- Operating tips

- Common malfunctions and their elimination

- E 01-02

- E 03

- E 05

- E 09

- E 10

- E 13

- E 16

- E 18

- E 27

- Other malfunctions of the Navien boilers

- Other causes of error 27

- Setting up a gas boiler Navien

- Heating setting

- Heating with air temperature control

- Hot water temperature setting

- Away Mode

- Setting the Timer Mode

- Heating circuit diagnostics

- microscopic defect

- What to do

- Note.

- Significant leak

- Boiler overheating

- Fixing the error:

- Critical flue gas temperature rise

- Main characteristic

- Types of equipment

- New Deluxe Model

- Technical device and principle of operation of the Navien gas boiler

- How to connect and set up

- Brief operating instructions: operation and adjustment

- Common mistakes and causes of problems

- Malfunctions of the gas boiler Navien

- The Navien boiler does not reach the set temperature

- The Navien boiler quickly gains temperature and cools down quickly

- How to fix error 03 in Navien boilers

- Causes of malfunctions and their elimination

Operating tips

The owners of any heating equipment, of course, are keenly interested in how to extend it use, how to eliminate various problems and delay major repairs. But it is even more important to take care of your own safety.It is strictly unacceptable to open the device and violate the sealing of its case, especially during operation. Inside there are many hot, sharp and live parts. If it was necessary to dismantle the boiler, this operation, as well as the installation of a new one, must be carried out only by qualified specialists.

During installation and during use, it is required to ensure that the wire supplying the boiler is not bent or crushed, does not touch hot surfaces and cutting objects. It is unacceptable to subject the boiler to vibration, to put heavy and hot objects on it. Also, do not use it as a stand or ladder. If you need to clean the device or part of it, you need to stand on a stable surface. Neither stools, nor stepladders, nor kitchen tables can be considered such a surface.

When cleaning any part of the boiler, only gentle compositions are allowed. It is undesirable to use solvents for this purpose. Likewise, flammable substances, especially liquids, must not be accumulated or even left for a short time near the heating system. Noticing the appearance of smoke and burning, soot emissions, the smell of carbon monoxide, you should stop the system in any weather, turn off the gas and electricity supply, ventilate the home and call specialists. Failure to follow any of these rules could result in injury, fire, or death.

Do not install gas boilers in places with high humidity, especially if it is still hot there. In such an environment, even strong metal is easily destroyed, scale is more likely to accumulate in pipes and other parts. If possible, construction and repair work near the heater, as well as any other actions accompanied by dust emission, should be avoided.This not only reduces the efficiency of the system, but can also result in its irreversible breakdown. And even if “only” the central board breaks down, the consequences will still be disastrous.

Monitoring the operation of the heating circuit involves more than one flush; it is very important that the contact of water with air is kept to a minimum. Even fuels as clean as natural gas form various deposits during combustion.

Therefore, the burner, as well as the chimney and ventilation, should be cleaned regularly. Invitation of specialists for technical control once every 6-12 months is mandatory, even if no cause for alarm is found.

This video presents the maintenance work of the Navien gas wall-mounted boiler.

Common malfunctions and their elimination

Consider the main ways to eliminate the errors that have arisen:

E 01-02

This error indicates that the equipment is overheating due to the lack of RH in the system. The solution to the problem is to clean the pipelines or check the pump. Alternatively, it is necessary to remove air from the system (primarily from the pump).

E 03

The function of the flame sensor is checked. Cleaning the ignition electrodes.

It is also necessary to check the presence of gas in the line or cylinders.

E 05

The malfunction of the temperature sensor is eliminated by checking its condition. The resistance of the sensor is measured at a certain temperature. If the readings correspond to the reference, it is necessary to clean the contacts.

If the sensor readings do not correspond to the table values, a replacement with a new, working instance is required.

E 09

First of all, you should measure the resistance on the fan windings, which should be 23 ohms.

Check if there is power at the terminals. If serious problems are found, the fan is completely replaced.

E 10

Most often, the problem lies in the sensor itself. It is necessary to check its condition, clean the contacts, if necessary, replace

E 13

The flow sensor often sticks due to clogging of the actuator with small debris, lime deposits, etc. If cleaning the sensor does not give the expected result, a possible breakdown on the control board is checked.

If there is no result, the sensor is replaced.

E 16

Overheating of the boiler can have several causes, the most common of which is the clogging of the heat exchanger and poor flow of RH. The protection is activated at 98°, the alarm is turned off when the boiler cools down to 83°.

There are two ways to solve the problem - first you should clean (in difficult cases - replace) the heat exchanger, in the absence of a positive result, the sensor is replaced.

E 18

Overheating of the smoke exhaust sensor occurs when the chimney is blocked. The reason may be the freezing of condensate, a strong wind outside, the ingress of foreign objects or debris into the chimney. If the elimination of interference with the removal of combustion products does not bring any results, the sensor should be replaced.

E 27

The lack of air pressure when the fan is running most often indicates a clogged air line or the need to replace the sensor. Most often, the reason lies precisely in it, since the ingress of foreign objects into a closed air channel is extremely difficult.

Other malfunctions of the Navien boilers

Even if the codes on the display do not appear, and you notice malfunctions, proceed to eliminate them.

Why is the boiler noisy and buzzing

At the same time, hot water does not come out of the tap, or a thin stream flows. The reason is the blockage of the heat exchanger due to poor-quality water.

The water contains potassium and magnesium salts. When heated above 55 degrees, they are deposited on the nodes and parts, the walls of the radiator. The thicker the scale layer, the narrower the passage for water. Therefore, the pressure decreases, and the liquid boils. As a result, there is no hot water, extraneous sounds are heard. Due to poor heat dissipation, heating is often switched on, which leads to high fuel consumption.

How to be:

- Rinse the heat exchanger, clean its tubes. Perform regular maintenance of the unit at least once a year;

- Install a purification filter that will “soften” the water;

- Do not set a high temperature - then the scale will not be deposited.

Heating does not work

If DHW heating is normal, but the heating circuit is not working, check the three-way valve. It switches the heating between the circuits. Perhaps it is jammed, or it is out of order. Carry out a replacement.

Remote control not working

Install new batteries.

Users of Navien boilers most often encounter such problems. If you follow the rules of operation and carry out regular preventive maintenance, you will be able to avoid many problems.

Other causes of error 27

The APS sensor controls the chimney draft, and the fault code is generated by the electronic module. Understanding this, it is easy to outline the search for the cause of the emergency stop of the Navien boiler.

Venturi device. Constant thermal exposure causes deformation of the plastic. It is easy to visually detect a defect after dismantling the Navien boiler fan unit (turbocharged): the device changes.

Tubes connecting the fan to the draft sensor. The accumulation of condensate is the cause of error 27.Eliminated by disconnection and purge.

Incorrect fan operation. It is checked by a light touch on the blades: the impeller must rotate freely. After removing dirt and dust from it, the error of the Navien 27 boiler disappears.

Chimney. A decrease in thrust is caused by blockage, the formation of frost on the filter (its contamination), and icing of the head. You don't need a professional to fix the problem.

Electronic board. Not repaired on site. You can restore the operation of the Navien boiler by replacing the module.

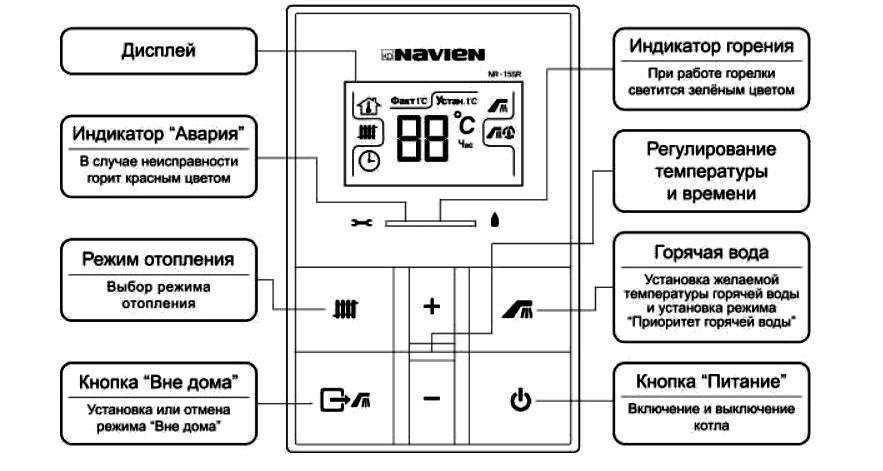

Setting up a gas boiler Navien

Next, we will consider how to set up the Navien Deluxe gas boiler with your own hands. Manipulations are performed using a remote control with a built-in room temperature sensor.

Heating setting

To set the heating mode and set the temperature of the coolant, hold down the button with the image of a radiator until the same icon appears on the screen. If the “radiator” picture flashes, it means that the set coolant temperature is displayed on the screen. If the symbol does not flash, the actual water heating level is displayed.

Wall-mounted gas boilers Navien - model range, pros and cons

How they work and what are the advantages of Navien Ace gas boilers

To set the desired temperature, use the "+" and "-" buttons with the "radiator" icon flashing. The possible range is between 40ºC and 80ºC. After setting the temperature, it will be automatically saved. The “radiator” icon will flash for a few seconds, after which the actual coolant temperature will be displayed on the screen.

Heating with air temperature control

To set the desired air temperature in the room, hold down the “radiator” button until the “house with a thermometer” image appears on the screen. It stands for "Heating with room temperature control".

When the “house with thermometer” symbol flashes, the desired room temperature is displayed on the screen. When the icon is fixed, the display shows the actual room temperature.

When the icon flashes, the desired level of heating in the room is set using the "+" and "-" buttons, adjustable in the range of 10-40ºC. After that, the temperature is automatically saved and the icon stops flashing.

Hot water temperature setting

To set the hot water temperature, hold down the “faucet with water” button until a similar flashing symbol appears in the right corner. The desired hot water temperature can then be set between 30ºC and 60ºC. The settings will be automatically saved and the water faucet symbol will stop flashing.

Note! In Hot Water Priority mode, the hot water temperature is controlled differently. Now let's look at how to set up the Navien Deluxe gas boiler in the "Hot Water Priority" mode. To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen

Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol

To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen. Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol

Now let's look at how to set up the Navien Deluxe gas boiler in the "Hot Water Priority" mode. To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen. Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol.

The "Hot water priority" mode means the preparation of a supply of water at a given temperature even if it is not used. It allows you to supply heated water to the consumer a few seconds earlier.

Away Mode

The "Away from home" mode implies the operation of a gas boiler for the preparation of hot water only. To transfer the unit to this mode, you need to press the button, which shows an arrow and a tap with water. If the water faucet symbol appears on the screen, it means that the Away mode is set. It displays the actual room temperature next to it.

Note! This mode is convenient for use in the warm season, when hot water supply is necessary, but there is no need for heating.

Setting the Timer Mode

The "Timer" mode is necessary to set the time to stop the operation of the gas boiler in the range from 0 to 12 hours. The unit will work for half an hour, turning off for the time of the specified interval.

To set the "Timer" mode, hold down the "radiator" button until the "clock" symbol appears. When the icon is flashing, use the "+" and "-" keys to set the interval time. The set value is saved, the “hours” stop flashing, and the display shows the actual air temperature.

Heating circuit diagnostics

A decrease in the volume of the coolant is often caused by leakage.Its intensity can be judged by the regularity of the Navien 02 boiler error. Two options should be considered here.

microscopic defect

The error is not displayed immediately after the system is filled with coolant. It may take several days before the boiler automation informs about the problem. It is pointless to look for a microcrack in pipes, radiators, joints. If the water in the circuit is prepared, of normal hardness, without impurities, then yellow spots, “rusty” stains are unlikely to appear at the site of the leak - the defect cannot be visually detected.

What to do

Switch off the boiler for a while. Any heating system is characterized by inertia. Depending on the scheme, the type of radiators, cooling occurs slowly, so the heat in the house will remain for a long time, and a decrease in temperature by 2–3 degrees is not critical. The essence of the technique is that, by definition, the coolant does not evaporate from cooled pipes and devices. Therefore, droplets flowing onto the floor are easy to detect visually, and the cause of the Navien 02 error will become clear.

Note.

In double-circuit boilers, the fault code may be caused by another reason. If error 02 appears with frequent (or intensive) consumption of hot water, then the Navien heat exchanger is probably the issue. An internal defect in the form of a crack between the "compartments" (for models with a combined device) leads to the overflow of liquid from the heating system into the DHW circuit.

Significant leak

Causes fault code 02 almost immediately after filling the system with liquid and starting the boiler. With open installation, you can quickly determine the problem area by going around the house and carefully inspecting the floors in the area of \u200b\u200blaying the heating main.But if the pipes are laid covertly, the matter becomes more complicated.

Leakage in the heating circuit

With proper wiring in rooms (collector circuit), the cause of error 02 of the Navien boiler can be found by turning off individual “threads” in turn. It will take time to locate the leak. If the system was installed without installing a distribution unit, you will have to open the floor covering or inspect the ceilings in the basement (basement) floor.

Boiler overheating

Fixing the error:

Allow the boiler to cool down: the overheating sensor is triggered in the temperature range (0C): +85 - switching on, +95 - blocking.

After cooling, restart the unit (on/off button with RESET function).

Low pressure of the coolant in the system: if the arrow on the boiler pressure gauge has left the green sector and turned into red), it is necessary to increase the pressure to a minimum threshold of 1 Bar

The make-up valve is located in the lower part of the heating installation, next to the cold water pipe connection pipe.

It opens counterclockwise until the characteristic noise of the incoming liquid appears, do not forget to close the tap in the reverse order, otherwise the pressure will creep into the reverse red zone and the relief valve will start to work (water will flow).

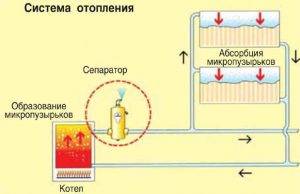

Air in the system: the accumulation of bubbles moving along the pipes along with the coolant reduces the flow rates, causing the pump to malfunction.

It is necessary to bleed air from the system, it is not worth relying entirely on the air vent in the boiler pump, over time it wears out and does not work out the air discharge so effectively, in such a case it is good to have an additional air vent at the highest point of the system (2nd floor) which is additionally mounted on the battery instead of the Mayevsky tap, if there is none, then you can manually bleed the air through the Mayevsky taps (until water appears).

It is necessary to bleed air from the system, it is not worth relying entirely on the air vent in the boiler pump, over time it wears out and does not work out the air discharge so effectively, in such a case it is good to have an additional air vent at the highest point of the system (2nd floor) which is additionally mounted on the battery instead of the Mayevsky tap, if there is none, then you can manually bleed the air through the Mayevsky taps (until water appears).

The boiler pump is faulty: problems with the pumping device also cause an error, while the pump may work, but not in the set mode: hence the decrease in circulation rate and overheating of the main heat exchanger.

You also need to check the rotation of the impeller: when the unit is turned off, a washer is removed that closes the air bleed hole. In the center, the tip of the motor shaft with a horizontal slot is visible.

In a working pump, the axle turns easily. Difficulty in its rotation is evidence of incorrect operation of the pump.

NTC sensor malfunctions: it is necessary to test the temperature sensor, for which it is necessary to drain the coolant from the boiler and remove it.

The dependence of the resistance of the RH sensor on temperature is linear, and to make sure that the NTC is working (or broken), you need to take measurements before and after immersing it in hot water.

If the multimeter shows 0, ∞, or the same resistance when changing conditions, the sensor must be replaced.

The three-way valve is faulty: when the boiler mode was changed from hot water to hot water, the valve did not switch.

The boiler heat exchanger is clogged: maintenance needs systematic maintenance, and if the deadlines are not met, the quality of the coolant (degree of purification, hardness index) is not taken into account when organizing work, overheating is inevitable over time.

To clean the TO, you need to use professional equipment (booster) or rinse the TO yourself using special liquids.

Malfunction of the electronic board: it is not difficult to replace the unit on your own: it is screwed to the rear wall of the unit, and the installation locations of wires and cables cannot be mixed up (ports differ in size and configuration).

If the board is for another modification of Navien, it needs to be configured, the setting is done by switching the pins (white micro keys on the board on the left), we simply duplicate it from the failed board.

Critical flue gas temperature rise

It is strongly recommended to connect heating boilers through a stabilizer (for a boiler) or a UPS, this will save you from unnecessary costs for replacing the control board.

Checking the functionality of the thermostat: The primary task of the thermostat is to control the temperature in the smoke exhaust duct. During its operation, any sharp increase in the value occurs due to a decrease in thrust, the sensor overheats and blocks the operation of the boiler.

A multimeter is used to test the overheating sensor at home.

The Navien overheating sensor can be considered out of order if it shows a break at normal (room) temperature. If, under room conditions, the sensor shows a resistance of less than 0.3 Ohm, then everything is in order with it, if R ˃ 0.5 Ohm - the thermostat is replaced with a new one).

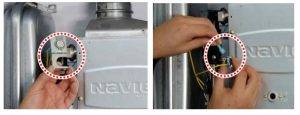

Replacing the sensor does not require special skills: turn off the power from the boiler (remove the plug from the socket or turn off the stabilizer), then unscrew 2 screws and disconnect the sensor, assembly is carried out in the reverse order.

Check the chimney: blockage reduces the flue gas outlet, icing on the tip also prevents the exhaust gases from being removed. With regard to Navien boilers with an open combustion chamber (air is taken from the room), it is necessary to ensure a good air flow into the room.

Pollution of the heat exchanger: for the heat exchanger of any boiler, it is necessary to carry out maintenance every 2-3 years, neglect leads to the shutdown of the boiler.

To eliminate it, it is necessary to clean the cavity of the combustion chamber, the fins of the heat exchanger with a toothbrush and a vacuum cleaner (in order to increase natural draft).

Malfunctions in the operation of the fan: it is not difficult to control the operation of the fan, you need to open the boiler cover and visually and audibly verify its operation (rotation and noise of the impeller), it often happens that the elements of the fan wear out (rotor, stator, bearings) and it does not enter the operating mode rotation/pull.

If the impeller is clogged, it can be cleaned with a toothbrush and a vacuum cleaner, it will also not be superfluous to disassemble and lubricate the bearing.

Draft sensor (pressure switch, manostat): the device controls the flow rate of combustion products and, in case of poor draft, gives a command to stop the operation of the Navien boiler in order to prevent smoke from entering the room. The sensor includes a membrane that controls a microswitch, the contacts of which are involved in the signal circuit, to check the integrity of the device, you need to blow into one of the holes, if characteristic clicks are heard, then the device is working.

It is also necessary to blow out the pipes from the condensate accumulating in them.

It is also necessary to blow out the pipes from the condensate accumulating in them.

inspect the Venturi device: with prolonged thermal exposure, it deforms, causing an error.

Main characteristic

Korean manufacturers have taken care of the convenience of consumers and have released an extensive range of heating systems. The equipment is highly reliable and affordable. Features of Navien gas boilers:

- The machine is equipped with an adjustment circuit that avoids problems caused by voltage fluctuations in the network. This function protects the system from breakdowns when the sensors are falsely started. This feature is very useful as the power grid voltage is not always stable.

- The heating system is able to stabilize its operation when the supply pressure is reduced to 4 bar.

- The device does not freeze even in the absence of gas supply. There is a pump for forced circulation of water.

- The system has a double heat exchanger designed to heat the coolant and water. Preheating can be programmed.

- Electronics is simple and convenient.

Navien gas boiler:

Types of equipment

Navien has a very wide range, including floor and wall equipment. The units can function normally even with an unstable supply of fuel and electricity. Models have a turbocharging function and are equipped with a frost protection system.

Outdoor equipment is ideal for country houses. It efficiently heats the room and provides it with hot water. The units are simple and compact. There is condensing equipment. Such devices significantly reduce the cost of heating the house.

Types of Navien boilers: The following Navien models are very popular: Ace (Ace), produced with different power levels, for example, 16 k or 20 k, Deluxe (Deluxe), Prime (Prime).

New Deluxe Model

Navien Delux is the latest heating system that has replaced the Ace. This model has a closed combustion chamber and a turbine for forced smoke removal. Equipment features:

- Increased frost protection. At a temperature of -6 degrees, the automatic burner turns on, and at -10 ° C, the circulation pump is activated, allowing the coolant to move continuously.

- Fan with adjustable speed. The speed of the turbine changes depending on the reading of the air pressure sensor.

- The heating system is made of stainless steel, which has a much longer life than other materials.

- Protection against the effects of voltage drops in the network and the ability to operate at low pressure of water and coolant.

Gas boiler Navien Deluxe: >All work is done using a separate remote control. It displays a temperature indicator and various information about the current status of the device, including error and malfunction codes.

There is also an air pressure sensor, which not only checks the draft, but also notifies about the reverse thrust and sends data for portion control to the control panel.

If there is excess pressure in the chimney, the gas will stop moving to the burner and the boiler will stop temporarily.

Navien error 02:

2 id \u003d "tehnicheskoe-ustroystvo-i-printsip-raboty"> Technical device and principle of operation of the Navien gas boiler

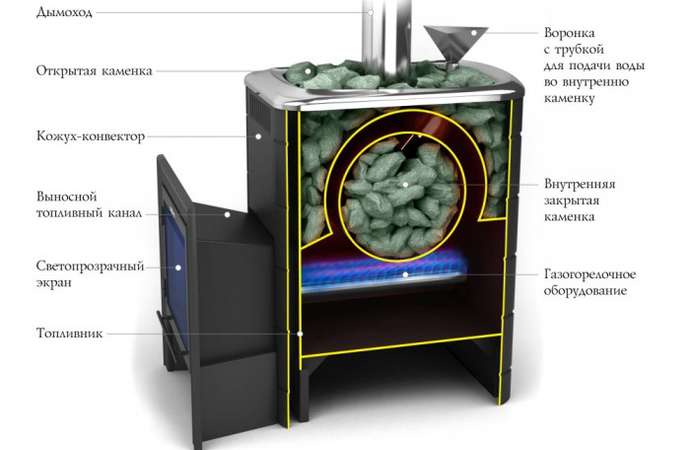

Consider the device of the double-circuit gas boiler Navien Deluxe Coaxial.

Navien gas boiler device

The device has two heat exchangers that prepare the heat carrier (main) and domestic hot water (secondary). Gas and cold water supply lines are connected to the corresponding pipes, which enters the heat exchangers, where it is heated to certain temperatures. Then, with the help of a circulation pump, the coolant is sent to the heating system of the house.

All operation of the device is controlled by an electronic unit that provides timely shutdown / on of the burner, which controls the temperature of the water in both circuits by means of special sensors. The control board is protected from power surges, but in areas with frequent or significant power surges, a stabilizer must be used.

Navien boilers have a remote control unit equipped with a display that shows the current mode, temperature, and other operating parameters of the device. In addition, the display shows the error code detected by the control unit in any system of the device.

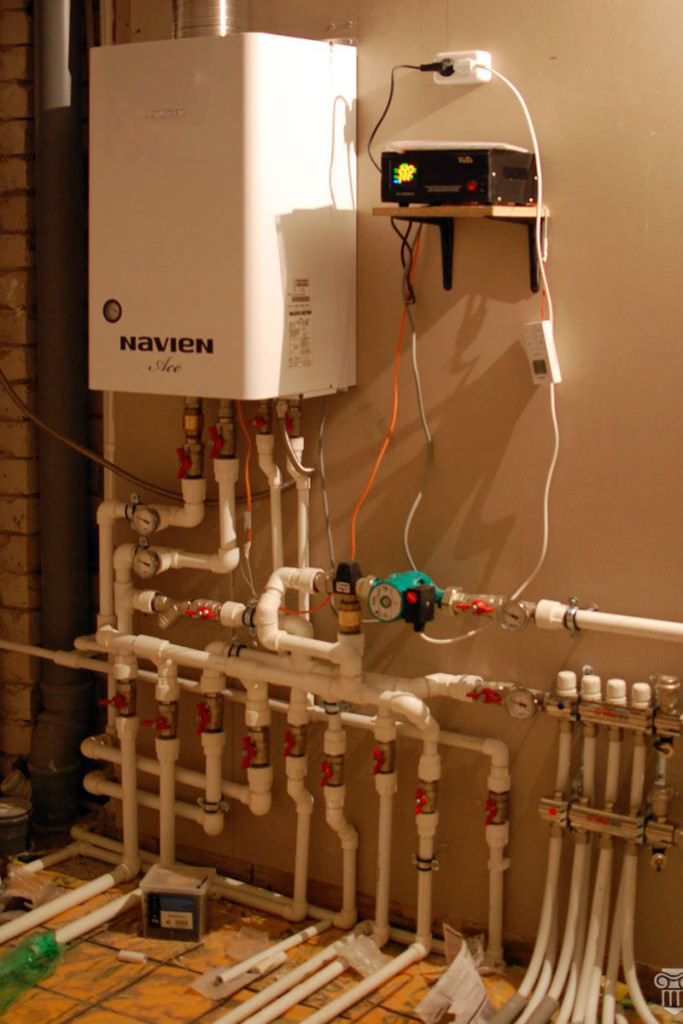

How to connect and set up

Installation of the boiler does not require any specific actions. Floor devices are installed in a certain place, mounted devices are hung on the wall using a standard hinged rail.

The boiler is hung through damper pads (rubber, foam rubber, etc.) so that the noise during operation does not spread throughout the house. Gas and water pipes, heating system and domestic hot water are connected to the corresponding branch pipes. An air supply and smoke extraction system is also connected (depending on the type of construction).

The boiler is adjusted by bringing the gas pressure to the standard value.To do this, turn off the water supply and adjust the minimum and maximum gas pressure corresponding to operation in different modes with the adjusting screw. Then restart the water supply. During operation, it is necessary to periodically check the condition of the boiler connections with a soapy solution - if they are leaking, bubbles will appear. If noise or other signs of an unplanned change in operating mode appear, turn off the gas supply and check the condition of the equipment.

Brief operating instructions: operation and adjustment

All actions with the boiler are performed using a remote control panel. The water temperature in the heating system is adjusted by pressing the "+" or "-" buttons on the remote control with the "heating" mode selected, which is indicated by a stylized battery image. The display shows the numerical value of the set temperature. It is also possible to set the mode according to the air temperature in the rooms, for which you need to turn on the corresponding designation on the display (the symbol of a house with a thermometer inside). The flashing display shows the desired temperature value, while the constant display shows the actual temperature. Hot water is adjusted in a similar way, you just need to switch the mode.

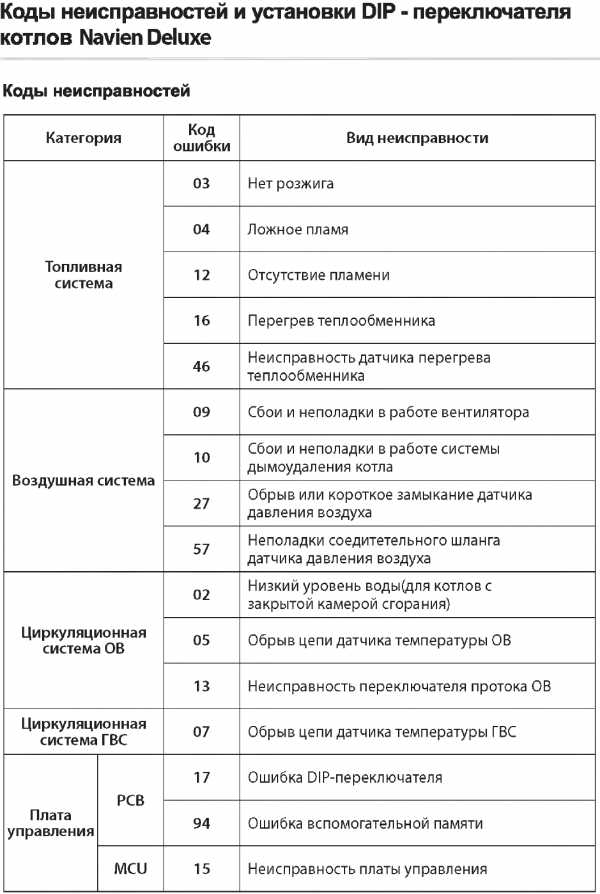

Common mistakes and causes of problems

Sometimes the boiler displays a special code on the display, indicating an error in the operation of any system. Consider typical errors and codes:

This table shows the common errors of Navien boilers

To solve the problems that have arisen, you should eliminate the source of the malfunction yourself or contact specialists. There are some special requirements that are specified in the instructions.For example, code 10 - an error in the smoke exhaust system - can occur when the system is working properly, just a strong wind has risen outside. In order to avoid errors, you should carefully study the user manual.

Navien gas boilers are practical and easy-to-use devices that are economically beneficial, with full functionality and capabilities. At relatively low prices, South Korean equipment is optimally suited for harsh Russian conditions, it allows you to create a comfortable temperature in the house, organize the supply of hot water. Installation, operation, maintenance of Navien boilers does not cause any difficulties, all actions are described in detail in the attached instructions. Detected malfunctions or problems that have arisen are promptly eliminated by specialists from service centers.

Malfunctions of the gas boiler Navien

In order for you to be able to repair Navien gas boilers on your own, we have compiled this guide. It will provide invaluable assistance in eliminating breakdowns and failures. Let's see what self-diagnosis systems can tell us - we will present the error codes of the Navien boiler in the form of a list:

Despite the huge number of possible breakdowns, most of them do not pose a serious problem and are solved fairly quickly and with little money.

- 01E - overheating occurred in the equipment, which was evidenced by the temperature sensor;

- 02E - in Navien boilers, error 02 indicates an open in the flow sensor circuit and a decrease in the coolant level in the circuit;

- Error 03 in Navien boilers indicates the absence of a signal about the occurrence of a flame. Moreover, the flame can burn;

- 04E - this code is the opposite of the previous one, as it indicates the presence of a flame in its absence, as well as a short circuit in the flame sensor circuit;

- 05E - an error occurs when there is a malfunction in the temperature measurement circuit of the coolant in the heating circuit;

- 06E - another temperature sensor failure code, indicating a short circuit in its circuit;

- 07E - this error occurs when the temperature sensor circuit in the DHW circuit malfunctions;

- 08E - an error of the same sensor, but diagnosing a short circuit in its circuit;

- 09E - error 09 in Navien boilers indicates a malfunction of the fan;

- 10E - error 10 indicates problems with smoke removal;

- 12E - the flame in the burner went out;

- 13E - error 13 indicates a short circuit in the flow sensor of the heating circuit;

- 14E - code for the lack of gas supply from the main;

- 15E - a rather ambiguous error indicating problems with the control board, but without specifically indicating the failed node;

- 16E - error 16 in Navien boilers occurs when the equipment overheats;

- 18E - malfunctions in the smoke exhaust system sensor (sensor overheating);

- 27E - electronics registered errors in the air pressure sensor (APS).

There are no repair instructions supplied with the boilers, since the repair work should be carried out by a service company. But nothing prevents us from repairing a faulty node on our own, without resorting to the help of specialists. Let's see how Navien boilers are repaired at home.

The Navien boiler does not reach the set temperature

In order to prevent the appearance of scale, install a system for cleaning and softening tap water - the costs will not be the biggest, but you will extend the life of your boiler.

First you need to clean the heat exchanger of the Navien gas boiler. At home, this is done with citric acid, toilet bowl cleaners, or special products (if available). We remove the heat exchanger, fill it with the selected composition, and then rinse it under high water pressure.

In a similar way, the heat exchanger of the DHW circuit should be cleaned if the Navien boiler does not heat hot water. In the most advanced cases, the exchanger must be completely replaced.

The Navien boiler quickly gains temperature and cools down quickly

A very complex error indicating some kind of malfunction or imperfection in the heating system. Try to correct the situation by adjusting the speed of the circulation pump, make sure that there is no air in the system. It is also necessary to check the filter and the clearance of the heat exchanger. In some cases, it may be necessary to replace the coolant.

How to fix error 03 in Navien boilers

For some reason, the electronics do not receive a signal about the presence of a flame. This may be due to a lack of gas supply or a malfunction of the flame sensor and its circuit. Sometimes an error appears after carrying out any work on the gas line. Another possible reason is that the ignition does not work. Troubleshooting:

- We check the presence of gas supply;

- We check the performance of the ignition;

- We check the ionization sensor (it could be dirty).

When using liquefied gas, it is recommended to check the operation of the reducer.

If there is no malfunction in the Navien gas boiler, error 03 may occur with some problems with grounding (if any).

Causes of malfunctions and their elimination

To understand how to fix a particular problem in a gas unit, you need to know the causes of malfunctions:

- Code 01E indicates an increase in the temperature regime in the device. This is possible due to a blockage in the ducts, which provoked their narrowing, or there were problems with the circulation pump.

- Code 02E indicates the presence of air, insufficient water, damage to the impeller in the circulation pump, a closed distribution valve, or the flow sensor has become unusable.

- Code 03E is displayed as a result of problems with the ionization sensor, lack of gas supply, ignition, with the tap closed, if the boiler is not properly grounded.

- Code 05E indicates poor contact between the temperature sensor and the controller, or a short circuit in the same area.

- The code 10E is displayed on the screen in case of failure of the fan, as well as in case of improper connection of the sensor tubes directly to the fan. In addition, a clogged chimney, a strong gust of wind can also cause appliance malfunctions.

- Code 11E, as a rule, is displayed on European-made boilers (with appropriate sensors).

- Code 13E indicates a short circuit in the heating water flow meter.

- The occurrence of noise and hum is possible with a poor coolant.

- The reason for the lack of hot water is the valve, which has become unusable. Optimal valve life is 4 years.

How to fix:

- Error 01E: carefully inspect the impeller in the circulation pump to detect various problems; check the resistance in the pump coil itself; examine the heating system for the presence of air (excessive bleed).

- Error 02E: bleed air; check the pressure, resistance in the coil; whether a short circuit has occurred; open the valve (distribution); check the resistance in the flow meter; remove the sensor housing and clean the flag.

- Error 03E: clean the flame sensor from debris (to get rid of the gray coating on the electrode, you can use fine-grained sandpaper).

- Error 05E: investigate the circuit from the controller to the sensor. If there is a problem, the sensor should be replaced with a new one. The meter and controller connectors must first be disconnected and then connected.

- Error 10E: repair the fan or replace it; check the connections on the tubes of the measuring device; clean the chimney of all kinds of debris.

- Error 13E: replace the sensor.

You can get rid of noise and hum if you disassemble the product and clean the heat exchanger. If the problem is not solved, then the part must be replaced. Inspect the taps, they should be opened as much as possible. Reduce water temperature.