- Polymer gas lines

- Features of plastic structures

- Pipe restrictions

- Performance of main gas pipelines

- Norms and rules for crimping

- In an apartment building

- Underground gas pipeline

- Internal low pressure gas pipeline

- What is a gas pipeline security zone and why is it needed

- Security zones in the design of gas pipelines: land acquisition and development

- Recommendations for the selection of gas pipelines

- Gas pipeline tightness control

- What is the case for the gas pipeline?

- Laying a gas pipe underground: technology, GOST, video

- Advice on laying

- Distinctive features of the product

- Trench for gas pipeline

- Performing gas pipeline calculations

- An example of calculating a gas pipeline line

- Another looping example

- The purpose of monitoring the condition of an underground gas pipeline

- Looping calculation example

Polymer gas lines

For above-ground gasification options, it is recommended to use pipes made of low-alloy steel alloys that are resistant to external influences.

Features of plastic structures

Underground laying allows the use of polypropylene pipes, which saves on installation costs and provides a number of other advantages.

The advantages are due, first of all, to the properties of the material:

- high corrosion resistance, which positively affects not only the cost of installation, but also reduces operating costs;

- ease of processing - the material is well cut, weldable, which simplifies installation;

- ideally even internal cavity provides good throughput properties, the features of the material make it possible to avoid their reduction during use;

- lack of sensitivity to electric currents, which ensures high safety, eliminates the need for additional protection.

In addition to these advantages, such pipes have a high level of flexibility, which allows them to be used in horizontal drilling.

Polypropylene pipes are gradually replacing metal counterparts due to their high reliability and durability.

To this should be added a small mass, which is several times lower than the steel counterpart. An important advantage is the service life of about 50 years. All this time the system works without loss of the set characteristics.

Pipe restrictions

Despite the high resistance to external influences, such pipes can not always be used. There are a number of restrictions under which their installation is not allowed.

These include:

- climatic conditions under which the temperature drops below 45 ° C, which leads to freezing of the soil and the walls of the outlet;

- the use of liquefied hydrocarbon options;

- high seismic activity with a magnitude of more than 7 points, when there is no possibility for ultrasonic control of the integrity of seam joints.

In addition, polypropylene materials cannot be used to create all types of above-ground communications, including bypass sections through natural or man-made barriers.

Highways and branches from them, passing over the road or other obstacles, must be made only of metal

Their laying through tunnels, collectors, channels is excluded. To enter the system into the house and wiring it, only steel analogues are used.

Additional recommendations for choosing pipes for laying a gas pipeline are given in the article - Gas pipes: a comparative overview of all types of gas pipes + how to choose the best option

Performance of main gas pipelines

The productivity of a gas pipeline is understood as the amount of gas that is transported through its pipes per year.

Russian gas pipelines differ in performance. The value depends on the fuel and energy balance of the area where the pipe laying is planned. Due to temperature fluctuations, different amounts of gas are used throughout the year, so the actual throughput is usually less important than the calculated one.

To significantly increase the productivity of the main pipeline, centrifugal compressors are installed at compressor stations, powered by gas turbines or electric motors.

To select a system for automatic control of pipeline performance, it is necessary to study transient processes in systems that are responsible for long-distance gas transmission. Transient processes in gas pipelines should not be uncontrolled. When an automatic control system is installed, these processes are usually characterized by attenuation.

Norms and rules for crimping

Operating standards

Control pressure testing of internal gas pipelines is regulated by GOST R 54983 2012. The general rules are the same for testing any part of the circuit under high and low pressure.

- Pressure testing of gas equipment and pipelines with air is performed before the line is cut into the central line.

- To check, air is pumped into the cut-in section of the gas pipeline under a pressure of 100 kPa and held for at least 60 minutes. Measure the pressure in the circuit with a manometer. The accuracy class of the device must be less than 0.6.

- If the circuit is sealed, the overpressure indicator is maintained until the end of the pressure test. If the pressure gauge detects a decrease in pressure, there is a leak in the pipe. According to SP 62.13330.2011, pressure testing is repeated six months after the control test.

In an apartment building

Crimping begins after an external inspection of the system within the apartment

Pressure testing of the intra-house internal gas pipeline is performed after an external examination. After maintenance, the gas pipeline is checked for strength. Air is pumped into the circuit at a pressure of 1 kgm / sq. see So they check the pipeline from the switch at the entrance to the house or to the landing to the taps on holidays to the apparatus. A complex gas pipeline is checked by dividing it into separate sections.

If gas meters are installed in the building, they are turned off during pressure testing, and the sections are connected by a jumper. The test starts 3 hours after the pressure rise. The possibility of leakage is checked with a soapy solution. If defects are found, the commission fixes them.

Pressure testing of gas inner pipes includes a tightness test.

- The gas pipeline is filled with air under pressure of 400 mm of water st. with running meters and gas appliances.If there are no meters in the circuit, air is pumped under a pressure of 500 mm of water. Art. The gas supply system has passed the test if, within 5 minutes, the pressure drop does not exceed 20 mm of water. Art.

- When connecting new gas equipment to an existing gas pipeline in an apartment building, pressure testing is carried out with gas. The emulsion is applied to all torn and threaded connections to check for leaks.

- Automation devices are checked only for density. The air pressure during pressure testing reaches 500 m of water. Art.

Underground gas pipeline

Each section of the underground gas pipeline from plug to plug is checked separately

Pressure testing of an underground gas pipeline is carried out after installation in trenches and full or partial backfilling - at least 20 cm. Each section of the line, from plug to plug, is checked separately.

- Tests begin with air pumping under test pressure. Maintain the time required for temperature equalization.

- Measurements are performed with pressure gauges with an accuracy class of 0.4 or 0.6.

- The section of steel and polyethylene gas pipelines is pressure tested separately.

- Pressure testing of underground external gas pipelines laid in cases is carried out three times. For the first time immediately after welding and before laying. Then, after backfilling in the trench, and finally, together with the entire gas pipeline.

- Multilayer pipes are tested in 2 stages. First, they are tested for strength by pumping air for 10 minutes at a pressure of 0.1 MPa, and then they are tested for tightness at a pressure of 0.015 MPa.

Testing of special technical devices is carried out according to the standards for lines with the same pressure.

Internal low pressure gas pipeline

vacuum gauge

Pressure testing of the equipment and the internal gas pipeline is carried out with an air mixture under a pressure of 1000 mm of water. Art. The surveyed area is from the main tap to the switch in front of the burners. Testing lasts 1 hour. During this time, a pressure drop of 60 mm of water is allowed. Art.

Pressure testing in an apartment building includes inspection and testing of household equipment.

- A pressure-vacuum gauge and any device with a variable volume will be connected to the nozzle of the gas stove. With its help, an excess pressure of up to 5 kPa is created.

- Open the valve of the burner to be checked and fill the tank with gas.

- Close the valve on the gas pipe. Gas is squeezed out of the container to create pressure.

- The burner tap is closed and the tightness is checked with a man-vacuum gauge: in 5 minutes the pressure can decrease by no more than 0.3 kPa.

- If the pressure drops faster, there is a leak. It is detected by applying a soap solution to the joints and threaded connections. After a leak is detected, turn the valve on the burner so that the gas pressure on it drops. Then one of the burners is lit, the gas is carefully squeezed out of the container and the pressure gauge and fixture are disconnected.

What is a gas pipeline security zone and why is it needed

This is a piece of land symmetrical about the axis of the gas pipeline, the width of which depends on the type of gas pipeline and is established by special documents. The establishment of gas pipeline security zones makes it possible to prohibit or restrict construction in the area where the gas pipeline passes.The purpose of its creation is to create normal conditions for the operation of the gas pipeline, its regular maintenance, maintaining integrity, as well as minimizing the consequences of possible accidents.

There are "Rules for the Protection of Main Pipelines", which regulate the establishment of security zones for various pipelines, which include gas pipelines transporting natural or other gases.

Agricultural work is allowed on the territory of the protected zone, but construction is prohibited. Works on the reconstruction of existing buildings, structures and networks must be agreed with the organization that maintains and operates the gas pipeline. Works that are prohibited from being carried out in the protected zone also include the arrangement of basements, compost pits, welding, the installation of fences that prevent free access to pipes, the creation of landfills and storage facilities, the installation of stairs based on a gas pipeline, as well as the installation of unauthorized connections.

Security zones in the design of gas pipelines: land acquisition and development

The Rules for the Protection of Gas Distribution Networks will help determine which gas pipeline security zone should be applied in each specific case. Typically, this documentation, along with other permissions, is provided by the designers. The question of who will coordinate the project with the services that operate the networks, as well as with local authorities, is determined by the contract for the production of works. The organization carrying out the project must have a license for these types of work.

The first step in creating a security zone is to perform a control survey.Its main purpose is to check the correctness of the bindings and their compliance with the design documentation.

The result of this survey is the specified coordinates of the characteristic points of the finished route, the location, number and geometry of the elements and parts of the gas pipeline, as well as the established regulatory points, measuring instruments, hydraulic fracturing and hydraulic distribution units, supports and other structures.

Security zones for gas distribution networks are determined by the Rules approved on November 20, 2000 by Government Decree No. 878.

The security zones of gas pipelines are regulated by the Rules approved by the Ministry of Fuel and Energy on 04/29/1992 and Gostekhnadzor (No. 9) on 04/22/1992.

The result of these works is a map or plan for a given land management facility, which is subject to agreement with the owners or users of land plots through which the gas pipeline passes. One copy of the land management file for this site is transferred to the state bodies of the land registry.

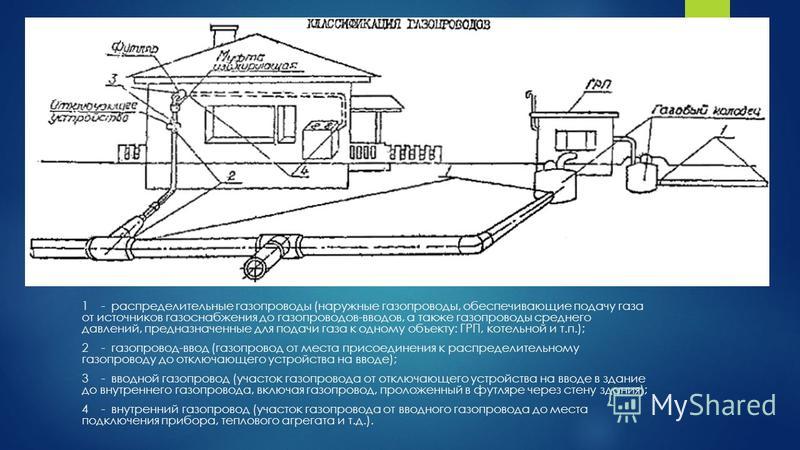

Recommendations for the selection of gas pipelines

Most often, gas pipelines for honest houses and apartments are equipped with metal products. Steel pipes for gas supply are characterized by their ability to withstand internal pressure perfectly. Such a pipeline is completely sealed, which reduces the risk of gas leakage to zero. When choosing steel pipes for gas pipelines, it is necessary to take into account the pressure in the gas pipeline.

Conditions in gas pipelines can be as follows:

- With low pressure - up to 0.05 kgf / cm2.

- With an average pressure - from 0.05 to 3.0 kgf / cm2.

- With high pressure - from 3 to 6 kgf / cm2.

What pipes are used for the gas pipeline? The use of thin-walled metal pipes is only permitted on low-pressure gas pipelines.This material has an exceptionally light weight, which makes it possible to equip systems with a complex configuration from it. Also, thin-walled metal pipes are distinguished by good flexibility: if necessary, to give such a product a small angle, you can do without a pipe bender, doing everything by hand.

Gas pipeline tightness control

Only after obtaining a satisfactory result according to the procedures described above, you can proceed to performance of pressing works. To do this, the system is connected to a special compressor and the pipes are filled with pressurized air. The design is then examined for deficiencies.

To perform pressure testing, air is injected into the system. If the required pressure level is maintained for a certain time, the test result can be considered positive.

If deficiencies are identified, they are eliminated, but if the system is completely sealed, it is connected to a common gas line. In the process of preparation, you will have to remove and install special plugs, rotary elements can be replaced with threaded connections. In general, the procedure for carrying out pressure testing should consist of the following operations:

- To disconnect the area to be treated from the main line, turn off the high-pressure valve and the low-pressure network tap.

- After that, plugs are inserted.

- When the flange breaks, shunt jumpers are used.

- To bleed the gas present inside the system, it is necessary to use a special sleeve made of rubberized fabric or perform this operation through a candle, which is usually installed on the condensate collector.

- The gas is flared, and if it is not possible to do so safely, it is moved to safe storage.

- Now you need to install adapters for connecting pressure gauges and a compressor.

- For pressure testing of systems of extended length, it is recommended to additionally use hand pumps.

Usually, control pressure testing is performed under a working pressure of 0.2 MPa. The recommended pressure limit is 10 daPa/h. In some industries, it is recommended to use a pressure of 0.1 MPa for pressure testing of the internal gas pipeline, and the allowable drop rate is 60 daPa / h or less.

Pressure testing of gas pipes inside the house is carried out along the entire length of the system from the valve at the entrance to the house, to the connection to gas consumers, for example, to the boiler

At non-industrial facilities, including when arranging gas pipelines in residential premises, control pressure testing is performed at a pressure of 500 daPa / h. The allowable pressure drop in these cases is 20 daPa in five minutes. Tanks intended for storage of liquefied gas are pressurized at 0.3 MPa/h.

If the pressure inside the system remains stable during the control time, then the pressure test result is considered positive. If this situation is reached, then the specialists remove the hoses connecting the system to the air duct. At the same time, it is necessary to check the condition of the shut-off communications installed in the area between the air duct and the gas pipeline. After that, install the plugs on the fittings.

If during pressure testing it was not possible to achieve stable pressure indicators in the system, the result of the procedure is considered negative.In this case, a technical inspection of the system is performed to identify deficiencies and eliminate them. After that, the procedure is repeated to ensure the quality of the work performed.

Only after a stable pressure is established in the system, pressure testing can be considered completed. If the system status check is not satisfactory, permission to connect to the trunk will not be issued. The reason for the refusal to put the gas pipeline into operation may also be violations committed during the pressure test.

After pressure testing is completed, the pressure inside the structure is reduced to atmospheric level. Then the necessary fittings and equipment are installed, after which it is necessary to hold the system under working pressure for another 10 minutes. To check the tightness in the places of detachable connections at this stage, use a soap emulsion.

To eliminate the identified defects, in accordance with the rules, you must first reduce the pressure in the system to atmospheric. If, after unsuccessful pressure testing, welding work was performed, their quality should be checked by physical methods.

After pressure testing is completed, an appropriate act is issued, on the basis of which gas industry specialists connect to the main gas pipeline

The procedure is recorded in a journal with operational documentation. Upon completion of the inspection and pressure testing, the results of the work are reflected in the acceptance certificate. This document should be kept together with other technical documentation related to the gas pipeline. In addition, the results of pressure testing are recorded in the construction passport.

What is the case for the gas pipeline?

In the device of underground gas communications, as a rule, steel or polyethylene gas pipes are used that can withstand the pressure of the medium passing through them. Their strength characteristics are designed for a load created by a soil thickness of up to 2.0-2.2 m. However, standard pipe products are not designed for a possible transport load from above, i.e. above the gas line.

It is also not taken into account that it is undesirable for pipelines through which gas is transported to the consumer to pass under other communication lines. There are also geological and hydrogeological restrictions, according to which the gas pipeline has to be laid above the established norms.

If it is impossible to find a laying route that does not intersect other engineering structures, according to the requirements of SNiP 42-01-2002, it is necessary to ensure a safe vertical distance between pipelines. This is 0.2 meters or more, which, as a result, changes the depth of the gas pipeline.

On difficult sections of the gas pipeline route that require protection of the pipe from damage, the laying is carried out in cases

The depth of the gas pipe is also changed if rocky rocks or an unstable level of groundwater interfere with laying at the normative depth mark.

How to protect the gas pipeline if additional load on the line is inevitable? In all these cases, cases are used, which are a rigid round or semicircular casing made of steel alloy, polyethylene or fiberglass. It is he who protects the path of blue fuel from possible damage.

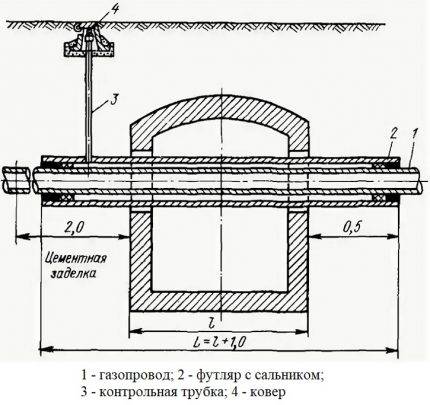

Note that with a gas pipeline protection device, it is even more difficult to monitor the condition of the pipe laid in the case.To facilitate the hard work of linemen, employees of the extractive industry and gas supply structures, a to the control tube gas pipeline.

We list all possible prerequisites for the installation of cases with control devices over gas pipelines:

- The proximity of the underground gas pipeline to a residential building or public building.

- Gas pipeline laying at shallow depth.

- The device under transport ways: automobile, tram, railway ways.

- The presence of a threaded connection or a weld on electric-welded metal pipes and polyethylene analogues.

- "Intersection", i.e. passage 0.2 m above or below the heating network and other communication lines.

- Entering the gas supply pipe into the house through the load-bearing wall and the vertical intersection of the floors.

- Construction of a control and measuring point with a protective carpet. They are installed throughout the entire route every 200 m within cities and other settlements. On a territory free from habitation, they arrange after 500 m.

All of the above options, except for crossing the ceilings with a gas pipe, as well as arranging the entrance and exit of the underground line to the surface, provide for installation on one of the edges of the control tube case.

Even in the case of installation over a problematic weld, it is allowed to use not cases as a base for attaching the tube, but a semicircular metal casing.

In the arrangement of underground gas pipelines, steel, polyethylene and fiberglass cases are used. Structurally, they are solid pipes, connected by two halves of the pipe or one semicircular casing

The control tube is placed in a place convenient for the control. Those.from the side from which the gasman's approach to carrying out monitoring operations is possible, safe and does not require obtaining permits.

If two gas pipelines are laid in one trench, which is allowed by building codes, then the location of the cases with the tubes connected to them should ensure that both systems are tracked.

A control tube is installed on each case designed to protect the gas pipeline, which is necessary to monitor the technical condition of the underground system and determine the moment of pressure drop

A control tube is installed on each case designed to protect the gas pipeline, which is necessary to monitor the technical condition of the underground system and determine the moment of pressure drop

Cases are installed both on newly laid gas pipeline lines and on existing branches by puncturing or punching the soil. They must go beyond the highway, tracks, load-bearing walls and other structures by 2 m from both edges.

Laying a gas pipe underground: technology, GOST, video

For laying an underground gas pipeline, it is necessary to provide that the roadway is blocked, and the company that installs the gas pipeline underground, using road projects, draws a terrain plan for the location of the equipment and indicates in the drawing the exact geometry of the objects that are adjacent to the buildings. This will ensure that traffic signs are properly positioned to restrict access to the highway or land where the underground gas system is planned to be laid.

Such an arrangement of prohibition signs must be agreed with the territorial authority of the road inspectorate, which, in turn, if a positive decision is made, must issue an authorization order for the installation of highways underground.

laying a gas pipe in a section above the ground

Advice on laying

So, when performing installation work, the following is taken into account

1. It is necessary to lay the gas system at a depth level, the indicator of which is at least 80 cm to the top of the structure (box). In areas where the passage of agricultural combines and equipment is not provided, a depth of at least 60 cm is allowed for the implementation of underground structures.

2. For terrain that is unstable to erosion and landslides, the depth level where the installation of the gas pipeline will take place must be at least the boundaries of the area where destructive processes are possible, and not less than 50 cm below the level of the sliding mirror.

3. In areas where highways and communication systems intersect underground for various purposes, highways that transmit a heat source, channelless systems, as well as in areas where the gas pipeline passes through the walls of wells, the structure must be placed in a box or case. If it intersects with heating networks, then installation in a metal box (steel) is needed.

4. If there are structures with different pressure indicators in a populated area, the duct should be installed at the level of engineering networks, which are located underground and which, in turn, are below the level of the gas pipeline. The ends of the box should be led out on both sides of the outer walls of the communication systems, taking into account the gap, which should not be less than 2 meters. If there is an intersection with the well, the gap must be kept at 2 cm. Using waterproofing, it is necessary to put plugs on the ends of the box.

5.At the top point of the slope (with the exception of the area where the walls of the well cross) on one side of the box, it is necessary to build a control tube, which will be located under the protective device.

6. It is not prohibited to lay an operating cable (eg, electrical protective wire, communication cable) in places between the system structures and the duct, which is intended for servicing distribution networks.

laying a gas pipe around the site with your own hands

Distinctive features of the product

In construction work, building elements and pipes made of polyethylene are used, which have a reserve index of such a property as strength, not less than 2. Such elements are installed, their pressure index is up to 0.3 MPa, in populated areas (cities, villages) and its circumference.

It is necessary to lay products using polyethylene connecting nodes and gas ones with a margin of at least 2.6. When laying systems whose pressure drop is in the range of 0.306 MPa in a populated area, it is necessary to use connecting nodes and pipes that have a reserve strength index of at least 3.2.

laying a gas pipe underground a private house

Trench for gas pipeline

The depth of laying (laying) of a low-pressure gas pipeline is determined by the regulatory document “SNiP 42-01-2002. Gas distribution systems” and is described in paragraph 5.2 as follows:

Laying of low-pressure gas pipelines should be carried out at a depth of at least 0.8 m to the top of the gas pipeline or case.In places where the movement of vehicles and agricultural machines is not provided, the depth of laying low-pressure steel gas pipelines can be at least 0.6 m.

When crossing or passing the gas pipeline communication under roads and other places of movement of vehicles, the laying depth must be at least 1.5 meters, to the top point of the gas pipeline, or its case.

Accordingly, the depth of the trench for the gas pipeline is calculated according to the following formula: the diameter of the gas pipeline + the thickness of the case + 0.8 meters, and when crossing the road - the diameter of the gas pipeline + the thickness of the case + 1.5 meters.

When a low-pressure gas pipeline crosses a railway, the laying depth of the gas pipeline from the bottom of the rail or the top of the road surface, and if there is an embankment, from its bottom to the top of the case, must meet safety requirements, but be at least:

in the production of works in an open way - 1.0 m;

when performing work by punching or directional drilling and shield penetration - 1.5 m;

in the production of work by the puncture method - 2.5 m.

When crossing other communications with a low-pressure gas pipeline - water pipelines, high-voltage cables, sewerage and other gas pipelines, it will be necessary to go deeper below these communications in the place where they pass, by at least 0.5 meters, or you can go above them if they lie at a depth of at least 1.7 meters.

The depth of laying low-pressure gas pipelines in soils of varying degrees of heaving, as well as in bulk soils, should be taken up to the top of the pipe - at least 0.9 of the standard freezing depth, but not less than 1.0 m.

With uniform heaving of soils, the depth of laying the gas pipeline to the top of the pipe should be:

not less than 0.7 of the standard freezing depth, but not less than 0.9 m for medium heaving soils;

not less than 0.8 of the standard freezing depth, but not less than 1.0 m for heavily and excessively heaving soils.

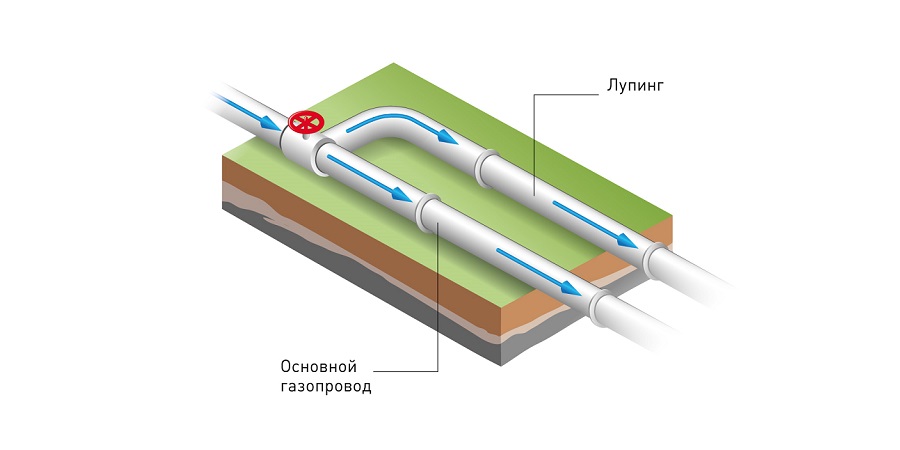

Performing gas pipeline calculations

Guidance documents allow you to calculate the looping only with the help of special formulas. Some of them will be attached below, but we can say in advance that only specialists will be able to make calculations.

Since when it is executed, a large number of different variables are used, which makes the task difficult.

That is, a person or organization interested in developing a project and building a looping will not be able to save even on preliminary calculations.

Because, unlike a number of other similar procedures, for example, hydraulic calculation, a simple and affordable computer method is not used. As a result, the designer must have a sufficient stock of special knowledge.

After the calculation is completed, it is recommended to contact Gorgaz for approval. If this is not done and the project is developed completely, then this can lead to significant financial losses. Since any of the numerous requirements of gas workers may not be met.

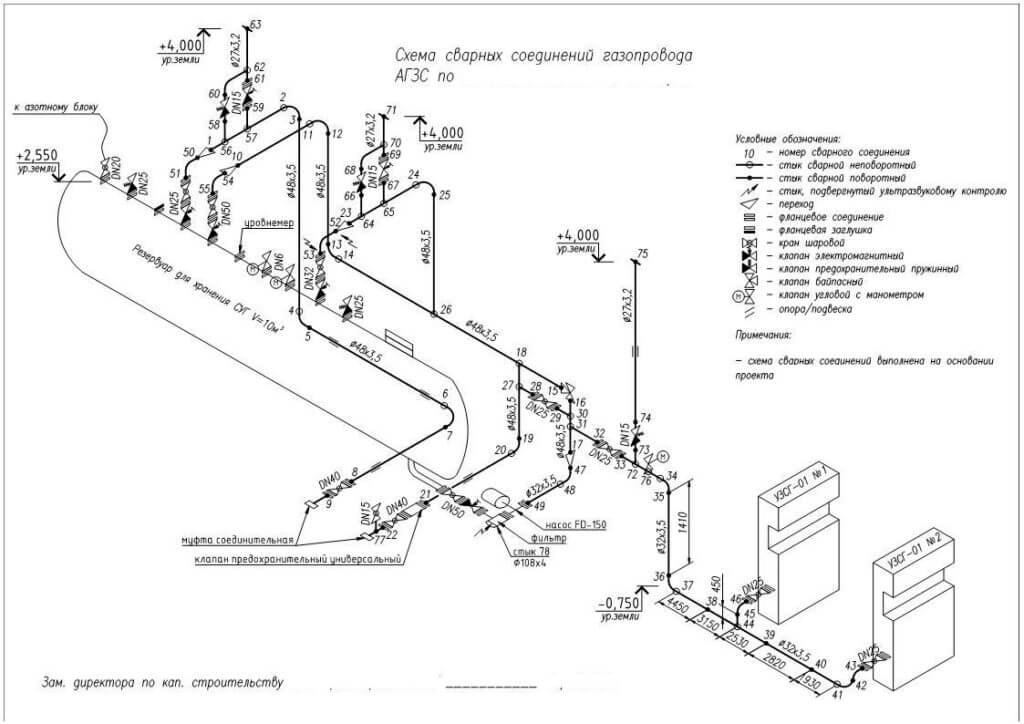

An example of calculating a gas pipeline line

To calculate a parallel gas pipeline line, it is necessary to know a number of initial data, including volumetric, hourly gas flow, gas resistance coefficient, fuel temperature and a number of other data. All the necessary information is taken from a pre-compiled scheme.

The complexity of the calculation example additionally indicates that this work should be done by specialists or errors cannot be avoided.Which will lead to loss of time and money.

Read more about how to calculate the gas pipeline system in this material.

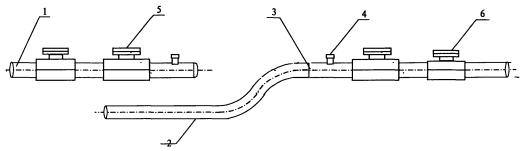

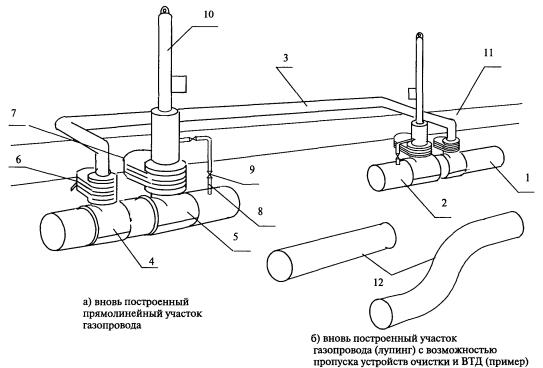

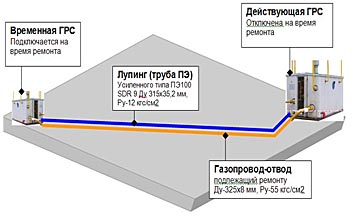

Another looping example

One of the most famous gas pipelines with looping put into operation in recent years is the parallel line of the Pelyatka-Severo-Soleninskoye mainline. Its length is 30 km, but for the construction it was necessary to equip a considerable 160 km of the road.

In addition, almost 90 km of cable had to be laid. The work was carried out by more than half a thousand qualified specialists for six months.

The arrangement consisted of the following stages:

- installation of piles, which was preceded by drilling;

- installation with subsequent welding of supporting structures;

- laying with welding of the looping pipes themselves;

- quality control of welded joints;

- looping cleaning;

- tests with subsequent launch in test mode;

- anti-corrosion treatment of all metal elements.

The steps are listed in the correct order. As a result, this looping makes it possible to transport gas to consumers at the lowest cost, and uninterruptedly.

As experts pointed out, the economic effect from the use of this 30-kilometer pipe will be an impressive 6.5 billion rubles, and this is only in 2 years from the date the line was put into operation.

The purpose of monitoring the condition of an underground gas pipeline

Gas pipelines laid in trenches need regular inspection no less than ground routes. Of course, they are not threatened with purely mechanical damage, as happens with open communications. However, gas workers have no less reason to worry about their condition.

If the pipe transporting blue fuel is immersed in the ground:

- It is difficult to monitor the mechanical condition of the gas pipeline, but its walls are affected by ground pressure, the weight of structures and pedestrians, as well as passing vehicles if the pipeline passes under a highway or a railway line.

- It is impossible to detect corrosion in a timely manner. It is caused by aggressive groundwater, directly the soil, which contains active components. The loss of initial technical characteristics is facilitated by technical fluids penetrating to the depth of the route.

- It is difficult to determine the loss of tightness due to a violation of the integrity of the pipe or welded assembly. The reason for the loss of tightness is usually the oxidation and rusting of metal pipelines, the banal wear of polymer structures, or a violation of assembly technology.

Despite the fact that the laying of gas pipelines in trenches provides for the complete replacement of aggressive soil with soil with neutral properties, and the device in places of possible spillage of technical liquids is completely prohibited, without special devices they cannot be considered completely protected from chemical aggression.

As a result of the loss of tightness, a gas leak occurs, which, as it should be for all gaseous substances, rushes up. Penetrating through the pores in the soil, the gaseous toxic substance comes to the surface and creates zones above the gas pipeline that are negative for all living things.

A gas leak can easily cause a serious catastrophe if the blue fuel that left the pipe “finds” any cavity in the ground for accumulation.When heated, for example, by elementary exposure to sunlight in a hot summer period, an explosion of accumulated gaseous fuel is almost inevitable.

The occurrence of a gas leak from the pipeline threatens not only with a violation of the ecological balance, but also with serious catastrophic consequences: explosions, destruction, fires

In addition, a gas leak entails considerable financial losses for the gas producing and gas transportation organization. Moreover, disagreements may arise between them, which it is not even worth going to court if a control tube for monitoring has not been installed on the gas pipeline case.

Looping calculation example

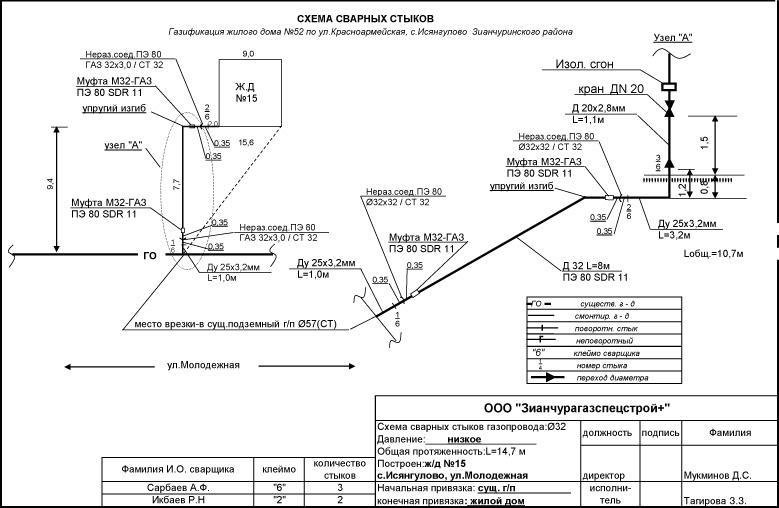

To calculate a parallel gas pipeline line, it is necessary to know a number of initial data, including volumetric, hourly gas flow, gas resistance coefficient, fuel temperature and a number of other data. All the necessary information is taken from a pre-compiled scheme.

An example of calculating a specific gas pipeline with a lupin, where the designer took into account various types of gas flow, its temperature, resistance coefficient and other parameters

The complexity of the calculation example additionally indicates that this work should be done by specialists or errors cannot be avoided. Which will lead to loss of time and money.