basic elements, additional tools will be needed to solder copper pipes, which can be found in every workshop or garage. To solder or weld copper products, additionally prepare:

- regular marker;

- roulette;

- building level;

- a small brush with stiff bristles;

- a hammer.

Before starting work, it is also important to decide how to solder copper pipes. There can be two main options: brazing copper (less commonly used) and using soft solder. When resolving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder

So, hard solders are used for soldering elements of refrigeration units and air conditioners. In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

When solving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder. So, hard solders are used for soldering elements of refrigeration units and air conditioners.

In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

Brushes for stripping the inner surface of a copper pipe before soldering

No. 11.Heating pipe diameter

Pipes made of different materials are presented in different diameters. To choose the most appropriate value, you need to study the entire scheme of the heating system and ask for the help of specialists. The approximate diameter can be calculated independently. Parameters such as the area of \u200b\u200bthe room, on which the thermal power depends, and the speed of the coolant, are taken into account.

Many mistakenly think that the larger the diameter of the pipe, the higher the efficiency of the system. In fact, when choosing pipes that are too large, the pressure in the system decreases, and heating disappears altogether - warm water cannot go around the entire piping system and radiators. The smaller the diameter, the higher the water flow rate. Ideally, the speed should be higher than 0.2 m/s, but less than 1.5 m/s, otherwise the coolant circulation process will be too noisy.

The diameter is chosen based on the calculation required heat output. For rooms with a ceiling height of up to 3 m, 100 W of energy is required for every 1 m2. For a room of 20 m2, for example, 2000 W of thermal power is needed, here it is worth adding 20% of the reserve, we get 2400 W. This thermal power is provided by one or two radiators, if there are two windows in the room - under each window. According to the table, we see that pipes with an inner diameter of 8 mm are needed to cover this power, but 10 mm is also suitable. Of course, these are all conditional calculations, but they will help you navigate the budget for the purchase of pipes.

Finally, we note that it is better not to save on heating pipes - this will save you from numerous problems.The products of such manufacturers as Akwatherm, Rehau, Banninger, Wefatherm, FV-Plast have proven themselves well.

Methods for connecting copper pipes

Welding

It occurs quite rarely. A welding torch connects large-diameter copper pipes for heating (starting with a diameter of 108 mm);

Connection of copper pipes with exhaust fittings.

A hole is made inside the pipe, cams are inserted and a socket is pulled out using a special tool. A rather laborious and expensive way to connect pipes, you need a special machine and installers do not respect this mounting option.

Rolling

The method of connecting copper pipes is good, but it is not used in heating systems. It is very rare to find a flared part, and then factory-made.

Compression fitting

Occurs quite often. It consists of three parts: a nut, an o-ring and the fitting itself in the form of a corner. Connection principle: a nut, a sealing ring and the fitting itself are put on a copper pipe. Then the nut is twisted and presses the pipe to the fitting. On the other hand, the same is done.

The disadvantage of this method of connecting copper pipe is that there is no recommendation with what force to tighten the nut on the fitting. Everyone does it the best they can, and as a result, water leaks can occur.

Another disadvantage is the conditional non-separability of the fitting, tk. the sealing ring, when dressed on the pipe, cuts into it and remains forever. Therefore, in order to repair a pipe section (remove a fitting), this pipe section has to be cut and a new one inserted.

If you are offered a compression fitting, it is better to refuse and ask for something else.

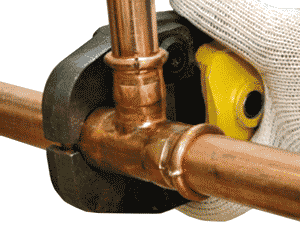

Press fitting

It is rare, because.the master needs a set of special pliers (about twelve) and an expensive press to install it. The principle of connection: the fitting is thrown over the pipe and clamped with tongs of the desired type. The result is a perfectly strong non-separable connection.

The difference between the processing of these soft and hard pipe fittings.

A support sleeve must be inserted inside the soft copper pipe when installing the compression fitting. The sleeve allows you to save the geometry of the pipe when compressing the support ring.

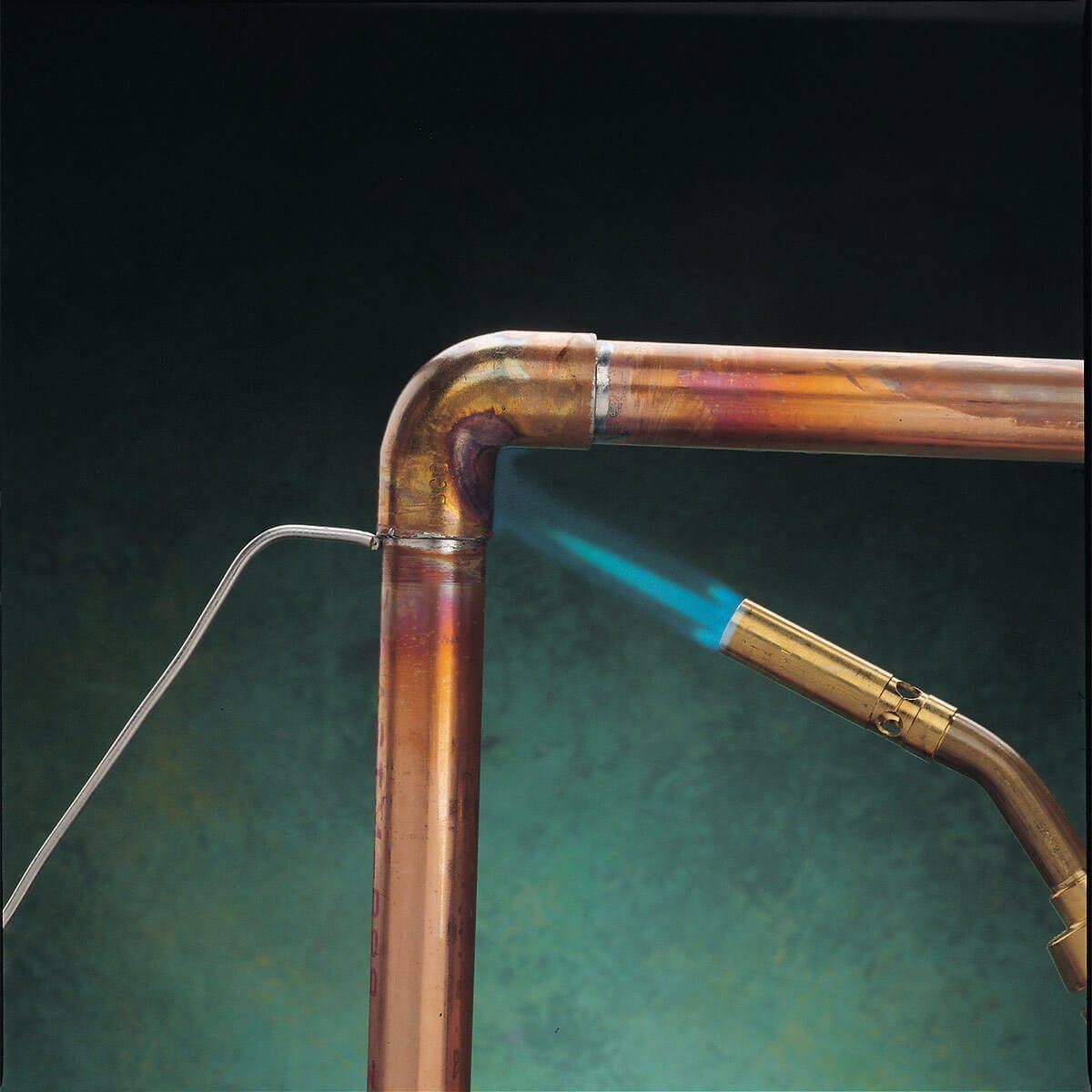

Soldering copper pipes

The method allows to obtain a high-quality connection of a copper pipe using inexpensive equipment. This is usually a propane torch for small pipe diameters. For pipes with a diameter of more than 54 mm, an acetylene-air torch is suitable.

There are two types of soldering - hard and soft (high and low temperature). Hard soldering is performed at a higher temperature than soft soldering. There is an opinion that hard soldering is stronger than soft soldering. This is not true.

Hard soldering is less technologically advanced than soft soldering. In order to solder using hard soldering, you just need to put the fitting on the pipe, heat the junction to a dark crimson color, and then attach the solder.

Soft soldering includes:

- Cleaning the joint to a metallic sheen,

- Cleaning the inner surface of the fitting,

- flux application,

- connecting parts,

- Removing excess flux

- Actually soldering.

The main difference between soft soldering and hard soldering is that after soft soldering, the copper pipe has a neater appearance than after hard soldering.During hard soldering, the pipe gets very hot, blackens in thickness, becomes covered with flakes - it is impossible to clean it, it will not look like a shiny copper pipe, it will be black. After hard soldering, the boiler room looks ugly, so if you are offered hard soldering, it is better to refuse. Only soft solder should be used.

Hard soldering of a copper pipe is suitable for those cases when not a liquid, but a gas will be transported through the pipeline. For example, for air conditioning systems, systems for transporting any gases, only hard soldering is allowed, because the flux residues applied to the pipe and the inner surface of the fitting get into the pipeline and must be washed out.

Soft soldering is suitable for hydraulic systems as it looks more aesthetic.

Limitations when using copper pipes

For copper, there are the following operational limitations due to the properties of the metal:

- The softness, which ensures the plasticity of pipes and the convenience of their installation, imposes a limit on the allowable water flow rates. For a long service life of the water supply system, values up to 2 m / s are optimal.

- Due to the softness of copper, the following requirements are imposed on the purity of water - it should not contain mechanical impurities, which is achieved by installing appropriate filters at the inlet. Suspended particles can cause erosion (washout of pipe wall material) due to mechanical impact.

- The surface of copper is covered with an oxide film that occurs naturally and is a protective layer. The chlorine present in the water transforms this film into a true patina, which provides the pipe with even greater protection.This occurs only when the total hardness of the water flow is 1.42–3.1 mg/l with a pH in the range of 6.0–9.0. Otherwise, the patina will be destroyed, and this will lead to its continuous restoration due to the consumption of copper, which can significantly reduce the life of the pipeline.

- In drinking water supply, the use of lead solder is not allowed for connecting pipes (lead is a toxic substance).

- When installing a copper pipeline, it is required to carry out all operations so as not to reduce the service life of the system from the estimated 50 years. When bending pipes, their creases are not allowed, as this will violate the laminar flow of water. The pipe must not be twisted. In the event of a jam, editing is carried out no more than 1 time.

- Burrs and burrs formed after soldering must be removed, as they contribute to the occurrence of turbulent eddies in the water flow with concomitant erosion, which will lead to a decrease in the service life of the copper pipeline.

- Overheating during soldering, especially strong, can lead to a leaky connection or loss of copper strength, up to a burst.

- The flux used in soldering must be removed by washing, as it is an aggressive substance and can contribute to pipe corrosion.

- It is forbidden to mount elements made of aluminum, zinc, steel after copper pipes in the direction of the water flow to prevent corrosion of the latter. If this condition is not met, the use of passive anodes (from magnesium, for example) is required.

- The transition from copper to a pipe made of other metals is recommended to be carried out through brass, bronze or stainless steel fittings in order to avoid rapid corrosion of the latter.

Despite the existing restrictions on the use, today copper pipes are considered the best material for arranging plumbing systems.

Methods for connecting copper pipelines

In practice, copper pipes for heating are connected in the following ways.

Capillary soldering is the most reliable mounting method. To do this, you will need a torch and special solder.

The next most reliable method is connection with press fittings. This method requires the use of pressing tongs. Despite the fact that this method is somewhat inferior to soldering in quality, it is used quite often, since it practically does not require special training. The use of this method of connection is possible if the pressure of the energy carrier does not exceed 10 atmospheres.

The next most reliable method is connection with press fittings. This method requires the use of pressing tongs. Despite the fact that this method is somewhat inferior to soldering in quality, it is used quite often, since it practically does not require special training. The use of this method of connection is possible if the pressure of the energy carrier does not exceed 10 atmospheres.

Connection with compression fittings. The easiest way to join the copper parts of the heating system, only wrenches of the right size are required from the equipment. This simplicity somewhat affected the quality of the connection, the reason for the problem most often lies in the quality of the fittings, and not in the pipe itself.

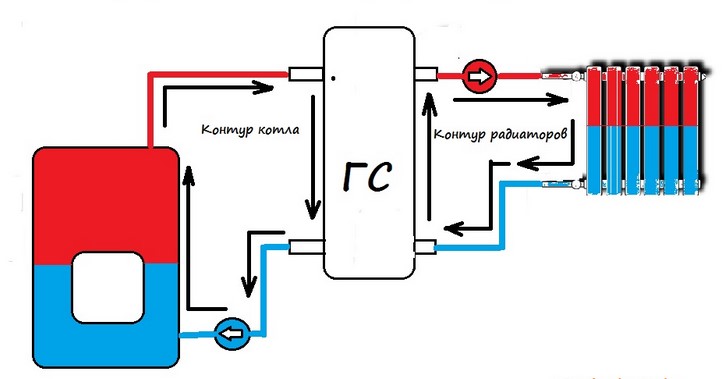

How to simplify the installation of heating

Here's what else is interesting to know about heating from copper pipes - the installation of the system can be greatly simplified and made more reliable. This is possible due to the fact that metal pipes are copper, they are highly ductile. In addition, such a pipe is produced not only in the form of measured materials, it is possible to buy it in bays of considerable length. This allows you to mount the system with virtually no linear joints.

In this case, the required configuration of the heating line is achieved by bending the pipe, you will not need to use corner fittings. There is also the possibility of transverse insertion of pipes with subsequent soldering.

In order to bend the copper pipe and prevent its deformation, proceed as follows.

To bend copper heating pipes without preheating, you will have to use a special device - a pipe bender. It allows you to get a given bending angle, while preventing pipe deformation. If you try to do it manually, you will get damaged material, since in almost all cases the internal section is significantly disturbed, which creates additional resistance, causing a decrease in the circulation of the energy carrier.

More simple, and even more so not requiring complex devices, is the bending of heated pipes. To do this, the pipes are heated by a burner, they must first be put on a special spiral, which will prevent a decrease in the cross section. The bend is made by a smooth movement without jerks.

Remember, it will be possible to correct the angle only after reheating, but this is also undesirable, such an impact can adversely affect the properties of the pipe.

Capillary soldering

This method of connecting copper pipes is based on the action of surface tension forces, which allow you to fill the joint of the connected elements with solder.

In order to obtain a high-quality connection, the following conditions must be met:

- The parts to be joined are connected by the socket method. To do this, the end of one element must be flared (expanded), keep in mind that the gap between the pipes at the joint should be tenths of a millimeter.For this purpose, it is better to use a special expander or flanging tool (for inserting a pipe).

- Pipes are cleaned, depending on the solder, they must be treated with flux.

- After the workpieces are connected, begin to evenly heat the joint. After reaching the required temperature, bring solder wire into the flame. During the melting process, the liquid solder will fill the entire space between the pipes at the joint.

The technology of capillary soldering, of course, has its own nuances, the consideration of which is impossible in the volume of one article. But this type of connection is the most used, because heating with copper pipes must be beautiful in order to match its cost.

No. 6. Copper pipes for heating

Let's continue the study of metal heating pipes. Copper pipes began to be used as early as the 17th century and are still actively used, despite the appearance of cheaper options.

Advantages:

- durability compared to the life of buildings. Copper pipes and fittings do not lose their qualities for 100 years or more;

- resistance to corrosion, high tightness, lack of ability to pass air and accumulate deposits on the inner surface, therefore, over the years, the throughput of pipes does not decrease;

- high thermal conductivity;

- resistance to temperature extremes (operating temperature range from -200 to +500С) and pressure surges in the system;

- aesthetic appearance.

The main disadvantage is the high price. Not only is the material itself expensive, but also the main manufacturers are concentrated outside the country.

If we take into account the durability of the material and the absence of problems in the next 100 years, then the cost does not look like such a significant drawback.If the issue of choosing heating pipes does not rest on the budget, then copper pipes will be the best option.

The installation process is specific, so it is better to seek help from professionals.

In order for the heating system to serve for many years, it is better not to combine copper pipes with unalloyed steel pipes. The latter will rust very quickly. If such a combination cannot be avoided, then let the steel pipes be in front of the copper pipes in the direction of water movement.

Variety of copper products

Copper pipes are classified according to different criteria. One of the main ones is the way they are made. According to this criterion, products are divided into the following types:

- Unannealed copper pipes. They are made of pure metal by rolling or stamping. Pipes have high strength and easily withstand pressure of 450 MPa. Using this method has some drawbacks. The result is a material with reduced plasticity, which somewhat limits its scope.

- Annealed. Pipe processing is carried out using a special technology. Its essence lies in heating the material to 700 degrees, followed by cooling. Cooling is carried out gradually. As a result of such processing, copper products lose their strength. Instead, its plasticity increases. Due to this feature, copper pipe is widely used for the construction of a pipeline that has a complex configuration.

According to the standards, copper pipes are manufactured in three types, which have characteristic differences in terms of mechanical and operational properties. So, depending on the degree of hardness, copper products are divided into the following types:

- Solid.The products are widely used for piping, which must have high strength. Distribution of the pipe during the installation process is carried out only by preheating. The pipeline may have multiple turns. To bend the pipe at the selected angle, you must use a pipe bender.

- Semi-solid. Copper pipes of this type can easily withstand expansion if the diameter is increased by 15%. The product has greater plasticity than the previous material. But, nevertheless, you need a pipe bender for bending.

- Soft pipes. Able to withstand distribution with a quarter increase in diameter. In this case, there are no gaps and cracks. The product is easy to bend. For this, the material does not need to be heated. Soft copper pipes are widely used for heating and water supply systems. They are also widely used in laying underfloor heating.

Also, copper pipes are classified according to the shape of the section. They are round or rectangular. The latter option is much more expensive. Rectangular pipes are used for the manufacture of special conductors in electrical equipment. Also, copper pipes can have different wall thicknesses (0.6 - 3 mm) and diameters (12 - 267 mm). In different areas, products with certain parameters are used. So, Pipes are used to construct a gas pipeline, the wall thickness of which is 1 mm, and in plumbing - 2 mm.

Production

For the construction of pipelines for water supply and heating, seamless copper products are used. They are made using three technologies:

- cold rolling - the deformation of the metal workpiece occurs when passing between rotating rolls. A through hole is created by the firmware method.Then the sleeve is calibrated to the desired dimensions;

- cold drawing - is based on pulling the workpiece through a drawing tool (drawing tool) with a special channel tapering in length. In the process of drawing, the metal is compressed to the required geometric parameters and stretched along the length;

- hot pressing - obtaining a pipe by extrusion (extrusion) through the outlet of the matrix.

In industrial production, one of these technologies or a combination of them can be used. The composition of equipment and technological operations may have some differences, but the main manufacturing process always consists of the following steps:

- preparation of the workpiece;

- cold rolling or drawing or hot pressing;

- heat treatment;

- lubrication of pipes and tools;

- processing of finished and intermediate products;

- cutting into measured parts or winding into coils;

- quality control of finished products.

Method #2: Grooving (Roll Groove)

Pipelines created by a connection with end grooves (knurling grooves) have been practiced for a long time on the construction of sprinkler (irrigation) fire systems. Since 1925, this completely reliable method of connecting pipes has been used on steel and iron pipelines for heating, ventilation, air conditioning and other systems.

Meanwhile, a similar knurled mechanical connection method is also available for copper pipes with a diameter of 50mm to 200mm. The knurled mechanical connection kit contains:

- couplings,

- gaskets,

- various fittings.

The mechanical knurling system offers a practical alternative to brazing larger diameter copper pipes. Accordingly, the knurling method does not require additional heating (application of an open flame), as in the case of soldering hard or soft solder.

The knurling groove on the end of the copper pipe is one of the main elements of the “knurled groove” connection method. Measurement after rolling determines the suitable fitting

Groove connection is based on the ductility properties of copper and the increased strength of this metal during cold working. The design involves sealing the clamping system, for which a synthetic elastomer gasket (EPDM - Ethylene Propylene Diene Methylene) and a specially designed clamp are used. A number of manufacturers around the world offer tools for creating groove joints - gaskets, clamps, fittings.

Fittings of various sizes and work clamps with gaskets are used in the design of connections made by the knurled groove method

Preparing and making a knurled groove connection

As with other solderless copper joining processes, proper preparation of the pipe end is of primary importance in creating a strong, leak-tight weld. The right choice of knurling tool for each type of copper pipe is also obvious. The manufacturer's recommendations must be followed to ensure safe, trouble-free preparation of these types of connections.

Table of permissible pressures and temperatures for this type of connection

| Connection type | Pressure range, kPa | Temperature range, ºC |

| Groove, D = 50.8 - 203.2 mm, type K, L | 0 — 2065 | minus 35 / plus 120 for K minus 30 / plus 80 for L |

| Roll groove, D = 50.8 - 101.2 mm, D = 50.8 - 203.2 mm type M | 0 — 1725 | minus 35 / plus 120 |

| 0 — 1375 | minus 30 / plus 80 |

Step-by-step process for assembling a knot with knurled grooves:

- Cut to size the ends of the copper pipes exactly perpendicular to the axis.

- Remove burrs after cutting and chamfer.

- Roll grooves to desired dimensions as required by the fitting manufacturer.

- Inspect fittings, gaskets, clamps for damage.

- Lubricate gaskets according to manufacturer's recommendations.

Prior to final assembly, inspect clamping surfaces for cleanliness and debris. Assemble the compound according to the manufacturer's recommendations.

Practically assembled fragment of the node using the "knurling groove" method. The elastic gaskets of the clamping bracket are treated with a small amount of lubricant before the final seating of the copper pipes.

The clamp nuts should be finally tightened to the required torque according to the manufacturer's recommendations. After tightening the screws, the clamp area should be re-examined to ensure that the assembly is properly assembled.

Testing the complete knurled system

Testing of a complete piping system may be performed by applying air or water pressure to the system. The hydropneumatic method is also not ruled out when a relatively high test pressure is applied.

However, it should be taken into account that the value of the test pressure should not exceed the maximum allowable working pressure specified by the manufacturer of the knurled groove system.

No. 7. Polypropylene pipes for heating

Polypropylene pipes are made on the basis of polymers, there are several types of such pipes, but PPs pipes from special propylene are usually used in the heating system. The materials of the thermoplastic group, which include all types of polypropylene pipes, are unstable to high temperatures, therefore, for heating systems, it is necessary to take only reinforced pipes, preferably with fiberglass. So, for example, pipes of the PN25 type are reinforced, withstand pressure in the system up to 25 atm and a temperature of +95C with a short-term increase to +120C.

Advantages:

- relatively long service life. According to the manufacturers, the durability reaches 50 years;

- corrosion resistance. The inner surface of the pipes remains smooth throughout the entire service life, without impairing the throughput. Due to the tightness, oxygen does not pass into the system and does not damage its metal elements;

- high mechanical strength;

- light weight;

- resistance to low temperatures. If water is frozen in the pipe, you don’t have to worry about integrity - due to the ability to expand, the material will not be damaged and will return to its original shape after thawing;

- hermetic connection, which is provided by special fittings and welding;

- relatively easy installation process. To connect individual elements with fittings, a special welding machine is used, which is often called an iron and a soldering iron by the people. It takes a few seconds to weld the joint, and it is not difficult to learn how to work with the device;

- low noise level when water moves through pipes, especially when compared with metal counterparts;

- complete harmlessness to health;

- relatively low price.Polypropylene pipes will cost less than metal-plastic or stainless steel pipes.

Among the disadvantages:

- inability to use in fire hazardous areas;

- high linear expansion results in the need to use compensators.

Often, the disadvantages include low heat resistance, low rigidity and instability to water hammer. This is due to the wrong choice of polypropylene pipes. For heating systems, only reinforced products are needed that do not sag, withstand high temperature and pressure. In addition, the production process is of great importance: if the technology is violated, pipes of inadequate quality come out, so it is better to give preference to trusted eminent manufacturers.

Comparative price overview

In construction, plumbing stores you can buy heating pipes that are made from different materials:

- Copper. The average price for 1 meter (diameter 20 mm) is 250 rubles. Permissible temperatures of the working fluid - up to 500 degrees Celsius. They transmit stray currents, which is a disadvantage.

- Polypropylene. The average price for 1 meter is 50 rubles. Suitable for liquid temperatures up to 95 degrees. They don't oxidize. Cannot withstand strong water hammer.

- Metal-plastic. The average price for 1 meter is 40 rubles. The temperature maximum is up to 150 degrees. The term of active operation is 15 years.

Prices vary depending on the diameter, wall thickness, fame of the manufacturer.

Copper pipes for heating

Copper pipes for heating

Kinds

Types of polypropylene pipes, depending on the design:

- solid - made of homogeneous plastic;

- reinforced - two or more materials are used in production, which are combined with each other.

Reinforced tubes have several differences from solid parts:

- the outer side is coated with aluminum foil;

- an additional aluminum coating may be inside the part;

- tubes can be reinforced with fiberglass.

Classification of polypropylene pipes with reinforcement:

- Aluminum. Can be reinforced with a continuous layer or mesh with small holes. The presence of an additional layer of metal provides a decrease in the thermal expansion of plastic, an increase in strength, resistance to pressure.

- Fiberglass. They have a layered structure. The main layers are two layers of polypropylene, between which there is a reinforcing layer of fiberglass.

- Metal-polymer. Consist of 5 layers. Outside and inside is polypropylene. Intermediate layers - adhesive. The center one is aluminium.

The technical characteristics of reinforced products are higher than those of parts made of a homogeneous material.

Various polypropylene pipes

Various polypropylene pipes

Specifications

Technical characteristics of polypropylene pipes:

- Frost resistance index - up to -15 degrees. Pipes made of this material are not suitable for the manufacture of outdoor water pipes.

- Low thermal conductivity. Due to this, the liquid reaches from one end of the pipeline to the other with a minimum temperature difference.

- The density of polypropylene is 0.91 kg/cm2.

- Chemical resistance of the material.

- High rate of linear expansion.

- Mechanical strength - 35 N / mm.

- Softening of polypropylene starts at 140 degrees.

- Heat resistance to heat carriers - up to 120 degrees.

- Plastic melting starts at 170 degrees.

- The operating pressure range is 10–25 atmospheres.

Pipes from this material are made with diameters from 10 to 125 mm. The parts are connected using a special soldering iron. Thanks to soldering, a strong, airtight seam is obtained.