- dangers

- Preparatory stage

- Design features of the multifunctional hearth

- Smoking technology

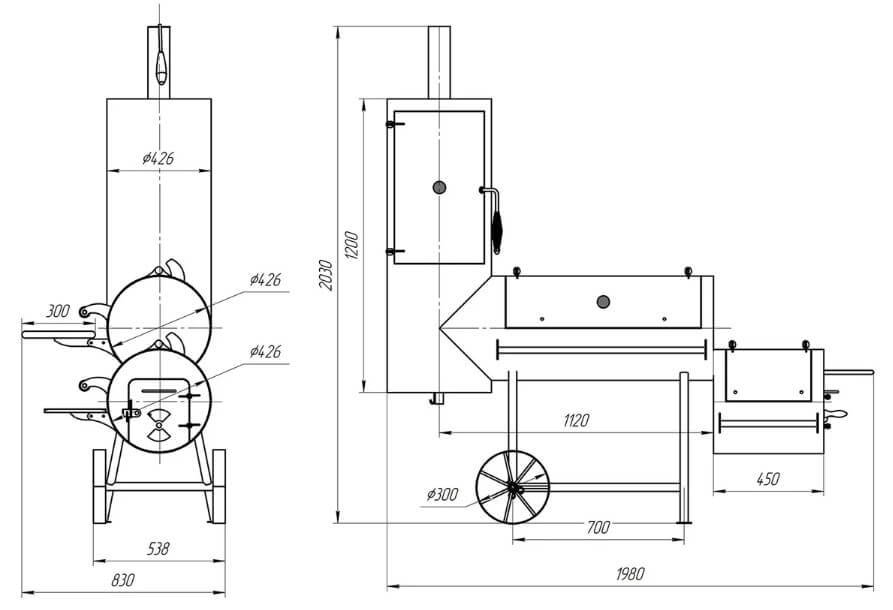

- Barbecue and barbecue sizes

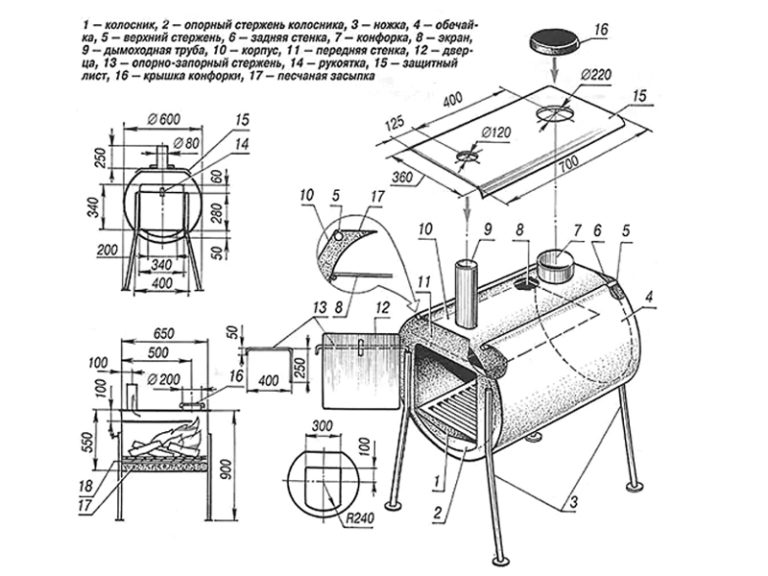

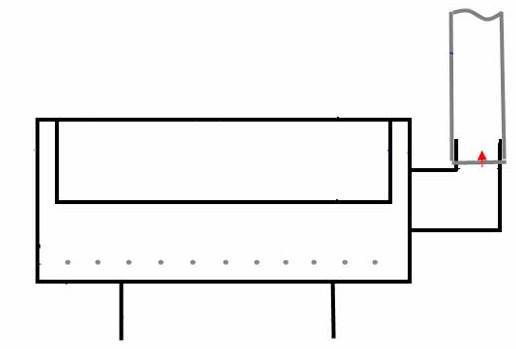

- The design of the brazier smokehouse

- Additional design attributes

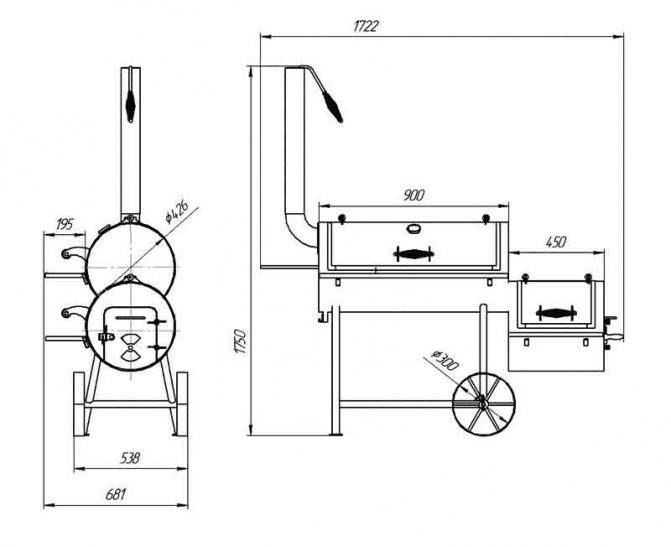

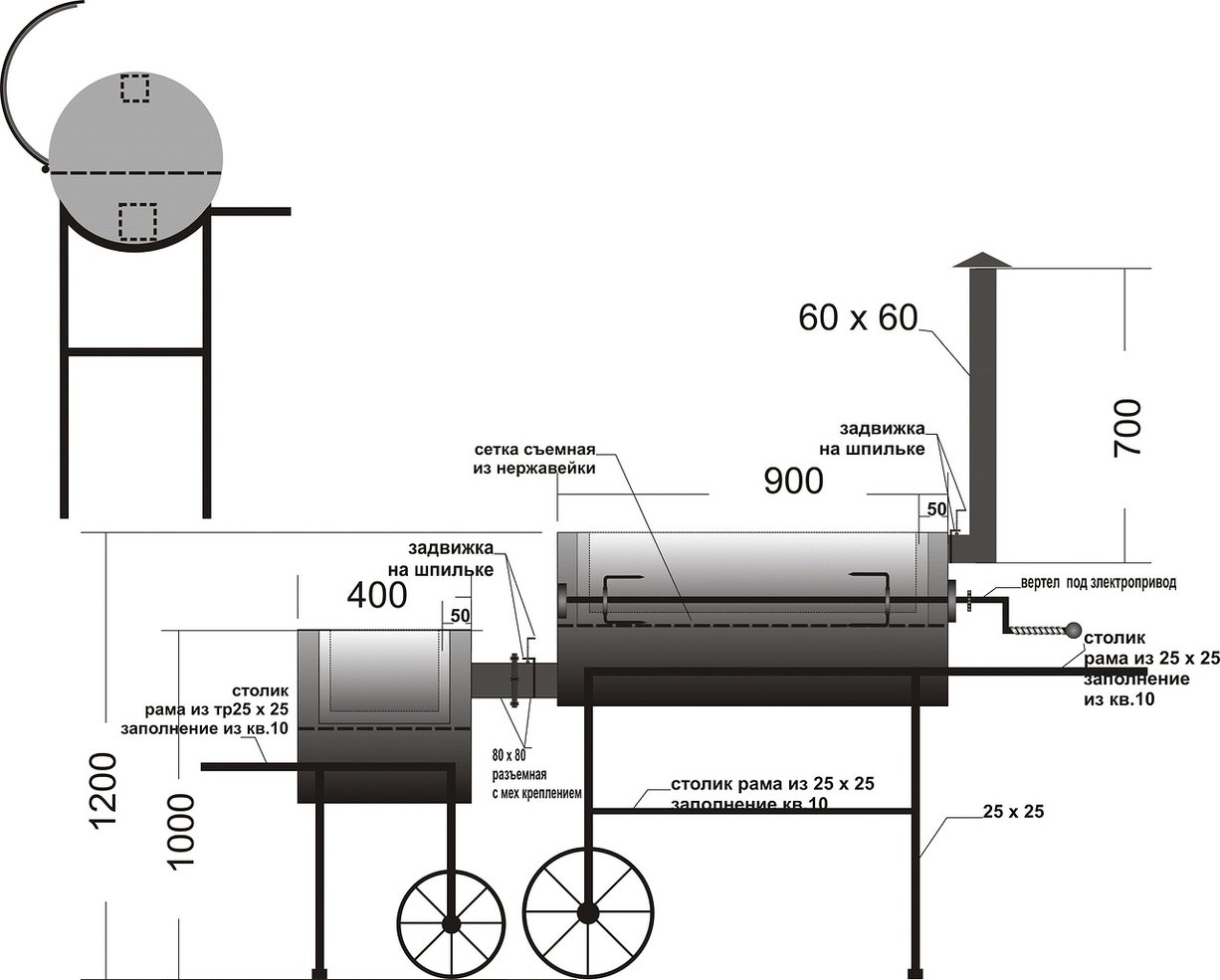

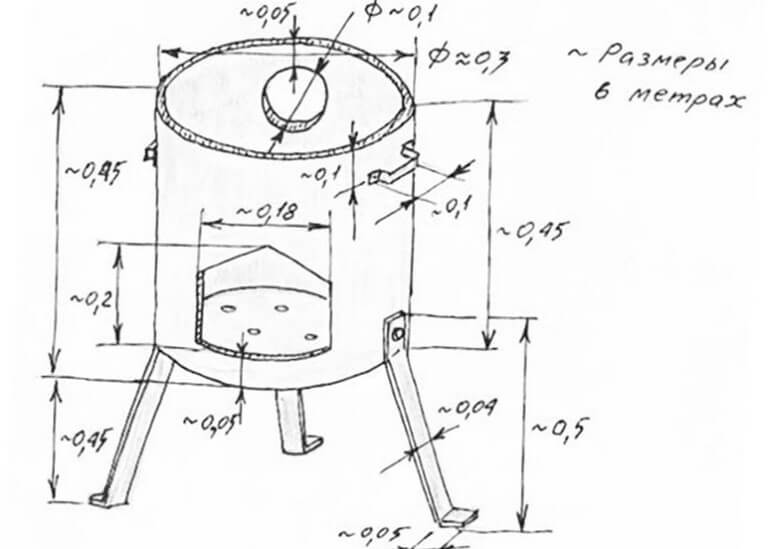

- Drawing of a brazier of a smokehouse from a gas cylinder: drawings for self-production

- Other design changes

- How to make a barbecue

- How to improve the grill

- Conclusion on the topic

- Manufacturing of handles and lids

- visual instructions

- Cylinder cutting

- Barbecue legs

- Installing the lid and handle

- Assembly

- Peculiarities

- Mangal manufacturing technology

- Marking and cutting

- Lid

- legs

- Step-by-step instruction

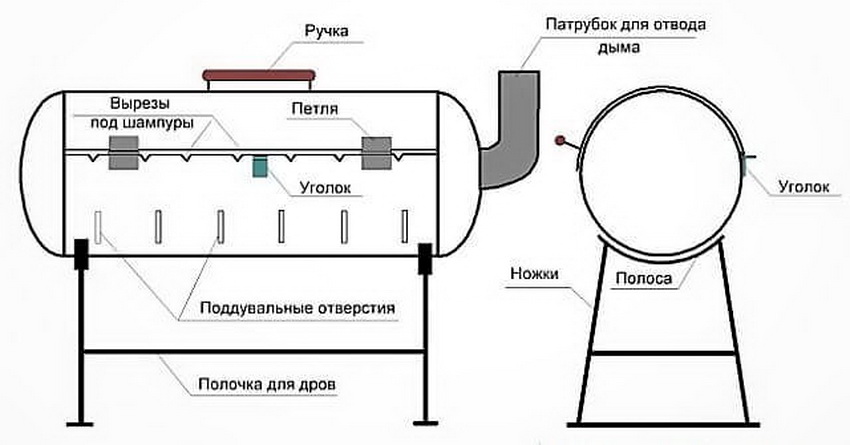

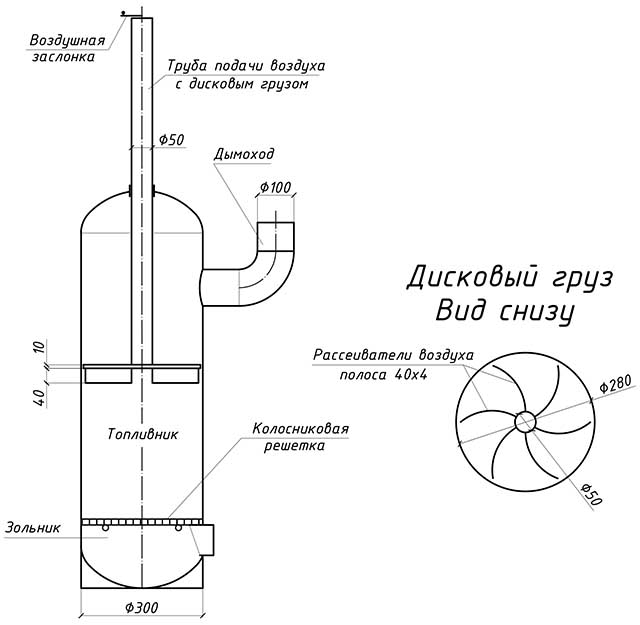

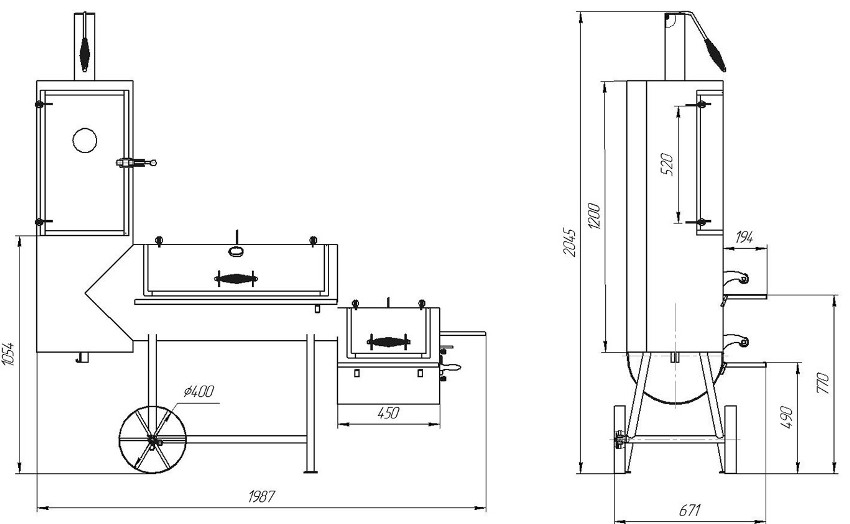

- How to make a brazier smokehouse from 2 gas cylinders with your own hands

- Installation of a chimney for a barbecue

- Marking the gas cylinder for barbecue

- Design features of the gas cylinder

- Table 1: Dimensions of propane storage and transport cylinders

- dangers

- Safety precautions when cutting a gas cylinder

dangers

When making a grill from a conventional cylinder, one must take into account potential hazards that may affect the quality of the product, namely:

- Poor welding work will definitely affect the strength of the grill. If you are not competent in this matter, it is best to use the services of experienced professionals.

- Using a heat-resistant coating for your product, you will significantly raise its aesthetic appearance.

- The finished structure will have an impressive weight, which will affect the ease of transportation.

Consider the above nuances when making your own barbecue.

Preparatory stage

Always follow the safety rules. The disadvantage of a propane tank is that gas vapors are kept in it for quite a long time. Even if there is no gas in the cylinder for a long time, it can explode from the slightest spark. Therefore, the first step is flushing. First, open the valve and bleed the gas that could remain in the cylinder. Then turn it over and get rid of the condensation.

Carefully cut off the valve of the gas cylinder, pour it with cold water from time to time. Then you connect the hose and fill the bottle with water, shaking it occasionally to make the gas escape better. The cylinder should stand with water for at least a day, only after that you need to empty it (do this away from residential buildings and not on the ground). Everything, the container is ready for work.

If you are making an open brazier or barbecue, then you do not need any drawings, the design is quite simple. And in general, there are no special requirements, it all depends on your preferences, in what proportions to cut the balloon. But it is worth reading the recommendations:

- If you plan to use a grill and ready-made coals on the grill, then it is better to cut the container in half.

- When using skewers and firewood as fuel, you need to make the base of a greater height.

The easiest option is to cut the container into two parts, weld legs to each, and you get two good open barbecues. But the functionality is limited and the appearance is not very attractive.And in any case, you need to install it on legs so that it is convenient to cook. As an option, weld two pipes across to put the structure on the ground. But squat near the brazier inconvenient, especially if you need to cook a lot of food. Therefore, it is better to make a full-fledged brazier with your own hands, with the function of a smoker and all possible little things that are useful during operation. Before proceeding with the manufacture, consider a photo of the designs, choose the most attractive option for yourself.

Design features of the multifunctional hearth

The main difficulty of combined foci is the unequal conditions for food preparation. Therefore, a brazier with a smokehouse from a gas cylinder should be designed with this nuance in mind.

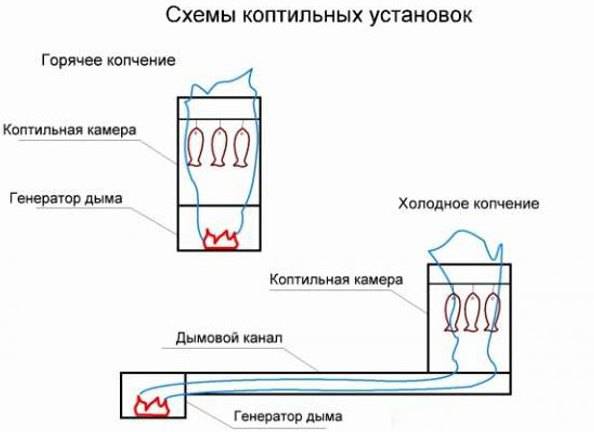

Smoking technology

There are several options for smoking products:

- cold - the smoke is first cooled inside a long pipe, enters the chamber with fish / meat for 1 - 3 days, ensuring the safety of the delicacy for 2 - 6 months;

- hot - the smoke generator is located directly next to the chamber with the products, the smoking process is sharply reduced, but the delicacies are stored for a couple of months, nothing more;

- semi-cold - the process takes 24 - 36 hours, the length of the pipe between the smoke generator and the medium-sized food chamber is 1.5 - 2 m.

Therefore, depending on the technology chosen, the cylinder smokehouse will by default have, in principle, the same design. But, its elements will be spaced from each other at different distances.

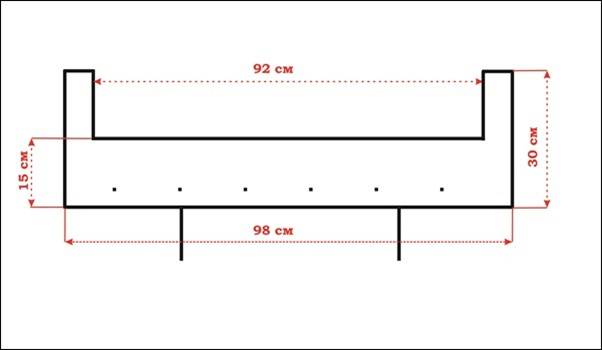

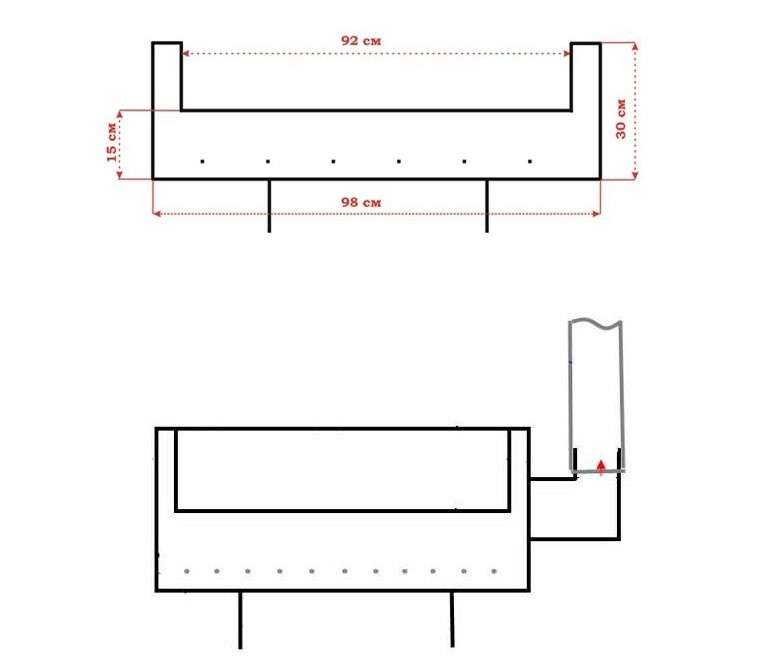

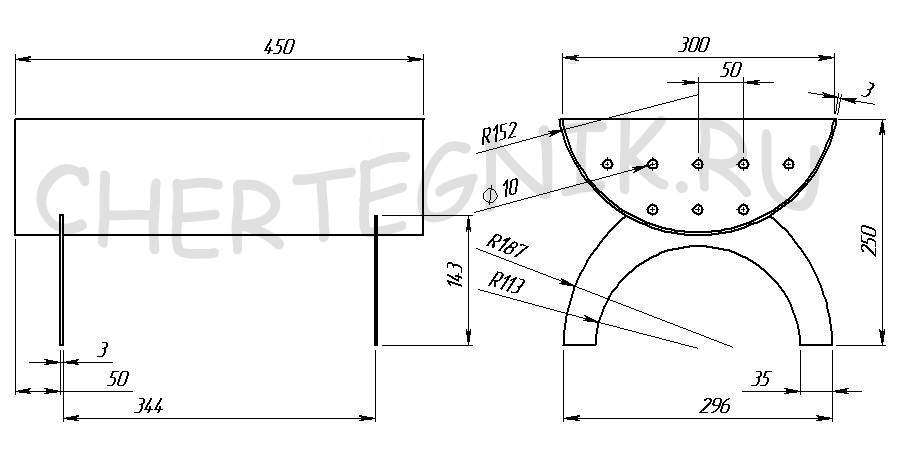

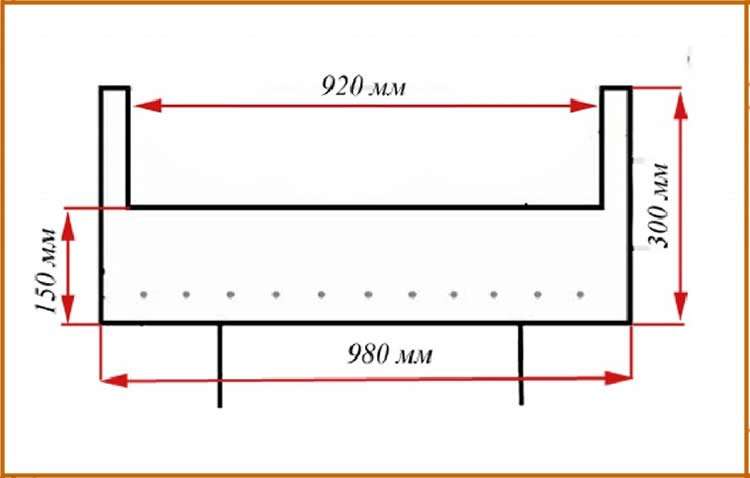

Barbecue and barbecue sizes

Braziers designed for cooking meat on skewers, called barbecues, have dimensions:

- length - arbitrary, depends on the number of skewers, the distance between which is 8 - 10 cm;

- height (depth) - 15 - 20 cm is considered the optimal distance from meat to coals;

- width - depending on the length of the skewer (produced by manufacturers 30 - 50 cm), the standard size is 25 - 40 cm;

- well, a real drawing from a real balloon, to see all the numbers, click on the picture to enlarge.

The height from ground level is less critical, in the manufacture of a stationary brazier it is usually 0.8 - 1.2 m. Barbecue is fried on grates, the height and length of the hearth remain the same, the width depends on a similar parameter of the grate itself. For grilling, the dimensions of the broiler are less critical, but a lid is required to maintain the same temperature inside the broiler.

Unlike a brazier made of sheet steel and a barrel, a brazier from a gas cylinder has the following advantages:

- wall thickness 2.5 mm;

- used cylinders are inexpensive;

- compact dimensions will save the space of the site;

- the body is in principle ready, which will reduce the complexity of the work.

Attention: For a multifunctional hearth, one cylinder will not be enough, as it will be used for barbecue. The smoke generator is constructed from a second 50 l tank of a similar purpose or from sheet steel

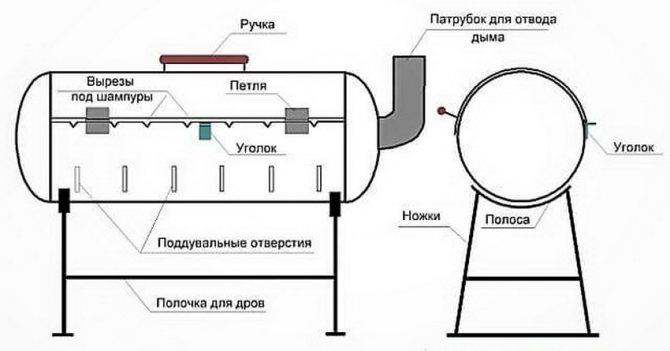

The design of the brazier smokehouse

Due to the above nuances, a grill, barbecue, barbecue and smokehouse may well be combined within one design. The classic brazier is ideal for the food chamber of the smokehouse with a sealed lid that does not let smoke out. It is necessary to add a smoke generator to the brazier connected to it directly (hot smoking) or a pipe (semi-cold and cold smoking) of the required length.

Since the hearth is stationary in 90% of cases, its supporting unit (legs, stand) can be decorated with twisted or forged elements, supplemented with a rain canopy. A chimney is necessary in any case.

Additional design attributes

When using the brazier for its intended purpose, deformations due to heating may occur. From the inside of the base, weld small metal corners along the entire brazier. Thanks to these protrusions, the skewer or grate will lie well on the brazier. To make a homemade barbecue more stable, weld pieces of a corner or pipes to the legs. You can make several crossbars if you wish.

In the bottom and sidewalls, you need to make holes that are necessary to create traction and drain the liquid after washing or rain. From the part of the tank with which the valve stood, you can weld a piece of pipe to remove smoke. But this is only true if the brazier is used with the lid closed. If cooking takes place without a lid, this is not necessary. For convenience, make holes for skewers at the base of the brazier. When cooking, they will be useful, as skewers with meat or vegetables will not turn over under their own weight. Since it is quite simple to make a brazier from a gas cylinder, you should not neglect such useful little things.

To improve the appearance, you can paint the entire structure. There are a large number of paints that can withstand temperatures up to 800 degrees.

This is an important condition, since ordinary paints will simply flare up when heated, and even poison the food if it is already on the brazier. Before painting, apply a coat of primer (it must also be heat resistant)

Red, black, silver - this is the color range available for heat-resistant paints. But this is quite enough. It is not difficult to make a brazier from a balloon, but deciding which type of construction to choose is an important point. The ideal option is to make a smokehouse and a barbecue in one design. Here's a couple good photo ideas, they increase when clicked:

How to do all this, look at the video:

If desired, you can make a stationary brazier by welding small tables on the sides and front. Since the temperature is high, it is better to make them from a metal corner. Such tables will be convenient when stringing meat or vegetables - you can put pots on them. And if the feast is expected to be long, then you can not put out the coals and place a kettle and pots of food nearby so that they stay hot longer.

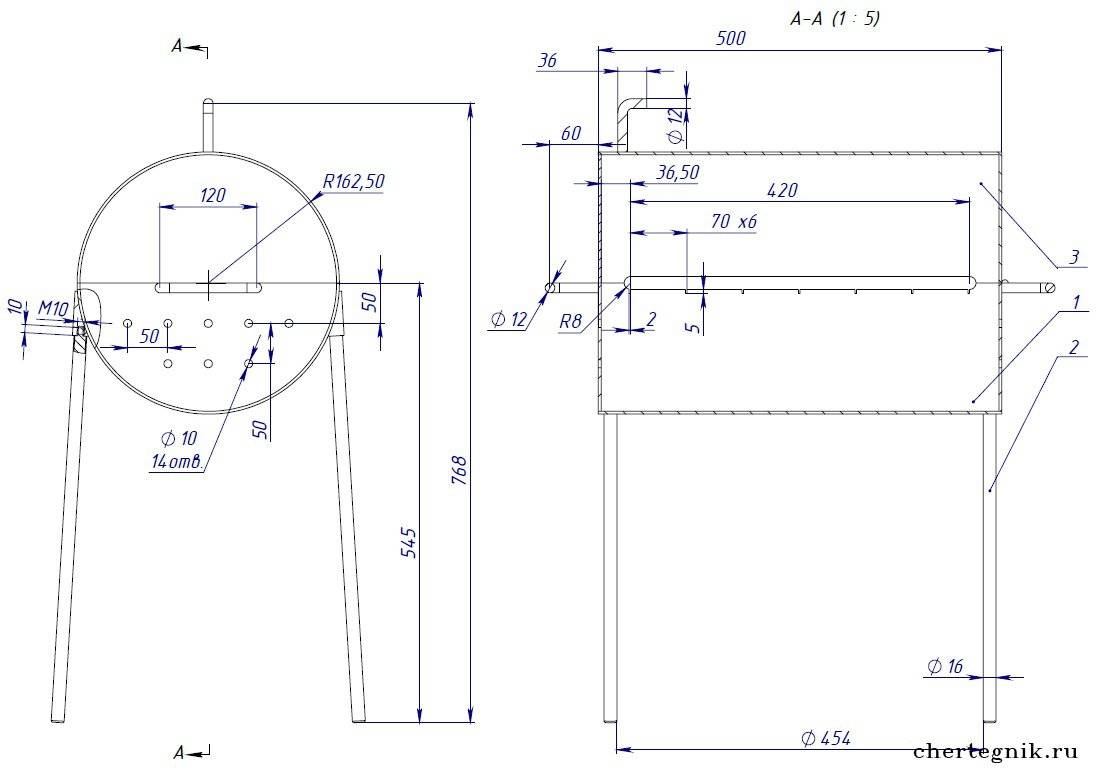

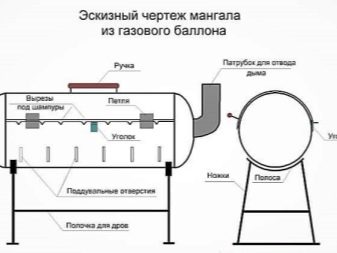

Drawing of a brazier of a smokehouse from a gas cylinder: drawings for self-production

The first thing to do is to decide on the size of the future structure. For grilling, it is recommended to use devices with a volume of at least 20 liters - then the design will turn out to be roomy. The product with a volume of 27 liters has a height of 595 mm, which is quite enough for a brazier. If you use larger dimensions, then it will not be easy to transport such a device.

You can make a smoker, a barbecue, a smoker or a traditional brazier with your own hands. The construction of the first option attracts particular interest - it is easy to cook meat, fish and other products here. The basis is the drawing, in order to depict it correctly, you must follow the advice:

- Calculate the height and width - for this you need to familiarize yourself with the dimensions of existing units.

- Calculate the dimensions of the inner hole - are selected according to the capacity and purpose of the structure.

- Consider air vents for oxygen - they should be located below.

- Draw a smoke outlet.

- Draw cutouts for skewers on the diagram.

- Consider a wood shelf.

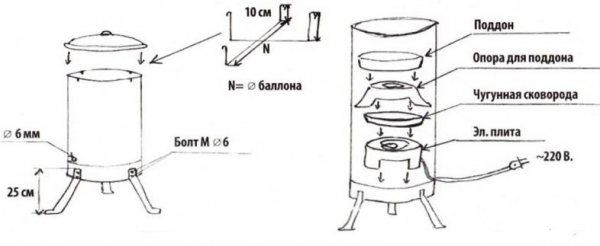

Do not forget about the lid for laying food. It is made from the upper part of the device, cut off with a grinder and fastened to loops or corners. In the manufacture of a vertical smokehouse, it is necessary to consider stationary legs and a lid for the container.

Other design changes

In principle, the brazier from the gas cylinder is almost ready. It remains only to weld the legs and make holes in the cylinder itself for installing skewers and supplying air to the coal combustion zone. Start with holes for skewers.

One of the applied longitudinal lines remained unused. It is necessary to apply additional marks along it, dividing the lines evenly into several segments. The length of the last 8 cm. At their ends, through holes with a diameter of 10 mm are made using a drill and a drill.

On the opposite side of the opening made on the welded steel strip, it is necessary to make grooves for skewers. They should be located exactly opposite the holes made. The grooves are made with a grinder and a cutting disc.

Now you need to make holes for air supply inside the barbecue. To do this, 10 and 20 cm must be set aside from the weld of the cylindrical part of the cylinder in two directions. Longitudinal lines are drawn along them, in general there will be four of them, two on each side of the seam. They also share marks with a distance of 5 cm.After that, the marks on the two paired lines are interconnected. Through them, a grinder and a cutting disc make through slots.

Holes and slots for skewers, slots for air in the barbecue from a gas cylinder

It remains to plug the hole into which the faucet was screwed. Here they simply take a plate 2-3 mm thick, which is welded to the hole, scalded with a continuous seam on all sides.

The video shows the sequence of operations for making a brazier from a gas cylinder:

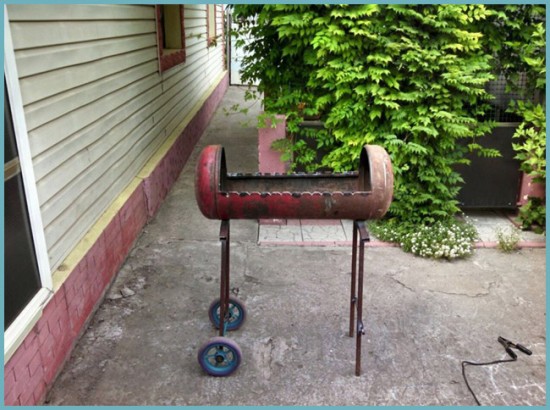

As for the legs, there are a huge number of options. The simplest - legs from a steel corner. The main thing is to accurately choose the height of the installation of the gas grill. It is optimally considered from 60 to 80 cm, that is, convenient for the growth of an adult. Although there are low modifications.

You can show your imagination and make the legs of the original shape, decorated with patterns. You can attach legs to them, make the device mobile, mobile, as shown in the photo below.

Grandma's sewing machine plus a gas cylinder = a "rare" brazier with original legs

How to make a barbecue

In principle, a barbecue from a gas cylinder is made in exactly the same way as a brazier, with only minor additions. First, a grill is installed inside. It is removable, but for it it is necessary to install support shelves inside the cylinder. They are made from a steel corner 25x25 or 32x32 mm. The length of each shelf is 10 cm, they are welded on two opposite sides of the opening, three pieces at the same distance from each other. Location in height - under the holes for the skewer. Accordingly, and from the opposite side at this height.

Secondly, you need to install a chimney. There are quite a few options here:

- on the lid;

- on the side, with a tie-in hole for a tap;

- next to the lid in the cylindrical part.

Barbecue from a gas bottle with a side chimney

How to improve the grill

There are many additional little things that will make the process of cooking meat, poultry or fish on a barbecue grill a convenient and easy process. Here are a few of those little things:

- A nut is welded to the cover of the device or to its cylindrical part, into which a thermometer is inserted. Now you can monitor at what temperature the meat dish is cooked.

- A tank can be installed on the chimney. Lattices are installed on top of each other. This accessory is an excellent smokehouse design.

- You can install a grill inside the brazier, for its entire length. This will be the grate. Its task is to hold the coals, but let the ash through itself so that it does not interfere with the burning of firewood.

As for the decorative design, there is also a huge field of activity. What the masters just do not invent. For example, here is such an option in the form of a steam locomotive, as in the photo below. Definitely, such a design will decorate the territory of the cottage.

Brazier-barbecue from a gas cylinder in the form of a steam locomotive

From the video you can learn how to create a brazier from a gas cylinder:

Conclusion on the topic

Today, finding barbecue grills from a gas cylinder with drawings and exact dimensions on the Internet is not a problem. All sorts of options are offered with simple designs and with additional convenient options. But the main thing, as practice has shown, is the exact observance of the height of the skewers above the coals. The distance is small - the meat will burn, the distance is increased - the dish will be cooked for a long time.

Manufacturing of handles and lids

The cover of a homemade barbecue is usually made at the stage of cutting the cylinder. They also fasten it first, after preparing and cleaning the metal. The most difficult thing is to weld the hinges correctly so that the lid closes tightly. As a rule, they are fixed at the very beginning, but the handles should be welded at the end. First you need to paint the brazier, let it dry under a canopy, and only after that they proceed to the final design (Figure 6).

Figure 6. When making additional elements, you can show imagination

Figure 6. When making additional elements, you can show imagination

If you want your brazier to be painted, you should first burn some wood in it. This will help to remove residual gas from the inner surface and degrease it. Only then can the structure be treated with heat-resistant paint.

visual instructions

So, the balloon is completely ready and washed. Now you need to cut it into 2 pieces. The easiest option is to simply cut the balloon into two halves lengthwise and get two classic open barbecues.

The easiest way is to cut the balloon in half and use it like a regular open grill

If you are making a brazier barbecue, then you need to “cut out” and cut off a rectangle that will be the lid of the brazier, and the second part remains as a base. Draw a rectangle on the surface of the cut lines, the horizontal lines will run approximately in the middle of the balloon or 5 cm above it, and the vertical (transverse) lines will be at a distance of about 20 cm from its edges.

Cylinder cutting

To cut the balloon, use a gas cutter or grinder. Mark the borders of the lid: from the welds connecting the base and the bottom of the container, step back 5 cm and mark the line along which the cut will be made.Saw from the middle towards the edge, while holding the grinder disk perpendicular to the balloon.

It looks like a cut balloon - blank for barbecue

Barbecue legs

Think about how high your brazier should be, and then start attaching the legs. You need to firmly install the brazier on the ground so that it is convenient to weld the lid.

The easiest way is to attach legs from an old sewing machine or a metal underframe from a small desk to the barbecue

You can build pipe legs by bolting them to the bottom. Make 4 holes in the bottom of the base, insert the bolts into them with the threads out. Secure them with nuts or weld them to secure. Attach the nuts for the bolts to the tops of the legs and screw them to the base of your brazier.

Installing the lid and handle

To attach the cover, make holes for the hinges, fix them with rivets and weld. If this is not done, the cover may come off due to high temperatures. You can install a removable cover without hinges, then inside the transverse edges of the brazier you need to attach metal strips so that the cover does not fall inward.

Attach the lid to the grill with welded door hinges

Bolts can be used to attach the handle to the lid. You just need to drill holes for them and fix them. Choose simple handles that are resistant to heat so that they do not burn later. Very comfortable handles can be made from a metal rod by welding it to the base.

Choose comfortable heat-resistant handles for the barbecue

Now you need to install a limiter on the cover. Make it from a corner or part of a pipe.And the cover itself can be fixed on one or both sides with the help of chains, thereby determining the maximum possible value of its “tilting”.

Assembly

-

You may experience deformation of the fryer when you cook on the grill. To avoid this, weld the corners to the inner longitudinal edges of the base. On the resulting ledge from the corner, you can put a barbecue grill or skewer. For the high legs of the brazier, additional fixation is also needed, which you can easily provide if you weld a corner along the outer perimeter of the structure, which will increase its rigidity.

-

Make holes in the bottom of the brazier with a drill. They are needed in order to conveniently pour out the coals or drain the water accumulated after the rain. In addition, the firewood in the barbecue will burn better if air is drawn from below.

-

In the hole where the valve was, install a smoke outlet pipe and weld it. Not everyone does this, someone leaves the grill without a chimney, especially if you plan to cook mainly with the lid open.

- If you did not attach a corner inside, with the help of a grinder you can make cuts in the sides of the base into which skewers will be installed.

Make grinder slots in the walls of the container for skewers

Peculiarities

The brazier from old gas cylinders is divided into several types that you can easily make yourself.

There are the following varieties:

- a simple brazier in which there is no lid;

- B-B-Q;

- smokehouse;

- smoker.

The last three home-made designs differ significantly from the first option, so you should familiarize yourself with their features in more detail:

The barbecue is a simple design that you can easily create with your own hands. To create such a brazier, you will need to cut off a part of the container, which will later be hinged and act as a door. Inside the structure there is a zone for coals and a grid on which products will be placed.

The smokehouse differs from traditional barbecues in that it has a firebox. The structure itself must be airtight in order to fulfill its tasks. To create it, half of the bottom is removed. The firebox is made of iron sheets. Some people use a different cylinder for this purpose. The part is welded and equipped with a special chimney pipe through which smoke will be removed.

A smoker is also called a "locomotive". It is a complex structure, which is characterized by multifunctionality. Such a product contains all the options that are available to such facilities: barbecue, barbecue, smokehouse, grill.

Barbecues are made from propane and oxygen cylinders. Cylinders act as an excellent basis for creating numerous designs. They have high-quality metal, almost finished shape and standard dimensions.

Due to the thick walls, the cylinders are able to withstand high temperature conditions, so such products are best suited for creating various smokehouses, barbecues and barbecues.

Advantages of a brazier from a cylinder:

- This design will not burn out even after prolonged contact with an open flame.

- Thanks to the optimal configuration and thick walls, the brazier will not be deformed by high temperatures.

- In such a barbecue, you can cook not only kebabs, but also bake vegetables, as well as smoke and fry.

- After cooking, you do not need to extinguish the coals with water. For these purposes, it will be enough just to close the brazier with a lid. It also allows you to store the barbecue outside. Due to the large size, you can cook portions for the whole company.

- Ease of installation. Even a beginner can make a brazier from a balloon.

- The job will take several hours.

- The design of the balloon is suitable for the implementation of any creative ideas.

Braziers created from cylinders have practically no drawbacks. Some users say that the disadvantages of the design are the large dimensions of the structure. However, you can purchase more compact products. Another category of people reports that the semi-circular bottom is inconvenient when lighting firewood.

According to professionals, the spherical structure of the walls of the barbecue is not very suitable for frying kebabs, since such a configuration limits the processes that contribute to the "disclosure" of the aroma of baked meat.

Mangal manufacturing technology

While the container is being washed, a drawing is created. It is not difficult to design a brazier from a propane cylinder - in the simplest version, the product consists of three elements: a body, a lid and legs. The diagram of a brazier-steam locomotive with a chimney for smoking looks more complicated. On the drawing, mark the dimensions, determine the location of the lid, cuts for skewers, fasteners for the grill grate, etc.

Drawing: brazier

The main work consists of three stages:

- sawing the balloon

- leg welding,

- cover installation.

An additional stage is decorating the finished barbecue.

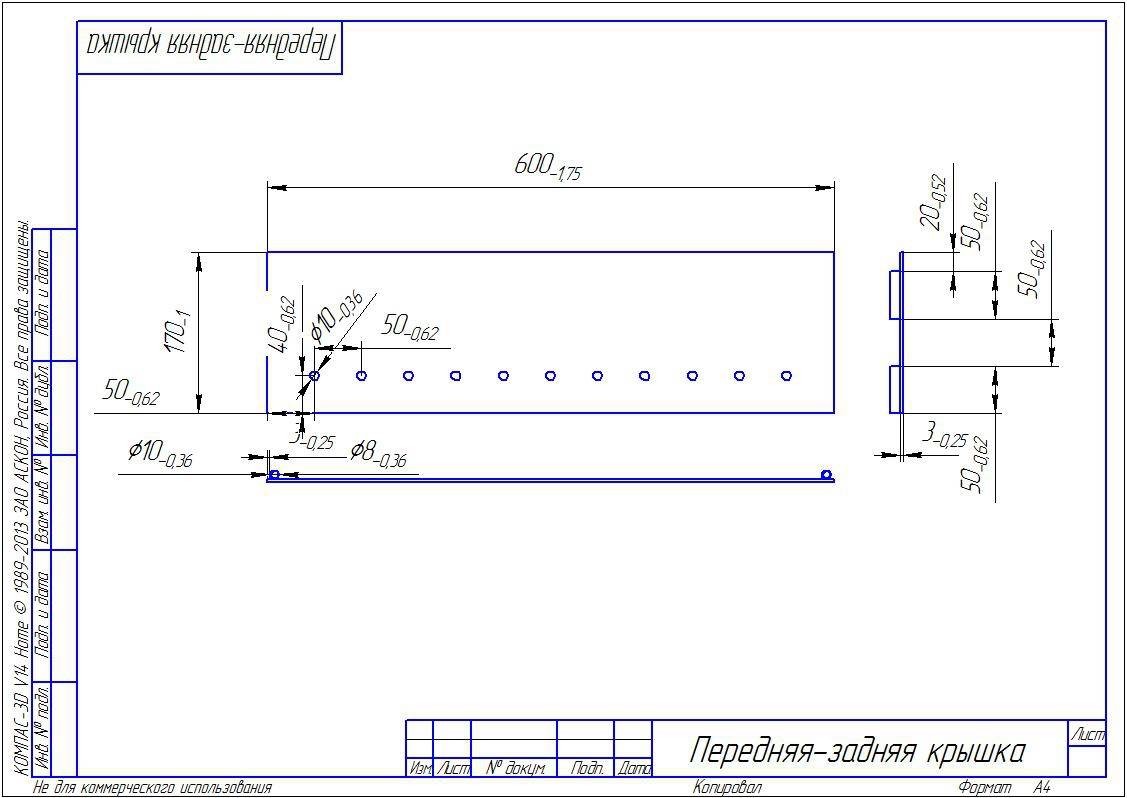

Marking and cutting

To divide the container into a brazier and a lid, a semicircular part of the container wall is cut out. The circumference of a standard propane tank with a volume of 50 liters is 96 cm. Marking is easy: there are marks on the tank that you can start from.

A welded seam runs along the entire length - 24 cm retreat from it in both directions and the boundaries of the hole are applied. Immediately make notches for fastening skewers. The extreme marks are located 3 cm from the welding rings; intermediate - arrange with any step, for greater convenience, a distance of 8 cm is recommended - then 6 skewers will fit. If you want to leave room for the grill grate, reduce the pitch between the notches.

Next, the balloon is sawn with a grinder. The wall thickness is 3 mm, so it is not difficult to cut the container. They start with longitudinal lines, and then move on to transverse markings - otherwise you can get injured when the wall moves away from the cut with force

It is important to use personal protective equipment - mask, gloves

After cutting the wall with a grinder, cuts are made under the skewers. Just below the drill, holes are drilled for the passage of air. The same gaps are made at the bottom of the barbecue. Only the bottom and the lid of the cylinder are not touched so that the wind does not blow out the coals.

Lid

At the second stage, a homemade brazier is equipped with a lid and a handle. This part is welded with metal loops - fasteners can fail under the influence of high temperature. To make it convenient to work alone, the cover is temporarily fixed with rivets. Loops are placed at an equal distance from each other.

Metal is used for the handle, since wood and plastic can deform, burn or melt during operation.

legs

Depending on whether the brazier is stationary or portable, the shape of the legs for it is selected. For the mobile version, these parts are made of pipes or metal corners, with wide areas welded to the ends so that the brazier does not go underground under the influence of its weight. The height of the products is selected individually; It has been experimentally established that it is more convenient to put the brazier on legs 20-30 cm long.

A stationary barbecue, as a rule, is mounted on a concrete or brick foundation. In addition, the design can be stylized - for example, forged wheels can be welded on to give the brazier the look of a steam locomotive.

This balloon barbecue is ready. All that's left is the finishing touches - welded grill mounts, heat-resistant paint on the body, and other finishes. To add the function of a smokehouse to the barbecue, a chimney is welded to one side wall, and a firebox to the other. When the lid is closed, a smoking chamber is obtained.

Thus, turning a standard gas cylinder into a universal fryer is not so difficult, the main thing is to observe safety precautions when working. A propane tank will allow you to implement various design ideas for the barbecue, which will be a great addition to a country weekend getaway.

Step-by-step instruction

The manufacturing process of the brazier consists of several stages.

Sawing. The balloon must be cut into two halves. This should be done along the weld, as close to it as possible. The side walls are best left uncut. They will serve as good dampers against fire and will help maintain the temperature.When sawing, try not to damage the side rings, because they will serve as a support for the cover.

Sawing a balloon

Sawing a balloon

Legs. The height of the legs depends only on your choice. You can screw the legs from an old-style sewing machine, or you can use pipe trimmings.

Legs can be equipped with wheels for ease of movement

Legs can be equipped with wheels for ease of movement

To fix the pipe, it is necessary to drill four holes in the bottom of the brazier, into which bolts are inserted so that the thread is outside the brazier. They can either be tightened with nuts or simply welded on. Nuts are welded to the top of the pipes and screwed to the barbecue.

Cover installation. The lid on the grill is attached to the hinges, which are fixed with rivets and then welded. You can make the cover removable if the canopies are directed in one direction. It is imperative to weld the hinges, because under the influence of high temperatures, the rivets can simply fly out. But for mounting the handle on the lid of the brazier, only bolts will be enough. When choosing a pen material, remember that it must be heat resistant. Additionally, you can make a limiter for the lid using chains or a corner. A chimney can be installed in the valve opening.

Lid can be secured with hinges

Lid can be secured with hinges

Assembly. To prevent the brazier from deforming under the influence of temperature, some craftsmen additionally weld a corner to the inner edges. It strengthens the perimeter and gives greater rigidity to the structure. In addition, it will serve as a stand for the grill and skewers. So that the ashes do not have to be raked out by hand, holes are drilled in the bottom of the brazier.In the absence of corners, the slots for skewers are cut out with a grinder.

Advice. For greater functionality and convenience, the internal space of the barbecue can be divided into two zones. In one part, make stands for the grill, and in the other, connectors for skewers. Install additional clamps at several levels - this will help you adjust the height of the grate above the coals.

The final touch will be coloring. This process is optional and is a personal matter for everyone.

Make notches for skewers with a grinder

Make notches for skewers with a grinder

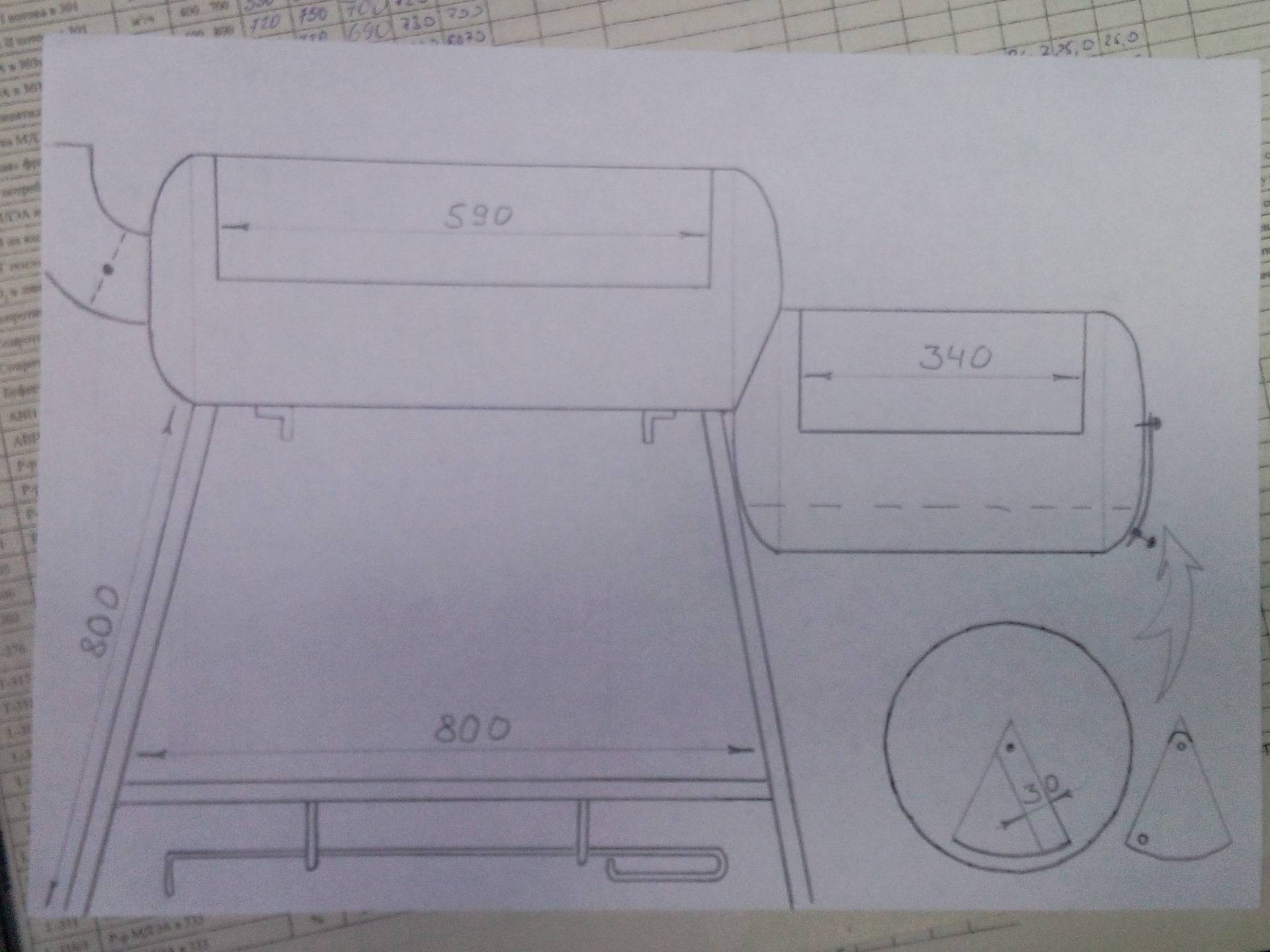

How to make a brazier smokehouse from 2 gas cylinders with your own hands

For work, two AG-50s with a capacity of 50 liters will be required.

Step-by-step instructions for making a brazier-smokehouse oven from two gas cylinders:

- The rim is cut from the bottom. The cylinder is cleaned with a grinding wheel for a grinder. Then they move on to marking. 24 cm retreat from the middle seam in both directions and draw a line with chalk. 3 cm recede from the lower and upper circular seams.

- Door hinges are welded to the cut-off part and the cylinder on one long side. A gap of 1 cm is left. On the opposite side of the balloon, an opening is cut out for placing skewers in increments of 10 cm. Holes are made under the door for air supply in increments of 5 cm, with a diameter of 1 cm.

- Legs from a metal profile 2 * 4 cm 80 cm long are welded to the cylinder. Openings for the chimney are cut out with a grinder: a round, oval inlet for hot smoking and barbecue, a square on the bottom - for the damper.

- For a smoke generator, the second cylinder is cut in half, the bottom is cut off and welded to the first half. Cut out the door and openings. From the inside, at a distance of 15 cm from the bottom, corners are welded. They place a grate for sawdust.

- On the bottom of the small and large compartments along the square holes, a steel corner is welded on both sides. The length is equal to two sides of the opening for convenient use of the damper.

- A pipe with a diameter of 10 cm and a length of 1.5 m is attached to the upper part of the brazier-smokehouse by welding. The oval holes of the firebox and barbecue are welded to each other.

- Move on to decorating the oven. Fasten by welding handles, forged decorative elements. Grind and degrease the surface. Painted with spray heat-resistant paint that can withstand 900 0C.

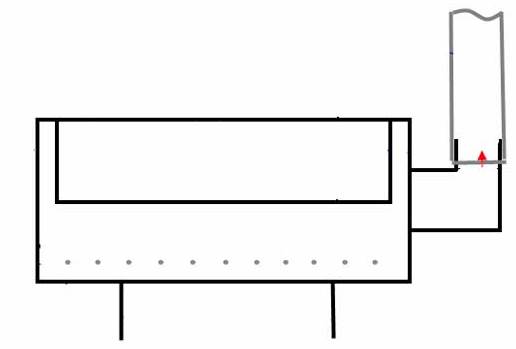

Installation of a chimney for a barbecue

A chimney is not an essential element of our homemade barbecue, but it gives a more aesthetic look and works as a regulator of the degree of smokedness of the cooked product.

For the manufacture of this element, a pipe with an outer diameter of 90m is quite suitable. and 70 cm long. Since the factory corners have a very smooth turn, you can weld the sharp corner yourself by first cutting out a pipe segment, which is marked from the turning point with a square in two directions at 45 degrees around the circumference of the pipe. Having cut a segment with a grinder, we bend the smaller part to the larger one, with the help of a corner we check the angle of 90 degrees and weld them in place. After that, we expose the pipe to the place of welding, where we installed the damper, and weld the pipe well in a circle. It should be noted that each seam must be cleaned with a cleaning disk. So it acquires a more aesthetic appearance and the quality of the weld is clearly visible.

When the pipe is welded, install a protective cap. It is fixed with a clamping bolt.

Marking the gas cylinder for barbecue

As we already wrote above, the dimensions of the structure will depend on how much capacity you are using.A 50-liter container is suitable for making a stationary brazier, and a 27-liter container is suitable for a mini brazier or a portable barbecue.

As for the markup, there are no clear criteria here. The main thing is not to cut through the factory seams so that the structure does not lose its rigidity.

But if you don’t know how to properly mark and weld the brazier: where to start and in what sequence to perform all operations, a simple step-by-step instruction will come in handy. The necessary information with dimensions can be found in our article.

As they say: it is better to see once, and everything will be clear. But in general, there is nothing complicated here. The main desire.

There are some other nuances that you need to pay attention to. You can make a country brazier from a gas cylinder of two types: without a lid and with a hinged lid that is attached to the hinges

In the first case, the container can be cut in half, and in this way two braziers can be obtained at once. In the second case, markings are first made, and a cover is cut out along it. We fasten it to two or three loops. We weld the handle.

In addition, it is necessary to mark the holes and grooves for skewers. If you are going to make a barbecue grill, then you additionally need to determine the location of the shelves under the grill.

It is also necessary to mark the holes in the lower part - for air intake. Otherwise, it will not be possible to achieve normal combustion of firewood and coals.

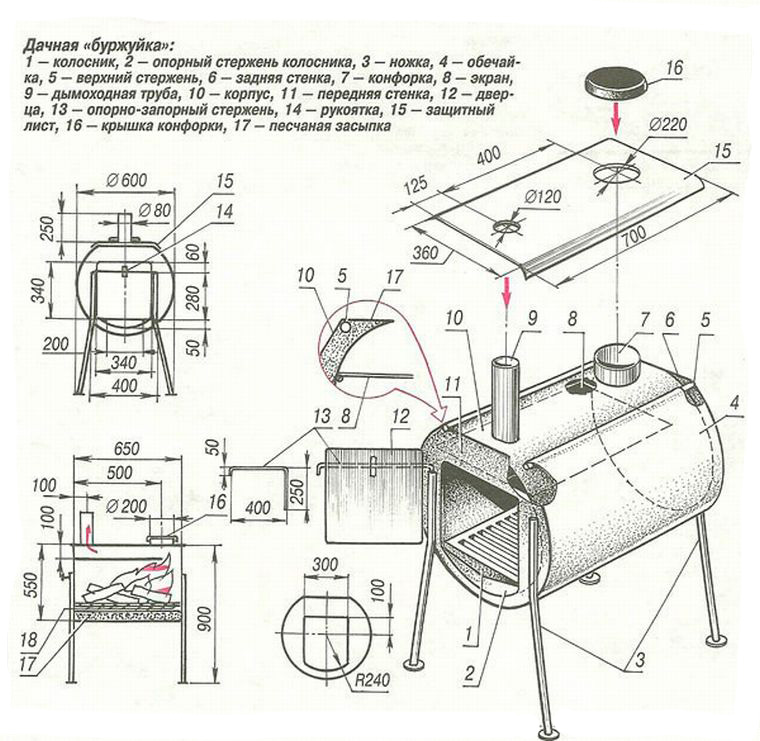

Design features of the gas cylinder

In 1953, the design of cylinders for individual gasification of apartments and houses was approved. Later, devices were developed that were installed not outside, but inside the building.

Gas cylinders for individual use according to GOST 15860-84:

1 - shoe; 2 – lower bottom (lower sphere); 3 - reinforcement belt; 4 – upper bottom (upper sphere); 5 - a place for a cylinder passport; 6 - collar (protective casing); 7 - valve; 8 - restrictive neck ring for cylinders without a shell and with a valve; 9 - shell; 10 - neck ring for cylinders with a shell and a valve; 11 - shut-off valve; 12 safety cap

For design, the main dimensions are important for craftsmen, they can be found in the attached table 1. Using the data, you can independently work out the type and parameters of the product that you intend to manufacture on your own.

Table 1: Dimensions of propane storage and transport cylinders

| Cylinder sizes, mm | Cylinder nominal capacity, l | |||||

| 2,5 | 5,0 | 12,0 | 27,0 | 50,0 | 80,0 | |

| D | 200±2,5 | 222±+3,0 | 222±+3,0 | 299±3,0 | 299±3,0 | 299±3,0 |

| D₁ | 200±3,5 | 200±3,5 | 200±3,5 | 270±4,0 | 299±4,0 | 299±4,0 |

| D₂ | 155±5,0 | 155±5,0 | 155±5,0 | 222±5,0 | – | – |

| D₃ | 160±3,5 | 160±3,5 | 160±3,5 | 230±4,0 | – | – |

| S | 2,0±0,3 | 2,0±0,3 | 2,0±0,3 | 3,0+0,3 | 3,0+0,3 | 3,0+0,3 |

| H | 225±2,0 | 285±2,0 | 470±2,5 | 575±3,0 | 960±3,5 | 1400±4,0 |

| H₁ | 136±2,0 | 197±2,5 | 384±2,5 | 474±3,0 | 830±3,5 | 1275±4,0 |

| Mass of liquefied gas in a cylinder, kg | 2,8±0,10 | 4,0±0,12 | 6,0±0,15 | 14,5±0,10 | 22,0±0,15 | 31,5±0,20 |

From the data presented, it can be seen that the wall thickness of large-volume containers is quite solid, it is 3 mm. For devices where solid fuel is burned, such walls will serve for quite a long time.

dangers

When making a grill from a conventional cylinder, one must take into account potential hazards that may affect the quality of the product, namely:

- Poor welding work will definitely affect the strength of the grill. If you are not competent in this matter, it is best to use the services of experienced professionals.

- Using a heat-resistant coating for your product, you will significantly raise its aesthetic appearance.

- The finished structure will have an impressive weight, which will affect the ease of transportation.

Consider the above nuances when making your own barbecue.

Safety precautions when cutting a gas cylinder

You can not immediately start cutting the workpiece.Combustible gas remains inside, along with gasoline (a gas in the form of a liquid). If you start any machining: drilling or cutting, a spark is possible that will cause an explosion. It is necessary to remove the remains of combustible substances from the inside of the container.

Unscrewing the valve

It can be quite difficult to unscrew the valve. Over many years of operation, fairly strong bonds are formed between the elements, diffusion of one metal into another is often observed. It is necessary to do so.

- Secure the cylinder from possible rotation around the axis. Belts or thick wire are used here.

- A gas key (No. 2) is installed on the valve.

- It can be extended with a pipe by about 1 m.

- Choose a position so that the resulting lever has a stroke of at least 40 ... 50 cm.

- Press the lever sharply, create a shock load.

In most cases, this approach is effective. To facilitate tearing off the valve, you can tap the neck with a hammer.

The balloon is filled with water. It will squeeze out all available combustible substances. Now you can cut the gas cylinder.

Attention! All procedures should preferably be carried out away from the residential area. There is a rather unpleasant smell.