- Used materials for pool waterproofing

- PVC films

- Waterproofing membranes

- Bentonite mat

- Liquid rubber

- Polymerizing impregnations or liquid glass

- Coating composition

- Bitumen

- Additional materials

- 5 ECOROOM

- Internal and external waterproofing

- More about internal waterproofing

- No. 6. Where to buy PVC film for the pool?

- Is it possible to do without waterproofing?

- Pool waterproofing: liquid glass and the nuances of its use

- Number 3. Advantages and disadvantages of PVC film

- What it is?

- Why waterproofing is needed

- Types of mixtures for waterproofing works

Used materials for pool waterproofing

Various materials are used for waterproofing pools. Materials for waterproofing for swimming pools - a lot. Each individual material has its own individual characteristics and features. Consider - pool waterproofing materials.

PVC films

Polyethylene films are the cheapest in hardware stores, and everyone can afford it. However, PVC films have a significant disadvantage - if some defect (hole) appears on the film, then the material will have to be completely replaced. To isolate the pool with your own hands from the film, use a durable product.

Waterproofing membranes

The strength of this tool has long been tested.But in order to install the material, the intervention of professionals is necessary. For self-waterproofing, the use of other materials is required. The main disadvantage is that you will have to spend a lot of money, since the waterproofing membrane costs a lot of money, and the installation of this material is expensive.

Also, the waterproofing membrane must be stored from various kinds of damage. Main advantages:

- the membrane has a huge operational life (fifty years);

- the material is completely environmentally friendly material;

- you can carry out self-repair of a damaged membrane.

Bentonite mat

This material is based on a natural sodium mat. A distinctive feature of the bentonite mat is that it can self-repair. A gel-like state is formed when a certain amount of moisture enters the material. The resulting gel-like state closes all defects (cracks, crevices, and so on).

The main advantage of bentonite mat is its high level of resistance to various mechanical damages. Also, bentonite mat has some disadvantages:

Might be interesting

Waterproofing

Clean water is a guarantee of health, waterproofing of concrete…

Waterproofing

The choice of materials, the methodology for carrying out waterproofing work ...

Waterproofing

Types of pasting waterproofing

Waterproofing

Optimum indoor air humidity

- bentonite mat cannot withstand high water pressure;

- A certain load (200 kg/sq.m.) is required to install the bentonite mat.

Liquid rubber

This material is great for any pool configuration.Liquid rubber does not have any seams. Liquid rubber is an environmentally friendly material, and it will not bring any harm to human health. Waterproofing the pool with liquid rubber is not often done.

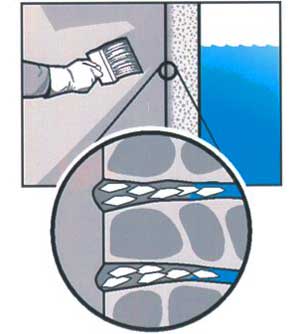

Polymerizing impregnations or liquid glass

Liquid glass for pool waterproofing is an emulsion of polymer resins. This emulsion penetrates the concrete of the structure. After a certain period of time passes, the material becomes plastic. Liquid glass is best suited for the top of the structure. After applying the polymerizable impregnation, a layer of plaster can be applied. Waterproofing the pool with liquid glass is an easy process of work.

Coating composition

The coating composition is intended for internal waterproofing structures. The coating composition is a waterproof solution. It becomes waterproof after it dries. This method of isolation from water has significant efficiency and reliability.

Bitumen

Although bitumen has a low cost in the construction market, it has many disadvantages:

- short service life;

- poor adhesion to any surface (adhesion);

- the surface on which bitumen is to be applied must be perfectly flat;

- if the base is uneven, then the material deteriorates in a short period of time.

The use of bitumen is not recommended.

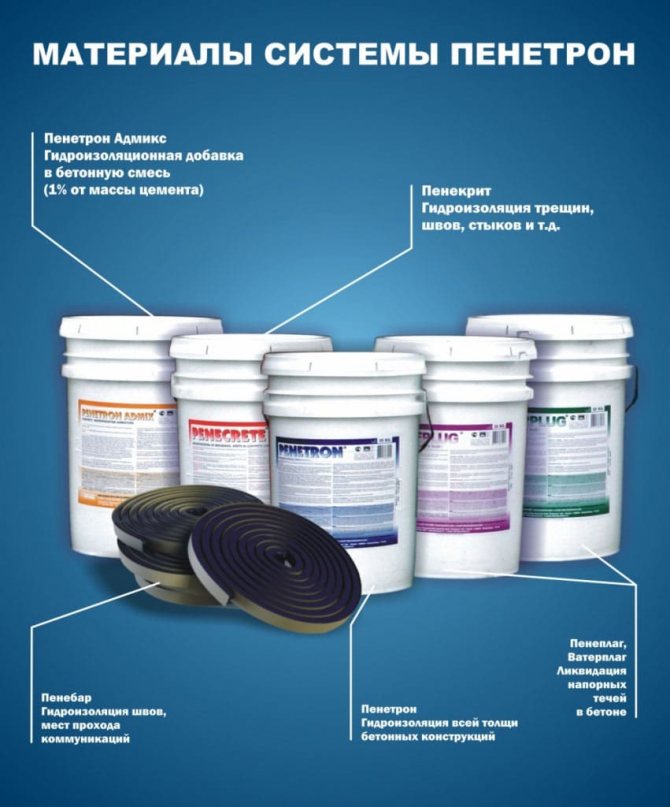

Additional materials

Sold materials that are intended for auxiliary purposes. For example, sealing cords are such material. Sealing cords are used to seal joints and cracks. They are also suitable for seams.

Tapes, which are also intended for sealing joints, are installed at the place where the wall joins the wall or where the wall joins the bottom.

In order to seal process waters, use "Penebar". "Penebar" is a tourniquet that has a rectangular section. At the base of this material is a polymer substance. As soon as "Penebar" is in contact with water, it begins to swell, thereby closing cracks and crevices. "Penebar" are also used to seal work seams.

5 ECOROOM

One-component waterproofing for foundations based on polyurethane is used to create a protective layer in building structures. It is based on a hydrophobic elastomer resin, which is combined with fillers that create a strong moisture barrier after curing. The main area of application is the processing of beams and ceilings made of concrete, tanks (wells, tunnels), basements, parking lots. The key advantages of this liquid coating mixture are high penetrating power and retention of elasticity in the cold.

The composition is ready for use, and, judging by the reviews, it is fully capable of providing not only reliable adhesion, but also environmental safety. The mixture completely hardens in about 6 hours, and polymerization takes up to 7 days. After the end of this process, it forms the most reliable and dense layer, not affected by precipitation, condensate or groundwater.

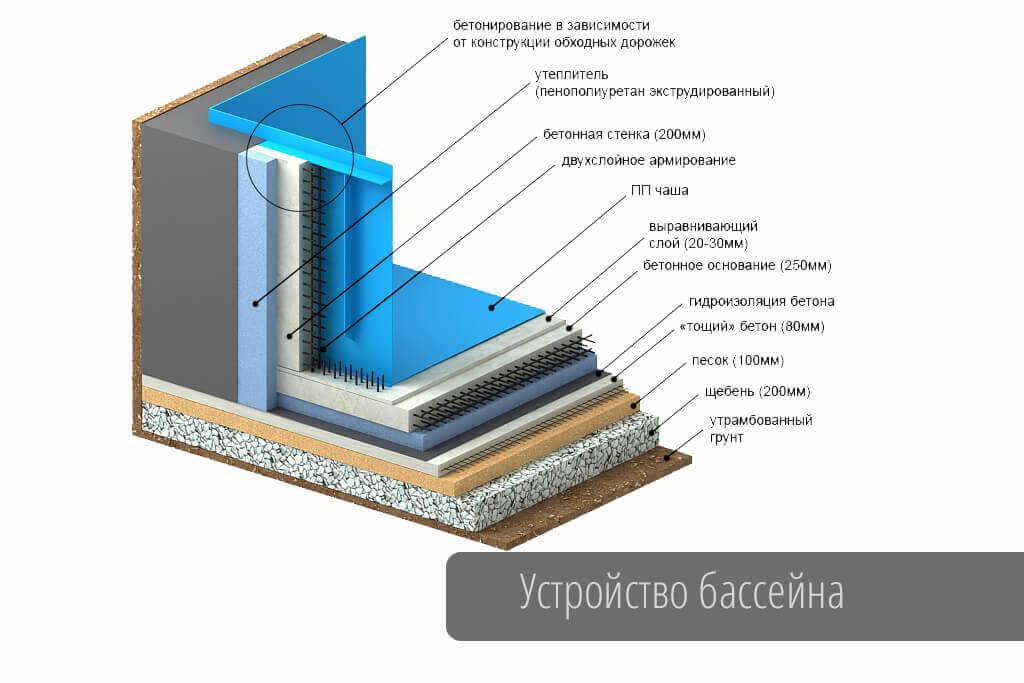

Internal and external waterproofing

A number of measures are taken to protect the outer surface of the base of the pool. In this case, we mean the laying of moisture-resistant materials from the side of the ground. The waterproofing of the pool is called external

It is equally important to protect the fine finish and all internal communications from exposure to the water contained in the bowl. Such waterproofing of the pool performs other functions and is called internal

The features of each of these layers should be studied in more detail. For example, external waterproofing significantly reduces the likelihood of groundwater impact on the structure base. At the construction stage, they are guided by the requirements that apply to foundations. However, the pool is subjected to more intense loads, since it is influenced not only by the heaving process and groundwater (from the soil), but also by dynamic loads, as well as shrinkage and possible changes in the geometry of the bowl, which occur due to thermal expansion and as a result of impact large volume of water.

Waterproofing layers

External waterproofing of the pool is carried out using different materials. The main options that are suitable for this purpose are:

- roll;

- coating;

- penetrating;

- membrane.

However, roll materials are more often used. In this case, it is not necessary to carefully prepare the surface. Additionally, clay castles are made. This is a natural way to protect against groundwater penetration, which is due to the properties of clay. However, such measures are not effective in some cases. So, if groundwater lies closer to the soil surface, and there is a risk that the liquid will wash away the base of the pool, measures must be taken to divert it. For this purpose, a drainage system is equipped.

The most effective option is that which involves the use of different types of waterproofing materials to protect the base of the tank. For example, the walls on the outside are insulated, insulated, and then another moisture-proof layer is laid, but of a different structure. For reliability, a clay castle is equipped.

Internal waterproofing - installation

More about internal waterproofing

For the pool, it is important to protect the base (external walls) and the bowl itself. You should know that concrete is a hygroscopic material, due to its porous structure. Gradually, it absorbs moisture, which reaches the metal structure provided to strengthen the pool. The frame, made of reinforcement, rusts over time. This means that it will become less durable. As a result, the entire structure will suffer, and it will be impossible to operate the pool.

When frozen, the liquid in the pores of the concrete can cause irreversible changes. During the thawing process, the degree of stress increases significantly. Cracks appear, and they appear inside. In addition, it is necessary to take into account the constant impact of aggressive environments on the materials from which the bowl is made.

All these factors can be eliminated or smoothed out as much as possible if the inner surface of the pool is covered with a waterproofing material. For this purpose, various types of protection are used:

- roll coating;

- penetrating compounds;

- liquid and coating insulation.

When arranging the pool inside the building and in the open air, various technologies are used.The internal insulation of pools is a mandatory step in any of the cases, but the protection of the external surface of the structure from the soil is necessary only for outdoor structures. If internal waterproofing of pools is performed, it is recommended to use coating, liquid materials. This is due to the fact that such compositions are characterized by high adhesion to surfaces. However, in this case, you will have to carefully prepare the pool bowl.

outdoor swimming pool

No. 6. Where to buy PVC film for the pool?

To purchase a really high-quality product, you need to contact specialized stores. When buying through the Internet or small points, you may encounter the following troubles:

- The seller will not provide you with a guarantee for the purchased product. And not from the manufacturer, not from your outlet, which should already arouse your suspicion and discourage you from purchasing goods here;

- In addition to the warranty, there may be no delivery. For people with personal transport, this may not be a problem, but for the rest, given the weight of the rolls, this will incur additional costs. After all, reliable distributors can always provide free or minimal shipping;

- Lack of a certificate confirming the compliance of the decoction with sanitary standards;

- And the most unpleasant thing is the substitution of goods. It may happen that you will be shown a sample of really high-quality film at the right price. You place an order, pay for it, after which you will be shipped a film of a similar thickness and color, but of a completely different manufacturer, of course, at a much lower cost.You can find out about this only if the film has a characteristic smell, like cheap analogues. Or when, after several years of operation, the waterproofing layer wears out.

Is it possible to do without waterproofing?

It may seem that the arrangement of insulation in the bathroom is an extra waste of effort and money. Supporters of this point of view motivate the position by the fact that ceramic tiles, which are most often used to decorate bathrooms, are completely waterproof.

This is true, but the tile joints perfectly pass moisture, as well as cracks and chips on the tile itself. Even if these cracks are microscopic.

You should not be sure about the quality of plumbing fixtures. Sooner or later, they may malfunction, and water will rush onto the floor in a stream, or, even worse, will accumulate under the equipment little by little, gradually destroying the floor covering or wall.

That is why plumbers and builders strongly recommend the arrangement of high-quality waterproofing of the bathroom. What is meant by this?

First of all, you need to isolate the floor. This is done so that water cannot penetrate the floor slab and seep into the apartment or basement below. And also so that moisture does not accumulate in the base, does not destroy it and does not provoke the growth of mold and fungus.

Ideal floor waterproofing looks like a kind of "trough" made of a special material. It is applied to the bathroom floor with a partial approach to the walls. The height of such an entry is about 20-25 cm. The insulating "trough" must be completely waterproof. But that's not all.

Bathroom walls also need insulation, even if they are tiled.As already mentioned, tile joints and cracks perfectly pass moisture, which will flow down the wall surface and accumulate in the most inappropriate places.

Bathroom waterproofing required. The best option - processing the most unprotected areas from moisture

To prevent this unpleasant phenomenon, it is worth equipping waterproofing protection in the most "dangerous" areas. They are located in close proximity to the sink, bathtub, shower boxes and other sanitary equipment.

In some cases, experts recommend waterproofing the bathroom ceiling. This is necessary if the bathroom is located in a multi-storey building and there are more apartments above it.

Pool waterproofing: liquid glass and the nuances of its use

Most people are unaware that such an intriguing name hides nothing more than ordinary stationery glue, which was widely used half a century ago, and today it has given way to PVA glue. So, this ordinary clerical glue, if anyone remembers it, after hardening creates a hard and durable film that resembles (both externally and in some physical ways) glass. It is this film that creates a barrier to water, preventing it from passing inside the concrete case. By itself, it is fragile and crumbles easily, but in combination with an ordinary cement-sand mortar it creates a durable and reliable waterproofing coating.

Liquid glass for pool waterproofing photo

It is possible to characterize liquid glass for pool waterproofing as a cheap and not very simple method, which has a number of significant drawbacks, which, against the background of one single advantage - low cost - make this material unattractive. The main disadvantages of liquid glass include the following points.

- The main drawback of this waterproofing material is that when combined with a cement mortar, it hardens almost instantly - the master has five minutes to do everything, no more. During this time, you need to have time to apply the prepared solution to the surface of the pool and level it with high quality. This property of liquid glass dictates some requirements for the performance of work: firstly, such a solution should not be mixed in large quantities; secondly, you need to apply it in a thin layer and, thirdly, you will have to work very quickly.

- Another disadvantage of waterproofing a concrete pool with liquid glass is its fragility. In essence, with this method of waterproofing, you create a layer cake on the surface of the pool bowl, the first layer of which is the usual leveling plaster, the second layer is waterproofing, and the third layer is glue and tile. Too many elements of unreliability - to ensure a reliable connection of all layers to each other, you will have to try hard. The slightest deviation from the technology leads to a reduction in the life of the pool almost twice.

In principle, if you look further, you can find a bunch of other shortcomings, but these two are enough to abandon this method of waterproofing the pool from the inside with your own hands.

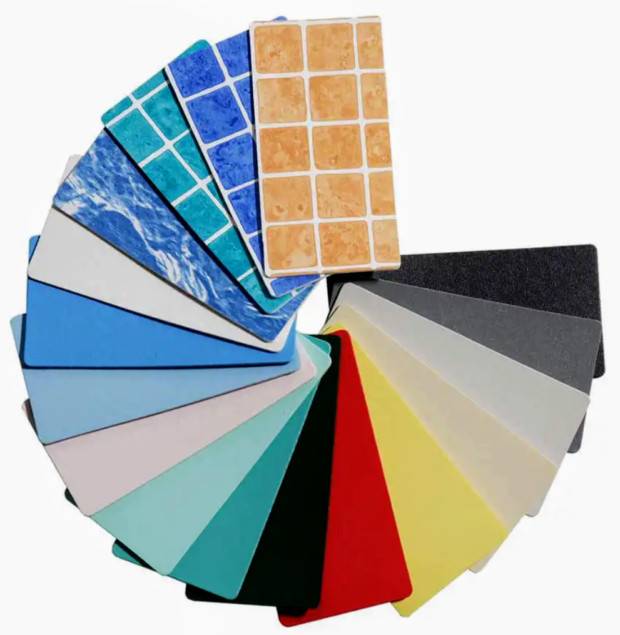

Number 3. Advantages and disadvantages of PVC film

We can safely say that the use of PVC film has made it possible to make a big step forward in the construction and finishing of swimming pools. After all, with the right selection and observance of installation technology, you can get a lot of advantages:

- One of the main advantages of the liner is the ability to carry out waterproofing work in the shortest possible time. In addition, one person can handle the job;

- The simplicity of the work performed. To work with the film does not require any special skills. And if you have such qualities as scrupulousness and accuracy, then you can completely master the independent installation;

- At the moment, this type of finish is the most economical in comparison with other finishing materials for pools;

- The film does not spoil the appearance of the pool. Along with waterproofing, the liner also performs a decorative function. After all, its surface can be of various colors or have a “mosaic-like” or “marble-like” pattern. Many argue that the joints of the canvases are a visible defect, since the canvases must be soldered with an overlap. This nuance is really noticeable - to a greater extent on plain films. But do not forget that a lot depends on the quality of the installation. When carried out at the proper level, the junctions can be almost invisible;

- Due to the increased plasticity and elasticity, with the help of the liner, it is possible to finish the pools of complex curvilinear shapes, which cannot be done with the help of tiles. In this case, the contours of the pool will not undergo any changes;

- You have the option to improve the safety of your pool by opting for a liner with an anti-slip and anti-microbial coating;

- When finishing with a film, there are no sharp traumatic corners, as happens with poor-quality laying of tiles;

- There is no possibility of spontaneous formation of cracks or chips;

- Reinforced film withstands sub-zero temperatures without losing its qualities;

- Material resistance to ultraviolet rays;

- In case of damage to the coating, it is not required to completely replace it. You can perform local repairs of waterproofing;

- The material is strong enough to be damaged, it is necessary to exert an intentional mechanical impact;

- The service life of a high-quality coating with proper installation reaches 10-15 years.

The disadvantages of the material include the following points:

- Small scratches and abrasions in places of intensive use, for example, on the sides or steps, cannot be ruled out;

- Labor-intensive cleaning process;

- Film without acrylic coating is not intended for use at low temperatures;

- Visible joints - perhaps for someone this is really a significant drawback.

As you can see, the advantages of the material are enough to prefer it to other types of finishes.

What it is?

House waterproofing is used to prevent moisture from entering concrete structures. In most country houses, walls, roofs, foundations and basements need protection, directly in the house or apartment itself - bathrooms, bathrooms, in a word, those rooms where flooding is possible.

In addition, there may be insulation or other materials in the house that need to be protected from any ingress of moisture in the form of precipitation or condensation.In general, it is necessary to ensure the impermeability of materials in all places where there is a possibility of negative influence on the material from washing or condensate waters. For these purposes, various types of waterproofing are used, which differ in the place of application, materials and purpose.

In recent years, the market has been developing rapidly, offering new and innovative solutions, while old-fashioned methods continue to operate - for example, laid roofing material. The group of waterproofing works includes a wide range of materials that provide, in addition to protection from water, also sound insulation and temperature maintenance.

Why waterproofing is needed

Waterproofing in construction is understood as a set of works aimed at arranging effective protection against moisture. Swimming pools are no exception. They must be protected from the damaging effects of water.

It must be understood that the bowl is a complex structure, inside which there is a fairly large mass of water. It puts pressure on the walls of the pool, and when filling or lowering, additional efforts are applied to them.

Image gallery

Photo from

Waterproofing measures necessary to protect the concrete bowl from the action of an aggressive environment are carried out both from the inside and outside the walls of the pool bowl

The waterproofing device uses a wide range of coating materials, two- and one-component, made on a cement basis

Waterproofing work is carried out much faster if a sprayed polymer agent is chosen as the material.

At the highest pace, work is carried out using rolled bitumen-polymer materials and polymer membranes

Waterproofing outside the pool

Coating waterproofing agents

Polymer sprayed waterproofing

Sealing waterproofing for swimming pools

The slightest cracks or any other defects will become a serious threat to the entire structure. Under the influence of moisture, even microscopic flaws quickly turn into a serious problem.

Therefore, it is very important to prevent contact between water and the walls of the structure. Concrete pools are often built

This is a porous material that instantly absorbs moisture. It is very bad that the water inside the concrete structures quickly destroys them.

Waterproofing is necessary to protect the concrete structure from groundwater and from water in the pool bowl, which as a result significantly extends the service life of the structure.

But not only concrete is threatened by excess moisture. From the inside, the walls of the bowl are usually reinforced with metal rods. The porous material freely passes water to the reinforcement. As a result, it corrodes and quickly crumbles. Thus, without proper waterproofing, a bowl that is under severe stress will literally crumble in the shortest possible time.

A swimming pool is a complex structure that experiences constant loads associated with the water that fills it. The slightest defects in the base can provoke destruction. Without waterproofing, this process will go many times faster.

High-quality waterproofing of the pool must meet the following requirements:

- Durability and long service life;

- High resistance to adverse external influences;

- Good adhesion.

- High elasticity.

Ideally, the insulating layer should have all the properties listed above and at the same time form a seamless monolithic coating that covers the entire surface of the bowl.

Not only the bowl needs protection from moisture, but also the outer side of the structure. For arranging external waterproofing, a clay castle is often used.

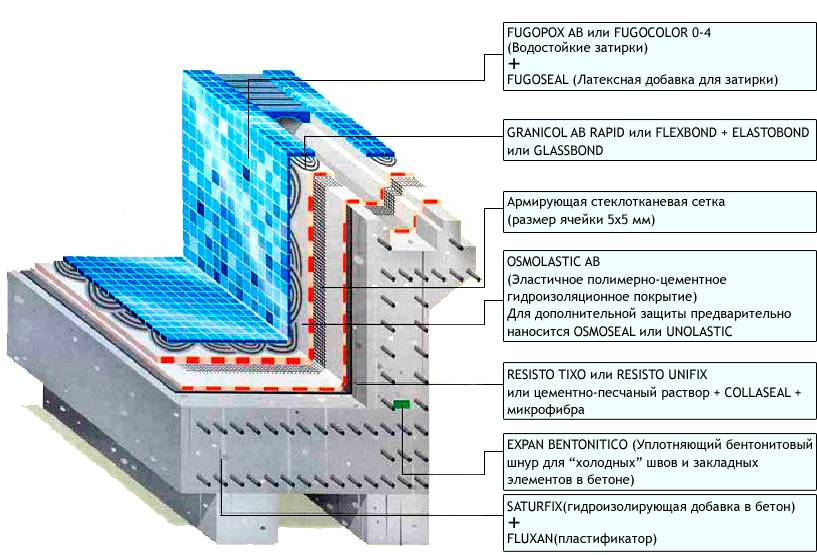

Types of mixtures for waterproofing works

Dry waterproofing mixtures of this category provide excellent water resistance of concrete structures, they can be used both at the initial stage of construction, and in the repair or restoration work of building structures.

Penetrating waterproofing

Waterproofing mixtures of this group are intended for volumetric waterproofing of porous waterproof material.

The principle of operation is as follows:

- penetration of the solution into the porous structure of the insulated material;

- fixation of the material in the capillary pores of concrete in the form of chemical compounds that do not dissolve;

- filling the pores with sparingly soluble crystals.

The principle of operation of mixtures of penetrating waterproofing

The penetrating waterproofing mixture, which includes special components, allows for additional modification of the qualities of the processed material:

- restoration of the technical properties of the "old" concrete coating;

- prevention of corrosion in reinforced concrete reinforcement;

- increasing the chemical resistance of the insulated material;

- elimination of fungal formations and mold.

A mixture for waterproofing penetrating action is used on such objects:

- different reservoirs;

- waterproofing of pools;

- mines and tunnels;

- dams and foundations;

- pumping stations;

- hydrotechnical and treatment facilities;

- production premises;

- recessed rooms, etc.

The range of mixtures on the construction market is huge, the following materials can be distinguished:

materials of the Lakhta system - cement-based dry mixes that are used in waterproofing foundations and culverts;

dry mix

materials of the Stromix system - high chemical resistance and strength characteristics make it possible to use these mixtures in repair and restoration waterproofing works of varying degrees of complexity;

Waterproofing Stromix

materials of the Kalmatron system are building mixtures that are a good protection for reinforced concrete and other porous building materials from the influence of aggressive environments of a different nature.

Waterproofing Kalmatron

Waterproofing dry mixes of this category are designed to protect the surface from water with a high-strength waterproof layer.

These materials are used in the manufacture of waterproof high-strength reinforced concrete and concrete structures, as well as protective reinforced layers, which are designed for a long service life and are distinguished by the following characteristics:

- homogeneity;

- high strength structure;

- maximum water resistance;

- frost resistance.

Booking waterproofing

The physical and chemical composition of mixtures for armored waterproofing differs according to different indicators.

To ensure longevity:

only the mineral elements that are included in the composition are used.

For waterproofing:

- the presence of a filler of a fine-grained structure;

- the absence of impurities that dissolve in water: clay, silt and more;

- use of high quality waterproofing cements.

To ensure good strength of reinforced concrete elements and structures:

- the use of coarse aggregate structure and only hard rocks;

- required reinforcement.

A waterproofing mixture of armoring action is used:

- for the manufacture of high-strength, waterproof monolithic concrete and reinforced concrete structures:

- underground and hydraulic structures;

- pools;

- foundations, etc.

- in the repair and reconstruction of waterproofing elements:

- basement waterproofing;

- bathrooms and sanitary cabins;

- plinths;

- warm floors, etc.

Among the range of armor mixtures, the following materials can be distinguished:

waterproofing mixture SII - intended for high-strength and waterproof plaster mortars, which are designed for a layer of plaster from 25 millimeters;

Dry mix hydro SII

waterproofing dry mix S + - is intended for the manufacture of high-strength and waterproof plaster solutions, designed for a layer of plaster from 10 millimeters;

Dry mixes hydro S+, SW

mixture-hydro 23 - high-strength reinforced mixture, with the addition of fiber.

Dry waterproofing mixtures will ensure a long period of operation of the protective layer of various structures, structures and construction sites.