- How to choose a solid fuel boiler

- Suitable fuel

- Advantages and disadvantages of wood-fired boilers and electricity

- Another significant plus

- Which solid fuel boiler to buy

- Advantages and disadvantages of solid fuel boilers

- 1 Lemax Forward-16

- Installation Requirements

- 3 Kentatsu ELEGANT-03

- Varieties of boilers

- By type of fuel used

- According to the principle of fuel combustion

- By type of fuel loading:

- According to the method of loading raw materials:

- Heating options:

- The best solid fuel boilers for direct combustion

- Viadrus Hercules U22

- Zota Topol-M

- Bosch Solid 2000 B-2 SFU

- Protherm Beaver

How to choose a solid fuel boiler

A competent approach to the acquisition of such equipment is very important, therefore, if possible, you should consult with the seller of a specialized store.

Main selection criteria:

Boiler power. There are models that are already focused on a certain area of \u200b\u200bthe room. If the consumer buys a device designed for a smaller area than in reality, there is a risk that the boiler, working for wear, will quickly fail. An attempt to take equipment “with a margin”, that is, designed for a larger heating area than necessary, will also not be successful. The fuel simply will not burn out completely, remaining on the pipe in the form of resin, which will inevitably lead to a deterioration in the operation of the boiler.Universal calculation formula: 1 kW of energy will heat approximately 10 square meters. m. of housing. A number of other parameters: the number of windows and doors, the height of the ceiling will give additional information, which experts will help to analyze.

Functionality. If the boiler is planned to be placed in the kitchen, then it makes sense to purchase it with a hob in the kit

Those who do not want to spend a lot of time servicing the device and laying raw materials into it should pay attention to long-burning boilers.

The type of fuel to be used. As a rule, a model focused on a certain type of raw material can also use an alternative

For example, coal-fired boilers can be loaded with wood, which, however, can reduce their power. Combustion features that affect the efficiency should be indicated in the technical data sheet.

The volume of the combustion chamber: the smaller it is, the more often you will have to reload.

Operating time at one time loading

If it is important for the consumer not to approach the boiler every 4-5 hours, then it is better to choose a modern model, which needs only one load of fuel to work for several days.

efficiency. This important indicator will tell you what part of the thermal energy is spent on heating the home.

The lower it is, the more fuel consumption will be.

What is the manufacturer's warranty period?

Popularity of the model: there are a number of units that have proven themselves well with users.

How much does the unit cost: domestic, as a rule, are cheaper than foreign ones. However, it is wrong to choose such equipment only at a low price: the technical parameters of a cheap boiler may not always be suitable for a particular situation.

Suitable fuel

The owners of such equipment mention in their reviews that various solid fuels are suitable for heating. It can be coal, peat and wood. Naturally, the chosen option affects the burning time:

- 5 hours - soft wood;

- 6 hours - hardwood;

- 8 hours - brown coal;

- 10 hours - black coal.

Experts recommend giving preference to dry firewood with a moisture content of up to 20% and a length of 45–60 cm. Thanks to them, a lot of heat is generated, and the life of the boiler is extended. If such high-quality firewood is not available, you can use other organic fuels:

- pellets;

- wood waste;

- some varieties of peat;

- coal;

- food waste containing cellulose.

It must be remembered that pyrolysis boilers will have a white flame and will not start to emit by-products, provided that fuel is used whose moisture content does not exceed 20%. If this parameter is higher, the release of water vapor is inevitable, which will lead to the formation of soot and a deterioration in calorific value.

Advantages and disadvantages of wood-fired boilers and electricity

Boilers for heating on wood and electricity are characterized by the following advantages:

- The presence of temperature support - will prevent the coolant from cooling too quickly;

- Balanced cost - equipment is distinguished by its low cost, which will be discussed in our review;

- No additional maintenance is required, as required by combined devices with liquid and gas burners.

Having installed a heating boiler on wood and electricity in your house, you will not jump up at night to lay a portion of firewood.

Not without traditional disadvantages - this is high power consumption and the need for hardy electrical wiring.

Another significant plus

The fuel gives off absolutely all the heat that is in it. Pure CO2 enters the chimney without any impurities.

The Bourgeois K pyrolysis boiler receives good reviews from consumers also because it remains environmentally friendly, even when aggressive fuels, such as rubber, are burned in it. All atmospheric emissions fully comply with MPC.

Which solid fuel boiler to buy

The first thing that the future owner of a solid fuel boiler plant should decide is the type of fuel used. This is what determines the type of unit: whether it will be coal, wood or work on pellets. Also on the market are widespread universal solid fuel heat generators that can use all of the above types of fuel.

The second most important selection criterion is power. For competent selection of equipment for this parameter, you should contact professionals. With a preliminary independent calculation of the required power, you can be guided by the following formula:

P = S x H x ∆K,

where: P is the power of the boiler unit;

S is the area of the heated room;

H - ceiling height;

∆K is the thermal insulation coefficient of the building.

Solid fuel boilers can only be used for heating (single-circuit) or for heating and hot water supply at home (double-circuit).

In addition, when choosing a solid fuel boiler, one should pay attention to the design and useful volume of the combustion chamber and the way it is loaded (top or front), the material of the heat exchanger. On sale there are non-volatile boiler units, and installations, for the operation of which it is necessary to connect to the power supply line

The former are less reliable, but can be used for heating and creating domestic hot water in case of interruptions in the supply of electricity. Volatile models are equipped with more sophisticated automation, which ensures maximum safety and efficiency of the boiler.

On sale there are non-volatile boiler units, and installations, for the operation of which it is necessary to connect to the power supply line. The former are less reliable, but can be used for heating and creating domestic hot water in case of interruptions in the supply of electricity. Volatile models are equipped with more sophisticated automation, which ensures maximum safety and efficiency of the boiler.

Separately, we should mention solid fuel boilers for long burning, which are equipped with the function of afterburning exhaust gases (pyrolysis). Pyrolysis models have higher efficiency with lower fuel consumption, which has made them so popular among consumers.

Advantages and disadvantages of solid fuel boilers

In order to make a decision in favor of choosing the type of solid fuel heating boiler, it is advisable to consider all the possibilities that this equipment offers. To do this, it is best to familiarize yourself with the advantages and disadvantages associated with the operation of this technique.

All boilers of this type are distinguished by the following positive qualities:

- efficiency of use - with the same power of the unit, the cost of fuel for a solid fuel boiler for long burning will be two times cheaper than for a gas boiler and three times cheaper than an electric one;

- simplicity of design - allows you to install equipment without the involvement of qualified specialists, and also serves as a guarantee of reliability;

- the device involves the use of various types of fuel, which allows the user to save significantly;

- autonomy - allows you to use this type of equipment in conditions remote from the benefits of civilization;

- compared to gas or electric heating boilers, solid fuel units have an acceptable cost;

- a wide variety of design solutions allows you to choose a unit that meets all the personal requirements of the consumer.

However, with many advantages of solid fuel boilers for long burning, they have their drawbacks that do not allow them to be used in all (without exception) cases.

Among the disadvantages are the following:

under the fuel storage it is necessary to allocate additional space;

for the effective use of the unit, it is important to follow a number of specific rules;

manual loading of fuel, the frequency of which depends on the boiler model;

budget installations are characterized by additional difficulties in operation, without automatic control;

The efficiency of most long-burning units does not exceed 70%.

The advantages and disadvantages of boilers of this type are determined by a number of factors: the area of \u200b\u200bthe heated room, the presence of various communications, the degree of resistance of thermal insulation. For this reason, equipment should be selected based on local conditions.

1 Lemax Forward-16

16 kilowatts of power of the Lemax Forward-16 boiler is enough for heating premises of the administrative and domestic levels, private residential buildings and even cottages, by independent or forced (with the installation of a pump) circulation of the coolant through the heating water system. This is one of the most successful examples of small but productive installations with an uncharacteristically high (about 75-80 percent) level of efficiency. The uncomplicated design contains the solution to many operational problems. From the point of view of the technologist, such measures as, for example, "tamping" the heat exchanger with channels to increase the ultimate tensile strength, look redundant, but justify themselves in terms of durability of use. Such a boiler can last a good seven to nine years, provided that all measures of proper operation are observed without exception.

Advantages:

- the presence of additional elements that positively affect the durability of the installation;

- optimal cost with acceptable quality;

- sufficiently high (atypical) level of efficiency;

- the ability to connect a pump to increase the circulation rate of the coolant;

- the possibility of converting the boiler to work with gas (carried out by installing a gas burner).

Flaws:

no serious deficiencies were found.

Installation Requirements

Judging by the reviews of owners and specialists, any Bourgeois-K pyrolysis boiler is demanding in terms of execution and proper connection of the chimney. It should be:

- made of stainless steel;

- insulated and sealed;

- made without horizontal sections and with a minimum of turns;

- have sufficient length to rise above the roof at least half a meter.

If all these requirements are not met, the boiler will quickly overgrow with soot from the inside, or even simply will not be able to enter the gas generation mode. That is, you will not get pyrolysis combustion, and Bourgeois-K will work like a regular solid fuel. As a rule, it is the failure to comply with the installation requirements that leads to inefficiency in the heating system, excessive fuel consumption and other problems. There are negative reviews, and the owners are thinking about buying other equipment.

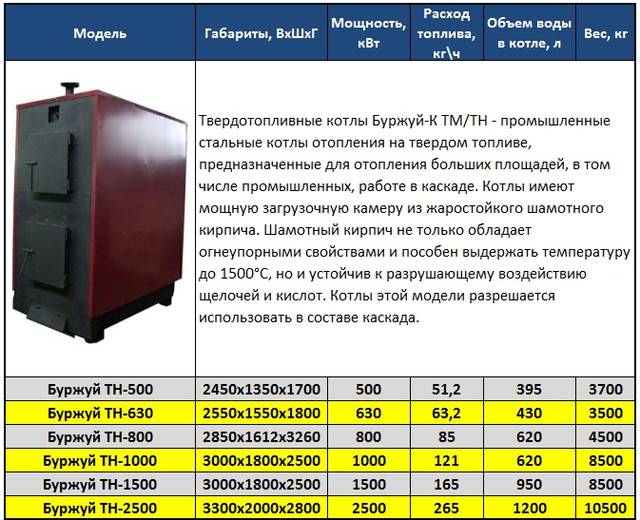

The lineup

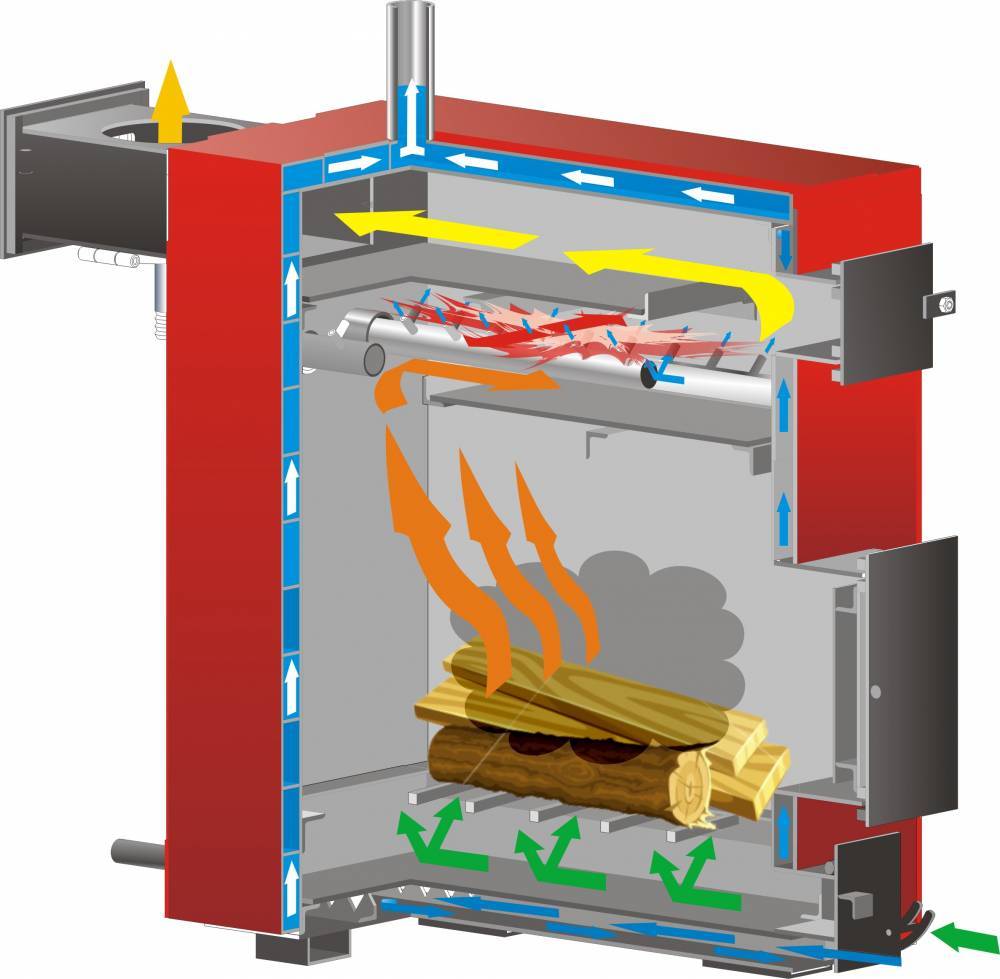

Having figured out how the pyrolysis boiler works, let's move on to a review of the Bourgeois-K devices. The entire range of equipment of a domestic manufacturer by purpose can be divided into two groups:

- Water heaters - as a heat exchanger they use their own double skin of the body. Some models can be connected to an additional DHW circuit.

- The pyrolysis hot air boiler is devoid of a water jacket, and therefore physically cannot produce power exceeding 150 kW.

In turn, TeploGarant highlights the lines of household (up to 100 kW), industrial (up to 800 kW) and universal mobile boilers. All of them differ from each other not only in performance, but also in the installation method. We will consider the characteristics of the most popular models from these series.

1. Bourgeois-K Standard.

A family of compact and inexpensive floor-standing boilers for domestic use. Since they are considered budget, the equipment does not have a mechanical traction control that controls the opening of the damper. But the duration and efficiency of burning each fuel tab will depend on it.There is no thermomanometer, but TeploGarant offers to buy the missing elements of the system separately.

Boilers of the Standard series with a power of 10 to 30 kW are in great demand, as they are able to heat a private house with an area of 100-300 m2. The all-welded steel structure has an additional sheathing with a heat-resistant coating and non-combustible basalt thermal insulation. The equipment is non-volatile, since, unlike foreign analogues, it works without forced pressurization.

2. Bourgeois-K Modern.

This series is more expensive and is represented by models that deliver power in the range of 12-32 kW. Unlike the Standard, here it is already possible to connect a DHW circuit to an additional heat exchanger. Just do not forget to revise the power characteristics at the same time, because part of the generated energy will be spent on water supply. The efficiency of Bourgeois-K Modern reaches 82-92%, and the design is supplemented with a draft regulator. This simplifies the management of work, since simple automation is able to control the air flow in the combustion chambers.

3 Kentatsu ELEGANT-03

Kentatsu ELEGANT-03 is a modified heating boiler model, which takes into account all the nuances and errors of previous installations. It is authentically known that those, in turn, did not have effective cooling and allowed the boiler to overheat. In this version, the grate water cooler has become such, and, as practice shows, it copes with the assigned task flawlessly. A thermometer is located on the front wall of the cast-iron housing, showing the actual temperature of the water coolant. A controversial step towards ensuring ergonomics was the breakdown of the boiler into sections.On the one hand, the useful area inside the model has increased, but on the other hand, this has a negative effect on the terms of service.

Advantages:

- the model took into account the mistakes of the past, including those with active cooling;

- availability of equipment for self-service;

- low price;

- high quality and durability of the cast-iron body;

- the presence of a thermometer on the front wall.

Flaws:

the breakdown of the boiler into sections complicates the process of repair and maintenance in the event of a breakdown.

Varieties of boilers

By type of fuel used

Wood. An important principle when buying firewood: their moisture content should be minimal and not exceed 20% for a gas-generating boiler. In classic models, the use of wet firewood is acceptable, but not very desirable. Therefore, the place where the logs will be stored must be dry and well protected from moisture.

Coal

When choosing which coal to use, you need to pay attention to its grade and fraction: they must comply with the technical conditions for the operation of heating equipment.

Pellet. This type of fuel is a pellet made from waste of various origins (peat, wood, agricultural)

Such boilers are characterized by high efficiency, but they are not cheap, like the pellets themselves.

On peat briquettes.

Universal.

There are combined boilers that run on solid fuel and electricity or gas.

According to the principle of fuel combustion

- Pyrolysis. The work is based on the combustion of gas released from firewood under the influence of high temperature. The wood is heated with minimal access to oxygen, resulting in the release of wood gas. Therefore, another name for such boilers is gas-generating.Gas is burned in a special chamber at a temperature of approximately 700 C. When using dry firewood, the efficiency of such equipment reaches 85%. However, they are harder to find and more expensive than regular ones. Another disadvantage is the high cost of the boiler and its complex multi-chamber design.

- Classic. They resemble an ordinary stove by burning fuel from the bottom up. Their advantages are simplicity of design, ease of operation, budget. Do not necessarily require high quality fuel. Disadvantages: frequent maintenance (it is necessary to add fuel 4-8 times a day), low efficiency (70-75%), low degree of power adjustment. Such a boiler will be a good option for heating a small house in which they do not live permanently.

- Long burning. It happens by analogy with a match or a candle: from top to bottom. Firewood laid in the boiler can burn up to three days, coal - up to five. Such efficiency is achieved due to the built-in electronic automation, turbine, special design of the combustion chamber. Pros: high productivity (efficiency of about 80%), environmental friendliness, independence from the quality of raw materials, automation of processes in energy-dependent models. Of the minuses, one can single out a rather big cost, the need to correctly observe the technology of loading fuel, the impossibility of reloading it.

By type of fuel loading:

- Manual. The combustion process is also controlled manually. Boilers are inexpensive, have a simple design, but require constant supervision and care, it is more difficult to maintain the required temperature in them.

- Semi-automatic. A person lays the raw materials, and automation controls the combustion. It is possible to precisely adjust the temperature.

- Automatic. All processes are automated.Fuel is supplied to the boiler from a special bunker, often by means of a screw mechanism. Pellet or coal models are the most economical. The boiler has a high efficiency, can work autonomously for a long time, and is safe to use. Of course, this convenience comes at a cost. Other disadvantages are energy dependence, large equipment sizes.

According to the method of loading raw materials:

Frontal (horizontal), as a rule, is typical for models with a cast iron heat exchanger. Ease of use when heating with wood. Possibility to report logs.

Top (vertical). It prevails in boilers with a steel heat exchanger. The high efficiency of this method is due to the fact that it is characterized by lower combustion of the fuel; its upper part is being dried

At the same time, it is very important to carefully stack the logs in the firebox, otherwise there is a risk of reducing the efficiency.

Heating options:

- Single-circuit (only heat supply of the room is carried out).

- Double-circuit (not only heat the room, but also provide hot water).

The best solid fuel boilers for direct combustion

Viadrus Hercules U22

The lineup

The model range of this series of Vidarus boilers is represented by seven solid fuel boilers with power from 20 to 49 kW. The most productive of them is able to heat a building up to 370 sq.m. All equipment is designed for a maximum pressure in the heating circuit of 4 atm. The operating temperature range in the coolant circulation system is from 60 to 90 ° C. The manufacturer claims the efficiency of each product at the level of 78%.

Watch product video

Design features

All models of the presented line are designed for floor installation.They have an open combustion chamber with air supply due to natural draft. The large square-shaped doors easily open wide, which is convenient when loading fuel, removing ash and inspecting the condition of internal elements.

The built-in heat exchanger made of high-quality cast iron is adapted to work in a single-circuit heating system. The boilers do not have devices powered by an external electrical network and are operated in a completely autonomous mode. All settings are mechanical.

Fuel used. The design of a spacious firebox is designed to use firewood as the main fuel, but coal, peat and briquettes can be used.

Zota Topol-M

The lineup

The line of six Zota Topol-M solid fuel boilers starts with a compact 14 kW model designed to heat a house for an average family, and ends with an 80 kW unit capable of heating a large cottage or production workshop. The boilers are designed for operation in systems with pressure up to 3 bar. Efficiency of thermal energy use is 75%.

Watch product video

Design features

Their distinctive feature is a slightly raised design, which makes it more convenient to open the ash pan door and empty it. Open type combustion chamber with chimney connection from the rear wall. There is a built-in temperature sensor. All adjustments are made manually.

A heat exchanger for a single-circuit heating system is mounted inside, connected to 1.5 or 2” pipelines. Boilers work offline. Products of this brand are easy to install and reliable in operation.

Fuel used.Firewood or coal is used as fuel, for which a special grate is provided.

Bosch Solid 2000 B-2 SFU

The lineup

Solid fuel boilers Bosch Solid 2000 B-2 SFU are represented by a number of models with a capacity of 13.5 to 32 kW. They are able to heat buildings with a usable area of up to 240 sq.m. Parameters of the circuit operation: pressure up to 2 bar, heating temperature from 65 to 95 ° C. Efficiency according to the passport is 76%.

Watch product video

Design features

The units have a built-in single-section heat exchanger made of cast iron. It is connected to a single-circuit heating system through standard 1 ½” fittings. The boilers are equipped with an open type combustion chamber with a 145 mm chimney. For normal operation, a connection to the electrical network with a voltage of 220 volts is required.

The temperature regulator and protection against an overheat of water is provided. The ash pan has a small volume, so it requires regular cleaning. Manufacturer's warranty 2 years. The design is simple, safe and highly reliable.

Fuel used. The boiler is designed to use hard coal. On this type of fuel, it demonstrates high efficiency. When working on wood or briquettes, the efficiency is noticeably reduced.

Protherm Beaver

The lineup

A series of solid fuel boilers Protherm Bober is represented by five models with power from 18 to 45 kW. This range completely covers any private house. The unit is designed to work as part of a single-circuit heating circuit with a maximum pressure of 3 bar and a coolant temperature of up to 90 ° C. For the correct operation of the control system and actuation of the circulation pump, connection to the household electrical network is required.

Watch product video

Design features

Boilers of this series are equipped with reliable cast-iron heat exchangers. The original design of the combustion chamber increases the efficiency of heat transfer. Exhaust gases are discharged through a chimney with a diameter of 150 mm. For connection to the heating circuit, there are branch pipes for 2”. Such boilers are designed for long-term operation.

Fuel used. The declared power is designed for burning firewood with a moisture content of up to 20%. The manufacturer has provided for the possibility of using coal. In this case, the efficiency of work increases by several percent.