- Kinds

- By shape

- Round

- oval

- Trapezoidal

- Universal

- By material

- Elasticated cuffs

- Silicone

- Polyurethane

- Which gasket to choose: rubber or another?

- Preparing to install the cuff

- Simple rubber cuff

- Corner cuff

- If the tank is located low?

- Types of sealing products

- Seal form

- Material

- How to choose?

- What are pads for?

- How to connect the cuff (straight and eccentric) for the toilet?

- Cuff cuff strife

- Why change the cuff and how is it done?

- Installation instructions for cuffs of various types

- #1: Installing the rubber seal

- #2: Quick Rules

- #3: Installing the pleated cuff

- How to connect a toilet without corrugations?

- Prevention of leaks from the toilet bowl

- Leak repair

Kinds

The industry produces several types of seals:

- rubber;

- silicone;

- polyurethane.

Manufacturers of plumbing fixtures, based on the design features of toilet bowls, produce gaskets of various shapes, thicknesses, colors, and materials used.

By shape

The shape of the gaskets can be round, oval, trapezoidal or polygonal. To improve the tightness in the section, the gaskets can be conical, rectangular.

Round

Round gaskets are the most common due to the manufacturability of production.They do not require complicated molds to produce them.

oval

Oval are rarely used due to the complexity of manufacturing and mounting on the toilet body. If 2 fastening screws are enough for round gaskets, then 3 or more are needed for oval gaskets. They require uniform tightening of the screws without distortion.

Trapezoidal

Trapezoidal are rarely used due to their large size and difficulty in uniform tightening. It not only seals the connection, but acts as a damper between the tank and the bowl. Such gaskets are used in TM SANITA products. Some systems use trapezoidal gaskets in combination with round gaskets. The trapezoidal ones play the role of a damper and additional seal, while the round ones directly seal the connecting node between the tank and the bowl.

Universal

Universal combine two functions: sealing and damping. They have a complex cross-section to ensure the sealing of the joint between the cistern and the toilet, plus a hexagonal outlet.

By material

In plumbing fixtures, three materials are used to seal joints:

- rubber;

- silicone;

- polyurethane.

Rubber products for sealing are used most widely. Rubber is made from synthetic or natural rubber with the addition of sulfur by vulcanization.

Silicone products are a large group of oxygen-containing high molecular weight organosilicon compounds. And they synthesize silicone from liquid glass (silicate glue) with the addition of methyl alcohol and other additives. Silicone gaskets have much better consumer properties than rubber ones. Silicones are used to make seals in all kinds of industries.Although they are more expensive than rubber ones, they last longer.

Polyurethane is the result of complex processing of petroleum isocyanate and polyol components. It is even more expensive than silicone, but exceeds it in many respects: durable, works in a wide temperature range, acid-resistant.

Vulcanization is the heating of rubber with the addition of various reagents.

Elasticated cuffs

This type of sealing products is used to seal the junction of the toilet outlet with a sewer pipe.

The cuff has a special corrugation for better sealing. Due to the elasticity of the material, a slight coaxiality between the outlet of the toilet bowl and the sewer pipe is allowed. If the holes do not match, use cuffs with an eccentric.

When buying, try stretching the cuff. It doesn't have to be hard like plastic.

Silicone

Silicone cuffs are rarely produced. They are mainly used for VIP-class products. Since there are no dynamic alternating loads at the point of release, in most cases rubber products or PVC seals are used.

Polyurethane

Polyurethane cuffs are produced in the same sizes as rubber and silicone. They are distinguished by a long service life and a much higher price than rubber ones.

Which gasket to choose: rubber or another?

Between rubber, silicone and polyurethane gaskets, the difference is not only in price, but also in terms of operation. Rubber tires wear out faster and require frequent replacement.

If possible, preference should be given to silicone and polyurethane. Although they are more expensive, they last longer and if you divide their cost by the service time, then the rubber is inferior in all respects.

Preparing to install the cuff

So, a suitable toilet has been selected and purchased, it remains to install it and connect it to the sewer. However, the first step is to dismantle the old toilet that has become unusable. Having completed this, sometimes difficult work, you can begin to try on.

Lay out the cardboard in the place where the toilet will be installed, and place it in the position as planned. Now you can see which cuff is required. So that you have a clear idea of what you may be offered to buy, carefully read the following section, which provides an overview of the various cuffs.

To make it clear what will be discussed, we will consider the existing types of cuffs and tell you how to install them.

Simple rubber cuff

A simple rubber cuff is suitable for connecting to an old cast-iron pipe.

After spreading with sealant, the cuff is inserted into the socket.

The outlet of the toilet bowl can be moistened with soapy water and inserted into the installed cuff.

On the floor, the attachment points of the device are marked. The toilet is pulled out and pushed aside. After that, holes for fastening are drilled in the floor. After installing the dowels, the toilet is installed in its place in the same way.

If the riser is misaligned, you need to move the toilet to the side, or the toilet outlet is too high, then an eccentric will do.

The installation procedure is similar to the previous one, the main thing is to set the toilet so that the cuffs do not pull it to the side.

It may be necessary to purchase a different, more suitable cuff, with a higher offset angle or a different length.

When turning the toilet bowl or removing it from the riser, it is recommended to use a corrugated pipe.

Two corrugations allow you to deploy the toilet at a right angle.Until the silicone seizes, the corrugation must be fixed.

In fairness, it must be said that the corrugation should be installed only when it is not possible to connect with sewer pipes, then blockages will occur much less frequently. In addition, the cuff will need to be replaced periodically, as its service life is short.

Corner cuff

If the sewer pipe is in the floor immediately behind the toilet, then you can connect a plumbing fixture with a horizontal outlet using the toilet corrugation at an angle of 90 °.

Many readers are familiar with this type of cuff. It serves to connect the pipe of the drain tank to the toilet. Soviet products served for a long time, and modern ones have to be changed several times a year. Therefore, it is quite understandable that many people want to ennoble the toilet by installing a new tank directly on the toilet.

For This uses a special adapter (additional shelf), but this time the cuffs will need a different one. Consider how to wear this product. The installation order is as follows:

One end of the cuff (lubricated with sanitary silicone on both sides) is put on the side shelf and secured with a steel clamp. If there is no clamp, then you can tighten it with wire.

Now the attached shelf needs to be fixed on the toilet with bolts of suitable size. First, the other end of the cuff is put on the toilet drain pipe, and then the bolts are inserted and the nuts are screwed onto them. When using metal fasteners, first put an iron washer on the bolt, then a plastic one. A plastic washer is put on from below, then a metal washer, and only then a nut is screwed on

If these precautions are not taken or the nuts are overtightened, the toilet may be damaged.

The other end of the cuff must also be fixed with a clamp.

Now that you have received the necessary information about the cuffs and how to install them, you can safely proceed to connect the toilet to the sewer, drain and water supply system.

If the tank is located low?

There are also cases when the tank is too low. This is a problem, but not so strong that it cannot be solved.

- The first step is to put on the cuff between the tank and the toilet on the end of the toilet shelf.

- Then, using a wire, we fix the eccentric in a stationary state.

- After that, we turn out the rubber part, and fasten the side shelf to the toilet bowl with bolts.

- We pull the eccentric on the outlet pipe of the sink. Using a sealant, we coat the junction with it and, tightening it with wire, fasten the cuff.

- After that, a test run should be performed to make sure there are no smudges. As in any plumbing connections, the bathroom must be mounted hermetically.

Types of sealing products

Known types of sealing products differ both in their configuration and in size and material from which they are made. Each of these features has its own characteristics.

Seal form

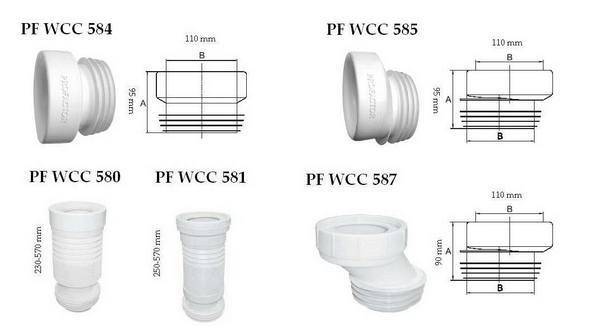

In accordance with this feature, cuffs for toilet bowls are divided into the following groups:

- oval, resembling a regular ring;

- trapezoidal seals;

- cone products;

- gaskets of complex multi-circuit configuration.

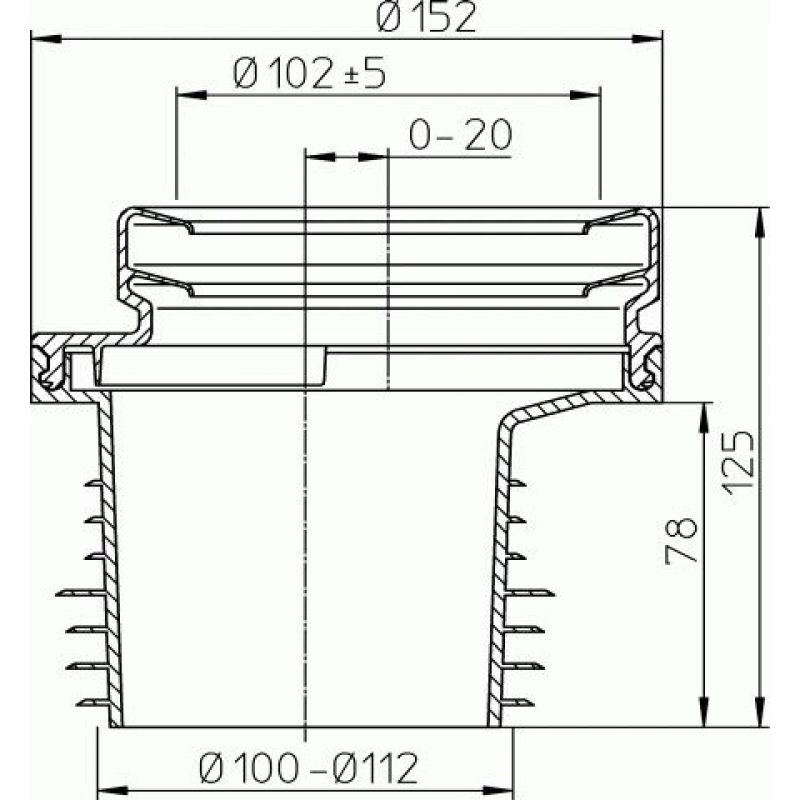

O-rings for toilet bowls are the most common type of cuffs used to articulate the bowl and tank.

They are used in most classic old-style designs.In modern models, gaskets of a more complex shape, resembling a truncated cone, are usually installed.

Recently, trapezoidal seals have become increasingly common in foreign-made products, resembling a triangle with cut-off corners.

In addition to the shape of the cuffs, all of them are characterized by another important property that determines the performance characteristics of the product. It involves a classification according to the type of material used in the manufacturing process.

Material

On this basis, all known samples of seals are divided into the following types:

- elastic cuffs, belonging to the category of the most popular and cheapest products;

- silicone blanks, characterized by increased elasticity and higher cost;

- polyurethane seals, which are the most expensive in their class.

Rubber cuffs are easy to manufacture and have a relatively low price. You have to pay for this with poor wear resistance and the need for frequent replacement. In contrast, expensive polyurethane products are very elastic, retain their shape well and have a long service life.

How to choose?

To buy a new toilet gasket, you need to go to a plumbing store. Most of them present common models of elastic bands of different sizes, made of rubber or silicone. Polyurethane gaskets can be purchased at an authorized dealer store, depending on the installed toilet model of a particular manufacturer.

It is better if the gasket is original, made by the same manufacturer as the toilet. But if the original model is not available, then you can purchase a universal gasket.Universal models of seals are most often presented on the market by Santek or Cersanit. Gaskets of these brands are made of high quality materials, suitable for most models of toilet bowls.

You need to select the right elastic band in accordance with the sample or model name of the toilet bowl

When buying, you should pay attention to a number of important points

- Exact match with a sample or model of plumbing. Even a slight deviation from the original sample can lead to a loose fit, which will lead to leaks.

- No damage or scratches on the surface of the product. When buying, you should slightly stretch the gasket, squeeze it between your fingers. If the spare part is hard to the touch or has a manufacturing defect, you should refuse to purchase it.

What are pads for?

The toilet bowl and the cistern must become a single system after the installation of the hygiene device in the sanitary area. This is the only way to avoid leaks and other unpleasant moments associated with plumbing. Everything must function smoothly and clearly. This can be achieved through the use of a special gasket. Such a product serves for a long time (for several years), and after wear it is easily replaced.

It is difficult to overestimate the value of the gasket, when installed between the toilet bowl and the cistern, it provides:

- creation of one well-coordinated "toilet-cistern" system;

- tightness of the connection of these elements;

- organization of a soft, elastic insert between two adjoining ceramic parts;

- elimination of problems of a leak between a tank and a toilet bowl.

Over time, this sealant loses its elasticity, cracks, dries out and begins to leak water - these characteristics are signs of the need to replace it. Do not be upset - you can replace the gasket with your own hands, without resorting to the help of an experienced plumber.

The price of this product is also low, so you just need to decide on the appropriate type of gasket and study the sequence of installation work.

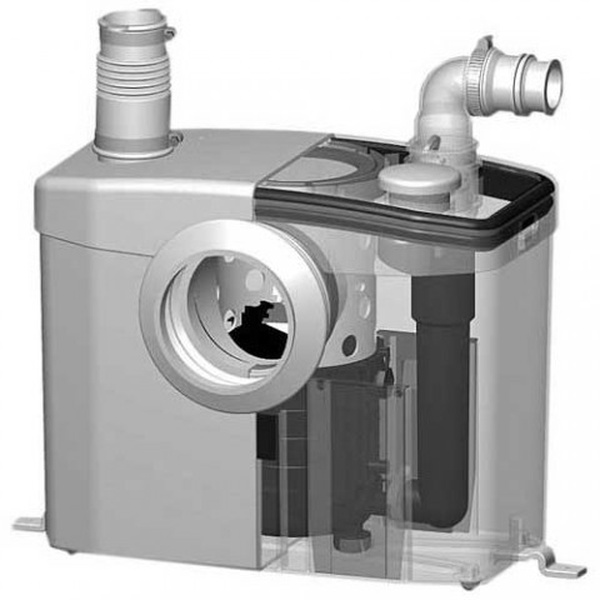

How to connect the cuff (straight and eccentric) for the toilet?

Installing a toilet requires some skill in work and quick installation, because. this plumbing fixture cannot be left out of use for a long time

Along with the speed of installation, it is necessary to pay attention to the quality of work, especially when connecting it to the sewer network. For a strong and tight connection of the outlet of the bowl with the branch pipe of the sewer system, a cuff for the toilet bowl is used

It can be eccentric and corrugated.

Cuff cuff strife

Polyethylene or polypropylene parts are complex in shape. The cuff represents two cylindrical surfaces connected together, but their longitudinal axes are shifted in relation to one another. Such an eccentricity is necessary in the case when, when connecting, the toilet outlet and the inlet pipe of the sewer pipe do not coincide with each other. For different mounting options, a long cuff and a short one are available.

Straight cuff and eccentric - visually distinguish very easily

For information: the toilet eccentric performs the function of connecting the outlet of a plumbing device with a sewer inlet.

The versatility of the corrugated version lies in the fact that it is applicable in extremely complex options for installing and connecting the toilet. Corrugation can always be maneuvered on the area of the bathroom, mounting it at any angle, transferring the sink to a convenient place.

Important: the use of a corrugated cuff is only advisable if the required slope is met

Why change the cuff and how is it done?

There are cases of water leakage from the water seal through the cuff or from under it. This can be detected while draining the water from the drain tank. Perhaps there was a displacement due to the skew of the tank, or maybe a crack appeared in the part itself. If it is not possible to fix the problem with improvised means, you should act radically: change the cracked component.

Installing a toilet using an eccentric is the best way out when working with old communications and new generation toilets

Standard replacement procedure

- Both the outlet of the toilet bowl and the inlet sewer pipe are cleaned until the dust, cement residues, etc. disappear completely. The treated surfaces must also be dry.

- The entire perimeter of the cuff is lubricated with a special silicone sealant.

- One end of the cuff with a waterproofing seal is effortlessly put on the outlet of the toilet drain. This is facilitated by preliminary waterproof treatment, which protects the contact point from leaks. For better adhesion, the sealant should be allowed to harden, and then continue to work.

- The other end of the connector is inserted directly into the sewer drain.

By the way: not all specialists use sealant for sealing.It is believed that the cuffs fit so perfectly that they themselves sit very tightly on the toilet outlet.

Toilet with horizontal outlet

When the sewer socket and the outlet of the toilet bowl are located on the same axis, you can use a straight cuff to connect. In case of mismatch between the levels of the two inputs, an eccentric toilet cuff is used.

Important! In this case, the distance between the socket and the outlet should not be more than 5 cm.

- A cuff is put on the nozzle of the shelf of an inverted tank from the end of a smaller diameter to a third of its length: the toilet neck and the distance between the ends will “pack” into the remaining 2/3 of the space. Work should be carried out when the float valve of the tank with a hard connection is disconnected in advance, the screws are removed from the shelf, tank cover.

- This remaining part is turned inside out, and then tightly put on the bell until its end is indicated. The cuff should be tightly strung on the neck of the toilet outlet.

- The tank and shelf are being installed, followed by the connection of all previously dismantled parts. With the structure fully installed and not yet fully fixed, the cuff is pulled from the shelf nozzle to the toilet outlet to the normal state.

Using an eccentric will allow you to place the toilet as compactly as possible. If you use corrugation in this case, then the loss of space will be significant

What if the tank is low?

- A rubber cuff for the toilet bowl is put on the end of the attached shelf and immediately fixed on it with a wire.

- The rubber part is turning out.

- An attached shelf is bolted to the toilet bowl.

- A cuff is pulled over the outlet pipe of the sink.

- The branch pipe with a rubber tight connection is clamped with a wire.

If the connection of the plumbing fixture to the sewer is done correctly, then this guarantees the smooth operation of the entire system without breakdowns and blockages.

Installation instructions for cuffs of various types

The principle of fixing rubber or plastic, smooth or corrugated parts is similar, but the process itself may differ in nuances - from choosing the location of the toilet bowl to using additional methods of fastening. Consider three common connection options.

#1: Installing the rubber seal

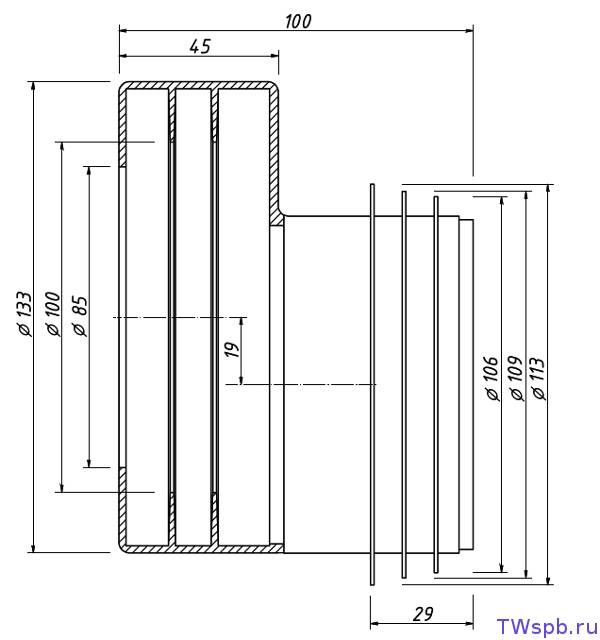

A rubber cuff is a short, dense element that is not pulled from the outside, but is inserted into the socket of a cast-iron pipe. This is a kind of seal or gasket that creates a tight connection between the drain hole and the plumbing fixture.

In addition, it protects the sanitary ware from chips and damage in case of unintentional violation of the stability of the installation.

Procedure for installing the rubber cuff:

If the toilet outlet enters the socket freely, then the soap solution is not needed. On the contrary, it is necessary to create a tighter abutment.

To do this, they usually use the traditional modern method - a sealant is applied over the entire surface of the adjacent parts. After hardening, it forms a dense hermetic ring.

#2: Quick Rules

You will find out that you need an eccentric at the stage of choosing a place to install the toilet. If the outlet of the plumbing fixture and the socket of the sewer pipe are not strictly opposite each other, a simple plastic connector is not enough. Axis offset requires a curved part.

High-quality rubber or polypropylene eccentrics are sold in plumbing stores and can cost from 100 to 250 rubles, depending on the manufacturer

Before installation, it is necessary to put the plumbing fixture in place, measure the length to the sewer drain and once again make sure that the toilet eccentric model is selected correctly. To check, you can simply attach the part to both holes.

An eccentric can be used if the drain hole is just above the toilet outlet. If the height difference from the outlet to the socket is more than 5 cm, flushing problems may occur - in this case it is better to replace the pipes and install them lower

Work order:

- we clean the sewer inlet from old deposits;

- we put the cuff with a wide end (110 mm) on the sewer socket, smearing the junction with sealant;

- we attach the second end to the oblique or horizontal outlet of the toilet bowl, also using a sealant;

- we carry out a test descent of water;

- if no leaks are found, we fix the toilet in a pre-prepared place with bolts.

The problem arises when, during installation, it turns out that the eccentric is not matched correctly. To avoid an uncomfortable situation, instead of a rigid structure, you can immediately buy a part with an elastic corrugated middle.

As required, the accordion eccentric can be slightly shifted to the right / left or slightly stretched, while maintaining its functional qualities.

A variant of the cascading use of eccentrics when the toilet model is incorrectly selected. If the pipes are located below, close to the floor or at its level, it is better to purchase a plumbing fixture with an oblique outlet

Moving parts are also relevant when there is a risk of loose toilet seating.Simply put, when the plumbing fixture is rocked, the tightness of the rigid connection will immediately be broken, while this does not threaten the corrugation.

#3: Installing the pleated cuff

When the installation of the toilet bowl is difficult due to the inappropriate form of the outlet or the difficult location of the sewer, an elastic corrugated pipe is often used. Its advantage is that it can easily change shape and length, therefore, it is suitable for almost all types of releases.

The only thing to consider when buying is the diameters of the fixing cylindrical ends. They can be 110mm/90mm, 110mm/80mm, etc.

It is the corrugation that is used for temporary installation of the toilet during repairs, with strong displacements relative to the central axis of the inlet / outlet (instead of the eccentric) and during the installation of the plumbing fixture at a distance of up to half a meter from the drain hole

The principle of replacing or installing corrugations is the same as for other types of cuffs:

- removal of the old worn out element;

- cleaning of inlets from dirt and deposits;

- inserting the sealed end into the sewer socket;

- fixing the second end on the outlet of the toilet bowl;

- test descent of water, elimination of shortcomings.

Experienced plumbers recommend not stretching the corrugation to the maximum, because as a result, it loses elasticity and fails faster.

It is better to choose a longer model or try to move the toilet closer to the sewer outlet. Another option is to buy a combined cuff, consisting partly of rigid elements.

How to connect a toilet without corrugations?

Here we will talk about a rigid connection, which is performed using fan pipes or special adapters.The phased work and its features will differ depending on the type of toilet outlet, there are three of them in total:

-

-

- oblique outlet - we can see such toilets in apartments and houses that were built in the 1960s and 1970s;

- vertical release - similar releases are even older than the previous version. But they will be a great option for a private home. Imagine there are no sewer pipes in the bathroom - they will all be located under the floor;

- horizontal release is a more modern option. But such plumbing is installed in rooms where it is possible to place the toilet bowl at the right distance from the riser itself.

-

Depending on the issue, the toilet is connected to the sewer in different ways.

Only one thing can be said for sure - the release of the toilet bowl must correspond to the release of the sewer network. Then the installation will be easier and faster, you will not think for a long time how to connect the toilet to the sewer.

Prevention of leaks from the toilet bowl

To prevent a leak from becoming a surprise, it is necessary to periodically take some preventive measures, as well as follow the rules for operating plumbing equipment:

- Avoid shock loading, especially if a ceramic version of the tank is installed.

- Avoid heating, for example, welding should not be carried out next to it. If such a need arises, ceramic and plastic containers must be protected from overheating.

- It is unacceptable to get hot water into the tank - this can damage plastic valves and rubber seals.

- It is recommended to clean the tank at least once a year.

- Simultaneously with cleaning, it is necessary to inspect all areas and assemblies of the tank where problems associated with water leakage may occur. These are, first of all, the places where rubber gaskets, connecting nodes, valve mechanisms are installed.

- If any problems are found and there is no experience in plumbing repair work, it is recommended to contact a qualified craftsman. Otherwise, in some cases, the situation can be aggravated.

And in conclusion - a few tips to help you choose high-quality plumbing accessories:

- When purchasing ceramic sanitary ware, you need to carefully examine it. Devices should not have chips, shells, even small cracks. The surface of the cistern or toilet must have a uniform coating of glaze. Its unevenness indicates the low quality of the product, which can lead to cracking of both the coating itself and the walls of the product.

- The kit with the tank and the toilet should include all the parts necessary for installation - these are gaskets and fasteners of the right sizes.

- In addition, instructions for assembling all parts into a single structure should be attached to the set of products. Proper installation is no less important for long-term operation than the quality of plumbing.

Now, knowing where to look and how to eliminate the causes of water leakage from the tank, you can try to deal with many of them yourself if you wish.

* * * * * * *

Readers will certainly be interested in the video in which the home master shares his secret to eliminating water leakage through the toilet bowl drain valve.

Leak repair

- nuts;

- rubber pads;

- sealant or FUM tape;

- wrench.

Float lever and valve

This issue is being resolved quickly. If the toilet cistern is leaking, the float lever is returned to the horizontal position. In the event of a float failure, there are three options:

- float replacement;

- elimination of breakage with plastic heated to a temperature of 130-170 degrees Celsius;

- wrapping the device in cellophane, thereby preventing contact with water.

The second and third options are temporary measures. Eventually, the defective part will need to be replaced.

Siphon membrane damage

One of the most common causes of leakage, gasket wear

There are two signs of failure:

- liquid from the tank continuously flows into the toilet;

- the drain button works after repeated pressing.

To fix the toilet cistern in this case, change the siphon membrane, following the following procedure:

- Instead of a drain tank lid, a crossbar is placed to which a lever is tied that holds the float.

- Drain the water from the container.

- The fixing nut that connects the flush pipe to the drain tank is unscrewed.

- The siphon nut is unscrewed, after which the device is disconnected.

- Replace the damaged membrane with a new one.

- The assembly of the drain volume fittings is carried out in the reverse order.

Important! The new membrane is selected so that it completely matches the size and shape of the old one. After completing the troubleshooting steps, check for leaks. After completing the troubleshooting steps, check for leaks

After completing the troubleshooting steps, check for leaks.

Saddle or pear problem

If the drain tank is leaking due to the loss of elasticity of the pear, the product is replaced. From the saddle (petal), plaque of various origins is eliminated.If you do not remove deposits on the product, then the pear will not fit tightly, causing the toilet bowl to leak.

Elimination of leaks under the tank

The cuff connecting the toilet bowl and the drain volume shifts from its original position over time. In order for the gasket between the tank and the toilet to get into the right position, I tighten it with clamps. If it is not possible to use clamps, adhesive tape, for example, plumbing tape, is used as a temporary method of fastening.

If the toilet is leaking from below, the cause is “bitten” gaskets. Where the toilet bowl is connected to the tank, the fasteners are unscrewed and the integrity of the rubber products is examined. If the gum between the tank and the toilet is damaged (cracked, blocked), it is changed. If everything is fine with the gaskets, they are dried, a sealant is applied to the surface. After that, set to its original position.

Gaskets when repairing a leaking toilet are selected from the following types:

- rubber;

- silicone;

- polyurethane.

Flexible and elastic pads do not leak. If cracks or sagging are found on the surface of the product, do not buy it. Before buying, the gasket is crumpled in the hands: dried parts are set aside, they will not cope with the sealing. The old gasket for the toilet bowl helps in the purchase, they take it with them, which makes it easier to select the part. The price of a gasket for a toilet bowl is on average 500 rubles.

Leaks in the place of fixing the drain volume occur due to malfunctions or damage to the toilet shelf. In this case, you need to replace the plumbing fixture.

WATCH VIDEO

Flexible piping repair

The problem is loose nuts.The cause of the leak is sought at the junction of the hose leading from the water supply and the toilet. The nut is tightened, controlling the force. If there are cracks in the nut, the fasteners are replaced with a new one. If there is a problem in the breakdown of the fastening of the reinforcement, it is changed entirely.

The causes of simple malfunctions of plumbing fixtures are eliminated independently. Disadvantages of hiring a plumber include:

- waiting time;

- the employee comes during the working day, so you need to take a day off from work and wait for the arrival of the master;

- financial expenses.

All these inconveniences can be avoided by studying on your own how to fix toilet leaks and familiarizing yourself with the solution to the problem.

</ul>

The toilet bowl and the cistern are one system, interconnected by a gasket made of rubber or silicone so that there are no water leaks. Functionally, the tank is raised to a small height of about 50 centimeters. This is necessary to create fluid pressure that washes away impurities. To increase the rate of water outflow from the tank, it pours out through small holes in the body. The gasket between the tank and the toilet seals the collapsible connections and prevents the outflow of water.