- What kinds exist?

- Design and principle of operation

- Classification of pressure gauges according to the type of measured pressure

- Classification by mode of operation

- Water

- Electrical

- Digital

- Other

- Device selection

- Gauge types

- Functional load

- Types of determined pressures

- Water pressure in the plumbing

- Liquid fill equipment

- Double tube mechanism

- Scheme of one-pipe execution

- EKM device

- Types of measuring instruments

- Device types

- Gas pressure measuring range

- Accuracy class

- The size

- Functional load

- Operating conditions

- Peculiarities

- Criterias of choice

- Description

- Rules for installing the device

- Tools and materials

- Direct mounting

- On a three-way valve

- With impulse tube

- Measuring pressure with a manometer

- General information

- Classification of pressure gauges according to the type of measured pressure

- exemplary

- Water

- Electrocontact

- Electrical

- Special

- Digital

- Ship

- Other

What kinds exist?

List of the main types of pressure gauges for water:

- The most common are general technical spring pressure gauges for water, with a measurement range from 0 to 10 or from 0 to 6 atmospheres. The case diameter can be from 40 to 160 mm, most often - 100.

- Boiler rooms - with a body diameter of 250 mm.They are needed to take readings from the device at a distance.

- Vibration-resistant manometers - filled inside with a viscous liquid, in particular a solution of glycerin or silicone oil. Measure pressure in conditions of strong vibrations. They are used at pumping stations, cars, compressors, trains.

- Corrosion-resistant pressure gauges - for working with chemically aggressive media.

- High-precision ones are needed for verification and pressure testing.

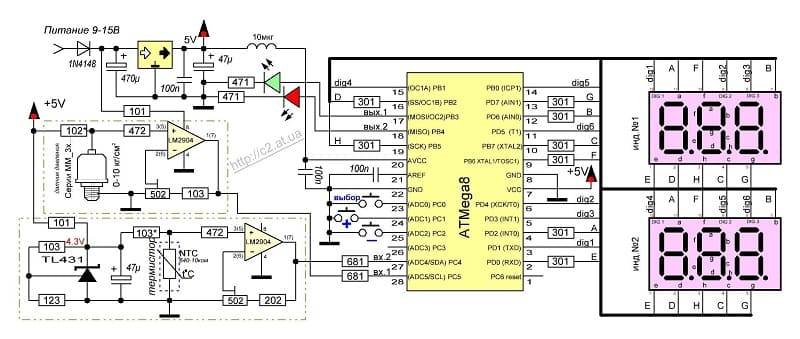

- Digital electronic - mechanical force is converted into an electrical signal. Readings are taken from the scoreboard, you can program, some devices can be connected to a computer.

- Electrocontact (signaling) - devices in which the upper and lower pressure limits are set. If they are overcome, the electronic device is triggered and transmits a signal to the control device.

- Thermomanometers are devices that measure pressure and temperature in a heating or water supply system. On the front side there are two scales on which readings are taken.

Design and principle of operation

In order to choose the most suitable version of the digital pressure gauge and properly maintain it, if necessary, you need to pay attention to design features. The principle of operation is as follows:

- The basis of the design is the principle of balancing pressure under the acting force.

- One of the ends of the movable element is soldered into the main holder, the other is connected to the mechanism. Due to this, the direct movement of the element is transformed and looped along the arrow.

- At the moment of impact, certain characteristics of the material change. At the same time, the design has a third membrane, which determines the force of impact.

- When a certain force is applied, the two plates are combined under a certain force, which will be comparable to the current strength. The resulting discharge between two quartz elements is converted into a normal signal, after which it is transmitted to the measuring device.

At the moment of pressure drop or its increase, the contacts close and the signal is applied to the coil.

By design, a fairly large number of different digital pressure gauges are distinguished, but the classic version is represented by a combination of the following elements:

- Frame. In most cases, in its manufacture, materials are used that are characterized by high resistance to aggressive environmental influences. The absence of a large number of mechanical elements determines its small size.

- Thermal bulb and connecting capillary.

- Dial and arrow to display the main parameters. Recently, versions with an electronic dial have become widespread.

In general, we can say that only too much load becomes the reason why the device can fail.

Classification of pressure gauges according to the type of measured pressure

Classification of regulators according to the type of pressure:

- vacuum gauges and manovacuum gauges;

- barometers;

- pressure gauges;

- differential pressure gauges;

- draft gauges.

The principle of operation of any of them depends on the structure, in addition, it must be borne in mind that the meters are divided into categories within a single class, taking into account the level of accuracy.

Devices operating on the vacuum principle are designed for rarefied gas. Pressure gauges are able to determine the parameters of the limiting pressure with indicators up to 40 kPa, draft gauges up to -40 kPa.Other differential devices help to recognize the difference in indicators at any two points.

Classification by mode of operation

According to the method of operation, devices can be water, electric or digital, in addition to these categories, there are other varieties.

According to the method of operation, devices can be water, electric or digital, in addition to these categories, there are other varieties.

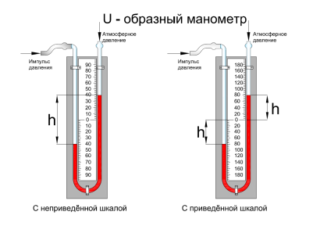

Water

Water devices operate on the principle of balancing a gaseous substance with pressure that forms a column with liquid. Thanks to them, you can refine the level of sparsity, difference, redundancy and atmospheric data. This group includes U-type regulators, which are designed like communicating vessels, and the pressure in them is determined taking into account the water level. Compensation, cup, float, bell and ring gas meters are also classified as water meters, the working fluid inside them is similar to the sensing element.

Electrical

Strain gauge electric pressure gauge

Strain gauge electric pressure gauge

This utility gas pressure measuring instrument converts it into electrical data. This category includes strain gauges and capacitive gauges. The former change the readings of the conductive resistance after deformation and measure indicators up to 60-10 Pa with minor errors. They are used in systems with fast processes. Capacitive gas meters act on a moving membrane electrode whose deflection can be determined by an electrical circuit and are suitable for systems with accelerated pressure drops.

Digital

Digital or electronic instruments are high precision devices and are most often used for mounting in air or hydraulic media. Of the advantages of such regulators, note the convenience and compact size, the longest possible service life and the ability to calibrate at any time.They are mainly used to monitor the condition of vehicle components. In addition, digital type gas meters are included in the fuel lines.

Other

In addition to regulators with standard characteristics and settings, other types of instruments are used to obtain accurate data. This list includes deadweight gas meters, which are original samples for verification of similar devices. Their main working part is a measuring column, the condition and accuracy of the readings of which change the magnitude of the error. During operation, the cylinder is held inside the piston at the desired level, at the same time it is affected by calibration weights on one side, and only pressure on the other.

Device selection

The industry today uses different types of pressure gauges. To make the right purchase of a measuring device that will be suitable in all respects for solving production processes, you need to know:

- Gauge type.

- Working range of pressure measurement.

- Its accuracy class.

- its installation environment.

- Case dimensions.

- The functional load of the device.

- Where it will be installed, as well as the thread size of the fitting.

- operating conditions.

If you follow the above list, then you can choose the best device, since all pressure gauge manufacturers adhere to established standards. Therefore, devices from different companies are essentially interchangeable.

Gauge types

Modern instrumentation offers several types of devices that are pressure meters in different ranges:

- Gauges operating from 0 to any value with a plus sign.

- Pressure vacuum gauges are designed to measure excess indicators from - to +.

- Vacuum gauges work with indicators below atmospheric in the range from -1 to 0. That is, they measure rarefied gases.

- Pressure gauges that work with extremely low values up to +40 kPa.

- Types of vacuum gauge are draft gauges and thrust gauges.

- Pressure gauges measure low overpressure at low levels.

In order to make the right choice of the device according to the permissible pressure interval, one should know the operating pressure values of the process, for which the purchase of a measuring device is made. Make no mistake about the plus and minus signs and add 30% to the performance.

special manometer

Functional load

The pressure measuring device is selected depending on the needs of the production process, it must correspond to the functions and operating conditions. Pressure gauges are divided into the following types of functional load:

- Showing. Technical direction. Designed to measure pressure.

- Signaling. Needed to control an external electrical circuit.

- For accurate measurement. Accuracy class from 0.6 / 1.0 units.

- exemplary. Used to check the accuracy of technical pressure gauges.

- Recorders. In the form of a diagram on paper, the measured pressure is recorded.

The purpose is indicated by the type of device case, it can be:

- Vibration resistant.

- explosion-proof.

- Corrosion resistant.

Manometers are used in systems of boilers, ship and railway equipment. There is a group of devices that can be used in the food industry. The material of the body of the meter allows you to meet the service conditions.

Types of determined pressures

It is known from the school physics course that three types of pressures are used for calculations. Among them are the following:

- Atmospheric. It has long been calculated and is constant for a certain point on the earth's surface. Atmospheric pressure affects all surrounding objects, including humans. But a healthy person does not feel it because of the balancing internal pressure.

- Excess. It is created by means of injection plants under the condition of a closed space. Increased pressure is mainly used to set power mechanisms in motion from a weak engine.

- Reduced (vacuum). The use of vacuum pressure is due to technological conditions. The created vacuum helps to draw the working medium into any container.

When studying at the institute, an additional concept appears - absolute pressure. This is the sum of atmospheric pressure and elevated pressure.

The appropriate instrument type must be selected for taking readings.

Water pressure in the plumbing

Small pressure level

With a sufficiently low pressure, which is manifested by a rather weak supply of water directly from the tap and indicates a completely low level. A fairly relevant and common problem is for residents of the upper floors, as well as owners of country dwellings. Weak pressure in the water supply will prevent many necessary household appliances from working, which will become a significant problem, and there will also be a desire to correct this situation.

Performing installation work to install equipment that can increase such an indicator is a fundamental technique to ensure that this issue is resolved.Naturally, before using modern units designed for these purposes, it should be determined whether the system is clogged, which may also be one of the reasons for this phenomenon.

In a certain way, such a problem can be completely eliminated with the help of a specialized pumping unit, which will either increase the pressure or modernize the system itself by integrating a pumping station with a storage tank.

Naturally, a more rational and appropriate method should be determined directly by the owner himself, which is determined by the goals pursued, as well as the necessary volumes of liquid that will be required to fully provide the home.

Liquid fill equipment

The design of devices of different types differs depending on the tasks that are set for them. The main parts of pressure meters are the case and the scale (graduated dial).

The peculiarity of the structure of the pressure gauge is in the actuator, which converts the energy of the pressure force of the medium being measured into a signal displayed on the scale: the movement of the slider, arrows, the glow of the LED. In a tubular metal manometer, the mechanism consists of a hollow arcuate tube, a lever, a gear sector, and an arrow. Liquid filled meters are available in single and double tube configurations.

Double tube mechanism

Gauges of this type with a visible level of the working fluid are often called U-shaped. The position of the boundary between the air and liquid medium indicates the value of the measured pressure. Components of the structure:

- two vertical tubes with an internal diameter of 8-10 mm made of glass, connected to each other by a flexible hose or made in the form of a single whole;

- the base is metal, wooden or plastic;

- scale;

- the working fluid (alcohol, water, glycerin, transformer oil, mercury) is filled up to zero.

The first tube is designed to supply the measured pressure into it, and the second one communicates with the atmosphere. In the case of measuring the difference in pressure, both tubes are connected to the loads. Two-pipe pressure gauges filled with water are used to measure vacuum, pressure, pressure difference in air circulation systems in the range of ± 10 kPa, and the use of mercury as a filler expands the limits to 0.1 MPa (1 kg / cm²).

Scheme of one-pipe execution

If we briefly characterize the device of this type of liquid manometer, then we can say that the first tube of the U-shaped meter is replaced by a bowl (wide vessel). This is where the greater pressure from the detected pressures is applied. The measuring tube is the second tube attached to the scale plate, which communicates with the atmosphere, and when measuring the difference in indicators, the smaller of the pressures is connected to it. Single-tube or cup liquid manometers differ from two-tube liquid manometers in the following parameters:

- high measurement accuracy;

- lower reading error when determining the pressure (±1%), which is due to taking readings from only one column of the working fluid;

- the minimum measurement range of a single-tube water-filled manometer is 1.6 kPa or 160 mm w.c. pillar.

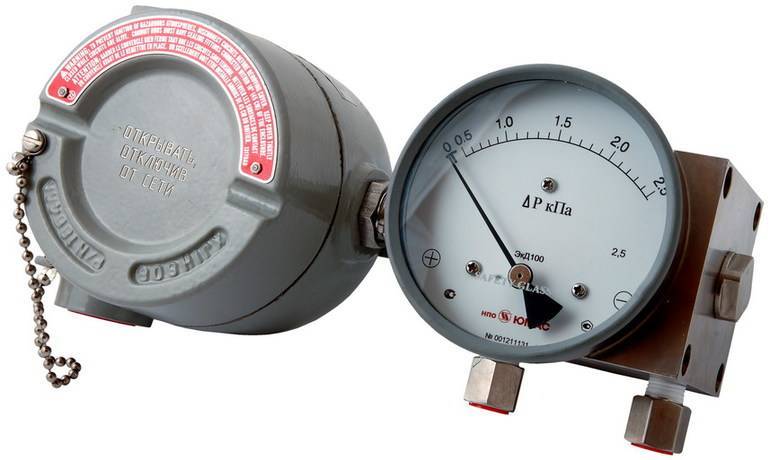

EKM device

The EKM is a device shaped like a cylinder and very similar to a conventional pressure gauge. But in contrast to it, the EKM includes two arrows that set the values of the settings: Rmax and Rmin (their movement is carried out manually on the dial scale).The movable arrow, showing the real value of the measured pressure, switches the contact groups, which close or open when it reaches the set value. All arrows are located on the same axis, but the places where they are fixed are isolated and do not touch each other.

The axis of the indicator arrow is isolated from the parts of the device, its body and scale. It rotates independently of the others.

Special current-carrying plates (lamellas) connected to the corresponding arrow are connected to the bearings with which the arrows are attached, and on the other hand, these plates are brought into the contact group.

In addition to the above components, EKM, like any pressure gauge, also has a sensitive element. In almost all models, this element is a Bourdon tube, which moves along with an arrow rigidly fixed on it, and a multi-turn spring is also used as this element for sensors measuring pressure of a medium above 6 MPa.

Types of measuring instruments

Instruments for measuring pressure are divided into the following varieties:

-

The thrust gauge is a pressure and vacuum gauge that has extreme limits of measurement not higher than 40 kPa.

- Traction gauges - a vacuum gauge that has a measurement limit equal to (-40) kPa.

- The pressure gauge is a manometer of low overpressure (+40) kPa.

- Pressure vacuum gauges are devices that are capable of measuring both vacuum and gauge pressures in the range of 60–240,000 kPa.

- A vacuum gauge is a device that measures vacuum (pressure that is below atmospheric pressure).

- A manometer is a device capable of measuring gauge pressure, that is, the difference between absolute pressure and barometric pressure.Its limits range from 0.06 to 1000 MPa.

Most imported and domestic pressure gauges are manufactured according to all generally accepted standards. It is for this reason that it is possible to replace one brand with another.

When choosing a device, it is necessary to rely on the following indicators:

- The location of the fitting is axial or radial.

- Fitting thread diameter.

- Instrument accuracy class.

- Case diameter.

- Limit of measured values.

Device types

According to the structure and principle of operation, there are 5 main types of sensors:

- liquid;

- spring;

- electrocontact;

- membrane;

- differential.

Spring and liquid devices are the most popular. They are quite accurate and reliable at their low price. These two types are well suited for private homes and small businesses. In most boiler rooms, spring pressure gauges are used.

Gas pressure measuring range

This is the most important parameter when choosing measuring equipment for a boiler room.

The main thing is that the working pressure in the boiler pipe falls within the range of 1/3-2/3 of the measuring scale of the device. If the pressure is less, then the measurement error is too high, and if it is more, the device will be overloaded and fail before the warranty period.

Accuracy class

The lower this indicator, the more accurate the device. The accuracy class is the percentage of measurement error from the measurement scale.

The error is easy to calculate, for example, if the device is 10 atm. has an accuracy class of 1.5 units, then its permissible error is 1.5%. If the indicator of the device is greater, then it must be replaced.

It is possible to establish a malfunction only with the help of a reference pressure gauge, this is done by a special organization that calibrates the equipment.A high-precision device is connected to the system, and then the readings are compared.

The size

The diameter of the device is selected depending on the purpose.

- 50, 63 mm - for installation on portable equipment or for monitoring the pressure of oxygen cylinders, welding machines.

- 100 mm is the most common size, most convenient in most cases.

- 160 mm, 250 mm - to control devices that are located visually far away, for example, under the ceiling of a boiler room.

Functional load

According to the type of functional load, the devices are:

- Showing - these are devices of a technical direction. Measure pressure.

- Signaling - control an external electrical circuit.

- For accurate measurement, they have an accuracy class of 0.6-1.0 units.

- References are used to check the accuracy of other instruments.

- Recorders record pressure as a chart on paper.

Photo 2. Exemplary pressure gauge for a gas boiler. The device has high accuracy, it is used to calibrate other devices.

Operating conditions

The device is selected taking into account the environment in which it will be used. The environment can be different, including aggressive

There are devices with different cases, it is important to consider whether it will work in conditions of humidity, dust, vibration, in order to prevent the development of corrosion or damage to the case

Peculiarities

Among the wide variety of measuring instruments, it is quite difficult to choose the best one, since the characteristics vary, and you also have to take into account many nuances of the upcoming operation of the device.Manometric thermometers have certain features that significantly distinguish them from other types of measuring instruments. In order to better understand the device of this equipment, you should familiarize yourself with its main characteristics in more detail.

Helium or nitrogen can serve as a substance for measuring temperature in a manometric thermometer. The main feature of such devices is a large size bulb, as well as a significant inertia of measurements. The temperature range of the device starts from -50 C and can reach +60 C. At the same time, the scale in the thermometer is uniform. Considering such characteristics, it can be stated with full confidence that there are practically no unfavorable conditions for the use of such devices.

In addition, the following can be attributed to the features of manometric type thermometers.

- In such devices, the elements of the measuring system are made of stainless steel or brass. Thus, the device is practically not exposed to negative external influences. For this purpose, the capillary tube is covered with a metal hose or copper braid.

- In certain models of measuring instruments, there are electrical signal elements.

- Taking into account the variety of the scale, the devices can be non-zero and zero (this also applies to vibration-resistant models).

A manometric thermometer showing the temperature of liquids, vapors and gases has some advantages and disadvantages. So, the advantages of this device include the following:

- ease of use and maintenance;

- vibration resistance;

- the ability to register indicators in the presence of special equipment;

- explosion safety;

- low cost.

In addition, it is worth noting certain disadvantages of the device:

- some difficulties may arise with the replacement of the capillary in case of breakage;

- increased inertia;

- small measurement errors.

Considering that the manometric thermometer has more positive points than negative ones, it is worth noting that today the device is quite popular, convenient and easy to use. Moreover, not only an experienced specialist, but also a beginner can understand the clear design of the device.

Criterias of choice

Before buying a device, you need to understand exactly what it is for and where it will be installed.

Important selection criteria:

- Measuring range. Rule: the working pressure in the pipeline should be no more than 2/3 of the maximum scale of measurements, but not less than 1/3. If the pressure in the pipe is 5 atm, then you need to buy a pressure gauge with a scale of 0 ... 10 atm.

- The accuracy class varies from 0.15 to 3. The lower, the more accurate. For a cold or hot water supply system, an accuracy of 1.5% is sufficient.

- The location of the fitting is radial or end, when it is from below; and axial or frontal when he is behind.

- Operating temperature range.

- Temperature conditions of operation.

- Working medium (water, steam, oil and so on);

- Diameter. It should be such that the device is placed in the chosen place, and the dial is clearly visible.

It is also necessary to pay attention to the connecting thread of the fitting. It can be metric - its parameters are measured in mm, denoted by the letter M, for example M20 / 1.5, which means an outer diameter of 19.9 mm, an inner diameter of 18.7 mm, a pitch of 1.5. Domestic manufacturers use it by default.

Domestic manufacturers use it by default.

Pipe threads are denoted by the letter G. G1 / 2 "means an outer diameter of 20.9 mm, an inner diameter of 18.6, a pitch of 1.8 mm or 14 threads per inch.

In the technical passport of the new device, a mark on factory verification must be melted. The verification period of less than a year confirms that the device gives the correct readings.

Description

The basis of the principle of mechanical pressure measurement is an elastic sensing element capable of deforming in a strictly defined way under the influence of a compressive load and reproducing the tested deformation. With the help of a pointer device, this deformation is converted into a rotational movement of the pointer.

The sensitive element of the pressure gauge is a tubular spring. With increasing pressure, the spring unbends and the movement of its free end with the help of a transmission mechanism is converted into rotation of the indicating arrow relative to the pressure gauge dial scale. The pressure gauge is made of stainless steel and is a combination sensor, pressure switch and diaphragm seal made of stainless steel. The scale and arrow of pressure gauges are made of aluminum.

A general view of pressure gauges with a metal diaphragm PN21122NR1R13 is shown in Figure 1. Sealing of pressure gauges is not provided.

Rules for installing the device

The pressure gauge must not be installed if:

- There is no seal or mark on the inspection.

- The validation period has expired.

- There are visible damages, such as cracks.

- The arrow does not return to zero when disabled.

- Installation at a height of more than 3 m from the site is prohibited.

The device is installed in such a way that the readings are clearly visible. The scale must be vertical or inclined by 30°.

The diameter of the pressure gauge should be at least 100 mm, at a height of 2-3 m - at least 160 mm.

The device must be sufficiently illuminated, but protected from direct sunlight and environmental influences.

The pressure gauge must be tightened on the tee, but the device itself must not be tightened so that all the air escapes unhindered.

Attention! If a breakdown of the device was detected, then it must be handed over to the service center, having previously cleaned

Tools and materials

For installation, you need a minimum set of tools that every home has. You will need: a locksmith set, a fitting and a wrench, the pressure gauge itself, a three-way valve and a impulse tube in cases where such a mounting method has been chosen where it is required. In some cases, an adapter is needed.

Direct mounting

The pressure gauge is screwed directly onto the pre-welded adapter with special seals. This method is the simplest, it is used where there are no constant pressure surges, and frequent replacement is not required.

On a three-way valve

A three-way valve is installed on the adapter welded in advance, and a pressure gauge is already on it.

Photo 3. Pressure gauge for a gas boiler mounted on a three-way valve. With this installation, the operation of the device is facilitated, it is easy to replace it.

This method is used if, during verification, it is necessary to transfer the equipment to atmospheric pressure using this valve. With this method of mounting, the pressure gauge can be replaced without interrupting the operation of the system.

With impulse tube

The device is also installed through the impulse tube, which will protect it from damage. To do this, a tube is attached to a pre-welded adapter, a three-way valve is attached to it, and a pressure gauge is screwed to it.

Thus, installation is carried out where contact of the measuring device with hot steam is possible. This method protects the pressure gauge from damage.

Measuring pressure with a manometer

Filed under: Experiments , Crafts , physics , Experiments | Tags: Measurement of pressure with a manometer, Experiments, Crafts, physics, experiment | June 20, 2013 | Svetlana

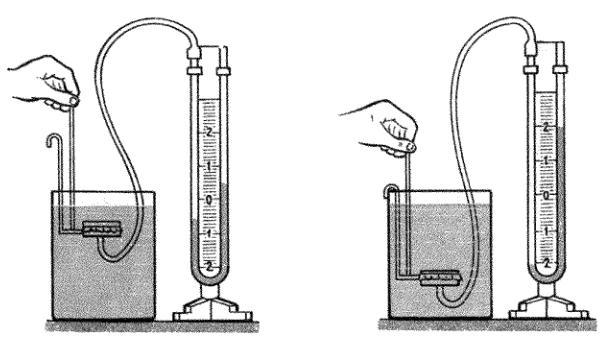

To measure the pressure of air or gas inside a vessel with a pressure gauge, it is necessary to attach its rubber tube to this vessel. Monitor the fluid level in both legs of the manometer.

a) If the liquid is at the same level in both knees of the manometer, consider the pressure of the gas inside the vessel to be the same as the pressure of the surrounding air.

b) If the liquid level in the short leg of the manometer is lower than in the other, consider the pressure inside the vessel to be greater than the ambient air pressure.

c) If the liquid in the short leg of the manometer is higher than in the other leg, consider that the pressure inside the vessel is less than the pressure of the surrounding air.

With a difference in liquid levels in the manometer tubes, the calculation of the difference in atmospheric pressure and pressure in the vessel is done according to the formula:

You can do the following experiments using your pressure gauge.

Putting the end of the rubber tube of the manometer firmly on the glass funnel, tighten the wide opening with a rubber film. When the liquid in the pressure gauge has calmed down, lower the funnel into a bucket of water. Watch how the pressure inside the water changes with the depth of the funnel. Having installed the funnel at a certain depth in the water, turn its hole in different directions, up and down, following the reading of the pressure gauge.

2.Open the chimney near the stove that was melted out shortly before the experiment. Insert the pressure gauge rubber tube into the oven. The water level in the short leg of the pressure gauge rises. Calculate the pressure of warm air in the furnace (with draft).

3. Slightly inflate the rubber bag of the medical heating pad with air and connect it firmly to the rubber tube of the manometer. Lay the bag horizontally and put thick books (load) on it one after the other. The pressure gauge will show well the change in air pressure closed in the bag.

4. If you get a glass tube with a total length of about 1.7 m, you can make a pressure gauge to measure a much higher excess pressure, for example, the highest air pressure when blowing by mouth. In this way, the "strength of the lungs" is controlled. It is necessary to blow not jerkily, but gradually increasing the pressure.

5. The same device can measure the greatest vacuum created by oral suction. In this case, you need to pull air from the upper end of the tube with your mouth.

6. If in the device of the 4th experiment, instead of a short elbow of the tube, a tube drawn to narrow is inserted, then when blowing into the long elbow, a fountain will beat from the short tube.

E.N. Sokolov "To the young physicist"

General information

Liquid and gaseous substances act with a certain force on the bodies in contact with them. The magnitude of this effect, which depends on the properties of the substance and external factors (temperature, compression, etc.), is characterized by the concept of pressure.

Pressure is the ratio of the force acting perpendicular to the surface to the surface area, provided that the force is uniformly distributed over the entire area. Distinguish between absolute and gauge pressure.

Absolute pressure is the total pressure of a gas or liquid, taking into account all acting forces, including atmospheric air pressure. Gauge pressure is the difference between absolute and atmospheric pressure, provided that the absolute pressure is greater than atmospheric pressure. In engineering, as a rule, excess pressure is measured.

Absolute pressure can be less than atmospheric pressure. If at the same time their difference is small, then it is called rarefaction, if it is large enough - vacuum.

Manometers are used to measure excess pressure, in connection with which this pressure is often called gauge pressure. Vacuum and vacuum are measured with vacuum gauges, atmospheric pressure with barometers.

The SI unit for pressure is newton per square meter (N/m2). However, manufactured devices are still calibrated in old units - millimeters of water column (mm of water column), millimeters of mercury column (mm Hg) and technical atmospheres (kgf / cm2).

One technical atmosphere is equal to the pressure on an area of 1 cm2 of a column of mercury 735.56 mm high at a temperature of 0 ° C or a column of water 10 m high at a temperature of 4 ° C, i.e. 1 kgf / cm2 = = 735.56 mm Hg. Art. = 104mm w.c. Art.

Vacuum is measured as a percentage of atmospheric pressure, or in the same units as pressure. The average value of atmospheric air pressure was determined as a result of numerous measurements and is 760 mm Hg,

Classification of pressure gauges according to the type of measured pressure

Classification of regulators according to the type of pressure:

- vacuum gauges and manovacuum gauges;

- barometers;

- pressure gauges;

- differential pressure gauges;

- draft gauges.

The principle of operation of any of them depends on the structure, in addition, it must be borne in mind that the meters are divided into categories within a single class, taking into account the level of accuracy.

Devices operating on the vacuum principle are designed for rarefied gas. Pressure gauges are able to determine the parameters of the limiting pressure with indicators up to 40 kPa, draft gauges up to -40 kPa. Other differential devices help to recognize the difference in indicators at any two points.

exemplary

Exemplary are measuring instruments that are used to calibrate others. This type of device is used to test equipment and accurately measure liquid and gas pressure, they have a higher accuracy class - 0.015-0.6 units. The increased measurement accuracy of these devices is due to the design features: the gear body in the transmission mechanism is made very accurately.

Water

Water devices operate on the principle of balancing a gaseous substance with pressure that forms a column with liquid. Thanks to them, you can refine the level of sparsity, difference, redundancy and atmospheric data. This group includes U-type regulators, which are designed like communicating vessels, and the pressure in them is determined taking into account the water level. Compensation, cup, float, bell and ring gas meters are also classified as water meters, the working fluid inside them is similar to the sensing element.

Electrocontact

These devices monitor the pressure limit and notify the system when it is reached. Typically, this type of measuring equipment is used for gas, steam, calm liquids that are not prone to crystallization.Devices can control external electrical circuits when critical pressure is reached using a contact group or an optical pair.

Photo 1. Electrocontact pressure gauge for a heating gas boiler. The device has a dial with divisions.

Electrical

This utility gas pressure measuring instrument converts it into electrical data. This category includes strain gauges and capacitive gauges. The former change the readings of the conductive resistance after deformation and measure indicators up to 60-10 Pa with minor errors. They are used in systems with fast processes. Capacitive gas meters act on a moving membrane electrode whose deflection can be determined by an electrical circuit and are suitable for systems with accelerated pressure drops.

Special

They are used to measure excess pressure in a gaseous medium. Each type of such a device is designed for a specific gas, the name of which is indicated on the scale. And also special pressure gauges are marked with different colors and letters in the name. For example, a device designed to measure the pressure of ammonia has a yellow body and the letter "A" in the name. This type is additionally protected against corrosion. Accuracy class of special devices 1.0—2.5 units.

Digital

Digital or electronic instruments are high precision devices and are most often used for mounting in air or hydraulic media. Of the advantages of such regulators, note the convenience and compact size, the longest possible service life and the ability to calibrate at any time. They are mainly used to monitor the condition of vehicle components.In addition, digital type gas meters are included in the fuel lines.

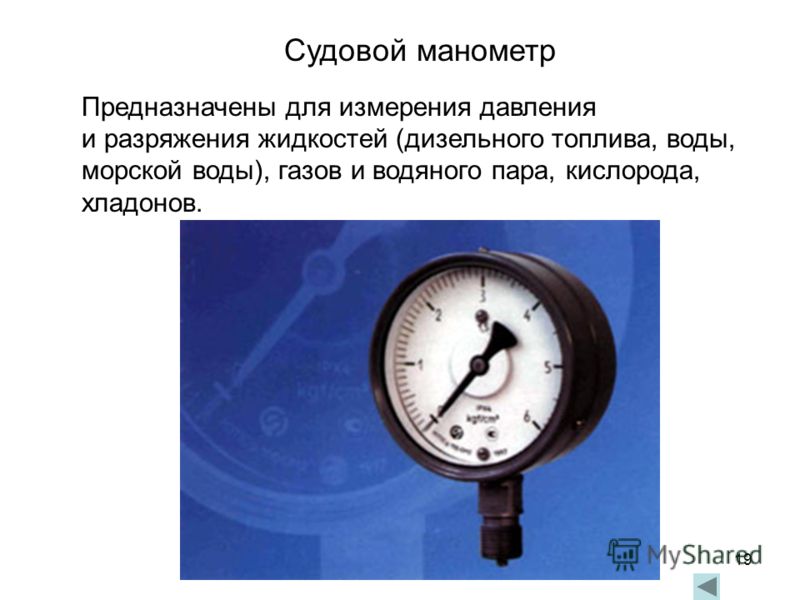

Ship

A feature of the devices is increased protection against moisture, dust, vibrations. Basically, these pressure gauges are used in shipbuilding, hence their name. Suitable for measuring the pressure of liquid, gas, steam.

Other

In addition to regulators with standard characteristics and settings, other types of instruments are used to obtain accurate data. This list includes deadweight gas meters, which are original samples for verification of similar devices. Their main working part is a measuring column, the condition and accuracy of the readings of which change the magnitude of the error. During operation, the cylinder is held inside the piston at the desired level, at the same time it is affected by calibration weights on one side, and only pressure on the other.