Boiler operation Zota Topol-M

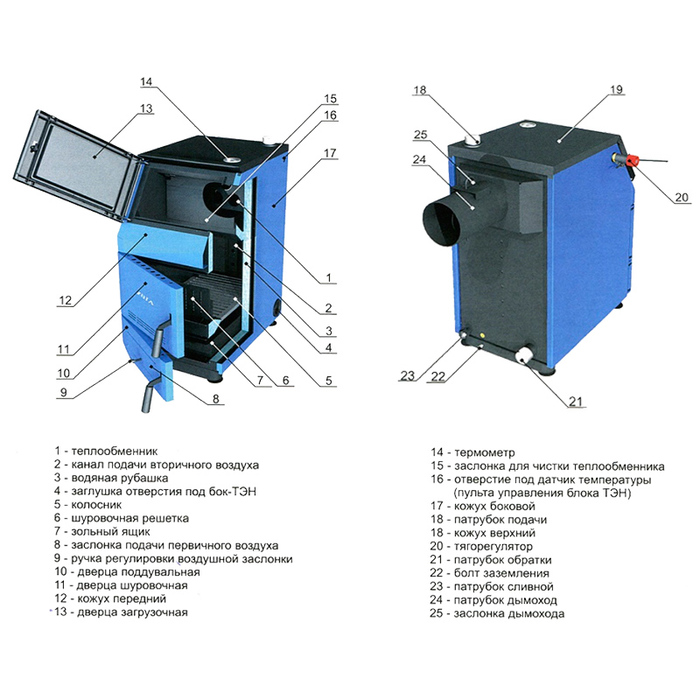

A user manual is supplied with each Zota Topol-M boiler. But these simple units are so simple that they do not need any instructions. Firewood is loaded here through the top door (shaft type), which is very convenient. To correct the logs in the firebox, the screw door on the front panel will help. A simple thermometer is provided to control the temperature.

Loading firewood for normal combustion is carried out through the shurovochny door. If it is necessary to ensure long-term burning, close it and lay firewood all the way to the top through the loading door in the upper part.

The launch of the Zota Topol-M boiler is carried out as follows - we put firewood on the grate, set it on fire, not forgetting to fully open the blower. As soon as the logs flare up, we put another portion of fuel. Remember that the firebox must be filled with firewood at least 15 cm. Until the heat exchanger warms up to a temperature above +60 degrees, condensation may form on it.

Power adjustment in Zota Topol-M is carried out using a valve in the chimney and a damper.If a mechanical traction control is used, set the +60 degree limit on it and wait until it is reached. As soon as the temperature of the coolant reaches the set value, set the length of the chain so that the damper (it also blows) is ajar by 2 mm. Now the boiler will be able to independently maintain the set temperature by opening or closing the damper.

Please note that Zota Topol-M boilers need periodic cleaning - they become clogged with soot, which does not differ in thermal conductivity. It is also necessary to clean the ash pan and the grate (especially before working in the long burning mode).

Characteristics

| Boiler type | Solid fuel classic |

| Heating area | 100 - 200 sq. m. |

| Power | 20 kW |

| Brand | Zota |

| Heating type | Water |

| Type of fuel loading | Manual |

| Fuel at manual loading | Firewood, Wood waste, Fuel briquettes, Coal, Brown coal |

| Fuel combustion control | Option |

| Contour type | single circuit |

| heat exchanger | Steel |

| Standard Hopper Capacity | 40 l |

| Chimney connection diameter, mm | 150 |

| Supply voltage, V | Not |

| Product color | Blue |

| efficiency % | 75 |

| The presence of a burner / stove | Not |

| Possibility of remote control | Not |

| Width, mm | 440 |

| Depth, mm | 820 |

| Height, mm | 760 |

| Warranty, years | 1 |

| Net weight | 128 kg |

| Country of manufacture | Russia |

Installation and operation

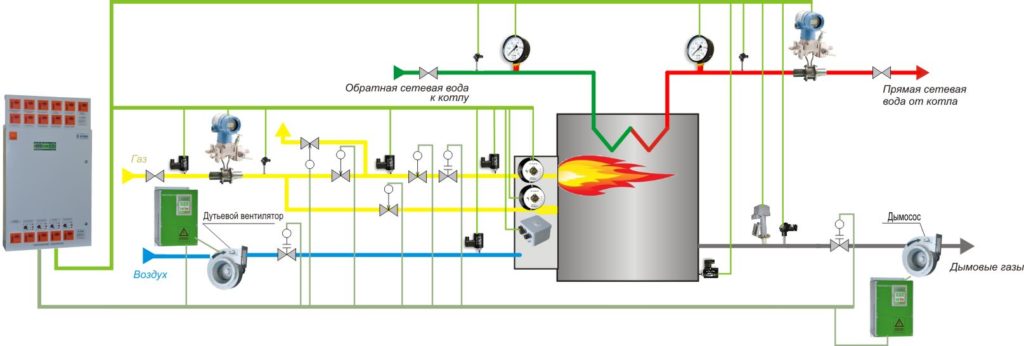

In the process of connecting Zota boilers, it is necessary to strictly comply with the requirements for the installation of any solid fuel heating appliances. It is necessary to install a security system: sensors that will be responsible for monitoring the temperature of the coolant and pressure relief valves.

You will find a specific installation scheme in the instructions, it describes in detail the ignition process and the operation of the device.

Very often there are situations when the technical and operational characteristics declared by the manufacturer do not coincide with what even a short experience of using the boiler can show. Feedback from owners of Zota boilers shows a real picture of how these units function and what their characteristics are:

- the ignition of the boiler takes place in a special mode. After the fuel flares up well, the furnace door closes and the control lever switches to the furnace mode;

- it is best to fire the boiler with dry wood and coal. Compliance with this condition is the key to high-quality heating. The temperature of the coolant at the outlet of the boiler will directly depend on the quality of the fuel used;

- cleaning the boiler from soot is not difficult. Due to the fact that the grate rotates, you can clean the firebox from soot without interrupting the combustion process. And large doors provide unhindered access to the entire smoke exhaust system.

Choice of coal

In order to have an idea of how to properly heat a long-burning boiler, it is necessary to consider the fuel used for this. Coal is a natural material that contains carbon and non-combustible elements. The latter, when burned, become ash and other solid deposits. The ratio of components in the composition of coal can be different, and it is this parameter, coupled with the duration of the occurrence of the material, that determines the grade of the finished fuel.

There are the following grades of coal:

- Lignite has the shortest age of occurrence among all coal grades, which is characterized by a rather loose structure.It is pointless to consider this material, since it is not suitable for heating private houses.

- Older deposits are brown and hard coal, as well as anthracite. Anthracite has the highest heat capacity, followed by hard coal, and brown coal is the most inefficient.

When deciding which coal to heat the boiler, it is necessary to evaluate the characteristics of a particular brand of raw material. Good coal for heating is distinguished by a rather high heat transfer and a long period of complete burn-out - one bookmark of fuel can burn up to 12 hours, which reduces the number of bookmarks per day to two. The presence of different types of coal on the market allows you to choose the most suitable material, depending on financial capabilities.

How to fire up a boiler

How to clean a coal boiler from soot

The composition of soot includes a non-combustible residue, which turns into slag during combustion. An additional problem is that under the influence of high temperatures, low-quality coal leads to increased formation of condensate, an acid that can corrode the metal of the heat exchanger.

Boiler cleaning is carried out in several stages:

- It is necessary to remove the ash from the ash pan, a chamber located immediately under the firebox and which is a capacious box closed with a sealed door. The ash pan is taken out, the ashes are poured out.

- Slag removal is carried out with a special tool, the appearance of which resembles a curved awl. Influxes are removed along the perimeter of the heat exchanger and from the grate.

In addition to regular cleaning of the boiler, measures are taken to prevent increased soot formation.The main reason why the heat exchanger becomes clogged with soot is the insufficient combustion temperature of the fuel. Layered stacking of firewood mixed with coal can solve the problem of increased soot formation.

How to clean the chimney of a coal-fired boiler

Proper operation of heating equipment includes measures to reduce the formation of soot in the chimney during operation of the boiler, as well as regular maintenance and cleaning of pipes. The SNiP stipulates the need for routine maintenance at least twice a year.

Pipe cleaning is carried out in the following ways:

Mechanical cleaning method - correct cleaning of chimneys is carried out using a special brush. Flexible plastic rods are attached to the rod. If necessary, the brush can be extended by attachable flexible bars. Cleaning is carried out from the roof. Soot is removed through special revision wells. The heaviest layers of soot accumulate at corners and chimney adapters

During cleaning, they are given the most attention. Cleaning chemicals - available as fuel additives

It is enough to place the bag in burning coal to effectively clean the chimney.

Chemicals are used as preventive measures and cannot completely replace the need for mechanical cleaning. Reducing soot emissions from coal combustion. Soot prevention is the best measure to control deposits on the chimney walls. As a preventive measure, several methods are used. They install a soot trap, provide the required temperature for burning coal, change the design of the chimney and install a deflector to improve traction characteristics.

All of these measures are aimed at maintaining the health of both the boiler itself and the chimney. Acidic condensate leads to a rapid burnout of the heat exchanger and chimney.

Proper operation of a coal-fired boiler includes: a competent choice of fuel, kindling and maintaining combustion in the chamber, preventing increased soot formation and regular maintenance of the heating unit and chimney.

general description

Solid fuel boiler Zota Topol-VK 16 is a novelty of 2019 from the manufacturing company ZOTA. Topol-VK 16 is designed for heat supply of individual residential houses and buildings for domestic purposes, equipped with a water heating system with forced and natural circulation, hot water supply using an indirect heating tank, in open and closed heating systems with a maximum allowable coolant temperature of + 95 ° C and a maximum allowable pressure 0.3 MPa. The heated area of Zota Topol-VK 16 is up to 160 m2.

Technical features:

• difference from previous Zota Poplar models are water-filled grates and a modified configuration of the heat exchanger with an increased area to increase heat transfer;

• 2 furnace doors with fixation on the lock allow to load fuel in 2 planes — vertical and horizontal;

• combustion is controlled by adjusting the blower damper of the ash pan door in manual and automatic modes (for automatic mode, an automatic draft regulator must be purchased separately);

• thermometer on the top panel allows you to quickly determine the temperature of the water supply;

• a dense layer of thermal insulation made of basalt cardboard significantly reduces heat loss;

• the boiler is cleaned through a removable heat exchanger damper, a cleaning hatch and an ash pan door.

Additional features (hardware sold separately):

• Boiler Zota Topol-VK 16 allows you to install a block heating element for heating on electricity and regulate the operation of the boiler through the control panel;

• the boiler can burn pellets using the Zota Fox kit;

• the Topol-VK 16 model can burn fuel in a long-term mode with the installation of the TurboSet kit;

• instead of a screw door, a gas burner for heating on gas can be installed.

Additional equipment (purchased separately):

• draft regulator FR 124-3/4 A;

• heating element block, no more than 9 kW;

• control panel PU EVT-I1;

• connecting copper cable (4 mm2, length 2 m).

Contents of delivery:

• boiler assembly /1 piece/;

• chimney pipe /1 piece/;

• ash drawer /1 piece/;

• thermometer /1 piece/;

• poker L=533 mm /1 piece/;

• skinning L=546 mm /1 piece/;

• scoop L=505 mm /1 piece/;

• operation manual /1 piece/;