- Laying underground gas pipelines

- Choosing the optimal set of earthmoving machines

- 2.1 Selection of dump trucks for sand delivery

- Construction of the main gas pipeline

- When the gasification project is ready

- Selecting a contractor and concluding a contract

- Commissioning of the gas pipeline

- Starting and setting up the system

- Main pipeline protection

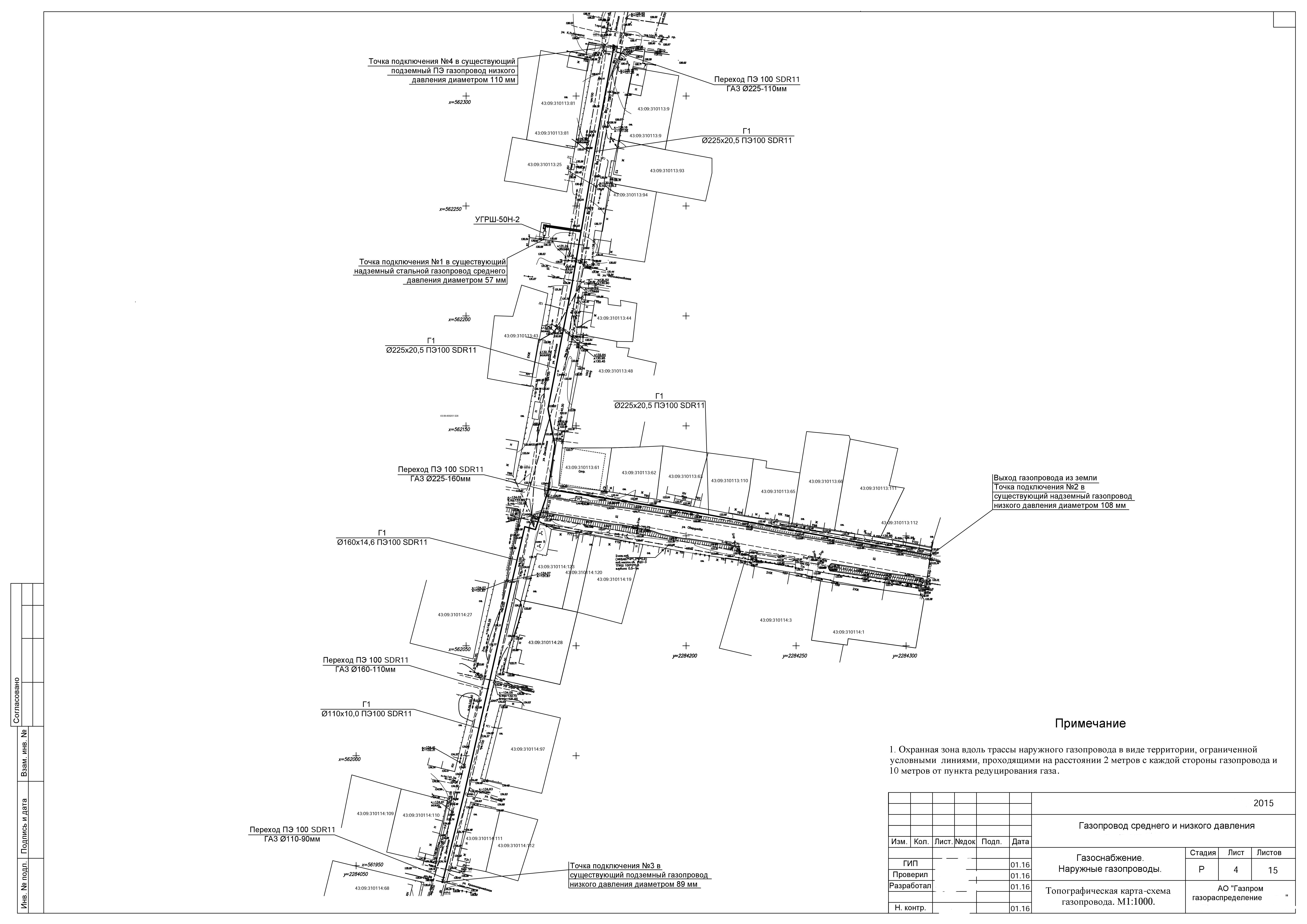

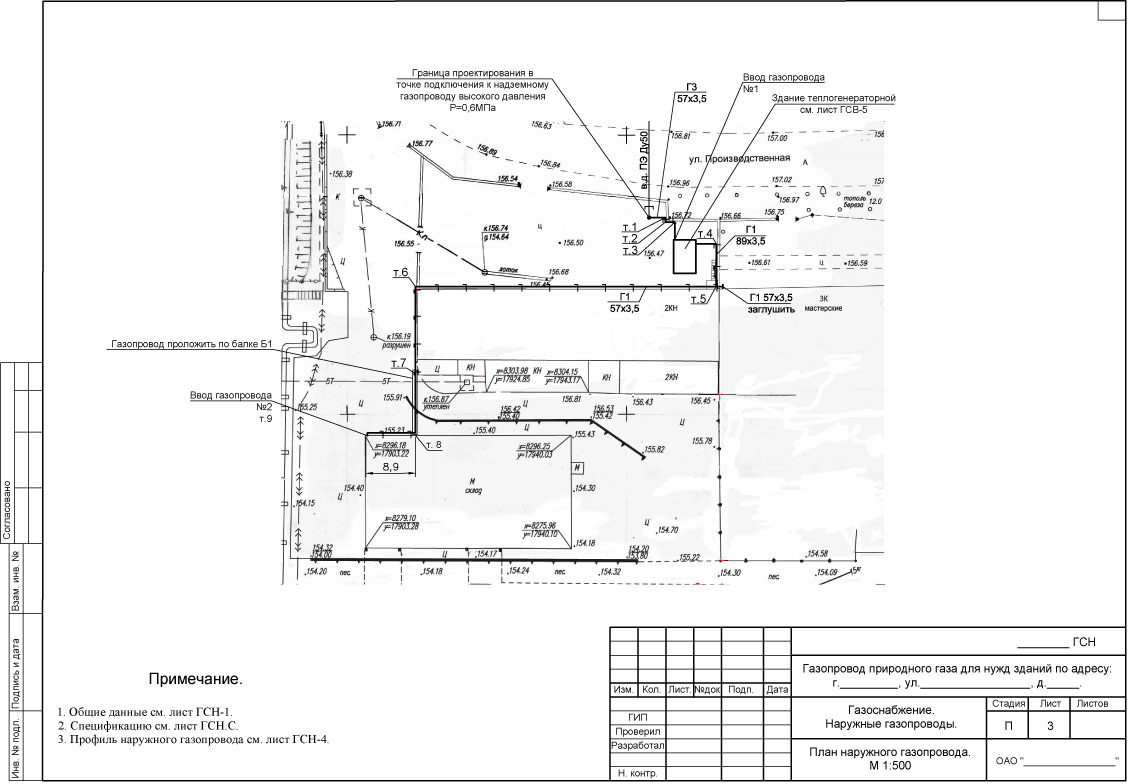

- Design of the main gas pipeline

- Construction scheme

- Construction of the linear part of the main gas pipeline

- Operation of main gas pipelines

- Compressor stations

- General characteristics of central gas pipelines

- Key points in network operation

- The composition of the main gas pipeline includes

- Warning about the use of cookies on the Info KS website

- Design of the main gas pipeline

- Construction scheme

- Gas line maintenance

- Conclusions and useful video on the topic

- Conclusion

- Conclusions and useful video on the topic

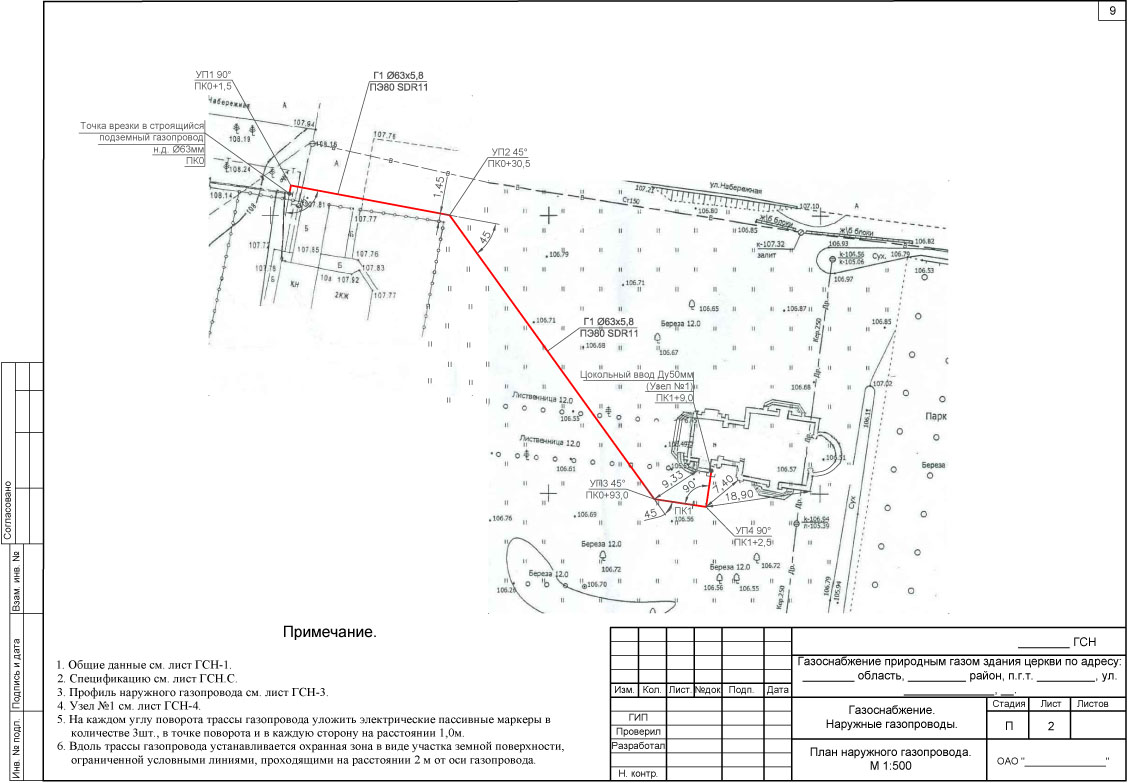

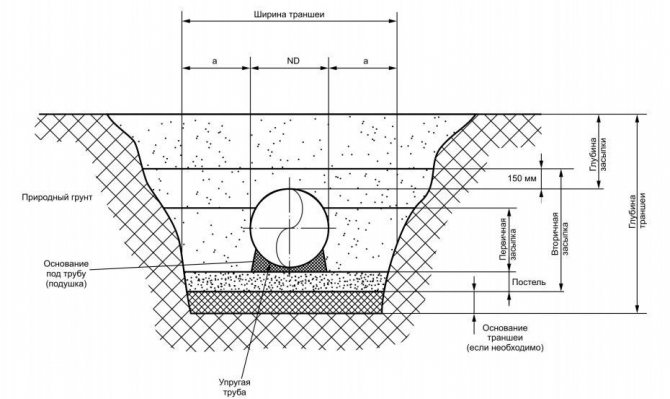

Laying underground gas pipelines

This type of installation includes laying a gas pipeline underground. As a rule, such installation requires pre-prepared dug trenches. In this case, the depth of the dug channel and the communication wiring should be taken into account according to the project, it should be at least 0.8 m.When choosing a location, it is necessary to take into account the distance to buildings, structures and other communications (sewerage, heating network). It is undesirable to lay an underground gas pipeline near trees, since their root system can make it difficult to repair and operate. When laying pipes and assembling a gas device in this way, the following points should be considered:

Scheme of laying an underground gas pipeline

- the gap between the gas pipeline and other underground utilities must be at least 0.2 m;

- at the intersection with communication collectors, gas pipes must be pulled in cases;

- the gas main is located above other engineering networks;

- cases should be removed from the intersection at a distance of at least 0.2 m;

- with the help of waterproofing materials, the ends of the cases are processed.

Types of trenchless pipe laying

Another way of underground installation is trenchless laying. This option is the least expensive. The advantages of the trenchless method of laying a gas pipeline are as follows:

- yareduces financial costs for the installation of a gas pipeline;

- reduces installation time.

The underground method of laying a gas pipeline is the safest, however, the implementation of such installation is more expensive.

Choosing the optimal set of earthmoving machines

2.1

Selection of dump trucks for sand delivery

The volume of sand in a dense body in the bucket of a mining loader

Amkodor 352 is calculated by the formula:

,

where vkov - the accepted volume of the loader bucket, (2.8 m3); Tonap

— bucket filling factor (0.8); Toetc - coefficient

initial loosening of sand (1.17).

Mass of sand in the loader bucket:

,

where is the soil density at natural

occurrence, t/m3.

The number of buckets of soil loaded into the body of a dump truck:

For a transportation distance of 17 km, we choose a dump truck

KAMAZ-65115 with a carrying capacity of 15 tons.

Rice. 6. Appearance of the KamAZ-65115 dump truck

Determine the number of loader buckets required for loading

dump truck:

bucket.

The volume of sand in a dense body, loaded into the body of a dump truck:

Construction of the main gas pipeline

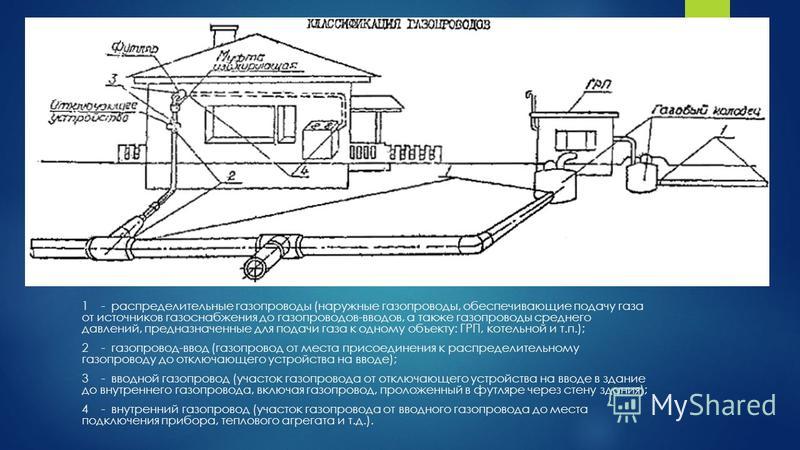

Although from the outside this structure resembles an ordinary pipeline, only in a larger version, in reality the difference is significant. Even in the simplest version, the main pipeline for gas contains the following structural elements:

- Directly the pipe circuit, which is directly interfaced with branches, transition nodes, valves, etc. This is the main main part of the gas pipeline, in the body of which connections to stations, control points and treatment facilities are also made.

- Condensate collectors and devices for introducing technical mixtures based on methanol.

- Control systems and telemechanics equipment.

- Means of providing electrochemical anticorrosive protection.

- Power lines and communications.

- Fire extinguishing devices.

- Reservoirs for gas storage and degassing.

- Service buildings for the operation of pipelines in the assigned areas.

- Pumping and intermediate pumping stations.

- Barns for gas storage.

When the gasification project is ready

A prerequisite for the transition from the design stage to construction and installation work is the coordination of the project with the technical department of the gas service. This procedure is usually completed within 2 weeks.

Selecting a contractor and concluding a contract

After approval, the project must be accompanied by:

- estimate for the performance of the work provided for by the project;

- agreement on technical supervision;

- an act on the inspection of smoke ventilation channels, drawn up and signed by a representative of the VDPO service.

When the entire list of necessary documents is in hand, you can proceed to the arrangement. As a rule, any design organization has a license for construction and installation work. If such a license is not available, you will have to take care of finding a contractor.

Since it is the installation organization that will be responsible for the construction and commissioning of the gas pipeline, it is desirable:

- check the license for gasification;

- see other permits;

- make sure that employees have the appropriate permissions.

Before concluding a contract, it is necessary to agree and approve the terms of installation, which should be fixed in the contract.

When performing installation, fire extinguishing equipment designed for fires of class "C" (burning gases) must be at hand

In the agreement for the performance of work, in addition to other obligations, the following conditions must be fixed:

- the employees of the organization working at the facility have a protective screen that protects the walls from heating, and all the necessary fire extinguishing equipment;

- issuance of executive technical documents to the customer immediately after the execution of calculations for the work provided for in the project;

- the obligation of the contractor to complete the installation within the agreed time, in accordance with the established standards and the required level of quality;

- the obligation of the contractor to timely draw up all the prescribed executive and technical documentation.

The contractor must provide the customer with the specified documents after the installation work has been completed, before the visit by the commission for the acceptance and delivery of the object.

Commissioning of the gas pipeline

The delivery of the finished gas pipeline is carried out in the presence of a commission, which includes representatives of the contractor, the gas service and the customer himself. During the acceptance process, it is necessary to check the availability of all equipment provided for by the project, the correctness of its installation and connection.

The commission accepts works from 2 weeks to a month. If no deficiencies are identified, the representative of the gas service issues a receipt for payment, which the customer pays, and transfers a copy of the document to the contractor.

After acceptance of the finished gas pipeline, the system meter must be sealed in the presence of the customer

The contractor transfers all technical documentation to the gas service, where it is stored for the entire period of operation. According to the results of the commission's work, the gas service must seal the meter within 3 weeks, after which the system is considered ready for gas supply.

The agreement with Gorgaz regulates the maintenance of the system, for which this service will be responsible. It is the basis for the gas supply.

In addition to the conclusion of the contract, you will need to undergo a safety briefing. It is carried out at the company's office or at the place of residence by a specialist with the appropriate clearance. In any case, after the briefing, the customer must confirm the completed briefing with a signature in the logbook.

Starting and setting up the system

The tie-in is carried out by the relevant service, the procedure is paid, it is carried out within a predetermined timeframe, when all the equipment has been accepted and recognized as functional.

Tapping into the main pipe under pressure must be carried out by specialists using the appropriate equipment

After that, a test run is carried out, checking the instrumentation and the meter for leaks. The final debugging of the equipment and the launch is carried out by the equipment supplier organization with which there is a service agreement:

- the system is starting up;

- it is adjusted to the optimal mode of operation;

- the representative of the company is obliged to explain all the nuances of the operation of the equipment, the rules for its operation.

In cases where malfunctions and other problems are noticed, the launch is suspended until they are eliminated.

If everything is in order and the launch was successful, a bilateral act is signed confirming the completion of the work.

Main pipeline protection

The central gas network is far from being a toy. Therefore, strict rules are established regarding its use.

The activity of business entities near the sections where the gas pipeline passes is limited. You need to get permission from the local authorities.

The owner enterprise must at least once a quarter inform the population of the adjacent territories about the location of the pipeline. Print media, local television or radio are used.

The pipeline is considered an object of increased danger. This is determined both directly by the peculiarities of transportation, and by the serious properties of oil, gas and other substances.Therefore, in case of destruction of the integrity of the pipe, the following are possible:

- explosion;

- destruction and pollution of the adjacent territory;

- the formation of a smoke cloud;

- fire;

- other negative consequences.

It is mandatory to place information signs in the immediate vicinity of the pipeline at a height of 1.5-2 meters from ground level. They must be legible and visible, at 500m intervals and at every turn in the course.

The intersection of the highway and the pipeline is undesirable, however, in some cases it cannot be avoided. Signs are posted in these areas.prohibiting cars from parking.

Design of the main gas pipeline

Integrated design involves several stages:

- Geodetic, geological, hydrological and environmental studies along the entire length of the future highway. Based on the information received, it is determined how to lay the pipe, where to install the pumps, whether additional maintenance equipment is required.

- Determination of efficiency and economic benefits: the volume of pumping, delivery areas, end and start points and points of intermediate selection are determined.

- Calculation of pipeline characteristics - pipe diameter, working and maximum pressure, number of pumping stations.

- Design of tanks, distribution stations, transmission and extraction units, treatment facilities and more.

- Economic justification for profitability: construction cost, comparison with other methods of fuel delivery.

The result of the design is a set of technical documentation, including estimates, calculations, drawings, layouts, feasibility studies, notes and other materials necessary for construction.

Construction scheme

Monofilament gas pipeline - a pipe of the same diameter throughout

Monofilament gas pipeline - a pipe of the same diameter throughout

There are different schemes for laying the main gas:

- monofilament - the system is mounted from pipes of the same diameter throughout;

- multi-line - several pipelines are laid in one technical corridor;

- telescopic - the diameter of the pipeline from the initial to the final station changes.

If the laying of the highway includes different structures - an underground circuit, above ground, underwater - more complex construction schemes are used.

Construction of the linear part of the main gas pipeline

COURSE PROJECT

Construction of a linear

parts of the main gas pipeline

Introduction

A pipeline is a structure consisting of tightly connected

between pipes, pipeline parts, shut-off and control equipment,

instrumentation, automation equipment, supports and suspensions,

fasteners, gaskets, materials and parts for thermal and

anti-corrosion insulation and intended for the delivery of bulk liquid and

gaseous products from their places of production to places of consumption.

Modern economic conditions have posed a number of problems

oil and gas industry construction industry: accelerating

rates, eliminating seasonality and improving the quality of pipeline

construction.

A comprehensive solution to these problems can be performed on

basis of system analysis and depends, first of all, on the adoption of optimal

design decisions, adoption of new materials and structures, raising the level

mechanization, development and implementation of more modern production technology

works, as well as progressive forms of organizing the construction of powerful

pipeline systems.

Linear construction, which includes construction

pipelines, has one important feature - the diversity and

variability of the nature of the terrain along the route of pipelines requiring

application of various technological schemes and construction technology. it

the change may be so significant that it requires full technical

re-equipment of construction units performing a certain type of work

This work is devoted to the design and development

technology for the construction of a gas pipeline section with a length of 1000 m and a diameter

1220 mm, passing in soils such as light loam. At the same time, constructive

laying scheme - underground with a rectangular trench shape.

We accept for use pipes in factory insulation, therefore

only the welded pipe joints are insulated on site. It should also be taken into account

availability of good quality access roads to the venue

works available as a result of the development of this territory.

The development of the trench is carried out by an excavator with reverse

shovel ET-26-30, because there are no solid inclusions and boulders in the rock.

The foundation of the trench is made with sand, which

delivered by dump trucks from a quarry located at a distance of 17

kilometers from the pipeline construction site. Loading sand into a dump truck

is carried out by the Amkodor 352 mining loader. Unloading sand into the trench

is made using a tray, the foundation of the trench is made

a team of excavators who level the foundation of the trench.

Delivery of pipes from the manufacturer is carried out

rail transport. Upon the arrival of the train at the point

unloading, located at a distance of 10 kilometers from the place of work,

unloading of railway cars with simultaneous loading of pipes

for pipe carriers.

Delivery of pipes over a distance of 10 kilometers is carried out

by a pipe-carrying road train as part of a tractor vehicle 596012 and

dissolution trailer 904702.

Unloading of pipes is carried out by a truck crane of the brand KS - 45721.

Thus, the main tasks of course design

become the development of a technological scheme, the justification of the used

construction, transport machinery and equipment, as well as the organization of

works.

Operation of main gas pipelines

The work process on gas pipelines is supported by managing organizations that have the appropriate qualifications. In particular, gas transmission companies may enter into an agreement with the owner of the facility, according to which they undertake to provide safe and reliable gas supply to consumers. During operation, the linear production management of gas pipelines will provide for the regulation of the state of shut-off valves at control nodes, the implementation of reconstruction measures, the inspection of functional parts, etc.

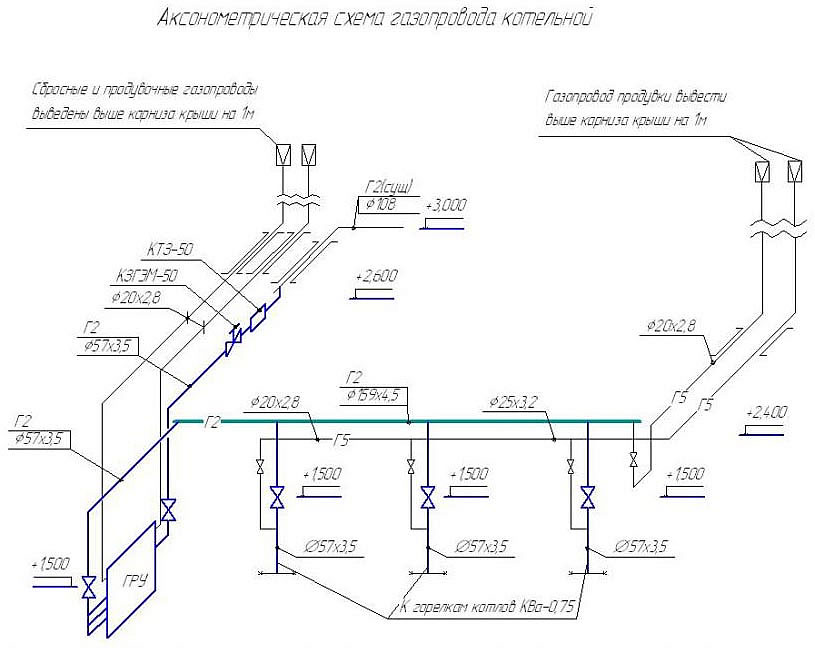

Compressor stations

Compressor stations are needed to maintain the pressure level and transport the required volume of gas through the pipeline. There, the gas undergoes purification from foreign substances, dehumidification, pressurization and cooling. After processing, the gas under a certain pressure returns to the gas pipeline.

Compressor stations, along with gas distribution stations and points, are included in the complex of surface structures of the main gas pipeline.

Compressor units are transported to the construction site in the form of blocks completely ready for assembly. They are built at a distance of about 125 kilometers from each other.

The compressor complex includes:

Compressor station of main gas pipelines

- the station itself

- repair and maintenance and service and maintenance units;

- the area where the dust collectors are located;

- cooling tower;

- water container;

- oil economy;

- gas-cooled devices, etc.

A residential settlement is usually erected next to the compression plant.

Such stations are considered a separate type of man-made impact on the natural environment. Studies have shown that the concentration of nitrogen oxide in the air on the territory of compressor installations exceeds the maximum allowable level.

They are also a powerful source of noise. Scientists have found that prolonged exposure to noise from the compressor station causes disturbances in the human body, and, as a result, causes various diseases and can lead to disability. In addition, noise forces animals and birds to move to new habitats, which leads to their overcrowding and a decrease in the productivity of hunting grounds.

Safety system installation unit

General characteristics of central gas pipelines

A trunk-type gas pipeline is a system of pipes and structures used to deliver fuel from production or manufacturing sites to customers. It includes main and additional pipes.The diameter of the latter is determined by the characteristics of the object of transportation, however, it cannot exceed 1420 mm.

Pipelines are divided into three classes depending on the pressure under which the substance is transferred. This indicator must be taken into account, since in case of exceeding the norm, the likelihood of an accident increases.

The pressure fluctuates in the range of 1.2-10 MPa. Most often, an indicator of 7.5 MPa is considered to be a working one.

Main gas pipelines are divided into aboveground, underground and underwater. The first due to a small rise do not interfere with the movement of vehicles. This delivery option is used to overcome water obstacles, ravines and other obstacles.

Underground networks are laid in special trenches. The depth of the latter depends on the level of soil freezing

Therefore, when organizing the transportation of wet gas, it is important to take into account the climatic features of the area, soil structure, pipe diameter, etc.

And for pipes with dried gas, a trench 0.8 m deep is suitable. Its bottom is covered with a layer of compacted sand, the pipes being laid are covered with several layers of bitumen-polymer mastic or polymer shell, then filled with soil.

Underwater systems are created for the purpose of transporting products from sea areas, along the bottom of rivers or large lakes.

The standard pipeline consists of a main and an intermediate compressor station. For example, gas passes through a special distribution point before reaching the end consumer. The pressure decreases to the level provided by local pipelines.

And to ensure the balance of the functioning of the system, special storage facilities are created directly in the area of consumption.For example, in the summer, gas can accumulate, which is used in the cold season.

Do not allow the destruction of pipes as a result of their contact with soil, water or air. This problem is solved by external anti-corrosion insulation.

Cathodic protection is also used, which operates on the basis of a negative potential.

It is important to ensure the reliability of the gas network. It is guaranteed by pumping equipment at compressor stations, the use of high-quality steel pipes, the creation of additional parallel lines that are combined with the main one thanks to jumpers

Key points in network operation

First, performance. It is calculated taking into account the fuel and energy balance of the areas where transportation will be carried out. Maximum loads are predicted. And also you need to take into account that a particular region may develop in the future, so the volume of gas delivered will also increase.

Looping is used to improve performance. If the pipeline operates at medium power, then centrifugal blowers do not particularly affect efficiency. But their role increases with increasing load.

Secondly, automatic adjustment. Experts analyze the features of the management of main gas pipelines. To do this, determine the stability of the system and detect processes that are not enough for balanced functioning.

The importance of automatic adjustment increases in direct proportion to the transport distance.

Modern technical means allow you to change the performance automatically. If the necessary equipment is not available, then the speed and efficiency of transportation drops to literally zero.

On the one hand, the movement of matter occurs under the influence of inertia. But on the other hand, the system slows down the movement both due to the rounding of the pipes, and directly due to internal resistance. Given the complexity of the equipment, both factors require an individual approach.

The state company is responsible for managing the main gas pipeline. In Russia, this is OAO Gazprom

The third key point is notation. Special symbols perform informational and warning functions. Placement of signs is a mandatory rule for the use of main gas pipelines.

Symbols allow you to define the objects, zone and depth of the pipeline. In fact, these are columns with two information blocks. The vertical area indicates the area of the territory of special danger, the place of occurrence and other important features.

And the horizontal one, with information about the location of the dangerous area, is set at an angle of up to 30 degrees relative to the earth's surface. It shows the distance in kilometers along the entire track.

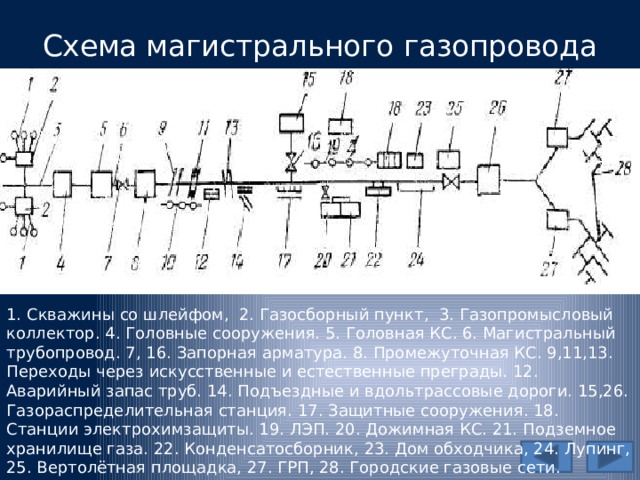

The composition of the main gas pipeline includes

- wells;

- gas collection point;

- booster compressor station;

- head structures (head compressor station);

- compressor stations;

- condensate collector;

- gas distribution station;

- linear crane unit;

- electrochemical protection (cathodic protection stations);

- siphon;

- looping;

- final gas distribution point.

MGs come in different diameters, depending on the amount of gas being transported.

Depending on the working pressure, MG are divided into three classes:

- high, more than 25 kgf/cm2;

- medium, 12-25 kgf/cm2;

- low, up to 12 kgf/cm2.

The gas pipeline is constructed of a constant or variable diameter in one or more threads that are laid in parallel. Parallel gas pipelines are constructed both along the entire length from the initial to the end point of the gas pipeline, and in separate sections.

Warning about the use of cookies on the Info KS website

Under EU law, digital content providers are required to provide users of their websites with information about their policies regarding cookies and other data. The site administration must obtain the consent of end users from the EU to store and access cookies and other information, as well as to collect, store and use data when using Google products.

A cookie is a file consisting of numbers and letters. It is stored on the device from which you visit the Info KS website. Cookies are necessary to ensure the performance of sites, increase download speed, and obtain the necessary analytical information.

The site uses the following cookies:

Necessary for the operation of the site: navigation, downloading files. There is a difference between a human and a robot.

Cookies to improve performance and collect analytical information. They help the site administration to understand the interaction of visitors to the site, provide information about the pages that have been visited. This information helps to improve the operation of the site.

Advertising cookies. These files provide information about visiting our pages, data about links and ad units that are of interest to you. The goal is to display content on the pages that is most focused on you.

If you do not agree to our use of cookies on your device, please leave the site.

By continuing to browse the Info KS website, you consent to the use of cookies.

Design of the main gas pipeline

Integrated design involves several stages:

- Geodetic, geological, hydrological and environmental studies along the entire length of the future highway. Based on the information received, it is determined how to lay the pipe, where to install the pumps, whether additional maintenance equipment is required.

- Determination of efficiency and economic benefits: the volume of pumping, delivery areas, end and start points and points of intermediate selection are determined.

- Calculation of pipeline characteristics - pipe diameter, working and maximum pressure, number of pumping stations.

- Design of tanks, distribution stations, transmission and extraction units, treatment facilities and more.

- Economic justification for profitability: construction cost, comparison with other methods of fuel delivery.

The result of the design is a set of technical documentation, including estimates, calculations, drawings, layouts, feasibility studies, notes and other materials necessary for construction.

Construction scheme

There are different schemes for laying the main gas:

- monofilament - the system is mounted from pipes of the same diameter throughout;

- multi-line - several pipelines are laid in one technical corridor;

- telescopic - the diameter of the pipeline from the initial to the final station changes.

If the laying of the highway includes different structures - an underground circuit, above ground, underwater - more complex construction schemes are used.

Gas line maintenance

Regular patrols of gas pipelines are carried out in order to detect malfunctions or malfunctions in certain areas. After analyzing possible accidents or breakdowns, a plan for repair procedures is drawn up. Next, preparations are made for work with cleaning the working area. The nature of the repair of the main gas pipeline depends on the location of the breakdown and its severity. The technical control service, in particular, can correct the position of shut-off valves, control and measuring devices and eliminate the leakage of fasteners. As preventive repair and restoration procedures, replacement of fences, painting of structures, strengthening of support blocks and restoration of insulation contacts with dielectrics are carried out.

Conclusions and useful video on the topic

Details on the nuances of designing pipelines of paramount importance:

Construction of the central gas network:

Corrosion protection of pipelines:

The main pipeline is an object of increased danger. During construction, it is necessary to take into account the requirements of regulations and involve only specialists with the appropriate certificates. In the future, it is necessary to strictly comply with the requirements for the operation of the facility. Then it will be a stable source of income for the owner and will provide end users with gas, oil and other transportation products.

Conclusion

During the implementation of the course project,

preliminary sketch study of the design of the construction of the linear part

main gas pipeline with the choice and justification of mechanization. Were

the accepted standard sizes of machines were specified with the help of engineering calculations,

final processing of the selected equipment.There is also a clear

the sequence of work on the construction of the gas pipeline, which allows

minimize unforeseen increases in the volume of work required, and

hence the increase in unforeseen construction costs. This project

compiled in accordance with the current GOST and SNiP, also taking into account

environmental requirements.

Conclusions and useful video on the topic

To make it easier to understand the nuances of gas supply to your cottage, we recommend that you familiarize yourself with a small selection of video materials.

About the execution of documents for connection to the gas main and the cost of certain types of work:

The procedure for performing work on gasification of the house - the nuances of connecting to the main pipeline:

Stages of gasification of a private house:

And finally advice. If the highway is far away or the specifics of the relief poses difficult problems for bringing the pipeline to the site, there is an alternative option for supplying "blue fuel" to the house - autonomous gasification with a gas tank.

Have you recently completed the gasification of your home and want to share your experience with other owners of country houses? Leave your comments in the block under the article - tell us how much this event cost you, did you do something on your own or entrusted the entire scope of work to specialists? What pipes did you recommend for laying the gas pipeline? Many users will be grateful for your advice.