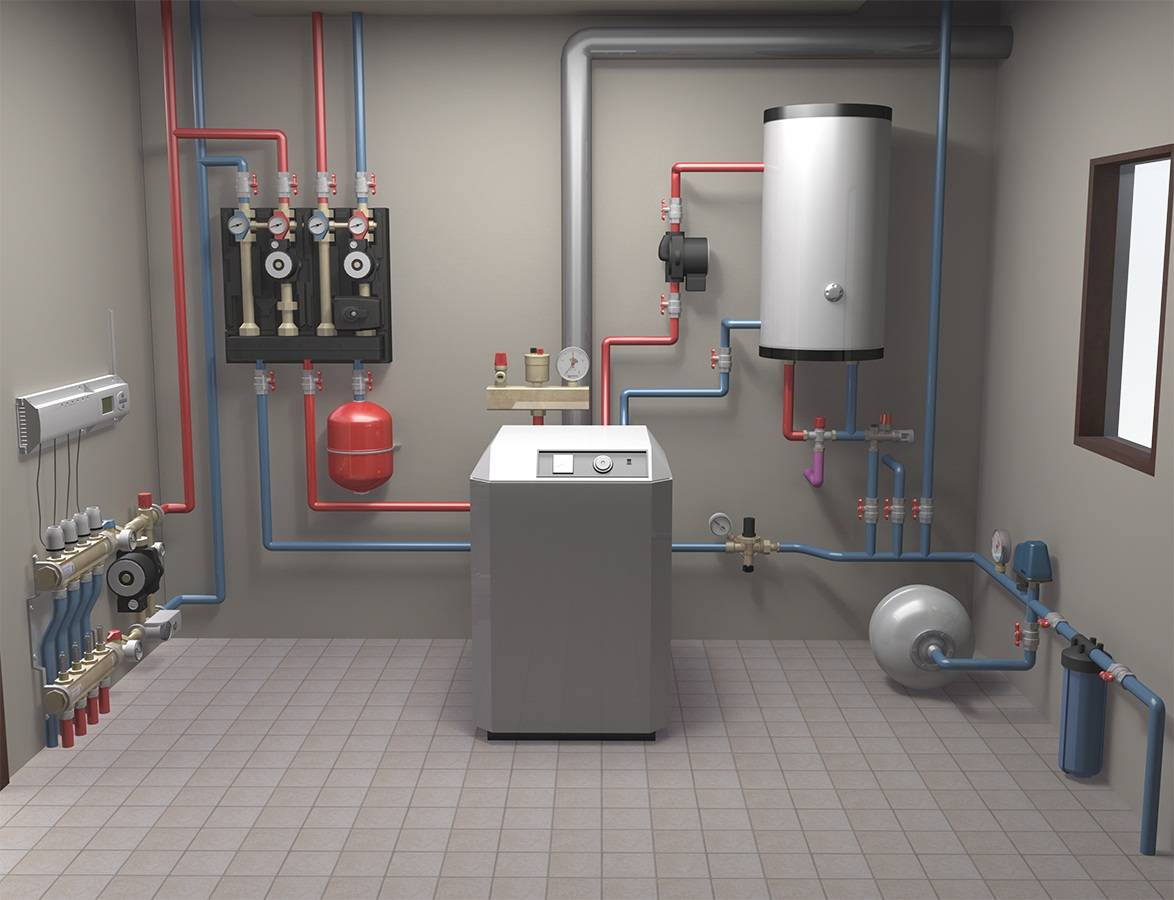

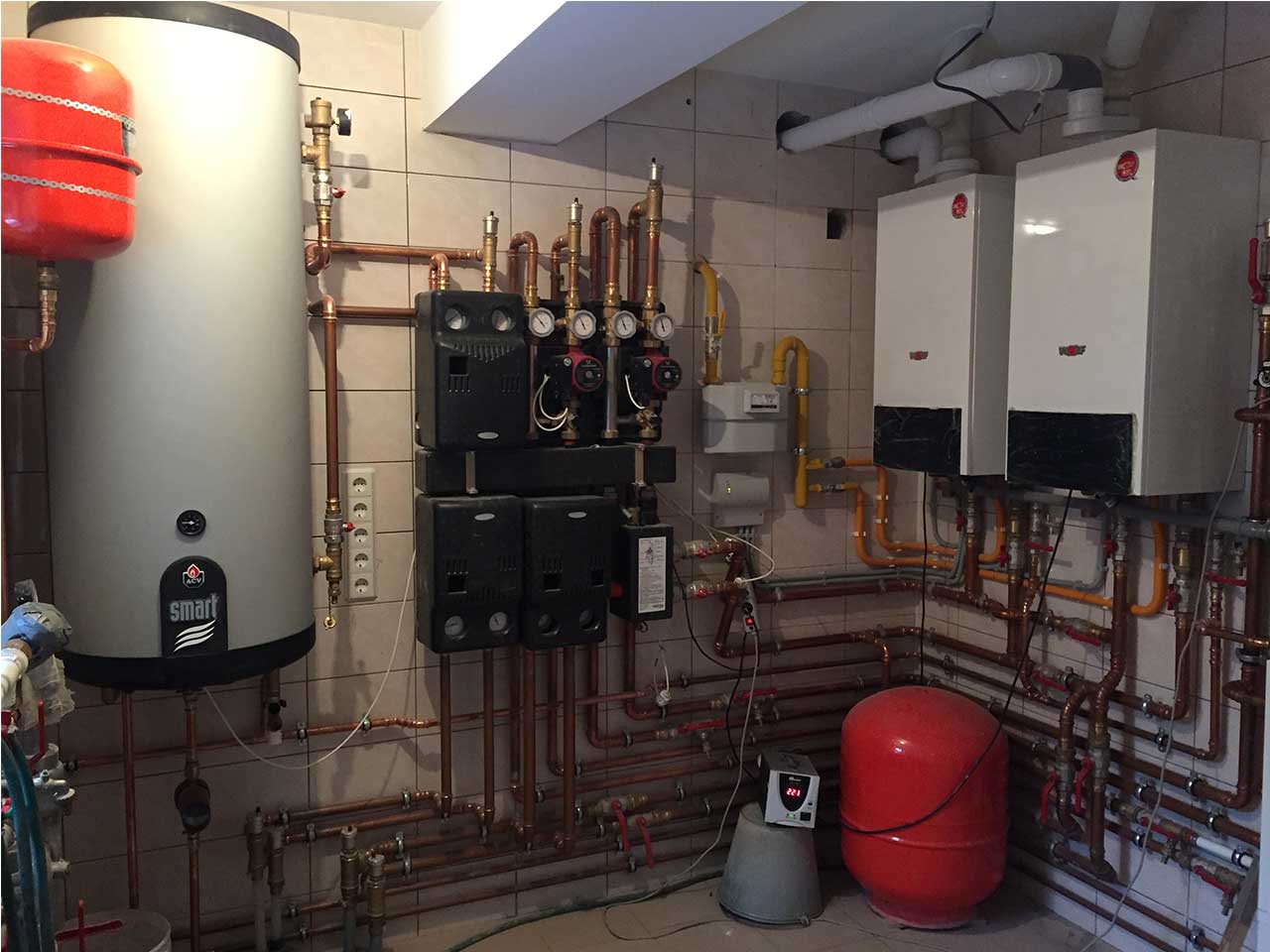

- Layout of thermal units

- Mounting Tips

- Electric, liquid and solid fuel boilers

- Selection of boiler equipment

- Fuel for heating boilers

- How to determine the power of the boiler?

- Comparison of installation methods

- Differences in the principle of operation

- Choosing a boiler and expansion tank for a boiler room in a private house

- Boiler room volume for different boilers

- No. 4. Boiler room in a private house: safety requirements

- Boiler rooms with gas boiler

- Boiler rooms with solid fuel boiler

- Boiler room with diesel boiler

- Boiler room with electric boiler

- Popular manufacturers

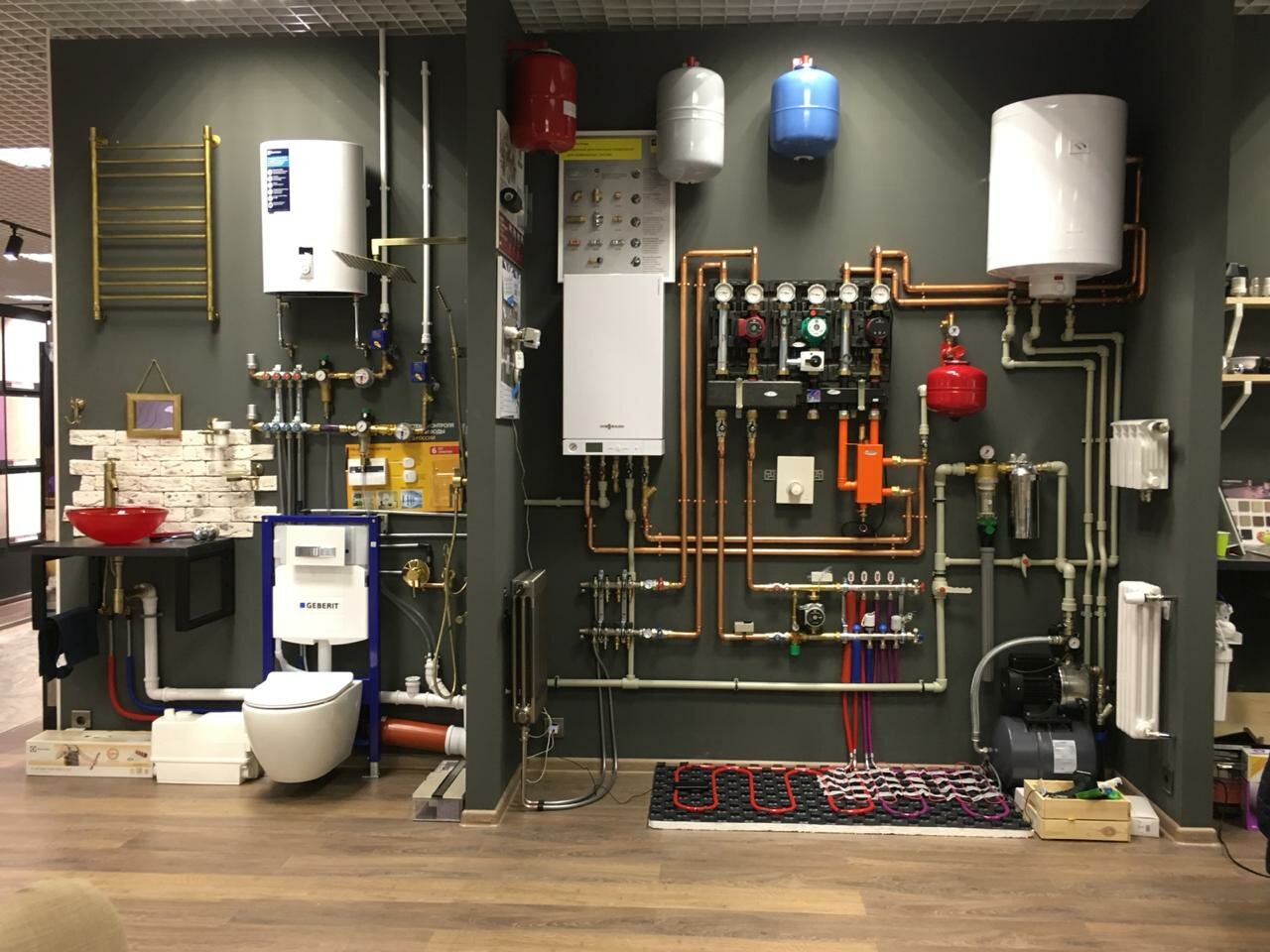

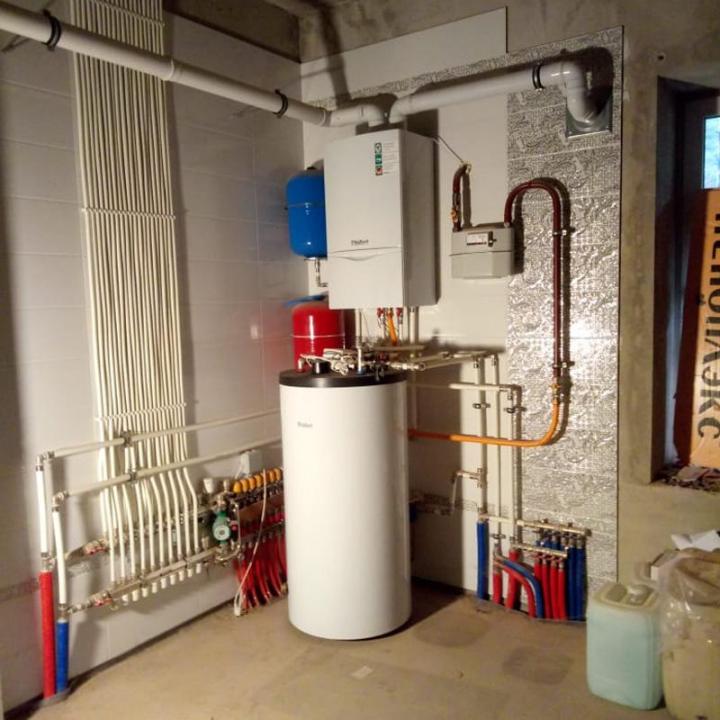

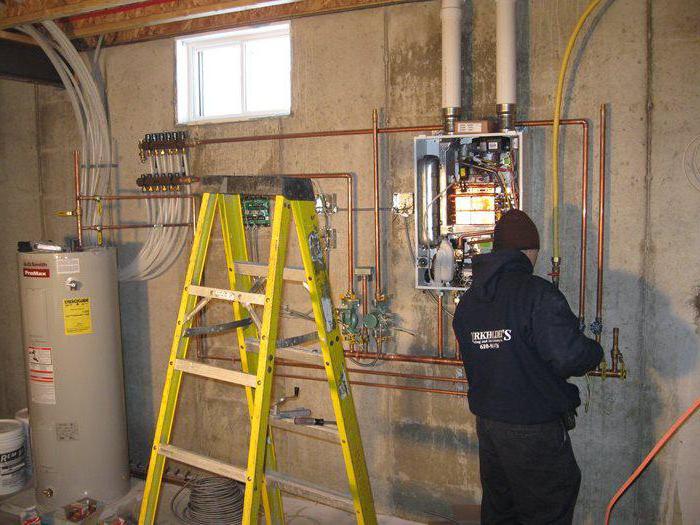

- No. 2. The main elements of the boiler room in a private house

- Necessary boiler equipment for a private house

- Primary requirements

- About the installation of gas-using installations

- Conclusions and useful video on the topic

Layout of thermal units

The layout of the boilers inside the furnace is developed taking into account the convenience of operation and maintenance, as well as regulatory requirements. They apply to both gas and solid fuel boilers and look like this:

- clearance between the wall and the protruding part of the front part of the boiler - at least 1 m;

- the distance between 2 heat generators on any type of fuel installed side by side is 1 m;

- the width of the passage for servicing equipment from the side where it is needed is 0.6 m;

- the passage between 2 boilers standing opposite each other is at least 2 m.

Passages must not be littered or blocked with pipelines and cables suspended below 2 m. Cables may be laid along the floor inside steel pipes, and heat mains along the walls, but not across the passage. In addition, the requirements for a boiler room in a private cottage require the installation of heavy floor units on their own foundations that are not related to the foundation of the house.

If it is necessary to install 2 floor heat generators, then a common reinforced concrete foundation in the form of a slab is cast under them. The foundation is supported by soil with a compacted cushion of crushed stone, and not a previously poured concrete screed. For the device of the base, part of the old screed will have to be dismantled. The time required for the concrete to harden and become ready for the installation of equipment is 28 days. After installing a solid fuel boiler, a steel sheet measuring 0.7x1 m is laid on the floor in front of it.

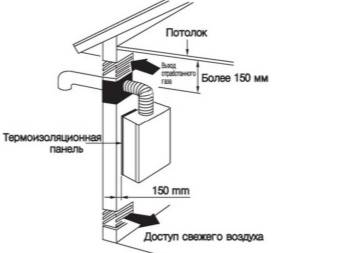

When installing a wall-mounted heater in the kitchen, it is necessary to isolate the unit from the wall by laying a sheet of metal protruding 10 cm beyond the boiler body. The horizontal section of the chimney pipe from the heat generator to the passage through the wall or ceiling can have no more than 3 turns.

Heating pipelines passing inside the boiler room are recommended to be covered with a heat-insulating layer. Electrical outlets and other electrical appliances must be located in such a way that, in the event of an accident or leakage, they cannot be exposed to water.

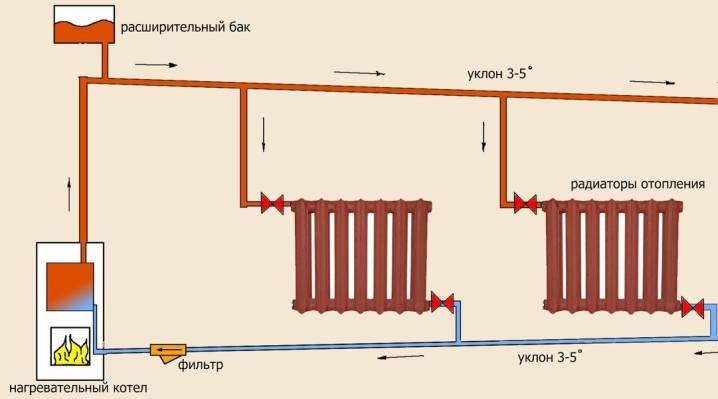

Mounting Tips

The scheme of the heating device in each private house is individual - and yet there are clear principles and criteria that are more or less universal. Order piping of heating boilers and hot do-it-yourself water supply implies, first of all, the division into open and closed groups. In the open version, the heating boiler is placed below all other components. The expansion tank is raised as high as possible: it is the difference in height between them that determines the overall efficiency of all equipment.

The easiest way to prepare an open circuit

In addition, it is non-volatile, which is very important for remote locations and for areas where power outages are frequent. But it must be understood that the continuous contact of the coolant with atmospheric air inevitably leads to clogging with air bubbles.

The coolant will circulate slowly, and it is impossible to accelerate its flow due to structural schemes. If these points are fundamental, and if there is a desire to also reduce the flow of the coolant, it would be more correct to make the heating according to a closed circuit.

If the boiler room is located in an extension, then it should be adjacent to a solid section of the wall. At the same time, at least 1 m of free space should be left to the nearest window or door. The building itself is made of fire-resistant material with guaranteed resistance to burning for at least 45 minutes. Wall-mounted boilers are mounted only on walls made of fireproof materials. Carefully monitor that all other walls are at least 0.1 m.

If powerful (200 kW and more) boilers are used, it is imperative to prepare a separate foundation for them. The difference between the height of this foundation and the height of the floor cannot exceed 0.15 m. When it is planned to use gas fuel, it is planned to install an apparatus on the pipe that urgently turns off the gas in a critical situation.Furnace rooms are equipped with unreinforced or weakly reinforced doors: in the event of an explosion, they are thrown outward, and this reduces the risk of destruction of the entire building.

When a boiler room built into the house itself is mounted, it is allowed to install thoroughly reinforced doors. However, they are already presented with another requirement: to contain the fire for at least ¼ hour. To improve ventilation, in any case, a hole is made in the lower third of the door, covered with a mesh. The entire volume of the walls from the inside is finished with fireproof materials. This must be done as soon as the installation of the boiler and its connection to communications is completed.

The number of circuits is also important. If you plan to limit yourself to heating, it is quite reasonable to choose a single-circuit boiler

For your information: it can also be used for hot water supply, but only in conjunction with a boiler. Installation of a boiler is justified under 2 conditions: a lot of hot water is consumed and there is a lot of free space. Otherwise, it would be more correct to order a double-circuit boiler.

Ventilation communications are mounted in the wall opposite the boiler. A mesh and damper must be installed in the ventilation pipe. In boiler rooms located in a separate room, you will have to make a ventilation duct in the door with a louvered grille.

An overview of the boiler room on gas equipment for a private house in the video below.

Electric, liquid and solid fuel boilers

If electricity is used to produce heat, then the placement of equipment is regulated by such design standards, like Device Rules Electrical installations (PUE).But there is no direct prohibition on installing an electric heater in a particular room in these rules, so it is better to put it in a separate room, which is dictated by practicality and safety considerations.

When a building is heated by heat sources that burn solid or liquid fuels, their location is regulated only by SNiP II-35-76. It says that it is necessary to place such heat generators in a special separate room. At the same time, the layout of the equipment is based on two principles: the sequence of technological processes and ease of maintenance, and the area of the boiler room is not standardized.

Arrangement according to technology assumes a certain order, starting from water filtration devices and ending with distribution manifolds and equipment for hot water supply. This norm is advisory in nature, as it provides some order in an autonomous boiler room, but its strict implementation is not always possible. But ease of maintenance is a mandatory criterion, therefore, the Rules for the Design and Operation of Boilers for this purpose provide for the following requirements:

- The distance from the burner of the liquid fuel boiler to the opposite wall is at least 1 m, from the front protruding part of the solid fuel unit to the same wall is at least 2 m.

- When 2 wood-fired heat generators are opposite each other, the clearance between them is 5 m, therefore, such an arrangement is unacceptable for a private developer, since in this situation the minimum dimensions of the boiler room will double.

- When the passport for heating equipment indicates that lateral or rear maintenance is required, then in these places it is necessary to provide a passage 1.5 m wide.If maintenance is not required, the clearance should be 700 mm.

- In places of passages, nothing should block the clearance up to a height of 2 m.

Selection of boiler equipment

Boilers differ in a number of parameters - the fuel used, power, installation method, principle of operation (single-circuit and double-circuit).

Fuel for heating boilers

Boilers in private houses can operate on the following types of fuel:

- natural and liquefied gas is a cheap fuel resource, gas boilers can be transferred from one type of gas to another;

- solid fuel - the operation of a solid fuel boiler must be monitored and firewood, coal, peat briquettes, coke should be regularly thrown into it;

- liquid diesel fuel (diesel fuel) - liquid fuel boilers help out in a situation where there is neither a gas pipeline nearby nor the ability to transport liquefied gas in cylinders, and if over time there is a prospect of acquiring gas, then it is easy to reconfigure it to the best type of fuel;

- Electricity is an expensive but environmentally friendly fuel resource.

It is good to have two boilers, electric and solid fuel, to reduce electricity consumption.

How to determine the power of the boiler?

The larger the heated space, the more powerful the boiler should be. Adding power consumption for water heating for shower, bath, kitchen and natural heat loss.

Approximate calculation (example):

To heat 10 sq. m at home, 1 kW of power is required. If the total area of the house is 150 sq. m, then the required boiler power is 15 kW + 10% for hot water supply, heat losses + 20% for reserve stock, otherwise the equipment will physically wear out, working at the peak of technical capabilities. We get the power of the heating boiler at least 19.5 kW.

You can read more about the calculation of the power of a heating boiler in this material.

Comparison of installation methods

According to the installation method, heating boilers are divided into two groups:

- floor - they require a separate room (boiler room) and compliance with some mandatory requirements in it;

- wall-mounted - a heat exchanger, a circulation pump, an expansion tank, a combustion products removal system, control and safety automation, temperature sensors, etc. are assembled in a compact case.

The maximum power of the wall-mounted mini-boiler room is 60 kW. If the power does not exceed 35 kW, it can be installed in the kitchen, hallway. The small dimensions of wall models make it possible to do without a separate room - all this is relevant for small and medium-sized private houses.

The gas wall-mounted boiler is sensitive to the chemical composition of the water. So that the equipment does not fail early on hard water, it is recommended to put a filter on the water supply or at the end of the heating season, each time to revise the boiler and pipes

Floor boilers are indispensable for heating large areas. In the floor version, heating units take up much more space, they have to be understaffed on their own, but there is one very significant plus - they have a long service life.

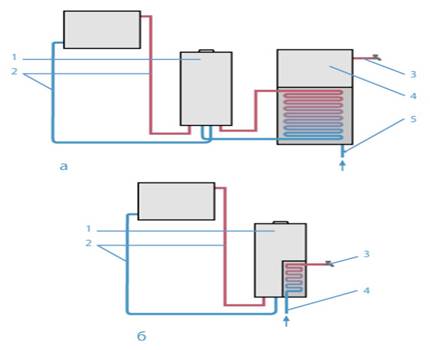

Differences in the principle of operation

The single-circuit boiler is intended only for heating the building.To supply water to the hot water supply system, such a unit must be supplemented with a 100-150-liter storage tank for water heated from a boiler (boiler).

A single-circuit boiler with a boiler is advisable if a lot of hot water is poured from the taps in the house. Otherwise, we have an overexpenditure of energy, since the boiler will have to constantly heat water, which is almost never used. In addition, for the boiler will have to allocate free space in the room.

Two functions were originally laid in the double-circuit boiler - it both heats the building and heats the water. A flow coil is installed inside it. The boiler supports the heating system, but when someone in the housethen turns on the hot water, the heating of the coolant in it stops and the switch to the hot water supply system takes place.

The difference in the operation of a single-circuit and double-circuit boiler: a) 1 - single-circuit boiler, 2 - heating system, 3 - hot water supply, 4 - boiler, 5 - cold water, 1 - double-circuit boiler, 2 - heating system, 3 - hot water supply, 4 - cold water

The difference in the operation of a single-circuit and double-circuit boiler: a) 1 - single-circuit boiler, 2 - heating system, 3 - hot water supply, 4 - boiler, 5 - cold water, 1 - double-circuit boiler, 2 - heating system, 3 - hot water supply, 4 - cold water

Double-circuit boilers are rationally designed, hot water is heated only when it is needed. Depending on the power of the unit, 10-15 liters of hot water are produced per minute.

This is not enough if several people use hot water in the house at the same time, but the problem is easily solved, since you can buy a double-circuit boiler with a small 25-50 liter boiler built into the body in order to have its supply.

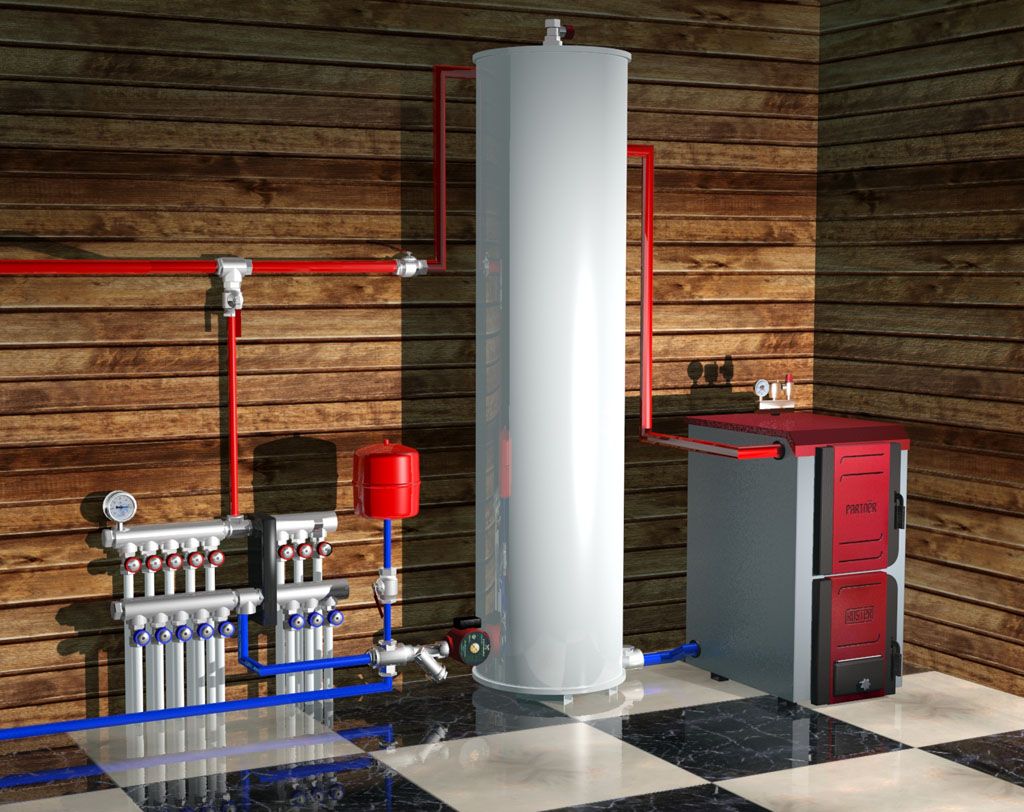

Choosing a boiler and expansion tank for a boiler room in a private house

Even if you have modern and high-quality heating equipment in the house, using hot water from the system for washing dishes or taking a shower is not the best option - the water quality will not meet the standards. In this case, it is worth installing a boiler separately.

If two or three people live in the house, it will be enough to choose a model for 60-70 liters. For a family of more than three people, it is worth buying a unit for 100 liters of water. And for a large family, a boiler of 150-200 liters is needed.

An expansion tank is a capacity necessary for organizing a competent heating system. Its presence can prevent accidents if the pressure in the system rises. The volume of the expansion barrel is selected depending on the total volume of liquid circulating in the boiler.

With a competent approach to the choice of heating equipment and the correct design of the boiler room, it is possible to provide a high-quality and safe heating system for a country house.

Boiler room volume for different boilers

If the total heat generation is up to 30 kW, then it is required to install the boiler in a room of at least 7.5 m3. We are talking about combining a room for a boiler with a kitchen or embedding it into a home space. If the device emits from 30 to 60 kW of heat, then the minimum volume level is 13.5 m3. It is allowed to use extensions or separate areas on any tier of the building. Finally, if the power of the device exceeds 60 kW, but is limited to 200 kW, then a minimum of 15 m3 of free space is required.

In the latter case, the boiler room is placed at the choice of the owner, taking into account engineering recommendations in:

- annex;

- any of the rooms on the first floor;

- autonomous building;

- plinth;

- dungeon.

No. 4.Boiler room in a private house: safety requirements

The fact that the boiler room is an object of increased danger does not need to be explained. The question lies elsewhere. How to equip the room in such a way as to ensure maximum safety, comfort and ease of access to equipment?

General requirements for a boiler room in a private house:

- walls should be made of concrete or building bricks. It is allowed to use ceramic tiles or plaster - these are non-combustible materials;

- when installing the boiler on the floor, a concrete screed is required, and the floor can also be covered with a sheet of metal;

- when installing a wall-mounted boiler, a section of the wall must be tiled or covered with a sheet of metal;

- explosive and flammable substances must not be stored in the boiler room. This does not apply only to fuel, which will be stored in a special way;

- Enough space must be left near the boiler so that it can be easily accessed for operation, maintenance and repair. If a small room is allocated for the boiler room, then it will not be easy to place all the equipment - it is better to first draw up a diagram of the location of the boiler and other elements;

- the door that leads from the boiler room to the house must be fireproof.

Ideally, even before the construction of the boiler house, it is better to draw up a project for the placement of equipment and take into account all the requirements that are put forward by such regulations as SNiP for boiler plants II-35-67, the Code of Rules for the Design of Autonomous Heat Supply Systems SP-41-104-2000 and Instructions for placement of heat generators MDS 41-2.2000.

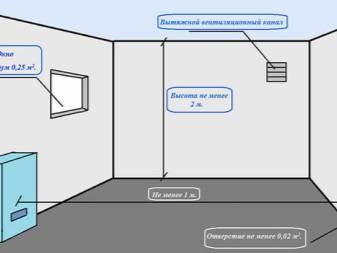

Boiler rooms with gas boiler

Gas boilers with improper installation and operation can cause a fire or even an explosion.

When installing a gas boiler, the following features should be considered:

- the room where all the equipment will be located should be at least 6 m2 in size;

- the height of the room is not less than 2.5 m;

- room volume - 15 m3 or more;

- the walls of the boiler room adjacent to the living quarters must have a fire resistance of at least 0.75 hours;

- the minimum size of the window opening is 0.03 m2 / 1 m3 of the room;

- the presence of a podium for a floor boiler with a height of at least 5 cm;

- there must be a free space of 1 m2 in front of the boiler, between equipment, walls and other objects there must be a passage at least 70 cm wide, otherwise access to the boiler will be difficult;

- mandatory ventilation and sewerage;

- the width of the doorway is at least 80 cm, the door opens outwards;

- for boilers with a power of more than 350 kW, it is necessary to build a separate building;

- if the boiler room is located in an annex, it must be near a blank wall. The minimum distance to the nearest window is 1 m.

This is in addition to the fact that it is necessary to fulfill all the general requirements.

Boiler rooms with solid fuel boiler

In this case, the following requirements should be taken into account:

- distance from the boiler to the nearest walls and objects - from 10 cm;

- for every 1 kW of power, 8 cm2 of window opening must be provided;

- the chimney along the entire length should have the same diameter and as few turns as possible;

- the inner surface of the chimney can be plastered, but this is not necessary;

- there must be a special opening in the chimney for its maintenance;

- for boilers that will run on coal or wood, the area of \u200b\u200bthe boiler room must be at least 8 m2;

- when using a coal-fired boiler, it is necessary to make hidden wiring, since coal dust is highly explosive;

- the space in front of the boiler must be free so that you can throw up fuel and clean the ash pan;

- walls made of insufficiently fire-resistant materials are sheathed with a sheet of steel 2.5 mm thick.

Boiler room with diesel boiler

The list of requirements is:

- in the boiler room, and preferably outside it, it is necessary to place a metal thick-walled tank with a volume of at least 1.5 m3. From it, fuel will flow into the boiler tank. There must be free access to the reservoir;

- there must be at least 1 m of space from the boiler burner to the opposite wall.

Boiler room with electric boiler

The electric boiler does not burn fuel, does not make noise and does not smell. It is not necessary to allocate a separate room for it, and there are no special requirements for ventilation. The only thing to remember is that the current-carrying terminals of the boiler must be grounded.

Popular manufacturers

The products of the Biysk boiler plant operating since 1942 are in demand. Sending part of the goods for export testifies in favor of the enterprise. The range includes both boilers and heat exchangers for them.

High-pressure boiler units are also made by a plant in Barnaul. Its products also include:

- fittings for locking and adjusting water;

- noise silencers;

- devices cooling steam;

- control cabinets and a number of other devices.

It is worth paying attention to the products of the following companies:

- "Izhevsk boiler plant";

- "Krasnoyarsk boiler plant";

- "East Siberian Boiler Plant";

- Nizhny Tagil Boiler and Radiator Plant;

- JSC "BKMZ" (also performs installation and warranty work);

- "Novomoskovsk Boiler-Mechanical Plant";

- "Rosenergoprom";

- Dorobuzhkotlomash.

Among foreign suppliers, firms that have worked for 100 years or more deserve attention. First of all, these are Buderus and Viessmann (Germany), as well as the Swedish CTC. Less perfect, but also more economically profitable goods from:

- Belgian concern Saint Roch;

- Belgian supplier ACV;

- German firm Winter Warmetechnik;

- Finnish company Kaukora Ltd (Jaspi brand).

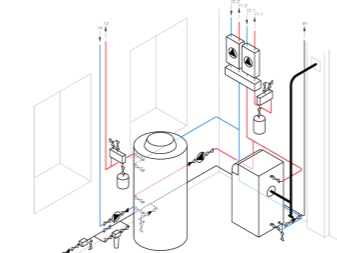

No. 2. The main elements of the boiler room in a private house

Well, if the house is small, and the problems of heating and hot water supply can be solved with one small double-circuit gas boiler. But in most cases this will not be enough - you will need a whole range of equipment, which may consist of a set of the following elements:

- the boiler is the heart of the entire boiler room. He will be responsible for heating the water for the heating system. Heat can be obtained by burning different types of fuel: liquid, gaseous or solid. A separate case - electric boilers. In some cases, two boilers are installed at once in order to provide a private house with complete energy independence;

- boiler. If a single-circuit boiler is used, then a boiler will have to be used to heat water for the hot water supply system;

- expansion tank. Water from the heating system will enter this container if the pressure in it rises. Thus, pipes and radiators are protected from bursting;

- heat accumulator. It is not always installed, despite the fact that this is a very useful element.This tank accumulates superheated coolant, "excess heat", which is then fed into the heating system. This saves a lot of resources and improves safety. The presence of this element is especially important for solid fuel boilers and in the presence of two boilers of different types;

- distribution manifold. It is necessary for the correct distribution of the coolant throughout the system, regulates the temperature;

- circulation pump. Required only in systems where the coolant circulates forcibly;

- chimney. Necessary for the removal of combustion products outside the house. A chimney is not needed only for an electric boiler;

- security and control group - a set of devices that monitor the temperature and pressure in the boiler and system. This may also include sensors that monitor the state of the air in the boiler room;

- automation receives commands from the user regarding the required temperature, collects data from the security group and allows you to correctly adjust the main parameters of the system;

- shutoff valves are necessary in order to control the flow of the coolant;

- pipes through which water from the boiler goes to the radiators;

- the filter is necessary to purify water before it enters the boiler and boiler. If the water in the region is saturated with salts and contains mechanical impurities, then you cannot do without a filter - otherwise the equipment may soon fail.

It is not necessary to use all these elements - their set depends on many factors. First of all, this is the area of \u200b\u200bthe house and the type of fuel.

Necessary boiler equipment for a private house

The most important thing for a boiler room is not only the room, but also its equipment.If you correctly select the equipment, you can get excellent functionality and quality of heating.

One boiler, of course, will not cope with the main task, namely, it will not be able to heat the whole house. To help him, you need to purchase additional equipment that is installed by specialists. You can equip a boiler room with your own hands, but this process requires special skills and knowledge. Therefore, it is better to entrust the arrangement of the boiler room to the masters of this business.

Boiler room equipment:

- Heating boiler;

- Expansion tank;

- heat accumulator;

- Boiler;

- Distribution manifold;

- Pump;

- Shut-off valves;

- Pipes;

- Automation;

- Chimney.

Having purchased all the elements, you can attach them yourself or hire a specialized craftsman. Boilers can be attached to the wall at a distance of 10 cm or simply placed on the floor. If the boiler is installed on the floor, then a foundation is required. The ceiling, floor and walls are best finished with heat-resistant materials. All parts are installed manually.

Primary requirements

The most important rules for the construction of gas boilers relate to the distance to buildings and structures. Industrial installations, which, unlike energy and heat supply, belong to risk category 3, should be located at least 300 m from the nearest residential building. But in practice, numerous amendments are introduced into these norms. Take into account the features of communications and the loudness of noise, the intensity of air pollution by combustion products.Attached boiler houses cannot be located under the windows of apartments (the minimum distance is 4 m), only free-standing structures can be used near kindergartens, schools and medical institutions, because even the best extensions do not guarantee proper protection.

However, there are strict requirements for the premises. So, wall-mounted gas boilers cannot be installed in rooms less than 7.51 m3. Be sure to provide a door with a passage for air. The minimum area of this passage is 0.02 m2. There must be at least 0.45 m of free space between the top edge of the heater and the ceiling.

Volume norms for the boiler by power are:

-

if the device generates less than 30 kW of heat, then it can be placed in a room of 7.5 m3;

-

if the power is above 30, but below 60 kW, a volume of at least 13.5 m3 will be required;

-

finally, in rooms from 15 m3 in volume, boilers of practically unlimited capacity can be installed - as far as it is expedient, it is permissible according to fire protection standards, of course.

But it is better to add 0.2 m3 for each additional kW of power. Rigid standards apply to the area of glazing. It is at least 0.03 sq. m. for each cubic meter of internal volume.

If the controllers find that the result is adjusted taking into account the frame, partitions, vent cases, and so on, they have the right to impose a substantial fine and even order to close the boiler room completely. And any court will support their decision. Not only that, the glass itself must be made using an easy-to-reset technology. We will have to use only ordinary window sheets - no stalinites, triplexes and similar reinforced materials.To some extent, double-glazed windows with a rotary or displaceable element can serve as a replacement.

Separate topic - supply ventilation in private house with a gas boiler. A continuously open window is very primitive and out of date. Where it would be more correct to use mechanized hoods and exhaust gas extraction systems. In any case, air exchange should provide 3 changes of all air every 60 minutes. For each kilowatt of thermal power, it is required to provide 0.08 cm3 of the volume of the ventilation duct.

Considering increased level of danger, necessary install a gas detector. It is selected only among certified and time-tested samples from well-known manufacturers.

When selecting a metering station, both technical and commercial aspects are taken into account. Both fuel consumption and coolant costs will have to be taken into account

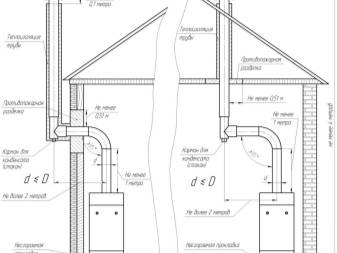

About the installation of gas-using installations

The most stringent requirements are imposed on a gas boiler house in a private house, since it is a source of increased fire and explosion hazard. But natural gas heaters are quite reliable and equipped with safety automatics. Therefore, for the placement of units, whose parameters in terms of power and dimensions are small, the SNiP standards do not express any special restrictions. Gas boilers with a heating capacity of up to 60 kW are installed in compliance with the following standards:

- The unit may be installed in a separate room on any floor, including the basement or basement. It is also allowed to install in the kitchen in the presence of ventilation and compliance with the conditions for its area and ceiling height.

- The kitchen, where the equipment for heating the house is located, must have a height of at least 2.5 m. The total volume of the kitchen is 15 m³ + 0.2 m³ per each 1 kW of boiler power. For the organization of supply and exhaust ventilation, a window (exhaust) and a supply grille with a passage area of at least 0.025 m², built into the entrance doors, are required.

- The SNiP imposes the same restrictions on other separate premises where it is planned to supply gas-using equipment with a capacity of up to 60 kW.

- The mandatory requirements for a gas boiler include the organization of air exchange in the required quantity. The inflow should be enough to burn gas in the boiler and to renew the air in the room 3 times in 1 hour.

- To burn liquefied gas, ventilation is equipped taking into account the fact that propane is heavier than air. Therefore, an exhaust hole with a grate is made in the lower zone, above the floor.

If equipment with a capacity of up to 150 kW is used for heating, then it cannot be installed in the kitchen; a gas boiler room is needed in a separate room on any floor. The limit on the volume of the furnace room is at least 15 m³, the height is not lower than 2.5 m. An additional requirement applies to the walls of the boiler room separating it from neighboring rooms: they must have a fire resistance of 45 minutes, that is, they must be built from non-combustible materials. Wall decoration should also not contribute to the spread of open flames.

Windows in the boiler room must be made of a certain area in order to provide standard natural lighting. The glazing area must be at least 0.03 m² for each cubic meter of the furnace volume. In addition, the windows in the boiler house play the role of easily dropped structures in case of a possible explosion of the gas-air mixture.

All of the above requirements must also be observed when placing heating equipment, whose total power reaches 350 kW. One amendment: such powerful units are allowed to be installed only in a separate room on the first or basement floor. From there, a direct exit to the street is made with the installation of type 3 fire doors.

Conclusions and useful video on the topic

Information about an autonomous boiler house in an accessible, even for a person far from this topic, form:

If you are at the stage of choosing boiler equipment, the information presented in this video will be useful to you:

Video with a detailed diagram of a boiler room with a solid fuel boiler:

The latest developments of companies producing boiler equipment are aimed at reducing energy consumption through low-temperature programs.

The main role in the issue of economy is automation, which allows you to select the optimal modes, regulate the temperature in such a way that the heating level decreases without compromising overall comfort

These nuances must be taken into account when drawing up a boiler room scheme for your home.

If you have experience in arranging a boiler room in a private house, please share the information with our readers. Leave comments and ask questions on the topic in the form below.