- What is insulation for?

- Norms and SNiP gas supply

- What gas is used in residential buildings

- What is the gas pressure in the gas pipeline of a residential building

- No. 6. Copper pipes for gas pipeline

- Gas production

- Preparation and transportation

- Types of gas pipelines

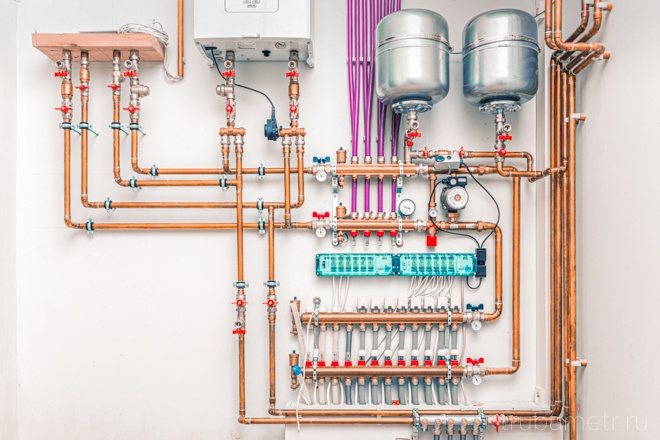

- 1 Copper pipes for water supply - technological features and advantages

- Metal-plastic products for the gas pipeline system

- Security zones

- Nuances

- Features of the installation of copper pipelines

- Ventilation and security

- Copper fittings and their types

- Norms of gas consumption for home heating

- Mounting

- Installation of copper pipes for water supply

- Necessary tools and materials

- Work progress

- Mounting Features

- Methods for connecting copper pipes

What is insulation for?

The presence of isolation in the arrangement of communications plays a very significant role. After all, copper has a high thermal conductivity. And in order for the coolant not to cool down during the operation of the heating and hot water supply system, thermal insulation is necessary. You can not do without insulation also in cases where the communication system will be mounted in a wall or concrete. In this case, isolation is needed for:

- Prevention of condensation;

- material protection;

- Protection against pipeline damage.

Thermal insulation for copper products is produced from the following materials:

- Thermaflex;

- Foamed polyethylene;

- rubber.

Thermal insulation is available both separately and immediately with a copper pipe. Insulated copper pipes can be used for various communication systems. They are installed:

- Indoors;

- Outside;

- Underground.

Copper pipes in isolation

Insulated copper pipes are not difficult to install, they are easy and simple to install. Their only drawback is the high cost of the material.

Norms and SNiP gas supply

An indicator of the quality of natural gas is the amount of methane. All other components of natural gas are unpleasant additives. There is another characteristic, according to which the gas pipeline is divided into categories - this is the gas pressure in the system.

What gas is used in residential buildings

Natural gas is a conditional concept that is used for a combustible gaseous mixture extracted from the bowels and delivered to consumers of thermal energy in liquid form.

The composition is varied, but methane always predominates (from 80 to 100%). In addition, the composition of natural gas includes: ethane, propane, butane, water vapor, hydrogen, hydrogen sulfide, carbon dioxide, nitrogen, helium. An indicator of the quality of natural gas is the amount of methane. All other components of natural gas are nasty additives that create polluting emissions and destroy pipes. Natural gas for residential buildings is not recognized by the senses in any way, therefore, strong-smelling gases are added to it - odorants, which perform a signal function.

What is the gas pressure in the gas pipeline of a residential building

A gas pipeline is the entire path that gas passes through pipes from a place of storage to a consumer. Gas pipelines can be divided into land, surface, underground and underwater.In terms of the complexity of the conducting system, they are divided into multi-stage and single-stage.

There is another characteristic, according to which the gas pipeline is divided into categories - this is the gas pressure in the system. For gas supply to cities and other settlements, the pressure is:

- low - up to 0.05 kgf / cm2;

- medium - up to 0.05 to 3.0 kgf / cm2;

- high - up to 6 kgf / cm2;

- very high - up to 12 kgf / cm2.

This difference in pressure is due to the purpose of the gas pipeline. Most of the pressure is in the main part of the system, the least - inside the house. For a system with a certain pressure, there is its own GOST, which is strictly forbidden to deviate from.

No. 6. Copper pipes for gas pipeline

Copper pipes have been used in the organization of the gas pipeline system relatively recently. They can only be used for laying pipes inside the house at pressures up to 0.005 MPa. For this purpose, drawn or cold-rolled pipes with a wall thickness of at least 1 mm are used.

Advantages:

- attractive appearance. Gas pipes cannot be hidden in walls or ducts - they must be easily accessible. Steel pipes can hardly be called an interior decoration, unlike the copper counterpart. It is unnecessary to hide such pipes - they look neat and attractive, they will fit perfectly into many interior styles;

- relatively simple installation, which is carried out using press fittings or soldering. In addition, copper pipes are easy to cut;

- plasticity and the ability to create a network of complex configuration;

- sufficient mechanical resistance;

- resistance to aggressive substances;

- durability up to 100 years.

Among the minuses are high price, a small assortment on the market and high thermal conductivity, which can lead to the formation of condensate. In terms of strength, copper pipes are inferior to steel pipes, but if we are talking about intra-apartment wiring, then this will not cause any special problems.

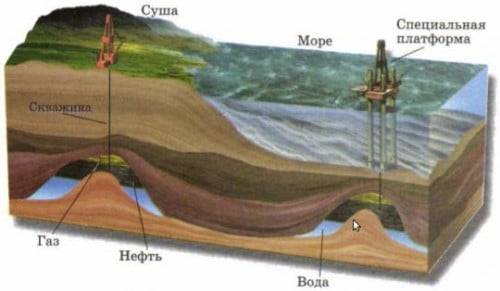

Gas production

The gas lies in the earth's crust at a distance of 1-6 km from the surface, so exploration is carried out first. Deep in the bowels of the planet there are very small pores and cracks that contain gas. The mechanism of natural gas movement is simple: methane is displaced from high pressure pores to lower pressure pores. Wells are evenly installed over the entire area of the deposit. Since the pressure underground is many times greater than atmospheric pressure, the gas itself goes into the well.

Preparation and transportation

Gas is not immediately allowed through the pipeline, first it is prepared in a special way in boiler houses, thermal power plants and chemical plants. They are dried from water vapor and cleaned of impurities: hydrogen sulfide (causes corrosion of pipes), water vapor (causes condensate, interferes with the movement of gas). The pipeline is also prepared: with the help of nitrogen, an inert environment is created in it. Further, the gas moves through large pipes with a diameter of 1.5 m (at a pressure of 75 atmospheres). Since during transportation the potential energy of the gas is spent on the friction forces between the particles of the gas itself and on the friction between the pipe and methane, there are compressor stations that raise the pressure inside the pipe up to 120 atmospheres. Underground gas pipelines are laid at a depth of 1.5 m so that the structure does not freeze.

Types of gas pipelines

- Trunk. The pressure in the system is 6-12 atmospheres maintained until the gas distribution station, which reduces the pressure to the desired level.

- Medium pressure lines. The pressure in the system is 3-6 atmospheres.

- Low pressure lines. The pressure during operation is from 0.05 to 3 atmospheres. This is the pressure in the gas pipe in an apartment or in a private house.

Distribution and control devices

- The gas pressure regulator is equipment for controlling the flow of the working medium.

- Gas control systems automatically shut off the gas supply.

- The reduction unit reduces the fuel pressure.

- The switch redistributes the main stream into separate branches.

- Pressure gauges and flow meters allow you to monitor the parameters of the system.

- Filters clean the gas mixture from impurities.

All these devices ensure the safety of main pipelines and are part of the automatic parameter control system.

1 Copper pipes for water supply - technological features and advantages

First of all, copper pipes for plumbing are attractive for their durability. Solid products with a diameter of 12 mm, having a wall thickness of only 1 mm, are designed for a working pressure of 100 bar at a temperature of 250 °C. Copper pipeline on fittings, assembled by hard soldering, withstands maximum loads of more than 500 atm and temperatures up to 600 °C. Many materials become brittle as the temperature drops. Copper is an exception - the strength and ductility of this metal increase with decreasing temperature.

This property ensures the admissibility of repeated freezing and thawing of copper pipes (depending on the hardness of the products up to 3 times). Even if an accident occurs, it is only in one place, unlike steel pipelines, in which the gust spreads throughout the pipe.Therefore, the elimination of the consequences of freezing copper products is not difficult, and the steel system must be completely replaced.

Copper pipes are easy to machine and very technologically advanced in any part of the installation: when passing holes, bending around corners and other obstacles, installing equipment, mounting a branch on an already finished pipeline. For all work, a simple mechanized and manual tool is needed.

Copper systems are universal - fittings and pipes of the same standard are used for all types of utilities. This ensures the use of a single installation method and the same equipment. The most common and most reliable method of joining copper pipes is capillary soldering. The soldering width, even with small diameters, is not less than 7 mm and gives the installation strength higher than that of known connection methods, including any type of welding.

During the tests, there was always a break in the body of the pipe, and the tightness of the joints, including the serviced ones, was never broken. Capillary soldering allows quick and easy assembly. Its advantages are especially evident when compared to welding, which requires greater precision and care when working with plastic pipes, or bulky equipment in the case of steel systems.

In addition to connections of high durability and reliability (pressing, soldering, welding), there are also those that do not require special skills and tools - using fittings for quick installation in case of accidents, as well as in non-pressure systems (self-locking, compression, and so on).This provides efficiency and flexibility in the work of the installer. It is forbidden to thread copper pipes, but combination fittings allow a simple transition to threading by pressing or soldering.

Due to the plasticity of copper, it is possible, using a mechanized or manual expander, to connect pipes by capillary soldering without the use of fittings. This makes it possible (in some cases significantly) to reduce the cost of the system during its installation. The fitting method of connection provides guaranteed stability of parameters and reliability of the system.

It is permissible to embed a copper pipeline in walls and floors, if products are used in insulation, corrugated pipe, shell, where thermal expansion is provided due to fluctuations in the temperature of the supplied water, or mounted in a box. Serviced connections must not be monolithic without providing access to them. When laid open, copper pipes are very aesthetically pleasing, can be painted, but require an arrangement that prevents the risk of accidental damage.

Metal-plastic products for the gas pipeline system

Metal-plastic pipes are actively used in gas pipelines. The inner surface of the metal-plastic pipe, in fact, is the same polyethylene. In addition, the supply of metal-plastic products often takes place in bays. This method allows you to lay the eyeliner of the required length with minimal connections. The connection of metal-plastic pipes is best done using press fittings, since they are able to provide a high level of tightness. However, there is one drawback, which is the use of specialized equipment for assembly.Although metal-plastic pipes are allowed to be used for gas pipelines, however, the mechanical strength of metal-plastic products remains a big question, therefore, it is recommended that the laying of metal-plastic elements be done in a hidden way. Metal-plastic refers to durable and elastic materials with a low coefficient of thermal expansion, so metal-plastic parts can be walled up. With the help of metal-plastic pipes, it is easy to equip lines between houses standing close to each other.

Security zones

If there is a construction of complexes or buildings that are not involved in the activities of the gas filling station system, the observance of the security zone, the length of which depends on the type of protected structure, will certainly be taken into account. Its dimensions:

- outside - 2 m on each side, even in cramped conditions;

- from the underground - 3 m from the delimiting gas pipeline;

- CNG stations and gas filling stations are limited to a vicious circle with a radius of at least ten meters from the established boundaries of the complex of capital construction projects.

Regulatory distances are the norm of distance from the gas pipeline to communications. Water supply, power lines, roads and railroad tracks must be at a certain distance, which is regulated by the reference table. The minimum horizontal distances in the light are taken into account (they depend on the pressure of the gas pipeline) and other existing requirements - electrochemical protection, climatic features, the presence of PUE and high-voltage lines, etc.

The distance from buildings and structures to the gas pipeline must strictly comply with the standards. Remote standards are regulated by the pressure of the supplied gas and the type of gas pipeline built.For low pressure aboveground, only a protection zone is required, due to existing operating rules. If necessary, it should be reconstructed.

Nuances

An additional application requires compliance with distances from boiler rooms, as fire hazardous industrial structures. Two pipes - only 4 meters away from the residential building. Windows and roofs require at least 0.2 meters, and up to the door - 50 cm.

Distancing from warehouses may be regulated by the enterprise, but it should not be less than in SNiP 2.07.01-89 and SP 42.13330.2011. The same applies to laying at the foot of the slope, which can be regulated by the builders and the administration of Russian Railways (sometimes the distance from the gas pipeline to the railway lines decreases, but less than the standard is not allowed, especially near the embankment).

LPG tanks are taken into account separately. There are several types of them. For example, according to their orientation in space, they are divided into vertical and horizontal, according to their location - underground and surface LPG tanks, single-walled and double-walled LPG tanks - according to the degree of endurance of the structure. The volume, location and type of the complex regulate the distances. The standard GPC has a maximum pressure value.

With regard to tank installations, the standards of SP 62.13330.2011 are taken into account, but in each specific case, the minimum distance is taken into account depending on the characteristics of a particular gas tank. Underground ones are deepened by 0.6 m, and the light distance between them is 0.7 m. Gas consumption metering point is a prerequisite when using such installations;

A gas consumption metering station is a prerequisite when using such installations; mixing units, if necessary, are mounted 10 meters away

Underground ones are deepened by 0.6 m, and the light distance between them is 0.7 m. A gas consumption metering point is a prerequisite when using such installations;

The design of buildings of any plan should be carried out near the gas pipeline only with the knowledge of controlling and supervisory organizations, which calculate the norm depending on the type of structures and the pressure supplied by valuable chemical raw materials and fuel.

Features of the installation of copper pipelines

Before proceeding with the installation of a copper pipeline, it is necessary to perform measurements and appropriate cuts. Here it is worth making sure that the cut is even. You can achieve this result using a special pipe cutter. The connection of pipes in the line is made by soldering or pressing.

The most common option is capillary soldering. With its help, you can achieve high reliability and tightness of connections. Often this method is used for joining rectangular copper pipes. In the process of capillary soldering, sockets and fittings are used. This option is ideal for the construction of a pipeline that will be used at high temperatures.

As for pressing, they are performed using various fittings. This is especially true for self-locking and compression products. In addition, compression clamps and special flanges are used in the construction of the pipeline.The compression joint is used in places where open fire will act on the pipeline.

Ventilation and security

When installing a geyser, a chimney must be used (read: “The nuances of installing chimneys for a geyser - expert advice”). A flexible corrugated aluminum pipe for these purposes is prohibited. Exhaust pipes for the column can only be steel or galvanized. A geyser, like any other heating device, is recommended to be equipped with fuses: they will cut off the gas supply in case of flame outage.

Features of arranging a gas pipeline in the kitchen from thin-walled metal pipes:

- Work begins with shutting off the gas supply valve.

- If the gas pipe in the kitchen needs to be relocated, the gas pipeline should be pre-purged to remove any remaining gas from the system.

- The gas pipe on the wall must be very well fixed. To do this, the product package includes clamps and brackets: they are used taking into account the diameter and length of the pipeline.

- When passing an electric cable near the gas pipeline, a distance of 25 cm should be observed between them. The gas system and the electrical switchboard should be 50 cm apart from each other.

- The gas-piped kitchen system should not be adjacent to cooling appliances such as a refrigerator or freezer. If you close the gas pipes with a refrigerator, its radiator will most likely overheat.

- When installing thin-walled gas pipes, heaters and a gas stove should be removed.

- It is forbidden to lay gas pipes in the kitchen on the floor surface, under the sink, near the dishwasher.

- When carrying out repair work, it is advisable not to use sources of artificial light. The room must be constantly ventilated.

Copper fittings and their types

All engineering systems, which will include a copper pipeline, require high-quality fittings for installation. We are talking about fittings that are designed to connect pipes into one system with a guaranteed absence of leaks.

With the detachable connection option, the use of a threaded or compression fitting is acceptable. For a permanent connection, it is better to use capillary or press fittings. Their main task in a pipeline for any purpose is to provide branches, turns, connection of two pipes with the same or different diameters. Without fittings, a high level of sealing of the heating, air conditioning or plumbing system cannot be achieved. Just like pipes, they have high ductility and corrosion resistance, are easy to install and operate for a long time without needing repair.

By design and purpose, they distinguish: adapters and adapters, a 45 ° or 90 ° elbow, coal and arc bends with one or two sockets, a coupling, a bypass, a plug, a cross, a tee, an elbow, a union nut; reducing - tee, coupling and nipple.

Such a large assortment will allow you to find those products that will form the basis of communications. Depending on the mounting method, fittings for copper pipes can be:

- The NTM self-locking push-in copper push-in fitting revolutionizes piping installation. It is enough to insert pipes into it from both sides, and the installation is completed.Inside such structures there is a system of rings. One of them is equipped with teeth. When a special mounting key presses on the toothed element, it is firmly fixed in the adjacent ring, and a perfect connection is obtained. These fittings are recommended for temporary pipe connections and are indispensable for repair purposes.

- A threaded fitting differs from other varieties in that it has a thread with which the connection is made. The best option for the case when the pipeline is supposed to be disassembled and reassembled several times.

IMPORTANT! Usually, it is not necessary to apply sealant to the connected sections of copper pipes. But if it is still used for better contact, it is imperative to make sure that particles of the material do not get on the thread. Such fittings are used in those places where access is needed for constant monitoring of the reliability of the connection

Couplings, 45 and 90 degree elbows or elbows, outlet fittings, crosses, tees, caps and special plugs are used as suitable threaded elements.

Such fittings are used in those places where access is needed for constant monitoring of the reliability of the docking. Couplings, 45 and 90 degree elbows or elbows, outlet fittings, crosses, tees, caps and special plugs are used as suitable threaded elements.

- A compression or compression (collet) fitting has a rubber ferrule to achieve a tight connection. It is indispensable for water supply systems in which there are pipes of various cross sections. It is used for installation of underground and above-ground pipelines from soft and semi-solid thick-walled copper pipes. Unfortunately, such a connecting element is at risk of leakage.If the connection is untwisted for replacement, the ferrule can no longer be reused.

- Capillary fitting that is used for soldering. With this type of connection, it turns out to be one-piece, very reliable and durable. It is performed using copper or tin solder. The process is based on the capillary effect. This phenomenon ensures that the solder is evenly distributed over the surfaces that are being joined. For decades, it was soldering that was the main type of installation, although in recent years the choice of fitting connections has expanded.

- A press fitting connecting the elements of a copper pipeline is used very rarely. For installation, you need a special press, which is not cheap. It is acceptable only when it is not possible to connect pipes in another way.

In fact, copper pipes are easy to cut and bend, installation of fittings is simple, and wiring systems in the house does not take up much space. Copper pipes in heating and water supply systems are valued for their durability, reliability and resistance to corrosion. In addition, the water in such a system is protected from various kinds of negative influences. Knowing these points, consumers are ready to purchase expensive copper pipes and fittings in order to have extra-class pipelines.

Norms of gas consumption for home heating

Restrictions in the consumption of utilities can be manifested in minimum tariffs, allowable power and resource release rates. The need for the existence of norms appears where there are no accounting counters.

The norms of natural gas consumption by the population are determined in the following areas of its use:

- cooking for 1 person per month;

- water heating with autonomous gas and water supply in the absence or presence of a gas water heater;

- individual heating of residential premises and outbuildings;

- for the needs of keeping pets;

Norms of gas for heating are calculated on the basis of consumption in equal shares by months of the whole year. They are measured in cubic meters per 1 m 2 of the heated area or per 1 m 3 of the heated volume. If the building is multi-storey, then the calculation is made for each floor separately. As a rule, attics, basement floors, as well as some basements are considered to be heated rooms.

Mounting

Installation of copper pipelines is carried out using special connections - fittings or using welding. Through press or collapsible fittings, the pipes are firmly joined to the elements of the heating system, however, welding is most often used. When installing annealed copper pipes in places where it is necessary, they can be bent so that the total number of joints and joints is reduced. For this, a pipe bender is used, thanks to which it is possible to obtain the necessary slope without compromising the overall patency of the system.

Installation of compression fittings does not require special equipment: the pipe is simply inserted into the groove until it stops, and then it is tightly screwed with a nut, while the material itself should be pressed against the fitting body. In order to achieve maximum fit and complete sealing, two keys must be used. That's all the equipment you'll need.However, one should not forget about the specifics of crimp fasteners, which involves complete control of tightness - such systems periodically begin to "drip", which is why the joints should not be walled up, access to the pipes should be open.

Press fittings are installed using special press machines, this is a rather expensive installation option, however, the connection is strong and reliable, but one-piece. Experts note that capillary soldering is considered the most universal method of installing copper pipelines; this method allows you to connect pipe segments of the same diameter to each other. To do this, flaring is performed at one of the ends, that is, its diameter is slightly increased, this allows you to insert one pipe into another.

The joint is cleaned with a special sponge or a metal brush, and then the joined surfaces are covered with flux - this is a special composition that provides maximum adhesion of the metal to the solder. Pipes treated in this way are sequentially inserted into each other so that the gap between them does not exceed a fraction of a millimeter. Next, the solder is heated with a welded torch, and when the material reaches the melting temperature, all the gaps that have arisen are poured with the molten composition.

After the seam is filled, it must be cooled, for this you can lower the joint into the water, or you can simply leave it in the open air. In general, this process, like repair, is quite simple, however, it requires accuracy, thoroughness and compliance with safety regulations.Copper pipes are aesthetically pleasing, but sometimes users paint such products so that the piping matches the overall concept of the interior.

It is very important that the paint used for this meets the following conditions:

- the coating should not change color under the influence of high temperature;

- paint must reliably protect against any type of external influences;

- even minimal peeling is unacceptable.

It is advisable to coat the pipes with a primer before applying the paint, experts recommend using a lead-red lead composition. Keep in mind that the paint does not absorb into copper, so you need to spread it very carefully with a brush. And even in this case, a more or less even coverage can be achieved only after 2-3 layers. However, you can also use paint from a spray can, it lays down much more evenly.

How to connect copper pipes with your own hands, see the following video.

Installation of copper pipes for water supply

Before starting work, you need to draw up a diagram of the future plumbing structure and, on its basis, calculate the footage of rolled pipe and the number of connecting elements (press couplings, tees, bends, adapters, etc.).

Necessary tools and materials

To perform the installation of pipe rolled copper alloy, you need to prepare a set of tools, consisting of:

- Hacksaws for metal or pipe cutter.

- Pliers.

- Manual calibrator.

- Wrenches or a gas burner (for heating the pipe section when connecting parts by soldering).

- File.

For joining pipe sections, depending on the selected connection method, the following materials will be required:

- Fitting.

- FUM - tape for sealing joints of detachable fittings.

- Solder and flux (in the case of soldering products).

Precautionary measures

Soldering copper products is carried out when they are heated to high temperatures, so when working it is necessary to wear protective clothing and use a fire shield. It is necessary to remove rubber or plastic braids from the parts to be joined in the contact zone. The valve to be installed must be unscrewed so that the sealing rings do not melt.

When soldering copper products in an already installed pipeline system, all shut-off valves should be opened so that the pressure level in the pipes does not exceed the permissible values due to the heating of some sections.

Work progress

Docking of pipe segments using fittings is performed in the following sequence:

- Cut pipe sections to the required size.

- If the water supply is assembled from copper pipes with PVC insulation, then this layer should be removed at the ends of the products.

- Clean the cut line with a burr file.

- Remove bevel.

- Put on the prepared part alternately the union nut and the compression ring.

- Connect the fitting to the nut and tighten the threads first by hand and then with a wrench.

- In places where a transition fitting is being installed from a copper pipe to a steel pipe, the tightness of the joints is ensured by the use of FUM - tape.

When connecting pipes by soldering with your own hands, you must follow the precautions described above and have certain skills. The preparation process and the soldering itself includes the following steps:

- Cutting the required lengths of pipes with a pipe cutter or a hacksaw.

- Removal of the heat-insulating layer (if any) and the resulting burrs at their ends.

- Removal of the oxide film in the soldering zone with a fine abrasive sandpaper.

- Fitting sanding.

- Lubrication of the outer surface of parts with flux.

- Inserting the end of the pipe into the fitting in such a way that a gap of no more than 0.4 mm remains between the parts.

- Warming up the contact zone of the gas burner elements (pictured below).

- Inserting solder into the gap between the fitting and the end of the copper pipe.

- Solder seam.

- Flushing the system from flux particles.

The process of soldering copper pipe rolled products can be viewed on the video:

Mounting Features

Mounting by soldering forms one-piece connections that do not need maintenance and are considered the most reliable in operation. But in order to solder copper plumbing, you must have sufficient experience in this type of work and relevant knowledge. Beginners can use the following recommendations:

- Cleaning copper products should not be done with abrasive cleaners, coarse sandpaper or a wire brush, as they will scratch the copper. Deep scratches on the surface interfere with the solder joint.

- Flux is a fairly aggressive substance with high chemical activity. Apply it in a thin layer using a brush. If there are excesses on the surface, at the end of the process of joining the parts, then they must be removed immediately.

- The contact zone should be warmed up sufficiently, but not excessively, so as to prevent the metal from melting. The solder itself should not be heated. It should be applied to the heated surface of the part - if it starts to melt, then you can start soldering.

- Pipes must be bent in such a way as to prevent creases and twisting.

- Installation of copper products should be carried out in front of aluminum or steel sections in the direction of water flow in order to prevent rapid corrosion of the latter.

- For the transition from copper pipes to sections of other metals, it is recommended to use fittings made of brass, bronze or stainless steel.

Methods for connecting copper pipes

Copper pipelines are reliable, durable, resistant to physical stress and corrosion. However, they can boast of such properties only with proper assembly. To combine individual elements into one system, there are several methods:

Crimp fittings. These are special elements used to connect copper pipelines: push-in fittings, crosses, bends, couplings. They are made of bronze, brass, copper.

One-piece connection method. This is a pressing technology that is carried out using press fittings, crimp sleeves. The strength of the finished connection is comparable to the soldering method.

Compression connection. It is detachable, with high strength. To carry out the work, you need hand tools, special collet clamps. However, this type of connection weakens over time from pressure surges, temperature changes.

It is important to observe him, periodically change consumables.

Soldering with copper fittings. A special element is used, which is called capillary

Solder is needed to create a secure connection.

It is important that after soldering, the products cool down under natural conditions. Compression fittings for connecting pipes

Compression fittings for connecting pipes

Compression fittings for connecting pipes