- Domestic boilers for diesel fuel

- Video - Diesel boilers

- Main varieties

- Design features of classic boilers

- Features of automation of heating equipment

- Oil powered device

- Oil burner

- The best pyrolysis solid fuel boilers

- Attack DP 25 Profi

- Buderus Logano S171-50W

- Trayan T15 2-CT

- Kiturami KF 35A

- Oil boilers and fuel

- Why choose universal boilers?

- How much is this pleasure?

- Why is it profitable for them to heat their homes?

- Should the boiler always be operated by a person?

- Is this device durable?

- How to switch the system to another type of fuel?

- Oil boiler

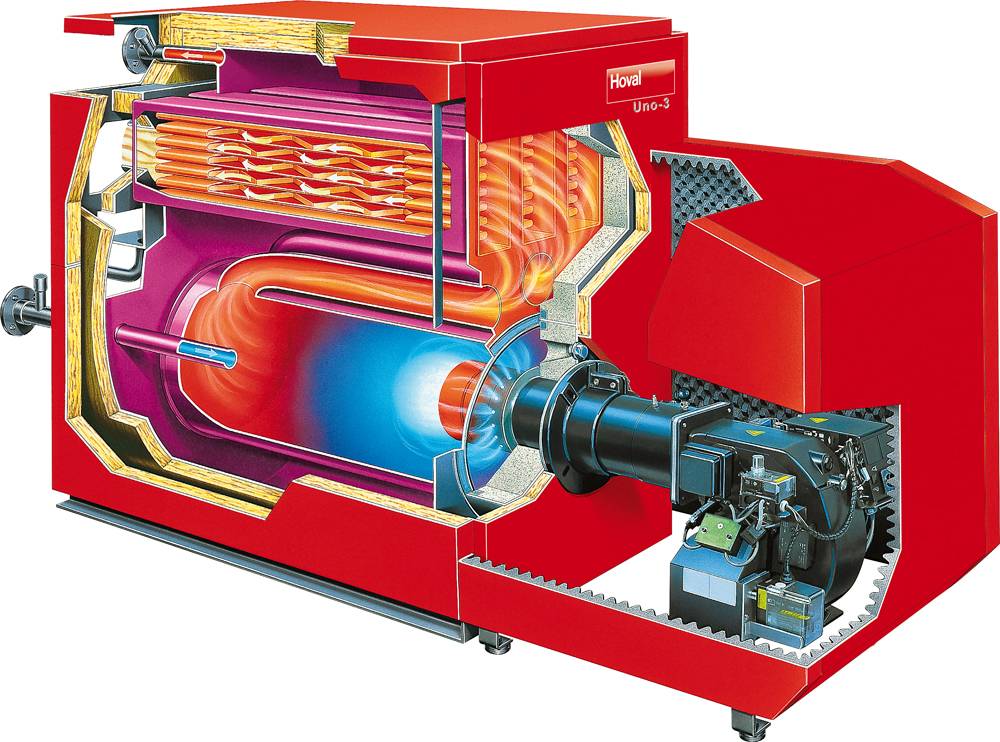

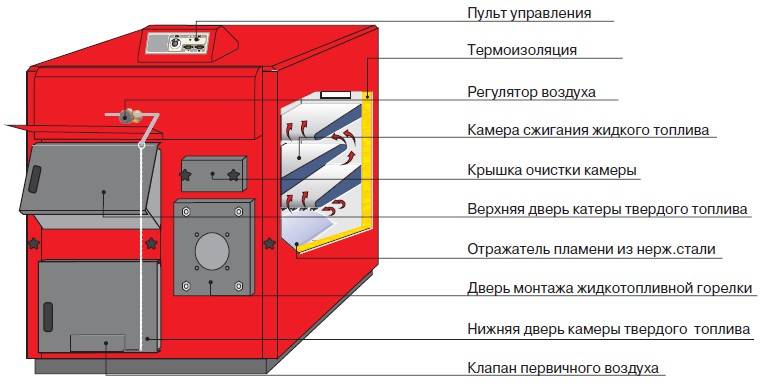

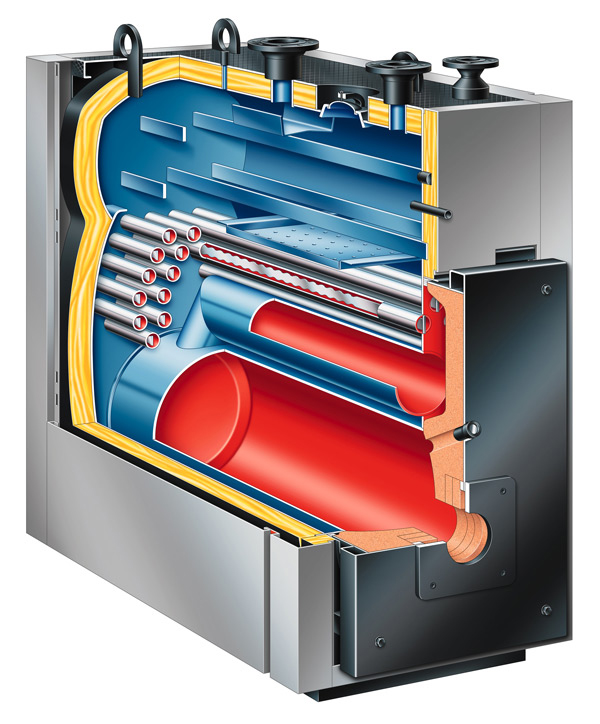

- The design of the boiler for liquid fuel

- The simplest device for a liquid fuel boiler

- Pros and cons

- note

- Types of liquid fuel

Domestic boilers for diesel fuel

For domestic use, that is, for heating ordinary private houses, Korean-made Saturn devices are perfect. They differ in that they are equipped with combustion catalysts and blast burners. Of course, their power is not too large, but for an average private house it is quite enough.

Video - Diesel boilers

The devices described are equipped with special oxygen scavengers that slow down the oxidation process and, as a result, significantly extend the life of the equipment. There are also various automatic systems that simplify the operation process.

Main varieties

In the photo - the boiler and the most popular types of fuel

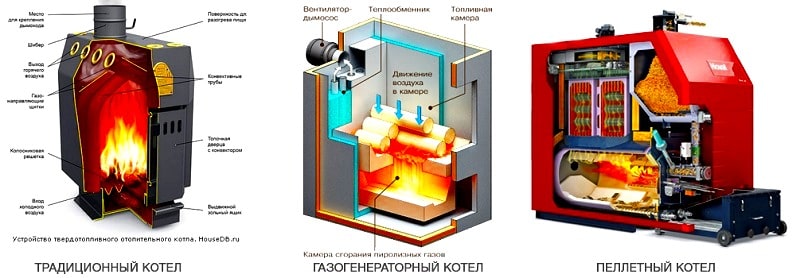

Modern solid fuel boilers for the home, in accordance with operational features, are divided into the following varieties:

- do-it-yourself modifications with fuel supply;

- modifications with automatic fuel supply;

- heating furnaces as a separate group of equipment.

Modifications with manual feed, in turn, are of the following types:

- traditional classic solid fuel heating boilers for the home;

- equipment operating due to the pyrolysis reaction;

- heating boilers of long burning on solid fuel.

Also, the instruction for the selection and operation of solid fuel boilers largely depends on their energy dependence. Classic devices with manual fuel supply and manual ignition do not require electricity.

More advanced automated devices require a constant supply of electricity. In this case, electricity is necessary for ignition and supply of fuel and for the stable operation of the forced exhaust gas system.

Modern solid fuel boilers, like other heating equipment, are divided into single-circuit and double-circuit modifications.

Single-circuit modifications are intended only for heating the coolant for subsequent supply to the system.

Double-circuit modifications are more functional, as they heat up not only the coolant, but also the water.Double-circuit heating boilers can be equipped with two or one heat exchanger.

If there are two heat exchangers, then water and coolant can be heated to the required temperature at the same time. If there is only one heat exchanger, then the coolant and water are heated alternately.

Depending on the type of fuel used, the power of household boilers can reach from 10 to 80 kW. The highest power is achieved when coal and coke are used as fuel.

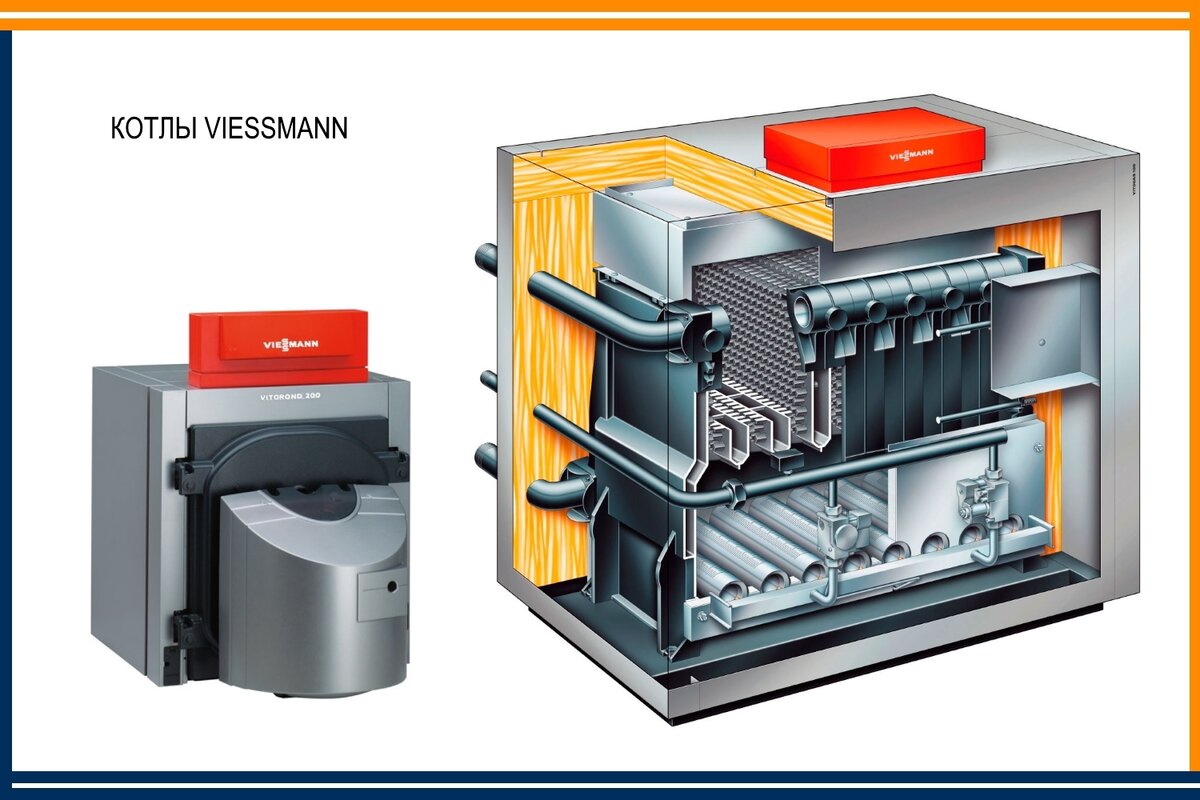

Design features of classic boilers

Scheme of the device of modern equipment

Classic solid fuel boilers for a private house are a wide range of equipment. But, in fact, all these devices are not much different from a conventional oven.

The only significant difference is the presence of a built-in capacity of the circuit through which the coolant circulates. Such structures have long been widely used both in private houses and in small stokers at housing or public buildings.

Solid fuel boilers for heating a private house - appearance

The principle of operation of a classic solid fuel boiler is simple - a certain amount of fuel is put into the furnace, which, when burned, releases the energy necessary to heat the water in the lower part of the circuit (in the heat exchanger).

Sizes and configurations of both steel and cast iron heat exchangers can vary significantly. And this largely determines the power and performance of the equipment.

Solid fuel boilers are equipped with an expansion tank, which is an indispensable element for ensuring natural circulation.In more complex installations, the circuit can be modified by using a circulation pump, which contributes to a more stable pressure maintenance.

Features of automation of heating equipment

Automated boiler with automatic feeder

In order for the heating of a country house with a solid fuel boiler to be less dependent on human participation, high-tech automation systems are used. Of course, due to the use of such systems, the price of equipment increases significantly.

Modern boiler room

Among the elements of automation, we note the following:

- Devices that supply fuel to the furnace are a bunker with a dosing device.

- Devices responsible for turning the grate.

- Ash pan cleaning devices.

- Separate modifications of the equipment provide the possibility of remote control via the Internet or mobile telephony.

Due to the use of automation systems, the boiler works autonomously for a week.

Oil powered device

Due to the special operation of the burner, a diesel boiler will not operate on fuel oil or waste oil. Additional burners for modernizing a diesel fuel boiler are very expensive, but it is not a fact that after changing the configuration of the unit with your own hands, it will work stably.

The oil fired boiler has the following advantages:

- incredibly high thermal conductivity;

- low rate of ash in the device;

- luminous flame, which contributes to the occurrence of radiative heat transfer in the furnace;

- can be used in both large and small boilers;

- extraction and storage of fuel oil;

- high price when buying "clean" fuel oil;

- high pour point + 25-30 o C.

The purchase of this kind of boiler is beneficial only if there are enough volumes of fuel in constant access. Otherwise, the unit will be expensive and will not pay for itself at all. Oil-fired boilers are predominantly used in places where this fuel is processed by one's own hands or created.

Oil burner

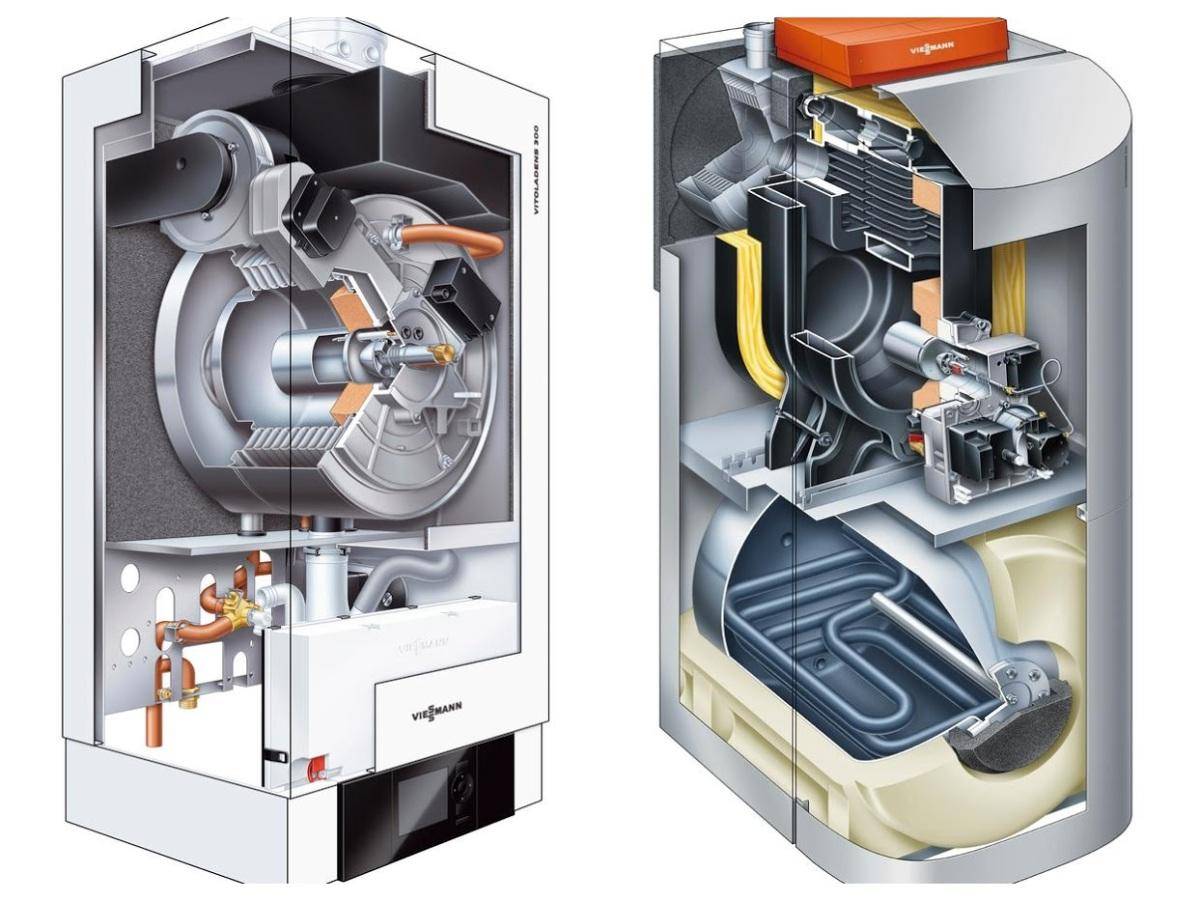

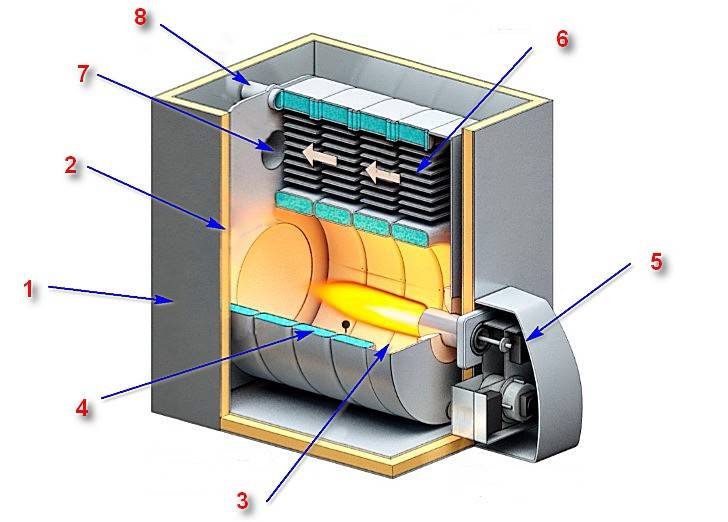

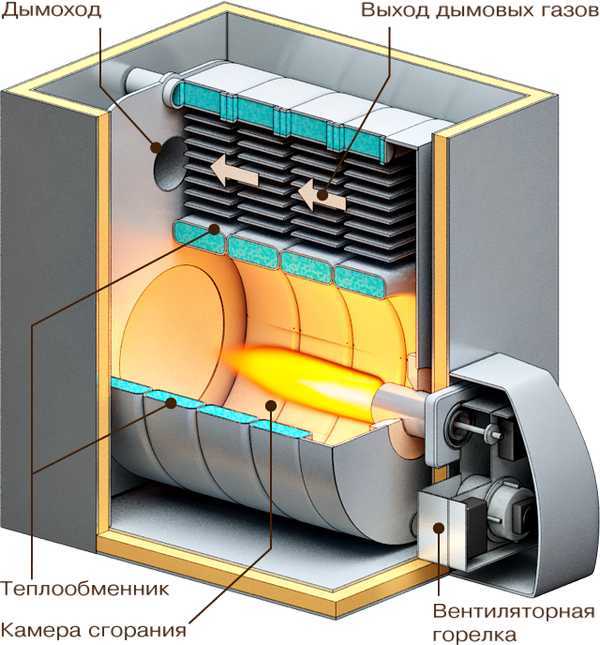

For liquid fuel heating units, fan (pressure) burners are used. They atomize the liquid fuel entering the burner under pressure with the required atomization ratio. Air is also forced into the burner, which is correctly called forced air.

The fuel mixture is ignited by electrodes. Further work of a copper is provided with the built-in automatic equipment.

Here it is time to notice that in the design of boilers there are a lot of electronics and equipment powered by electricity (fans, pumps). This makes diesel boilers electrically dependent and this must be taken into account when purchasing and installing. If the house has frequent problems with electricity, then you need to take care of the backup power supply.

The best pyrolysis solid fuel boilers

The principle of operation of such installations is based on the afterburning of pyrolysis gases resulting from the combustion of fuel in an oxygen-depleted environment. This solution provides greater energy efficiency and a long period of equipment operation on one tab.

Attack DP 25 Profi

5

★★★★★editorial score

100%

buyers recommend this product

The novelty of 2019 from a well-known manufacturer of heat engineering from Slovenia has absorbed all the advanced ideas and technological solutions of the world leaders in this industry.The Attack DP 25 Profi pyrolysis boiler is a highly efficient and economical boiler plant with a capacity of 25 kW, designed to work with wood and its derivatives. Allows you to use firewood with a length of 1 m.

The main feature of the device is electronic control of combustion processes and coolant circulation with the display of all indicators on the display. Automation independently adjusts the power of the unit to the real need of the house for heat. The duration of work on one tab reaches 12 hours. The cost is 95,000 rubles.

Advantages:

- High efficiency heat exchanger.

- Impressive efficiency.

- power modulation.

- Auto shutdown after fuel burnout.

- Water after-cooling circuit (additional protection against overheating).

- Ease of maintenance.

Flaws:

Impressive weight and size indicators.

An excellent boiler plant for organizing economical heating of residential buildings, workshops, shops.

Buderus Logano S171-50W

4.9

★★★★★editorial score

92%

buyers recommend this product

Buderus Logano is a classic wood-burning single-circuit boiler with electronic control. A power of 50 kW is enough to heat a rather large private house of 2-3 floors or a production facility. The efficiency of the unit reaches 90% due to the well-thought-out design of the afterburning of pyrolysis gases and control of the intensity of combustion.

The main feature of the model is the presence of electronics that allows you to control the boiler, remotely control the operation of the boiler, integrate it into the "smart home" system, etc.

Advantages:

- Energy efficiency.

- Manufacturability.

- Easy loading and easy maintenance.

- High security.

Flaws:

- Big weight (466 kg).

- The price is almost 220 thousand.

This model will be an excellent (albeit very expensive) solution when creating an autonomous heating system in a large cottage or at an enterprise.

Trayan T15 2-CT

4.8

★★★★★editorial score

88%

buyers recommend this product

A modern wood-burning pyrolysis boiler is designed for heating and hot water supply of buildings and structures with an area of up to 150 m2. The case of the unit is made of heat-resistant steel 5 mm thick. With a power of 15 kW, the duration of burning on one tab is 8 hours.

The model is equipped with an automatic air supply regulator, which allows you to change the power in the range from 40 to 100%, where the highest efficiency of 82-85% is achieved.

Advantages:

- Two heating circuits.

- Possibility of installation of TEN.

- Long battery life.

- Reliability and safety.

- Affordable cost - a little more than 58 thousand.

Flaws:

- Installation is possible only in a system with natural circulation of the coolant.

- Not the highest efficiency.

Trayan is suitable for organizing heating and hot water supply in private houses, industrial and office premises, shops.

Kiturami KF 35A

4.7

★★★★★editorial score

72%

buyers recommend this product

Kiturami is a modern pyrolysis boiler designed to work with wood waste, which can significantly reduce the owner's operating costs for heating. At nominal power 24 kW efficiency heating is 92%, and DHW systems - 91%. The duration of work (up to 16 hours) is provided by a large volume of the combustion chamber, which can hold up to 50 kg of firewood.

The main feature of the model is the heat exchanger made of stainless steel.This solution ensures a long service life and eliminates the appearance of scale. Management is electronic.

Advantages:

- Profitability.

- Good heat output.

- Impressive efficiency.

- Full electronic control.

- High level of security.

Flaws:

High cost - from 110 thousand rubles.

An excellent model for autonomous heating of a private house, up to 240 m2, which will also solve issues with hot water supply.

Oil boilers and fuel

It so happened that speaking of domestic liquid fuel boilers, it is a priori understood that these boilers run on diesel fuel (diesel fuel). In fact, the burners of these boilers can also operate on other types of liquid fuels (which should be indicated in the documentation):

- Kerosene;

- light oil;

- various oils;

- Fuel oil.

The main requirement for fuel is the absence of moisture and the absence of abrasive impurities. It is also worth noting that each type of fuel affects the performance of the boiler and the frequency of its maintenance.

It is also important to understand that the fuel that the boiler runs on must be indicated in the documentation for the boiler and there are no omnivorous liquid fuel boilers yet.

Why choose universal boilers?

Although at the moment the choice of heating systems is very wide, universal heating models have a large list of advantages. I propose to consider some of them.

How much is this pleasure?

If earlier the acquisition of universal type systems was very expensive and its only a select few could afford, it is now a widely available product.

Why is it profitable for them to heat their homes?

For heating, you can use not only expensive fuel.Sawdust, shavings and other waste are perfect as a material.

It is also possible to maintain heat with electricity.

Should the boiler always be operated by a person?

Universal heating systems are equipped with reliable automation, so that the boiler can turn on and off on its own, as well as switch to electricity. It is also possible to install programs.

Is this device durable?

Yes, the minimum service life for such a heating system is 15 years. At the same time, the manufacturer guarantees that during this period the boiler does not require repairs or expensive maintenance.

The quality of work always remains at a high level.

How to switch the system to another type of fuel?

Most models use different burners for different types of fuel. This means that in order to change the type of fuel, it is enough to install another burner. Most often, any special knowledge is not required to change the burner, and an ordinary person can carry out such manipulation.

Oil boiler

In principle, a liquid fuel boiler (or several twin boilers) can be used as a boiler station, but then it is more profitable to heat it with fuel oil, because with the same consumption of fuel oil and gas, the specific heat released from gaseous fuel is much less. True, there is one sin with such heating devices, which not only spoils the overall picture, but makes you think about the fundamental installation. We are now talking about ignition (beginning of operation), which is the basis of the boiler and the beginning of the heating season.It is no secret that any hydrocarbon is eventually a combustible material (some require appropriate processing), but, unlike gasoline, oil and diesel fuel start the combustion process at higher temperatures (this can be seen if you try to light a few drops of gasoline from a match and oil).

The design of the boiler for liquid fuel

That is, all other things being equal, heavier hydrocarbons have a higher ignition temperature, from which it can be concluded that the design of a liquid fuel boiler must have a serious igniter and heat-resistant heat exchanger elements. Diesel fuel, fuel oil and oil provide stable and long-term combustion, provided that fuel is systematically added to the combustion chamber.

The simplest device for a liquid fuel boiler

The easiest option for understanding and describing the properties of these types of boilers is a do-it-yourself oven with a dropper. A firebox standard for stoves has a door for kindling with ordinary wood, and at the top there is a steel dropper through which fuel enters directly into the combustion chamber. To ignite the unit, it is necessary to flood it, like a conventional stove, let it heat up, and then open the dropper to a minimum. Adjusting the dosing of liquid fuel automatically increases or decreases the combustion temperature, and the combustion force (intensity) is regulated by a blower (supply ventilation). The smaller the volume of incoming air, the weaker the combustion, the more conserved the fuel and the more stable the heating temperature.

Heating on liquid fuel can only be organized with an uninterrupted supply of fuel, therefore it is not recommended to extinguish boilers on liquid fuel for a short time (only for the summer period). Creating conditions for the correct supply of flammable liquid and timely replenishment of the stock in the tank creates another nuance - a characteristic smell.

Pros and cons

Among the qualitative and technical indicators, there are no unequivocal minuses or pluses, since some, at first glance, negative features may be for the sake of expanding the list of positive points. Everything has already been discussed in the article, but it will not be superfluous to recall and classify all the nuances.

So the pros:

- autonomy (in this case, we should talk about isolation from engineering systems and electricity);

- depending on what fuel can be used: if only one type is a minus, and if the boiler is represented by a combined system, this is a plus;

- stable combustion and maintaining an even temperature (subject to the same dosage, maintaining combustion, even with wind or precipitation, is not difficult).

As 100% cons, we note:

- heavy heating of the fuel to reach the ignition temperature;

- lack of pauses in the operation of the heater (unjustified fuel consumption);

- regulated minimum temperature in the system (each has its own and depends on the volume of the coolant, the size of the combustion chamber and the density of the hydraulic piping).

Do-it-yourself waste oil boiler (video)

note

Installing a diesel boiler in a house is a rather important issue, so it should be taken more than seriously, because comfortable living in a country house during the cold season directly depends on it.

For heating with diesel fuel, it is first recommended to determine the type of power that will be required to fully heat the whole house. To do this, it is necessary to carry out a special calculation, which will fully take into account the total living area of the entire room, as well as the heat-insulating properties of the materials of your suburban building, the height of the ceilings and the presence of windows. In addition to these data, you need to estimate the maximum minus temperature in the region of your residence.

The principle of heating a house with diesel fuel.

Let's look at what important characteristics diesel fuel has in terms of heating the premises of a country house. First of all, it is worth noting autonomy, which means independence from central systems. Diesel heating installed in the house does not require additional permits for the installation and further operation of the boiler, which will entail a significant reduction in costs for the entire heating process. It should be noted right away that at the very beginning this is not a very impressive amount, but if you calculate the annual percentage of savings, you get a lot. Thanks to the high level of automation of the entire system, you can not only comfortably control the entire system, but also significantly save diesel fuel consumption.

We will not hide the fact that in order to install a boiler for heating with diesel fuel in a house, a number of mandatory conditions will need to be observed.The main condition can be considered the acquisition and installation of a special container in which the supply of all fuel will be stored. The room in which the boiler will operate must be equipped with exhaust ventilation according to safety rules.

Scheme of a liquid fuel boiler.

In order for the boiler for diesel fuel to last longer, you need to use only high-quality fuel. This fact will force you to purchase combustion products from trusted suppliers who have proven themselves. If you fulfill this condition, then the heating system will not have to be constantly repaired.

Recently, liquid fuel boilers, which are equipped with special replaceable burners, have become very popular. The basis of such technological equipment is the possibility of replacing the burner. If everything is done efficiently and professionally, then such equipment can be easily converted to gas heating. This question is relevant in the sense that your country house will soon be connected to the gas main.

Types of liquid fuel

The list of types of liquid fuel is quite extensive. The choice of a specific type depends on the model of the boiler. Most commonly used:

- fuel oil;

- diesel fuel;

- kerosene;

- waste oil.

This is interesting: the choice of a diesel boiler for a private house.

Fuel oil and diesel fuel are fairly light fuels. They are easy to transport and store. Due to the low viscosity of the fuel, it burns as efficiently as possible. The minimum amount of ash and sulfur in the composition ensures the safety of equipment and minimizes emissions to the environment.

When choosing fuel for an oil-fired heating boiler, attention should be paid to the viscosity and the amount of sulfur in the composition. The price of a low sulfur product is higher, but its use has advantages:

- economical consumption;

- low costs for maintenance and repair of equipment;

- minimum amount of harmful emissions into the atmosphere.