- Rules and regulations for installing a boiler in a private house

- Requirements for the installation of gas boilers

- Requirements for the placement of diesel equipment

- Requirements for the installation of solid fuel and electric boilers

- Tools and materials for building an extension

- Boiler room with solid fuel boiler

- What should be the room

- Equipment for solid fuel boiler

- Smoke extraction systems

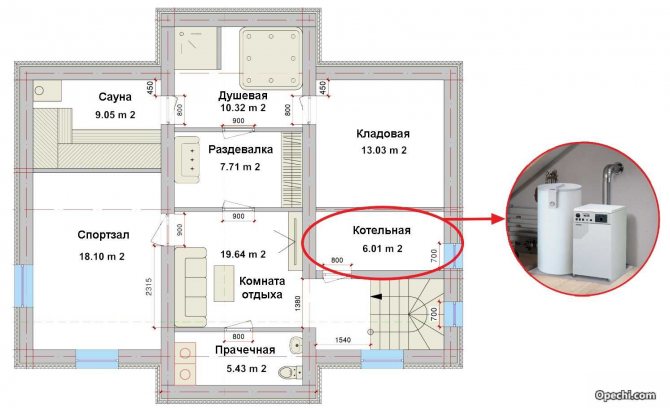

- Determine the optimal location for the boiler room

- Design of biomass boiler houses

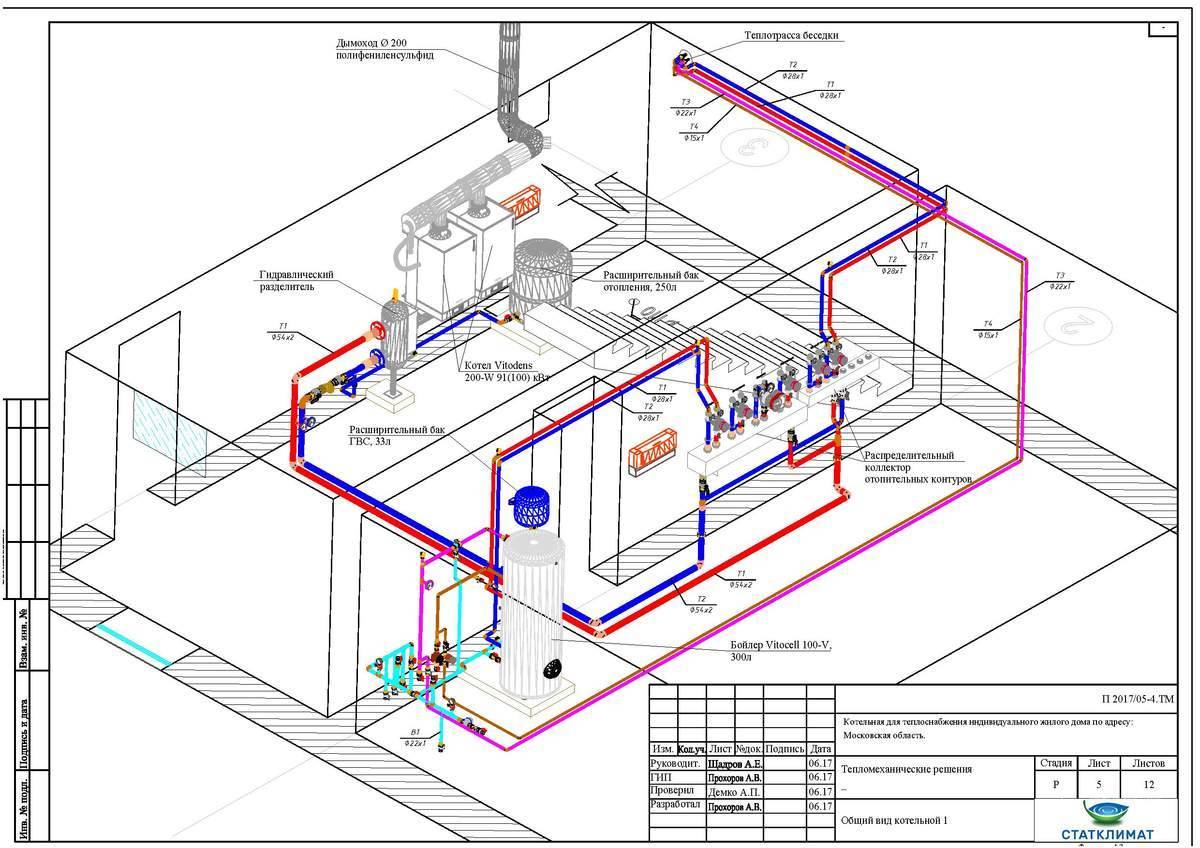

- Our projects:

- Accommodation Requirements

- No. 4. Boiler room in a private house: safety requirements

- Boiler rooms with gas boiler

- Boiler rooms with solid fuel boiler

- Boiler room with diesel boiler

- Boiler room with electric boiler

- Description of species

- built into the house

- In the annex

- Detached building

- Block-modular

- Cottage heating equipment

- Standards for the room for the installation of an electric boiler

- Requirements

Rules and regulations for installing a boiler in a private house

Starting the construction of a boiler house, you should study a number of requirements that apply to it. First of all, you need to familiarize yourself with the norms of SNiP with the designation II-35-76. In modern houses, the following types of boilers are installed:

- Embedded. With their help, a built-in boiler room is equipped in a private room.

- Standing apart.

- Attached.

However, due to the high cost, compact structures are not in demand, therefore, as an alternative, owners of country houses mount equipment in the basement.

Requirements for the installation of gas boilers

A boiler room in a wooden house with gas equipment should be equipped in such parts of the house:

- First floor.

- Basement or cellar.

- Attic space.

- Kitchen. In this room, installation of boilers with a power of up to 35 kW is allowed.

To get a detailed description of the standards for placing a gas installation in a private house, you should contact the nearest gas service. Specialists must provide a complete list of requirements and help draw up a project. You can also consult with the designer developing the floor plan.

Knowledge of the norms will ensure error-free installation of gas boiler equipment and optimal conditions for its well-coordinated work in the future. Depending on the power indicators of the system, the following installation rules apply:

- 150 kW - it is allowed to place the boiler on each floor with a separate space.

- 150-350 kW - the units will be in a separate room, but not higher than the 1st floor. You can also put them in extensions.

Provided that the power indicators exceed 350 kW, it is forbidden to install equipment in a private house.

If the attached boiler rooms in the cottage will be located in the kitchen, and the total power of the equipment does not exceed 60 kW, you need to take care of the following conditions:

- The allowable size of the room under the boiler should not exceed 15 m³. As the power of the unit increases, 1 m³ per kW is added.

- The height of the building must be at least 2.5 m.

- The ventilation system must provide an extract in 3 times the size of the boiler room. The inflow rate should be similar.

- In the boiler room itself, you need to install a window with a window.

Requirements for the placement of diesel equipment

The building of the boiler house with diesel equipment must meet the following requirements:

- Automation. For comfortable use of the system, it is necessary to equip it with special sensors and thermostats that guarantee uninterrupted operation without the constant presence of a person.

- Safety. All components of the system must comply with environmental requirements and be safe for operation. Pumps, sensors and other related components can be connected to the unit if they comply with Rostekhnadzor standards and have the appropriate certificates.

The attached boiler room is equipped according to the following standards:

- Units with a power of up to 60 kW are located inside the living space and are separated from other rooms by a partition made of non-combustible material. If the power indicators exceed 60-350 kW, it will be necessary to equip a separate boiler room for a private house.

- In the part of the house where the diesel boiler will be located, it is necessary to provide high-quality supply and exhaust ventilation and place windows with vents. Their width should correspond to the performance indicators of the generator.

- Floor coverings and wall structures must be made of non-combustible materials. Ceramics, plaster or gypsum fiber board are used as cladding.

Requirements for the installation of solid fuel and electric boilers

A private boiler room with a solid fuel heat generator should be equipped according to the following principles:

- The optimal distance between the wall and the unit is 10-12 cm.

- When installing equipment in a wooden building, you must first seal the wall with steel sheets.

- It is better to concrete the floor covering.

- Attached premises should have an area of 8-10 m².

Tools and materials for building an extension

The construction of an extension to the house for the equipment of a boiler room requires the use of tools for engineering, general construction and facing works, they are not scarce and technically complex and, as a rule, are present in every household:

- shovels and scrap for earthworks;

- concrete mixer, containers for transferring mortar for pouring the foundation;

- carpentry tools for formwork;

- mason's set: rulers, corners, plumb lines, trowel, trowel and spatula for masonry work;

- grinder, drill, hammer, pliers for installing a reinforced belt and fixing formwork for the foundation;

- chainsaw for roofing.

Wall material is purchased according to design specifications by type and quantity with a margin of 10-15%. If these are foam blocks, then an adhesive dry mix will also be required.

Boiler room with solid fuel boiler

According to the requirements of building codes, solid fuel boilers are installed only in non-residential premises. If the capacity of the unit is large, the construction of a separate boiler room will be required.

What should be the room

A number of requirements are put forward for a room for a solid fuel boiler:

- the distance between the furnace door and the wall is from 1.2 to 1.5 m;

- the distance from the side walls of the boiler to the wall made of fireproof material or protected by a special screen is at least 1 m;

- the gap between the rear wall of the boiler and the surface of combustible material with a protective screen is at least 0.5 m for boilers with rear connection;

- a ban on superstructures above the boiler room;

- effective supply ventilation, located in the lower part in the form of a gap between the door and the floor or a hole in the wall.

If the wall is made of a material that meets fire safety requirements, then it is permissible to attach the pipe behind the boiler to it using brackets.

To operate a HP with parameters of 1x0.8 m at the base with at least a minimum of comfort, you need to install it in a room of 2.8x2.5 m. With an increase in the dimensions of the unit, the area of \u200b\u200bthe boiler room also increases.

It is necessary to plan the installation of a solid fuel boiler even at the stage of building a house in order to allocate space under the chimney in advance

If the boiler room looks like an extension, then the correct location for it is a blank wall. The distance to windows and doors, both in vertical and horizontal directions, must be at least 1 m. If the boiler room is located in the basement, basement or first floor, it is necessary to install a door that opens outwards.

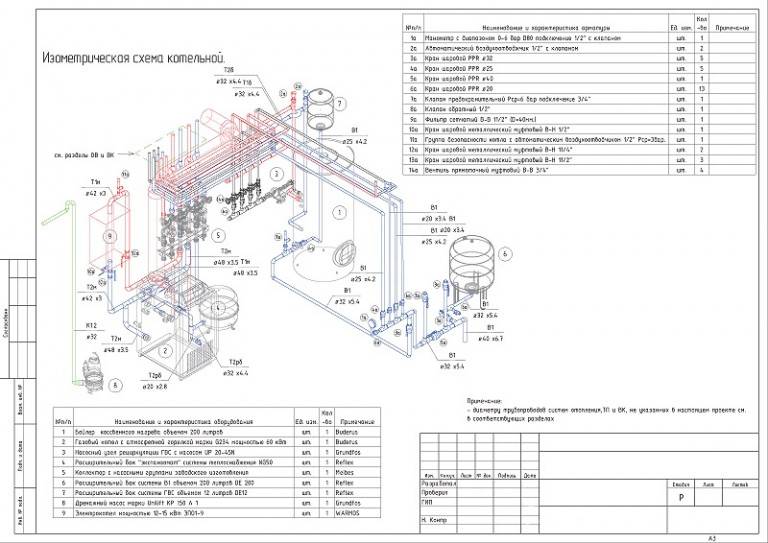

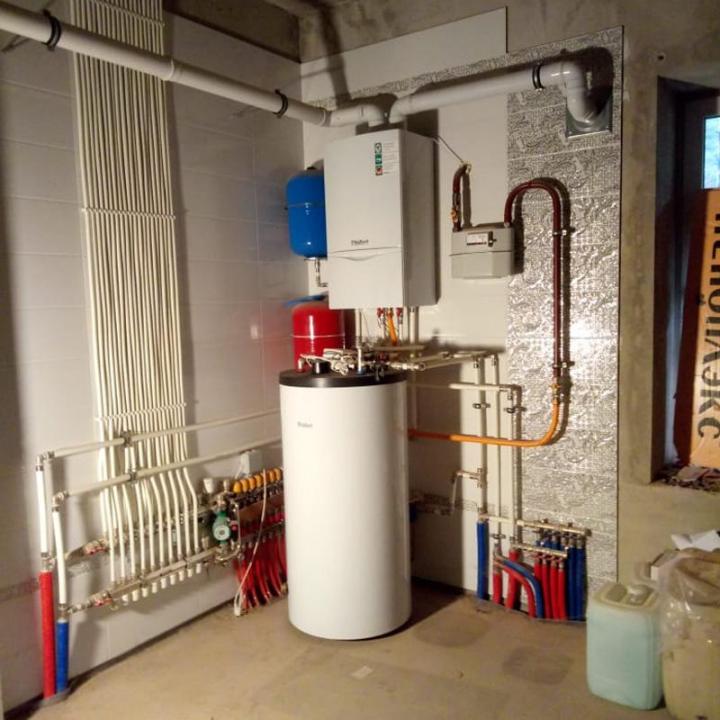

Equipment for solid fuel boiler

A functional and well-designed scheme of a boiler room with a solid fuel boiler should include a number of elements:

- Heat generator equipped with appropriate bunkers, chambers for fuel, etc.

- Boiler TT piping, consisting of a circulation pump, a 3-way valve, a safety group.

- Chimney.

- Storage water heater for domestic hot water supply.

- Automation - weather-dependent or intra-house.

- Fire extinguishing system.

Coal, peat, firewood are used as fuel for TT. The diameter of the chimney in a boiler room with a TT unit must be equal to the cross section of the boiler nozzle. The room requires exhaust ventilation, calculated so that for every 8 cm² of its area there is 1 kW of boiler power. If the boiler is installed in the basement, this parameter is multiplied by 3.

A steel sheet must be laid around the base of the boiler. It is necessary that it protrude from each side by 1 m. The layer of plaster on the walls should be no less than 3 cm thick.

In the chimney itself, which has the same cross section along its entire length, holes are provided for collecting and removing soot. Fire extinguishers are required.

A high-quality solid fuel boiler is able to convert any type of solid fuel into thermal energy. This saves money

There should be about 0.08 m² of glazing area per 1 kW of HT boiler output. The maximum allowable area of the boiler room is 8m². If the firebox is planned to be loaded with coal, then the electrical wiring must be protected from coal dust, because. it can explode at a certain concentration.

Smoke extraction systems

The smoke ventilation system of the boiler room is used to create a vacuum in the gas path of the boiler unit and to remove flue gases from the boiler into the atmosphere. It consists of a smoke exhauster, a fan, chimneys and a chimney.

Control and measuring devices and safety automation (I&C) are designed to control the operation of the installation according to regime maps, adjust the boiler load and ensure the safe operation of the equipment.

In all modern boiler units, the installation of instrumentation and automation is a mandatory requirement, in accordance with the rules and regulations for the operation of boiler plants.

Protection of boiler equipment is activated with the inclusion of sound and light alarms to alert the operating personnel.

Instrumentation protection parameters:

- separation of the torch in the boiler;

- high pressure of steam, gas, water;

- low vacuum in the boiler furnace;

- power outage;

- low water level in the boiler;

- low air, water and gas pressure.

When the alarm is triggered, after a short time, if the operating personnel has not corrected the failure, the boiler is stopped by the instrumentation and control system, through the forced shutdown of the gas supply to the furnace.

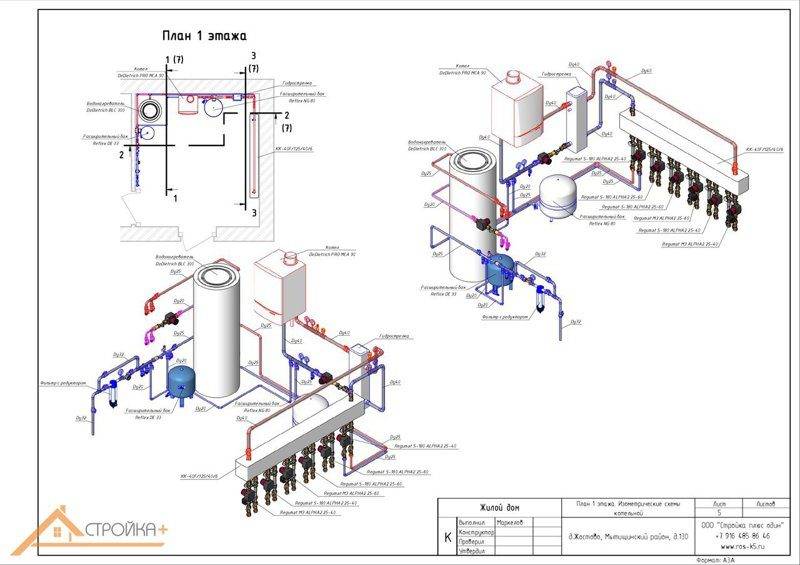

Determine the optimal location for the boiler room

Let's say you started a large-scale renovation of an old private house. There must be a boiler room in it, however, the outdated layout limits the possibility of placing it in the house. You can’t squeeze boiler equipment into a tiny room without ventilation, you can’t pull a chimney from bottom to top through a bedroom or living room.

You can, of course, build an extension to a country house for a boiler room, but this architectural excess is unlikely to fit well into the general view. There is still the construction of a separate boiler house - a good, but expensive idea.

A separate boiler room should not be located too close to the house. But if you place it far away, there will be heat losses due to an unreasonably long heating main

And with new construction, the procedure for designing a boiler room inside the house does not cause any problems if you study the requirements for installing boiler equipment in advance:

- the volume of the room for heating boilers with a power of up to 30 kW should be at least 7.5 m3, from 30 to 60 kW - 13.5 m3, over 60 kW - 15 m3;

- ceiling height - at least 2.2-2.5 m, width of entrance doors - 80 cm;

- the norm of natural lighting is 300 sq. cm of glazing per 1 m3 of the room, the window should be with a transom for ventilation;

- take only metal pipes for supplying gas to gas boilers; it is forbidden to use flexible hoses;

- in the power supply circuit of the boiler, it is necessary to provide a thermal protection relay, and in rooms with a gas-fired boiler, it is necessary to install a gas analyzer - a device that detects a gas leak and sends a signal to the emergency shutdown of the gas pipe;

- the boiler room should be separated from neighboring rooms by walls made of a material with a zero flame spread index - concrete, brick, wood with fire retardant impregnation;

- on issues of explosion and fire safety, the project is coordinated with the fire inspection.

Details of all the rules and regulations are written in the SNiP for boiler plants with the code II -35-76, the Code of Rules SP-41-104-2000 for the design of autonomous heat supply systems, the document MDS 41-2.2000, which sets out the instructions for placing units for heating and water heating in low-rise residential buildings.

The place for the boiler room is selected in each case individually, taking into account the technical features and financial capabilities of the owner - the first floor of the house, basement, basement, extension, attic or a separate building

Compliance with numerous requirements is dictated not by bureaucracy, but by safety precautions. A stand-alone boiler room is a chore with the construction of a foundation, main walls, pipe connections and their thermal insulation.

But in the house you get a 100% absence of harmful chemical impurities that inevitably accompany any combustion process, and complete confidence not to suffer during an accident, the probability of which is negligible, but theoretically not excluded.

We also recommend reading our other article, which describes in detail the schemes of boiler rooms for a private house.

Design of biomass boiler houses

| The scope of the Institute's activities includes the design of biomass boiler houses developed using the latest energy saving technologies. The main advantages of using biofuels: Economic efficiency (the cost of biomass as a fuel in terms of energy unit (Gcal) is significantly less than the cost of natural gas) Improvement of the ecological situation Low cost of received thermal and electric energy Renewable energy production based on waste recycling Depending on the individual characteristics of the facility, biomass boilers can use the following types of raw materials as fuel: wood chips, peat, straw, pellets, oilseed husks, sawdust, as well as waste products of domestic animals and the person himself. The use of biomass for thermal energy is environmentally friendly and cost-effective, because biomass can replace the most commonly used fuels for heat production, such as gas, oil products, and coal. When converting a boiler house from natural gas to biofuel, the return on investment is 2-3 years. |  |

Our projects:

| Water-heating gas boiler house in the microdistrict "Solntsevo Park" Design work for the construction of a boiler house with a total heat output of 88.2 MW. | Hot water boiler house for the territorially isolated innovation center "Innopolis", Kazan Pre-project work and feasibility study of the project for a hot water boiler house with a capacity of 32 MW. | Boiler room of a multifunctional administrative-trading and industrial-warehouse complex Development of design and estimate documentation for the construction of a 7.0 MW boiler house (MO, Leninsky district, near the village of Rumyantsevo, now the territory of the "New Moscow"). | Autonomous source of heat supply for the low-rise residential complex "Shemyakinsky Dvorik" Design of an autonomous hot water boiler house 2.1 MW. |

| Hot water boiler house CJSC "House of creativity Maleevka" Development of design and working documentation for a 2.6 MW hot water boiler house. | Autonomous source of heat supply for the rehabilitation building of the National Healthcare Institution “Central Clinical Hospital No. 2 named after N.A. Semashko of JSC Russian Railways” Design work for the construction of an autonomous heat source with a capacity of 4.2 MW for backup heat supply of the rehabilitation building with supply networks. | Boiler room, MO, Podolsk, st. Pleshcheevskaya, 15A Design of a boiler house with a total heat output of 4.1 MW. |

Accommodation Requirements

These requirements will apply directly to the room in which the gas boiler should be placed. What does the instruction manual say about this? So, the room should have a total area of more than 7.5 m². Ceiling height - at least 2.2 m.

Scheme of a gas boiler from Vaillant.

In addition, the room must have a window, which, if necessary, can be opened. It must go outside. This is required by fire safety.

As for the door in this room, it should open in the direction of movement from the room. There should be no switches in the room itself. They should be moved outside the room.

A ventilation system (supply and exhaust) is required. Approximately 15 m² of air is needed per 1 m² of gas burned. You also need three air changes.

When installing the boiler itself in the room, fire safety precautions must be strictly observed. So, from the boiler to the combustible elements of the room, a distance of at least 25 cm must be measured. As for fireproof elements, a distance of 5 cm is allowed here.

The distance between the chimney and combustible parts is 40 cm, and between the chimney and non-combustible parts - 15 cm.

The gas boiler must be installed on a perfectly flat surface, on which no slopes are observed.

This is important for safe use

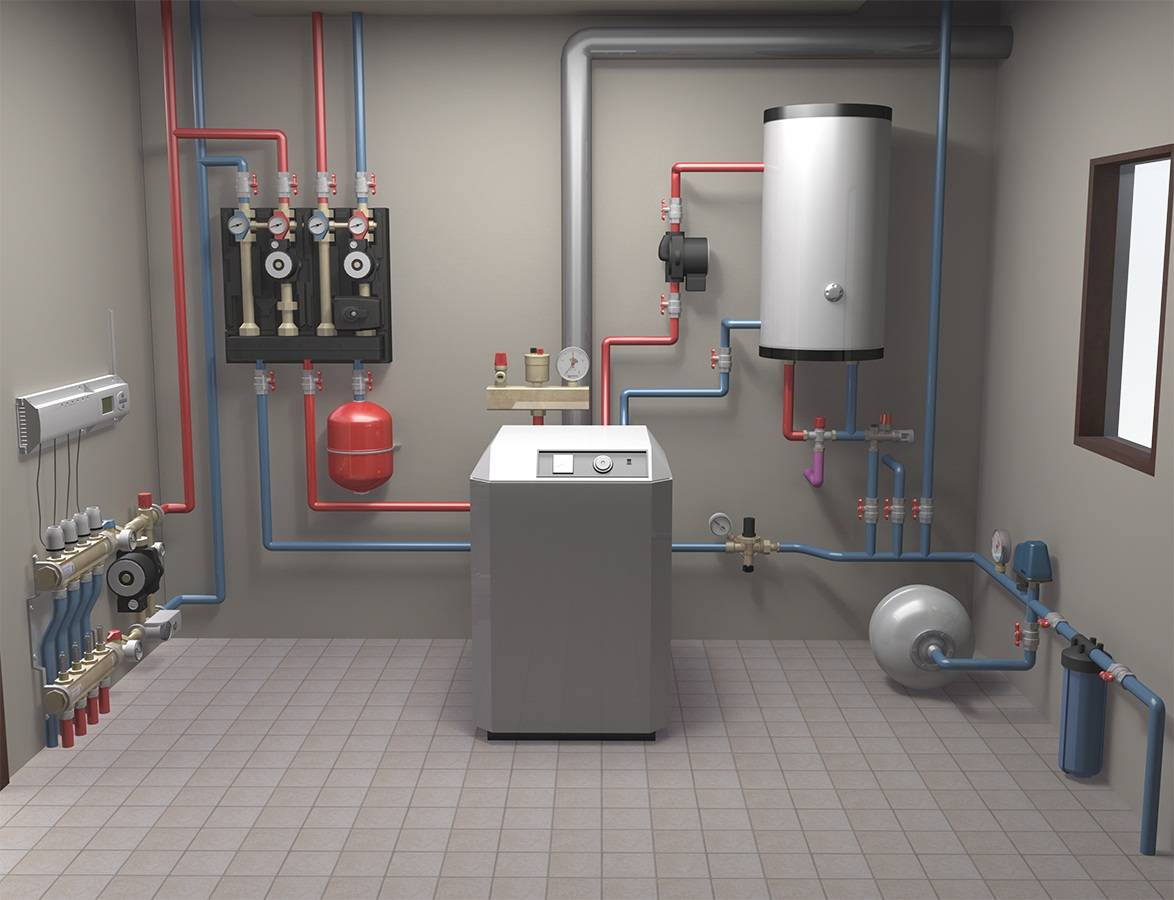

No. 4. Boiler room in a private house: safety requirements

The fact that the boiler room is an object of increased danger does not need to be explained. The question lies elsewhere. How to equip the room in such a way as to ensure maximum safety, comfort and ease of access to equipment?

General requirements for a boiler room in a private house:

- walls should be made of concrete or building bricks. It is allowed to use ceramic tiles or plaster - these are non-combustible materials;

- when installing the boiler on the floor, a concrete screed is required, and the floor can also be covered with a sheet of metal;

- when installing a wall-mounted boiler, a section of the wall must be tiled or covered with a sheet of metal;

- explosive and flammable substances must not be stored in the boiler room.This does not apply only to fuel, which will be stored in a special way;

- Enough space must be left near the boiler so that it can be easily accessed for operation, maintenance and repair. If a small room is allocated for the boiler room, then it will not be easy to place all the equipment - it is better to first draw up a diagram of the location of the boiler and other elements;

- the door that leads from the boiler room to the house must be fireproof.

Ideally, even before the construction of the boiler house, it is better to draw up a project for the placement of equipment and take into account all the requirements that are put forward by such regulations as SNiP for boiler plants II-35-67, the Code of Rules for the Design of Autonomous Heat Supply Systems SP-41-104-2000 and Instructions for placement of heat generators MDS 41-2.2000.

Boiler rooms with gas boiler

Gas boilers with improper installation and operation can cause a fire or even an explosion.

When installing a gas boiler, the following features should be considered:

- the room where all the equipment will be located should be at least 6 m2 in size;

- the height of the room is not less than 2.5 m;

- room volume - 15 m3 or more;

- the walls of the boiler room adjacent to the living quarters must have a fire resistance of at least 0.75 hours;

- the minimum size of the window opening is 0.03 m2 / 1 m3 of the room;

- the presence of a podium for a floor boiler with a height of at least 5 cm;

- there must be a free space of 1 m2 in front of the boiler, between equipment, walls and other objects there must be a passage at least 70 cm wide, otherwise access to the boiler will be difficult;

- mandatory ventilation and sewerage;

- the width of the doorway is at least 80 cm, the door opens outwards;

- for boilers with a power of more than 350 kW, it is necessary to build a separate building;

- if the boiler room is located in an annex, it must be near a blank wall. The minimum distance to the nearest window is 1 m.

This is in addition to the fact that it is necessary to fulfill all the general requirements.

Boiler rooms with solid fuel boiler

In this case, the following requirements should be taken into account:

- distance from the boiler to the nearest walls and objects - from 10 cm;

- for every 1 kW of power, 8 cm2 of window opening must be provided;

- the chimney along the entire length should have the same diameter and as few turns as possible;

- the inner surface of the chimney can be plastered, but this is not necessary;

- there must be a special opening in the chimney for its maintenance;

- for boilers that will run on coal or wood, the area of \u200b\u200bthe boiler room must be at least 8 m2;

- when using a coal-fired boiler, it is necessary to make hidden wiring, since coal dust is highly explosive;

- the space in front of the boiler must be free so that you can throw up fuel and clean the ash pan;

- walls made of insufficiently fire-resistant materials are sheathed with a sheet of steel 2.5 mm thick.

Boiler room with diesel boiler

The list of requirements is:

- in the boiler room, and preferably outside it, it is necessary to place a metal thick-walled tank with a volume of at least 1.5 m3. From it, fuel will flow into the boiler tank. There must be free access to the reservoir;

- there must be at least 1 m of space from the boiler burner to the opposite wall.

Boiler room with electric boiler

The electric boiler does not burn fuel, does not make noise and does not smell. It is not necessary to allocate a separate room for it, and there are no special requirements for ventilation. The only thing to remember is that the current-carrying terminals of the boiler must be grounded.

Description of species

There are several types of boilers.

built into the house

This type of boiler room is appropriate both in the basements of one-story houses and on their first floors. The main disadvantage is the lack of security. In addition, many boilers create a lot of noise. To some extent, this is justified by the convenience of using boiler equipment. Most often, built-in complexes are located in kitchens and corridors. There must certainly be a separate exit to the outside and a number of fire partitions.

In the annex

A boiler room attached to a residential building (located, for example, in a garage) will suit those who do not need particularly high power. The boiler room will be cozy and will save money. The door will have to be upholstered with sheet iron and / or asbestos. In the neighborhood with residential premises, additional sound insulation is carried out. It is not prescribed by the standards, but it is necessary.

From the attached boiler room there should always be an exit to the outside. In some cases, access to the house itself is not allowed. Only experienced engineers can understand these limitations. The thermal power of the equipment should not be selected with a margin, but only in full accordance with the needs of the residents. The regulations apply not only to heating equipment, but also to the methods of heat supply to the building itself from its extension.

Detached building

Such buildings are trying to bring as close as possible to residential buildings.A variety of technical communications are used to communicate between them. It will be possible to place any kind of heating boilers in individual boiler houses, use any type of fuel. The use of boilers of almost unlimited power is allowed. Heating mains are used to supply heat to the dwelling.

Block-modular

This option is optimal when it is impossible to put a boiler room inside the house, and it will not be possible to build a separate building. Such structures are assembled on the basis of factory components and are mounted quite quickly. The length of the special container is a maximum of 2.5 m. The steel structure is insulated inside. The delivery set usually includes multilayer heat-insulated pipes. Block-modular boiler rooms can be powered by:

- liquefied gas;

- coal;

- diesel fuel;

- firewood;

- natural gas.

Cottage heating equipment

The heart of the heating system is the boiler for the cottage. A variety of models makes it possible to choose any type of fuel depending on the situation. The best option is when gas is supplied to the house, in which case you need to install a gas floor or wall-mounted boiler. It can also run on liquefied gas, which is stored in a gas tank.

The heart of the heating system is the boiler for the cottage. A variety of models makes it possible to choose any type of fuel depending on the situation. The best option is when gas is supplied to the house, in which case you need to install a gas floor or wall-mounted boiler. It can also run on liquefied gas, which is stored in a gas tank.

In the absence of gas, alternatives have to be found. Electric heating costs the most. Heating with solid fuel is the cheapest, but inconvenient, since you constantly need to add firewood or coal.

Also in the boiler room of the cottage there are the following elements of the heating system:

- circulation pumps;

- hydraulic arrow or collector;

- expansion tank;

- security group;

- automatic air vents;

- chimney.

If you have a solid fuel boiler, then you definitely need to install a heat accumulator.This is a large-volume tank that smooths out temperature fluctuations in the coolant, prevents the boiler from boiling over and extends the periods between fuel loads.

Standards for the room for the installation of an electric boiler

Electric boilers are the most popular among owners of private houses and cottages. With this boiler, you can not only heat the living space, but also provide it with hot water. In Europe, electric boilers have been used for a long time. We also use these boilers quite actively. But do not forget that when installing an electric boiler, you must comply with the basic requirements for the boiler room.

- It is impossible for the boiler to be located close to the ceiling. The required distance is 0.2 meters;

- The wall where the boiler will be attached must be made of a special non-combustible material;

- The room must be dry and warm;

- There must not be a power cable under the electric boiler;

- Do not place the boiler directly on the floor, the distance from the floor should be approximately 1.5 meters.

The electric boiler is the safest. For him, the requirements for placing a boiler room in a private house are the weakest. To install it, it is not necessary to have a separate boiler room. No harmful combustion products are emitted during operation. Specially create ventilation, if it is not in the house, it is not necessary. The boiler operates silently, so it will not disturb the inhabitants of the house in any way. Probably, this heating system has only one drawback - it will not work without electricity.

Requirements

One of the most important stages in the arrangement of the heating system of a private house is the design stage.It is necessary to provide for all the design features of the premises and communications so that in the future there will be no problems during operation

If the installation of an autonomous boiler room is carried out in a residential area where repairs are being carried out, then some points may appear that should be paid close attention

Among the main requirements that apply to the premises, the following can be distinguished.

- Boiler equipment may not be installed in every room. According to building codes, only a kitchen or a separate extension is suitable for this, where it will be possible to install a furnace. Often, a basement is used as a place for arrangement.

- A thermal boiler is best installed in an extension adjacent to the main object. In addition, in the presence of powerful ceilings, such equipment can be mounted on the roof without any problems.

- In accordance with domestic regulations, boilers cannot be installed in the kitchen if their power is more than 60 kW.

- The height of the ceilings in the room with boiler installations cannot be less than 2.5 meters.

It is best to build a separate building, which will contain all the elements of such a system. This is not only convenient, but also provides safety in the event of an emergency.