- Types of solid fuel boilers

- Pyrolysis boilers

- Upper combustion boilers

- Fuel supply method

- Choosing a boiler for the house

- Video - How to choose a heating boiler for your home

- What types of fuel can be used in boilers

- How to choose the right boiler?

- Brands of Russian-made solid fuel boilers

- Power

- Pellets

- Principle of operation

- Choosing a boiler

- Classic boilers

- Pyrolysis boilers

- Automatic boilers

- Long burning boilers

- What types of solid fuel boilers exist

Types of solid fuel boilers

It is possible to divide solid fuel boilers into types according to various criteria:

- heat exchanger material;

- energy dependence;

- method of fuel combustion;

- fuel delivery method.

Solid fuel heating systems can be non-volatile, that is, they can operate independently of the supply of electricity. These are traditional boilers operating due to natural draft.

Volatile equipment has a forced air supply system, which improves its performance and efficiency, and also allows the use of additional electronic equipment. The disadvantage of such systems is the shutdown of work in the absence of power supply.

According to the material of the heat exchanger, boilers are divided into cast iron and steel.Each of the materials has both advantages and disadvantages. Cast iron have a longer service life, are less sensitive to water hardness, and less often require cleaning of the heat exchanger.

Having a significant weight, they almost always require a separate foundation and are much more expensive than steel ones. Cast iron is afraid of sudden changes in temperature, so the water to feed the heated system should not be cold.

Steel boilers require frequent cleaning, as they are sensitive to the formation of tar, acids and condensate, are subject to corrosion, but are subject to repair and, if necessary, leaking parts can be welded. Steel sometimes does not withstand overheating when using the boiler at maximum power.

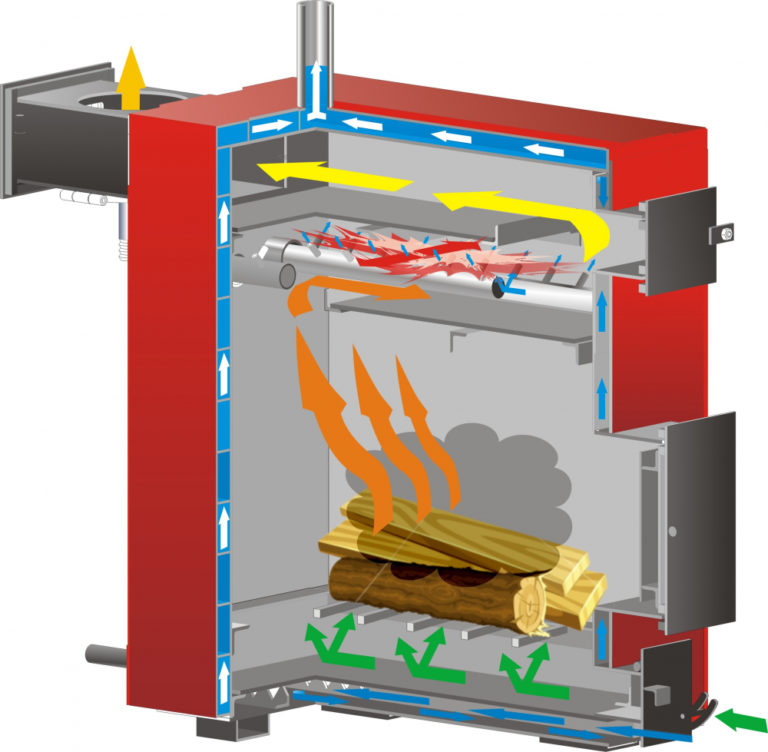

Pyrolysis boilers

In pyrolysis (gas generating) boilers in one of two chambers, the fuel burns slowly at high temperature and lack of oxygen. As a result, gases are released that burn out in the second chamber. The draft is provided by an exhaust fan.

Such boilers have a very high efficiency and economical fuel consumption, however, they are extremely demanding on its quality. Usually they work on wood or briquettes, which must have a moisture content of not more than 20%.

We recommend wood aged in a dry room for at least a year. This requires a large storage for the supply of firewood.

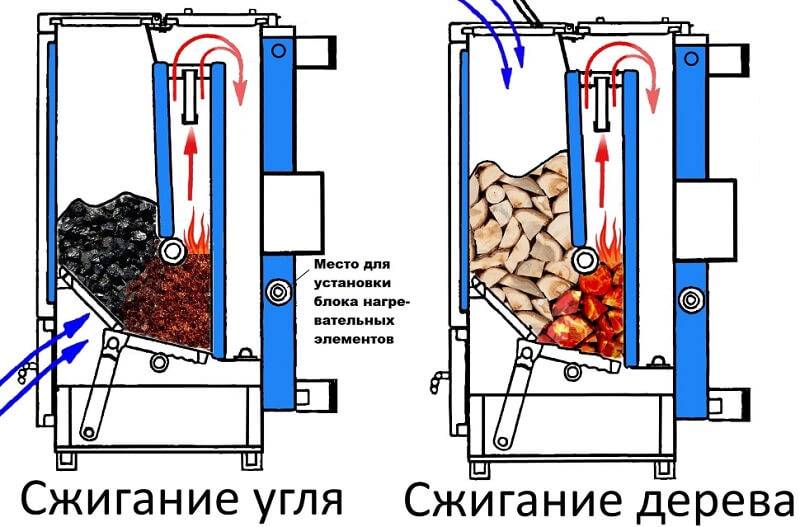

Upper combustion boilers

In traditional heating systems, fuel combustion occurs from the bottom up. The principle of upper combustion allows to achieve long-term operation of the boiler with a single load.

One bookmark of firewood can last more than a day, coal - up to five days.The long-term (upper) combustion boiler is a combination of two steel cylinders (one inside the other), between which the coolant circulates.

The telescopic pipe for supplying air to the flame is lowered into the combustion chamber. As the fuel burns out, it falls lower, so that combustion occurs at the desired level. The resulting ash is not an obstacle to combustion and requires cleaning 2-3 times a month.

The upper combustion boiler occupies a not very large area with a significant height. The disadvantage is the impossibility of reloading fuel during the combustion process, which can sometimes create certain difficulties.

Fuel supply method

If there is an automatic fuel supply system, in addition to the main part with a heat exchanger and a burner, a bunker is provided for loading fuel. Coal fraction 5-25 mm or pellets (wood, straw, sunflower husks, etc.) are placed in it.

Depending on the type of fuel, one load provides three to five days boiler operation. Only regular filling of the hopper and cleaning of the ash chamber is required.

The size of the bunker is determined by the capacity of the boiler. Fuel supply from the bunker can be screw or piston. The controller sets the coolant temperature, which is maintained automatically by metered fuel supply.

The combustion air is supplied by a blower fan. Boilers with manual loading are more common. They use the following types of fuel:

- coal of any fraction;

- firewood;

- wood briquettes from various species;

- pellets from waste wood, straw, sunflower husks;

- sawdust, wood chips;

- peat briquettes;

- briquettes from coal dust;

- various wood waste.

The heat exchanger circulates and heats the coolant (water) from an open flame. The reliability and service life of the boiler depends on the material of the heat exchanger, its thickness and quality of welds.

The fuel loading chamber may have a different size. The frequency of fuel loading depends on this. Some models provide both automatic and manual loading. This allows you to change the type of fuel if necessary. Knowing the differences between different types, it is easier to figure out how to choose a solid fuel boiler.

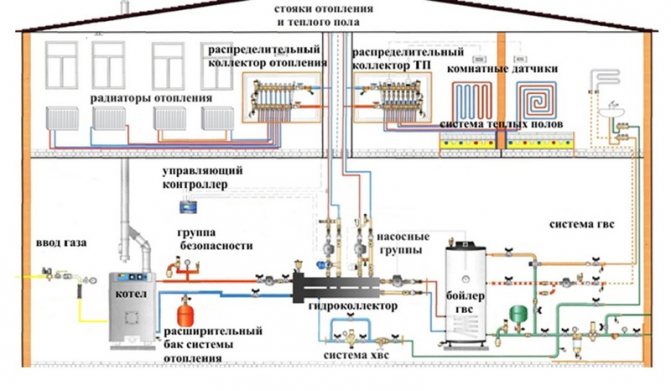

Choosing a boiler for the house

The choice of a solid fuel boiler is a responsible matter, especially if it is planned to purchase an expensive unit. However, if you know all the intricacies of work and the characteristics of the installations, then choosing a device will be quite simple.

Step 1. First you need to decide which fuel will be most convenient to use

Here you should pay attention to prices. In some regions it is cheaper to buy coal, in others - wood

Choice of solid fuel

Step 2

It is important to decide whether you need a boiler that can heat water for domestic use, or it will only work for heating. If hot water is needed in large volumes, then it is advisable to buy a single-circuit boiler, and in addition to it, take a boiler

If water is needed in relatively small volumes, then it makes sense to buy a two-circuit unit.

Scheme of operation of a solid fuel boiler

Step 3. Choosing the right power of the boiler is also not an easy task, since with its excess it will be a pity for the funds spent on a more powerful installation, while with a shortage it will be too cold in the house, and the equipment will spend all its resources to warm the room.

Boiler power calculation table

Step 4. Now you should choose the material from which the heat exchanger should be made - cast iron or steel. In order to save money, you can buy a steel installation.

Cast iron heat exchanger

Step 5. An important factor when choosing a unit – ease of maintenance. You should not take a boiler that is difficult to maintain and operate, especially if there is not so much time to mess around with it. The same applies to the duration of operation of the installation without additional fuel supply.

Cleaning process

Step 6. It is worth choosing an installation with maximum efficiency - the higher this indicator, the more efficient the unit works, which means that it is more economical.

Video - How to choose a heating boiler for your home

Now all that remains is to opt for specific models and read reviews about them, and then you can go to the store to buy

After purchasing the boiler, it is also important to install and connect it correctly. High-quality installation is the key to successful and long-term operation of the equipment

Careful maintenance will help prolong the life of the boiler.

Solid fuel boilers: overview of models and selection the best

How to choose a solid fuel boiler for a private house

Solid fuel boiler device

solid fuel boiler

Modern boiler room equipped double-circuit solid fuel boiler with storage tank for hot water

Cleaning a solid fuel boiler with a spatula

According to the possibilities and purpose

According to the material of manufacture

According to the principle of operation and the method of combustion of fuel

By way of air supply

By way of loading fuel

Any type of organic fuel can burn in a solid fuel boiler

The choice of solid fuel boiler

Long burning boiler Stropuva S10

Boiler Dakon DOR F 16

Zota Pellet 25

Viessmann Vitoligno 100 VL1A025

Stropuva S 40

Lamborghini WBL 7

Bosch Solid 2000 B K 16-1

GEFEST QUO 20 TE

Stropuva S10

Choice of solid fuel

Scheme of operation of a solid fuel boiler

Boiler power calculation table

Cast iron heat exchanger

Cleaning process

Boiler on solid fuel of long burning Stropuva S 10U (station wagon)

Solid fuel boiler Viessmann Vitoligno 100-S

Top loading boiler

Solid fuel boiler in the house

Steel solid fuel boiler

Solid fuel boiler has its advantages and disadvantages

What types of fuel can be used in boilers

When creating a heating system for a house where it is planned to live all year round, the type of fuel that the heating equipment runs on is of particular importance. It is proposed to choose from several options: brown or hard coal, peat, firewood, coke, pellets.

Important! The power of the boiler, where this or that type of fuel is used, will vary. Each type of raw material has certain calorie values, which directly affects the strength of the boiler and the amount of fuel needed to fill the combustion chamber.

So, if you fill the heating boiler with fuel with a lower calorie content, the power of the unit may decrease by twenty to thirty percent of that provided for by the project. If the fuel has a high moisture content, the power loss will be even more noticeable.

As a rule, the type of fuel that is more suitable for a particular boiler model can be found in the equipment manual. Manufacturers usually write what options it can be replaced with.

According to experts, it is better to follow the recommendations of the boiler manufacturer: this way it will work more efficiently and for a longer time.

Modern solid fuel heating boiler in the interior of a residential building

How to choose the right boiler?

The only objective criterion for choosing a combined boiler for your home is the required power to ensure the functioning of the heating system. Moreover, this indicator should not be affected by the number of connected circuits.

It makes no sense to pay more for a powerful boiler in the hope of adjusting its operation with automation. This approach contributes to the "idle" operation of the device, which leads to a faster failure. In addition, this mode of operation contributes to the acceleration of the condensation process.

As for the calculation of power, theoretically, to heat an area of 10 m2, it will be necessary to use 1 kW of heat energy.

But this is a rather conditional indicator, which is adjusted based on the following parameters:

- ceiling heights in the house;

- the number of floors;

- degree of building insulation.

Therefore, it is advisable to use a one-and-a-half coefficient in your calculations, i.e. in calculations, increase the margin by 0.5 kW. The power of a multi-circuit heating system is calculated with a surcharge of 25-30%.

So, in order to heat a building with an area of 100 m2, a power of 10-15 kW is required for single-circuit heating of the coolant and 15-20 kW for double-circuit heating.

To select a gas burner in a solid fuel boiler, you need to accurately measure the dimensions of the combustion chamber. It is these proportions that will correspond to the size of the gas burner

An equally important criterion when choosing a combined heating boiler is the price category. Price device depends on the power, number of functions and manufacturer.

For users, other characteristics are no less important:

- DHW;

- material of manufacture;

- ease of management;

- dimensions;

- accessories;

- weight and installation features;

- other.

The issue with hot water supply will immediately have to be resolved: a boiler will provide hot water or there is an electric boiler for this.

In the case of determining the first option, the preferred method is chosen - storage or flow, as well as the parameters of the water reservoir according to needs (calculated based on the number of residents).

As for the dimensions of the equipment, they only matter in the case of installation in a room with a small area.

According to the material of manufacture, a wide range of boilers is presented. But the most popular options - steel or cast iron. Also, such a boiler is able to withstand a high and prolonged temperature load, has a longer service life.

Judging by the intensity of sales and relying on consumer reviews, the following models are actively in demand:

Management automation affects on ease of use, as well as the security system depends on how automated the process of combustion of energy carriers is. Most models can be controlled using convenient remote controls or panels.

Most models are optional. This includes the presence of a hob for cooking, injectors, draft regulators, burners, a soundproof casing, etc.

The choice of a boiler according to this parameter should be based on personal preferences and the allocated amount for the purchase.

When choosing a heating boiler with a combination of wood / electricity, it is necessary to calculate the required power of the heating element. It is recommended to choose models with an indicator of at least 60% of the required coefficient for home heating

But the weight of the equipment and the complexity of its installation should immediately pay attention. Installation in a residential building of most floor models of combined boilers for heating, equipped with several combustion chambers, requires an additional concrete pedestal device, because a standard floor covering cannot withstand such a load

The best solution is to equip a separate boiler room

Installation in a residential building of most floor models of combined boilers for heating, equipped with several combustion chambers, requires an additional concrete pedestal device, because a standard floor covering cannot withstand such a load. The best solution is to equip a separate boiler room.

Knowing the main parameters that affect the choice of a combined boiler, you can choose the most suitable model.

Additional recommendations for selection, as well as comparative overview of different heating units for a private house are given in.

Brands of Russian-made solid fuel boilers

An analysis of the technical characteristics will help to get a general idea of solid fuel boilers for long burning. Consumer reviews on independent forums give an objective assessment of domestic developments.

Table 1. Solid fuel boilers Zota Mix and Pellet production plant of heating equipment and automation (Krasnoyarsk):

Table 1. Solid fuel boilers Zota Mix and Pellet manufactured by the heating equipment and automation plant (Krasnoyarsk)

- The efficiency of boilers of the Zota Mix model range is 80%, Pellet is 90%;

- combined steel solid fuel boilers Zota Mix operate on any type of fuel (liquefied or natural gas, electricity, liquid fuel);

- the combustion chamber and the ash box are located inside the water jacket;

- adjustable chimney damper, mechanical draft regulator and air suction by an ejector, which is installed in the furnace door, ensure complete combustion of fuel with minimal draft;

- the outer surface of the body is coated with an anti-corrosion polymer composition;

- a removable door behind the front panel provides access for cleaning the flue;

- the possibility of repair.

Boiler design Zota Mix

- need a supply of fuel and a place to store it;

- costs of delivery, unloading and storage of firewood, coal, briquettes;

- decrease in productivity of Zota Mix boilers when using low-quality fuel (lignite by 10÷20%, raw firewood by 60÷70%);

- for Zota Mix - manual loading of fuel, cleaning the ash pan, furnace walls, gas ducts and flue pipe;

- mandatory preparation of boiler water (hardness up to 2 mg-eq / l);

- installation in a separate room;

- for boilers of the Zota Mix line, it is necessary to install a heat accumulator, a smoke exhauster, and a boiler.

Table 2. Apparatuses combined solid fuel with a water circuit (AKTV). Manufacturer OOO Sibteploenergomash (Novosibirsk):

Table 2. Apparatuses combined solid fuel with a water circuit (AKTV). Manufacturer Sibteploenergomash LLC (Novosibirsk)

- a budget option for solid fuel boilers with a water circuit for the home (price 11,000 ÷ 25,000 rubles);

- compact size;

- the water heat exchanger covers the furnace from all sides (except the front);

- retractable ash drawer;

- mounting socket for draft regulator;

- the ability to connect to a chimney of any configuration;

- a steel heat exchanger allows a simplified connection to the heating piping (without admixture);

- the design is adapted to work on gas and electricity.

Boilers "Karakan" from the manufacturer LLC "Sibteploenergomash"

- outdated design, primitive low-quality automation;

- the technical characteristics declared by the manufacturer (power, heated area and efficiency), according to consumer reviews, do not correspond to actual indicators.

Table 3 Solid fuel pyrolysis boilers Bourgeois & K from NPO TES LLC (Kostroma):

Table 3. Solid fuel pyrolysis boilers Bourgeois & K from NPO TES LLC (Kostroma)

- ensures stable combustion of fuel of any grade and degree of humidity;

- effective operation of the boiler from one tab for 8 hours;

- economical fuel consumption;

- generator compatibility with natural or forced circulation systems;

- environmentally friendly unit, the fuel goes through a cycle of complete combustion, without forming harmful emissions into the atmosphere;

- the design of the firebox provides an effective mode of operation in 40 minutes.

Solid fuel pyrolysis boilers "Bourgeois & K"

- complex installation: the connection must be made by employees of specialized enterprises licensed for this type of activity (otherwise the guarantee from the manufacturer does not apply to the unit);

- manual loading of fuel and cleaning of the combustion chamber;

- great weight.

Installation and operation of solid fuel boilers must be carried out in accordance with fire safety rules

For heating a country house. garage or greenhouse, it is possible to manufacture solid fuel boilers for long burning with your own hands. Videos with materials on this topic can be found on the Internet. But remember that the main condition for the use of heating equipment is fire safety. And only a certified manufacturer can guarantee the fulfillment of this condition under proper operating conditions and equipment installation.

Power

In order not to choose models with high power, take care of the heat loss of your home.

When choosing a unit, you should pay attention to its power. There are no special requirements here, for every 10 sq.

m. area, we need 1 kW of thermal energy. That is, for an average house of 150 square meters. m. you will need a solid fuel boiler with a capacity of 15 kW. We also add a small margin of 10-20% - it will be required in case of unexpected frosts or when using low-quality fuel.

You also need to deal with heat losses. To do this, we evaluate the presence of insulation of windows, walls and attic. Losses can be reduced by installing triple-glazed windows, lining the main walls with bricks and additional thermal insulation (penoizol, mineral wool), insulating attic spaces and doors.

The wildest heat leaks occur in rooms with lots of exterior walls. For example, if you want to heat a one-room country house, you can safely take a margin of 30%, since here all the walls will be external.

Pellets

Pellet boilers are one of the most advanced solid fuel systems.

Pellets are small fuel pellets that look like oblong cylinders 2-4 cm long and about 7 mm thick.The raw materials for their manufacture are sawdust, wood chips, bark, as well as substandard wood, which is unsuitable for other purposes.

Expert opinion

Torsunov Pavel Maksimovich

Depending on the proximity of waste sources, pellets may also include agricultural waste - husks, dried stems, husks. Sometimes peat or coal chips are added to pellets, which increases their calorific value.

Pellets are produced by drying and pressing. When the mixture is subjected to pressure, the temperature inside it rises, the wood component lignin is released, which firmly glues the particles together.

Torrefied fuel pellets are considered the most valuable fuel. They are fired without access to oxygen, acquiring a dark color. As a result, their heat capacity increases. In addition, they are not afraid of moisture, do not crumble over time.

Pellets have a number of advantages:

- Ecological cleanliness and production using waste-free technology. Pellets are made not just from wood, but from production waste, which otherwise would go to a landfill or for recycling incineration. The use of agricultural by-products, which are regarded as nothing more than garbage, make pellets one of the most progressive types of solid biofuels.

- High combustion efficiency. Thanks to the production technology, pellets contain a small amount of moisture - only 8 - 12%, while naturally dried wood will still contain 25 - 30%, and fresh - 50% or more water. When burning fuel pellets, approximately twice as much heat is generated than when burning wood.If we compare the calorific value with hydrocarbons, then it is only two times less than when burning fuel oil or gas.

- Low ash content. Pellets are practically devoid of the main drawback of wood - they form a small amount of fireproof residues, and the content of soot and soot is reduced in the composition of the smoke. The share of ash in pellets is only 3%, so boilers and chimneys require less frequent cleaning when using them.

- Good transportability. Due to relatively high mechanical strength, small size and high density, pellets are light and easy to transport. In production, they are packaged in various containers weighing up to one ton in big bags and can be delivered by any type of transport.

- Possibility of automated filing. Due to the same size of small granules, they can be fed into the boiler automatically, with special dispensers, Archimedes screw screws and other devices. This allows you to endow the solid fuel boiler with a high degree of autonomy.

Unfortunately, pellets have two significant disadvantages:

- The high cost, which follows from the costs of production: drying, pressing, firing. Therefore, compared to other wood fuels, the cost of pellets will always be higher.

- Enterprises that produce fuel pellets are not located in all areas. Buying pellets with delivery over long distances can completely negate their economic advantages.

Pellets are most widely used in European countries, where ecological fuel is in greatest demand.The possibility of useful processing of waste, coupled with high energy efficiency, makes it the number one solid fuel, especially since there are almost no large forest areas allowed for felling in Europe.

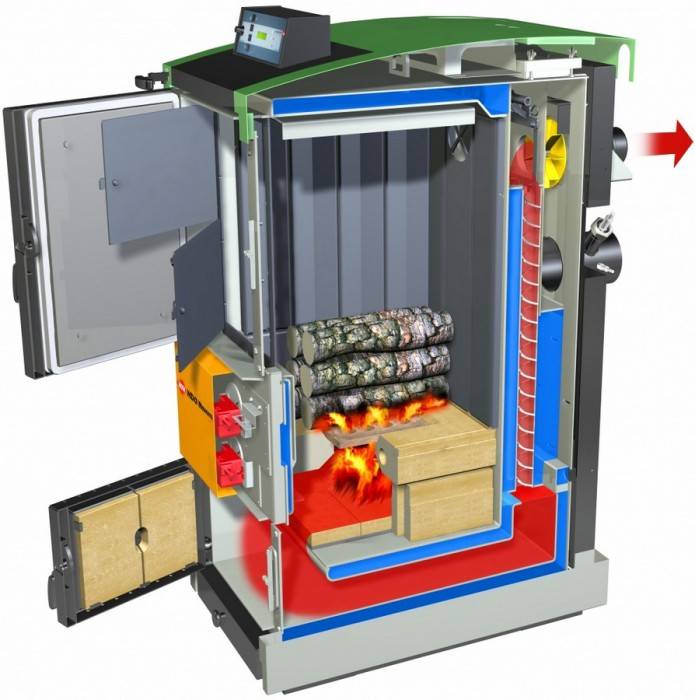

Principle of operation

The increase in the duration of the combustion process is achieved not only by a large firebox. The organization of furnace combustion in the form of stratified combustion with top combustion and top supply of blast air has a significant impact on efficiency and heat transfer, so gas-air flows do not circulate in the lower fuel layers at all.

The principle of operation of a boiler unit with long-term combustion of solid fuel:

The air required for fuel combustion is taken directly from the combustion room and passes through the preheating stage in the upper heating chamber of the upper combustion boilers.

A pipe air distributor is mounted in the heating chamber to supply hot air to the combustion device. The feed system can be gravitational and forced.

The air distributor is equipped with channels directed vertically. Before fuel loading, it is raised using a built-in mechanism, then fuel is added and the distributor is lowered, which rests on the upper fuel level. As it burns out, it falls down the furnace space. This movement of the distributor provides air supply to the top layer of hot fuel.

Here, combustible substances completely burn out, transferring heat through the walls of the furnace to the heating coolant circulating in the built-in heat exchanger.

Flue gases are discharged through the flue pipe into the chimney.The ash is collected in an ash box located at the bottom of the boiler, under the firebox. The volume of the box allows you to clean it at intervals of 2 to 5 loads.

Choosing a boiler

After you have decided on the fuel that will use the solid fuel heating of a country house, you should choose a boiler. Conventionally, solid fuel boilers can be divided into the following groups:

- classic;

- automatic;

- pyrolysis;

- prolonged burning.

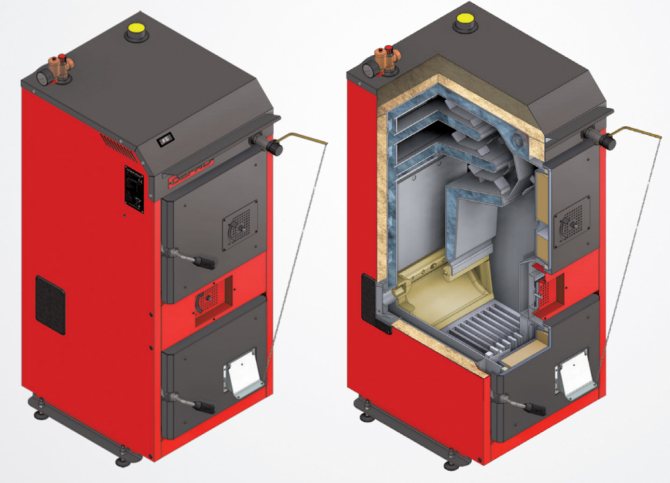

Classic boilers

Classical boilers imply the following principle of operation: solid fuel burns in a flame in order to get heat, as is the case with an ordinary fire. Combustion is optimized by a special grate in order to supply combustion air from below. And the amount of this air is regulated by the settings of the scraper and the supply of air mass to the combustion chamber manually. Fuel is loaded through the top door, and the ash is removed and combustion is regulated through the bottom one. The boiler heat exchanger can be made of steel or cast iron. The advantages of classic boilers: the ability to operate on 2 types of fuel (minimum), often it is also possible to mount a gas or liquid fuel burner, independence from energy. Among the disadvantages: frequent loading of fuel is required, a place to store fuel and a separate room for the boiler room are also needed.

Classic solid fuel boiler

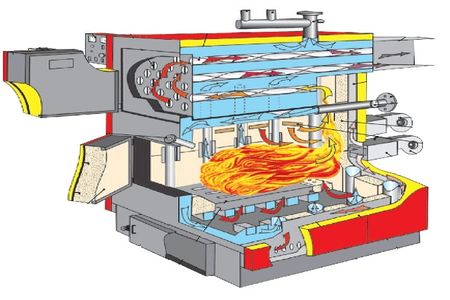

Pyrolysis boilers

Pyrolysis boilers - used for combustion gases from the decomposition of fuel. This is due to the action of high temperature with insufficient air. The structure of the boiler includes two chambers, which are separated by grates: the lower one for loading and the combustion chamber.

The combustion process here is as follows: the fuel is laid and ignited, the combustion chamber door closes. A blower fan is activated in the upper chamber, which serves to mix the smoldering air of the lower chamber with clean air. The mixture begins to ignite and directs fire through ceramic nozzles to the fuel. Without access to oxygen, the fuel is burned - this is how pyrolysis happens, that is, decomposition and gasification of the fuel. So, the process will continue until the fuel is completely burned. This is how solid fuel heating works. Advantages of pyrolysis boilers: high efficiency (up to 90%), fuel burns on one load up to 10 hours, reduced requirements for the chimney, high level of environmental friendliness. Disadvantages: high cost, dependence on energy, unstable combustion at partial load, very high requirements for the dryness of firewood, etc.

pyrolysis boiler

pyrolysis boiler

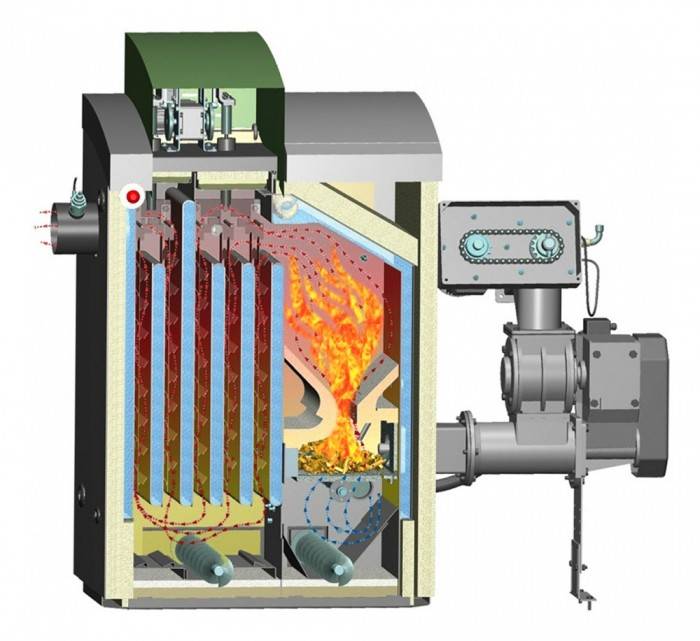

Automatic boilers

Automatic boilers - processes such as fuel loading and ash removal are automated here. In boilers of this type there is a bunker for automatic fuel supply - conveyor or screw. For combustion to be stable, the fuel must be uniform in composition and size. The advantages of such boilers: high efficiency (up to 85%), duration of operation, limited capacity of the hopper designed for automatic feeding, and fuel homogeneity provide the ability to fine-tune the combustion process. Among the disadvantages: high price, dependence on energy, the need for a separate room, a separate fireproof ash collector, as well as qualified service.

Automatic solid fuel boiler

Automatic solid fuel boiler

Long burning boilers

Another type of boilers that uses solid fuel heating of a country house is long-burning boilers. Here, long-term combustion is maintained by special techniques. Such combustion can be provided by two systems: the Canadian system of boilers Buleryan and the Baltic system Stropuva. Buleryan is a two-chamber wood burning stove, which is divided horizontally. Smoldering takes place below, the gases go to the upper chamber, where they mix with secondary air through the jet, after which the fuel is burned. Stropuva is a high barrel up to 3 m high, filled with firewood and covered with a movable lid with a chimney. First, firewood is set on fire, after which they burn economically, heating the heat carrier along the barrel jacket, the air supply is regulated automatically.

Long burning boiler

What types of solid fuel boilers exist

The modern market offers many options for heating boilers for the home. Before you buy equipment, you should carefully study the features of each of them. The main differences relate to the fuel used in the boiler, the material from which it is made, as well as the fuel combustion technology used in the device.

- The traditional unit is made of cast iron or steel. In appearance, the design of the furnace and chimney, and according to the principle of operation, such devices are similar to conventional furnaces. They usually work on wood or coal. This option is considered the simplest and most reliable. It does not use complex electronic devices, which makes the cost of the units quite low. In addition, automation often becomes the most vulnerable point: it is simply absent in traditional boilers.The coolant temperature is controlled by a mechanical regulator. Such boilers work without failures for a long time.

- Pyrolysis (gas generating) boiler. Such a unit is able to operate on a small amount of fuel and at the same time has a high efficiency. It produces the same amount of thermal energy as a traditional apparatus, but much less fuel is spent on it. In a pyrolysis boiler, the process of fuel combustion takes place in three stages: first it is dried, then combustible materials are synthesized to a gas state, and then they burn, releasing heat. The synthesis process uses about 85% of the fuel. Fresh air is supplied to the furnace by means of a fan. The intensity of combustion is increased by the supply of secondary air, which has already been previously heated.

- Long burning devices. These boilers run on wood or coal. Their main feature is the minimum maintenance requirements. At the same time, they are quite effective, which becomes due to the use of a certain method of fuel combustion. There is no open flame in the combustion chamber of such a boiler, and heat is produced due to the fact that the fuel layer smolders.

- Heating boilers on pellets. Here, pellets are used as fuel - small granules that are made from woodworking waste. Such solutions are suitable for regions where the woodworking industry is well developed. Combustible material is fed into the combustion chamber automatically.

Modern universal single-circuit solid fuel boiler "Cooper OK-9". This is an example of compact equipment for installation in any premises with an area of up to 90 m2.