- Performance characteristics

- Manufacturers and cost

- Option number 4. Spots

- Characteristics of quaril

- Comparison with other materials

- Pros and cons

- Types of acrylic bathtubs

- The main types of bathroom breakdowns and how to avoid them

- Minuses

- Comparative characteristics of bathtubs

- Variety of forms and firms

- Weight and dimensions

- Complexity and types of installation

- Surface Care Tips

- Durability of operation

- Comfort in use

- Product cost

- Installation technology of quartz plumbing

- Built-in bath installation

- Freestanding bowl placement

- Freestanding

- Villeroy&Boch Aveo new generation

- Manufacturing technology

- How to choose the size and shape

- What is quaril?

- Manufacturing technology

- Flaws

- Device

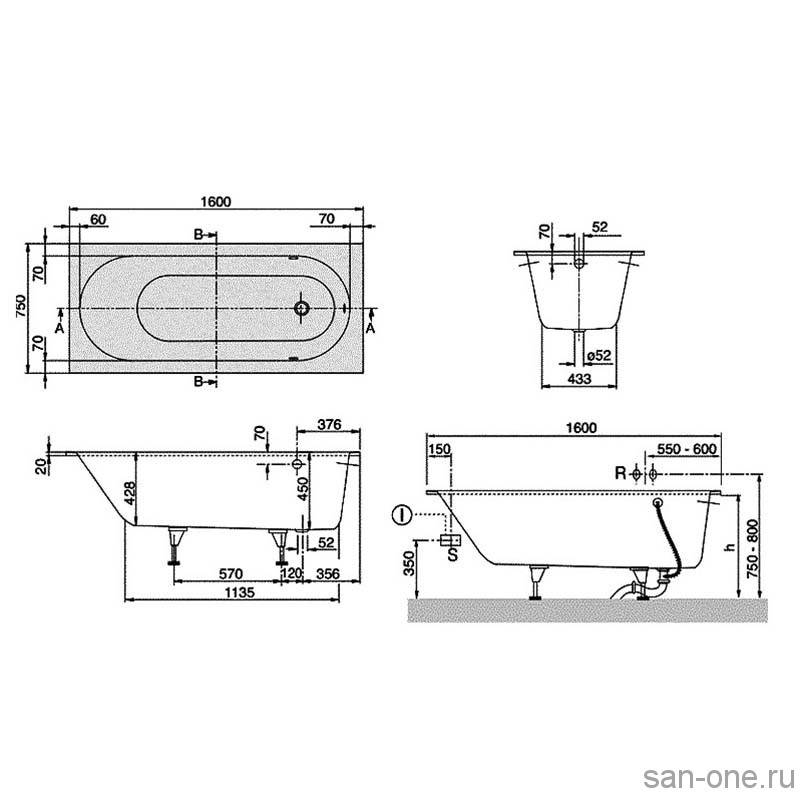

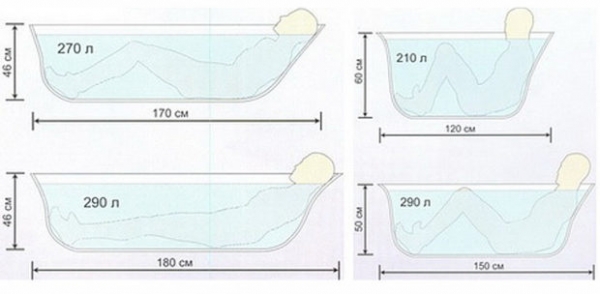

Performance characteristics

Cast iron and steel bathtubs are produced according to state standards. For cast iron GOST 18297, steel - GOST 23695. For other types of materials such as acrylic, quartz, natural stone, glass, etc. manufacturers develop TU (Specifications) or STO (Organization Standard).

This means that the enterprise can independently set any operational parameters of the manufactured product: dimensions (depth, length, width), configuration, type of external and internal coating, etc.within the framework of the law (if there are direct instructions or references in legislative acts). Therefore, different manufacturers have different performance characteristics of the hot tub:

- product weight - 15-30 kg acrylic, 35-45 kg - quartz;

- depth - from 40 cm (shallow) to 60 cm (very deep). The norm is 50 cm (deep);

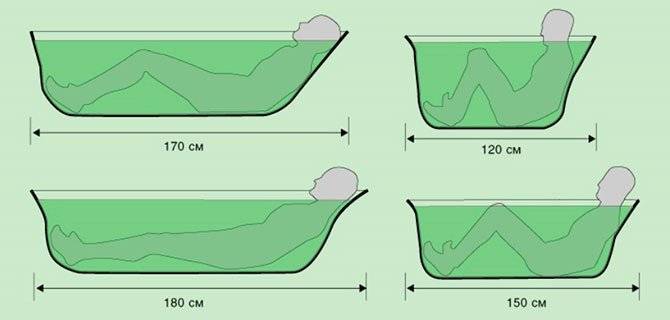

- the length has four main sizes (you can also meet non-standard ones, for example, 100 or 200 cm):

- 120 cm - for taking water procedures in a sitting position;

- 150 cm - you can be in the font only with your legs bent at an angle of 90o;

- 170 cm - the classic size, which came from cast-iron baths, where the legs are slightly bent;

- 180 cm - for tall people. For owners of medium height, this size allows you to be in the water in a comfortable state. There is only one problem: often the dimensions of the bathroom are designed for a bowl length of 170 cm, which does not allow installing plumbing fixtures of a greater length.

the width is more conservative: only three sizes - 70, 75 and 80 cm;

- the standard height of the acrylic bathtub above the floor is 60±2 cm (for bathtubs up to 50 cm deep);

- withstand weight. Details are needed here.

Buying a light weight bath, there are doubts about its reliability, especially among obese people. The question immediately arises, how much weight can an acrylic bathtub withstand? Can a person weighing 100-120 kg swim in it?

Laboratory tests have shown that cast acrylic can withstand a weight of 500 kg. Composite bath even more. But that's in theory. In practice, the figure of 400 kg will be real. This is the weight of the collected water, and the person taking the bath. So that our readers do not carry out complex calculations, we will immediately reassure.

Manufacturers are aware of these features of acrylic and produce fonts up to 290 liters.This means that the depth, length and width are calculated in such a way that when they are multiplied, the volume indicator does not exceed the value given above. Given that the human body is heavier, in such a font the weight of the bather and water cannot exceed 310-320 kg.

But there are some nuances here.

People weighing more than 60 kg are not recommended, and people weighing more than 80 kg are forbidden to sit on the side of the bowl.

You need to enter the bath carefully and with a full foot, evenly distributing your weight. It is advisable to use additional support points (wall or side).

Squats and jumps are not recommended.

The given strength figures were calculated at a water temperature of 38-40oC

Hotter water softens acrylic, reducing its strength characteristics. This must be taken into account when taking a too hot bath.

Larger fonts are additionally reinforced from the outside.

Manufacturers and cost

Today, a large number of manufacturers of quartz baths can be found on the worldwide network, but such a company as Villeroy Boch is considered the leader among them.

This company is German, but has one feature - historically French roots. Thanks to this original combination, the company combines French sophistication and high German quality. The history of the existence of this company has about 250 years.

At first, Villeroy Boch was engaged in the production of porcelain and ceramic sanitary ware. Today, one of the main directions of the company is the production of quartz baths. The company can produce these copies both built-in and free-standing.

Often, bathtubs of this company are equipped with additional useful functions, for example, massage.Massage in the bathroom can be either hydro or aero, depending on the preferences of the buyer.

Villeroy Boch has supplemented the production of quartz bathtubs with two powerful technologies, Ceramic Plus and Acivecare. Due to the Ceramic Plus technology, a perfectly smooth surface of the products is achieved, and thanks to the Acivecare technology, an antiseptic surface is created, which contains silver ions in its composition.

For all its products, the manufacturer gives a guarantee for a period of 10 years, and this characterizes the high quality of this product. The cost of Villeroy Boch quartz bathtubs varies on average from 30,000 to 300,000 rubles. It is noteworthy that the company has an extremely extensive geography of sales of its copies, has about 100 countries around the world.

It should be noted that the production of quartz bathtubs is a fairly new phenomenon, therefore, models of one or two companies are presented on the sanitary ware market. So, today only such a German company as Ukuson can compete with Villeroy Boch. Russian firms have not specialized in the production of such products so far.

In conclusion, it should be said that the appearance of quartz bathtubs has revolutionized the field of sanitary ware. However, not every person in our country can afford to purchase such models, although in European countries quartz baths are quickly gaining popularity and becoming more accessible to average citizens. In Russia, for now, this item of sanitary ware remains in the elite category, so most of our fellow citizens basically install all the same acrylic bathtubs, which have their drawbacks, but are much cheaper.

However, those Russians who have already installed similar products in their homes share the most flattering reviews about them.

Many of us are well aware of acrylic bathtubs.

And Quaryl baths are a logical continuation of improvements designed to negate the significant disadvantages of acrylic baths - susceptibility to scratches and the need to install a power frame.

So what is quaril? This is a modern material that has replaced the well-established acrylic, which significantly increases the resistance of products to mechanical damage.

Quaril is made up of quartz sand and acrylic, making it more durable.

Modern baths made of quartz are heavier than acrylic due to hardening additives, but lighter than cast iron. The wall thickness of the product is about 10 mm, which allows you to create durable bathtubs for frameless installation.

Otherwise, they inherited all the advantages of their predecessor:

- relatively light weight;

- low thermal conductivity;

- refined appearance;

- the possibility of giving any form.

Option number 4. Spots

Cleaning an acrylic bath

If small stains appear on the surface, you can remove them with a cleaning agent. If they are more serious, then they cannot be removed just like that - this will require toothpaste, acrylic or silver polishing.

Method one. Treat the stain with chem. and wait a couple of minutes, then rinse with a sponge and rinse with water. If necessary, you can repeat the procedure.

Whitening stains with toothpaste

Method two. Fill the bowl with water, dilute the detergent there. Wait 1-2 hours, drain the water and rinse the surfaces well.

Acrylic bath care

Method three. If the previous methods did not give the desired result, use liquid acrylic. Seal the stain with acrylic, then treat with toothpaste.

General recommendations for the repair of acrylic bathtubs

Characteristics of quaril

Quaryl is considered a relatively new material. Products from it are gaining popularity every year.

Comparison with other materials

A quartz bath is heavier than an acrylic one. This is due to the addition of quartz sand to the material from which the first bowl is made. Quarry construction differs from cast iron in the lightness of the material, a large number of models, a smooth surface, and a modern appearance.

Steel bowls do not retain heat well, have low sound insulation. There are no such significant drawbacks in quaryl baths. Natural stone structures are more expensive than acrylic and quartz bowls. Ceramic products are inferior to quartz products in terms of strength.

Pros and cons

The advantages of kvaril baths include the following characteristics:

- Modern appearance.

- Good soundproofing.

- The lightness of the material.

- No roughness.

- Sustainability.

- Hygiene.

- Functionality.

- Easy care.

- Increased strength.

- No risk of corrosion.

- Variety of shapes and sizes.

- Low thermal conductivity.

Thanks to the smooth surface, germs and bacteria do not linger on the surface and are easily washed off with water. Additional options are hydromassage, auto-cleaning, underwater lighting, etc. Such models cannot be called budgetary. Containers with handrails are also produced.

The disadvantages of bathtubs from kvaril include the following indicators:

- High price. It is 45-400 thousand rubles.

- The sensitivity of the material to hot water. There is a risk of deformation of the bowl when interacting with boiling water.

- The appearance of scratches due to improper use. For example, they can occur when using abrasive cleaners.

Types of acrylic bathtubs

At the stage of origin, bathtubs were cut in stone, then they began to be made portable from the same material. At the same time, a wooden analogue was used - a font, a furako, a vat, bowls of other shapes, sizes with various names. Then came cast-iron, steel plumbing fixtures. With the advent of polymeric, composite materials, it became possible to manufacture bowls of any shape, embedding additional functions in them.

The category of acrylic bathtubs includes several sanitary wares made of unequal structural materials:

- PMMA - cast polymethyl methacrylate, two-layer acrylic;

Cast acrylic sheet.

-

PMMA/ABS - acrylic coated plastic;

- quaryl - trademark Quaryl (Germany), a composite of 35% binder (acrylic resin) and 60% filler (quartz sand), the remaining 5% modifying additives to improve properties.

Kvaril

In fact, the first option is pure acrylic with a reinforcing layer on the bottom. PMMA/ABS tubs are a thin layer of acrylic over cheap plastic. Quaril is actually a kind of artificial stone - a quartz agglomerate. Acrylic can also be included in this category, but it does not contain mineral additives. The difference between these materials is as follows:

- first, a sheet is made from acrylic by extrusion or casting, then heated, and a product of complex shape is formed;

The process of stamping an acrylic bath.

- kvaril does not have thermoplasticity, therefore, after mixing quartz, acrylic resin, it is immediately poured into molds, getting a bath bowl.

So any pros and cons of acrylic bathtubs should be considered separately for quaryl, PMMA and PMMA/ABS.

The main types of bathroom breakdowns and how to avoid them

Plastic tolerates temperature changes well, but it is not recommended to draw water above 95 degrees into the bowl, as the material softens and its deformation begins. Acrylic bathtubs have low resistance to mechanical shock loads, they are easily damaged by falling sharp and cutting objects.

To prevent the bottom from breaking under the weight of an adult, conscientious manufacturers provide a metal frame complete with a bowl. Since plastics can be easily cleaned with detergent solutions, we do not recommend the use of abrasive cleaners, as well as household chemicals containing corrosive compounds.

Minuses

Depending on the wall thickness, steel baths may exhibit the following disadvantages:

1. Susceptibility to deformation. From accidental strong blows, even with blunt objects, dents can form. This happens with bathtubs whose wall thickness is less than 3 mm. Also, in thin-walled fonts, the shape can be broken even from everyday stress, for example, when bathing a fat person. This implies their instability, which is felt if you stand in such a bath with both feet in full growth.

2. High thermal conductivity. Those. rapid release of heat into space. This is the only drawback that is difficult to compensate. Although you can reduce heat loss by insulating the outer walls with foam or special insulating materials.

3. Susceptibility to corrosion.If the enamel is damaged, the font immediately begins to rust. This, rather, is not a drawback, but a problem that the owners find for themselves when cleaning the bathtub with abrasive powders with special zeal.

3. Susceptibility to corrosion.If the enamel is damaged, the font immediately begins to rust. This, rather, is not a drawback, but a problem that the owners find for themselves when cleaning the bathtub with abrasive powders with special zeal.

Now there are enough products for enamel coatings with a gentle cleansing action on the principle of "apply, wait, rinse."

4. Slippery inner surface. It is compensated by applying an anti-slip coating, indicated in the characteristics of the font.

5. Acoustic resonance. They are often accompanied by a set of water in a steel bath. This phenomenon is caused by the shape of the font, coupled with the sound-conducting properties of steel. The buzz and vibration can be easily compensated by a set of water through the shower, placed on the bottom of the bowl. Another option: turn the faucet faucet so that water flows down its wall. As in the case of thermal insulation, you can cover the outer walls of the bathroom with mounting foam, it isolates sound well.

To determine which bath, with the same dimensional characteristics, has thicker walls and in the end will be more durable, just look at the price. The thicker the steel, the higher the price. The weight of such a bath should also be 10-12 kg more than a cheap analogue.

Comparative characteristics of bathtubs

Made from different raw materials, similar to each other in terms of individual indicators, bathtubs also have individual characteristics.

Variety of forms and firms

Cast iron baths - the most "conservative" - rectangular and oval. This is due to the peculiarities of the metal - it is both strong and fragile at the same time, so it is rather difficult to give it a different shape. The most famous European manufacturers are Roca and Novial (Spain), Castalla (Italy), Jacob Delafon (France).In Russia, Novokuznetsk "Universal" and the Kirov Plant can be distinguished.

Since acrylic baths are the most popular among consumers, there are many manufacturers on the world market that produce such products. Among the best are Vagnerplast and Ravak (Czech Republic), Riho (Holland), Cersanit (Poland), PoolSpa (Spain), 1Marka, Bas, Triton (Russia). Popular manufacturers of steel baths are BLB (Portugal), Roca (Spain), Kaldewei and Bette (Germany), Verkh-Isetsky Metallurgical Plant (Russia).

The walls of glass bathtubs most often have a rectangular shape. Such products are produced by Gruppo Treesse and Regia (Italy), Knief (Germany), Doctor Jet (Russia).

The configuration of bathtubs made of solid natural stone depends on the features of the “removing all unnecessary” equipment, made of cast marble - on the form for pouring. Domestic manufacturers Estet, Astra-Form, Esse and their European competitors Victoria+Albert (Great Britain), Jacob Delafon (France) and Riho (Holland) are leading in the Russian market of marble chips.

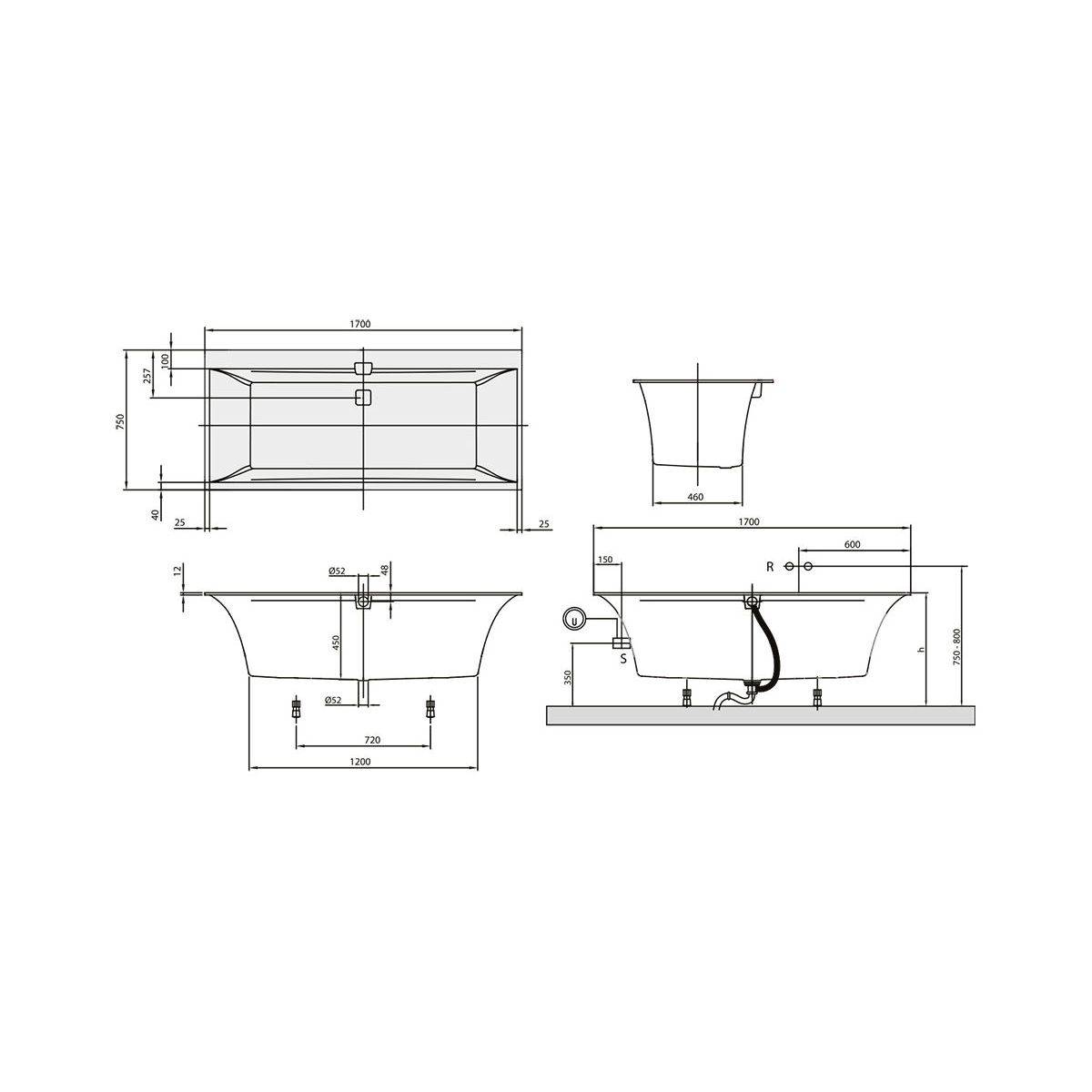

Weight and dimensions

The mass of the product depends on the structure of the material, wall thickness, dimensions (length, width, height) and equipment. Approximate weight:

- cast iron bath from 80 to 150 kg;

- steel - from 25 to 55 kg;

- acrylic - from 15 to 50 kg;

- glass - from 70 kg;

- marble - from 100 kg.

Exclusive models may weigh more.

Standard parameters of bathtubs:

- length: from 120 to 180 cm;

- width: from 70 to 85 cm;

- depth: from 35 to 50 cm.

In non-standard products, dimensions are limited only by the imagination of the manufacturer.

Thinking about the size of the bath, you need to take into account the dimensions of the bathroom. In typical apartments, standard bathtubs are more often installed: seated or full-sized (150-180 cm long)

Complexity and types of installation

A variety of bath designs require different types of installation. Its complexity depends on many factors:

- features of the floor in the bathroom (smooth or not);

- weight (the lighter the bath, the easier the installation);

- the distance from the floor to the bottom of the product and the location of the drain holes;

- the presence of "stuffing" in the form of hydromassage and other devices.

At the place of attachment, the bath happens:

- wall;

- angular;

- standing separately.

By installation method:

- on legs;

- on the frame;

- on the floor (assuming a completely flat bottom);

- on the podium.

Surface Care Tips

It should be regular, then the use of aggressive agents will not be needed, although cast-iron and steel bathtubs are not particularly afraid of them. But acrylic and marble baths do not tolerate alkali, acids and abrasive particles.

The main problem of glass bathtubs is streaks on dry glass, otherwise they are perfectly cleaned with a soft sponge with liquid products. To add shine, you can use a spray and a dry cloth.

Durability of operation

The service life with proper care for acrylic baths is from 10 to 15 years, steel and glass baths - up to 30 years (depending on wall thickness), marble - about 40 years, cast iron - up to 50 years or more.

Comfort in use

The most comfortable are cast-iron and stone bathtubs. They are stable, silent, slowly give off heat. Acrylic and glass are also quite convenient if they are installed evenly, preferably on a frame.Steel baths are a good option if you provide them with heat and sound insulation.

Product cost

The final figure, in addition to the material, is influenced by many indicators, including dimensions, equipment and design. The most "democratic" price for steel and cast iron specimens. The most expensive are glass and marble models.

Installation technology of quartz plumbing

The sequence of installation work is almost identical to the installation of bathtubs from other materials. One of the important features of the kvaril tank is the absence of an overflow and drain hole. This somewhat complicates the installation, but allows you to independently determine the place of connection of communications.

Built-in bath installation

The first stage, regardless of the method of placement, is the marking and preparation of drain holes. Even at the planning stage, you should decide on the installation site of the bath, the point of entry to the sewer system, the placement of the mixer, handrails, nozzles and other equipment.

Holes in quarile are drilled with a diamond core bit of the appropriate diameter. It is better to entrust painstaking work to a professional - a minor oversight can ruin expensive plumbing

Following actions:

- Set the bowl on the cleaned base.

- Adjust the horizontal position of the container by twisting and adjusting the height of the support legs.

- Install the faucet, mount taps in the side of the bathtub or the adjacent wall. An alternative option is to install a floor mixer separately from the bowl.

- Connect the siphon, connect the drain system to the sewer pipe.

- Evaluate the quality of sealing joints at the joints. Fill the bowl with water, leave for a couple of hours. In case of leaks, eliminate gaps.

- Install a decorative screen. If necessary, cover the front panel with finishing material.

The final stage is the sealing of the joints between the wall and the bathroom. One of the advantages of quarillic models is their precise geometric shapes. Therefore, the seam between the edge of the plumbing and the tiles will be minimal, provided that the wall is even.

Freestanding bowl placement

A separate bathtub is the undisputed dominant of the interior of the room. To install it, it is advisable to choose a place so that the distance from the walls of the container to surrounding objects is at least 50 cm.

It is important to adhere to an asymmetrical or axial interior composition.

A feature of the installation of a free-standing variety is the need to lay water supply pipes and a sewer outlet in the thickness of the floor. Not enough space under the bowl siphon connections and communication systems, as in the installation of traditional wall-mounted plumbing. Strobes are prepared in the floor screed, pipes are laid in the channels.

Water supply is carried out through a floor-type mixer - pipes are connected to the rack. To discharge water into the sewer, a siphon is connected to the bathroom, which, using adapter fittings, is mated with a sewer pipe

Sequence of work:

- Lay plumbing piping in the thickness of the floor.

- Place the kvaril bowl on stands, for example, bars. Raising the bath will give access to its base for connection work.

- After connecting the bowl with communications, remove the stands and install it on hidden legs.

- Align the horizontal position of the tub.

- Test the tightness of the joints and mount the front panels.

A rational way to install a quartz bath is to arrange a podium, behind which all plumbing equipment will hide. The solution will simplify the repair work and effectively emphasize the area where water procedures are accepted.

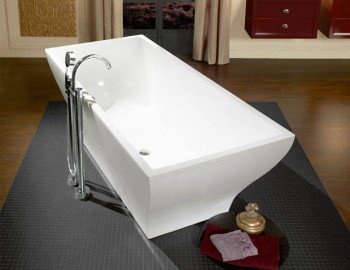

Freestanding

Villeroy&Boch Aveo new generation

The most ergonomic and comfortable form according to customer reviews. Great depth and a high headboard will allow you to sit comfortably, thick walls retain the initial temperature of the water for a long time.

This model features a sophisticated design suitable for modern and luxurious interiors.

The final choice comes down to the individual needs of the buyer, the possibilities of the configuration budget, the size and layout of the room where the hot tub will be installed.

Characteristics:

- Length, width, depth - 194x95x83,

- Shape - oval

- Type - detached

- Installation - floor.

Choosing a bathtub is a purely individual decision, but knowing what you should pay attention to, you can choose plumbing equipment that will be convenient to use and beautiful in the interior. Faucets and shower racks are purchased additionally

Thanks to a wide range of modern sanitary products, it is possible to choose a suitable model for any bathroom.

Taps and shower racks are purchased additionally. Thanks to a wide range of modern sanitary products, it is possible to choose a suitable model for any bathroom faucet.

The production of sanitary ware is currently constantly developing and improving. In the last decade, plumbing items such as acrylic bathtubs have become widespread, but they have a number of drawbacks.Manufacturers of sanitary ware came to the decision to level the shortcomings of acrylic bathtubs and as a result created completely new quartz bathtubs. Therefore, this article will address the issue of a revolutionary novelty: what is it?

As mentioned above, the shortcomings of acrylic baths served as an impetus for the creation of a new revolutionary material. They became kvaril. This material is synthetic and in composition is a combination of acrylic and quartz sand.

This combination is reflected in the very name of the raw material. Due to the colossal strength of quartz sand, quartz sand is an extremely resistant raw material for the production of bathtubs. And from acrylic, the new material got an aesthetic appearance and excellent plasticity.

The invention of new raw materials for the production of sanitary items belongs to the Finns. Quaril production technology is the conclusion of the smallest particles of quartz in plastic cells, and all the free space between these cells is filled with a liquid acrylic mixture.

The production of the baths themselves is carried out by casting. This technology has been brought to perfection in Finland today. Although at first, kvaril was used only as a raw material for the restoration of well-known acrylic and cast-iron bathtubs. Over time, they began to produce independent sanitary items from the new material kvaril.

Kvarilovye bathtubs - a novelty in the plumbing market, they are predicted to be very popular over time

Manufacturing technology

The technology for the production of quartz was invented and patented in Europe by the German company Villeroy & Boch several years ago. Initially, kvaril was used to restore old, lost their appearance, acrylic bathtubs. Some time later, manufacturers saw it as a full-fledged replacement for acrylic and focused on the production of sanitary ware from quartz. Subsequently, it turned out that in many respects it is superior to acrylic. Kvaril baths are cast in special moulds. The product is so rigid that it does not need additional reinforcement. At the final stage of production, the surface of the bath is coated with a special varnish.

How to choose the size and shape

Perhaps one of the central questions. It depends on the size of the bath whether bathing will become a pleasant relaxing procedure or you will have to suffer, getting comfortable.

There are plumbing fixtures of any size on sale: from miniature fonts in which you can only sit, to spacious appliances where you can sit at full height.

It is believed that a person should be located in a reclining position, while water covers the knees. On average, for most people, a length of 170 cm is suitable, but you can pick up reduced or vice versa enlarged devices.

The optimal height of the bowl will be 50 - 60 cm

At the same time, please note that here we mean the depth of the bowl itself: from the bottom to the top drain hole. The height of the device from the floor to the side can reach 60 - 70 cm

The width of the container should be such that the most “overall” member of your family still has at least 5 cm of free space on the sides.

Of course, in mansions with spacious bathrooms, there is no problem of placement and selection of uniforms.Only the style of the room and the taste preferences of the owner are important here. But residents of typical apartments have to dodge in order to place all the furnishings in the room. Properly selected bath configuration will help to gain additional centimeters:

- Rectangular - the most common type, although often not very convenient due to the "protruding" corners. But they require less water to fill.

- Oval and round - suitable for spacious bathrooms and are the central part of the interior.

- Corner - can be symmetrical and asymmetrical. The first ones are more overall, but the second ones fit perfectly into a tiny area and at the same time allow you to comfortably accommodate for washing.

The inner surface can also be different: in some models there are various shelves, recesses, handles. The wall is gently sloping, which is made specifically for comfortable lying.

What is quaril?

Kvaril is a development of the European manufacturer Villeroy & Boch.

This is a unique composite material, which is based on:

- quartz sand (60%), which provides reliability, wear resistance and rigidity of the finished material;

- acrylic resins: quartz particles are enclosed in an acrylic shell, and the gaps between the grains are filled with a mixture of acrylic and additional impurities;

- environmentally friendly polymer additives (responsible for flexibility at the processing stage).

Initially, the material was created for the repair of sanitary ware. After a detailed study, they began to make full-fledged bathtubs and stands for booths from it.

Manufacturing technology

The technology for the production of quartz was invented and patented in Europe by the German company Villeroy & Boch several years ago.Initially, kvaril was used to restore old, lost their appearance, acrylic bathtubs. Some time later, manufacturers saw it as a full-fledged replacement for acrylic and focused on the production of sanitary ware from quartz. Subsequently, it turned out that in many respects it is superior to acrylic. Kvaril baths are cast in special moulds. The product is so rigid that it does not need additional reinforcement. At the final stage of production, the surface of the bath is coated with a special varnish.

Flaws

Of course, a quartz bath does not consist entirely of merit.

She also has disadvantages, which, however, are much less than the advantages:

- The first and most significant drawback of such baths is the high price. A quartz bath will cost you much less than, for example, a bath made of natural stone, but on average it costs several times more than a cast-iron, steel or acrylic bath.

- Although quartz baths boast a greater variety of shapes and sizes than their predecessors, they are still made by casting in preformed moulds. Therefore, the choice of forms is still limited.

- Today, only bathtubs and shower trays are made from quartz, so a quartz bath is a unique product in some way. It is sometimes not easy to pick up a sink and a toilet in an ensemble that matches the style and color.

- The strength of quartz is higher than that of acrylic, but less than that of steel and cast iron. Therefore, there is still a chance of scratching the surface of the quartz bath.This disadvantage is not particularly significant, since the surface of a bathtub made of quartz can be easily restored at home using a special paste.

- Despite the fact that the quartz bathtub is unpretentious in care, the use of aggressive cleaning products that contain abrasive substances should be avoided, as they can damage its surface.

- Kvaril is afraid of exposure to high temperatures, so if very hot water is poured into the quaril bath often and for a long time, it can become deformed.

Device

Due to the presence of quartz particles, quartz has a high compressive strength, withstands significant pressure and shock loads, does not require reinforcement, unlike acrylic bathtubs.

Products are made by pouring liquid material into a mold, followed by pressing under heat, so that the surface is smooth, without pores and irregularities.

For manufacturing, templates of various shapes are used: rectangular baths, oval, triangular, with complex wall geometry and several bottom levels.

Regardless of the complexity of the product, there are no welds and joints in the design.

Monolithic structures are mounted directly on the floor or in a specially prepared box. There are bathtubs on special legs supplied in the kit.

Quarry tubs have a number of advantages over acrylic, steel or cast iron tubs:

- Strength, installation of frame supporting elements is not required;

- They keep the temperature well while keeping the water hot;

- Easy to clean and maintain - standard detergents without abrasive materials are used for cleaning.

Plumbing from kvaril differs in high rates of hygienic and sanitary safety.

The monolithic surface without pores does not allow fungi, mold and bacteria to multiply.