- Difficulties in manufacturing, how to make the boiler more economical

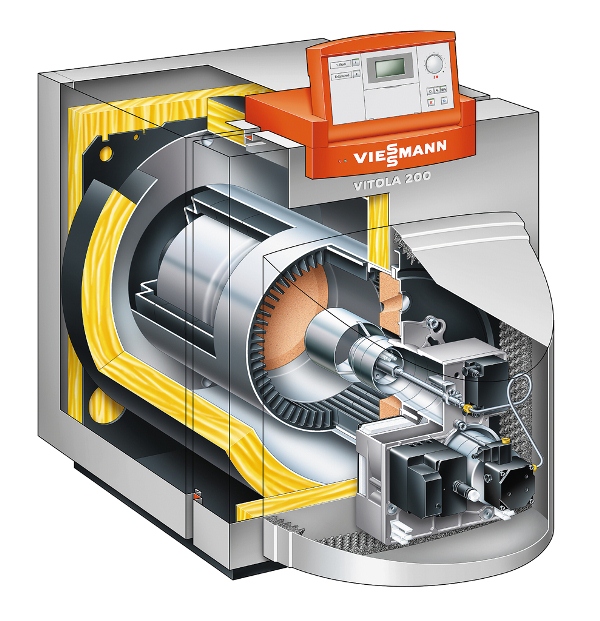

- Viessmann oil-fired boilers solutions for all heating applications

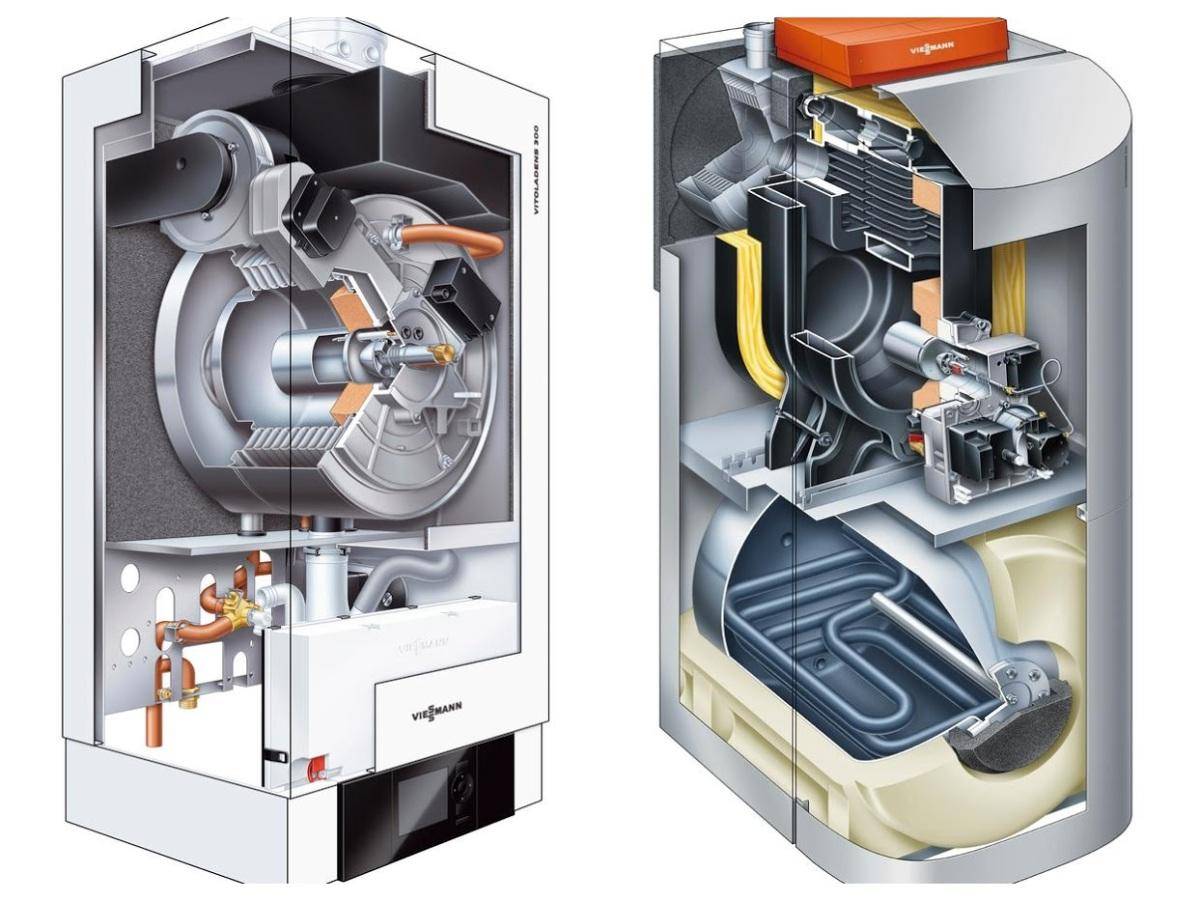

- 300th Vitotrans model

- The best dual circuit devices

- Kiturami Turbo 13R

- Navien LFA 13K

- ACV Delta Pro S 25 26 kW

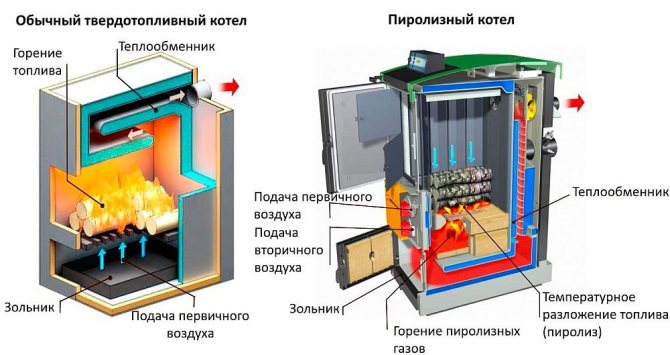

- Classification

- Automation

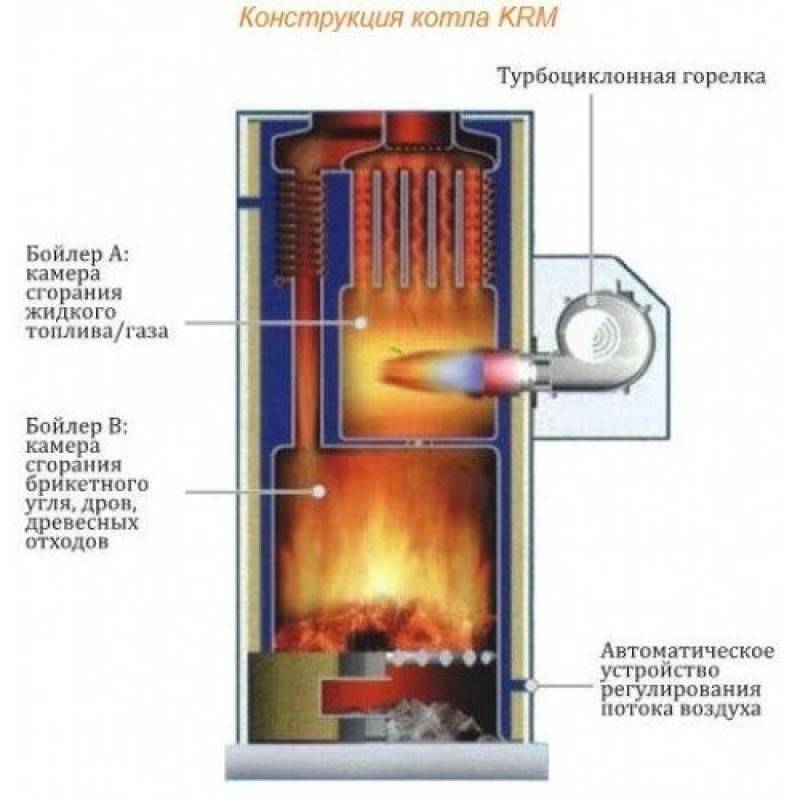

- The main types of combined boilers

- Oil evaporation technology

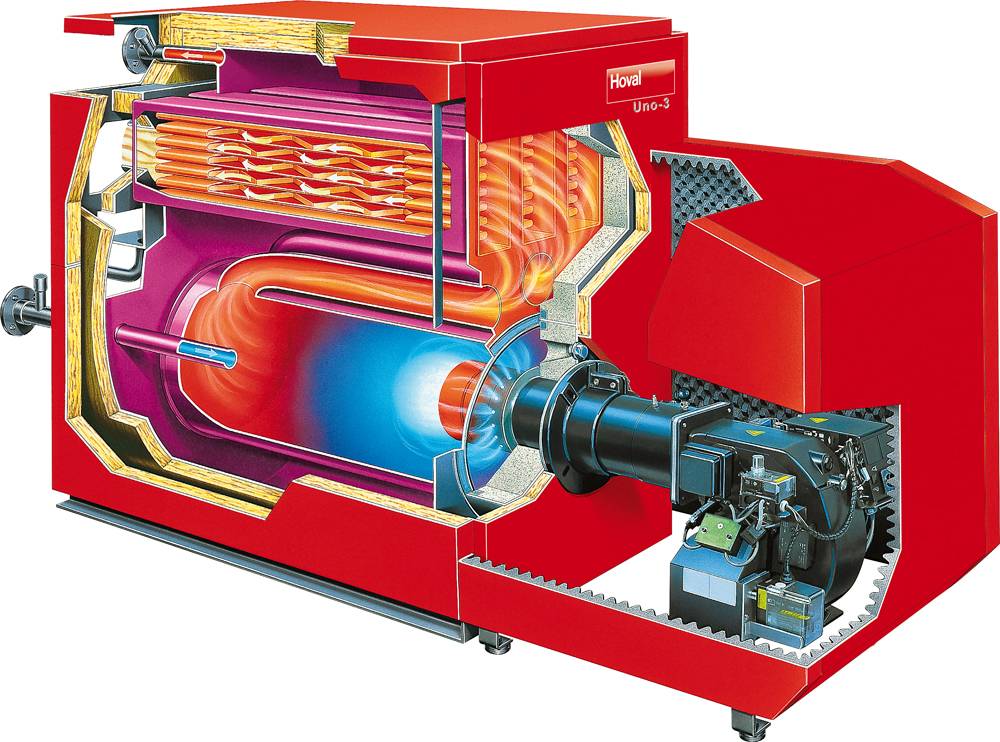

- The device and principle of operation of the boiler

- The main working units of the heat generator

- How is space heating

- How does a liquid fuel boiler work

- Advantages and disadvantages

- The main criteria for choosing boilers

- Advantages and disadvantages of equipment

- What are the advantages of liquid fuel boilers?

- Advantages and disadvantages of liquid fuel boilers

- The principle of operation and arrangement of a liquid fuel boiler

- Operation features

- Most Common Problems

- How to choose a heat source - recommendations

- What is important to consider before installing such thermal equipment?

Difficulties in manufacturing, how to make the boiler more economical

The rules prohibit supplying gas to the basements and basement floors of the building, so the owner must allocate a separate room in the house that meets the standards, otherwise the installation of the unit will not be approved by the services.

An attempt to save on automation of heating equipment leads to overheating of the heating system and even rupture of pipelines.

Overheating also occurs due to lack of circulation. In this case, check the pump, filter and overheating thermostat.

Incorrect calculations of the required power will lead to the fact that the heat received from the boiler will not be enough to heat the premises.

If the pressure does not rise during the heating of the boiler, then the tightness of the system may be broken and the connections must be tightened, after which a little pressure should be added.

Problems can arise if the project did not take into account the features of a particular object: power surges in the network, poor fuel quality, insufficient gas pressure, proper ventilation is not organized, or recommendations on permissible distances from the boiler to other equipment and walls are not followed. When repairing, it will be necessary to modernize engineering work.

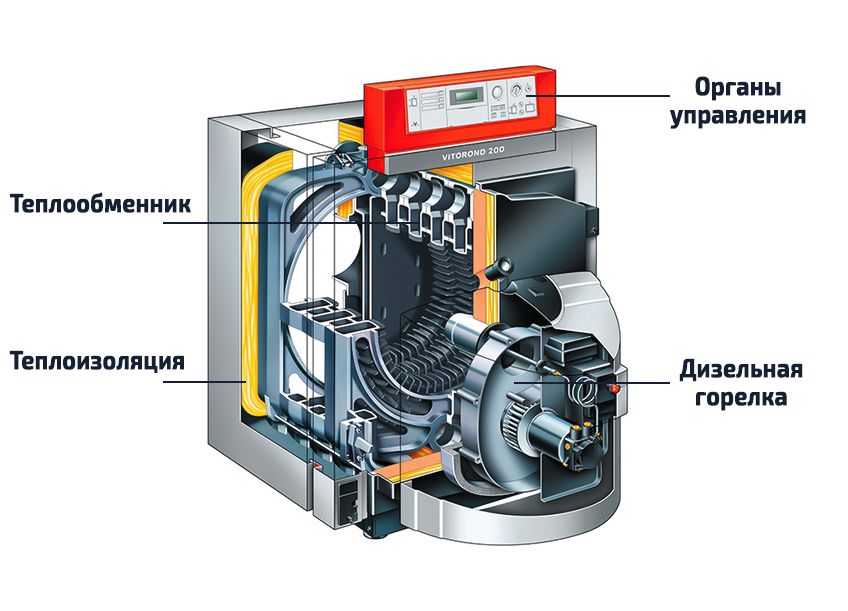

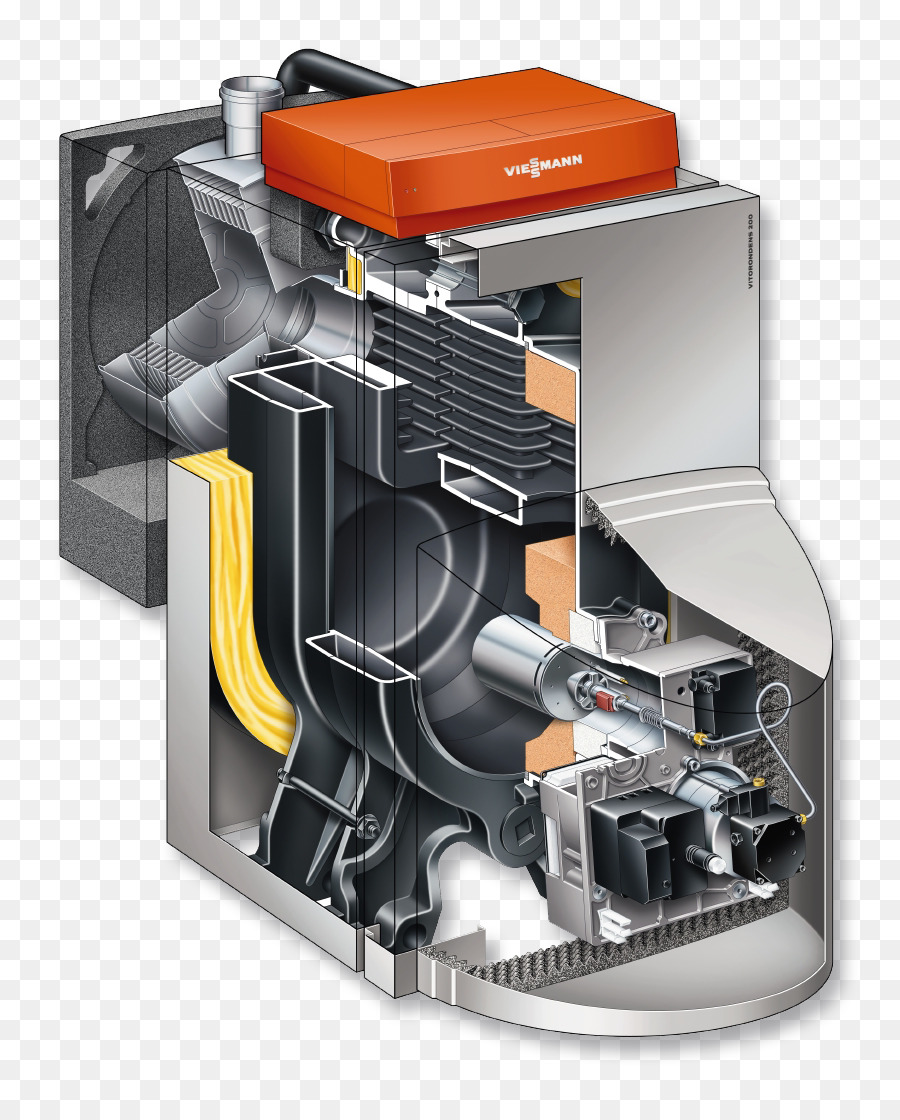

Viessmann oil-fired boilers solutions for all heating applications

Viessmann's product range covers systems from 1500 watts to 115 megawatts. This allows the use of Viessmann boilers in any segment of heat supply from private houses to industrial enterprises.

In the product range for domestic use in houses, cottages, summer cottages, apartments, there is a predominance of thermal heating generators operating on natural gas fuel and liquid fuel. Usually gas and liquid fuel boilers are not very efficient and the consumption of non-renewable energy sources becomes expensive for the consumer.In the boilers of this manufacturer, for efficient fuel combustion, condensing heating technology (chilled mirror) is used, which significantly increases efficiency.

300th Vitotrans model

This model included boilers ranging from 90 thousand watts to 6.6 megawatts. Runs on two types of fuel, gas or liquid fuel. InoxCrossal (up to 1.74 mW) or InoxTubal heat exchangers are used. They are placed vertically, which, according to the manufacturer, is good for long-term operation.

Made of steel heat exchangers, it uses capacitor technology to increase power by 7% for liquid fuels and 12% for gas.

The heat exchanger of this model is made of steel, so you should pay attention:

- Steel "stainless steel" grade 1.4571 is designed for continuous operation on gas with switching to liquid fuel.

- Steel grade 1.4539 is suitable for long-term operation on liquid fuels.

The best dual circuit devices

The devices have a complex internal structure. All models are adapted for domestic hot water and space heating. Double-circuit equipment is inferior to single-circuit equipment in terms of reliability.

Kiturami Turbo 13R

The country of origin is South Korea. Construction type - floor. The model runs on diesel fuel. The body is made of heat-resistant steel. The heat flow is injected into the system by means of a circulation pump.

Adjustment of modes of operation is made from the control panel. With it, set the temperature of heating air and water. Kiturami Turbo 13R is used for heating houses with an area of up to 250 sq.m, and for hot water supply.

Characteristics:

- overall dimensions - 365x650x930 mm;

- weight - 79 kg;

- Efficiency - 91.5%.

Service life - more than 15 years. The average cost is 39 thousand rubles.

Advantages:

- the ability to quickly heat rooms;

- profitability;

- democratic price.

Main disadvantage:

noise at work.

Review

| Vasily F. |

| The model has overall dimensions that allows to install it in small rooms. Quickly fills the system with heat. Does not fail during long-term operation. |

Navien LFA 13K

The country of origin is South Korea. Construction type - floor. The model has a closed type combustion chamber. Operating modes are set and controlled by an electronic control unit.

The type of fuel used for heating is diesel fuel. The heat exchanger is made of of stainless steel.

Characteristics:

- overall dimensions - 320x754x520 mm;

- weight - 49 kg;

- Efficiency - 90%.

Service life - more than 15 years. The average cost is 32 thousand rubles.

Advantages:

- heats a large house well and quickly;

- profitability;

- democratic price.

Main disadvantage:

cools down quickly when turned off.

Review

| Yuri W. |

| When diesel fuel is burned, unpleasant odors do not fill the room. To maintain heat in the house, it is necessary that the boiler is constantly working. |

ACV Delta Pro S 25 26 kW

Country of origin - Belgium. Construction type - floor. The model is designed for heating large houses and industrial premises.

Execution material – stainless steel. ACV Delta Pro S 25 26 kW runs on diesel, LPG and natural gas. The boiler works for heating and hot water.

Characteristics:

- overall dimensions - 165x540x584 mm;

- weight - 145 kg;

- Efficiency - 91.9%.

Service life - more than 15 years. The average cost is 136 thousand rubles.

Advantages:

- economical fuel consumption;

- uninterrupted work;

- high water temperature.

Flaw:

great weight.

Review

| Leonid I. |

| The heat generator quickly heats up the water. Works flawlessly. |

Classification

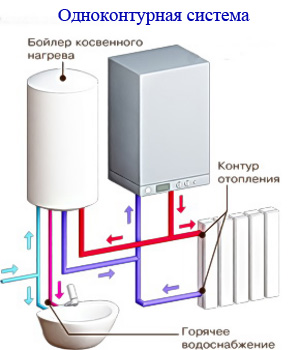

Depending on the possibilities of heating water diesel heating boilers fuel are divided into

- single-circuit, which are not intended for heating water;

- double-circuit with heating element or storage boiler.

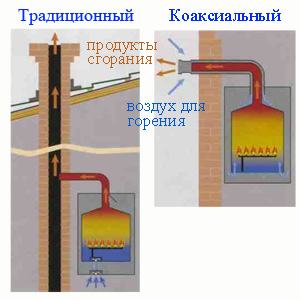

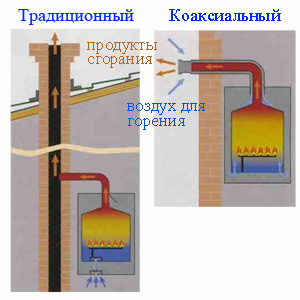

Diesel boilers can have natural draftwhen gases are removed through a chimney or forced.

Forced draft is provided by draft fans and requires the installation of a coaxial chimney (it is built on the “pipe in pipe” principle - combustion products are removed through the inner pipe, and combustion air through the outer one).

A feature of oil boilers is the presence of an oil heating system.

Almost all modern models have automatic control, a built-in thermostat, operation control sensors, forced removal of combustion products.

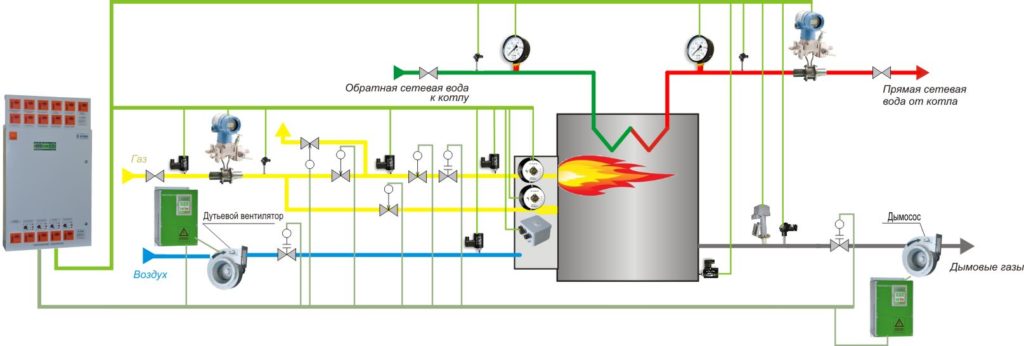

Automation

- compliance with the temperature regime in the system;

- control of pumps in the main and auxiliary (mixing circuit) circuits;

- maintenance of the set temperature of hot water supply;

- control of coolant flows using a three-way valve.

In the presence of an automation unit, a person only needs to set the required temperature and load the fuel, then the combustion process is automatically controlled according to the specified settings by controlling the supply of oxygen to the furnace. If the heating is carried out using a pellet unit, then the fuel is loaded automatically.

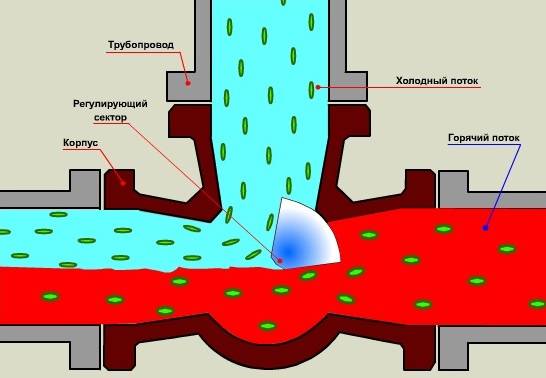

The principle of operation of the three-way valve

In the presence of a three-way valve, the system works on the principle of mixing hot water from the boiler into the main flow when the temperature drops below the set temperature.This principle allows you to heat only the required amount of water. It can be supplied either directly from the boiler or from a buffer tank. At the same time, it can also be heated by alternative sources, such as a solar collector.

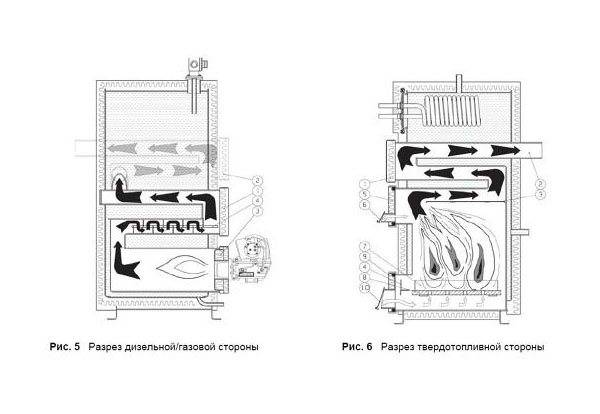

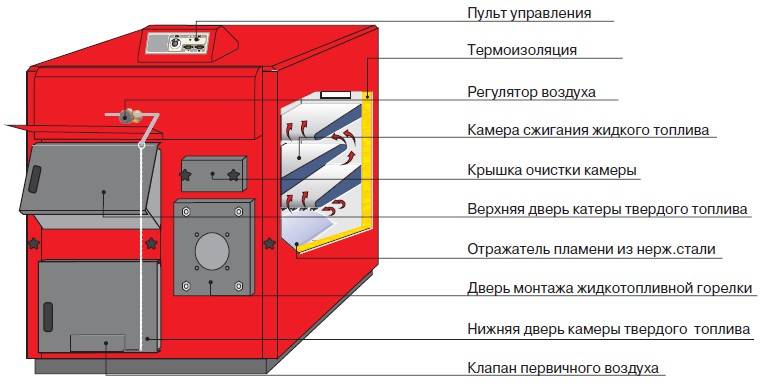

The main types of combined boilers

Combined type heating equipment is focused on loading and processing of two or more types of fuel materials.

The type of fuel material used allows us to conditionally divide the equipment into 2 main groups:

- standard - use no more than two different types of fuel;

- universal - able to work on three or more fuel options.

In most cases, it is possible to replace the burner in order to change the fuel supply function. On sale there are also models equipped with hobs and even two burners with electronic or electromechanical type of control.

There is only one catch here - the more expanded the functionality of such a unit, the more difficult the process of its installation will be.

The pellet boiler belongs to solid fuel installations. It burns granular pellets made from wood waste (+)

The pellet boiler belongs to solid fuel installations. It burns granular pellets made from wood waste (+)

The owners of country houses, whose heating is carried out by a combined heating boiler, unanimously declare its indisputable advantage. Especially if the house is located far from large settlements, and the lack of gas supply and frequent power outages are the norm in this area.

In addition, the combined boiler, which is also called universal, has many other advantages.

They allow you to compete with the most popular types of one-component systems:

- the ability to connect multiple circuits;

- a wide range of resources for technical modernization - burner replacement, boiler installation;

- modern level of program management;

- absence of interruptions in the heating system - at the moment of stopping the supply of one of the types of fuel, it is possible to apply an alternative option;

- economical expenditure of funds for the provision of the heating system.

Models with electromechanical control will become simply indispensable in homes located in areas often faced with power outages.

This option allows, if necessary, to transfer the boiler installation to manual adjustment mode, without losing the productivity of its operation.

The performance of the boiler becomes the main thing when choosing a boiler from the presented wide model range

Oil evaporation technology

In furnaces of this type, it is not oil that burns, but its vapors. That is, mining is heated up before the start of combustion, it begins to evaporate, and already the vapors are ignited. This technology allows dirty, heavy, poorly burning fuel to be decomposed into lighter components, and then burn them. It is she who, with the right parameters, makes it possible to achieve almost smokeless and complete combustion of fuel, in which there are practically no emissions: everything burns out.

Do-it-yourself boiler for working out: evaporative boiler principle oils

The easiest and most effective way to implement this technology is to use a red-hot bowl into which mining is dripped.

When in contact with hot metal, the oil evaporates sharply, the vapors mix with the air supplied here, flare up and burn out.The amount of heat generated in this case is large. To achieve maximum efficiency and complete combustion, it is required that the burning mixture be in the combustion chamber for a long time. Therefore, at the mouth of the duct, it is necessary to install a fixed impeller, which will create the required turbulence in the combustion chamber.

Do-it-yourself steam boiler for working out can be implemented in this form

Despite the high efficiency and “omnivorousness”, this principle of operation is rarely implemented in factory boilers manufactured in the USA and Europe. On the other hand, Russian manufacturers produce mining boilers that work specifically on evaporation technology. The main stumbling block in the implementation of such boilers is the method of preheating the bowl. Those who make these boilers on their own do it simply: they throw a wick soaked in gasoline into the bowl, pour a little diesel fuel or the same gasoline, set it on fire, waiting until the bowl warms up to the required temperatures. After that, open the oil supply.

In Europe and the USA, such a solution is unacceptable: it is unsafe. But our manufacturers also use this method of ignition of their stoves.

Another version of the plasma bowl oven

The video demonstrates one of the options for heating a garage with a working furnace. But in this embodiment, a non-drip fuel supply is implemented: it flows in a trickle and burns far from completely

It is for this reason that the author of the project paid such attention to the insulation and sealing of all removable parts: to minimize the ingress of smoke into the room and made a high chimney for better draft

It is interesting: Combined heating boilers for at home - an overview of the units, brand reviews

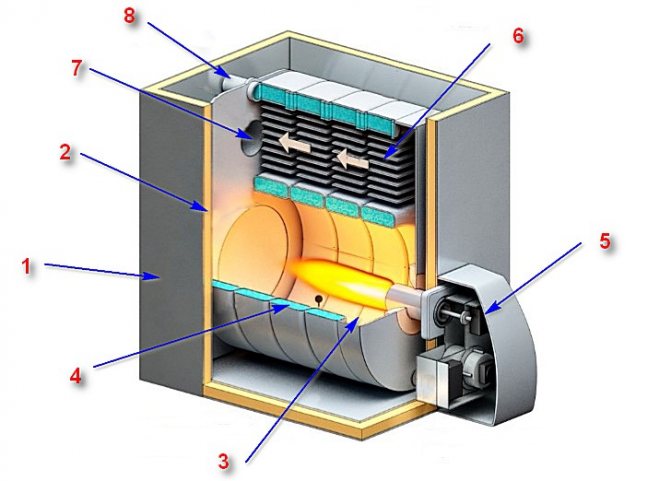

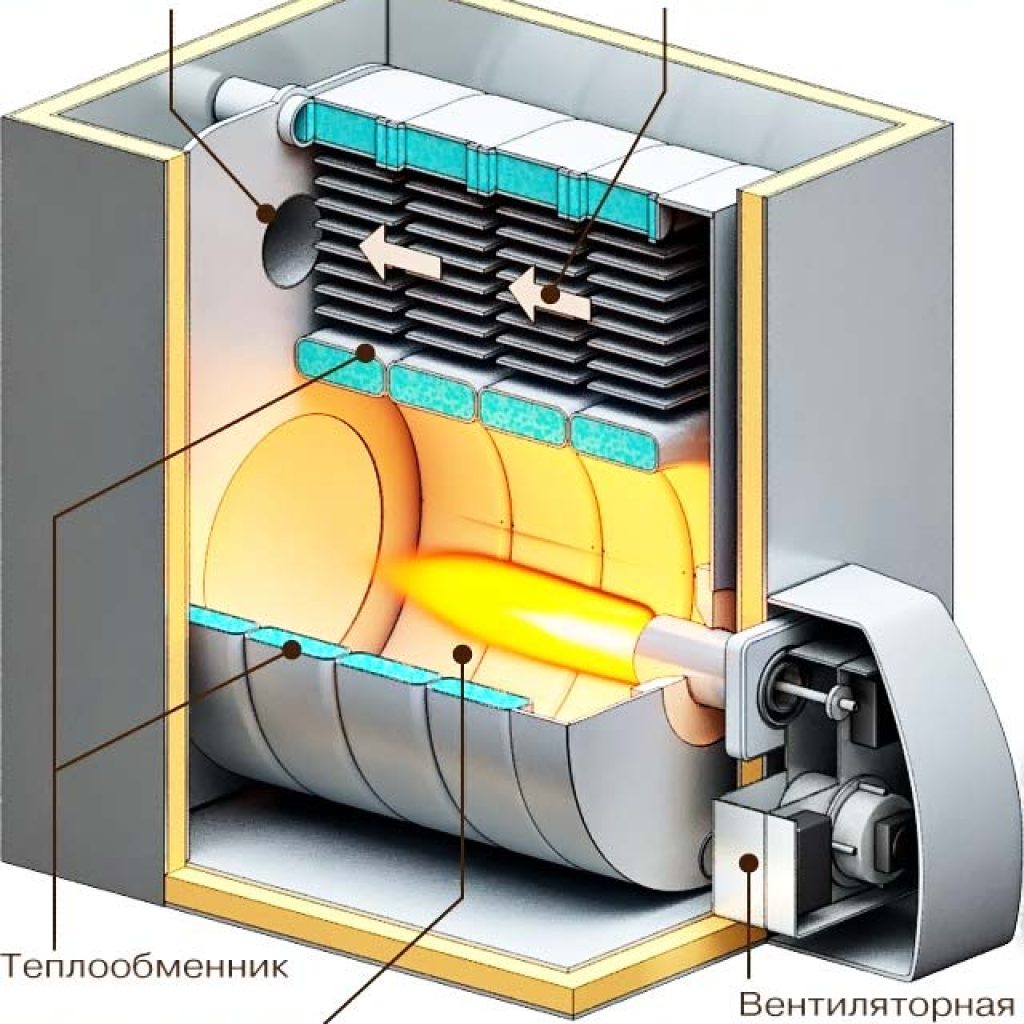

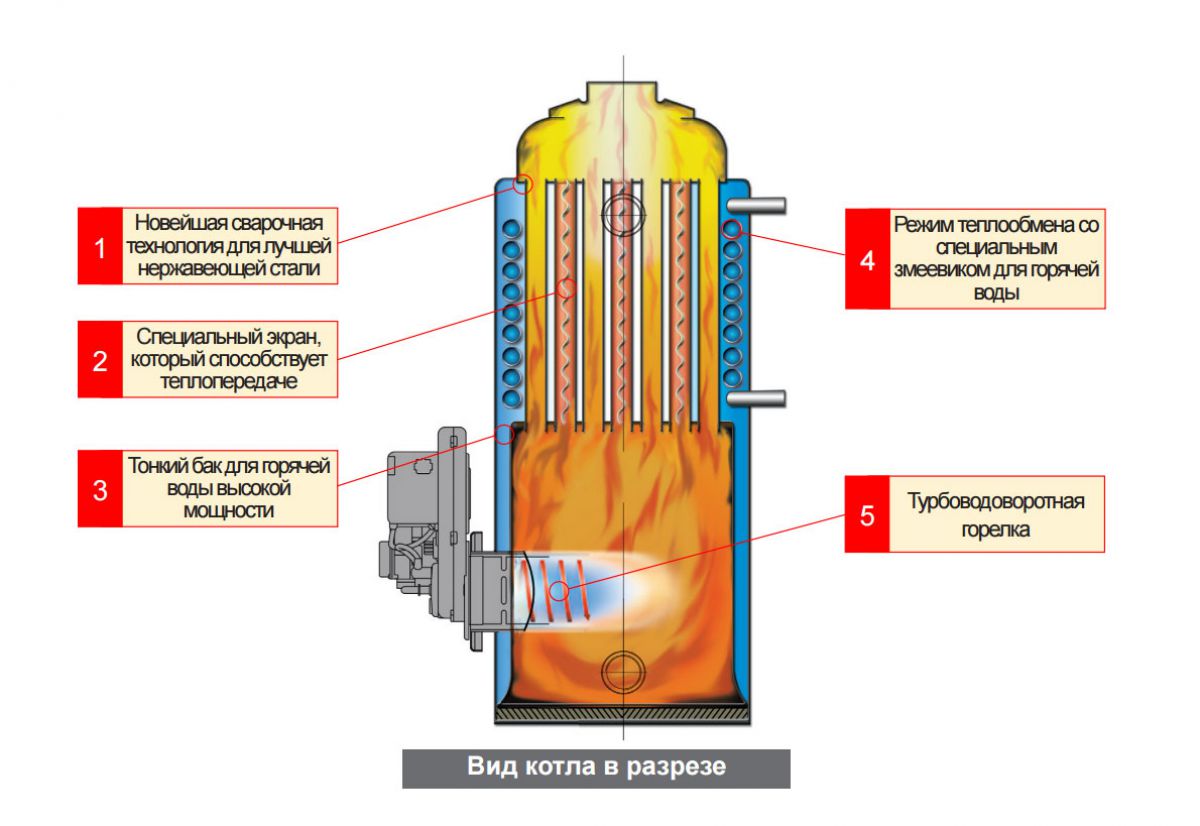

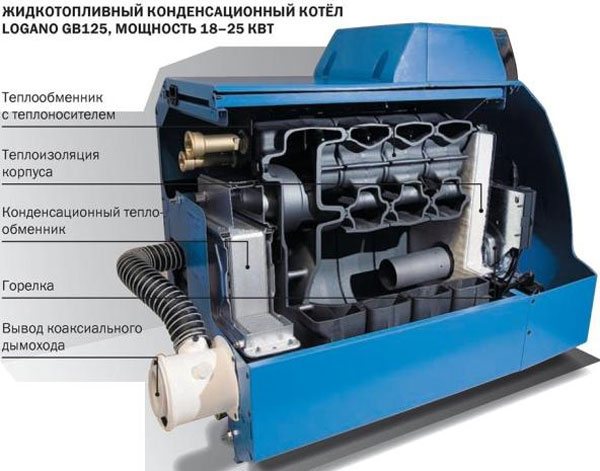

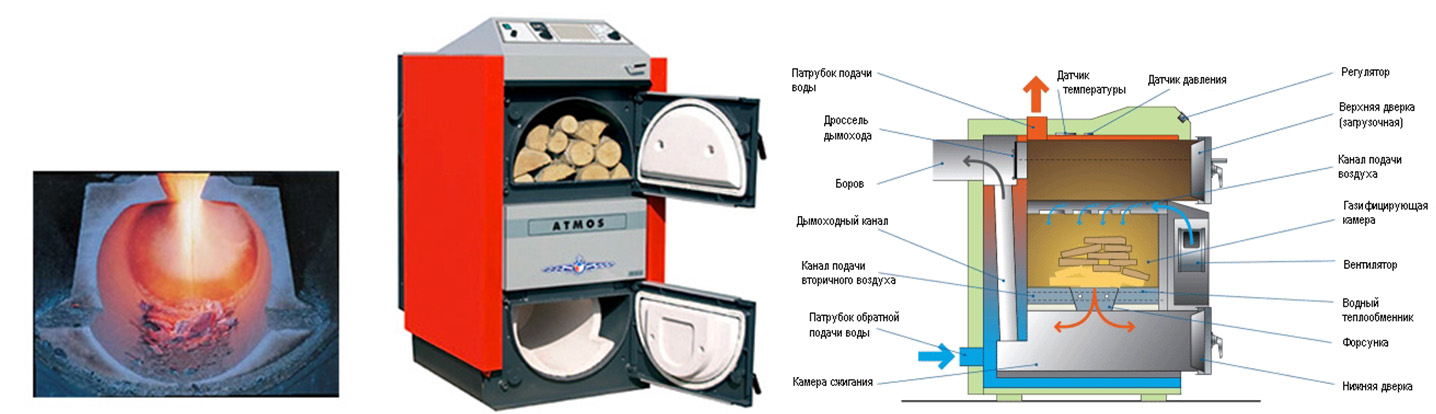

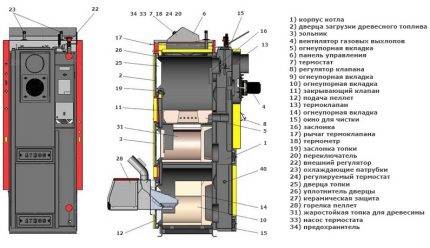

The device and principle of operation of the boiler

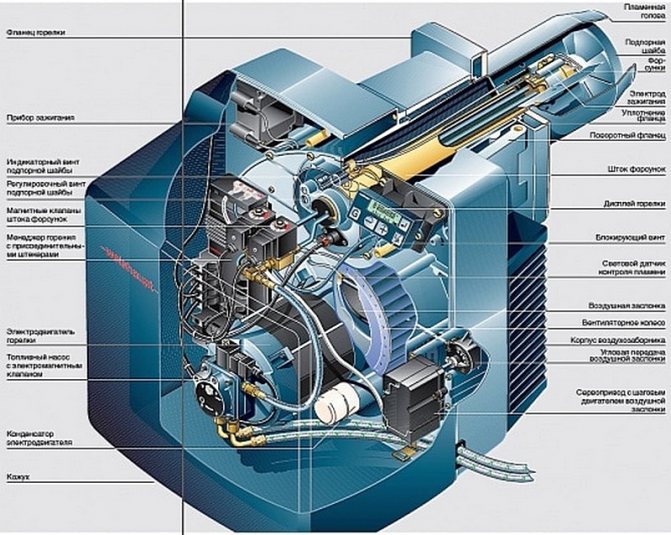

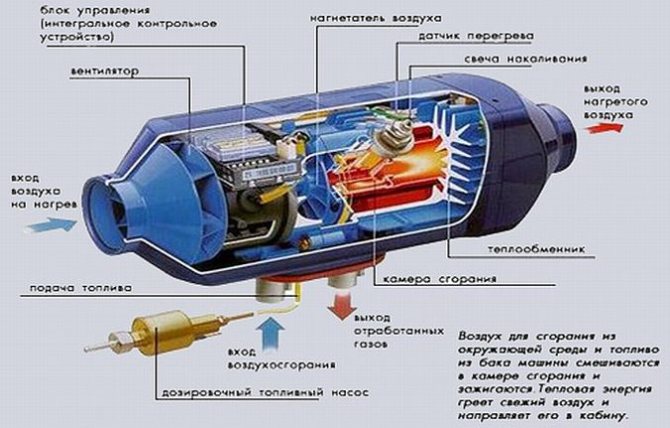

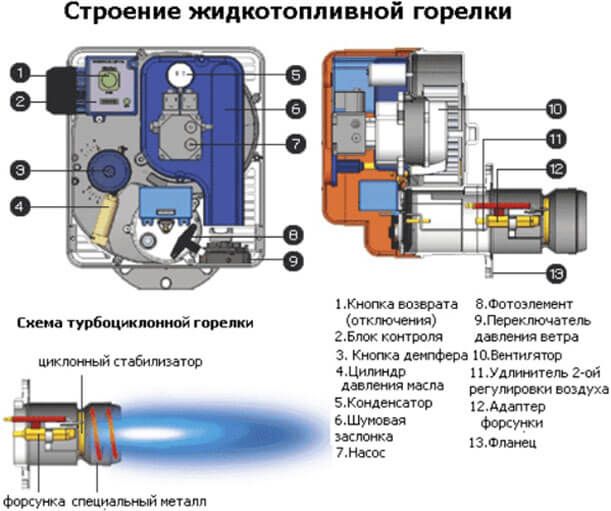

Liquid fuel units operate on the same principle as gas units. The main difference lies in the use of a fan burner (nozzle). The type of device largely determines the efficiency and economy of the boiler.

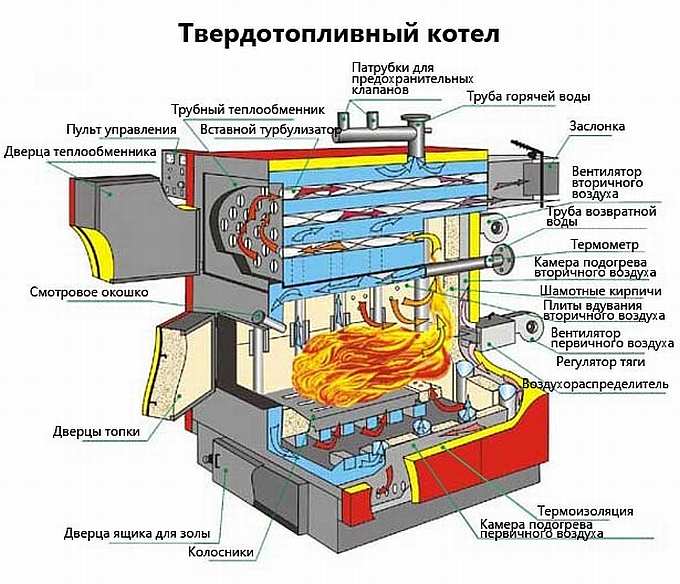

The main working units of the heat generator

Structural elements of a liquid fuel boiler:

- burner;

- the combustion chamber;

- heat exchanger;

- chimney;

- Control block;

- frame.

The liquid fuel heating installation is completed with a line with a pump that provides fuel supply and a fuel storage tank.

Burner. The main module of the plant, responsible for the preparation of the fuel-air mixture and transferring it in the amount necessary to maintain the operation of the heat generator.

Standard equipment for a burner for a liquid fuel boiler:

- Ignition transformer. Generates a spark that ignites the fuel.

- Control block. Defines the start-up phases, monitors and stops the burner. The connection of a photocell, an ignition transformer and an emergency shutdown sensor is provided.

- Solenoid valve. Adjusts the supply of fuel to the combustion chamber.

- Air regulator with filter. The device normalizes the air supply, preventing the ingress of solid particles.

- Preheater. Changes the state of the fuel, reducing its viscosity. The more liquid fuel enters the nozzle hole, the more economically it is consumed.

- Fuel overflow pipe. It connects to the tank, where the fuel is heated.

- Flame pipe. Through the main, thermal energy enters the place of heating of the coolant, which then circulates in the heating system.

The burner can be initially built into the boiler without the possibility of increasing the power of the unit. Mounted modules allow you to modify equipment.

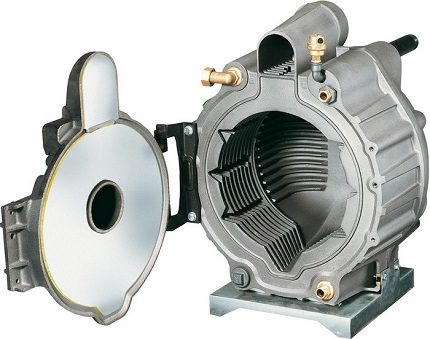

The combustion chamber. In fact, this is a heat-resistant container with an inlet and outlet. As a rule, it has a round or rectangular cross section.

Heat exchanger. Through the walls of the heat exchanger transfers thermal energy to the coolant. In modern models, the coating of this element is made according to the principle of a radiator device - this allows you to maximize the use of thermal energy obtained during the combustion process.

Chimney. Air intake is carried out from the street or from the boiler room. When supplied from the outside, the air is supplied through a coaxial chimney or through a separate channel. To improve efficiency, the smoke channels are equipped with steel plates - the exhaust gases form turbulent flows that reduce their speed. Traction is maintained.

Control block. Automation is designed to maintain the set temperature. Auxiliary functions reduce the cost of boiler operation. From a technical point of view, weather-dependent units are considered the most advanced, which change the heating temperature of the coolant based on the readings of external sensors.

Frame. All elements of the system are enclosed in a durable heat-insulating case. This "shell" reduces heat loss and increases the efficiency of the boiler. Outside, the case is pasted over with a layer of heat-insulating film, which remains cold when heated and protects the operator from burns.

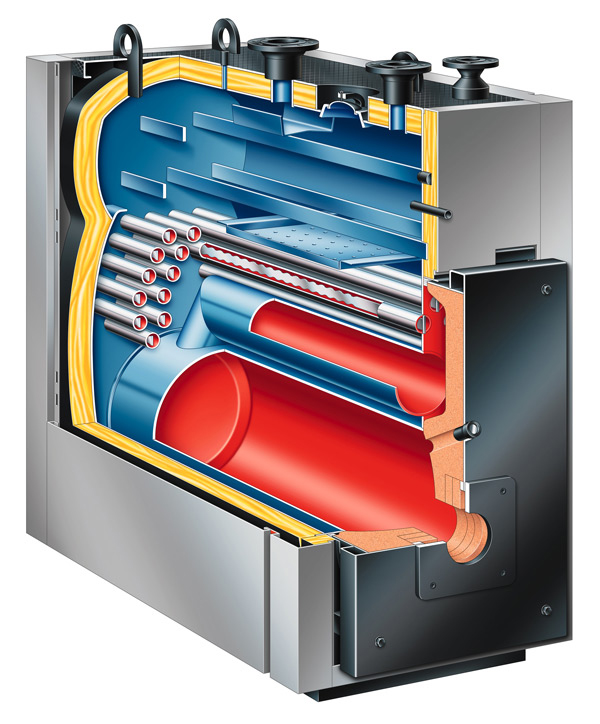

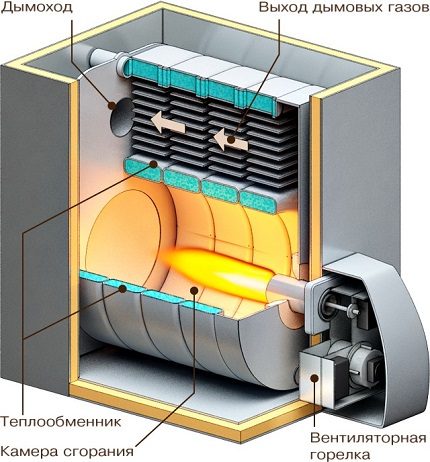

How is space heating

The whole process of generating heat in a liquid fuel boiler and transferring heat energy to heating radiators can be divided into several stages.

Stage 1.Diesel fuel or other fuel is poured into the storage. The fuel pump supplies liquid to the burner - pressure is created in the pipeline. At the same time, the fuel pump, using sensors, determines the quality of the fuel and the percentage of its thickening.

Stage 2. Diesel fuel enters the preparation chamber. Here the fuel is mixed with air, the mixture is heated and diluted.

Stage 3. The fuel-air composition is supplied to the nozzle. Under the action of the fan, the mixture is sprayed and the fuel mist is ignited in the combustion chamber.

Stage 4. The walls of the chamber are heating up. Due to this, the heat exchanger and the coolant are heated. Warm water enters and circulates in the heating system.

Stage 5. During the combustion of a combustible substance, gases are formed that are removed through the chimney. Rushing outward, the smoke passes through a series of heat exchange plates and also gives off its heat.

How does a liquid fuel boiler work

The operation of diesel fuel boilers is similar to that of a gas boiler. The leading role is played by a burner with a fan. She sprays fuel. In the combustion chamber, the fuel mixes with oxygen (air) and ignites. From the combustion of the fuel mixture, the heat exchanger with the coolant is heated.

In a double-circuit boiler, there is a second circuit along which water from the water supply moves, creating a hot water supply system.

Speaking about the similarities in the operation of gas and diesel boilers, it is worth remembering that most liquid fuel boilers can be quickly converted to work on gas (and vice versa). Only the boiler burner is replaced and that's it.

For example, a De DietrichGT123 boiler running on liquid fuel or gas.When purchased, it works with a pressurized oil burner, which can be replaced with a gas burner for gas operation. The diagram shows a similar double-circuit boiler Kiturami.

Advantages and disadvantages

Main advantage solar boiler is that its application is possible in the absence of all energy carriers. The exception is electricity, it is still needed a little, approximately up to 100 W / h. Other advantages of oil fired boilers are:

- High efficiency indicator, the efficiency of the units lies in the range of 90-97%.

- The absence of inertia during shutdown, which will protect the coolant from overheating.

- A high level of automation (in foreign units), thanks to which it is possible to organize weather-dependent regulation of home heating.

- Possibility of switching to natural gas by replacing the burner.

- Small overall dimensions allow to put a heater in the small room.

As usual, in any business is not without flaws. In this case, the main disadvantage is the high cost. Expensive equipment, fuel and maintenance. The latter should be carried out quite rarely, manufacturers say, but in fact, our diesel fuel is not of good quality, and therefore there is a prospect of often fiddling with the burner. This also includes the cleaning of smoke pipes from soot, which inevitably occurs during the combustion of low-quality diesel.

The main criteria for choosing boilers

Hundreds of foreign and domestic manufacturers offer thousands of models of heating equipment. It is not easy for an unprepared buyer to navigate all this variety of goods. I want it cheaper and the quality is better.

All heating boilers differ in the type of fuel and are divided into the following categories:

- solid fuel (processing firewood, peat, pellets, coal);

- liquid fuel (units operating on diesel fuel);

- gas (conventional and condensing);

- electrical (requiring the supply of electricity);

- universal (using either gas or electricity).

Before choosing an option, it will not be superfluous to conduct a small analysis and find out which energy carrier is profitable to use in your area. After that, you should decide how safe, reliable and comfortable the boiler should be in operation in terms of every penny invested in it.

To choose one or another type of heating equipment, you must first familiarize yourself with the advantages and disadvantages of each of them.

In order not to make a mistake and not to waste your hard-earned money, you need to carefully consider the process of choosing equipment. To do this, it is necessary to take into account a number of nuances that significantly affect the final result.

When choosing a boiler, you should:

- to understand in detail the advantages and disadvantages of each type of boilers;

- calculate the optimal power of heating equipment for your home;

- determine the number of circuits;

- choose a place where the equipment will subsequently be placed.

The maximum permissible dimensions and weight depend on the location of the future location of the boiler. Indeed, for a small room it is impractical to choose a heavy cast-iron unit.

The choice of heating equipment must be approached responsibly. This is the only way to buy high-quality equipment that will last far more than one year.

Advantages and disadvantages of equipment

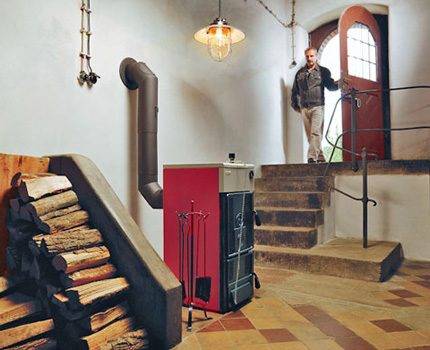

Heating boilers for liquid fuel make the house completely autonomous in the scheme of heating and hot water supply.They have their pros and cons that you should be aware of. The main benefits include the following:

- ease of installation;

- ease of operation and maintenance;

- automatic fuel supply;

- no need to obtain a special permit for installation;

- high power and efficiency;

- the ability to use for heating both residential and industrial premises;

- boilers are fully automated.

In this video, we will consider liquid fuel boilers:

If necessary, the type of fuel can be changed, for this you need to replace the nozzle. The devices are highly efficient. The main disadvantages are the following:

- noise during operation;

- the need to create a separate room for the boiler and fuel storage;

- availability of uninterrupted power supply;

- the need to install a chimney.

Read more: do-it-yourself chimney.

What are the advantages of liquid fuel boilers?

The main advantage of boilers that burn diesel fuel, mining and heavy heating oil is autonomy. The unit is indispensable when there are no other energy sources - firewood, gas and electricity in the required volumes.

There is no need to monitor the combustion process, the device operates in automatic mode until the diesel fuel runs out. Installation does not require any permissions, but the initial start-up and adjustment of the burner should be done by an intelligent master.

This is where the pluses of diesel units end, then there are solid minuses:

- high cost of equipment and fuel;

- constant smell of diesel fuel in the boiler room;

- maintenance - as needed, which occurs quite often due to the quality of the fuel;

- for the same reason, it is necessary to constantly clean the chimney;

- you need to monitor the level of diesel in the tank;

- in terms of weight and dimensions, the unit is comparable to a floor cast-iron boiler.

An example of a diesel boiler house with two heat sources. Fuel tanks and fuel pumps are installed at the end of the room.

If it comes to your mind to heat the house with used engine oil, add to the list of shortcomings the dirt in the furnace and an additional 2-4 squares of area for barrels - sumps.

Advantages and disadvantages of liquid fuel boilers

Liquid fuel boilers, despite the ability to effectively heat a building and technical excellence, are not as common as gas or solid fuel heat generators.

Equipment that runs on diesel fuel or mining is very popular in Western Europe.

Among the significant advantages of a liquid fuel heating boiler are:

- High work efficiency. The efficiency of most models reaches 95%. Fuel is consumed practically without loss.

- Great power. The performance of the units allows you to heat both compact living quarters and spacious production workshops.

- High level of work automation. The boiler operates for a long time without human intervention.

- Autonomy from energy sources. Except for electricity. If necessary, you can get by with a generator.

- Possibility of transition to gas fuel.

There are additional advantages of such equipment. The installation of the boiler does not require approval and obtaining permission. In addition, the absence of a gas pipeline greatly facilitates installation work.

Difficulties in the installation and operation of a liquid fuel boiler:

High fuel costs. With intensive use of the equipment, the annual fuel consumption can reach several tons.

A separate building is being built for fuel storage. As an option, a warehouse with containers made of opaque plastic or steel is equipped in the ground

An important condition is protection from sunlight.

The unit must be placed in a separate room with good ventilation and a powerful hood.

If the diesel boiler house is located close to the house, then additional sound insulation will be required - a burner makes noise during operation.

When equipping underground fuel storage facilities, it is necessary to take into account the hydrogeological characteristics of the area.

Many models provide for climatic adjustment of the boiler - setting a comfortable temperature regime in the house, taking into account the temperature outside

The principle of operation and arrangement of a liquid fuel boiler

The main element of the heater on liquid fuel - this is a burner

From the name it is already clear that the main difference between long-burning liquid fuel boilers is the fuel itself on which they operate. Since it is a liquid, the problem arises of how to burn it in a dosed manner. Accordingly, some device must be provided in the liquid fuel boiler device that will be responsible for this process. In addition to the main elements of the unit, which are no different from the standard set of any boiler, the burner plays a key role. This, one might say, is the heart of the device. It was invented by Robert Babington and patented at the end of the twentieth century, more precisely, in 1979. The device was named after him.

It is clear that the principle of operation of a long-burning liquid fuel boiler is to heat the coolant by means of an open flame.The coolant flows through the heat exchanger, which, in turn, is heated by fire. There are no tricks in this.

Let's start with the design:

- air supply pipe;

- fuel supply pipe;

- small bore nozzle.

It would seem that such a simple scheme, but in fact there are many nuances that we will consider a little later, talking about how to make it yourself. The design of the unit largely determines how much fuel it will burn in a certain period of time. Almost the main question asked about a liquid fuel boiler is fuel consumption per hour. And this is not surprising, because the "selfish" question is still of great importance.

Operation features

In order for liquid fuel heating boilers to work efficiently and properly, it is necessary to adhere to the basic operating recommendations. You need to constantly monitor the amount of fuel in the boiler.

The equipment is regularly inspected and maintained. It is recommended to carry out cleaning and detailed inspection for damage at least 2 times a year. The first inspection is carried out before the start of the heating season, and the second immediately after its end.

An important nuance is the use of only high-quality fuel and the installation of a special filter to clean it. Periodically, it is necessary to check the integrity of the containers in which liquid fuel is stored.

Long-burning oil-fired boilers with proper operation can serve for a long period

It is important to carry out technical inspection and troubleshooting on time. Only in this case, the operation of the device will be not only effective, but also safe.

2 id="samye-rasprostranennye-problemy">Most common problems

Even at the design stage, the future owner of a liquid fuel boiler faces a number of common problems. And the reason for this is mainly the architectural feature of his house. The heating methods familiar to us cannot be used in this case, and liquid fuel heat generators are completely satisfactory in almost all cases.

The fuel that we mentioned earlier, which is necessary for the operation of the device, is available in all parts of the country. The same cannot be said about gas pipelines, which, to be honest, are not laid everywhere.

We also talked about the fact that this boiler is very similar to a gas one (which is already there, it can become one), but it is convenient and, more importantly, very high efficiency - about 95 percent. Yes, and the fuel fluid is supplied in a slightly different way - there is a special burner that supplies air

And air is vital for the operation of the system - so the fuel will burn more evenly.

As a small conclusion

As a result, we note that if we add to the high cost of fuel the cost of the boiler itself (about 36,000 rubles) and its installation (which includes the equipment of a separate room - the installation of a fuel tank, the arrangement of sound insulation), then it turns out that heating a house with liquid fuel can hardly be considered at least an economical option. Although it should be added that more modern liquid fuel boilers are equipped with special sound silencers, so there will be one less problem.

How to choose a heat source - recommendations

If you have carefully studied the previous material, many questions have probably disappeared.Let's summarize our review of heat sources with general recommendations and tell you which boiler to choose in certain conditions:

Always start with energy availability. The best option for residents of the Russian Federation is gas heaters, wood-burning ones are in second place. In countries where the price of blue fuel is high, priority remains with TT boilers.

Count on 2 types of fuel. For example, liquefied gas and electricity at a nightly rate or firewood and electricity.

To provide a family of 2 people with hot water, a double-circuit heat generator is enough. If there are more residents, buy a single-circuit unit and an indirect heating boiler. An alternative option is to install a separate water heater.

Do not rush to purchase an expensive condensing boiler. Take a "aspirated" or a turbo unit - you will not lose in efficiency, but you will win in terms of initial and operating costs.

From solid fuel devices, we want to single out boilers of direct and long-term combustion. Pyrolysis plants are capricious, and pellet plants are too expensive. If you plan to fire with coal, be sure to choose a model sharpened for a high combustion temperature.

We do not recommend purchasing steel TT-boilers with upper combustion of firewood of the Stropuva type

The units are not bad, but "famous" for significant shortcomings - freezing of fuel, the inability to load "on the go" and similar troubles.

It is important to properly tie solid fuel installations - to organize a small circulation ring through a three-way valve. Electric and gas heaters are easier to connect - they are not afraid of condensate in the furnace.

When choosing an electric boiler, give preference to products that heat the coolant with heating elements - the devices are reliable in operation, maintainable and undemanding to water.

Diesel, combined or pellet heating boiler choose as needed. Example: during the day you want to heat with coal, at night you want to use electricity at a cheap rate. Another option: the budget allows you to buy an automatic TT boiler, pellets are inexpensive, and there are no other energy sources.

Instead of a combined wood-electricity boiler, it is better to purchase 2 separate units and connect them in parallel with check valves

What is important to consider before installing such thermal equipment?

Before installing such a heating system in your home, it is worth fulfilling several important requirements. The boiler, as well as the entire system, must be installed:

- in a separate room;

- at a sufficient distance from the walls;

- only on a concrete foundation.

When the boiler with its elements is placed in an isolated room, this guarantees your safety. In no case should you store any objects, things, clothes or shoes in such a room. In short, there should not be any flammable elements near the boiler, except for fuel for equipment or boiler elements.

Of course, if you are not a professional in this matter, then it is best to turn to the masters for help in installing. They will do their job well and flawlessly. At the same time, if you have certain skills, you can take on this job yourself. All necessary materials and tools can be purchased at the store where the boiler was sold.