- Power

- How to improve boiler performance

- Protection of a solid fuel boiler against overheating

- Scheme of connecting a solid fuel boiler to a closed heating system

- Types of solid fuel boilers

- Constant burning heaters

- Long burning devices

- Pyrolysis solid fuel

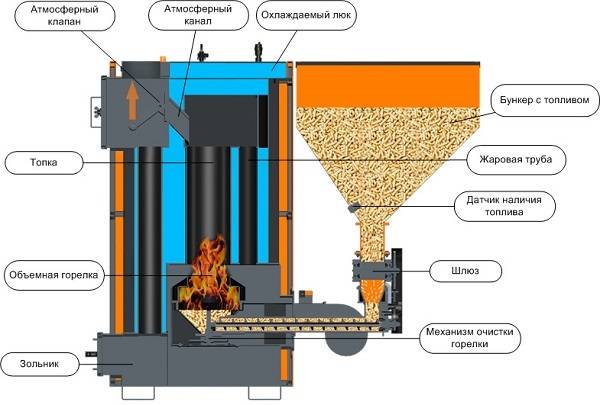

- Pellet

- Recommendations for choosing a solid fuel boiler

- Fuel used

- Construction device

- Power

- Dimensions and weight of the device

- Number of circuits

- Additional functions

- The principle of operation of automatic long-burning boilers

- Solid fuel boilers

- Scope of use

- Popular models of solid fuel boilers

- Model Hercules U22С-3

- Model SIME SOLIDA 3

Power

In order not to choose models with high power, take care of the heat loss of your home.

When choosing a unit, you should pay attention to its power. There are no special requirements here, for every 10 sq.

m. area, we need 1 kW of thermal energy. That is, for an average house of 150 square meters. m. you will need a solid fuel boiler with a capacity of 15 kW. We also add a small margin of 10-20% - it will be required in case of unexpected frosts or when using low-quality fuel.

You also need to deal with heat losses. To do this, we evaluate the presence of insulation of windows, walls and attic.Losses can be reduced by installing triple-glazed windows, lining the main walls with bricks and additional thermal insulation (penoizol, mineral wool), insulating attic spaces and doors.

The wildest heat leaks occur in rooms with lots of exterior walls. For example, if you want to heat a one-room country house, you can safely take a margin of 30%, since here all the walls will be external.

How to improve boiler performance

A self-assembled solid fuel boiler, as a rule, is characterized by significant heat losses associated with the escape of heat into the chimney. Moreover, the straighter and higher the chimney, the more heat is lost. The way out in this case will be the creation of a so-called heating shield, that is, a curved chimney, which allows you to transfer more thermal energy to the brickwork. The brick, in turn, will give off heat to the air in the room, heating it. Often such moves are arranged in the walls between rooms. However, such an approach is feasible only if the boiler is located in the basement or on the basement floor, or if a bulky multi-stage chimney is built.

Alternatively, the efficiency of the boiler can be increased by installing a water heater around the chimney. In this case, the heat of the flue gases will heat the walls of the chimney and be transferred to the water. For these purposes, the chimney can be made from a thinner pipe, which is built into a larger pipe.

The most effective way to increase the efficiency of a solid fuel boiler is to install a circulation pump that forcibly pumps water. This will increase the productivity of the plant by about 20-30%.

Of course, it is necessary to design the boiler so that the coolant can circulate on its own if the electricity is turned off in the house. And if it is available, the pump will speed up the heating of the house to comfortable temperatures.

Protection of a solid fuel boiler against overheating

In a solid fuel boiler, burning fuel, and the boiler itself, have a rather large mass. Therefore, the process of heat release in the boiler has a large inertia. The combustion of fuel and the heating of water in a solid fuel boiler cannot be stopped instantly by cutting off the fuel supply, as is done in a gas boiler.

Solid fuel boilers, more than others, are prone to overheating of the coolant - boiling water if the heat is lost, for example, when the water circulation in the heating system suddenly stops, or more heat is released in the boiler than is consumed.

Boiling water in the boiler leads to an increase in temperature and pressure in the heating system with all serious consequences - the destruction of the heating system equipment, injury to people, damage to property.

Modern closed heating systems with a solid fuel boiler are especially prone to overheating, as they contain a relatively small volume of coolant.

Heating systems usually use polymer pipes, control and distribution manifolds, various taps, valves and other fittings. Most elements of the heating system are very sensitive to overheating of the coolant and pressure surges caused by boiling water in the system.

The solid fuel boiler in the heating system must be protected against overheating of the coolant.

To protect the solid fuel boiler from overheating In a closed heating system that is not connected to the atmosphere, two steps must be taken:

- Shut off the combustion air supply to the boiler furnace in order to reduce the combustion intensity of the fuel as soon as possible.

- Provide cooling of the heat carrier at the outlet of the boiler and prevent the water temperature from rising to boiling point. Cooling should take place until the release of heat is reduced to a level at which boiling water becomes impossible.

Consider how to protect the boiler from overheating, using the heating circuit as an example, which is shown below.

Scheme of connecting a solid fuel boiler to a closed heating system

Scheme of a closed heating system with a solid fuel boiler.

1 - boiler safety group (safety valve, automatic air vent, pressure gauge); 2 - a tank with a supply of water for cooling the coolant in case of boiler overheating; 3 - float shut-off valve; 4 - thermal valve; 5 - group for connecting an expansion membrane tank; 6 - coolant circulation unit and boiler protection against low-temperature corrosion (with a pump and a three-way valve); 7 - heat exchanger protection against overheating.

Boiler protection against overheating works as follows. When the temperature of the coolant rises above 95 degrees, the thermostat on the boiler closes the damper for supplying air to the combustion chamber of the boiler.

Thermal valve pos.4 opens the supply of cold water from the tank pos.2 to the heat exchanger pos.7. Cold water flowing through the heat exchanger cools the coolant at the outlet of the boiler, preventing boiling.

The supply of water in the tank pos.2 is necessary in case of lack of water in the water supply, for example, during a power outage. Often a common storage tank is installed in the water supply system of the house.Then the water for cooling the boiler is taken from this tank.

A heat exchanger to protect the boiler from overheating and coolant cooling, pos.7 and a thermal valve, pos.4, are usually built into the boiler body by boiler manufacturers. This has become standard equipment for boilers designed for closed heating systems.

In heating systems with a solid fuel boiler (with the exception of systems with a buffer tank), thermostatic valves and other automatic devices that reduce heat extraction must not be installed on heating devices (radiators). Automation can reduce heat consumption during the period of intensive fuel burning in the boiler, and this can cause the overheating protection to trip.

Another way to protect a solid fuel boiler from overheating is described in the article:

Read: Buffer tank - protection of a solid fuel boiler from overheating.

Continued on next page 2:

Types of solid fuel boilers

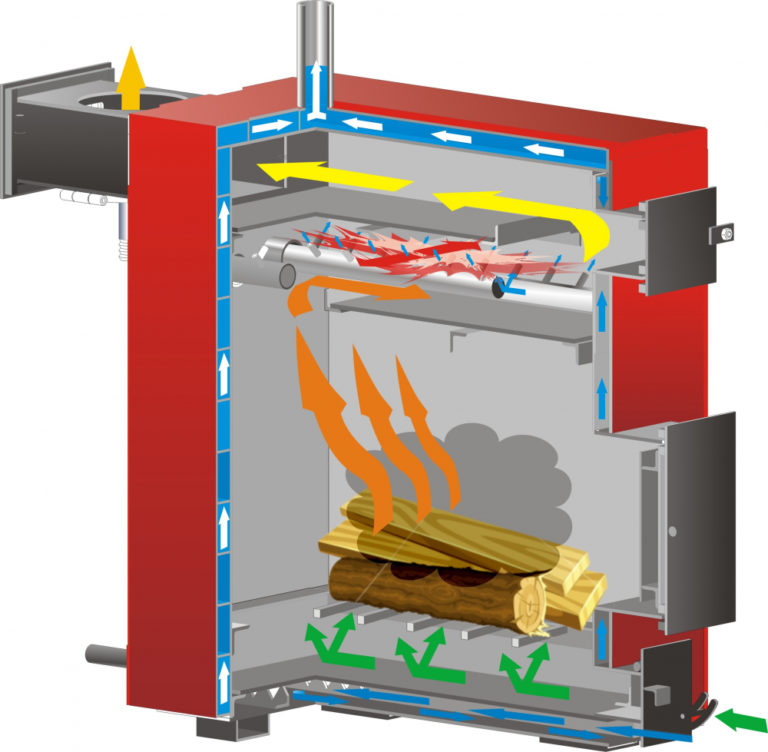

These devices differ in the types of fuel used, the number of furnaces and combustion chambers, the method of fuel supply, and the material from which they are made. There are several types of solid fuel boilers.

Constant burning heaters

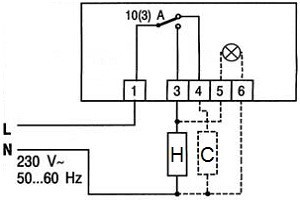

They are made of cast iron or steel, contain one or two fireboxes, work only on coal and wood, the work cycle is 4-6 hours, the fuel is supplied manually. The control scheme of such equipment is mainly mechanical, the boiler temperature is 60–70 degrees, the difference between supply and return is 20 degrees.

Power consumption from 7 to 50 kW, and efficiency - 80-90%.

Long burning devices

Steel single-furnace units - the furnace is located on top, which ensures longer burning of one bookmark (firewood for more than 24 hours, coal - up to 144 hours) and uniform heating of the coolant.

It works on firewood and its derivatives (briquettes, sawdust, shavings, etc.), as well as on coal. The temperature of the boiler is 70–80 degrees, the power is up to 50 kW, the efficiency is 90–95%. Fuel is supplied manually.

Pyrolysis solid fuel

They are made of steel, have two chambers connected by a nozzle. The technology lies in the fact that the main fuel (dry firewood with a moisture content of not more than 25%), burning in the first chamber, emit combustible wood gas, which ignites in the second chamber.

The operation cycle in case of connecting a buffer tank is possible from 6 hours to a day, the operating temperature of the boiler is from 70 to 95 degrees, the power consumption is up to 120 kW, the efficiency is 90–95%.

Pellet

Steel aggregates operate on granules (pellets) made from wood waste - sawdust, shavings, etc. In the presence of removable grates, it is possible to use coal and firewood.

Achieved temperature - 70-80 degrees, power up to 400 kW, duty cycle from 24 to 144 hours.

The fuel supply scheme in such boilers can be automated, electronic control. This type of equipment is used for heating rooms with a large area.

Recommendations for choosing a solid fuel boiler

Among the variety of options solid fuel boilers is important to choose which will be better suited to specific conditions. Both the parameters of the house and the surrounding conditions are taken into account

Fuel used

When choosing a solid fuel boiler, the following parameters are taken into account:

- price;

- efficiency;

- time of one download;

- prevalence in the area.

Fuel is loaded into solid fuel pellet boilers up to once a month, into coal - once every few days. Wood boilers work from one bookmark for no more than a day.

If possible, it is better to install a heating boiler that requires less maintenance. But if you can buy, for example, only firewood without problems and interruptions, you will have to opt for them.

Construction device

Automatic loading greatly simplifies the process of heating a house, but such solid fuel boilers require electricity. Therefore, this method is not suitable for dachas, where there are often interruptions with it or the allocated power of electricity is hardly enough for other needs.

Of the types of boiler design, it is better to choose pyrolysis or long-term combustion. In them, resources are spent more efficiently, that is, costs are reduced.

Power

From this parameter depends on what area of the house the installed solid fuel boiler can heat. If it is not enough, it will be too cold. But it's also not worth choosing with a large margin.

Otherwise, the room will be too hot. In addition, heating costs will increase significantly.

To determine the required boiler power, calculate the heat loss of the house. They depend on its size, materials and climate.

But for an approximate calculation, it is enough to know the total area. 1 kW is enough to heat 10 square meters. m. with a ceiling height of about 2.5-2.7 meters.

To take into account climatic conditions, special coefficients are used. The resulting value is multiplied by:

- 1.5-2 for the northern regions;

- 1-1.2 for the middle band;

- 0.7-0.9 for the southern regions.

These calculations are correct only for heating the house. If it is also planned to heat water for domestic needs, the capacity is increased by another 20-25%.

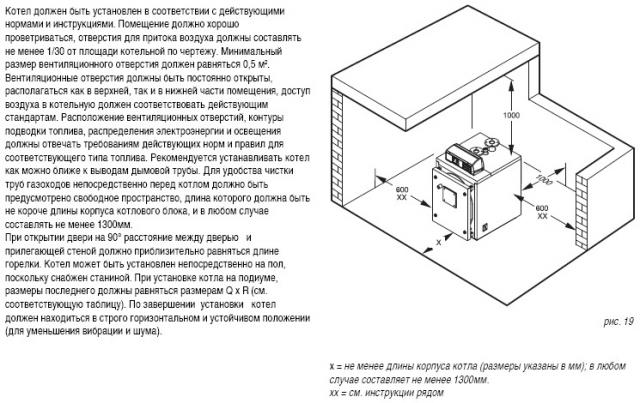

Dimensions and weight of the device

The size of the solid fuel boiler depends on which furnace is required. The distance to the walls should be at least 20-25 cm.

Take up more space solid fuel pellet boilers with automatic loading. Their bunker in size sometimes exceeds the device itself.

In general, all solid fuel heating boilers are of considerable weight. Therefore, they are installed on the floor, and not hung on the wall.

Reference. Cast iron solid fuel boilers are heavier than steel ones. Often they require the installation of a foundation.

Number of circuits

Single-circuit models of boilers perform only one function - heating the house. Other technologies will have to be used to heat water.

Photo 3. Single-circuit solid fuel boiler. It is connected to the heating system, through which the coolant circulates.

In a double-circuit solid fuel boiler, there are two outlet pipes. A system of radiators is connected to one of them, and water for domestic needs comes out to the other. This is more convenient - you will not need a second device, but the consumption of resources will increase. And in the event of a breakdown, there will be neither heat nor hot water.

Additional functions

Some models of solid fuel boilers have one or more of the following functions:

- A hob that allows you to cook food. This is especially useful for small houses.

- Automatic ignition of firewood.

- Pressure sensor.

- Thermal accumulator.

A heat accumulator is a tank filled with water. It is located on the chimney or connected separately. During the fire, the water in it heats up.Then it is used for domestic needs or (less often) goes for heating (after cooling the "main" liquid in the system). The use of this technology makes the operation of the equipment more efficient.

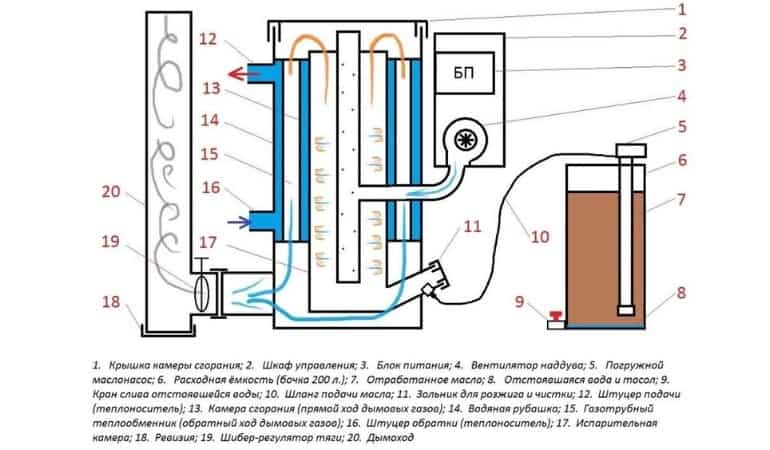

The principle of operation of automatic long-burning boilers

The automatic long burning solid fuel boiler is a powerful installation with a bunker in which solid fuel is stored. A similar part can be integral to the boiler or placed in a separately equipped room.

In the first case, the storage is fixed at the top or side of the boiler equipment. But due to the limited amount of fuel, most consumers stop at the second option and prepare a special room.

To move firewood or sawdust from the "warehouse" to the combustion chamber, a loading mechanism is activated. It is screw or pneumatic. A pneumatic conveyor is used as a feed mechanism - a pipe through which pellets of fuel cells are transferred with the help of air masses.

Source

Source

The main advantage of such equipment is partial energy dependence, since the fuel chamber is loaded once a day. Of the minuses, there are high costs of electrical energy during the operation of fuel supply units.

A large number of units support the screw feed of granules, and the loading intensity is determined by automation.

Solid fuel boiler with automatic fuel supply has the following features:

- To adjust the temperature of the coolant, the intensity of the air supply to the tank is changed.

- The system is controlled according to the following principle: the temperature sensor sends an electromagnetic signal to the control mechanism, as a result of which the air damper is opened or closed.

- To regulate the air temperature inside the room, a thermostat and 3-way valves are used.

- To compensate for pressure drops in the heating system and protect it from overheating of the coolant, components of the safety group are equipped in the boiler. These include an expansion tank, a safety valve with an air vent and a measuring device (pressure gauge).

- To protect the coolant from overheating, protective sensors and cooling circuits with natural circulation are placed in the boiler.

- With the help of a draft sensor, the operation of the boiler is suspended in the event of a decrease in the draft in the furnace.

- To monitor the functionality of the unit and select the optimal temperature regime, a control module is placed in the unit.

- If you install an additional GSM module, you can provide remote control and management of the heating system using a smartphone or tablet.

When choosing automatic solid fuel boilers, it is important to pay attention to such nuances:

- The consumption of fuel materials is determined by their quality (calorie content, humidity, ash content). At the same time, high-quality raw materials are expensive, and the degree of their consumption depends on external temperature conditions.

- The frequency of fuel supply depends on the volume of the bunker.

- The power of the boiler is selected taking into account the area of \u200b\u200bthe heated building. It makes no sense to purchase high-performance units for small spaces.The optimal operating parameters are determined by the following formula: 2 kW per 10 m².

- With an identical amount of fuel burned, 2 boiler plants may have different efficiency indicators. The average range varies from 60 to 85%.

- Depending on the level of automation, uninterrupted autonomous operation of the equipment without human intervention is ensured.

Automatic solid fuel boilers have the following advantages:

- Economical consumption of solid fuel. At the same time, coal and wood waste are sold at affordable prices.

- Almost complete autonomy and independence from human participation.

- Compliance with environmental standards.

- Ease of equipment installation.

In addition to the advantages, such units also have disadvantages. So, if wood chips are used as a fuel raw material, during prolonged downtime, it can stick together or cake on the bottom of the tank. Wet material does not provide the desired degree of heating.

For the smooth operation of the boiler, it is important to constantly clean it from dirt.

Solid fuel boilers

If we talk about this type of fuel equipment, then these are traditional boilers that have the simplest design. The fuel burns in the usual way, heating water, which carries heat throughout the house. The advantage is that the price of a solid fuel boiler for heating a private house will be low. Among the shortcomings, the following can be distinguished: loss of released energy, the need to often lay fuel.

The modern design of solid fuel boilers will allow them to fit into any living space.

If earlier, when the technologies of efficient fuel boilers were not yet used for private use, this was the most used equipment.Currently, it can be bought for country houses, where a short stay is planned during the cold season.

Firewood is an affordable and economical type of fuel.

Firewood is an affordable and economical type of fuel.

Scope of use

It is noteworthy that this equipment is used not only for private purposes, but also to meet industrial needs - this fact implies the existence of various models. The main difference between the heating systems used in production is that the fuel is supplied automatically, although the principle of operation remains the same.

They also have a special ash removal system, which makes them truly innovative. Household boilers that are installed in private homes, as a rule, do not have such options, since automation is expensive, and not every user can afford it.

Popular models of solid fuel boilers

Model Hercules U22С-3

ViadrusHercules U22С-3

By purchasing this boiler, even a large family can easily solve the problem of not only heating, but also supplying hot water for domestic needs. A simple connection of the storage boiler is enough. The mineral insulation of the boiler body ensures minimal heat loss, so much less fuel is used for heating. The peculiarity of the Hercules U22С-3 boiler is that, if desired, it can be converted, and then it can operate on gas or liquid fuel.

Model SIME SOLIDA 3

Another, no less popular model of a solid fuel boiler is SIME SOLIDA 3, from Fonderie Sime Spa, whose factories are located in Italy, Spain and the UK. The equipment presented by the company has earned the trust of customers for simple operation. For heating a house with an area of about 165 sq.m, one of the four types of fuel that can be used for heating is suitable - coal, wood, coke or anthracite.

The boiler body is insulated with a layer of glass wool, which minimizes heat loss and saves fuel. The heat exchanger itself is made of cast iron, has three sections, due to which there is a balanced combustion of all fuel without residue. This significantly reduces the emission of harmful gases into the atmosphere. The intensity of fuel combustion is regulated by a device that opens the door slightly and lets some air inside. Wide doors provide convenient and safe loading of fuel into the boiler, while greatly facilitating its cleaning.

The priority of this model is that it is quite safe and easy to maintain. Plus, you don’t have to constantly monitor the combustion process, and cleaning the boiler is not laborious, since you don’t have to clean the ash pan often, and the whole procedure will not take much time.