- Gas boilers for home heating, wall-mounted double-circuit

- The principle of operation of an atmospheric boiler

- TOP-5 single-circuit gas boilers

- Lemax Premium-10 10 kW

- Lemax Premium-20 20 kW

- Protherm Wolf 16 KSO 16 kW

- BAXI ECO-4s 1.24F 24 kW

- Lemax Leader-16 16 kW

- The device of a double-circuit gas-fired boiler

- Distinctive features of heat exchangers

- No. 3 - Baksi MAIN 5 24 F

- The principle of operation of gas boilers

- Boilers with open and closed combustion chamber

- What to look for when choosing?

- 1. Type of combustion chamber

- 2. Boiler type

- 3. Heat exchanger material

- 4. Boiler power

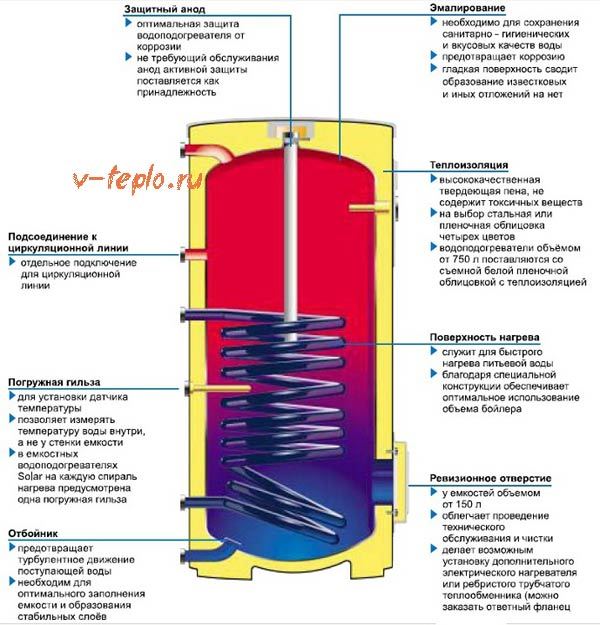

- 5. The presence of a built-in boiler

- Secrets of choosing a floor boiler

Gas boilers for home heating, wall-mounted double-circuit

About the advantages of wall-mounted gas boilers

Not every private house has the possibility of allocating a separate room for a boiler room, although this is highly recommended for security reasons. Manufacturers have long thought about small and wall-mounted gas boilers, and they began to appear around the middle of the 20th century. The pioneers in their development and production were leading companies from Europe. In this part of the world, one population density is one of the highest on the planet, which is reflected in the size of the average private houses - they are usually small or medium.A house with a total area of 200 m² or more is already considered large there, and the average values are in the range from 75 m² to 150 m². For the purposes of heating such houses, boilers with a capacity of 8 kW to 20 kW are quite suitable, and they have small dimensions. The widespread introduction of two-pipe closed heating systems, and even with forced circulation, made it possible to greatly reduce the volume of the heat exchanger and combustion chamber, which also affected the size of the boilers - they became even more compact.

Then another idea came to “hide” the circulation pump, various sensors, valves, an expansion tank and automation in the boiler. And this happened without sacrificing size. But they didn’t stop there either, since there was another idea to build a hot water preparation unit into the boiler. And this, too, was successfully implemented. As a result, wall-mounted gas boilers for heating and hot water supply appeared at the disposal of a person.

Currently, almost all well-known global manufacturers of gas equipment are also engaged in wall-mounted double-circuit boilers. And, despite the abundance of brands and models, they all have a generally similar design, which we will consider in detail below. Moreover, besides the high-tech "stuffing", manufacturers also think about design so that the boiler not only does not disturb the interior, but in some cases can be its decoration. The talents of Italians and French are known in the world, who from any, even the most rigorous technical device, will also make an art object that people with high artistic taste will admire. And if you hide all the supplied pipes, then sometimes it will not be possible to guess that a beautiful “box” hanging on the wall heats the house and prepares hot water.

Wall-mounted gas boiler fits perfectly into a modern interior

There are many advantages of wall-mounted gas boilers and we will definitely mention them:

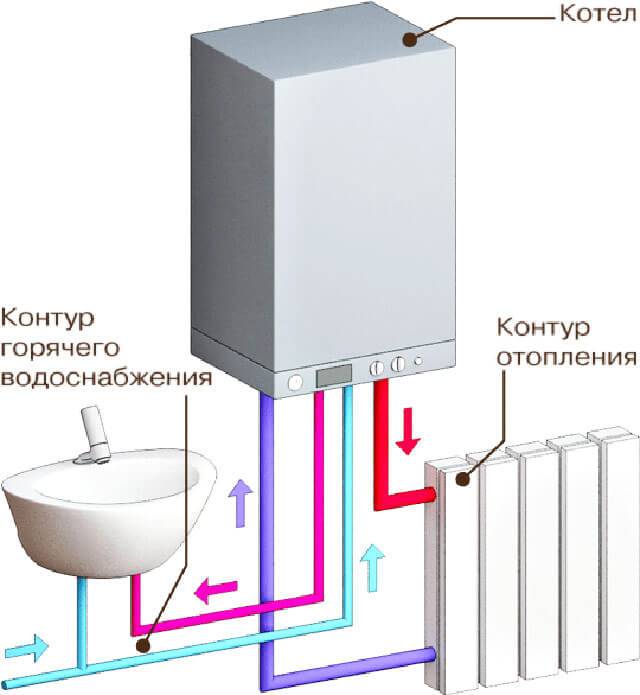

- Wall-mounted double-circuit gas boilers, in fact, are mini-boiler rooms, where all equipment is installed for both heating and hot water preparation. For most cases, this is enough and you do not need to purchase anything extra.

- For wall-mounted gas boilers, it is not necessary to allocate a separate non-residential premises - a boiler room, which has an impressive set of requirements.

- For wall-mounted gas boilers with a closed combustion chamber, a separate vertical chimney is not needed. The inflow of outside air for gas combustion and the exit of combustion products are provided through a coaxial chimney, which is led outside through the wall closest to the boiler.

The exit of the coaxial chimney on the street does not spoil the exterior of the house at all

The compact dimensions make it possible to place the boiler in a convenient place without compromising the area. And it also allows you to hide it in cabinets and niches, which does not affect its performance in the least.

This "baby", snugly hidden in a locker, heats a large house and gives out 12 liters of hot water per minute.

- Modern gas wall-mounted gas boilers have very "advanced" automation that allows you to maintain a constant temperature in the room, regardless of the weather outside. And also the preparation of hot water goes exactly with the set temperature, regardless of the pressure.

- Wall-mounted double-circuit boilers have a high efficiency, they are very economical, both in gas consumption and in electricity.

- Wall-mounted boilers do not create much noise. In neighboring rooms, they are inaudible even when operating at full power.

- Wall-mounted boilers have a very reasonable price and a long service life. Service and repair are available in any region.

Of course, gas-fired double-circuit wall-mounted boilers for home heating also have disadvantages. But we suggest that readers first get acquainted with the device and the principles of operation, and only then “scold” these wonderful heaters a little.

The principle of operation of an atmospheric boiler

Typically, atmospheric gas boilers are used for heating a private house or for individual heating of an apartment. The average power of the units is in the range of 15-40 kW. This indicator is considered sufficient for heating a room up to 400 sq.m.

The atmospheric burner is the main heating device, it consists of the following parts:

- Nozzle;

- Burner head;

- Ejection tube with burner holes;

- Burner;

- Flame control sensor.

Atmospheric type burners are of the following types:

- Single-stage - work in the "on" and off modes.

- Two-stage - capable of operating in reduced or full power mode;

- With flame modulation function - provide optimal gas supply mode.

To make it easier to understand the principle of operation of an atmospheric boiler, imagine that a heat exchanger is installed above a lit gas stove, and a ventilation duct is placed above.

The boiler, into which air enters, works similarly, the products of combustion are removed under the action of natural draft. The presence of a chimney is the main condition for the possibility of installing and operating an "atmospheric".

The main purpose of an open gas burner is to pre-mix the gas with air, followed by the resulting mixture being fed directly into the combustion zone.

Atmospheric gas burner provides mixing of gas with air with subsequent supply of the mixture to the combustion zone

Atmospheric gas burner provides mixing of gas with air with subsequent supply of the mixture to the combustion zone

Efficiency is due to increased flame due to the supply of oxygen and reduced fuel consumption.

TOP-5 single-circuit gas boilers

Single-circuit models are used either only for heating, or in conjunction with an external indirect heating boiler. This option allows you to get hot water without restrictions on the volume of water and without temperature fluctuations. Consider a few popular models:

Lemax Premium-10 10 kW

Single-circuit gas boiler of domestic production. Designed for heating 100 sq.m. The energy-independent design allows  operate the unit without being connected to the mains.

operate the unit without being connected to the mains.

The main parameters of the boiler:

- type of installation - floor;

- power consumption - independent;

- Efficiency - 90%;

- gas consumption - 1.2 m3/hour;

- dimensions - 330x748x499 mm;

- weight - 41 kg.

Advantages:

- energy independence;

- well-organized service and supply of spare parts;

- the design was built taking into account Russian climatic conditions.

Disadvantages:

- when heated to 50 °, condensation appears in small quantities;

- there is no display, it is not possible to obtain information about the state of the boiler units.

Non-volatile models are reliable and simple. They are quite safe, but need a quality chimney.

Lemax Premium-20 20 kW

Russian-made gas boiler. The power of the unit is 20 kW, which is suitable for rooms up to 200 sq.m. Equipped with fully mechanical control.

Boiler parameters:

- type of installation - floor;

- power consumption - non-volatile;

- Efficiency - 90%;

- gas consumption - 2.4 m3/hour;

- dimensions - 556x961x470 mm;

- weight - 78 kg.

Advantages:

- reliability, stability of work;

- Ease of controls;

- low cost.

Flaws:

- complex ignition;

- you have to adjust the gas pressure so that there are no pops during ignition.

Domestic non-volatile boilers are much simpler and cheaper than European counterparts. This is both a plus and a minus of the units.

Protherm Wolf 16 KSO 16 kW

Slovak gas boiler with a capacity of 16 kW. Ideally suited for heating a house of 160 sq.m.

Main technical characteristics:

- type of installation - floor;

- power consumption - independent;

- Efficiency - 92.5%;

- gas consumption - 1.9 m3/hour;

- dimensions - 390x745x460 mm;

- weight - 46.5 kg.

Advantages:

- simplicity and reliability;

- no need to connect the power supply;

- economical fuel consumption;

- stable operation in automatic mode.

Flaws:

- there is no indication of the state of the main components of the boiler;

- ignition using a piezoelectric element is somewhat difficult.

Gas boilers of Slovak engineers are highly rated by users, which confirms the high demand.

BAXI ECO-4s 1.24F 24 kW

Gas boiler from a well-known Italian manufacturer. The power of the unit is 24 kW, which corresponds to a serviced area of 240 sq.m.

Options:

- installation type - wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 92.9%;

- gas consumption - 2.73 m3/hour;

- dimensions - 400x730x299 mm;

- weight - 29 kg.

Advantages:

- compactness, light weight;

- reliability, stability of work;

- full control over all systems and nodes using self-diagnosis;

- there is a display showing all the parameters of the unit, both current and constant.

Flaws:

- when the power supply is turned off, the operation of the boiler stops;

- high price for the boiler itself and for spare parts.

Italian heating engineering is considered elite. It successfully competes with German models in all respects, enjoys well-deserved recognition and high demand among buyers.

Lemax Leader-16 16 kW

Russian single-circuit non-volatile boiler. Its power is 16 kW, which allows heating rooms up to 160 sq.m.

Main characteristics:

- type of installation - floor;

- power consumption - independent;

- Efficiency - 90%;

- gas consumption - 1.9 m3/hour;

- dimensions - 431x856x515 mm;

- weight - 95 kg.

Advantages:

- stable, sustainable work;

- low cost of the boiler and repair work;

- independence from the power supply.

Flaws:

- minor flaws made during assembly;

- great weight.

Floor gas boilers are not limited in terms of mass and size of units, which allows you to create more powerful and durable units.

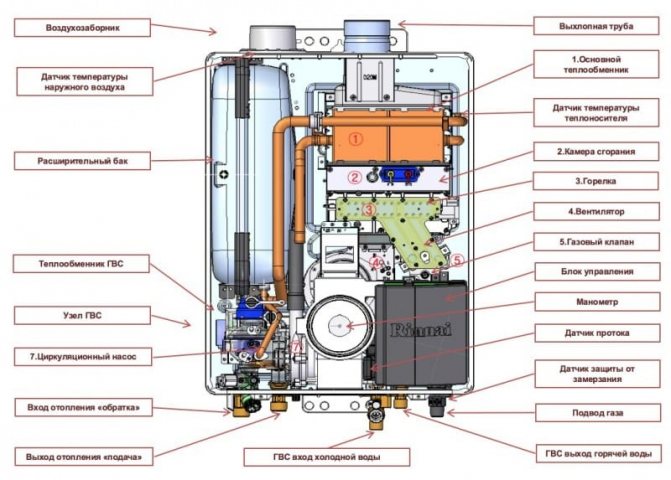

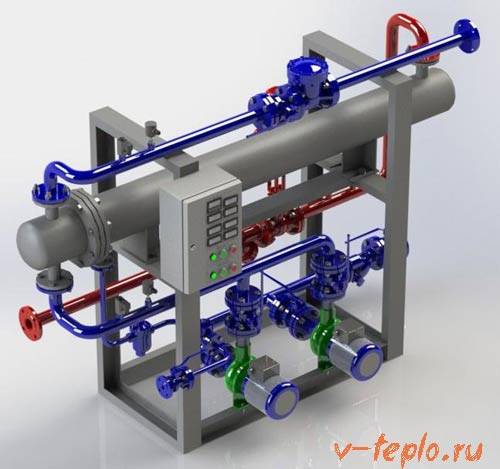

The device of a double-circuit gas-fired boiler

The market is rich in a variety of models, which are gas double-circuit heating boilers from a variety of manufacturers. Some of them are similar to each other, others have many important differences.

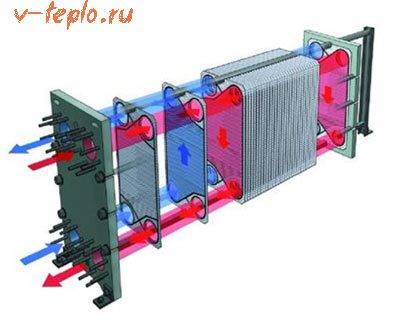

One of the main differences between double-circuit heating boilers is how the heat exchanger is arranged, which transfers the heat released by the combustible fuel to the coolant. This element in most models is placed at the top of the equipment, under which the burner is located.

When the fuel burns, it releases upward heat. The latter heats the heat exchanger through which water circulates.Heat exchangers can be made of stainless steel, aluminum or copper. However, stainless steel models are considered the most common and resistant to aggressive coolant.

Conventionally, double-circuit boilers can be divided into the following two categories:

- With bimetric heat exchanger

- With two heat exchangers

Bimetric heat transfer models are a "pipe in pipe" system. The main external circuit is necessary to ensure the heating of the coolant flowing inside the second circuit. The main advantage is low cost, however, too high a thermal load can disable the equipment after a short 6-7 years.

Double-circuit gas heating installations with primary and secondary heat exchangers are much more reliable, but they are characterized by a more significant cost. This construct works like this:

- As a primary heat exchanger, a system of copper tubes is used, on which copper plates are soldered - it is necessary for heat transfer

- A secondary type heat exchanger (its second name is plastic) is designed to transport heat between the coolant and water to provide a DHW line

- When hot water is needed, the coolant moves in a closed circuit inside the boiler, without entering the heating system and giving off heat to the hot water line

Distinctive features of heat exchangers

The heat exchange unit of the heating device is cast iron, steel or copper.The cast iron version retains heat for a long time, is almost not affected by corrosion due to the high wall thickness and is resistant to aggressive coolants. It is heavy and therefore mainly integrated into floor standing boilers.

It requires great care during installation, since any impacts violate the structural integrity of the material and lead to the formation of microcracks.

The steel structure weighs little, is not afraid of mechanical impact, calmly tolerates temperature changes in the coolant, is easily transported and mounted. Has some tendency to rust. The control system of the boiler helps to avoid it, which prevents the temperature of the coolant from falling below the critical point.

Copper elements are an order of magnitude more expensive than their cast-iron and steel counterparts, but they compensate for the solid cost with a large number of advantages. Inside the copper heat exchanger, sediment and scale are formed at a minimum and do not interfere with the normal circulation of the working fluid. The walls of the device are heated evenly and do not cause local overheating of the coolant.

No. 3 - Baksi MAIN 5 24 F

The Italian wall-mounted boiler Baxi MAIN 5 24 F is rightly placed in the 3rd place in the rating. This is a double-circuit unit with a closed-type furnace and a turbocharged chimney. The heat exchanger is bithermic. Power - 24 kW, which is regulated over a wide range. The design provides for numerous sensors for monitoring the parameters of gas, water, heating system, draft, burner operation. A reliable Grundfos pump has been installed. The dimensions of the apparatus are 70x40x28 cm.

Advantages:

- reliable electronic control;

- high efficiency;

- small dimensions;

- convenient display with full information about the operation of the equipment;

- ease of operation.

Among the shortcomings, the danger of voltage drops in the network is noted. However, this disadvantage is easily eliminated by installing a stabilizer. No other cons found. The unit fully meets the highest requirements.

The principle of operation of gas boilers

All existing models can be divided into two main groups:

Convection boilers have a simpler design and low cost. You can find these models everywhere. Heating of the coolant occurs solely due to the effect of an open flame of the burner. In this case, most of the thermal energy is transferred to the heat exchanger, but some (sometimes quite significant) part of it is lost along with the discharged products of gas combustion. The main drawback is that the latent energy of water vapor, which is part of the removed smoke, is not used.

Convection boiler Gaz 6000 W

The advantages of such models include a fairly simple design, the possibility of diverting combustion products due to natural draft (if there are chimneys that meet the requirements).

The second group is convection gas boilers. Their peculiarity lies in the following - convection equipment cannot use the energy of water vapor removed with smoke. It is this drawback that the condensing circuit of a gas boiler allows to eliminate.

Gas boiler Bosch Gaz 3000 W ZW 24-2KE

The essence of the operation of such devices is that combustion products that have a sufficiently high temperature pass through a special heat exchanger, into which water enters from the return of the heating system.Provided that the temperature of such a coolant is below the dew point for water (about 40 degrees), steam begins to condense on the outer walls of the heat exchanger. In this case, a sufficiently large amount of thermal energy (condensation energy) is released, which provides preheating of the coolant.

But there are some negative points that characterize the condensation technique:

To operate in condensing mode, it is necessary to provide a return temperature of no more than 30-35 degrees. Therefore, such units are mainly used for low-temperature (not more than 50 degrees) heating systems. Also, boilers of this type can be used in systems with high heat transfer, for example, in systems with a warm water floor. Boilers in which a condensing heat exchanger is used to provide hot water have proven themselves quite well.

Maintenance and adjustment of the optimal operating mode of the boiler can only be performed by a competent specialist. In the regions, there are not too many craftsmen who can understand condensing boilers. Therefore, maintenance of the device can be quite expensive.

In addition, the very cost of equipment of this class is high, it will not be possible to attribute such equipment to the budget option even with a strong desire.

But is it really worth giving up the opportunity to save more than 30% of the energy carrier because of such shortcomings. It is this savings and the short payback period of condensing boilers that make their purchase expedient from an economic point of view.

Boilers with open and closed combustion chamber

Such boilers differ significantly in their technical capabilities, while the conditions for their use also differ.

Atmospheric boilers are equipped with an open combustion chamber. The air necessary for gas combustion enters the chamber directly from the room. Therefore, when choosing such boilers, it is necessary to strictly control compliance with the regulatory requirements for air exchange in the room. An effective ventilation system must operate in the room, in addition, the removal of combustion products in the natural draft mode is possible only with the installation of high chimneys (smoke removal above the level of the roof of the building).

Wall-mounted gas boiler Logamax U054-24K atmospheric double-circuit

The advantages of such boilers include a fairly reasonable cost, simplicity of design. But it should be borne in mind that the efficiency of such units is most often not too high (compared to more advanced models).

The turbocharged wall-mounted double-circuit boiler is equipped with a closed-type combustion chamber. Such units are connected mainly to coaxial chimneys, which provide not only the removal of combustion products, but also the supply of fresh air to the combustion chamber from the street. To do this, a low-power electric fan is built into the design of the boiler.

Gas boiler FERROLI DOMIproject F24 wall-mounted double-circuit turbocharged

The main advantage of a turbocharged boiler is increased productivity, while the efficiency of the device reaches 90-95%. This makes it possible to reduce fuel consumption. But it is worth considering that the cost of such boilers is quite high.

What to look for when choosing?

Before buying a dual-circuit model, you should pay attention to five important indicators:

1. Type of combustion chamber

There are devices with an open and closed combustion chamber. Devices with an open chamber take air from the room, and the combustion products are removed through the chimney. For safety reasons, such a chimney must be at least 4 m in height. Since oxygen from the room is consumed in this case, ventilation should be well organized in such a house.

With closed combustion, air is taken from the street, and the combustion products at this moment are brought out. Thus, the oxygen in the room does not burn out and the overall atmosphere is much more favorable. Models with a closed chamber are suitable for those who have poorly organized ventilation in the house. They can also be installed in the kitchen or bathroom. Devices with a closed combustion chamber are the only possible option for apartment buildings.

2. Boiler type

There are classic (convection) and condensing devices.

Classic wall-mounted gas boilers with two circuits, the 2020 rating of which will be given below, generate heat only by burning gas. On average, their efficiency is from 85 to 95%.

Condensing appliances generate additional heat by condensing water vapor, which is formed naturally during combustion. Due to this, the efficiency of the boiler increases and can range from 100 to 110%. Given this, the condensing model can reduce gas consumption by 10-15%. This savings will be especially noticeable when using a warm floor. If you really want to save on heating and water heating, then take the condensation model. Such models will definitely be included in our rating of double-circuit wall-mounted gas boilers in terms of reliability.

3. Heat exchanger material

The heat exchanger of the device can be made of the following materials:

- Cast iron. It is used in the cheapest models. It generates heat well, but the efficiency usually does not exceed 90%. Boilers with cast iron heat exchangers are heavier and bulkier, which complicates their installation.

- Stainless steel. It is used for the budget and middle class. Stainless steel is quite durable and can be easily repaired if necessary. However, the heat transfer is less than that of copper.

- Copper. Copper heat exchangers are installed in models of the middle and expensive class. They are durable and give off heat well.

If you want to take a classic model and are going to mount it yourself, take it with a stainless heat exchanger. For underfloor heating and hot water supply, we recommend taking a condensing type device with a copper heat exchanger.

4. Boiler power

On average, 1 kW of power of the device is able to heat about 8 m2 of area. Divide the total area you need to heat by 8 to get the required power. Add 1 kW for water heating. If you want to more accurately calculate the power of the device, use the formula that we gave for single-circuit boilers.

5. The presence of a built-in boiler

A separate type of double-circuit boilers can be additionally equipped with a boiler for heating and, most importantly, storing water. Sometimes it is very convenient to have such a boiler, since with a strong pressure drop in the pipeline, the boiler may simply not heat the water, and the water in the boiler will always be hot. The purchase of a model with a built-in boiler makes sense only in cases where there is a frequent drop in pressure in the city water supply. Otherwise, it's a waste of money.

Secrets of choosing a floor boiler

Of course, the first thing that draws attention is the power of the gas unit.It is usually proposed to calculate the required power as follows: 1 kW of power per 10 sq.m. This is an average value that does not take into account the height of the ceiling, the number of windows in the room, thermal insulation

The correct calculation can only be done by a specialist

This is an average value that does not take into account the height of the ceiling, the number of windows in the room, and thermal insulation. The correct calculation can only be done by a specialist.

Some advise to purchase a boiler with a small margin of power. The stock should be small, otherwise the wear of the equipment will come much earlier. For single-circuit boilers, the power reserve is no more than 15%, for double-circuit boilers - no more than 25%.

The most economical boilers are condensing models, they consume fuel 15-30% less than traditional ones. Also saves and electronic ignition. Piezo ignition will lead to excessive gas consumption due to the constant operation of the burner. An electronic burner does not need this, so the cost is of course higher, but the quality and service life are corresponding.

It is necessary to take into account the area of \u200b\u200bthe building: for a small building it is better to purchase a double-circuit boiler, provided that hot water is needed. For large areas, the power of a double-circuit boiler is not enough and the safety of the system may suffer.

It is better to choose the material - cast iron or steel. Will last longer. The copper heat exchanger will have to be changed after a while. Most often choose a node made of cast iron.

The higher the power, the higher the price. It is considered the norm if the efficiency of a floor gas boiler is from 80 to 90%. Condensation models - from 104 to 116% (according to passport data). The higher the efficiency, the less fuel and the more efficient the work.

Safer and more convenient boilers with automatic control. There is no need to control their work. This is a very expensive system.A more budgetary option involves constant monitoring of work, which is not always convenient.

The size of the boiler, of course, is chosen based on the area of \u200b\u200bthe room where it will stand. The choice is huge

It is important to remember that all additional equipment has free access.