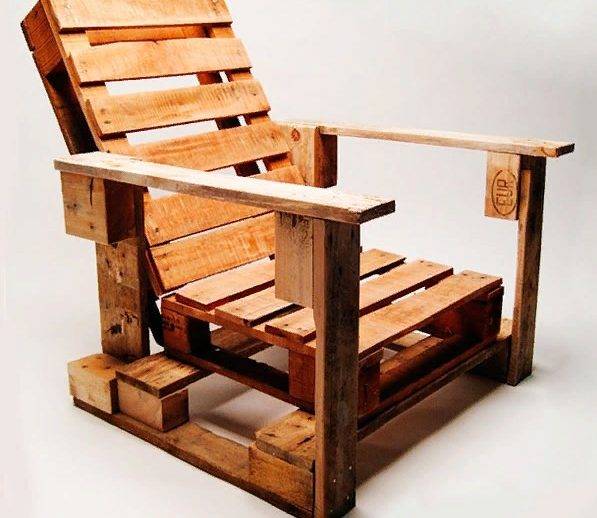

- Chair for giving from pallets

- Prices for wood preservatives

- DIY garden chair

- Prices for the range of drills

- How to make a rocking chair with your own hands

- Plywood rocking chair

- sidewalls

- frames

- Boarding

- Finishing elements

- How to make a rocking chair out of wood

- purpose

- Manufacturing materials

- Making a rocking chair for two

- materials

- cutting

- How to make a rocking chair with your own hands: the most affordable options

Chair for giving from pallets

You can make such a design with your own hands, while spending only a few hours. In the process, you will need the following:

- wooden pallets (you can buy new ones or dismantle old ones that are no longer in use);

- a hammer;

- nails;

- sandpaper;

- fastenings;

- primer.

Prices for wood preservatives

Impregnation for wood

Step-by-step instruction

Step one: in this case, we will need to take two pallets of the same size, which will then be divided into parts. At the same time, if the design involves the presence of additional decorative elements, then more pallets will be needed.

Dividing the pallet into parts

Step two: the surface of the wood should be carefully treated with sandpaper.

Sanding the surface of the pallets

Step Three: First you need to connect the parts of the seat and back together. At this stage, you can make a small cut to get the slope of the back.

Connecting the back and seat

Step Four: It is better to fix all the details with screws, because the nail connection is not very reliable.

DIY garden chair

Before starting work on the manufacture of the chair, it is necessary to prepare the following materials and fixtures:

- cedar veneer;

- screws;

- wood glue;

- sandpaper;

- finishing varnish;

- drying oil;

- scotch;

- thick paper for patterns;

- plane;

- saw;

- milling equipment;

- hacksaw;

- drill;

- clamps;

- simple pencil;

- measuring tape.

Prices for the range of drills

Drill

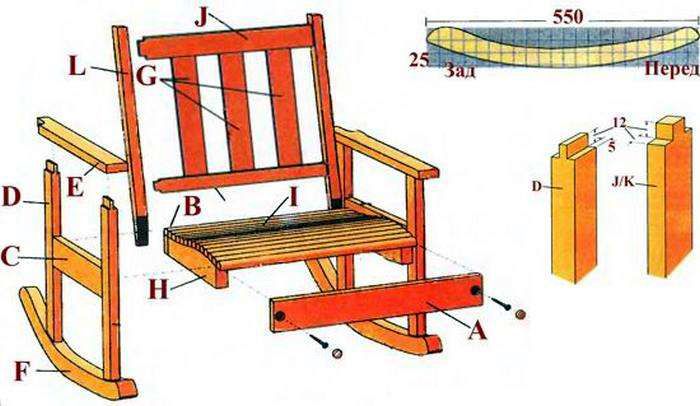

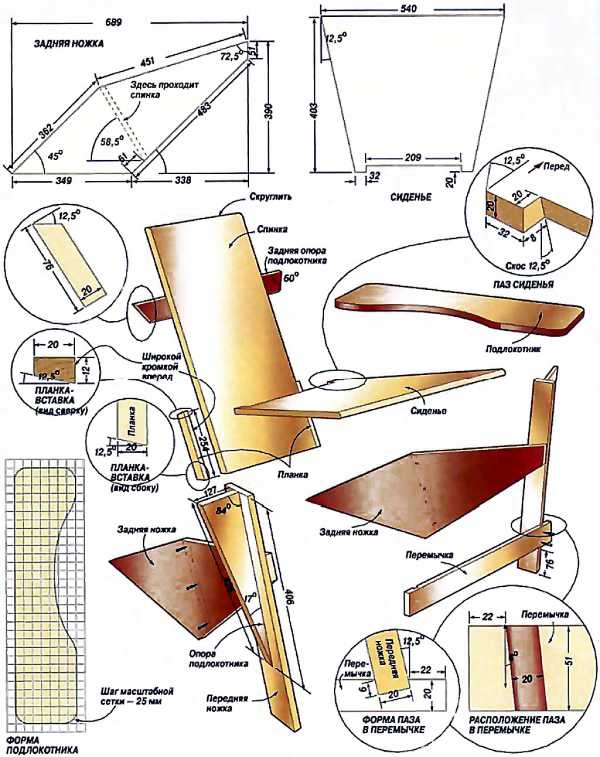

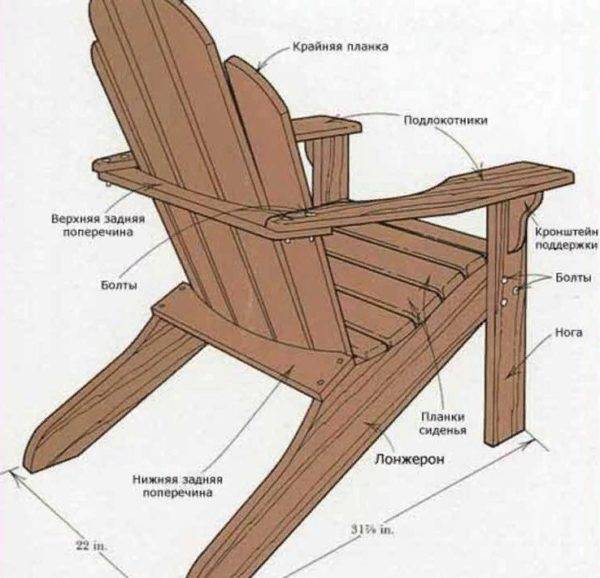

An approximate scheme for creating a chair

Part preparation

Step one: first you need to make patterns for the design, indicating the dimensions of the parts on thick cardboard. In our case, the following elements should be obtained:

- legs (4 pieces) - 2x25x78 centimeters and 2 × 7.6 × 53 centimeters;

- back - 2x28x91 centimeters;

- armrests - 2x12x40 centimeters (2 pieces) and 2 × 7.5 × 61 centimeters;

- connecting bar - 2x5x58 centimeters;

- additional bar (2 pieces) - 1.2x2x2.5 centimeters.

garden chair elements

Step two: you need to cut out the parts from cardboard, and then transfer them to wood (circle), after which you can cut parts of the future chair. This should be done very carefully - the peculiarity of cedar boards is that they are prone to chipping, so you should only cut along the fibers.

Sawing the details

Connection of parts

Step one: before starting assembly, all parts must be carefully treated with an antiseptic agent for fungus and dried.Only then can you proceed to the next steps.

Preparing the treatment

Step two: we adjust the finished parts to the desired size and at the same stage we leave the markings for the holes for the fasteners.

We trim the parts of the structure exactly along the intended contour

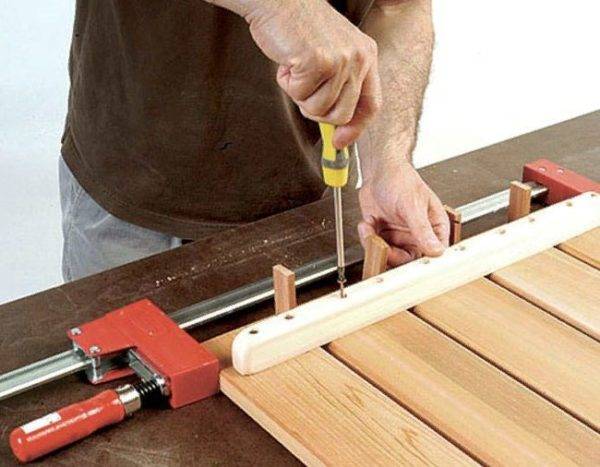

Step three: using a drill, make holes for the fasteners, and then fix the parts together.

The location of the boards affects the strength of the entire frame of the chair

Step four: we fix the leg of the chair (back) at an angle of 90 degrees, we fix it on the other side in the same way. It is necessary to connect the sidewalls of the structure.

The end parts of the planks and the opposite ends of the legs must match, which will allow you to get the correct location of the structure.

Step Five: We put the supports, and then fix them with clamps.

The joint must be very tight.

Step six: install the backrest guide from above with screws, fitting it to the cross bar from below. We set aside the markings with a simple pencil on all crossbars, as well as on part of the back, after which we make a hole while holding the bar.

We fix the strips one by one

Step seven: we make roundings, cutting the boards along the marked lines.

Installing the rail on the seat

Step Eight: The last step is to sand the entire surface of the chair with sandpaper.

It is important to achieve perfectly even wood without burrs. Then it is necessary to process the product with heated drying oil and cover with several layers of varnish

After applying the varnish, the chair should dry for some time.

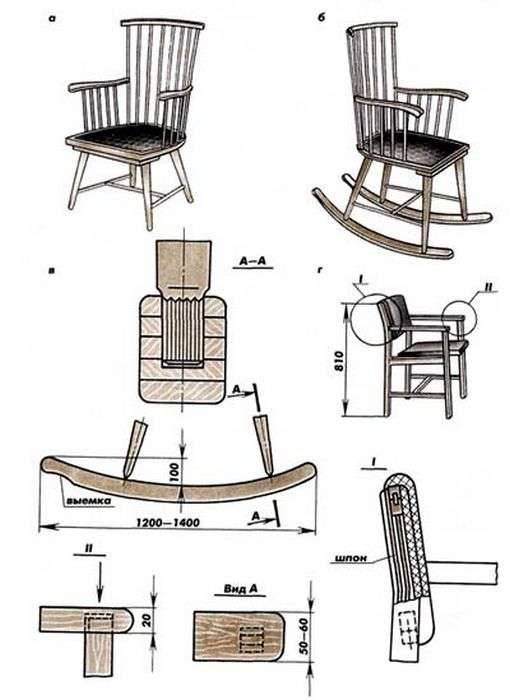

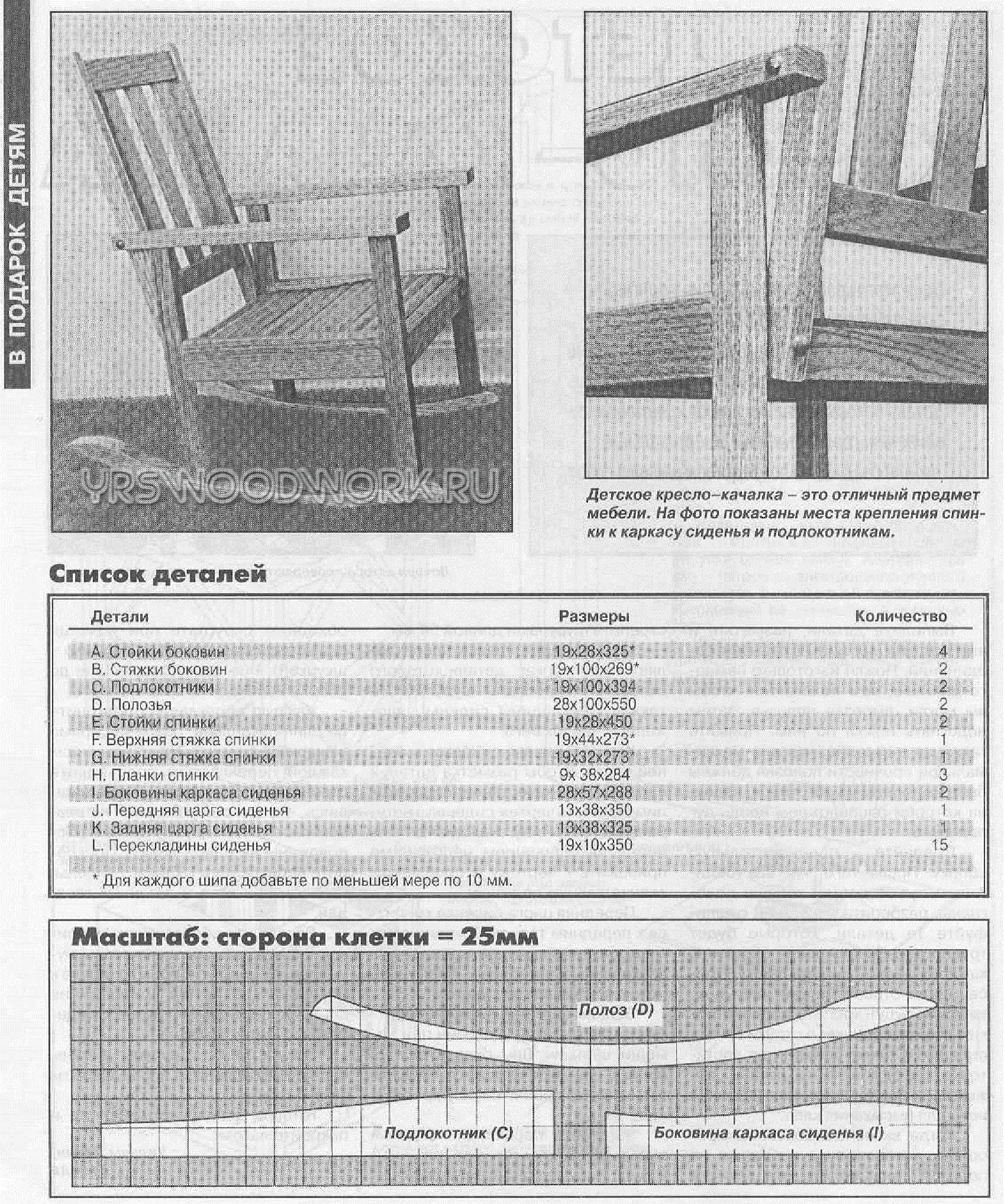

How to make a rocking chair with your own hands

From the selection of high-quality material depends on how high-quality and durable the chair you made will be.After all, the material should be light and durable, since the owner of this chair may get used to carrying it around. Those who do not want to pay big money for such a thing ask themselves how to make a rocking chair with their own hands at home, while choosing the most suitable and high-quality materials. Therefore, when choosing materials, we advise you to make a rocking chair from wood, reeds, and vines. Also, sometimes the chair is made of light metals.

A rocking chair is the perfect way to create an atmosphere of comfort and tranquility.

A rocking chair is the perfect way to create an atmosphere of comfort and tranquility.

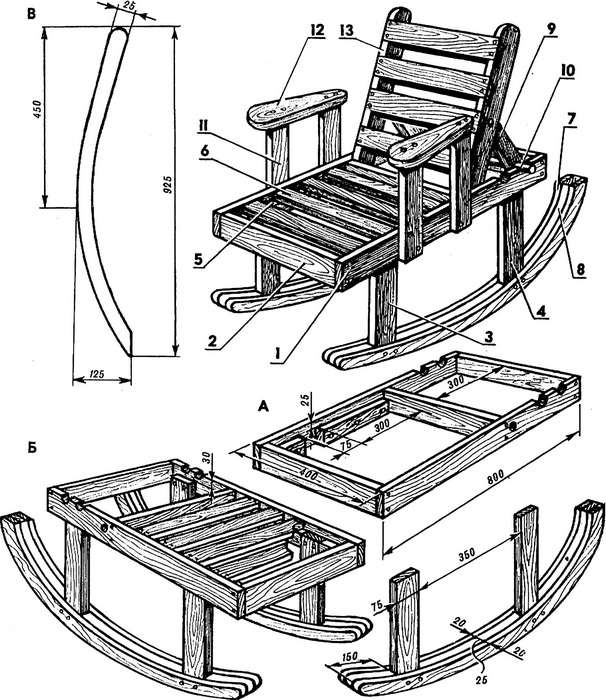

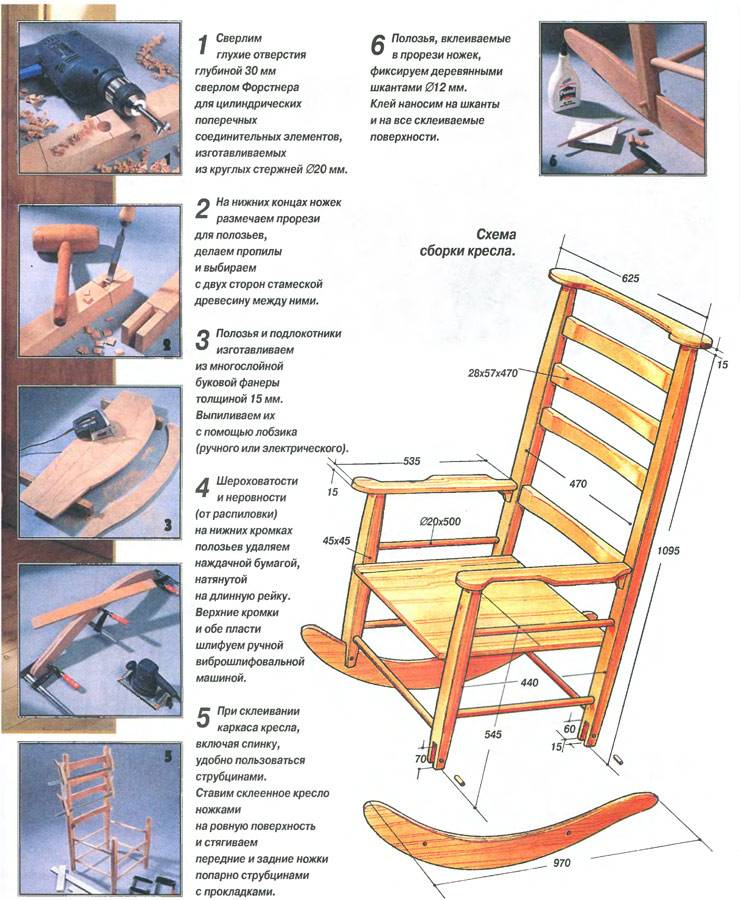

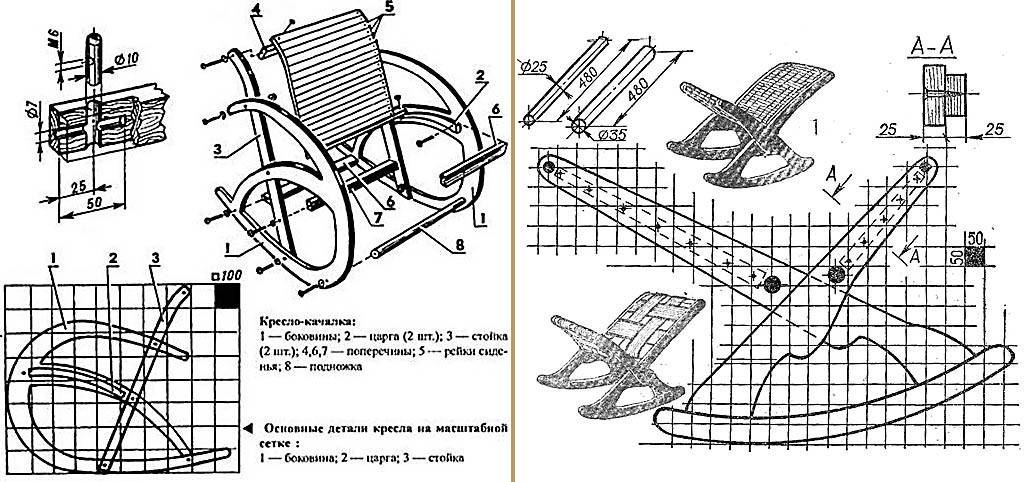

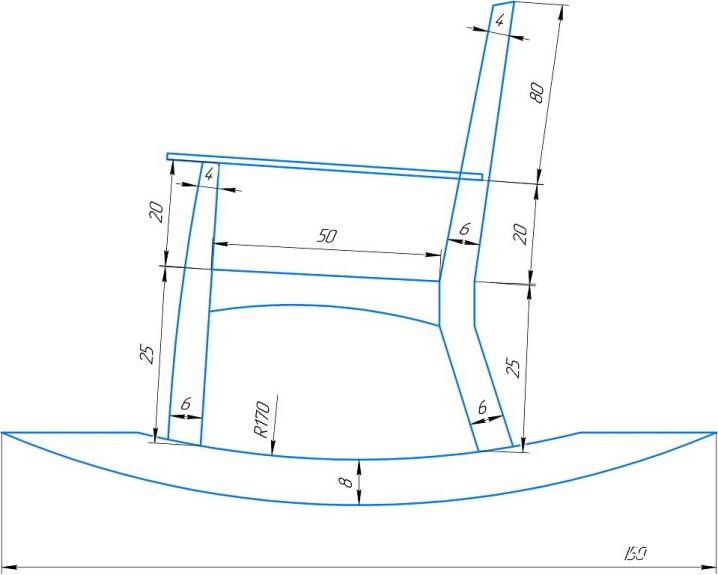

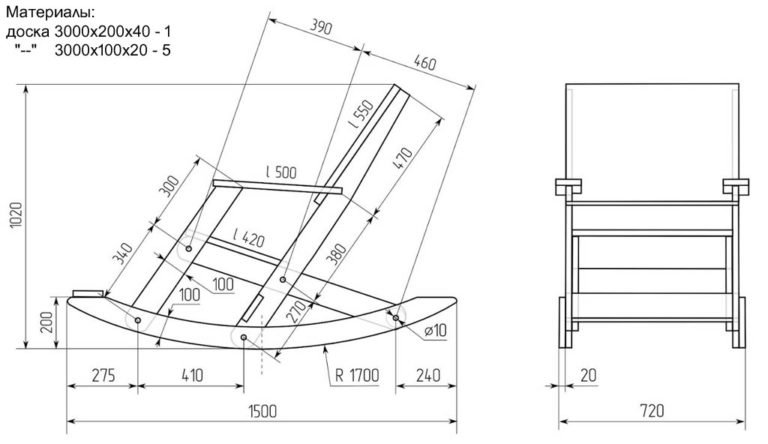

Plywood rocking chair

Plywood - may fall apart due to water, but it is also a great option for creating a chair. Because of this, many are interested in how to make a rocking chair with their own hands drawings from plywood. We advise you to make such chairs for a house or apartment. Therefore, if you want to make such a chair, then you should carefully monitor it if it is in the yard.

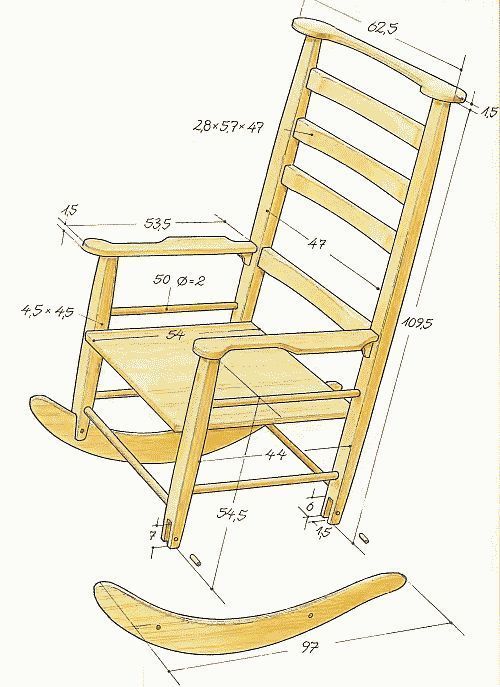

Rocking chair, made by hand in a classic style with curved runners, will be a great option for the first furniture making experience.

Rocking chair, made by hand in a classic style with curved runners, will be a great option for the first furniture making experience.

To create a simple and comfortable rocking chair, you need to prepare:

- For the sides: plywood sheets (1200x1400 mm, a moisture-resistant type of plywood would be an excellent option) 30 milliliters thick;

- For the base: 3 boards (20x150x800 mm);

- For sitting: 32 small boards (15x39x1200);

- Portable router;

- Screwdriver;

- Electric jigsaw;

- Portable electric machine for grinding;

- Self-tapping screws (20 pieces);

- wood glue;

- putty;

- Varnish.

Making a rocking chair with your own hands is not at all difficult, a minimal set of tools and a great desire are enough.

Making a rocking chair with your own hands is not at all difficult, a minimal set of tools and a great desire are enough.

sidewalls

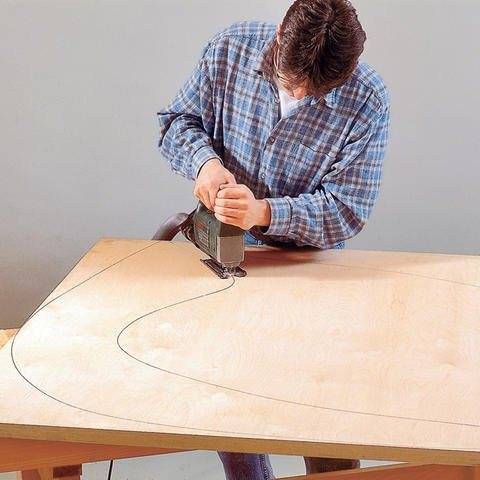

To begin with, the side parts are being prepared, which, along with this, are the skids, as well as the base for the chair. Two parts are cut with a jigsaw.

To begin with, according to the template, we will draw 2 sidewalls of the chair and carefully cut them out according to the markings with an electric jigsaw.

To begin with, according to the template, we will draw 2 sidewalls of the chair and carefully cut them out according to the markings with an electric jigsaw.

frames

With this action, they are created with markings on the sidewalls, which are drilled (20x150x800 mm). One of the main conditions of this operation is its accuracy. After that, grooves are made that correspond to the grooves of the jumpers. They are 5mm deep. Coat these holes with glue before installing the frames. So that the material does not burst under it, holes are made in advance.

All edges of the parts must be sanded with sandpaper.

All edges of the parts must be sanded with sandpaper.

Boarding

Mark the holes in the boards (15x39x1200) that make up the seat. From each edge mark 20 cm, outline the lines where the screws will be fixed. The distance between the parts is 1 cm.

We glue the supports to the walls of the sidewalls with wood glue and, for reliability, fix each of the bars with a self-tapping screw.

We glue the supports to the walls of the sidewalls with wood glue and, for reliability, fix each of the bars with a self-tapping screw.

Finishing elements

It is made with putty dissolved with sawdust, hide the holes where the boards were attached, level the surface. Grind after putty dries. Then they are varnished on the water, after which you can put a mattress or carpet on the chair for convenience. It is better to do this, because the stationary mattress will be wet from the rain.

The ends of the sidewalls can be varnished or painted with glossy paint.

The ends of the sidewalls can be varnished or painted with glossy paint.

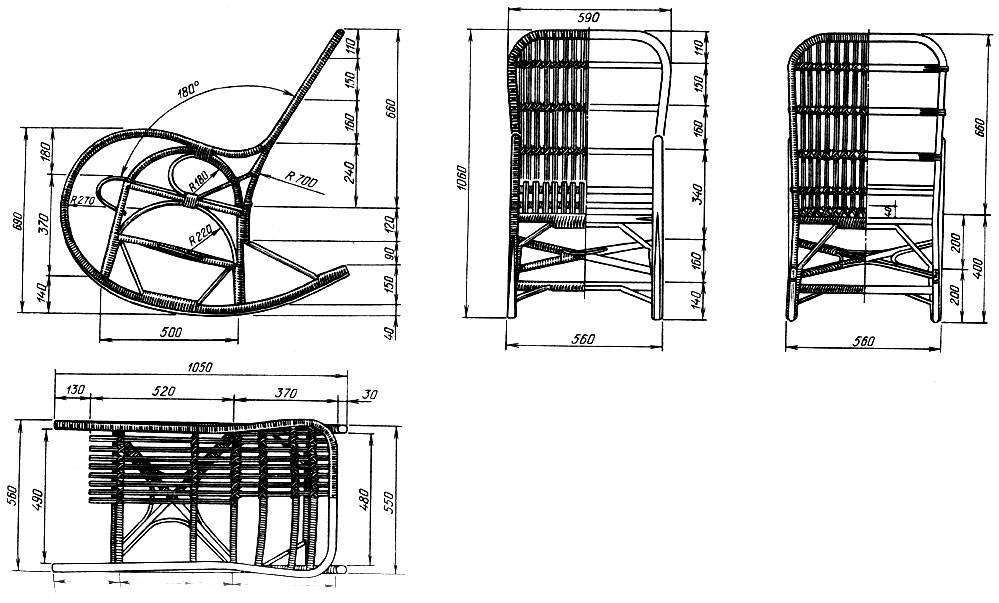

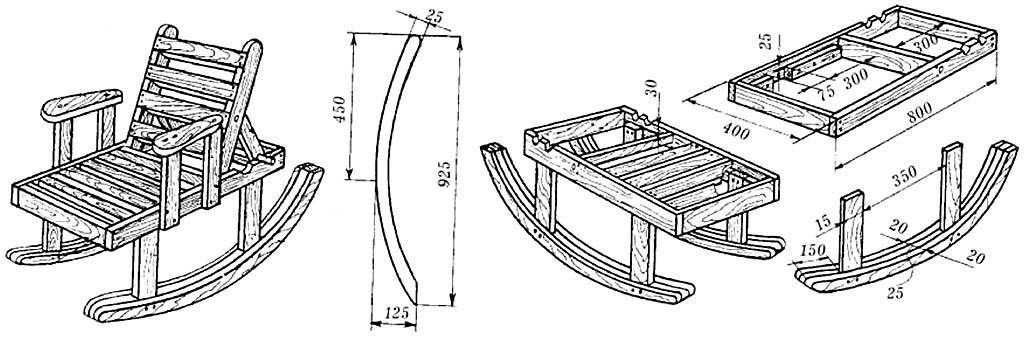

How to make a rocking chair out of wood

At the beginning of creating a chair, many people ask themselves: how to make a rocking chair with your own hands from wood, while finding suitable drawings and sizes? They search for a long time on various sites, ask on forums and so on. In this section, we will tell you how it can be made high-quality, reliable, convenient and modern.

Such rocking chairs are beautiful and will be able to decorate your interior in the apartment, on the balcony or in the courtyard of the house.

Such rocking chairs are beautiful and will be able to decorate your interior in the apartment, on the balcony or in the courtyard of the house.

In order to create a chair, you will need:

- hacksaw with fine teeth;

- planer to process the structure;

- belt machine for grinding parts;

- folding milling machine;

- plumb;

- screwdriver;

- a hammer;

- portable ruler and pencil;

- clamp;

- tassel.

The drawing can be created at your own discretion and to fit your size, or you can find it on the Internet.

The drawing can be created at your own discretion and to fit your size, or you can find it on the Internet.

To begin with, in a wooden board measuring 4.5 by 4.5 centimeters, make grooves of 1 meter. Grind the ends of the boards to fit in the slots of the runners. Lay the boards for the skids in hot water until the wood is pliable for bending. Using a tool, bend the board to a suitable radius and set aside in this state until it is completely dry. Put the dried runners on the legs, pre-treating the grooves with glue.

Everyone can make a new homemade rocking chair at home

Everyone can make a new homemade rocking chair at home

purpose

As for the purpose of the chairs, they are:

- For garden. For outdoor use, the chair is constructed from different materials: pallets, stumps, wood, metal, tires. There is no limit to the imagination when choosing materials and designs.

The main thing is that the product is resistant to negative factors and has high technical characteristics.A good option for installation in the garden are models of rocking chairs or hanging structures.

All types of chairs are easy and simple to make with your own hands, have an attractive design and are easy to use.

- Gaming (gaming, computer, for a car simulator). Such models are made of plywood, metal and textiles and are often equipped with furniture rollers for easy movement around the room. For their manufacture, it is necessary to have skills in working with wood, fabric and metal structures. Their main purpose is comfortable work at the computer.

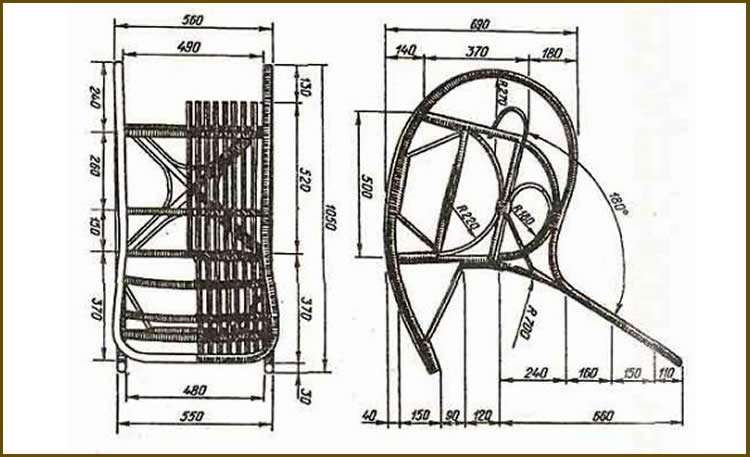

- Karpov. They are necessary for fishermen for a pleasant pastime. The feeder chair should be light in weight, compact, stable, and able to withstand heavy loads. In its manufacture, the possibility of adjusting the legs and backrest is considered. The presence of a fishing chair will allow you to comfortably spend time fishing in anticipation of a large trophy.

- In a PVC boat (or boat). Boat models are divided into: hard, soft and inflatable. Each individual option can be made independently. When choosing a particular design, it is worth considering the ease of use, the ability to withstand heavy loads, the resistance of the product to negative factors and dimensions. Some models are equipped with swivel mechanisms, others have an adjustable backrest, others are ergonomic and are suitable for even the smallest PVC boats.

- Balcony. To create a comfortable seating area on a balcony or loggia, you need to place an armchair here.

Most often, people prefer hanging models that do not take up much space and have an attractive design.It must be in harmony with the environment.

As a rule, balcony chairs are small in size. For glazed balconies in the manufacture of furniture, different materials are used.

Here you can install a soft frameless product, a wooden folding model or a textile deck chair. If the balcony is open and not heated, it is recommended to choose products that are resistant to negative environmental factors.

- Fireplace. These models have a different type of design. Some people prefer rocking chairs, others like solid wood products with a high back and wide armrests. You can complement the chair with a banquette for legs, so that the rest by the fireplace is as comfortable and enjoyable as possible. For classic styles, wooden products covered with leather or textiles are selected. For the direction of Provence, models with light upholstery are suitable; for an oriental interior, you should choose the patchwork technique.

- For a bath. Furniture for a bath should be made of reliable materials that are resistant to high moisture. The frame of the chair is made of wood or metal.

The main thing is to treat the materials with antiseptic impregnations from rust (if the product is metal) or from decay (if the frame is made of wood).

The main requirements for the manufacture of bath chairs are: low heat conductivity, simple design, strength, moisture resistance, fire safety, safety in use. It is best to make a product from natural wood.

- For kitchen. As for the choice of model for the kitchen, there are no restrictions. The design and dimensions of the chair will directly depend on the tastes and preferences of the owners and on the characteristics of the room.It would be appropriate to place a wooden armchair with soft upholstery here. Folding models that do not take up much free space are considered popular. They can be made entirely of wood or metal and fabric.

If there is a large free space, an armchair can be placed in this room - a bed with or without a frame. This is an ideal option for people living in small apartments and who like to meet guests overnight.

Reference: functionally all chairs are interchangeable. It all depends on your imagination and current needs.

Manufacturing materials

Before proceeding with the manufacture and assembly of a rocking chair, it is necessary to determine the design, dimensions and materials of its manufacture.

As for the materials for making the frame, it can be made from:

Metal. Such products are highly durable. They can be decorated with wrought iron elements to give aristocracy. You can put metal furniture in any room: living room, bedroom, on the veranda. The metal product can withstand weight up to 300 kg.

Rattan. The wicker model features an elegant openwork design. Rattan products are found in country houses and cottages. Their advantages include: the ability to withstand heavy weight, environmental friendliness and safety, long service life of more than 15 years, strength and reliability of the design.

tree. Wooden structures are the most common

They are able to decorate any room interior or courtyard exterior with their noble and elegant appearance. It is important to choose the right wood here.The ideal option would be: needles, oak, larch.

Willows, vines

These rocking chairs are in high demand. The material has a unique composition that provides furniture items with high wear resistance. You can weave a rocking chair with your own hands. To do this, you need to choose a suitable scheme and stock up on consumables. The advantages of wicker furniture include its low weight, compact size and high strength.

Plywood. It is easy and pleasant to work with her. It pleases with a long service life, naturalness and the ability to make products of any design.

profile pipe. The features of the material include: light weight, strength and resistance to stress, ease of use (PVC pipes are assembled into interesting designs), affordable material cost.

Some models of chairs are decorated with textile upholstery:

- Natural leather. It is distinguished by durability, wear resistance, resistance to negative factors.

- Eco-leather. The material has an affordable cost, a wide choice of color palette, practicality.

- Artificial leather. It is characterized by low cost, resistance to high moisture, resistance to deformation and tearing. Dust does not collect on its surface, and stains do not remain.

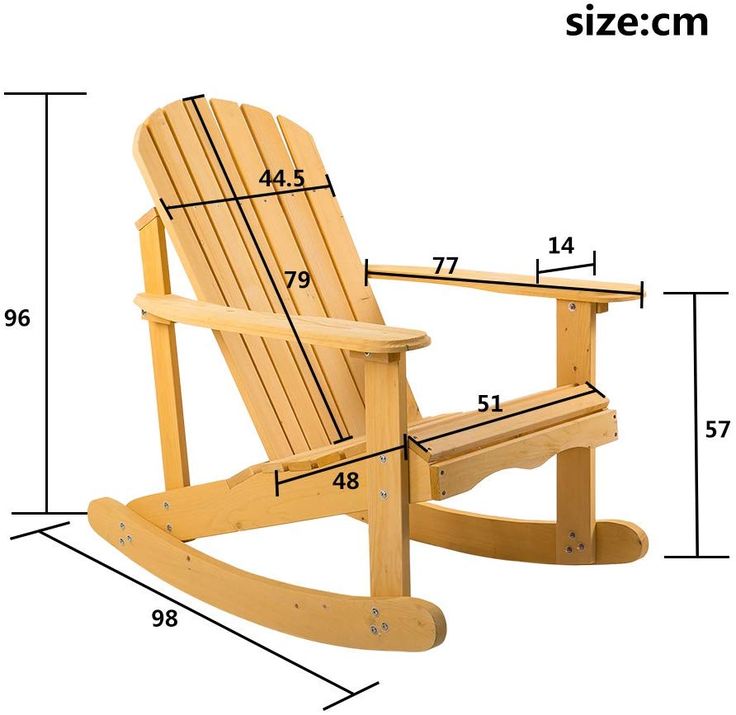

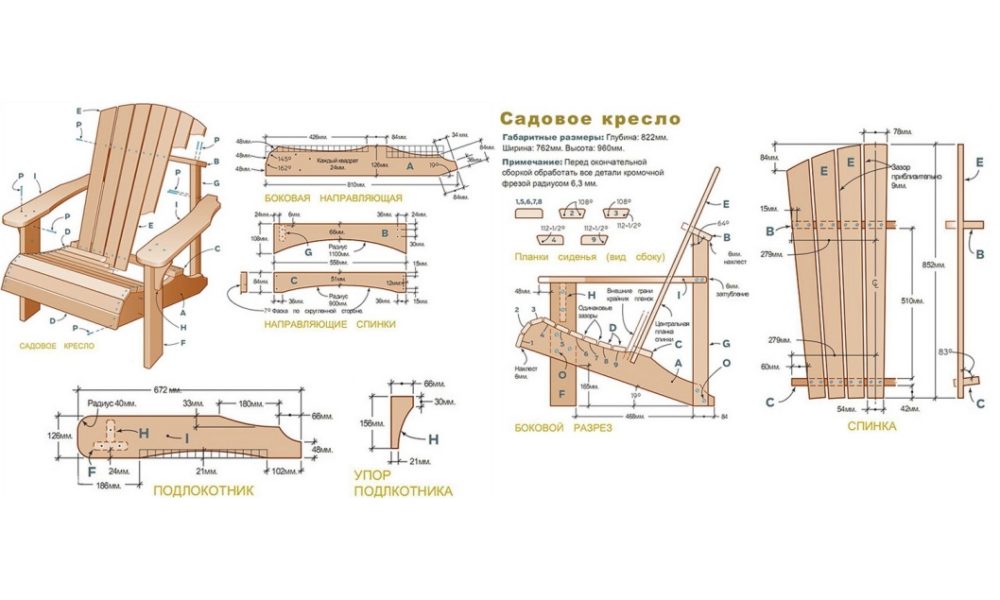

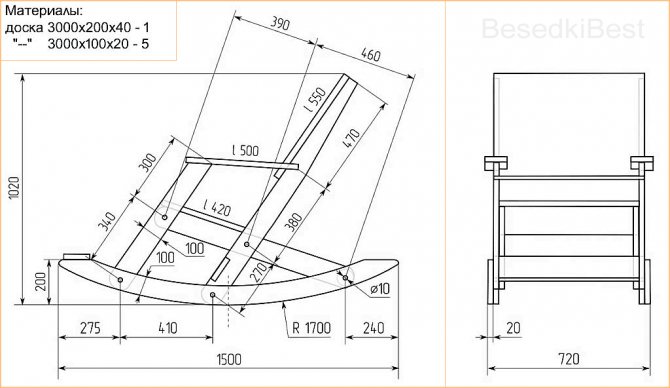

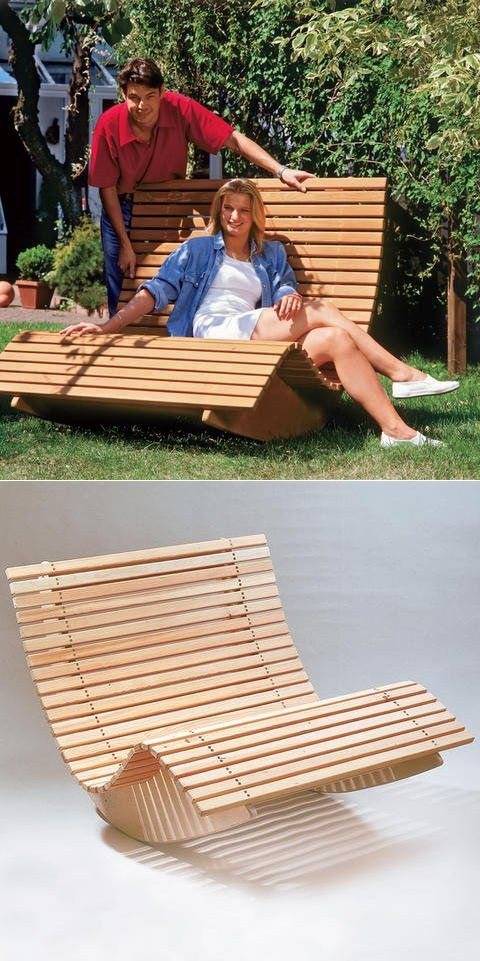

Making a rocking chair for two

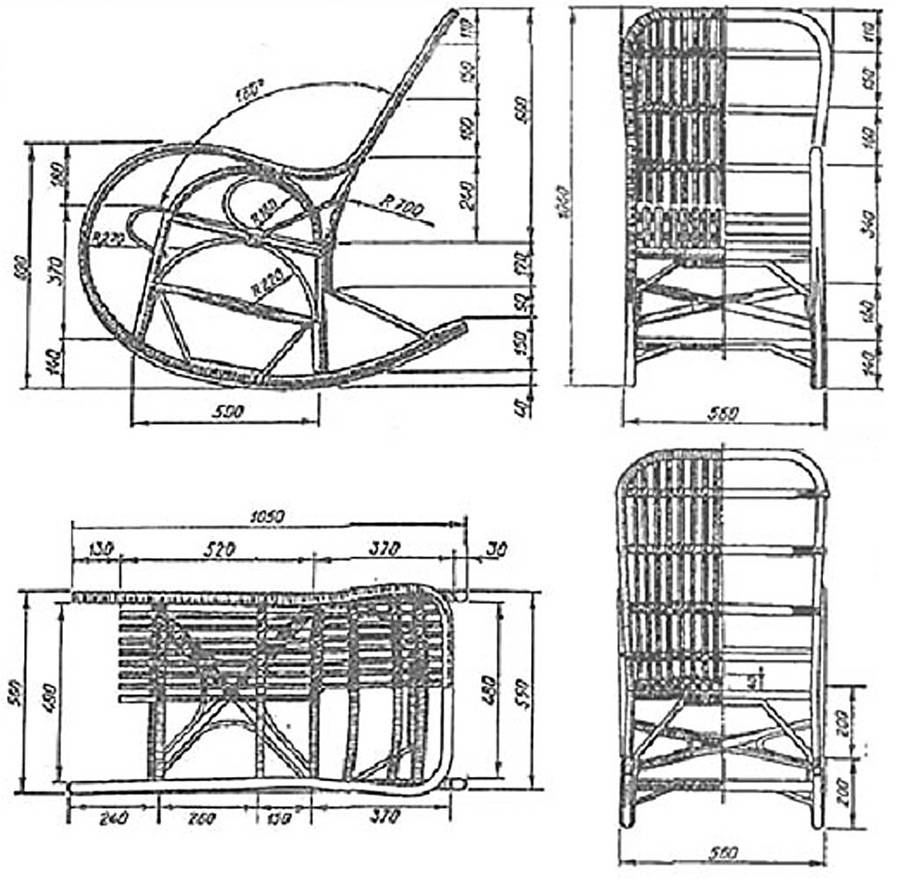

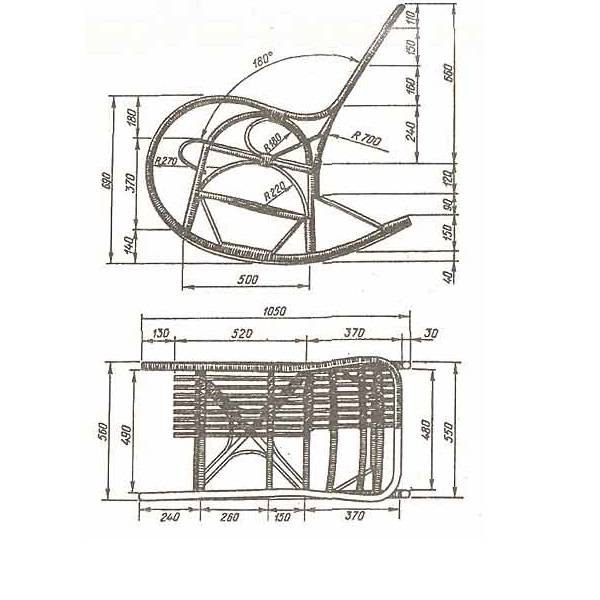

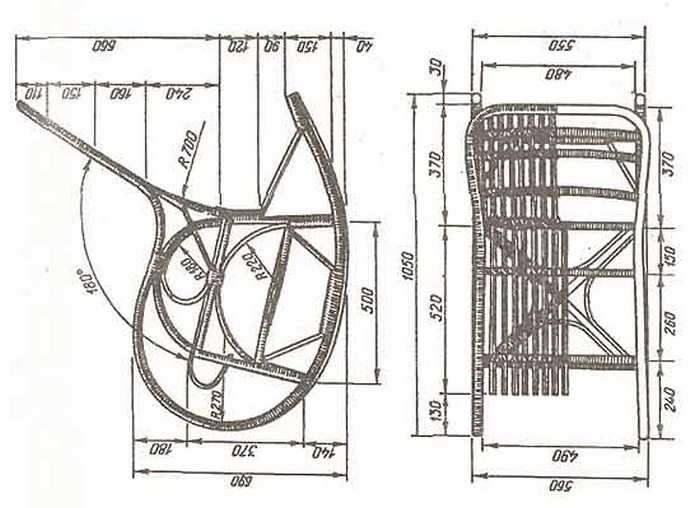

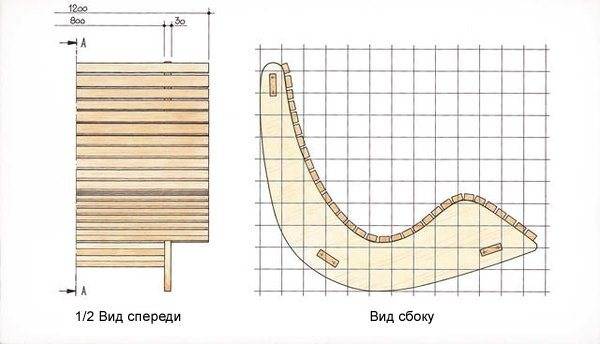

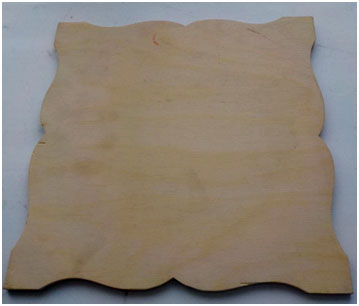

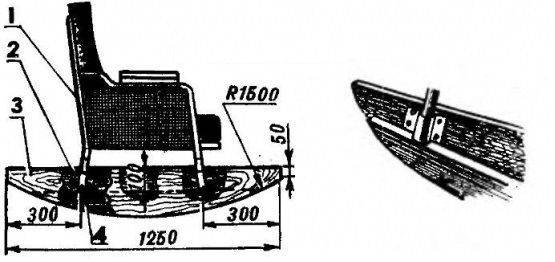

A rocking chair allows you to create a special atmosphere of coziness and comfort in the garden, making your vacation truly relaxing. Even a beginner can assemble such a structure; a simple and understandable drawing will help him in this. This chair model consists of three sides, two sidewalls, as well as 35 transverse rails, from which the seat and back are formed.

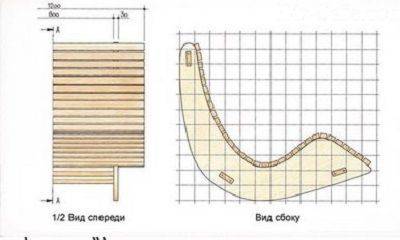

The most difficult stage of work is cutting out the sidewalls. To do this, you must first prepare special patterns.The cutting shown in the drawing is applied to a metric grid in 10 cm increments. According to this cutting, you need to make a template, and then transfer it to a sheet of plywood or other material with a thickness of at least 3 cm. This material will be used to make the supporting elements of the chair - sidewalls, king.

Then you need to cut two sidewalls with an electric jigsaw. In the manufacture of structural parts, certain errors are allowed, however, the sidewalls must be strictly the same in shape and size, otherwise the product will be skewed and unstable. When both sides are ready, they need to be chamfered with a milling cutter, and then sanded with a grinder or sandpaper.

At the next stage, three drawers should be cut out of plywood, it is not necessary to remove chamfers from them. The width of the drawers should be 10 cm, and the length should be 120 cm. Their length can be reduced, but it is undesirable to increase it, as this can reduce the reliability of the structure. Then, from a 50x25 mm beam, you need to cut 35 elements 120 cm long, grind each segment, chamfer it.

On the sidewalls, it is necessary to make marks in those places where the drawers will be attached (at the head, in the middle part, near the legs). Then, through holes should be drilled in the side pieces using an 8 mm drill. After that, similar holes are made in the ends of the drawers, but in this case a 5 mm drill is used.

Then you need to assemble the frame of the future chair, connecting the sidewalls with the sidewalls with the help of confirmations. To assemble the entire structure, the master needs to purchase 12 confirmations 5x120 mm, 140 self-tapping screws for wood 4x45 mm. At the next stage, pre-cut bars are attached to the seat with self-tapping screws.At each end of the beam, two self-tapping screws are screwed into pre-drilled and countersunk holes.

After that, it remains to putty all the cracks and cracks, treat the surface of the structure with fine-grained sandpaper and a primer, and then open it with varnish in three layers. The chair is ready!

materials

Knowing what types of rocking chairs are, and choosing the easiest option for your own production, it remains to consider possible materials for use. Beginners are advised to stop at lumber - it is easier to work with them, and everyone can find the necessary carpentry tools.

Modern models of rocking chairs differ in execution in terms of materials. Possible options:

wood is the most common material used in the form of lumber and raw wood. Such furniture always looks fashionable and rich. In addition, it is strong and durable;

plywood - easy to work with, as it can take any shape. But such chairs are undesirable for outdoor placement. This option is budgetary - does not require large financial investments

Only to create reliable and durable furniture is it important to select thicker plywood sheets;

metal - is used for the production of skids or the entire structure. Metal rocking chairs are extremely durable and can last for decades.

It is recommended to take profile pipes - they are easy to process. The only negative of the finished product is the severity;

rattan or wicker - allow you to create truly exclusive products, but require certain skills and strength, due to the complex technology of weaving.As a starting material, willow and vine or any woody vines are possible. Rattan refers to the bark of the rattan palm tree. The advantage of such chairs is to create depreciation for the person in it.

In working with wood, preference is given to conifers, as they have a low density. They are also easier to carpentry.

Upholstery is chosen practical. It can be flock, tapestry or jacquard. Natural fabrics are preferred, but they strongly absorb dust. In this sense, it is more reasonable to dwell on the skin - soft and resistant to negative external factors. If it is expensive, then eco-leather will serve as an alternative - no less high-quality material.

cutting

Before starting work, it is recommended to watch a video where you can see the details of the manufacture of the chair

After studying the drawings, transfer them to graph paper. Having cut out the patterns, mark the plywood. It is necessary to arrange the elements on the surface of the sheets so that the material is used sparingly.

The material should be cut only with a suitable tool:

- for sheets less than 15 mm thick, use a jigsaw;

- more than 15 mm - a circular saw.

Sheets are cut, taking into account the direction of the fibers - always along. Otherwise, the edges of the parts will delaminate. If it is necessary to make a transverse cut, notches are first applied to the surface of the plywood using a bench knife.

You need to apply the cutting tool not directly to the marking line, but going beyond half a millimeter. Then, after grinding the ends of the plywood, the parts will retain the desired size.

Cutting plywood. Chair detail

Cutting plywood. Chair detail

The edges of each part are treated with medium-grain sandpaper. You should not skip this step, even if the cuts look smooth in appearance. There may be small, imperceptible particles of wood on the edges, which, during the operation of the chair, can stick into the skin. The surface of the plywood is sanded with fine-grained sandpaper.

If, according to the selected sketch, the parts should have rounded edges, they are processed with a file or special tools: a drill with a milling nozzle, a grinder.

Focusing on the drawings, they mark places for fasteners on the prepared elements. Drill holes with a suitable drill bit. It must enter the material strictly vertically. If this condition could not be met, it is better to drill another hole, retreating some distance from the originally intended point.

After the rocking parts are ready, they are coated with a primer. You should choose antiseptic compounds that increase the resistance of wood to moisture. They wait until it is completely dry, after which they begin to assemble the chair.

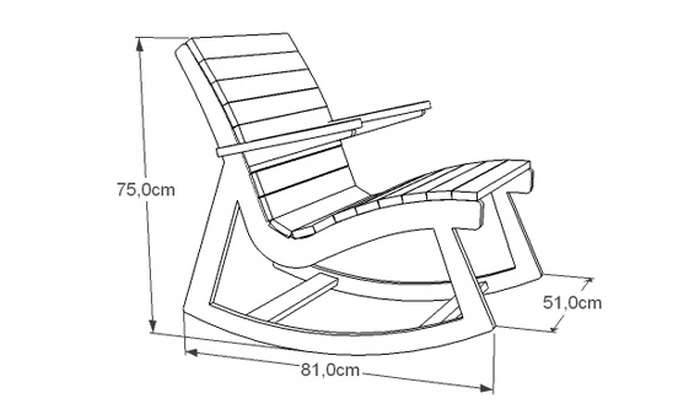

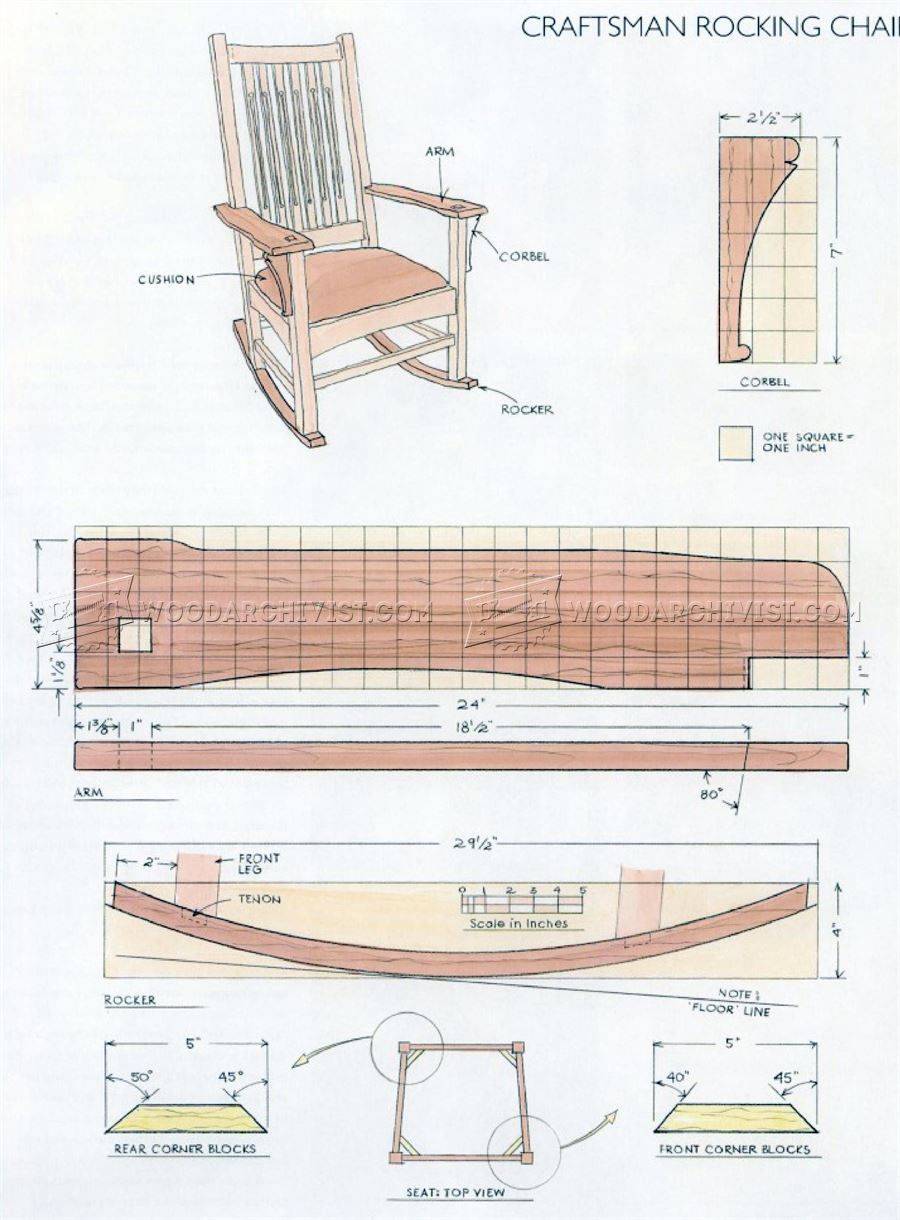

How to make a rocking chair with your own hands: the most affordable options

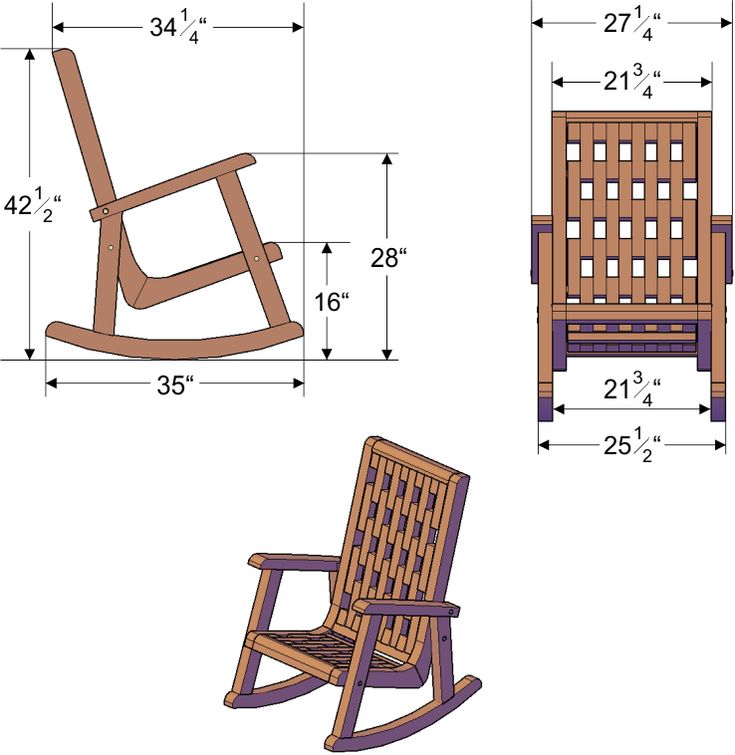

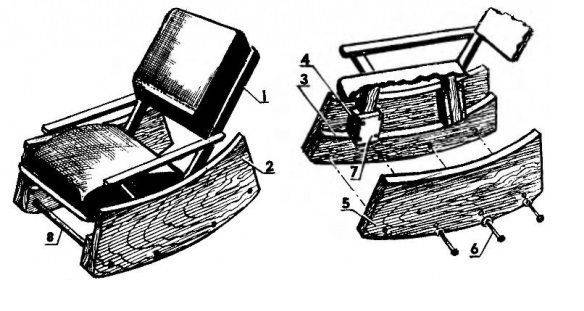

The main part of the design of the rocking chair is two runners (skis) that have an arched shape, due to which, in fact, the chair can rock. These skids can be short or long. In chairs with long skids, the depth and amplitude of rolling are quite large, a person moves from a sitting position to a semi-lying position. Rocking chairs with short skids provide a calm and sedate swing, which is why they are especially popular with older people.

Short runners, and you sway measuredly and calmly away from all worries

To make a simple rocking chair, you do not even need a detailed drawing of a rocking chair. It is enough to take a ready-made, for example old, chair (1) with wooden legs. Let's make two supports (2), for this we make two elements from the bars, which will have the same curved base. We also cut out the cheeks (3), which we will use later as the bottom for the legs of the chair.

Scheme of a simple rocking chair

For each leg of the original chair, we cut out two restrictive bars (4) - a total of eight. We nail the appropriate limiters at the required distance for each support for all legs. At both supports, we screw in three (6) furniture bolts from the outside - this will give the chair stability and ensure safe rocking. Let's prepare a closing plate (7) for each restrictive bar. Having inserted the legs of the chair into the prepared grooves with limiters, we cover the limiters with closing plates and fix them with a perforator. For convenience, a footrest (8) can be added to the front.

Drawing diagram of a rocking chair

Similarly, you can upgrade a chair with metal legs by making special metal mounting loops.

Sample rocking chair from a regular chair and homemade runners

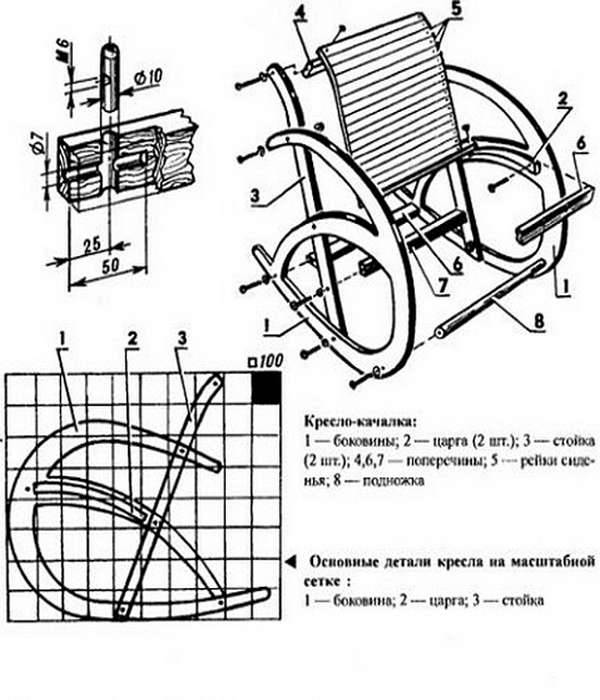

Plywood rocking chair

For plastic modeling, plywood is the most favorable material. Using a jigsaw, you can get a design that will greatly simplify the process, because structurally it combines the two most important (and most difficult to manufacture) elements of a rocking chair - skids and sidewalls. In addition, the absence of joints significantly increases the strength of the structure.

For the manufacture we need:

- jigsaw

- screwdriver

- plywood - a sheet with a thickness of at least 15 mm

- oak (pine) slats with a section of 10x50 mm - about 20-35 pieces, the length depends on the manufacturing option - a single or double chair. For a single chair, the rail length is 1200 mm.

- timber (pine, oak is better) - 30x50 mm, 3 pcs, equal in length to the rails

- self-tapping screws

We draw a pattern on graph paper, transfer the pattern to plywood and cut out the sidewall with an electric jigsaw.

After that, we sand all the details and remove small chamfers

If the rocking chair is intended for summer cottages, the ends will require special attention - they require maximum protection against dampness. Therefore, the ends of all parts are impregnated with hot drying oil, after which the wood fibers are slightly flattened with a hammer - so moisture will be absorbed much less

Before starting the general assembly, the processing-varnishing procedure for the ends must be carried out twice.

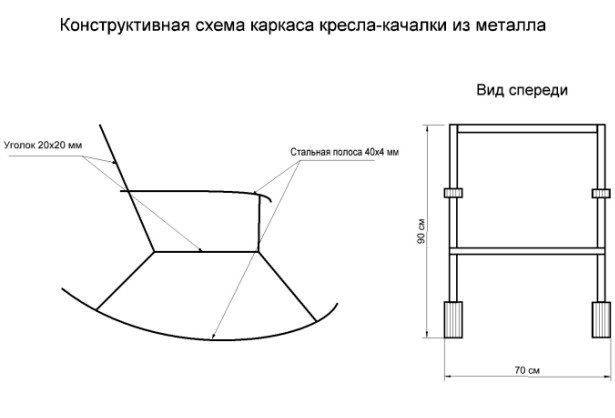

We mark the holes for the connecting bars (tsargs) at the foot, middle part and at the head. To achieve maximum accuracy, after preliminary marking, the sidewalls are aligned and a hole is drilled. The drawers are fixed with euro screws and additionally fixed with wood glue. After that, we evenly fix the rails on the already assembled frame with self-tapping screws. After the assembly is completed, it is necessary to putty the holes above the screws, once again sand all the details with fine sandpaper, treat with an antiseptic, cover with stain (if you like dark wood tones) and cover the resulting chair with waterproof varnish.

If it is possible to use a grinder and a welding machine, you can assemble a metal frame. To do this, you need a steel corner (20x20x3 mm) and a steel strip (4 mm thick, 40 mm wide).After assembly, the frame is painted, after which holes for self-tapping screws are drilled along the entire length of the seat and backrest, with which wooden facing strips will be attached.