- The best fireproof mats for underfloor heating

- Unimat Boost-0200

- Veria Quickmat 150 2-C

- Teplolux Express

- Heat of Crimea EO-224/1

- Bases and types of heaters

- Expanded polystyrene and foam

- Cork

- Mineral wool

- Foamed polyethylene

- Recommendations for choosing mats

- Screed device for underfloor heating

- Necessary materials and tools

- Wet screed instructions

- Varieties of mats used for water heated floors

- Foil mats

- Thin mats made of extruded polystyrene

- Coated XPS mats

- Expanded polystyrene profile mats

- Materials for a warm water floor

- Underfloor heating pipes and laying schemes

- Screed

The best fireproof mats for underfloor heating

A feature of such models is reinforced insulation of conductive wires. Fireproof mats are designed for installation under thin and flammable flooring: linoleum, laminate, parquet, carpet, etc.

Unimat Boost-0200

4.9

★★★★★

editorial score

94%

buyers recommend this product

High-tech flexible rods are used here as heating elements. They are made of a composite material based on carbon, graphite and silver, they are resistant to mechanical damage and heavy loads.The self-regulating effect ensures economical energy consumption.

The heating area is 1.66 m², the dimensions of the mat are 200x83 cm. The package includes connecting wires, a corrugated tube and everything you need for self-installation and safe use. Surge protection extends the life of your underfloor heating.

Advantages:

- high strength and durability;

- simple installation;

- low power consumption;

- not afraid of network surges;

- rich equipment.

Flaws:

short cable.

Unimat Boost can be installed in residential or unheated areas. Universal solution for office, apartment, hospital, school, etc.

Veria Quickmat 150 2-C

4.8

★★★★★

editorial score

92%

buyers recommend this product

The Quickmat cable is 3.5 mm thick and has a high temperature internal and external PTFE insulation. It is equipped with adapter and end sleeves, fixed on a synthetic self-adhesive mesh with a connecting wire.

The power of the mat is 525 W, the maximum heating area is 3.5 m². The tape is not afraid of heavy loads and mechanical damage. Shielding the cable with aluminum foil prevents interference.

Advantages:

- fast installation;

- high strength;

- large working area;

- cable shielding;

- safety of use due to combined insulation.

Flaws:

small belt width.

Veria Quickmat is mounted under linoleum, carpet or laminate in residential areas.

Teplolux Express

4.8

★★★★★

editorial score

90%

buyers recommend this product

The main feature of the model is its mobility: it is ready for use immediately after purchase and does not require installation.To start using the mat, just put it in the right place and connect it to the network. The shell is made of artificial felt, is not afraid of moisture and is easy to clean.

Power - 540 W, protection class IPX7. The universal plug can be connected to any type of socket. The heating cable is resistant to heavy loads and practically does not protrude above the cover, which ensures comfortable use under a thin carpet.

Advantages:

- universal plug;

- Ease of use;

- small thickness;

- durable shell;

- ease of maintenance.

Flaws:

high price.

Teplolux Express can be taken with you on a trip. An excellent solution for connecting in a country house or operating in a rented room under a carpet.

Heat of Crimea EO-224/1

4.8

★★★★★

editorial score

87%

buyers recommend this product

The model does not require a complex installation procedure and can be used under any floor covering that does not have thermal insulation properties. When overloaded, the power is cut off, which guarantees fire safety.

The maximum heating area is 1.14 m² with the actual dimensions of the mat 180x63.5 cm. The small thickness allows you to keep the floor level almost unchanged. A carbon fiber acts as a heating element.

Advantages:

- fast installation;

- ease of carrying;

- thickness is only 0.3 cm;

- low power consumption;

- automatic shutdown.

Flaws:

small heating area.

Mats Teplo Kryma EO-224/1 are recommended for installation under a carpet or carpet. Inexpensive additional heating for a private house or apartment.

Bases and types of heaters

A variety of foundations can serve as a foundation.

concrete option.Such a floor, often found among all types of installation. For it, a cement-sand screed is used.

wooden version. This base uses edged boards, chipboard, plywood, MDF and more.

In order to choose the right thermal insulation material, it is recommended to take into account the technical features of the room and the type of base. Heaters have the same degree of thermal conductivity, but the layer thickness must be selected. Today, such heaters are most in demand: glass wool, cork cloth, polystyrene foam, foam plastic, foamed heat insulator. When buying, you should first familiarize yourself with the characteristics of the material.

Expanded polystyrene and foam

For the manufacture of the first option, technology is used when the texture acquires tubules for the movement of steam and air. The second copy is lighter in weight, "breathes" (let water vapor through). Expanded polystyrene has sufficient strength, withstands high mechanical pressure.

Penoplex sheets are produced in different sizes, for example: 120 X 240 cm, 50 X 130 cm, 90 X 500 cm. The density of polystyrene is 150 kg / m³, polystyrene - 125 kg / m³. Characteristics of materials can be changed by the manufacturer, depending on specific applications.

Comparative characteristics: the foam is inferior in density to "extrusion", it is subjected to deformation from various physical influences, which reduces the thermal insulation qualities. It is advisable to use it in floor structures between the lags.

Cork

This is an expensive natural material, made from oak bark. It is sold in stores in the form of rolls or sheets. Both forms have no differences in technological characteristics. They differ only in size and thickness. Cork gaskets are different:

- Low thermal conductivity.

- Waterproof.

- Environmental friendliness.

- Light fastness.

- Fire safety.

- Resistant to temperature fluctuations.

- Resistance to chemical reactions.

If there is a choice between products, it is better to take a cork. This substrate saves heat resources, especially if the structure is installed on the ground. The material does not change, does not shrink when exposed to a concrete screed. It is avoided by harmful insects, mice. It also does not damage mold fungus. However, it is worth considering that the cork substrate "hides" the height of the room.

Mineral wool

This is an old-generation insulation, it is fire resistant, so it is an order of magnitude more expensive than similar materials. It is produced in the form of plates, which is very convenient for installation. If the insulation is laid on an aluminum base, then the efficiency of the material increases significantly, even on the ground. It also absorbs noise and retains heat for a long time, the rigid structure is resistant to chemicals. Despite the positive properties, cotton wool has a minus - the content of toxins and carcinogens that are harmful to humans. Mineral fiber, in addition to everything, is hygroscopic. When laying on the floor, it must be protected from moisture.

Foamed polyethylene

Penofol is now readily used by consumers. The material is produced in rolls, with a wall thickness of 3-10 millimeters. The surface of the canvas consists of a foil coating, which has reflective properties. Allows you to reduce the height of the overall laying of the base, because you do not need to additionally place waterproofing. Foamed polyethylene is available in the following types:

- with a one-sided layer of foil - under the letter A;

- double-sided material - indicated by the letter B;

- self-adhesive - marked with the letter C (one side with foil, the other with an adhesive base);

- combined - "ALP" (the top is covered with foil, the bottom is covered with a special film).

All of them are designed for the device of the base of the water floor, they do a good job of thermal insulation in the device of the water floor. The technical characteristics of polyethylene are not inferior to polystyrene, both have high efficiency. It should be noted that the material is able to absorb moisture, as a result, the thermal insulation properties of the product are reduced.

Also, a wet screed containing chemicals in the composition simply corrodes the foil layer. Given this problem, manufacturers had to change the technology. They began to produce sheets where a layer of lavsan film is applied over the foil. This design perfectly protects the screed and the floor covering from the aggressive alkaline environment.

Recommendations for choosing mats

When choosing a heater, you should pay attention to such various technical and operational indicators. Main selection criteria:

Main selection criteria:

- waterproofing;

- the ability of the material to withstand static and dynamic loads;

- pipe diameter;

- features of the room in which the laying of the water floor.

So, roll material, due to its low waterproofing characteristics, is not suitable for laying on basement floors.

It should also be used with caution in apartments where people live below, because in the event of a pipe leak, it will not be able to retain moisture, and water will flow directly into the neighboring apartment.

Sheet mats and foiled polystyrene foam blocks, on the contrary, have good waterproofing qualities, which eliminates the possibility of leakage. In addition, they are materials whose thermal conductivity is very low, due to which, when they are used, the maximum level of heat transfer to the floor is ensured.

When organizing a water-heated floor, such a material characteristic as load retention is of no less importance. Profile mats made of expanded polystyrene with a density of 40 kg / m3 perfectly cope with this. Flat slabs and foil mats also have a high density.

These heaters can be safely used to organize an underfloor heating system in an apartment or in a private house, which will be used as the main heating.

But the rolled material remains outsiders in this position as well. Its density is not enough to withstand loads, so it can only be used to organize additional heating.

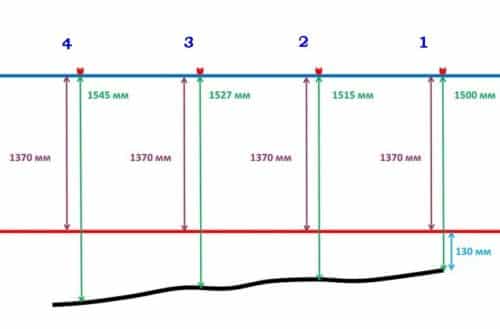

The above diagram shows what values the total thickness of the layers of the water floor is made up of, and what height of the room it can take (+)

Another parameter to take into account is the thickness of the mat. If there is already some kind of thermal insulation on the floor, thinner slabs can be used.

Also, the height of the room itself, the diameter of the pipes, the thickness of the future screed and the floor facing are taken into account.

Screed device for underfloor heating

Experienced finishers for the organization of a warm floor prefer to use the traditional pouring of the screed with concrete.The semi-dry screed technology can significantly reduce the time it takes for the base to be finished, which is a plus, but this type of floor leveling also has significant disadvantages compared to conventional concreting:

- Even with the most thorough compaction of the dry mixture, air pockets remain in the thickness of the layer, which are an obstacle to the passage of heat waves from the heater. As a result, the efficiency of underfloor heating drops sharply;

- Losses are especially noticeable if a semi-dry screed is performed on the first floor. In this case, the efficiency is 0.5.

The denser structure of the concrete base allows heat waves to pass without interference, respectively, to obtain the specified parameters for heating the air in the room, much less energy is needed than when operating in a semi-dry screed.

Necessary materials and tools

Before you start laying a warm water floor in a screed with your own hands, you will need to purchase the following materials:

- pipes with a cross section of 16-25 mm made of plastic, cermet or copper;

- collector for the estimated number of outputs;

- polystyrene foam lining with markings applied to it for installation;

- polyethylene film;

- connecting fittings;

- fiberglass reinforcing mesh, the recommended mesh size is 3 mm;

- clamps for attaching pipes to the base;

- damper tape;

- cement, it is best to choose the M500 brand;

- quarry sand;

- guides for lighthouses;

- fiberglass;

- plasticizer for concrete.

To work, you will need the following tools:

- a container for preparing the mixture;

- hand mixer;

- laser level;

- rule;

- construction knife;

- yardstick;

- pliers;

- PVA glue;

- Master OK.

Wet screed instructions

When performing work, you should adhere to a certain technology:

- Before starting work, it is necessary to free the surface from dust and dirt.

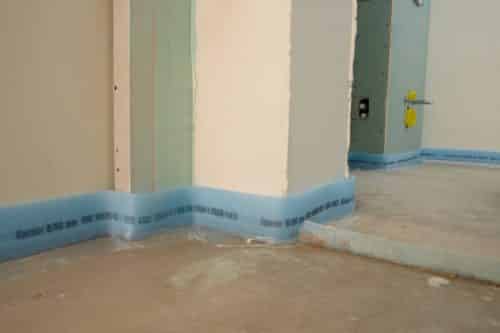

- In order to ensure the waterproofing of the floor, the surface is covered with plastic wrap. The film is overlapped, the joints are glued with adhesive tape, at the walls the film rises by 150 mm.

The damper tape is installed on the PVA glue along the bottom of the walls. Using a laser level, a horizontal mark is applied to the surface of the walls at a height of 1200 mm from the floor. Then find the maximum point. The calculation of the floor layers is carried out from this mark, it is necessary to take into account the thickness of the polystyrene base or foil substrate, the cross section of the pipes, the height of the reinforcing mesh and the minimum thickness of the fill. Thus, the height of the screed above the water-heated floor is determined.

- A heater is laid on the surface, which will not allow heat to escape into the thickness of the floor slab.

- Next, a mesh is laid, which performs reinforcing functions for the screed.

- At a distance of 50 mm from the wall, the first row of pipes is mounted, then the spiral is unwound with a gap between adjacent pipes of at least 120 mm.

- Pipe clamps are attached to the grid.

Install guides for pouring the solution.

- The solution should be poured onto the finished base at once, without interruptions, therefore, to prepare the solution, you will need a large container or several people who will constantly prepare new portions. For screed, it is recommended to use cement and sand in a ratio of 1 to 3, for each cubic meter of mortar, 800-900 grams of fiber should be added, which is poured into the mixture in small portions.The volume of water is approximately equal to the volume of cement, but the optimal amount is selected based on the plasticity of the finished mixture.

- The solution is ready, you can pour the base. Work begins from the far corner and gradually, leveling the surface with the rule along the beacons, they reach the doorway.

- For two weeks, it is necessary to spray the fresh screed with water daily to prevent cracking of the surface. After wetting, a plastic film is laid on the floor.

- When the base hardens, cut off the excess plastic film and damper tape from the wall. Then it is necessary to remove the beacons, close up the recesses with a solution.

The flooring of the finishing coating is started 28 days after pouring.

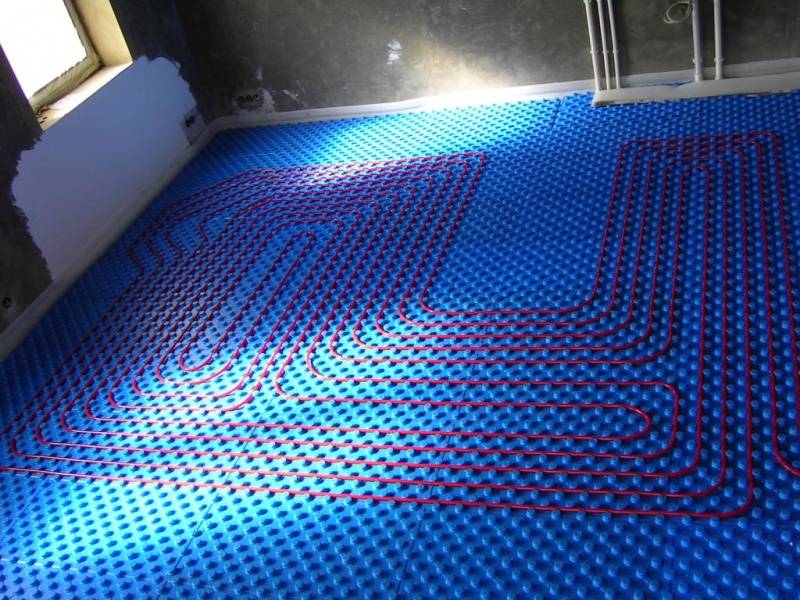

Varieties of mats used for water heated floors

Several types of mats are produced, differing in the material of manufacture, the method of attaching pipes, and the purpose for specific types of premises.

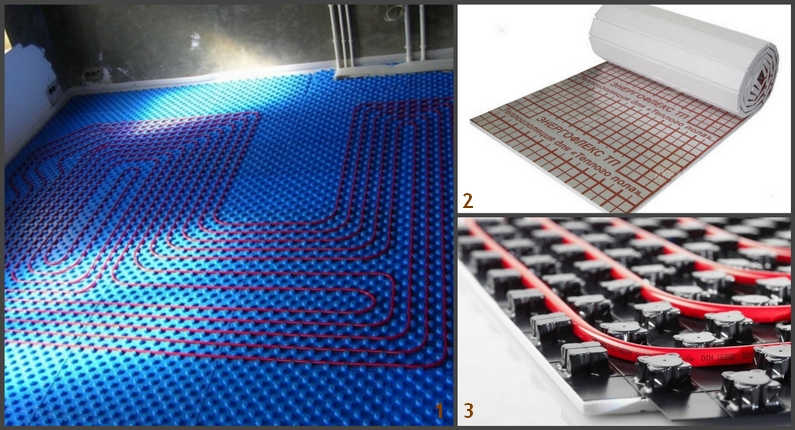

Foil mats

Foil mats are made from foamed polymers (most often polyethylene, penofol), and have a layer of foil on one side. They are necessarily covered with a foil part outward, and pipes for the coolant are laid out on this surface.

The simplest, thinnest polyethylene foam foil mats

The option is not the most successful, and is possible only if the base of the floor already has a sufficient level of thermal insulation, and the warm floor itself is considered only as an addition to the existing heating system. This type of mats is absolutely not applicable in the apartments of the first floors, under which there are basements or basements. They are also ineffective in private one-story construction.

Another significant disadvantage is that for laying pipes on top of such coatings, special additional structures will be required - a metal mesh, "combs", etc.

Fixing pipes to a metal mesh

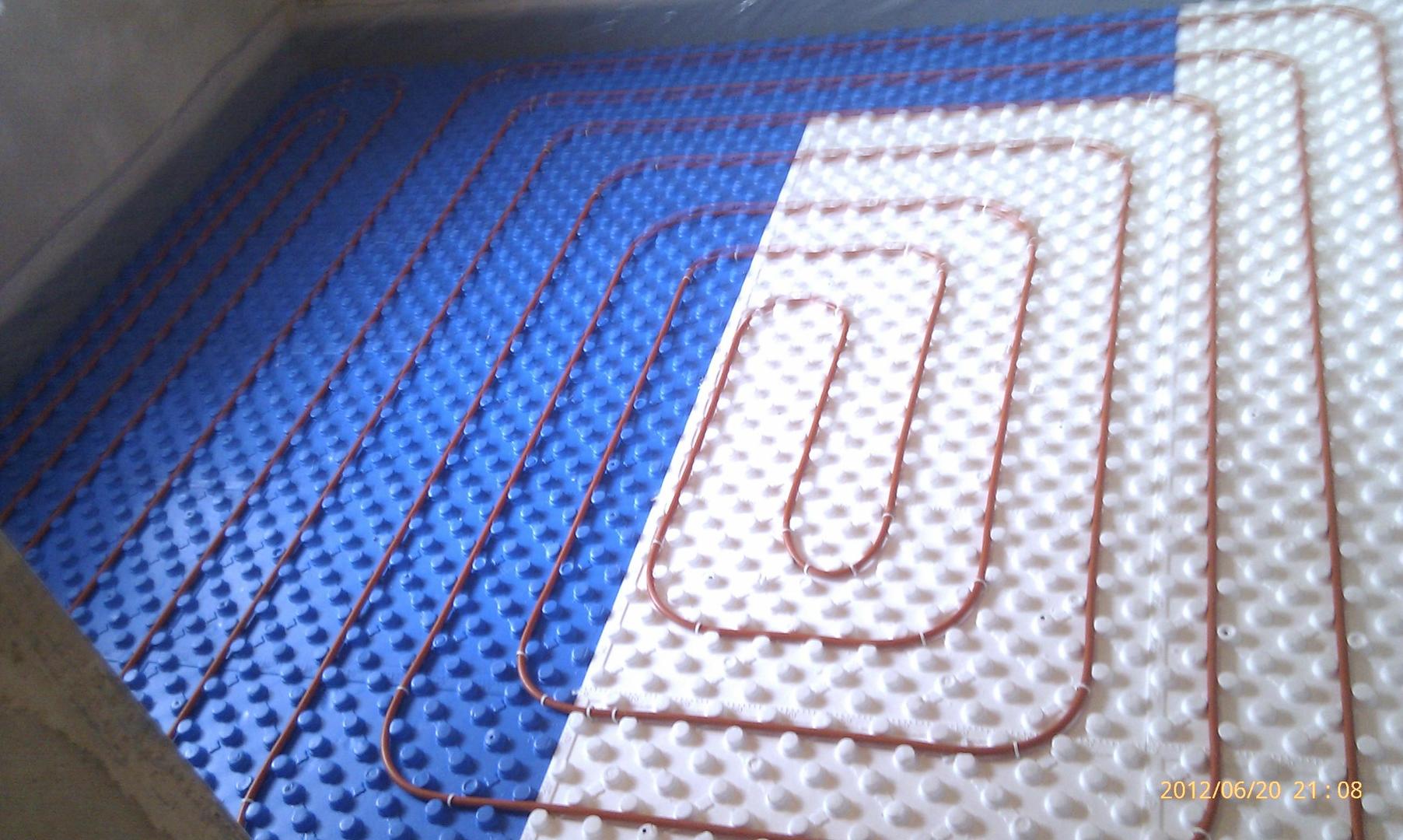

Thin mats made of extruded polystyrene

Flat mats made of extruded polystyrene (EPS) with a thickness of 40 ÷ 50 mm with a foil coating are quite applicable for a water heated floor, but with some reservations. The high density of PPS is important - about 40 kg / m³. The material itself does not have hydroprotection, so it will be necessary to lay it with plastic wrap before laying pipes.

A slight inconvenience on some mats of this class is the absence of marking lines, so they will have to be applied on their own. But fastening the pipes in place is very simple - with the help of special brackets.

Bracket for fixing the pipe

The use of such mats allows you to mount a warm floor, which can become the main source of heating in the room.

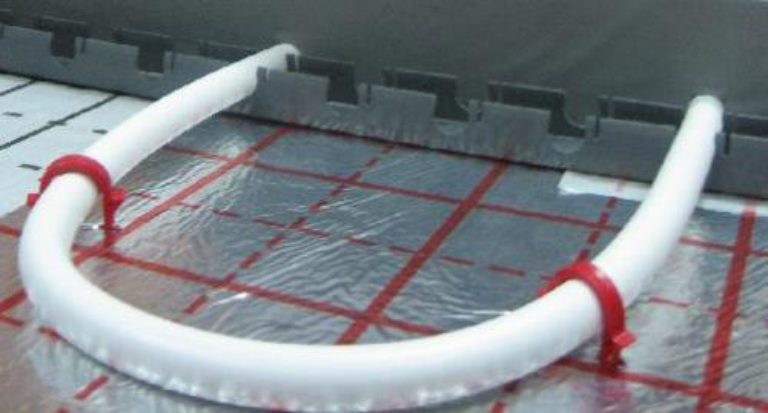

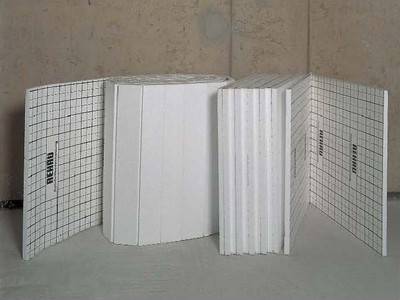

Coated XPS mats

More advanced are XPS mats made of high-strength material, which, in addition to the foil layer, also have a film coating with a marking grid applied to it, which greatly simplifies the process of laying pipes in accordance with a pre-drawn scheme.

Coated XPS mats

Such mats are extremely convenient in laying on the floor. They roll out of rolls like a tractor caterpillar, turning into a dense monolithic surface without any gaps. To pair adjacent rows, special grooves are provided - lamellae. Fastening to such mats is also carried out using brackets or "combs".

Their installation is simple and convenient.

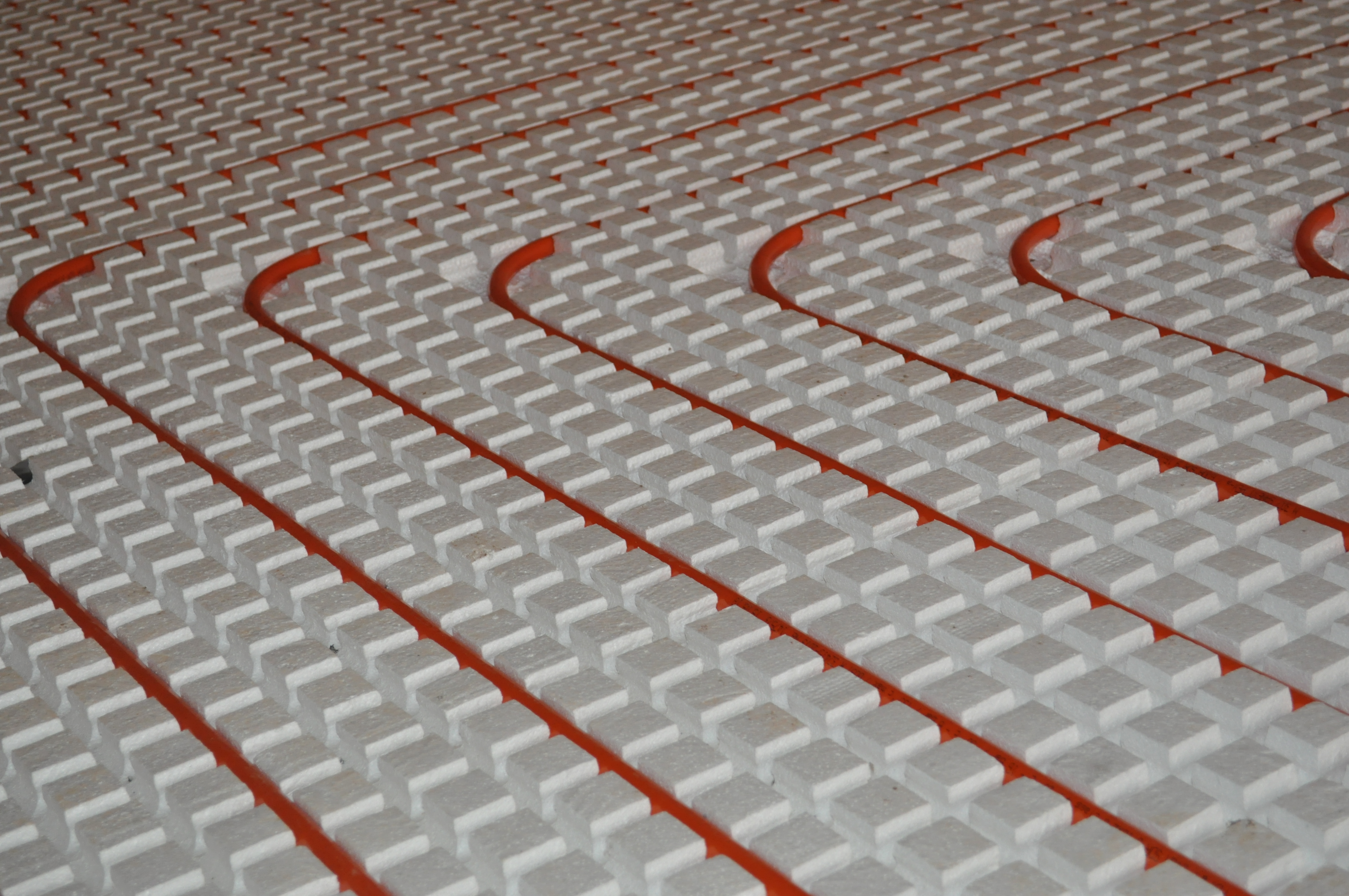

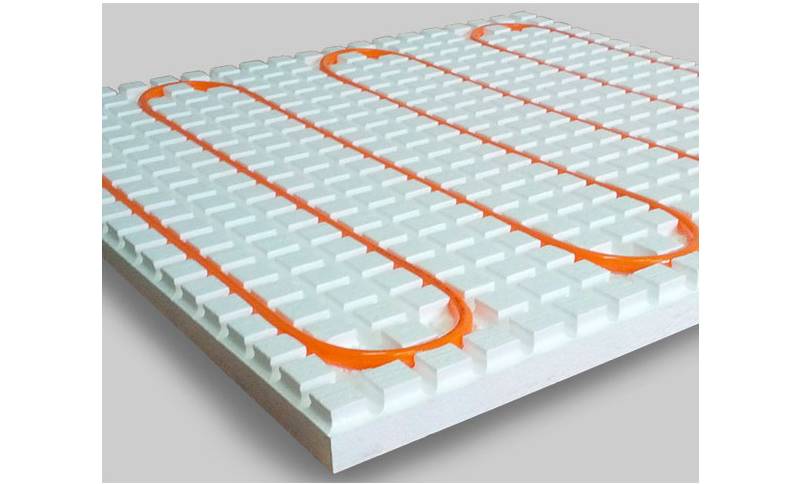

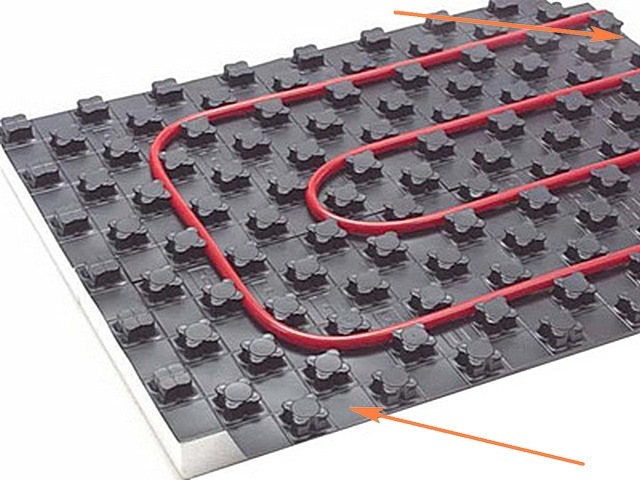

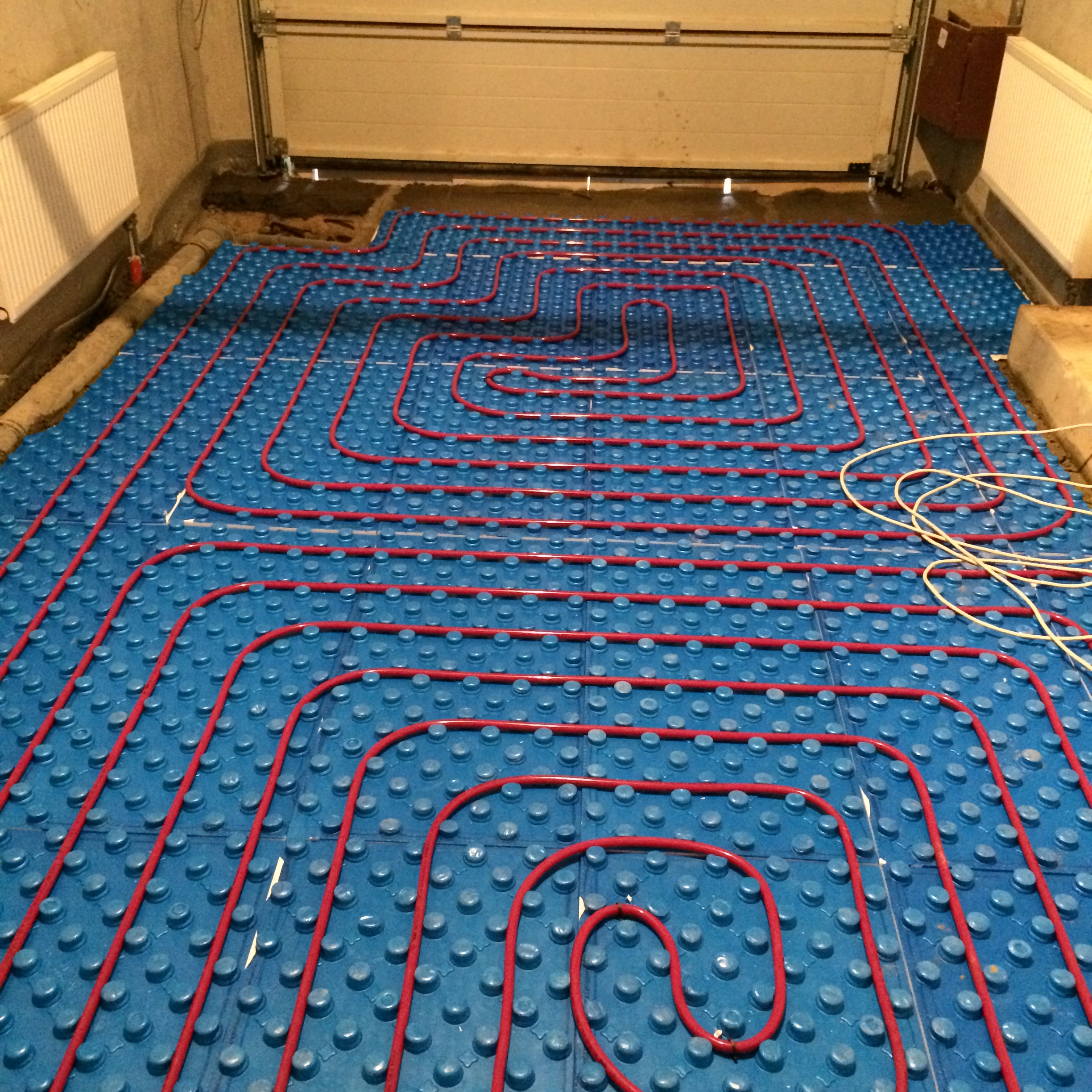

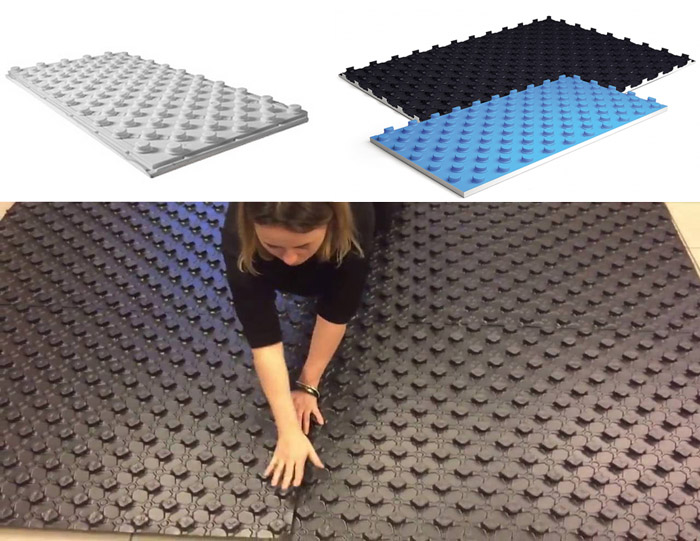

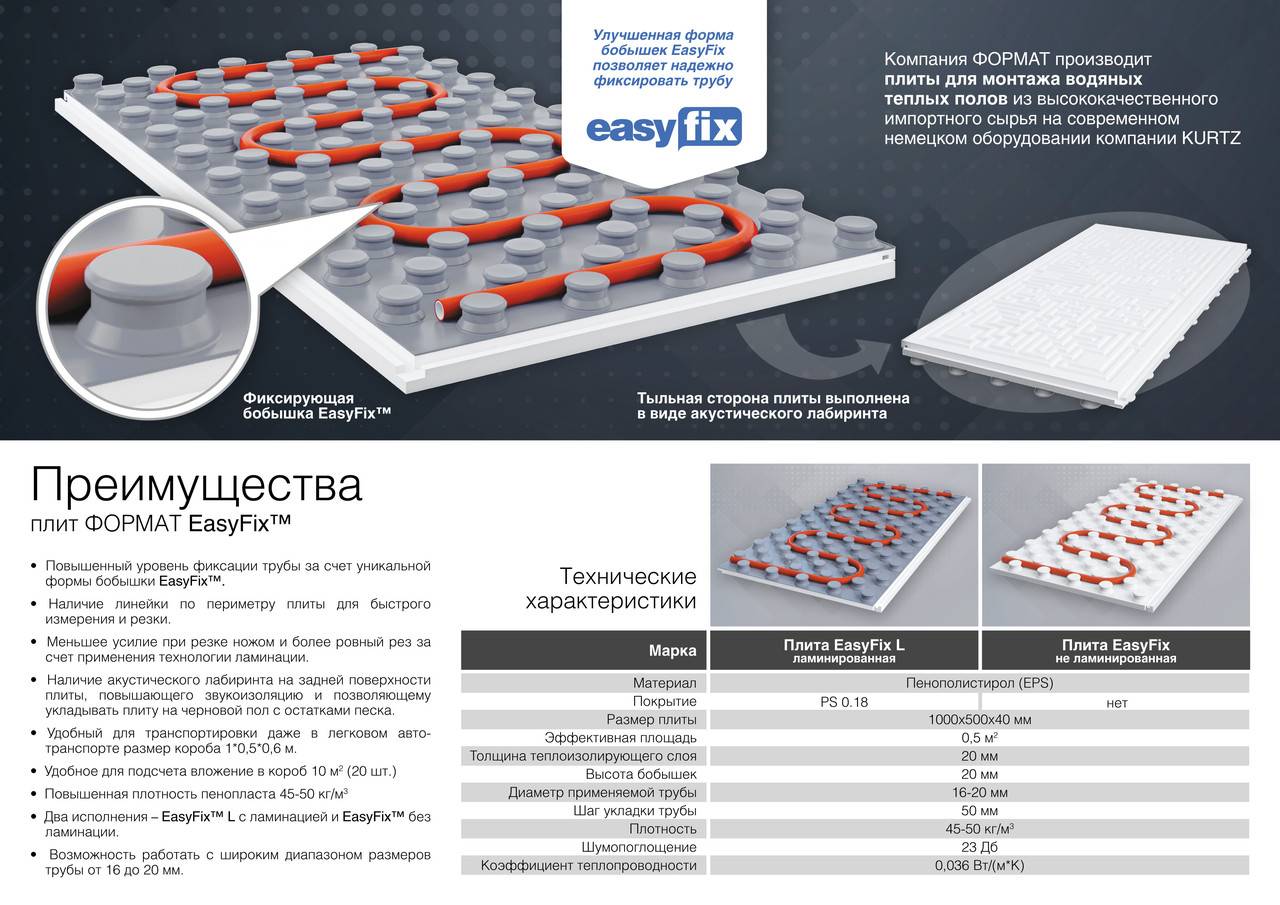

Expanded polystyrene profile mats

Of course, the most convenient for a warm water floor are polystyrene foam profile mats. They are made using stamping technology, which allows them to be given a complex configuration. On the upper surface of such a material there are curly protrusions of various shapes (rectangular, cylindrical, triangular, etc.) with a height of 20 to 25 mm (the so-called bosses).

Laminated mat with laid pipe

In the grooves formed between the bosses, the heating pipes are tightly laid, while obtaining excellent fixation, which completely excludes the displacement of the pipes during the pouring of the screed.

Profile mat without lamination

On sale there are polystyrene foam mats with bosses without a laminating film coating, but it is better to opt for coated mats - they are a little more expensive, but their reliability is much higher, since they also serve as a waterproofing layer.

Such mats have many advantages:

- The density of the expanded polystyrene used in their manufacture is 40 kg / m³, which allows them to easily withstand all mechanical loads.

- The thermal conductivity of the material is extremely low, from 0.035 to 0.055 W / m² × ºС - they perfectly retain heat, preventing unnecessary heating of interfloor ceilings or a flooded floor base.

- Both the physical characteristics of XPS and the complex cellular configuration of the mats make them excellent sound absorbers - the room receives additional sound insulation.

- As already mentioned, the film layer has good waterproofing qualities.In addition, a special system of end centering mat locks allows you to assemble them into a solid surface, without gaps at the joints that can pass moisture.

Usually mats are produced in standard sizes 1.0 × 1.0 or 0.8 × 0.6 m, with a thickness (without bosses) from 5 to 50 mm. The placement of the protrusions allows you to strictly maintain the pipe laying step - from 50 mm or more, with a distance that is a multiple of 50.

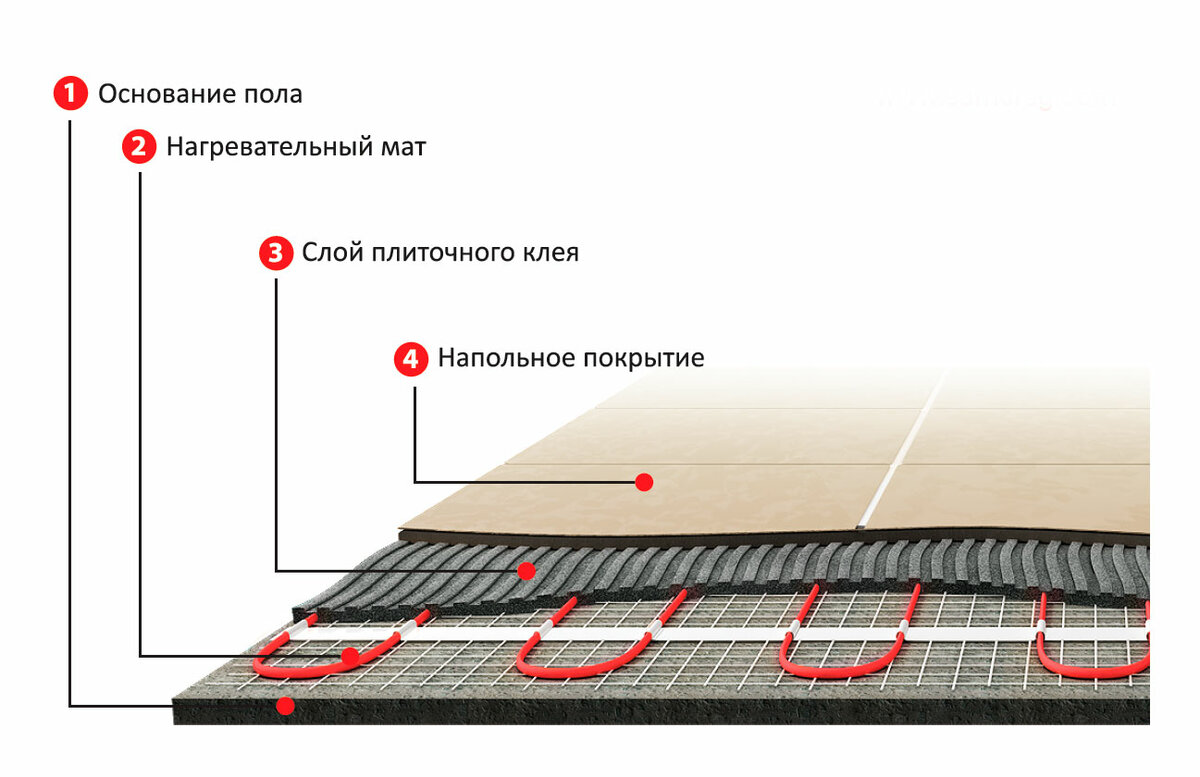

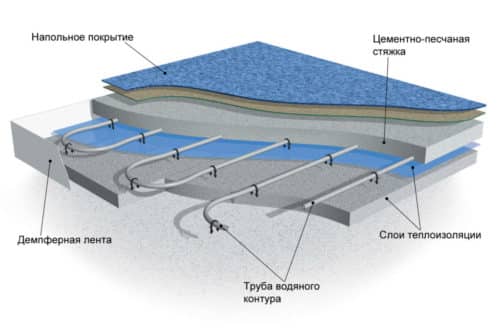

Materials for a warm water floor

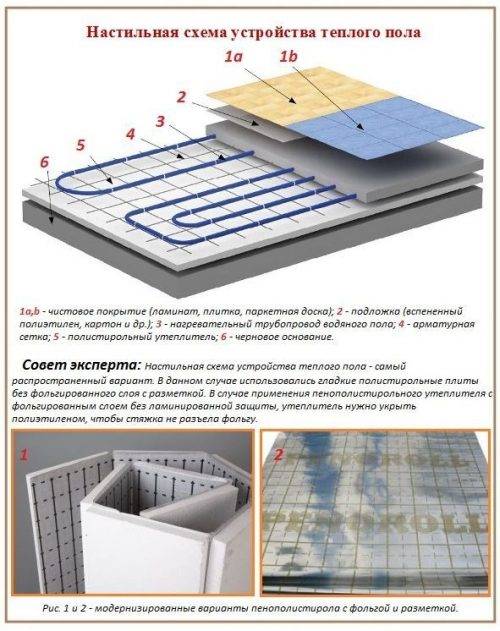

Most often they make a water-heated floor in a screed. Its structure and necessary materials will be discussed. The scheme of a warm water floor is presented in the photo below.

Scheme of a warm water floor with a screed

All work begins with leveling the base: without insulation, heating costs will be too high, and insulation can only be laid on a flat surface. Therefore, the first step is to prepare the base - make a rough screed. Next, we describe step by step the procedure for work and the materials used in the process:

- A damper tape is also rolled around the perimeter of the room. This is a strip of heat-insulating material, no more than 1 cm thick. It prevents heat loss for wall heating. Its second task is to compensate for the thermal expansion that occurs when materials are heated. The tape can be special, and you can also lay thin foam cut into strips (no more than 1 cm thick) or other insulation of the same thickness.

- A layer of heat-insulating materials is laid on the rough screed. For underfloor heating, the best choice is polystyrene foam. The best is extruded. Its density must be at least 35kg/m&span2;. It is dense enough to support the weight of the screed and operating loads, has excellent performance and a long service life.Its disadvantage is that it is expensive. Other, cheaper materials (polystyrene, mineral wool, expanded clay) have a lot of disadvantages. If possible, use polystyrene foam. The thickness of the thermal insulation depends on many parameters - on the region, the characteristics of the foundation material and insulation, the method of organizing the subfloor. Therefore, it must be calculated for each case.

- Further, a reinforcing mesh is often laid in increments of 5 cm. Pipes are also tied to it - with wire or plastic clamps. If expanded polystyrene was used, reinforcement can be dispensed with - you can fasten it with special plastic brackets that are driven into the material. For other heaters, a reinforcing mesh is required.

- Beacons are installed on top, after which the screed is poured. Its thickness is less than 3 cm above the level of the pipes.

- Next, a clean floor covering is laid. Any suitable for use in an underfloor heating system.

These are all the main layers that need to be laid when you make a do-it-yourself water-heated floor.

Underfloor heating pipes and laying schemes

The main element of the system is pipes. Most often, polymeric ones are used - made of cross-linked polyethylene or metal-plastic. They bend well and have a long service life. Their only obvious drawback is not too high thermal conductivity. This minus is not present in the recently appeared corrugated stainless steel pipes. They bend better, cost no more, but due to their low popularity, they are not often used yet.

The diameter of pipes for underfloor heating depends on the material, but usually it is 16-20 mm. They fit in several schemes. The most common are spiral and snake, there are several modifications that take into account some features of the premises.

Schemes for laying pipes of a warm water floor

Laying with a snake is the simplest, but passing through the pipes the coolant gradually cools down and by the end of the circuit it is already much colder than it was at the beginning. Therefore, the zone where the coolant enters will be the warmest. This feature is used - laying starts from the coldest zone - along the outer walls or under the window.

This drawback is almost devoid of a double snake and a spiral, but they are more difficult to lay - you need to draw a diagram on paper so as not to get confused when laying.

Screed

You can use a conventional cement-sand mortar based on Portland cement to fill a water-heated floor. The brand of Portland cement should be high - M-400, and preferably M-500. Concrete grade - not lower than M-300.

Semi-dry screed for underfloor heating

But ordinary “wet” screeds gain their design strength for a very long time: at least 28 days. All this time it is impossible to turn on the warm floor: cracks will appear that can even break the pipes. Therefore, so-called semi-dry screeds are increasingly being used - with additives that increase the plasticity of the solution, significantly reducing the amount of water and the time for "aging". You can add them yourself or look for dry mixes with the appropriate properties. They cost more, but there is less trouble with them: according to the instructions, add the required amount of water and mix.

It is quite possible to make a water heated floor with your own hands, but it will take a decent amount of time and a lot of money.