- Incorrect air supply

- Economical gas boiler with high efficiency

- How to calculate the efficiency of a heating boiler

- How to increase efficiency

- How to download?

- Team game

- How to calculate the efficiency of a heating boiler

- How to increase the efficiency (efficiency) of a solid fuel boiler

- What is efficiency - coefficient of performance

- How to increase the efficiency of a solid fuel boiler

- Ways to increase efficiency

- What's wrong with too much power?

- The cyclicity of the gas unit and its consequences

- Boiler Efficiency Improvement Methods

- Rules for the operation of boiler devices, compliance with which affects the value of efficiency

- What is the efficiency of heating devices

- Step-by-step instructions for building a solid fuel boiler

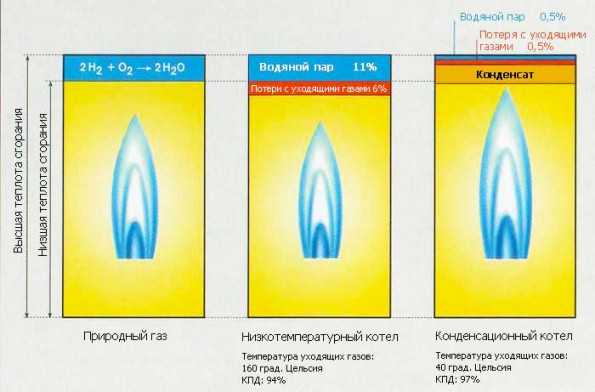

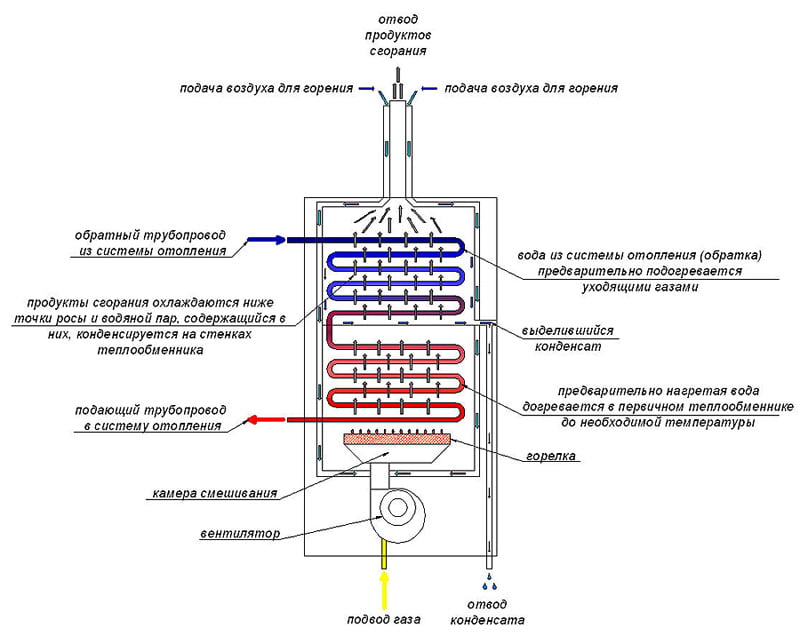

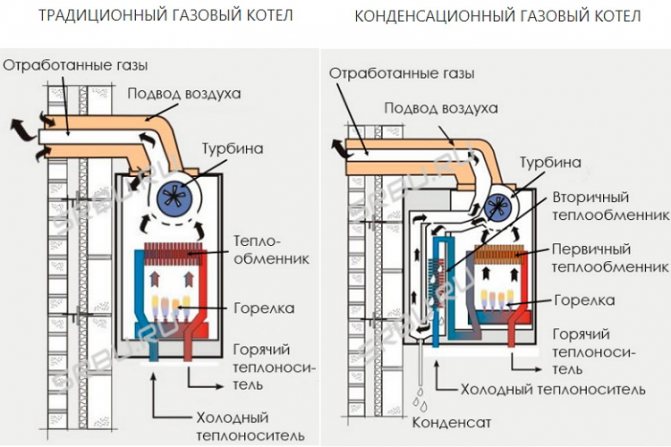

- How does a condensing type heat generator work?

- Calculation of efficiency taking into account various factors

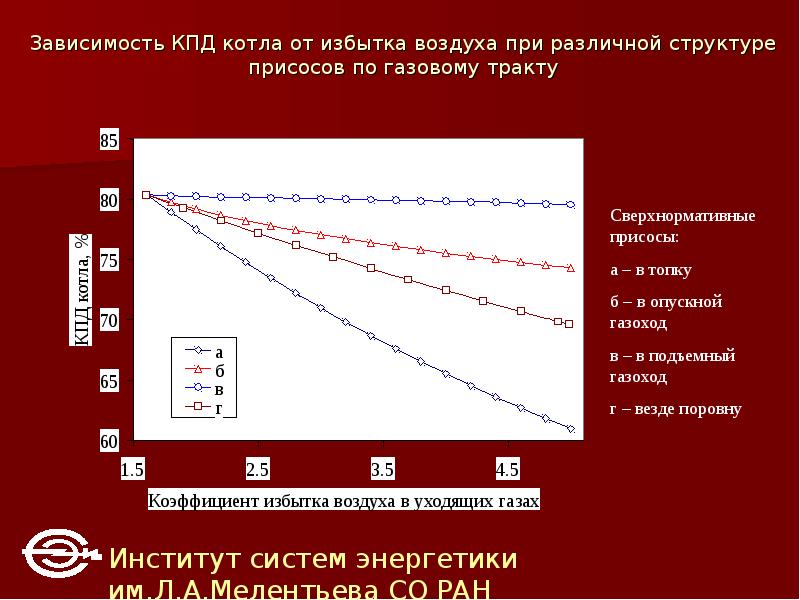

Incorrect air supply

The work of the flame depends on how much oxygen enters the furnace. In order for the fuel to burn normally and give off the maximum amount of heat, it needs a strictly defined amount of air - no more, no less. If there is little air, the hydrocarbons released during combustion will be poorly oxidized, which means less heat will be released.If a lot of air enters, and, as a rule, it enters cooled, the temperature of the emitted gases decreases and they do not have time to burn out (again, settling soot on the pipes) and thereby release useful heat. It is worth noting that the air contains moisture, the evaporation of which also consumes heat (instead of heating the house).

Most solid fuel boilers on the market work according to the following principle. They have a thermostat that regulates the temperature of the water circulating through the heating system of the house to heat it. If the water gets too hot, the thermostat reduces the air supply to the boiler (this is how the power of the solid fuel boiler is regulated). It turns out that at the moment when the fuel flared up and the efficiency with the power of the solid fuel boiler became maximum, which means that the flame began to need more oxygen - the thermostat artificially reduces the efficiency by limiting the air supply.

After the temperature has dropped, the thermostat starts to supply air again. But by that time, the fuel is already burning out and it does not need so much oxygen. The heating efficiency is again reduced due to the cooling of the emitted gases, as mentioned earlier.

It turns out that the principle of operation of most solid fuel boilers is absolutely contrary to the concept of high efficiency.

Economical gas boiler with high efficiency

As practice shows, and also proves the technical documentation, boilers of foreign manufacturers have a higher efficiency. European organizations are focusing their efforts on improving energy-saving technologies. Foreign gas boilers are characterized by high performance, because their design implies:

- modulating burner. Boilers of popular companies are distinguished by two-stage or modulating burners, which boast automatic adaptation to the actual operating parameters of the heating system. There is a minimum amount of residues at the exit.

- Liquid heating. A good boiler is equipment that heats the coolant to a maximum of 70 ° C, while the exhaust gases are heated to no more than 110 ° C, this gives the best heat output. However, there are some disadvantages with low-temperature heating of the liquid, such as low thrust and active formation of condensate. Heat exchangers in high-performance gas units are made of high-quality stainless steel and have a special condenser unit, which is necessary for extracting energy from condensate.

- Heating of the supply gas and air that enters the burner. Closed-type units are connected to a coaxial chimney. The air circulates into the combustion chamber through the outer cavity of the pipe with two cavities, before which it is heated, which helps to reduce the required heat costs by a couple of percent. Burner devices with preliminary production of a gas-air mixture also heat the gas before it is fed to the burner.

- Installation of an exhaust gas recirculation system. In this case, the smoke does not immediately enter the combustion chamber, but circulates through the chimney, mixes with clean air and ends up back in the burner.

The highest efficiency is observed when heating the formation of condensate or "dew point". Units operating at low temperature heating are called condensing units.Their difference is in the small amount of gas consumed and high thermal efficiency, which is very visible when connected to equipment from gas cylinders and a gas tank.

There are many brands of condensing units, the most popular of which are only a few. You can choose from the following brands of gas boilers with high efficiency for the home:

- Wissman;

- Buderus;

- Vaillant;

- Baksi;

- De Dietrich.

How to calculate the efficiency of a heating boiler

There are several ways to calculate values. In European countries, it is customary to calculate the efficiency of a heating boiler based on the temperature of the flue gases (direct balance method), that is, knowing the difference between the ambient temperature and the actual temperature of the flue gases through the chimney. The formula is pretty simple:

ηbr = (Qir/Q1) 100%, where

- ηbr (read "this") - the efficiency of the boiler "gross";

- Qir(MJ/kg) is the total amount of heat released during fuel combustion;

- Q1 (MJ/kg) - the amount of heat that could be accumulated, i.e. use for home heating.

The direct balance method does not take into account the heat losses of the boiler itself, fuel underburning, deviations in operation and other features, therefore, a fundamentally different, more accurate method of calculation was invented - the “reverse balance method”. The equation used is:

ηbr = 100 – (q2 + q3 + q4 + q5 + q6), where

- q2 - heat loss with outgoing gases;

- q3 - heat loss due to chemical underburning of combustible gases (applicable to gas boilers);

- q4 - loss of thermal energy with mechanical underburning;

- q5 - heat loss from external cooling (through the heat exchanger and housing);

- q6 - heat loss with the physical heat of slag removed from the furnace.

Efficiency "net" of the heating boiler according to the inverse balance method:

ηnet = ηbr - Qs.n, where

Qs.n - the total consumption of heat and electricity for own needs in% terms.

How to increase efficiency

It is possible to create the correct operating conditions for a gas boiler and thereby increase the efficiency without calling a specialist, that is, with your own hands. What do I need to do?

- Adjust the blower damper. This can be done experimentally by finding at what position the coolant temperature will be the highest. Carry out the control using a thermometer installed in the boiler body.

- Be sure to ensure that the pipes of the heating system do not overgrow from the inside, so that scale and mud deposits do not form on them. With plastic pipes today it has become easier, their quality is known. And yet, experts recommend periodically blowing the heating system.

- Monitor the quality of the chimney. It should not be allowed to clog and stick to the walls of soot. All this leads to a narrowing of the cross section of the outlet pipe and a decrease in the boiler draft.

- A prerequisite is cleaning the combustion chamber. Of course, gas does not smoke much like wood or coal, but it is worth washing the firebox at least once every three years, cleaning it of soot.

- Experts recommend reducing the draft of the chimney in the coldest time of the year. To do this, you can use a special device - a thrust limiter. It is installed on the uppermost edge of the chimney and regulates the cross section of the pipe itself.

- Reduce chemical heat loss. There are two options here in order to achieve the optimal value: install a draft limiter (it was already mentioned above) and immediately after installing the gas boiler, properly configure the equipment. We recommend that you entrust this to a specialist.

- You can install a turbulator.These are special plates that are installed between the firebox and the heat exchanger. They increase the area of thermal energy extraction.

Timely cleaning of the units

These are the reasons, by eliminating which you can count on improving the efficiency of boiler equipment. Of course, there are many such reasons, but these are considered the main ones that answer the question: how to increase the efficiency of a gas boiler.

Don't forget to rate the article.

What to do to increase personal efficiency in World of Tanks. It is not very easy to achieve good statistics in the game, but the task is quite feasible.

It must be said right away that increasing (raising) the efficiency will take time and this is the most valuable thing that will have to be sacrificed in pursuit of a beautiful “status”.

An old account with more than 20-25 thousand fights will be extremely difficult to raise, but it is also possible.

The essence of the method is that you will have to imagine for a while that you are starting everything from scratch. Only from the real creation of a “twink”, you will have to take those tanks for which the statistics are depressing. Including sold tanks, you will also need to buy them back and take them out of the hangar for “pumping”. To see which tanks you have have the most terrible statistics, you can use the notorious "deer gauge" mod.

Having equipped tanks with low efficiency to the maximum with additional equipment, it will take from 30 to 300 battles to play like a typical “extra”. Of course, it depends on the level and degree of drawdown of that same efficiency of a single piece of equipment. The effect of pumping indicators for individual tanks will smoothly flow into an increase in overall efficiency.

How to download?

Pretty simple answer.If there is no longer a small experience in the game, then you will have to endure the insults of the allies. First of all, we get the frags of the allies. In the truest sense of the word, we wait and deliver the final blow.

Shot from afar. It will not be superfluous to develop the skill of long-range combat, even on heavy and light tanks

It is important to shoot at least 100% damage from your XP. Accordingly, we are actively learning to fight from the bushes, if we did not know how before. We work comprehensively on frags and fill the maximum "damage" per battle

We do not go out for frontal attacks and keep our distance from the main collisions. The allies will be indignant at such a game, but without this the life of an extra is not complete

We work comprehensively on frags and fill the maximum "damage" for the battle. We do not go out for frontal attacks and keep our distance from the main collisions. The allies will be indignant at such a game, but without this the life of an extra is not complete.

Team game

Another method that can be quite effective is a team game. Use the game as a platoon, having a couple of experienced players as friends, you can very quickly drag the lagging behind to the desired efficiency level with platoon battles.

How to calculate the efficiency of a heating boiler

There are several ways to calculate values. In European countries, it is customary to calculate the efficiency of a heating boiler based on the temperature of the flue gases (direct balance method), that is, knowing the difference between the ambient temperature and the actual temperature of the flue gases through the chimney. The formula is pretty simple:

ηbr = (Q1/Qir) 100%, where

- ηbr (read "this") - the efficiency of the boiler "gross";

- Q1 (MJ/kg) - the amount of heat that could be accumulated, i.e. use for home heating.

- Qir(MJ/kg) is the total amount of heat released during fuel combustion;

The direct balance method does not take into account the heat losses of the boiler itself, fuel underburning, deviations in operation and other features, therefore, a fundamentally different, more accurate method of calculation was invented - the “reverse balance method”. The equation used is:

ηbr = 100 – (q2 + q3 + q4 + q5 + q6), where

- q2 - heat loss with outgoing gases;

- q3 - heat loss due to chemical underburning of combustible gases (applicable to gas boilers);

- q4 - loss of thermal energy with mechanical underburning;

- q5 - heat loss from external cooling (through the heat exchanger and housing);

- q6 - heat loss with the physical heat of slag removed from the furnace.

Efficiency "net" of the heating boiler according to the inverse balance method:

ηnet = ηbr - Qs.n, where

Qs.n - the total consumption of heat and electricity for own needs in% terms.

How to increase the efficiency (efficiency) of a solid fuel boiler

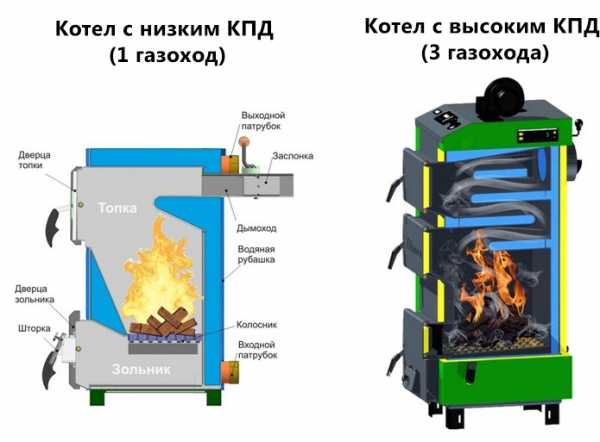

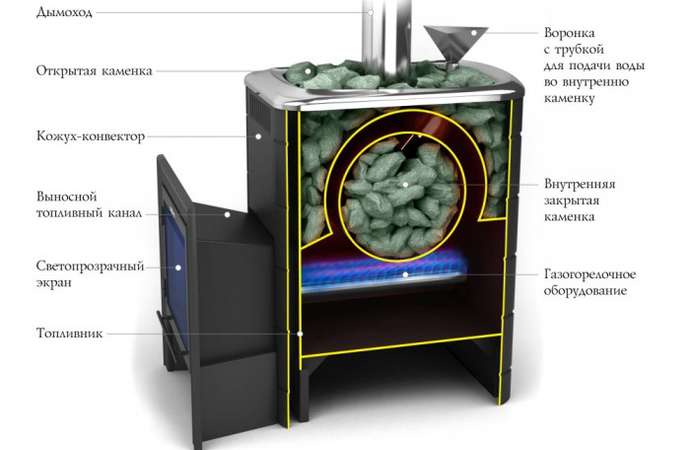

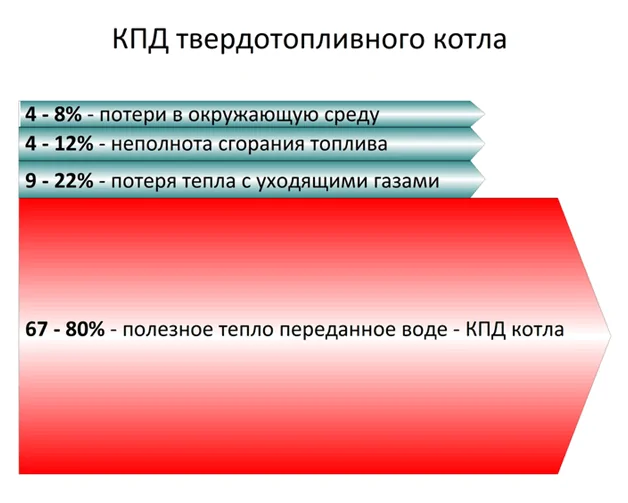

Solid fuel boilers (hereinafter referred to as SPH) have a sufficient percentage of efficiency compared to other heating units (gas boilers, for example) to be competitive and lead the market. The latest TTH models are equipped with the latest automation systems to optimize performance.

Solid fuel boilers operate on the principle of stove heating: heat is transferred to the coolant (water) by generating energy during the combustion of coal, firewood, pellets in the furnace. Useful coefficient action or efficiency each boiler has its own and depends on many conditions: the choice of fuel, operating rules, installation quality, etc. Let us consider in more detail what is the efficiency of heating appliances, and how to increase this coefficient for solid fuel boilers.

What is efficiency - coefficient of performance

For the correct selection of the boiler power relative to the square of the room to be heated, we recommend paying attention to the efficiency of the unit, its efficiency, especially when it comes to solid fuel boilers. The coefficient of performance or efficiency is an indicator that is calculated based on the ratio between the energy expended (thermal - when products are burned in the furnace) and useful heat - which enters the heating system for transmission to the room

After calculating a simple formula, we get the percentage of efficiency

The coefficient of performance or efficiency is an indicator that is calculated based on the ratio between the energy expended (thermal - when products are burned in the furnace) and useful heat - which enters the heating system for transmission to the room. After calculating a simple formula, we get the percentage of efficiency.

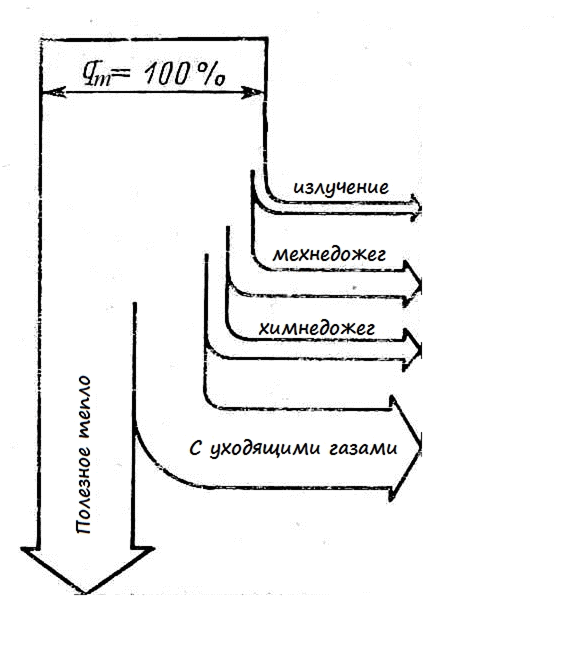

q1 + q2 + q3 + q4 + q5 = 100%

Deciphering:

q1 is an indicator of the heat that was transferred to the coolant - water.

q2 - physical underburning - heat loss with exhaust gases.

q3 - chemical underburning - heat loss during incomplete combustion of fuel.

q4 - heat loss during heat dissipation.

The percentage of efficiency increases when the boiler is optimized.

The key point that affects the efficiency indicator is how well the solid fuel boiler was installed. In addition, the choice of fuel (coal, firewood, pellets), the presence of ventilation, and operating conditions are taken into account.

Let's take an example.

If the passport of the purchased boiler indicates an efficiency of 90%, it should be noted that this is an indicator that can be achieved if the unit operates in nominal mode, high quality fuel and low ash content is burned.With other factors during operation, the efficiency of a solid fuel boiler can be reduced to 60% or 70%.

How to get closer to the ideal and squeeze out the heat as much as possible during the operation of the heat pump?

How to increase the efficiency of a solid fuel boiler

Consider some recommendations on how to make a solid fuel boiler work at its maximum, work economically, consuming a minimum of wood, coal or pellets.

- Load only dried fuel into the fuel pump. If you burn wet wood or coal, part of the energy is spent on drying them.

- Do not use fuel with a large amount of debris, impurities, dust, because these inclusions will quickly clog both the heat exchange channels of the boiler, and the grate and chimney.

- Solid fuel boilers require mandatory periodic cleaning of the chimney and internal surfaces of the boiler, because any heat pump becomes clogged incomparably more than another gas boiler.

- Ensure proper draft in the chimney channel: it should not be too strong, but not too weak. If we exclude the moment of correct design of the chimney, then for this there is a throttle valve on the chimney or on the TPH, which regulates the air draft in the chimney - it should be set to the correct value. In order to load a solid fuel boiler once or twice a day and ensure the efficient operation of heating in general, it is necessary to design a buffer tank (heat accumulator).

- Purchase a solid fuel boiler only with a draft fan that can accurately regulate the combustion process in the boiler and control the temperature of the flue gases.

We will select equipment, design and install a solid fuel boiler room for your premises in order to save heat and money as much as possible.

Ways to increase efficiency

In order for the heating system to work with minimal heat loss, you should familiarize yourself with effective methods, how to improve the efficiency of a gas boiler. To do this, it is necessary to exclude all types of heat loss as much as possible.

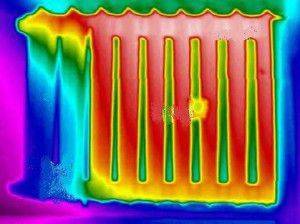

- To reduce the percentage of physical underburning, you should monitor the condition and cleanliness of the flame tubes and the water circuit. Soot forms on the pipeline, and scale builds up on the circuit, so these elements of the heating system require regular cleaning.

- There should be no excess air in the gas boiler, since heat, which could be used to heat the coolant, also goes into the chimney with it. This problem can be solved by installing a draft limiter on the chimney.

How gases circulate in the boiler

- Throttle adjustment. This can be done using a thermometer installed in the boiler. You just need to put the damper in such a position that at the same time the maximum temperature of the coolant is reached.

- Ensure that normal traction is maintained. It decreases as a result of the narrowing of the cross section of the chimney. You can avoid this if you regularly clean the outlet pipe, because soot sticks to its walls.

- It is necessary to clean the combustion chamber regularly, as soot forms on the surface of its walls, which increases fuel consumption.

Installation of a coaxial chimney

If you are looking for options on how to increase the efficiency of a gas boiler, pay attention to which chimney is installed. Traditional discharge pipes have a number of disadvantages, the main of which is the dependence on weather conditions.An alternative to a conventional chimney can be a coaxial chimney, which has the following advantages:

An alternative to a conventional chimney can be a coaxial chimney, which has the following advantages:

- significantly increases the efficiency of a gas boiler;

- resistant to high temperatures;

- can be made in different versions;

- allows you to save fuel;

- ensures long-term temperature maintenance in the room.

coaxial chimney

The device of a coaxial chimney does not require much effort. The design consists of two exhaust pipes of different diameters, exhaust gases are transported through one, oxygen-saturated air through the other.

If you do not have experience with heating equipment, but there is a need to resolve the issue of how to improve the efficiency of a gas boiler, contact the specialists. They will perform work at the highest level, ensuring the most efficient functioning of the heating system of your home.

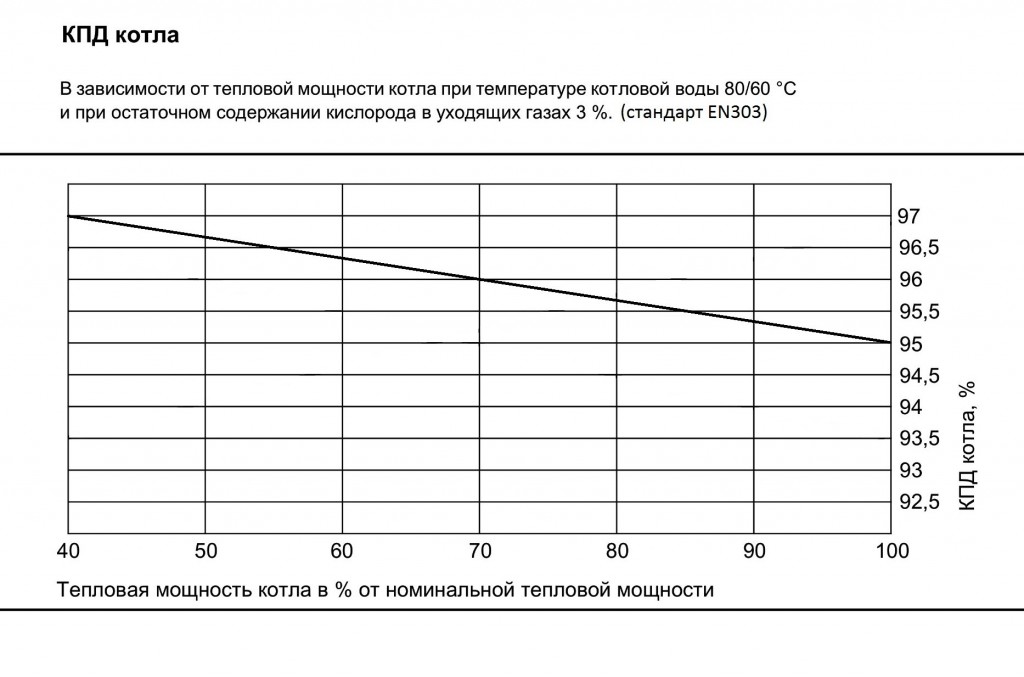

What's wrong with too much power?

Consider setting the power of a gas boiler using the Protherm Gepard 23 MTV double-circuit device as an example. This model is analogous to the Protherm Panther unit (Panther). The same manufacturer that produces Protherm gas devices manufactures Vaillant brand boilers in another production. Their price is an order of magnitude more expensive, since they use better components. In terms of design and settings, Vaillant gas appliances are very similar to Protherm models.

The operating instructions say that the useful thermal power of the Protherm Gepard 23 MTV boiler is adjustable from the maximum - 23.3 kW to the minimum - 8.5 kW. In production, the units are set to a power of 15 kW.

It is good if the heating system to which the gas boiler is connected has a power within the capabilities of the burner, in our case, from 8.5 to 23.3 kW. But what if the existing radiators require less performance?

…

For example, let's take an apartment of 50 m². For its heating there are radiators with a thermal power of 4 kW. The installers installed the gas boiler, but did not set the right power. A 4 kW heating system will not be able to accept the installed unit capacity of 15 kW. A large difference between the produced and the required indicator makes it impossible to automatically adjust the boiler. Then you need to adjust the device with your own hands.

Note! Experts categorically do not recommend installing a gas boiler, the power of which significantly exceeds the required one. This leads to the cyclical operation of the unit and its rapid failure.

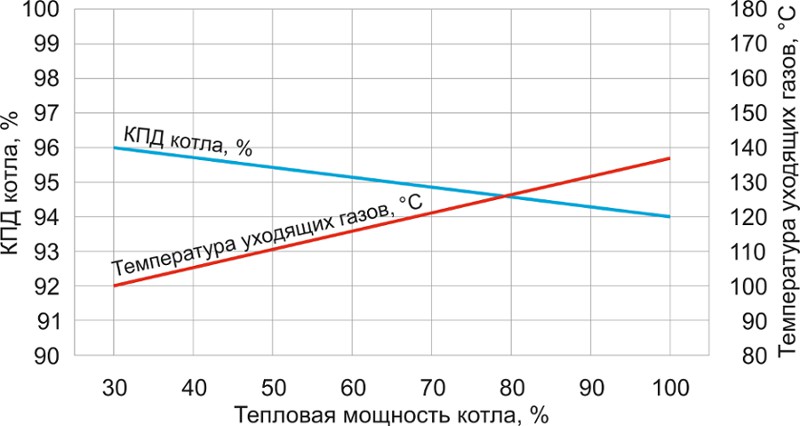

The characteristics of the Protherm Gepard 23 MTV gas boiler indicate that the efficiency of the device when operating at full thermal power is 93.2%, and at the minimum - 79.4%. If the unit operates at a capacity of 4 kW, then its efficiency will decrease even more. It turns out that almost a quarter of the thermal energy will "fly out into the pipe."

The cyclicity of the gas unit and its consequences

The cyclicity or "clocking" of the gas boiler implies that the burner, after turning on, quickly turns off when the liquid reaches the set temperature in the pipe at the outlet of the unit. But the batteries do not have time to warm up. After a short period, the circulation pump drives cold water from the heating system into the circuit of the unit, and the burner turns on again.

…

The difficulty also lies in the fact that heating pipes of low power have a smaller diameter and higher hydraulic resistance, respectively, the coolant flows in them more slowly. If the liquid in the heat exchanger is heated with high power, it will reach the set temperature very quickly and the burner will turn off. At the same time, the rest of the mass of water that did not have time to reach the burner will remain cold.

Automation without human intervention will not be able to respond to the situation and adjust the optimal power of the device.

Note! With the correct settings of the heating system, the temperature difference between the inlet and return should not exceed 15ºC. The cycling of a gas boiler significantly reduces the life of the unit and increases fuel consumption

It is known that the nodes suffer the most wear at the moment of switching on. Also, during ignition, the maximum portion of gas is supplied to the burner, most of which escapes into the pipe. Frequent re-ignition of the burner further increases fuel consumption and reduces efficiency. To avoid this, it is necessary to adjust the power of the unit, that is, to equalize the performance of the gas boiler and the heating system

The cycling of a gas boiler significantly reduces the life of the unit and increases fuel consumption. It is known that the nodes suffer the most wear at the moment of switching on. Also, during ignition, the maximum portion of gas is supplied to the burner, most of which escapes into the pipe. Frequent re-ignition of the burner further increases fuel consumption and reduces efficiency. To avoid this, it is necessary to adjust the power of the unit, that is, to equalize the performance of the gas boiler and the heating system.

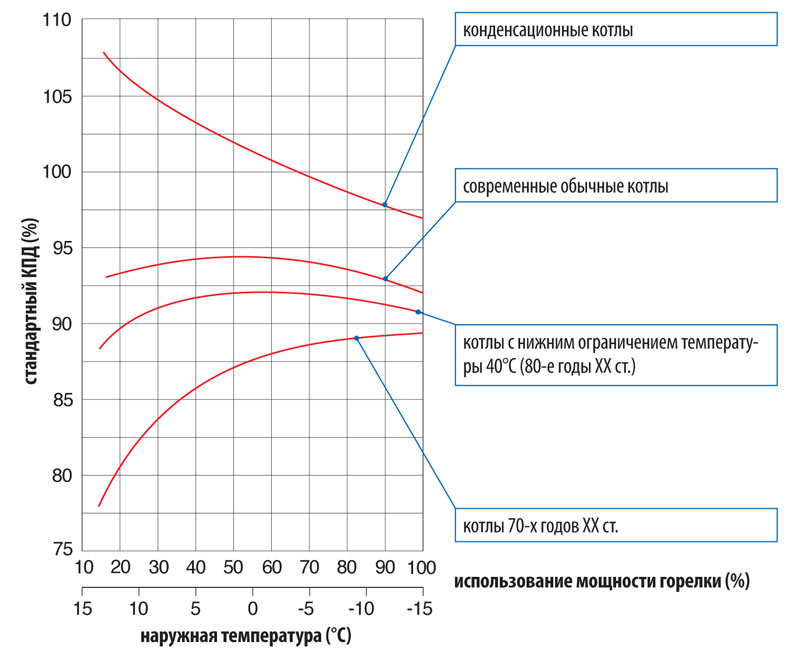

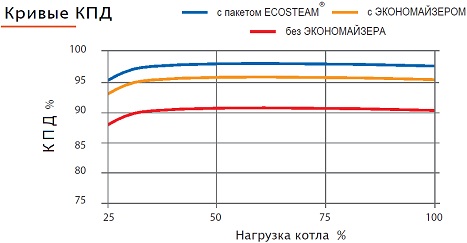

Boiler Efficiency Improvement Methods

At the first stage, you need to choose the right type of heating equipment. The determining indicators for the organization of heating with high efficiency are the type of fuel used and the power of the boiler. Gas-powered models have proven themselves best.

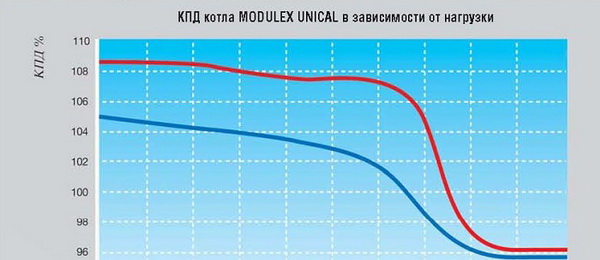

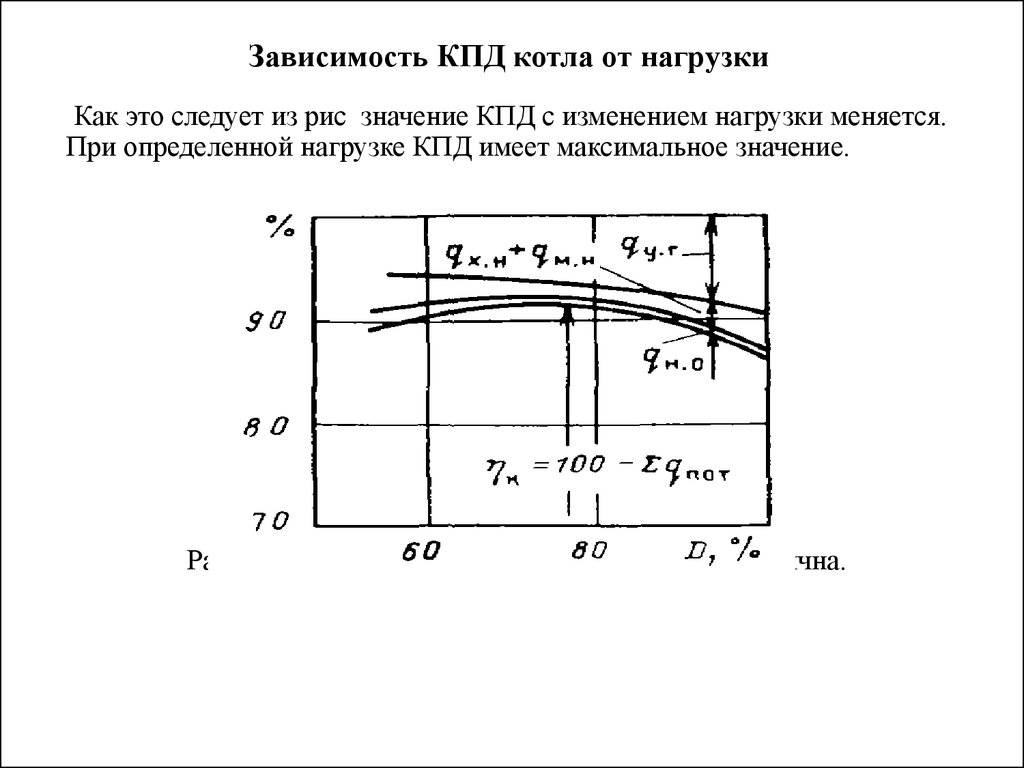

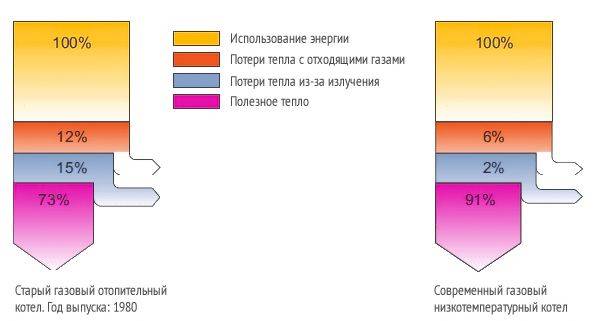

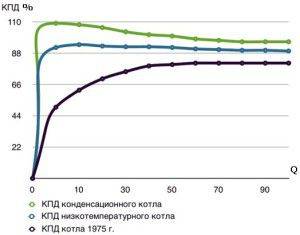

As can be seen from the graph data, there is no significant difference when the boiler is operating in normal mode. The difference in efficiency for gas heating boilers occurs only at the time of start-up until the required temperature regime is reached (50-70 ° C). Then there is a stabilization of the work and the performance indicator. But to improve the latter, you can take the following steps:

- The difference between the calculated and actual power of the boiler should not be more than 15%. Exceeding the value will lead to incomplete combustion of gases, which will further increase fuel consumption;

- Use of the condensation factor. This will slightly increase the efficiency of the entire heating system. However, the cost of condensing boilers will differ from traditional ones by 35-40%;

- Reducing heat loss through the chimney. The increase in the efficiency of the heating battery directly depends on this factor.

By fulfilling these conditions, it is possible to increase the efficiency of heating devices by 1-1.5 percent. But it is best to initially purchase a suitable cat model that best matches the parameters of the entire system.

Rules for the operation of boiler devices, compliance with which affects the value of efficiency

Any type of heating unit has its own optimal load parameters, which should be as useful as possible from a technological and economic point of view.The process of operation of solid fuel boilers is designed in such a way that most of the time the equipment works in the optimal mode. To ensure such work allows compliance with the rules for the operation of solid fuel heating equipment. In this case, you must adhere to and follow the following points:

- it is necessary to observe acceptable modes of blowing and operation of the hood;

- constant control over the intensity of combustion and completeness of fuel combustion;

- control the amount of carryover and failure;

- assessment of the state of surfaces heated during fuel combustion;

- regular cleaning of the boiler.

The listed points are the necessary minimum that must be adhered to during the operation of boiler equipment during the heating season. Compliance with simple and understandable rules will allow you to obtain the efficiency of an autonomous boiler declared in the characteristics,.

We can say that every little thing, every element of the design of the heating device affects the value of the efficiency. A properly designed chimney and ventilation system provide optimal air flow into the combustion chamber, which significantly affects the quality of combustion of the fuel product. The work of ventilation is estimated by the value of the coefficient of excess air. An excessive increase in the volume of incoming air leads to excessive fuel consumption. Heat escapes more intensively through the pipe along with combustion products. With a decrease in the coefficient, the operation of the boilers deteriorates significantly, and there is a high probability of the occurrence of oxygen-limited zones in the furnace. In such a situation, soot begins to form and accumulate in large quantities in the furnace.

The intensity and quality of combustion in solid fuel boilers require constant monitoring. The loading of the combustion chamber must be carried out evenly, avoiding focal fires.

During combustion, it is important to prevent failures of the fuel resource, otherwise you will have to face significant mechanical losses (underburning) of the fuel. If you do not control the position of the fuel in the furnace, large fragments of coal or firewood that have fallen into the ash box can lead to unauthorized ignition of the remains of the fuel mass products. Soot and tar accumulated on the surface of the heat exchanger reduce the degree of heating of the heat exchanger

As a result of all these violations of operating conditions, the useful amount of thermal energy required for the normal operation of the heating system decreases. As a result, we can talk about a sharp decrease in the efficiency of heating boilers

Soot and tar accumulated on the surface of the heat exchanger reduce the degree of heating of the heat exchanger. As a result of all these violations of operating conditions, the useful amount of thermal energy required for the normal operation of the heating system decreases. As a result, we can talk about a sharp decrease in the efficiency of heating boilers.

What is the efficiency of heating devices

For any heating unit, whose task is to heat the internal space of residential buildings and structures for various purposes, an important component was, is and remains the efficiency of work. The parameter that determines the efficiency of solid fuel boilers is the efficiency factor.Efficiency shows the ratio of the spent heat energy produced by the boiler in the process of burning solid fuel to the useful heat that is supplied to the entire heating system.

This ratio is expressed as a percentage. The better the boiler works, the higher the interest. Among modern solid fuel boilers there are models with high efficiency, high-tech, efficient and economical units.

The efficiency of heating equipment is highly dependent on what type of fuel is used and what are the design features of the device.

For example: when burning coal, firewood or pellets, different amounts of thermal energy are released. In many ways, the efficiency depends on the technology of fuel combustion in the combustion chamber and the type of heating system. In other words, each type of heating devices (traditional solid fuel boilers, long-burning units, pellet boilers and devices operating due to pyrolysis), has its own technological design features that affect the efficiency parameters.

The operating conditions and the quality of ventilation also affect the efficiency of the boilers. Poor ventilation causes a lack of air necessary for the high intensity of the combustion process of the fuel mass. The condition of the chimney affects not only the level of comfort in the interior, but also the efficiency of heating equipment, the performance of the entire heating system.

The accompanying documentation for the heating boiler must have the equipment efficiency declared by the manufacturer. Compliance with the real indicators of the declared information is achieved due to the correct installation of the device, strapping and subsequent operation.

Step-by-step instructions for building a solid fuel boiler

So, the whole process of how to make a boiler with your own hands according to the drawings can be divided into several successive stages:

- Using a grinder, you need to cut blanks from pipes and profiles. The profiles will be racks, in which a gas cutter needs to cut round holes for joining with pipes. You will need to make 4 holes through a Ø50 mm pipe in the front pillars and the same number in the rear ones. In addition, more holes are needed for tie-in to the heating system. Sagging and soot as a result of cutting or welding must be cleaned with a grinder so that they do not interfere with the movement of water through the pipes.

- Next, the blanks are assembled into a single structure. You will have to work together - the welder will need an assistant to hold the tubes in a stationary position. To make it more convenient, you can put the racks with pipes on a flat surface and weld the front and back of the boiler.

- Now you need to ensure the supply and outflow of water from the boiler. The inlet and return pipes are welded to the finished frame, and the ends of the rectangular profiles are welded with pieces of metal 60 × 40 mm.

- Before mounting the heat exchanger, it is checked for leaks. To do this, it is installed vertically, the bottom hole is closed and filled with water. If there are no leaks at the seams, then you can work on.

- The boiler body is built of bricks and a heat exchanger is built into it, leaving a gap between them of at least 1 cm. The register must be installed in such a way as to create a lift towards the outgoing hot water. The level difference between the outlet and the front right upper corner of the heat exchanger must be at least 1 cm. This will improve the circulation of the coolant and eliminate air pockets.

- Brickwork should cover the heat exchanger from above by 3-4 cm.A cast-iron slab is laid on top of the masonry. The chimney is installed at the discretion of the owners - brick, metal, or taken out into a ready-made pipe.

How does a condensing type heat generator work?

This type of boiler is the younger brother of the conventional gas convection boiler. Conventional gas boilers, the principle of operation of which is similar, have an efficiency of approximately ~ 90%. And where are the other 10% lost? The answer is simpler than you can imagine - they fly out into the pipe. The products of gas combustion, which leave the system through the chimney, are heated to a temperature of about 150 - 250 ° C, therefore, the lost 10% heat the air outside.

The principle of operation of a condensing gas boiler is somewhat different. After working out the main combustion process and giving up most of the heat released during the process to the heat exchanger, the unit cools down the gaseous products of the combustion results to 50-60 ° C, that is, until the formation of water condensate begins. This is quite enough to significantly increase the efficiency, in a particular case, the amount of heat energy that is transferred to the coolant. But that's not all.

Upon reaching the dew point (temperature 56 ° C), vapor particles begin to collect into drops, in scientific terms - a condensation process occurs. At this time, additional energy is released from the condensed vapors, which was previously spent on the evaporation of water and in standard gas boilers goes into the pipe together with the vapor-gas mixture. The condensing boiler "takes" the heat that is released during the condensation of water vapor and transfers it to the coolant.

Manufacturers of condensate-type boilers are sure to draw the attention of their future customers to the fact that the efficiency of the device is much more than 100%.How does this happen? No laws of physics are violated in this case, just a different system of calculations is used in this situation.

When evaluating the efficiency of heating boilers, the part of the generated heat that is transferred to the coolant is taken into account. If we sum up the heat that the boiler transfers to the coolant at the time of its operation and the heat from deep cooling of the gaseous combustion products, the result will be 100%. But if we also add to these values the heat that is released during the condensation of steam, then the result will be about 108-110%.

If we consider the calculations from a physical point of view, then we can say that they are not entirely correct. Efficiency of more than 100% is a tricky move by marketers who use the inaccuracy of outdated calculations. And yet, gas heating condensing boilers, unlike a standard convector, “squeeze” almost everything out of fuel combustion. The advantages are more than obvious - less resource consumption and higher efficiency.

Calculation of efficiency taking into account various factors

The above formula is not entirely suitable for evaluating the efficiency of the equipment, since it is very difficult to accurately calculate the efficiency of the boiler, taking into account only two indicators. In practice, a different, more complete formula is used in the design process, since not all of the heat generated is used to heat the water in the heating circuit. A certain amount of heat is lost during the operation of the boiler.

A more accurate calculation of the boiler efficiency is made using the following formula:

ɳ=100-(q2+q3+q4+q5+q6), wherein

q2 - heat loss with outgoing combustible gases;

q3 - heat loss as a result of incomplete combustion of combustion products;

q4 - heat loss due to fuel underburning and ash precipitation;

q5 – losses caused by external cooling of the device;

q6 - heat loss together with slag removed from the furnace.